Magtrol DSP6000 User Manual

Model DSP6000Model DSP6000

Model DSP6000

Model DSP6000Model DSP6000

High Speed PHigh Speed P

High Speed P

High Speed PHigh Speed P

Dynamometer ControllerDynamometer Controller

Dynamometer Controller

Dynamometer ControllerDynamometer Controller

rogrammablerogrammable

rogrammable

rogrammablerogrammable

UserUser

User

UserUser

’s Manual’s Manual

’s Manual

’s Manual’s Manual

MAGTROL, INC.MAGTROL, INC.

MAGTROL, INC.

MAGTROL, INC.MAGTROL, INC.

Sales and TSales and T

Sales and T

Sales and TSales and T

Buffalo, New York 14224 USA

Tel: (716) 668-5555 or 1-800-828-7844

wwww

ww

wwww

Hysteresis Brakes and Clutches

While every precaution has been exercised

in the compilation of this document,

Magtrol, Inc. assumes no responsibility

for errors or omissions. Additionally, no

liability is assumed for any damages that

may result from the use of the information

contained within this publication.

echnical Assistanceechnical Assistance

echnical Assistance

echnical Assistanceechnical Assistance

70 Gardenville Parkway

Fax: (716) 668-8705

w.w.

mm

w.

w.w.

Manufacturers of:

Motor Test Equipment

agtragtr

m

agtr

mm

agtragtr

oo

l.cl.c

oo

o

l.c

o

oo

l.cl.c

oo

!

mm

m

mm

74M041 062200

®

LabVIEW

National Instruments Corporation.

RadioShack

the RadioShack Corporation.

is a registered trademark of

®

is a registered trademark of

Safety NotesSafety Notes

Safety Notes

Safety NotesSafety Notes

1. Make sure that all Magtrol dynamometers and electronic products are earthgrounded, to ensure personal safety and proper operation.

2. Check line voltage before operating the DSP6000.

3. Make sure that dynamometers and motors under test are equipped with

appropriate safety guards.

iii

This page intentionally left blank.

iv

TT

able of Contentsable of Contents

T

able of Contents

TT

able of Contentsable of Contents

SALES AND TECHNICAL ASSISTANCE .............................................................................................. ii

SAFETY NOTES..................................................................................................................................... iii

1 - INTRODUCTION ................................................................................................................................ 1

About This Manual ............................................................................................................................................. 1

Shipping .............................................................................................................................................................. 1

UNPACKING YOUR DSP6000 ............................................................................................................................................ 1

About the Model DSP6000 Dynamometer Controller ....................................................................................... 1

FEATURES ......................................................................................................................................................................... 1

SPECIFICATIONS ................................................................................................................................................................. 2

Front Panel .......................................................................................................................................................... 3

Figure 1. Front Panel .................................................................................................................................... 3

ENABLING SECONDARY FUNCTIONS ..................................................................................................................................... 3

FRONT PANEL CONTROLS AND BUTTONS ............................................................................................................................. 4

Vacuum Fluorescent Display (VFD) .................................................................................................................. 5

STATUS DISPLAY MESSAGES ..............................................................................................................................................5

DISPLAYING DESIRED INFORMATION .................................................................................................................................... 5

Rear Panel ........................................................................................................................................................... 6

Figure 2. Rear Panel ..................................................................................................................................... 6

Figure 3. Brake Connector ............................................................................................................................ 6

Figure 4. Accessory Torque/Speed Output.................................................................................................... 6

Figure 5. Dynamometer Connector ............................................................................................................... 6

REAR PANEL FUNCTIONS ....................................................................................................................................................7

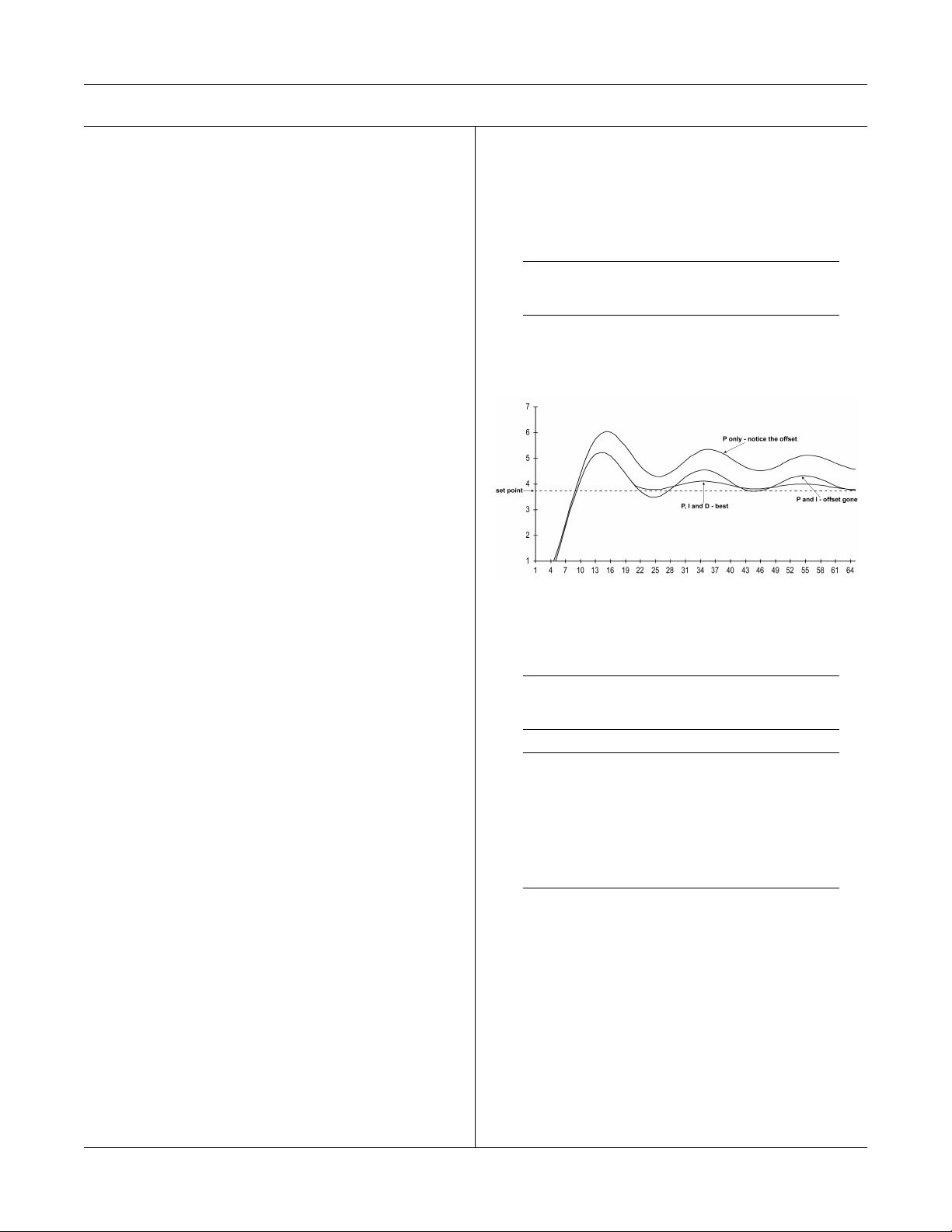

2 - ABOUT THE PID LOOP..................................................................................................................... 8

P (Proportional Gain) ......................................................................................................................................... 8

I (Integral) .......................................................................................................................................................... 8

D (Derivative) .................................................................................................................................................... 8

Figure 6. PID Loop ....................................................................................................................................... 8

Setting The Correct PID'S For Your Motor ........................................................................................................ 8

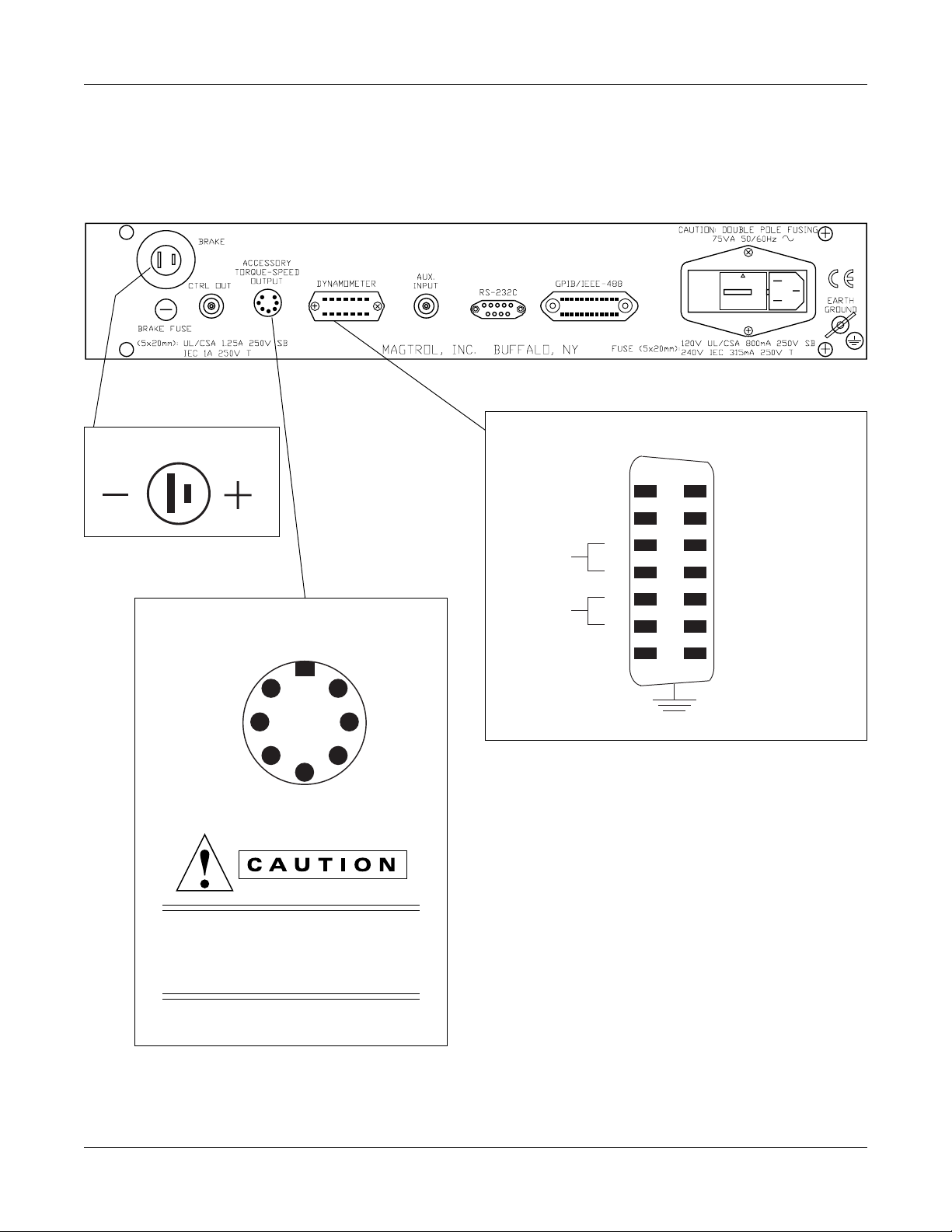

3 - INSTALLATION................................................................................................................................ 10

Setting Unit for Line Voltage ........................................................................................................................... 10

Figure 7. Cover for Voltage Selector, Fuses ...............................................................................................10

Checking Your DSP6000 .................................................................................................................................. 10

4 - THE DSP6000 AS A STAND-ALONE UNIT (LOCAL CONTROL) ................................................. 12

Setting Desired Operating Parameters .............................................................................................................. 12

SET DISPLAY TO DESIRED POWER UNITS (WATTS OR HP) .................................................................................................. 12

SET DISPLAY TO DESIRED TORQUE UNITS .........................................................................................................................12

SET UP DISPLAY FOR DYNAMOMETER ............................................................................................................................... 12

SET UP COMMUNICATIONS WITH PC .................................................................................................................................12

SET UP AUXILIARY INPUT ................................................................................................................................................ 12

SET TORQUE CONTROL ....................................................................................................................................................12

SET SPEED CONTROL ....................................................................................................................................................... 13

SET OPEN LOOP CONTROL ...............................................................................................................................................13

SET UP I/O PARAMETERS ................................................................................................................................................ 13

Setting Dynamometer Load .............................................................................................................................. 14

Using Internal Memory..................................................................................................................................... 14

STORING DATA POINTS ....................................................................................................................................................14

RECALLING DATA POINTS ................................................................................................................................................ 14

v

EXITING THE MEMORY MODE .......................................................................................................................................... 14

CLEARING THE MEMORY .................................................................................................................................................. 14

5 - THE DSP6000 WITH A PC (REMOTE CONTROL) ......................................................................... 15

About the GPIB Interface ................................................................................................................................. 15

Figure 8. GPIB (IEEE-488) Interface .........................................................................................................15

I

NSTALLING THE GPIB (IEEE-488) CONNECTOR CABLE ................................................................................................... 15

CHANGING THE GPIB PRIMARY ADDRESS .........................................................................................................................15

Checking the DSP6000-To-PC Connection...................................................................................................... 16

Programming .................................................................................................................................................... 16

CODES FOR CR - LF ....................................................................................................................................................... 16

DSP6000 Command Set ................................................................................................................................... 16

COMMAND SET FOR DSP6000.........................................................................................................................................17

Acquiring Speed-Torque Data .......................................................................................................................... 20

Selecting the Baud Rate for the RS-232 Interface ............................................................................................ 20

Figure 9. Connector Pin-Out ...................................................................................................................... 20

6 - CALIBRATION ................................................................................................................................. 21

Closed-Box Calibration .................................................................................................................................... 21

Calibration Schedule ......................................................................................................................................... 21

Basic Calibration Process ................................................................................................................................. 21

INITIAL CALIBRATION PROCEDURE .................................................................................................................................... 21

TORQUE OFFSET AND GAIN .............................................................................................................................................. 21

ACCESSORY TORQUE OFFSET AND GAIN ............................................................................................................................22

AUXILIARY INPUT OFFSET AND GAIN ................................................................................................................................22

ALTERNATE CALIBRATION PROCEDURE.............................................................................................................................. 22

Figure 10. Alternative Calibration ................................................................................................................ 23

7 - TROUBLESHOOTING ..................................................................................................................... 24

APPENDIX A: LABVIEW® PROGRAMMING EXAMPLES................................................................. 25

Simple Read ...................................................................................................................................................... 25

Torque Stabilized .............................................................................................................................................. 26

Speed Stabilized ................................................................................................................................................ 27

APPENDIX B: INERTIA CORRECTION .............................................................................................. 28

Inertial Effect on Motor Test Data.................................................................................................................... 28

Procedure for Inertia Correction ....................................................................................................................... 28

KEY CONDITIONS ............................................................................................................................................................ 28

APPENDIX C: FRONT PANEL/DISPLAY MENU FLOW CHARTS..................................................... 29

Dyno Setup Menu ............................................................................................................................................. 29

Com Setup Menu .............................................................................................................................................. 30

Aux Setup Menu ............................................................................................................................................... 31

Power Units Menu ............................................................................................................................................ 31

Torque Units Menu ........................................................................................................................................... 32

APPENDIX D: SCHEMATICS .............................................................................................................. 33

Encoder/Switch Board ...................................................................................................................................... 33

Power Supply .................................................................................................................................................... 33

DSP & Memory ................................................................................................................................................ 34

Analog I/O ........................................................................................................................................................ 35

GLOSSARY OF ABBREVIATIONS AND TERMS................................................................................ 36

MAGTROL LIMITED WARRANTY ....................................................................................................... 37

vi

1 - Introduction1 - Introduction

1 - Introduction

1 - Introduction1 - Introduction

ABOUT THIS MANUAL

This manual contains information about the DSP6000

Dynamometer Controller and procedures for optimal

use. To obtain the best results from your unit, please

follow the procedures for operation.

SHIPPING

Your DSP6000 was packaged carefully for shipping.

Please notify your carrier and Magtrol Customer Service

if you believe your unit was damaged in shipping.

UNPACKING YOUR DSP6000

1. Save all shipping cartons and packaging material

until you inspect the DSP6000.

2. Inspect the DSP6000 for any evidence of damage

in shipping.

3. Make sure the carton contains the following:

• DSP6000 Dynamometer Controller

• Line cord

• User's Manual for the DSP6000

• Calibration certificate

ABOUT THE MODEL DSP6000 DYNAMOMETER CONTROLLER

Magtrol's Model DSP6000 Dynamometer Controller

provides superior motor testing capabilities by using

state-of-the-art digital signal processing technology.

The DSP6000 both controls the dynamometer and

provides digital readouts on the front panel. The

DSP6000 is designed to work with all Magtrol load cell

dynamometers, including the following dynamometer

models:

001-DH 015-DH 008-DH 517-DE

601-DH007-DH508-DH518-DE

004-DH 507-DH 018-DH 001-DTH

005-DH017-DH518-DH002-DTH

505-DH 517-DH 528-DH 003-DTH

FEATURES

Fast, full curve data acquisition

Free-run to locked rotor in seconds.

High-speed data acquisition

120 torque and speed points per second via IEEE

(GPIB) bus.

Speed and torque operating modes

Each mode provides independent PID settings for

improved dynamometer control.

Programmable digital PID values

Controlled and stored either with Magtrol M-Test

software or manually.

Single point or programmed load control

Single or multi-point torque and speed stabilized testing

using Magtrol M-Test software.

Two standard computer interfaces

RS-232 and IEEE-488.

Additional analog input

Accepts any ± 5 VDC transducer.

Vacuum fluorescent display

Displays torque, speed, power, auxiliary input and PID

values.

Many torque measurement options

Includes English, metric, and SI torque readings as

standard.

Closed box calibration of torque and auxiliary input

Eliminates need to open box for adjustments.

The DSP6000 is designed to work with any personal

computer using an IEEE-488 or an RS-232 interface,

or as a stand-alone unit. In a computer-controlled

environment, the DSP6000 provides the following

motor testing capabilities:

• Proportional (P), plus Integral (I), plus

Derivative (D) closed loop control (PID loop).

• Torque (Q) and Speed (N) data acquisition at a

rate of up to 120 readings per second.

• Automatic progressive loading in either

decreasing or increasing speed mode.

• Ability to remove the Effects of Inertia from

dynamically obtained data. (See Appendix B)

• Complete curve capability for most motor

types, including single/poly phase induction,

AC/DC series, PMDC, brushless DC, air and

internal combustion (if suitably coupled).

1

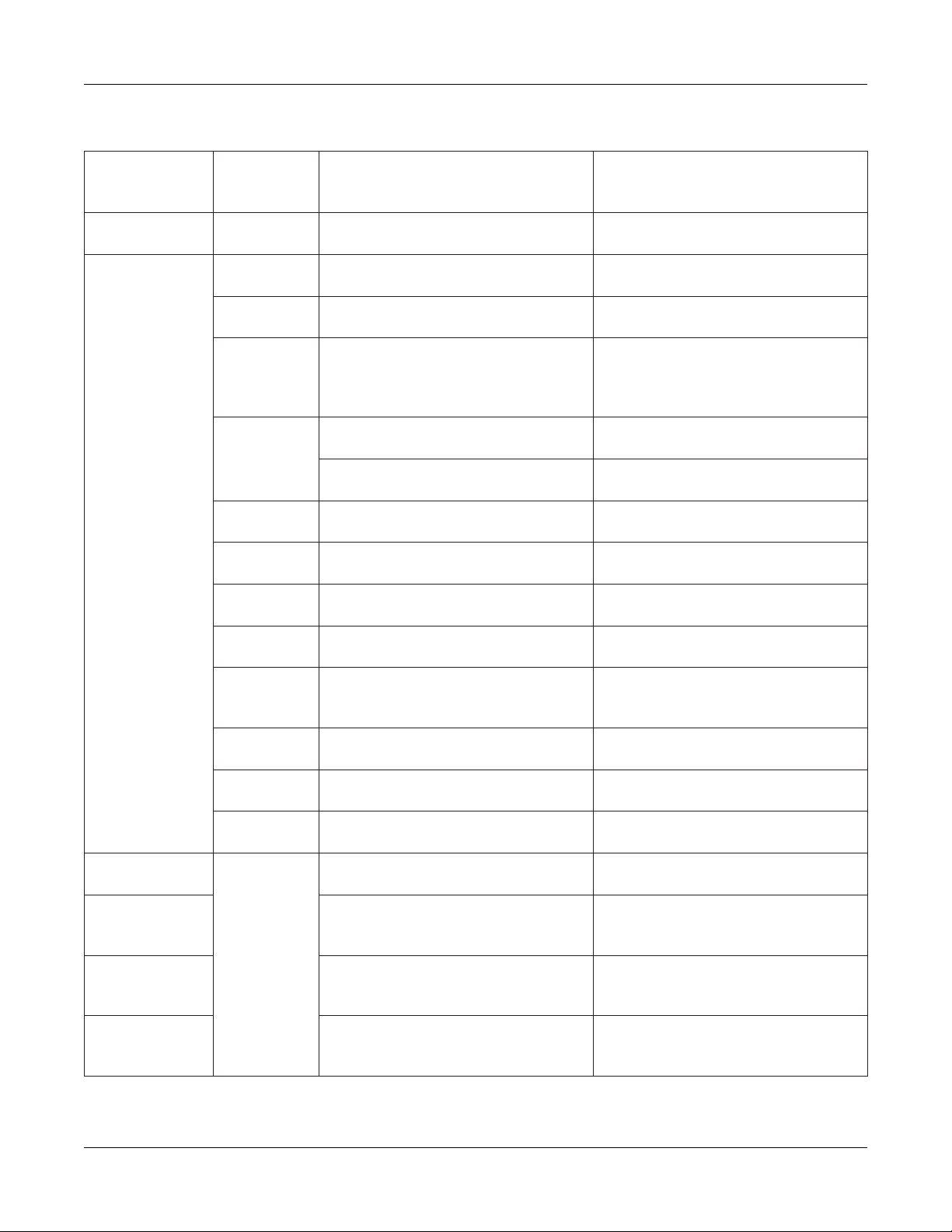

SPECIFICATIONS

Magtrol Model DSP6000 Dynamometer ControllerChapter 1 - Introduction

snoisnemiD

thgieW

erutarepmeTgnitarepO

ytidimuHevitaleR

ycaruccA

tneiciffeoCerutarepmeT

tupnI.xuA

tuOlrtC

tuptuOdeepS/euqroTyrosseccA

)mm02x5(sesuF

stnemeriuqeRrewoP

stnemeriuqeRegatloV

deepSmumixaM

euqroTmumixaM

egatloVecnailpmoCmumixaM

bl5.61

C°52otC°81

%08<

:deepS

:euqroT

:xuA

CDV5±

CDV3-0

:euqroT

:deepS

:ekarB

:)V021(rewoP

:)V042(rewoP

AV57

MPR999,99

stinu0002

CDV54

H"5.3xD"8.31xW"91

MPR000,001otMPR01morfgnidaerfo%10.0

)V2±(egnarfo%2.0

)V5±(egnarfo%1.0

C°/egnarfo%100.0

CDV2±

elcycytud%05,ver/seslupLTT06

A52.1

A1

Am008

Am513

zH05/06V042/021

ASC/LU

CEI

ASC/LU

CEI

052V

V052

V052

V052

BS

T

BS

T

2

Magtrol Model DSP6000 Dynamometer Controller Chapter 1 - Introduction

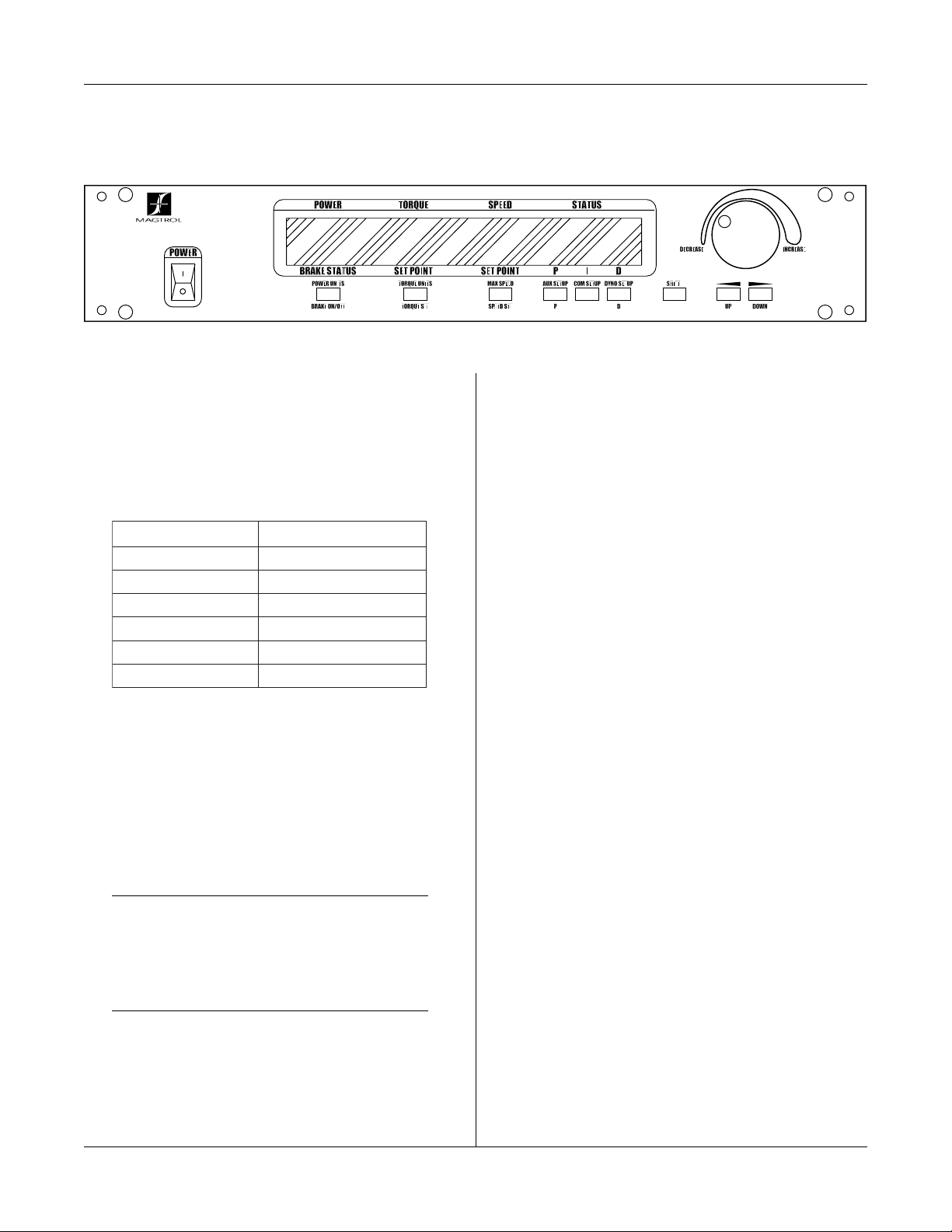

FRONT PANEL

Figure 1. Front Panel

MODEL DSP6000

DYNAMOMETER CONTROLLER

The front panel provides a power switch, eight control

buttons, a Decrease/Increase Dial, and Vacuum

Fluorescent Display (VFD). The front panel controls

and buttons, from left to right, are:

• Power switch

• Six double-function control buttons:

noitcnuFyramirPnoitcnuFyradnoceS

FFO/NOEKARBSTINUREWOP

TESEUQROTSTINUEUQROT

TESDEEPSDEEPSXAM

PPUTESXUA

IPUTESMOC

DPUTESONYD

• Three single-function control buttons:

• SHIFT (to enable secondary functions printed

in blue above control buttons)

!

• Up/Left arrow

(scroll up, increase

magnitude)

"

• Down/Right arrow

(scroll down,

decrease magnitude)

• Decrease/Increase Dial

ENABLING SECONDARY FUNCTIONS

To enable the secondary function of the double-function

control buttons:

1. Press the blue SHIFT button and release it. (The

word SHIFT appears in the display.)

2. Press a control button to enable the function shown

in blue letters above the control button:

POWER UNITS, TORQUE UNITS, AUX SETUP,

COM SETUP or DYNO SETUP.

3. Press the SHIFT button again to exit the secondary

function.

NOTE: Refer to the table, “Front Panel

Controls and Buttons” later in

this chapter for further

explanation of button features

and use.

3

FRONT PANEL CONTROLS AND BUTTONS

Magtrol Model DSP6000 Dynamometer ControllerChapter 1 - Introduction

elgniS/slortnoC

noitcnuF

snottuB

REWOP

TES

-elbuoD

noitcnuF

snottuB

REWOP

STINU

EKARB

FFO/NO

EUQROT

STINU

EUQROT

DEEPSXAM

TESDEEPS.nottubsihtsserP.gnidaoldeepsroftnioptesswohS

PUTESXUA

.nottubsiht

.nottubsiht

.peeb

.nottubsiht

.nottubsiht

esUoTnoitcnuF

otOsserPNOrewopnrutotIsserP

.FFOrewopnrut

sserpneht;esaelerdnaTFIHSsserP

.nottubsihtsserP.NOroFFOekarbselggoT

sserpneht;esaelerdnaTFIHSsserP

.nottubsihtsserPgnidaoleuqrotroftnioptesswohS

dnoceslitnunottubsihtdlohdnasserP

sserpneht;esaelerdnaTFIHSsserP

sserpneht;esaelerdnaTFIHSsserP

.FFOroNOrewopsnruT

.sttaWotyalpsidrewopsteS

sserP.erusaemfotinuderisedsteS

PU ! NWODro " eesotnottub

elbaneotTFIHSsserP.snoitpo

.noitpo

.gnidaolpoolneporoftnioptesswohS

.rellortnocehtfoegnardeepsehtsteS

.FFOroNOyalpsidyrailixuasnruT

.ecivedtupniyrailixuafognilacssteS

P.nottubsihtsserP.niaglanoitroporpstsujdA

I.nottubsihtsserP.largetnistsujdA

ONYD

PUTES

D.nottubsihtsserP.evitaviredstsujdA

TFIHS

TFEL/PU ! .sserP

THGIR/NWOD " .sserP

ESAERCED

ESAERCNI/

LAID

PUTESMOC

.nottubsiht

.nottubsiht

.nottublortnocderisedsserp

sserpneht;esaelerdnaTFIHSsserP

.tsartnocyalpsid

sserpneht;esaelerdnaTFIHSsserP

.redocne

neht,esaelerdnanottubsihtsserP

.nottublortnocevoba

.)deeps.xamroeuqrot

.)deeps.xamroeuqrot

.esiwkcolcretnuocroesiwkcolcnruT

.detcelesretemarap

ehtsesaercnirosesaerceD

dnasserddayramirpBIPGstsujdA

stsujdaoslA.etarduab232-SR

deepsdnastinueuqrottupnistceleS

eulbninettirwnoitcnufehtsetautcA

nehwegnahcfoedutingamsesaercnI

,deeps(eulavlaciremunagnitsujda

nehwegnahcfoedutingamsesaerceD

,deeps(eulavlaciremunagnitsujda

4

Magtrol Model DSP6000 Dynamometer Controller

Chapter 1 - Introduction

VACUUM FLUORESCENT DISPLAY (VFD)

The VFD provides information about the control

functions, the motor under test, and an auxiliary input

device (if connected). The displays, from left to right,

are:

woRpoTwoRmottoB

REWOP

)sttaWropHnidesserpxe(

EUQROT)EUQROT(TNIOPTES

DEEPS)DEEPS(TNIOPTES

SUTATSroTUPNIXUA

YALPSID

P

I

D

SUTATSEKARB

)FFOroNO(

The DSP6000 is shipped with the Contrast setting at

zero (lowest) in order to prolong display life. If it is

necessary to increase the contrast for improved

readability, use the lowest possible setting to achieve

that result. Using a setting higher than necessary may

cause display segments to burn-in over a period of time,

resulting in uneven illumination from segment to

segment.

STATUS DISPLAY MESSAGES

egasseMgninaeM

TFIHS.desserpsawnotubtfihS

XUA

DEEPSXAM

RORREO/I

STINU

QCATSAF

ETOMER

NWODPMAR

PUPMAR

.delbane

.retupmoc

dnadehcattasitinuyrailixuA

.MPRrotommumixaM

morftnessawdnammoctcerrocnI

.tnemerusaemfotinueuqroT

.edomdeeps-hgihniatadgniriuqcA

.delbaneCPaivlortnocetomeR

ybdeepsrotomesaerceD

.rotomnodaolgnisaercni

ybdeepsrotomesaercnI

.rotomnodaolgnisaerced

DISPLAYING DESIRED INFORMATION

Local control:

1. Press SHIFT and release; then press POWER

UNITS to see UNITS displayed.

!

2. Press UP

or DOWN

available choices.

3. Press SHIFT to exit.

4. Press SHIFT and release; then press TORQUE

UNITS to see UNITS displayed.

!

5. Press UP

or DOWN

options for units.

6. Press SHIFT to exit.

7. Press RECALL to view memory contents; last in =

first out.

8. Press SHIFT to exit.

Remote control:

Refer to “DSP6000 Command Set” in Chapter 4 - The

DSP6000 with a PC for a list of commands recognized

by the DSP6000.

Auxiliary Input:

1. Press SHIFT and release; then press AUX SETUP.

2. Rotate Decrease/Increase Dial to select scale.

3. Press SHIFT to exit.

"

to scroll through

"

to scroll through

5

Magtrol Model DSP6000 Dynamometer ControllerChapter 1 - Introduction

1

2

3

4

5

6

7

8

9

10

11

12

13

14

COMMON

D.P.

TACH. SIGNAL

N/C

D.P.

TORQUE COMMON

TORQUE SIGNAL

N/C

N/C

+

-

+

-

TACH. +5.0 VDC

ISOLATED

22 VDC

ISOLATED

22 VDC

CONNECTOR SHELL

& CABLE SHIELD

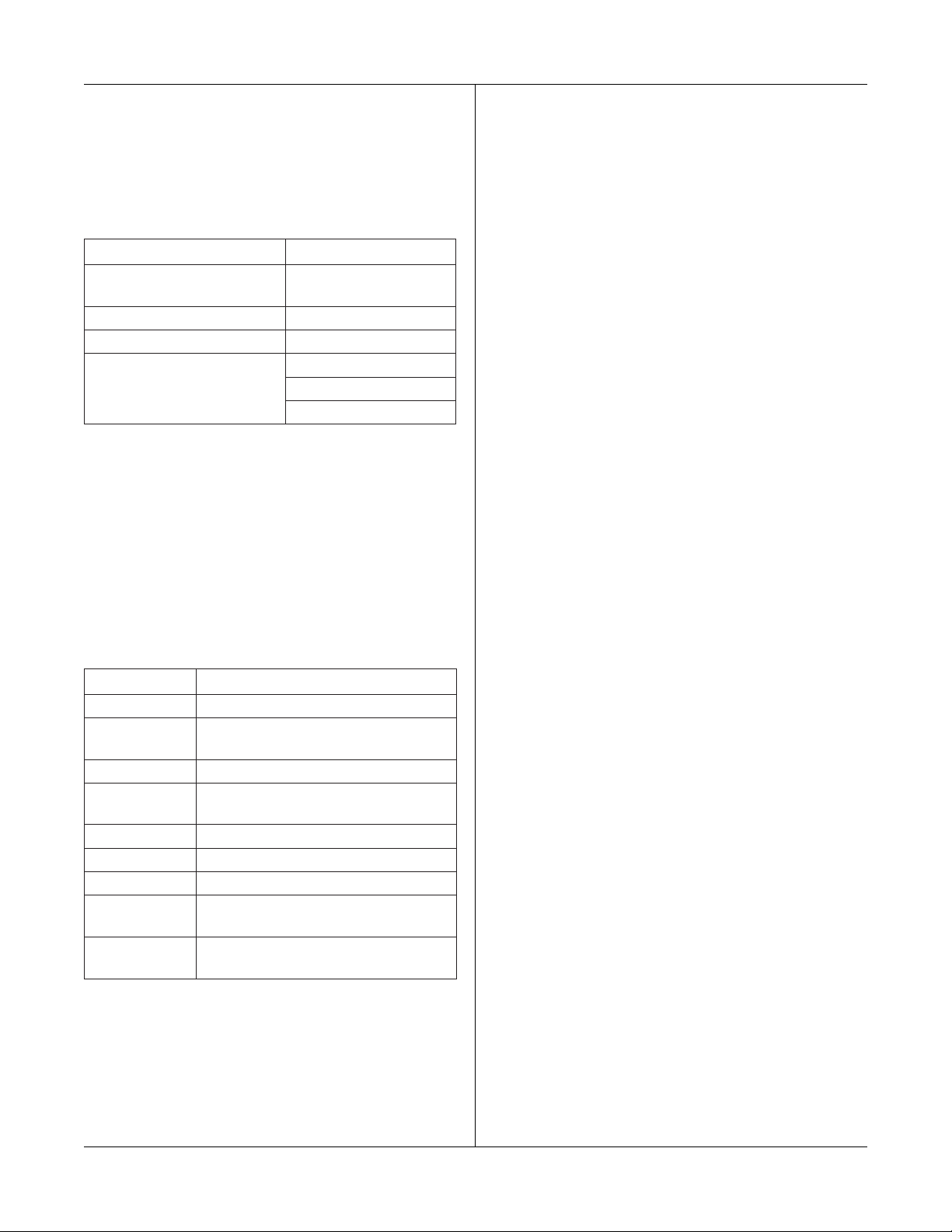

REAR PANEL

The rear panel provides connectors and receptacles for connecting to appropriate equipment.

Figure 2. Rear Panel

Figure 3. Brake Connector

Figure 4. Accessory Torque/Speed Output

TACH.

COMMON

TACH.

SIGNAL

TORQUE

COMMON

67

D.P.

13

45

2

N/C

TORQUE

OUTPUT

Figure 5. Dynamometer Connector

D.P.

6

For use with Magtrol Readouts

only. Connecting another device

to this output may cause

equipment failure.

Magtrol Model DSP6000 Dynamometer Controller Chapter 1 - Introduction

g

g

g

g

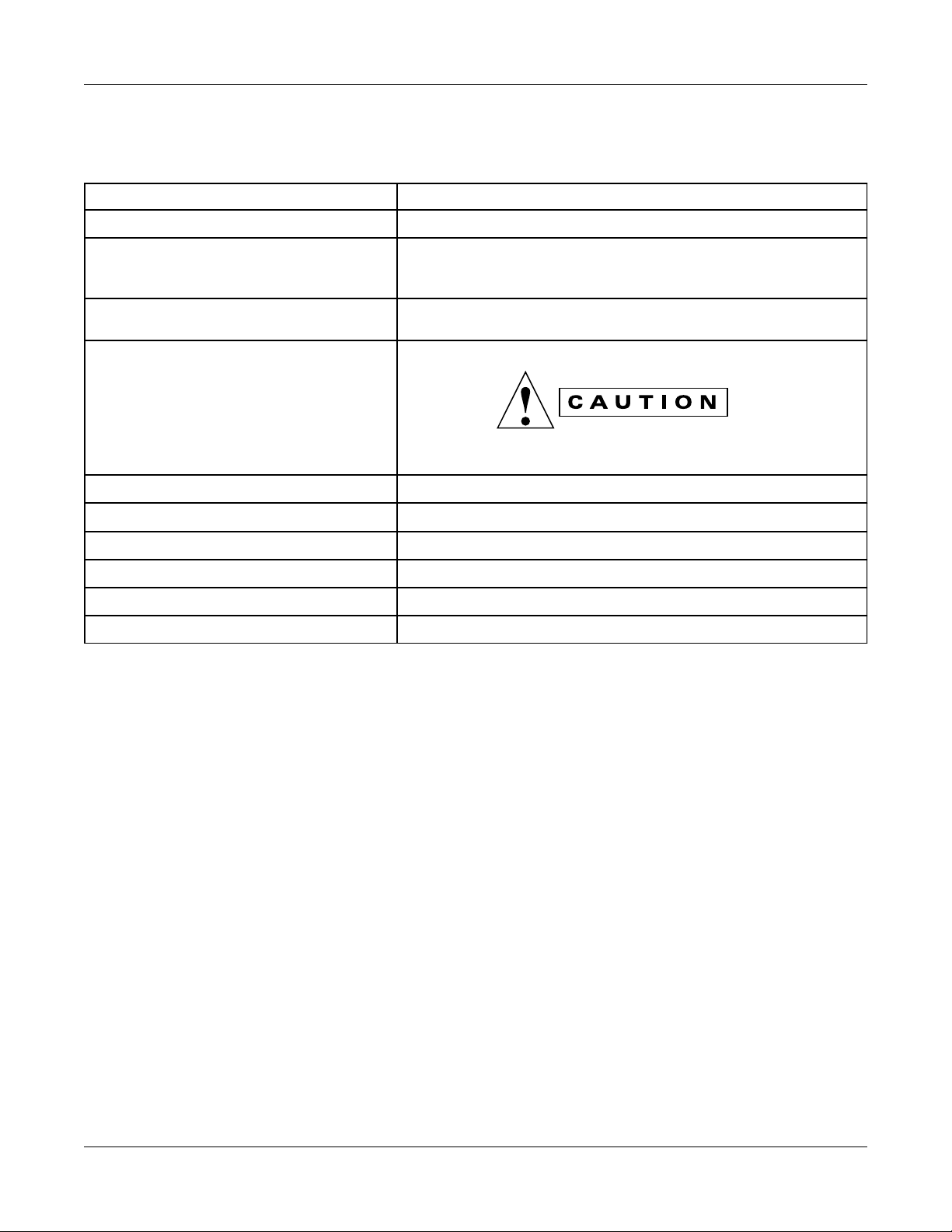

REAR PANEL FUNCTIONS

The rear panel, from left to right, provides the following functions:

Label Function

BRAKE Connect dynamometer brake cable here

Contains brake fuse (5 x 20mm)

BRAKE FUSE

CTRL OUT

ACCESSORY TORQUE-SPEED OUTPUT

UL/CSA 1.25A 250V SB

IEC 1A 250V T

Connect to Model 5241 Power Amplifier when usin

Dynamometer

Connect accessory output cable here (optional).

HD-825

For use with Ma

this output may cause equipment failure.

DYNAMOMETER Connect dynamometer si

AUX INPUT Connect auxiliary instrument cable here

RS-232C Use this socket for RS-232 connector cable

GPIB/IEEE-488 Use this socket for GPIB cable (meets IEEE-488 specifications)

POWER Attach power cord here

EARTH GROUND Attach earth

trol Readouts only. Connecting another device to

nal cable here

round here

7

2 - About the PID L2 - About the PID L

2 - About the PID L

2 - About the PID L2 - About the PID L

oopoop

oop

oopoop

The DSP6000 has PID adjustment capability for both

the speed and torque modes to provide you with the

best system response. The PID Loop comprises the

following three variables:

P = Proportional Gain

I = Integral

D = Derivative

The setpoint is the desired load or speed. Error is the

difference between the setpoint and the actual

measurement.

P (PROPORTIONAL GAIN)

With proportional gain, the controller output is

proportional to the error or to a change in measurement.

Deviation from the setpoint is usually present.

Increasing proportional gain will make the PID loop

unstable. Increasing integral value eliminates this

instability. For best loop control, set the proportional

gain as high as possible without causing the loop to

become unstable.

I (INTEGRAL)

With integral, the controller output is proportional to

the amount of time the error is present. Increasing the

integral value eliminates the offset from the setpoint. If

the response becomes oscillatory, increase the derivative

value.

D (DERIVATIVE)

With derivative, the controller output is proportional to

the rate of change of the measurement or error.

Derivative can compensate for a changing measurement.

Derivative takes action to inhibit more rapid changes

of the measurement than proportional gain.

When a setpoint change occurs, the derivative causes

the controller gain to go the "wrong" way when the

measurement gets close to the setpoint. Derivative can

be used to control overshoot. If derivative is used, higher

gain and integral values are usually necessary.

Magtrol offers a comprehensive motor-test program

which would satisfy most of your needs. Call Magtrol

Sales at 1-800-828-7844 or 1-716-668-5555 to request

your custom software.

NOTE: To set PID values, see Chapter 3

- Installation.

Figure 6. PID Loop

SETTING THE CORRECT PID'S FOR YOUR MOTOR

NOTE: Each type of motor may have it's

own optimum PID setting.

NOTE: The PID settings are scaled to the

maximum speed setting;

therefore the maximum speed

setting should be adjusted to just

higher than the free-run speed of

the motor being tested.

When testing a new motor where the optimal PID's are

unknown:

1. Begin with the Proportional Gain (P) and the

Integral (I) both set to a low value and the Derivative

(D) set to zero. This will allow the best opportunity

for finding the optimum in the lowest amount of

steps.

2. Using the DSP6000 in the speed mode: Set the

speed target at approximately 90% of the free-run

speed.

8

Loading...

Loading...