Magnetek Quattro DC Elevator Drive, TM7310rev01 User Manual

r

Quattro

™

DC Elevator Drive

Technical Manual

TM7310 rev 01

© 2006 Magnetek Elevato

WARRANTY Standard products manufactured by the Company are warranted to be free from

defects in workmanship and material for a period of one year from the date of

shipment, and any products which are defective in workmanship or material will be

repaired or replaced, at the Company’s option, at no charge to the Buyer. Final

determination as to whether a product is actually defective rests with the Company.

The obligation of the Company hereunder shall be limited solely to repair or replace,

at the Company’s discretion, products that fall within the foregoing limitations, and

shall be conditioned upon receipt by the Company of written notice of any alleged

defects or deficiency promptly after discovery and within the warranty period, and in

the case of components or units purchased by the Company, the obligation of the

Company shall not exceed the settlement that the Company is able to obtain from the

supplier thereof. No products shall be returned to the Company without its prior

consent. Products which the company consents to have returned shall be shipped

prepaid f.o.b. the Company factory. The Company cannot assume responsibility or

accept invoices for unauthorized repairs to its components, even though defective.

The life of the products the Company depends, to a large extent, upon type of usage

thereof and THE COMPANY MAKES NO WARRANTY AS TO FITNESS OF ITS

PRODUCTS FOR THE SPECIFIC APPLICATIONS BY THE BUYER NOR AS TO

PERIOD OF SERVICE UNLESS THE COMPANY SPECIFICALLY AGREES

OTHERWISE IN WRITING AFTER PROPOSED USAGE HAS BEEN MADE KNOWN

TO IT.

This warranty does not apply to experimental products for which no warranty is made

or given and Buyer waives any claim thereto.

THE FOREGOING WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING, BUT LIMITED TO, ANY

WARRANTY OF MECHANTIBILITY OR OF FITNESS FOR A PARTICULAR

PURPOSE AND BUYER HEREBY WAIVES ANY AND ALL CLAIMS THEREFORE.

LIMITATIONS IN NO EVENT SHALL MAGNETEK BE LIABLE FOR LOSS OF PROFIT,

OF LIABILITY INDIRECT, CONSEQUENTIAL OR INCIDENTAL DAMAGES WHETHER

ARISING OUT OF WARRANTY, BREACH OF CONTRACT OR TORT.

QUATTRO is a trademark of Magnetek, Inc.

All rights reserved. No part of this publication may be reproduced or used in any form or by any means - graphic, electronic, or

mechanical including photocopying, recording, taping, or information storage and retrieval systems - without written permission

of the publisher.

© 2007 Magnetek, Inc.

Table of Contents

Introduction.............................................................................................................10

Drive Ratings and Specifications ....................................................................................................... 10

Software Operating Features............................................................................................................. 10

Drive Model Numbers ........................................................................................................................ 11

Quattro startup guide .............................................................................................12

Initial Inspection ................................................................................................................................. 12

Grounding considerations.................................................................................................................. 13

Initial adjustments after power up ...................................................................................................... 13

Interconnections.....................................................................................................15

Drive Sequencing....................................................................................................21

NORMAL operating sequence........................................................................................................... 21

ABNORMAL Operation Sequence.....................................................................................................22

Quattro Pre-Charge ........................................................................................................................... 22

Drive Operation and Feature Overview.................................................................23

Analog Velocity Follower.................................................................................................................... 23

Preset Speed & Profile Generator ..................................................................................................... 23

Serial Link Follower............................................................................................................................ 23

Pre-Torque......................................................................................................................................... 23

Torque Feed Forward ........................................................................................................................ 23

Torque/Current Ramp-Down ............................................................................................................. 23

Motor Field Current Control and Field weakening ............................................................................. 24

DSPR ................................................................................................................................................. 24

Over-Speed Test................................................................................................................................ 24

Fault & Alarm Reset........................................................................................................................... 24

Electronic Motor Over-Load............................................................................................................... 24

Armature Voltage Feedback .............................................................................................................. 24

Status Indicator Lights ....................................................................................................................... 25

MONITOR / Adjust / Set-up Parameters:...........................................................................................25

Parameters ..............................................................................................................26

Parameter Introduction ...................................................................................................................... 26

Menu Navigation ................................................................................................................................ 27

Parameter Tree.................................................................................................................................. 28

Adjust A0 menu.......................................................................................................30

Drive A1 submenu ............................................................................................................................. 30

S-Curves A2 submenu....................................................................................................................... 39

Multistep Ref A3 submenu................................................................................................................. 41

Motor Side Power Convert A4 submenu ........................................................................................... 43

Line Side Power Converter A5 submenu........................................................................................... 46

Motor Parameters A6 submenu......................................................................................................... 47

Configure C0 menu.................................................................................................50

User Switches C1 submenu .............................................................................................................. 50

Logic Inputs C2 submenu .................................................................................................................. 61

Logic Outputs C3 submenu ............................................................................................................... 63

Analog Outputs C4 submenu............................................................................................................. 65

Display D0 menu.....................................................................................................66

Elevator Data D1 submenu................................................................................................................ 66

MS Power Data D2 submenu ............................................................................................................ 68

1

LS Power Data D3 submenu ............................................................................................................. 69

Utility U0 menu........................................................................................................70

Fault F0 menu..........................................................................................................76

Maintenance ............................................................................................................78

Maintenance Overview ...................................................................................................................... 78

Drive Servicing................................................................................................................................... 78

Troubleshooting......................................................................................................79

Appendix..................................................................................................................95

Auto Tune Procedure......................................................................................................................... 95

Inertia Calculation .............................................................................................................................. 96

EMC Compliance ............................................................................................................................... 97

Re-Assembly Procedure for 200A / 250A drives ............................................................................... 98

Control Power Consumption............................................................................................................ 102

Watts Loss ....................................................................................................................................... 102

Input / Output Ratings ...................................................................................................................... 102

Wire Terminal Specs........................................................................................................................ 103

Dimensions / Weights ...................................................................................................................... 104

Component Locations ...................................................................................................................... 109

Spare Parts Quattro DC Drive ......................................................................................................... 116

Index.......................................................................................................................119

2

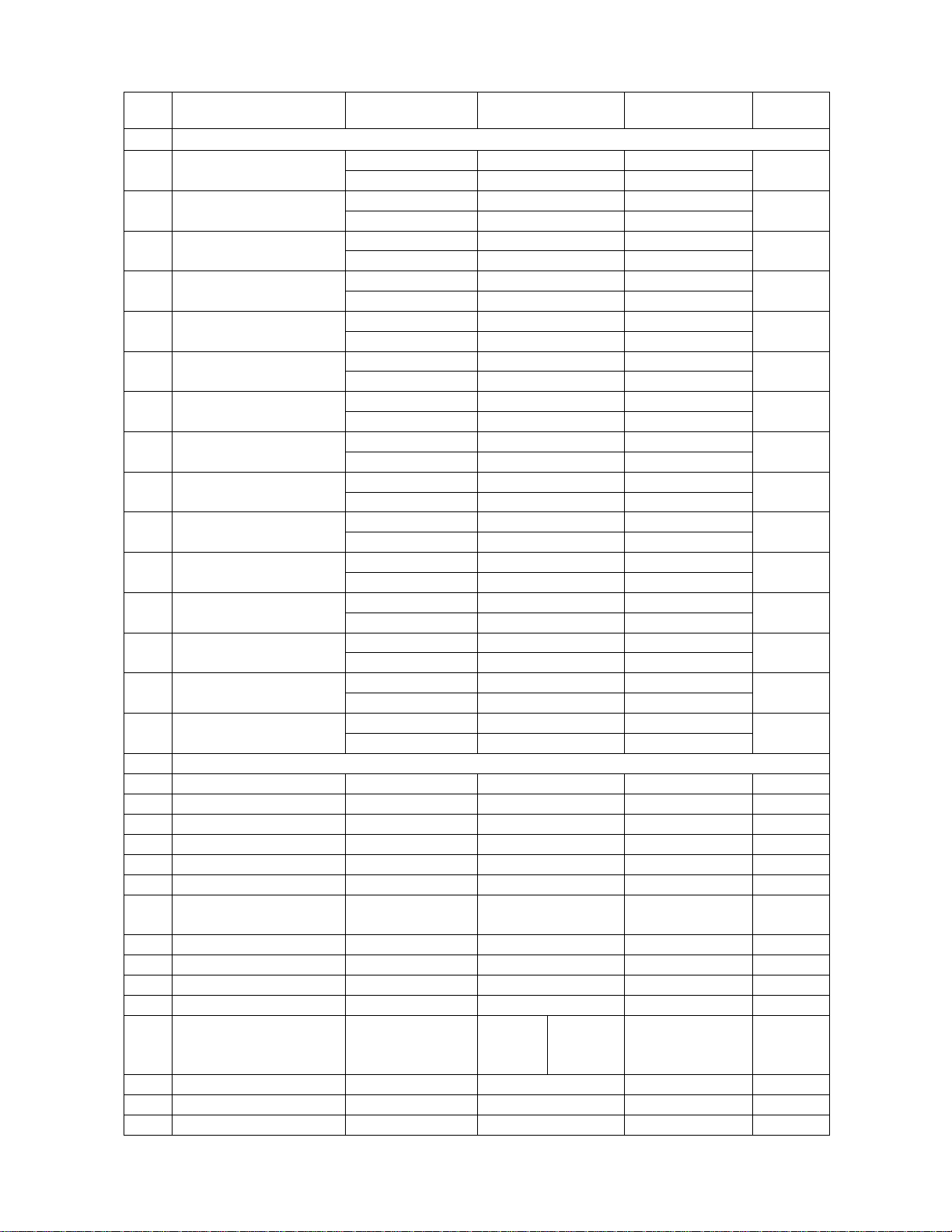

Quattro DC Quick Parameter Reference

Sub

menu

A1 Drive A1 Submenu – See Drive A1 submenu on page 30.

Parameter Units Range Default

A1 CONTRACT CAR SPD

A1 CONTRACT MTR SPD RPM 30.0 – 3000.0 1130.0

A1 RESPONSE rad/sec 1.0 – 20.0 10.0

A1 INERTIA sec 0.25 – 50.00 2.00

A1 INNER LOOP XOVER rad/sec 0.1 – 20.0 2.0

A1 CURRENT LIMIT % 0.0 – 275.0 200

A1 GAIN REDUCE MULT % 10 – 100 100

A1 GAIN CHNG LEVEL % of rated spd 0.0 – 100.0 100.0

A1 TACH FILTER BW rad/sec 1 – 100 100

A1 TACH RATE GAIN none 0.0 – 30.0 0.0

A1 SPD PHASE MARGIN degrees 45 – 90 80

A1 RAMPED STOP TIME sec 0.00 – 2.50 0.20

A1 CONTACT FLT TIME sec 0.10 – 5.00 0.50

A1 BRAKE PICK TIME sec 0.00 – 5.00 1.00

A1 BRAKE HOLD TIME sec 0.00 – 5.00 0.20

A1 OVERSPEED LEVEL % of contract spd 90.0 – 150.0 115.0

A1 OVERSPEED TIME sec 0.00 – 9.99 1.00

A1 OVERSPEED MULT % 100.0 – 150.0 125.0

A1 ENCODER PULSES PPR 600 – 10000 5000

A1 SPD DEV LO LEVEL % of contract spd 0.1 – 20.0 10.0

A1 SPD DEV TIME sec 0.00 – 9.99 0.50

A1 SPD DEV HI LEVEL % of contract spd 0.0 – 99.9 10.0

A1 SPD COMMAND BIAS volts 0.00 – 6.00 0.00

A1 SPD COMMAND MULT none 0.90 – 5.00 1.00

A1 EXT TORQUE BIAS volts -6.00 – +6.00 0.00

A1 EXT TORQUE MULT none -10.00 – +10.00 1.00

A1 ZERO SPEED LEVEL % of contract spd 0.00 – 99.99 1.00

A1 ZERO SPEED TIME sec 0.00 – 9.99 0.10

A1 UP/DWN THRESHOLD % of contract spd 0.00 – 9.99 1.00

A1 ANA 1 OUT OFFSET % -99.9 – +99.9 0.0

A1 ANA 2 OUT OFFSET % -99.9 – +99.9 0.0

A1 ANA 1 OUT GAIN none 0.0 – 10.0 1.0

A1 ANA 2 OUT GAIN none 0.0 – 10.0 1.0

A1 FLT RESET DELAY sec 0 – 120 5

A1 FLT RESETS/HOUR faults 0 – 10 3

A1 UP TO SPD LEVEL % of contract spd 0.00 – 110.00 80.00

A1 RUN DELAY TIMER sec 0.00 – 0.99 0.00

A1 AB ZERO SPD LEV % 0.00 – 2.00 0.00

A1 AB OFF DELAY sec 0.00 – 9.99 0.00

A1 CONTACTOR DO DLY sec 0.00 – 5.00 0.00

A1 TRQ LIM MSG DLY sec 0.00 – 10.00 0.50

A1 ROLLBACK GAIN none 1 – 99 1

A1 NOTCH FILTER FRQ Hz 5 – 60 20

A1 NOTCH FILT DEPTH % 0 – 100 0

A1 STNDBY FLD TIME sec 0 – 999 30

A1 DSPR TIME min 0 – 999 120

A1 FULL FIELD TIME min 0 – 99 5

fpm 0.0 – 1500.0 400.0

m/s 0.000 – 8.000 2.000

Site

Setting

3

Quattro DC Quick Parameter Reference

Sub

menu

A2 S-Curves A2 Submenu – See S-Curves A2 submenu on page 39.

Parameter Units Range Default

A2 ACCEL RATE 0

A2 DECEL RATE 0

A2 ACCEL JERK IN 0

A2 ACCEL JERK OUT 0

A2 DECEL JERK IN 0

A2 DECEL JERK OUT 0

A2 ACCEL RATE 1

A2 DECEL RATE 1

A2 ACCEL JERK IN 1

A2 ACCEL JERK OUT 1

A2 DECEL JERK IN 1

A2 DECEL JERK OUT 1

A2 ACCEL RATE 2

A2 DECEL RATE 2

A2 ACCEL JERK IN 2

A2 ACCEL JERK OUT 2

A2 DECEL JERK IN 2

A2 DECEL JERK OUT 2

A2 ACCEL RATE 3

A2 DECEL RATE 3

A2 ACCEL JERK IN 3

A2 ACCEL JERK OUT 3

A2 DECEL JERK IN 3

A2 DECEL JERK OUT 3

ft/s2 0.00 – 7.99 7.99

2

m/s

0.000 – 3.999 2.435

ft/s2 0.00 – 7.99 7.99

2

m/s

0.000 – 3.999 2.435

ft/s3 0.0 – 29.9 0.0

3

m/s

0.000 – 9.999 0.000

ft/s3 0.0 – 29.9 0.0

3

m/s

0.000 – 9.999 0.000

ft/s3 0.0 – 29.9 0.0

3

m/s

0.000 – 9.999 0.000

ft/s3 0.0 – 29.9 0.0

3

m/s

0.000 – 9.999 0.000

ft/s2 0.00 – 7.99 7.00

2

m/s

0.000 – 3.999 2.134

ft/s2 0.00 – 7.99 3.00

2

m/s

0.000 – 3.999 0.090

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s2 0.00 – 7.99 3.00

2

m/s

0.000 – 3.999 0.090

ft/s2 0.00 – 7.99 3.00

2

m/s

0.000 – 3.999 0.090

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s2 0.00 – 7.99 3.00

2

m/s

0.000 – 3.999 0.090

ft/s2 0.00 – 7.99 3.00

2

m/s

0.000 – 3.999 0.090

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

ft/s3 0.0 – 29.9 8.0

3

m/s

0.000 – 9.999 2.400

Site

Setting

4

Quattro DC Quick Parameter Reference

Sub

menu

Parameter Units Range Default

A3 Multistep Ref A3 Submenu – See Multistep Ref A3 submenu on page 41.

A3 SPEED COMMAND 1

A3 SPEED COMMAND 2

A3 SPEED COMMAND 3

A3 SPEED COMMAND 4

A3 SPEED COMMAND 5

A3 SPEED COMMAND 6

A3 SPEED COMMAND 7

A3 SPEED COMMAND 8

A3 SPEED COMMAND 9

A3 SPEED COMMAND 10

A3 SPEED COMMAND 11

A3 SPEED COMMAND 12

A3 SPEED COMMAND 13

A3 SPEED COMMAND 14

A3 SPEED COMMAND 15

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

ft/min -3000.0 – +3000.0 0.0

m/sec -16.000 – +16.000 0.000

A4 Motor Side Power Convert A4 Submenu – See Motor Side Power Convert on page 43.

A4 ARM RESISTANCE ohm 0.0001 – 2.9999 0.5000

A4 ARM INDUCTANCE mH 0.01 – 327.67 15.00

A4 MTR REV VLT LIM % 0.01 – 30.00 4.80

A4 If REG INT GAIN none 0.00 – 30.00 0.90

A4 If REG PROP GAIN none 0.00 – 16.38 6.07

A4 AUTO TUNE MOTOR none

A4 GAIN SELECTION none

A4 GAIN BANDWIDTH A rad/sec 100 – 2000 500

A4 GAIN BANDWIDTH F rad/sec 1 – 40 5

A4 PWM FREQUENCY kHz 2.5 – 16.0 6.0

A4 FAN OFF DELAY sec 0 – 999 180

A4 MAIN FAN CONTROL none

A4 UV-ALARM LEVEL % 80 – 99 90

A4 UV FAULT LEVEL % 50 – 99 80

A4 FLD CARRIER FRQ kHz 3 – 10 3

− Start Autotune?

− manual

− autotune

− auto

− temp

− off

− low

− medium

− high

-

MANUAL

TEMP

Site

Setting

5

Quattro DC Quick Parameter Reference

Sub

menu

Parameter Units Range Default

A5 Line Side Power converter A5 Submenu – See Line Side Power Converter on page 46.

A5 Id REG PROP GAIN none 0.00 – 9.99 0.30

A5 Id REG INTGRL GAIN none 0 – 999 10

A5 Iq REG PROP GAIN none 0.00 – 9.99 0.30

A5 Iq REG INTGRL GAIN none 0 – 999 40

A5 DC BUS REG P GAIN none 0.00 – 9.99 3.00

A5 DC BUS REG I GAIN none 0 – 999 40

A5 INPUT L-L VOLTS volts 110 – 552 480

A5 DC BUS V BOOST volts 15 – 75 30

A5 SW BUS OV LEVEL volts 100 – 850 850

A5 BUS VREF SOURCE none

A5 PLL FILTER FC Hz 0.0 – 150.0 40.0

A5 LS PWM FREQ kHz 2.5 – 16.0 10.0

A6

Motor A6 Submenu – See Motor Parameters A6 submenu on page 47.

A6 MOTOR ID none - -

A6 RATED MOTOR CURR amps 1.0 – 400.0 0.0

A6 ARMATURE VOLTS volts 55 – 600 0

A6 FULL FLD CURRENT amps 1.0 – 40.0 0.0

A6 WEAK FLD CURRENT amps 1.0 – 40.0 0.0

A6 STANDBY FIELD amps 0.0 – 40.0 0.0

A6 FLUX CONFIRM LEV % 25.0 – 99.0 0.0

A6 ARMATURE IR DROP % 0.0 – 25.0 0.0

A6 OVLD START LEVEL % 100 – 150 110

A6 OVLD TIME OUT sec 5.0 – 120.0 60.0

− track line v

− trk vin param

TRK Vin PARAM

C1 User Switches C1 Submenu – See User Switches C1 submenu on page 50.

− analog input

C1 SPD COMMAND SRC none

C1 RUN COMMAND SRC none

C1 FIELD ENA SOURCE none

C1 HI/LO GAIN SRC none

C1 SPEED REG TYPE none

C1 MOTOR ROTATION

C1 ENCODER CONNECT

C1 SPD REF RELEASE

C1 CONT CONFIRM SRC

C1 TACH FILTER

none

none

none

none

none

− multi-step

− ser mult step

− serial

− external tb

− serial

− serial+extrn

− external tb

− serial

− 2-bit serial

− enable on run

− external tb

− serial

− internal

− elev spd reg

− pi speed reg

− external reg

− cemf reg

− forward

− reverse

− forward

− reverse

− reg release

− brake picked

− none

− external tb

− off

− on

MULTI-STEP

EXTERNAL TB

ENABLE ON RUN

INTERNAL

ELEV SPD REG

FORWARD

FORWARD

REG RELEASE

NONE

OFF

Site

Setting

6

Sub

menu

C1

Parameter Units Range Default

User Switches C1 Submenu continued …

C1 PreTorque SOURCE none

C1 PreTorque LATCH

C1 PTorq LATCH CLCK

C1 FAULT RESET SRC none

C1 OVERSPD TEST SRC

C1 BRAKE PICK SRC

C1 BRAKE PICK CNFM none

C1 BRAKE HOLD SRC

C1 RAMPED STOP SEL

C1 RAMP DOWN EN SRC none

C1 BRK PICK FLT ENA

C1 BRK HOLD FLT ENA

C1 EXT TORQ CMD SRC none

C1 DIR CONFIRM

C1 S-CURVE ABORT

C1 ENCODER FAULT

C1 PRIORITY MESSAGE

C1 STOPPING MODE

C1 AUTO STOP

C1 DSPR ENABLE

none

none

none

none

none

none

none

none

none

none

none

none

none

none

none

Quattro DC Quick Parameter Reference

Site

Setting

− none

− analog Input

− serial

− not latched

− latched

− serial

− external tb

− external tb

− serial

− automatic

− external tb

− serial

− internal

− serial

− none

− internal time

− external tb

− internal

− serial

− none

− ramp on stop

− external tb

− run logic

− serial

− disable

− enable

− disable

− enable

− none

− analog input

− serial

− disable

− enable

− disable

− enable

− disable

− enable

− disable

− enable

− immediate

− ramp to stop

− disable

− enable

− disable

− enable

NONE

NOT LATCHED

EXTERNAL TB

EXTERNAL TB

EXTERNAL TB

INTERNAL

NONE

INTERNAL

NONE

EXTERNAL TB

DISABLE

DISABLE

NONE

DISABLE

DISABLE

ENABLE

ENABLE

IMMEDIATE

DISABLE

DISABLE

7

Quattro DC Quick Parameter Reference

Sub

menu

C2

C3 Logic Outputs C3 Submenu – See Logic Outputs C3 submenu on page 63.

Parameter Units Range Default

Logic Inputs C2 Submenu – See Logic Inputs C2 submenu on page 61.

C2 N.C. INPUTS None Hex Number 0x01

C2 LOGIC INPUT 1 TB1(1)

C2 LOGIC INPUT 2 TB1(2)

C2 LOGIC INPUT 3 TB1(3)

C2 LOGIC INPUT 4 TB1(4)

C2 LOGIC INPUT 5 TB1(5)

C2 LOGIC INPUT 6 TB1(6)

C2 LOGIC INPUT 7 TB1(7)

C2 LOGIC INPUT 8 TB1(8)

C2 LOGIC INPUT 9 TB1(9)

LOGIC OUTPUT 1

C3

TB1(25)

LOGIC OUTPUT 2

C3

TB1(26)

LOGIC OUTPUT 3

C3

TB1(27)

LOGIC OUTPUT 4

C3

TB1(28)

LOGIC OUTPUT 5

C3

TB1(29)

LOGIC OUTPUT 6

C3

TB1(30)

LOGIC OUTPUT 7

C3

TB1(31)

C3

SSR1 TB1(21/22) NO FUNCTION

C3

SSR2 TB1(23/24) NO FUNCTION

RELAY COIL 1 TB2

C3

(1/3/5)

RELAY COIL 2 TB2

C3

(8/10/12)

− contact cfirm

− ctr pwr sense

− drive enable

− extrn fault 1

− extrn fault 2

− extrn fault 3

− extrn /flt 4

− fault reset

− field enable

− low gain sel

− mech brk hold

− mech brk pick

− no function

− ospd test src

− alarm

− alarm+flt

− auto brake

− brake hold

− brake pick

− brk hold flt

− brk pick flt

− car going dwn

− car going up

− charge fault

− close contact

− contactor flt

− curr reg flt

− drv overload

− encoder flt

− fault

− flux confirm

− ground fault

− in low gain

− motor trq lim

− mtr overload

− no function

− pre-trq latch

− run

− run down

− run up

− s-curve sel 0

− s-curve sel 1

− ser2 insp ena

− step ref b0

− step ref b1

− step ref b2

− step ref b3

− trq ramp down

− up/dwn

− not alarm

− over curr flt

− overspeed flt

− overtemp flt

− overvolt flt

− ovrtemp alarm

− phase fault

− ramp down ena

− ready 2 start

− ready to run

− regen trq lim

− run commanded

− run confirm

− speed dev

− speed dev low

− speed ref rls

− speed reg rls

− undervolt flt

− up to speed

− uv alarm

− zero speed

CONTACT CFIRM

CTR PWR SENSE

NO FUNCTION

DRIVE ENABLE

RUN

UP/DWN

STEP REF B0

STEP REF B1

FAULT RESET

CLOSE

CONTACT

RUN

COMMANDED

MTR OVERLOAD

ENCODER FLT

FAULT

SPEED REG

RLS

SPEED REG

RLS

NO FUNCTION

NO FUNCTION

Site

Setting

C4 Analog Outputs C4 Submenu – See Analog Outputs C4 submenu on page 65.

ANALOG OUTPUT 1

C4

C4 ANALOG OUTPUT 2

− arm current

− arm voltage

− aux torq cmd

− bus voltage

− est motor spd

− field current

− iarm error

− pretorque ref

− motor mode

− spd rg tq cmd

− speed command

− speed error

− speed feedbk

− speed ref

− tach rate cmd

− tach speed

− torque ref

SPEED REF

SPEED FEEDBK

8

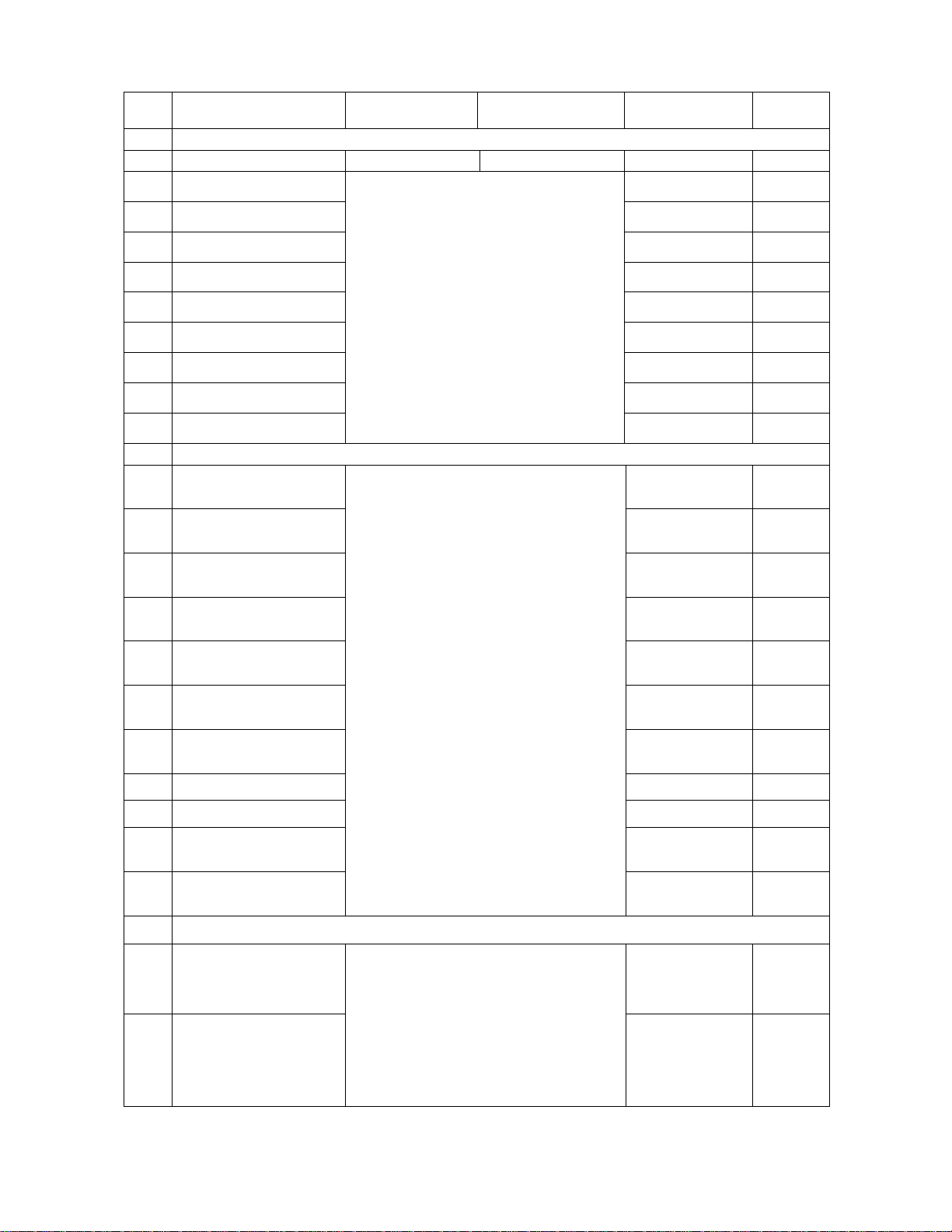

Menu Parameter Unit

D1 Elevator Data Submenu

D1 Speed Command ft/min or m/sec

D1 Speed Reference ft/min or m/sec

D1 Speed Feedback ft/min or m/sec

D1 Speed Error ft/min or m/sec

D1 Pre-Torque Ref % of rated torque

D1 Ext-Torque Cmd % of rated current

D1 Spd Reg Torq Cmd % of rated torque

D1 Tach Rate Cmd % of rated torque

D1 Aux Torque Cmd % of rated torque

D1 Est Inertia Seconds

D1 Rx Com Status 1 = true; 0 = false

D1 Logic Outputs 1 = true; 0 = false

D1 Logic Inputs 1 = true; 0 = false

D2 MS Power Data Submenu

D2 Armature Current Amps

D2 Field Current Amps

D2 Armature Voltage Volts

D2 MS Bus Voltage Volts

D2 Motor Mode None

D2 Torque Ref %

D2 Est Spd Fdbk ft/min or m/sec

D2 Encoder Spd ft/min or m/sec

D2 DS Module Temp °C

D2 LS Module Temp °C

D2 Highest Temp °C

D2 Field IGBT Temp °C

D2 Armature Cur Err Amps

D2 Auto Fld Int none

D2 Auto Fld Prop none

D2 Auto Meas Arm L mH

D2 Auto Meas Arm R Ohm

D2 Auto Field Res Ohm

D2 Auto Field Tc sec

D3 LS Power Data Submenu

D3 LS Pwr Output kW

D3 DC Bus Voltage Volts

D3 DC Bus Volts Ref Volts

D3 LS Overload %

D3 LS Input Current Amps

D3 LS D Axis I %

D3 LS Q Axis I %

D3 LS D Axis Volts %

D3 LS Q Axis Volts %

D3 Input Hz Hz

D3 Input Vab Volts

D3 Input Vca Volts

D3 LS Module Temp °C

Quattro DC Quick Parameter Reference

Menu Parameter Unit

U1 Password U1 Submenu

U1 Enter password U1 New password U1 Password Lockout -

U2 Hidden Items U2 Submenu

U2 Hidden Items Enable -

U3 Units U3 Submenu

U3 Units Selection -

U4 Ovrspeed Test U4 Submenu

U4 Overspeed Test -

U5 Restore Dflts U5 Submenu

U5 Restore Motor Dflts U5 Restore Drive Dflts U5 Restore Utility Dflts -

U6 Motor Side Info U6 Submenu

U6 MS Type U6 MS Code Version U6 MS S/W Date U6 MS S/W Time U6 MS FPGA Version U6 MS Cube ID -

U7 Line Side Info U7 Submenu

U7 LS Type U7 LS Code Version U7 LS S/W Date U7 LS S/W Time U7 LS FPGA Version U7 LS Cube ID -

U8 Hex Monitor U8 Submenu

U8 Hex Monitor -

F1 Active Faults F1 Submenu

F1 Display Active Faults F1 Reset Active Faults -

F2 Faults History F2 Submenu

F2 Display Fault History F2 Clear Fault History F2 Display Fault Counters -

9

Quattro DC Introduction

Introduction

Drive Ratings and Specifications

The Quattro drive is designed for connection to

a 4 wire grounded 3-phase input along with a

single-phase 230 VAC control power input.

Basic Drive Specifications

• 125, 200, 250 amps DC armature output

(Elevator Run Current) at up to 550VDC in

2 basic model sizes

• 150% overload for 60 seconds

• 250% overload for 6 seconds

• Up to 40 ADC motor field control

• <8% utility input current harmonics at full

power (<5% on 125 amp unit)

• Unity Power Factor (1.0 Service Factor)

• 0–45ºC (32–115ºF) ambient temp range

• Fully regenerative operation

• Includes motor armature contactor w/

provision for armature DB resistors

• 4+ Million Start-Stop operating cycles

• (9) 24VDC Programmable Logic Inputs

• (11) Programmable Logic Outputs:

− (7) 24VDC

− (2) Solid-State Relays

− (2) Relays

• 5V or 12V Isolated encoder power source

w/ differential receivers

Service Conditions

• Required: 200-480 VAC, 3-phase, 50/60 Hz

input power, Line Impedance Z < 6%

• Required: 220-240 VAC, single-phase

control power, 50/60 Hz, 3.5/5.5 amps

maximum for 125/200-250 amp drives

respectively

Software Operating Features

The General Purpose Quattro-DC elevator

drive is a four-quadrant torque and speed

regulated motor drive with low power line

harmonic currents and unity power factor. It

can be configured to operate geared and

gearless elevators and lifts. Basic features

include...

• User choice of operating speed reference

(see pg 23)

− External analog reference follower

− Serial link reference follower

− Internal reference generator with

controlled S-Curve smoothing to one of 15

preset speeds

• User choice of ft/min or m/sec speed

programming and display units (see pg 71)

• User choice of input control logic for Run-Up /

Run-Down or Run / Direction relay control

with internal preset speeds (see pg 23)

• User choice of P-I type or MagneTek

exclusive E-Reg, elevator velocity

regulators (see pages 59 and 60)

• Optional CEMF speed regulator for use

during initial construction stage start-up

• Torque Feed-Forward when available from

the car controller (see pg 23)

• Pre-Torque at drive start to reduce roll-back

(see pg 23)

• Controlled torque Ramp-Down to prevent

elevator brake thumping at stops (see pg 23)

• Internal frequency notch filter to reject rope

resonance interference (see pg 38)

• Closed loop motor field current regulator

with simplified motor field weakening and

stand-by adjustments

• Quiet, variable speed cooling fan

• Drive Stand-by Power Reduction (see pg 24)

• User selectable choices for relay logic

outputs, including (see Logic Outputs C3

submenu on pg 63):

− Drive OK / No Faults relay

− Alarms Relay

− Drive operating, OK to release brake

− Car above/below speed X threshold

− Car above/below Zero speed threshold

− Car Moving Up

− Car Moving Down

− Speed Error above/below X threshold for Y

secs

− Drive Standby Power Reduction (DSPR)

− Elevator Brake actuation

• User selectable analog trace outputs for

system diagnostics (see Analog Outputs C4

submenu on pg 65)

• Diagnostic indicator for verifying logic input

and output conditions

• Programmable Alarm Relay to indicate

important but non-critical conditions

− Motor thermostat over-temperature

− Motor Over-Load

− Drive Over-Heating

− Low Utility Line Input

• Safety related fault trapping with

diagnostics, including:

− Motor Over-Current

− Motor field Malfunction

− Contactor Failure

− Severe Utility Line disturbances

− Encoder Loss

− Over-Speed Trip

• User selectable automatic or external

commanded Fault Reset (see User

Switches C1 submenu on pages 50-58)

10

Quattro DC Introduction

p

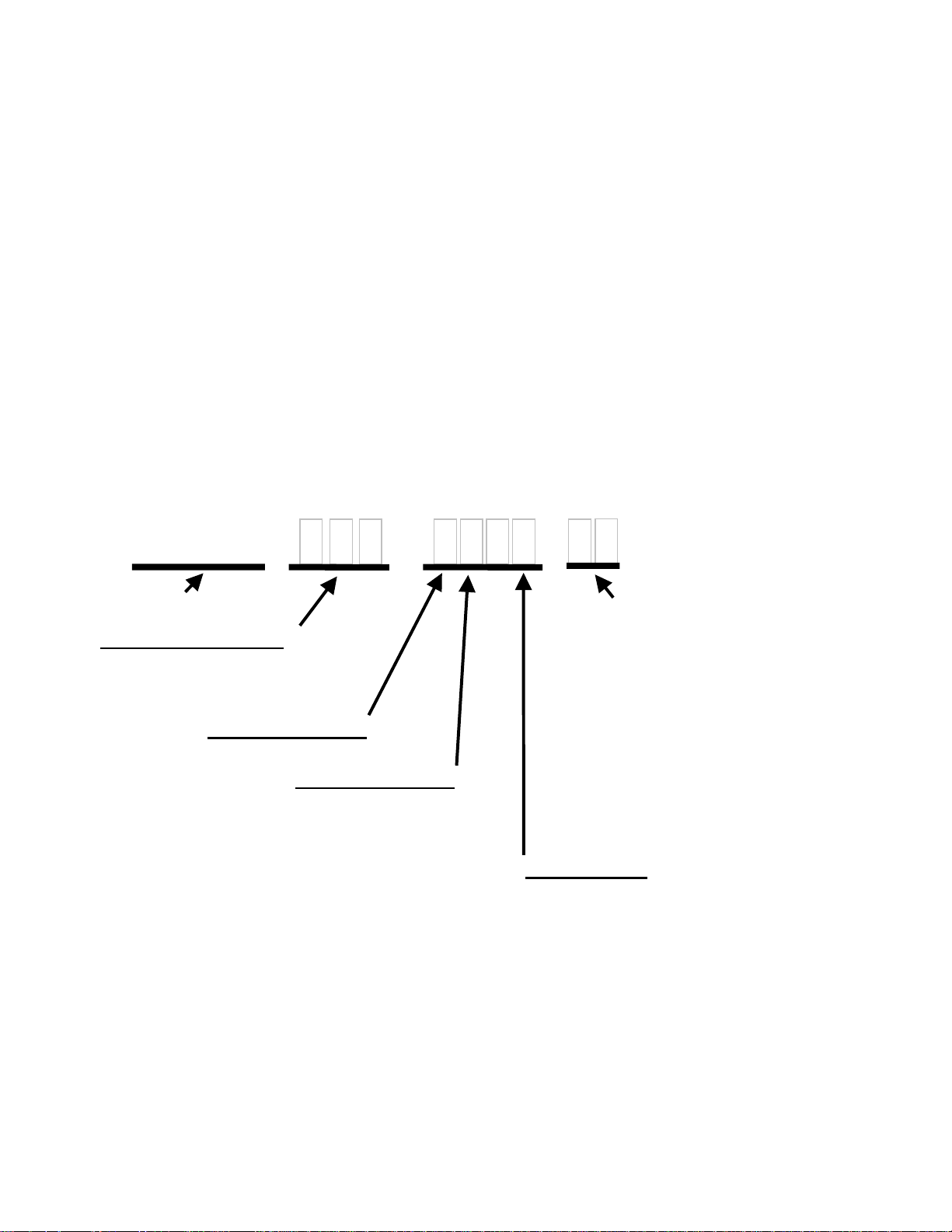

Drive Model Numbers

The Quattro DC drive is currently available

with three different output currents and a

variety of options.

The enclosure options consist of a customer

I/O panel and a side Dynamic Braking Resistor

box. The Dynamic Braking Resistor box is an

optional box that is attached to the right hand

side of the cabinet. It is used to hold the

dynamic braking resistors. The customer I/O

panel is an optional larger width cabinet that

allows for customer interfacing within the

supplied cabinet. See Dimensions / Weights

on page 104.

QDC

1 0

- -

The next option consists of shipping, either

domestically or internationally. Due to

international standards, the shipping crate

must be heat-treated.

The final option section determines the type of

motor contactor and Magnetek Operator. The

Magnetek Operator is not required to start

running, but allows for easy access to

parameters, overspeed test, and auto tuning.

drive

output current rating

125 = 125A output current

200 = 200A output current

250 = 250A out

ut current

software program

enclosure options

1 = no customer I/O panel, no side DBR box

2 = no customer I/O panel, side DBR box

3 = customer I/O panel, no side DBR box

4 = customer I/O panel, side DBR box

options

00 = No operator, ABB type

01 = Operator, ABB type

02 = No Magnetek Operator,

03 = Operator, Dual DC

shipping type

1 = domestic

2 = international

Contactor

Contactor

Dual DC Contactor

Contactor

11

Quattro DC Startup Guide

Quattro startup guide

Initial Inspection

Unpacking

1. When unpacking, check drive for any

shipping damage.

2. The 200A and 250A versions of the

Quattro arrive in separate shipping

containers, which require connection in the

field. Prior to connecting enclosures,

check serial numbers on each cabinet

section to insure mating compatible units.

Proper mating of enclosures and wiring

between is important. Refer to the reconnection instructions on page 98.

3. Review the technical manual, shipped with

the drive.

4. Verify the proper drive model numbers and

voltage ratings as specified on the

purchase order.

5. Location of the Quattro is important for

proper operation of the drive and normal

life expectancy.

Installation

The installation should comply with the

following:

− DO NOT mount in direct sunlight, rain or

extreme (condensing) humidity.

− DO NOT mount where corrosive gases or

liquids are present.

− AVOID exposure to vibration, airborne dust

or metallic particles.

− DO NOT allow the ambient temperature

around the control to exceed the ambient

temperature listed in the specification.

Observe the following precautions:

1. Wiring guide lines

For Logic Input and Output I/O

connections, use quality, multiconductor cable or discrete stranded

wire only.

For Encoder and Analog I/O

connections, use quality, multiconductor braided shield cable*.

For Communication I/O connections,

use quality, multi-conductor braided

shield* cable or twisted pair wire.

*Cable shields to be terminated with a 180/360

degree metal cable clamp attached to Control

Tray panel flange. Refer to the EMC

Compliance on page 97.

2. Never connect main AC power to the

output terminals

3. Never allow wire leads to contact metal

surfaces. Short circuit may result.

4. SIZE OF WIRE MUST BE SUITABLE FOR

CLASS I CIRCUITS.

5. Motor lead length should not exceed 20m

(60 ft). If lead length must exceed this

distance, contact Magnetek for proper

installation procedures.

6. The following are required to be contained

in individual conduit runs: 3-phase

incoming power, control power, DC

armature wires, and DC shunt field.

7. Use UL/CSA certified connectors sized for

the selected wire gauge. Install

connectors using the crimping tools

specified by the connector manufacturer.

8. Control wire lead length should not exceed

20m (60 ft). Signal leads and feedback

leads should be run in separate conduits

from power and motor wiring.

9. Verify that the input voltage matches the

drive’s rating.

10. Verify that the motor is wired for the

application voltage and amperage.

11. Tighten all of the three-phase power and

ground connections. See Table 1 for

torque specs.

Wire References Torque Specs

Power Terminals 56.6 N-m (500 in-lbs)

Plastic Cover Screws 0.23-0.28 N-m (2-2.5

in-lbs)

Ground Terminals 31.0 N-m (275 in-lbs)

Table 1: Input Power Torque Specs

12. Check that all control and signal

terminations are also tight.

CAUTION: TO PREVENT DAMAGE TO THE

DRIVE. THE FOLLOWING CHECKS MUST

BE PERFORMED BEFORE APPLYING THE

INPUT POWER.

− During shipping, connections may loosen;

inspect all equipment for signs of damage,

loose connections, or other defects.

− Ensure the three-phase line voltage is

within ±10% of the nominal input voltage.

Also verify the frequency (50 or 60 Hz) is

correct for the elevator control system.

− Remove all shipping devices.

− Ensure all electrical connections are

secure.

− Ensure all transformers are connected for

proper voltage.

12

− Open F1 and F2 and ensure control power

brought into fuse F1 and F2 is 230VAC!

IMPORTANT: Double-check all the power

wires and motor wires to make sure that they

are securely tightened down to their respective

lugs (loose wire connections may cause

problems at any time).

Grounding considerations

1. Encoder

a. Encoder isolation

− The encoder must be electrically

isolated from the motor frame and

the motor shaft.

b. Encoder cable

− The cable type should PVC braided

shielded type with three 22ga

twisted pairs. A and A/, B and B/,

common and V should be the

signals paired together.

− The encoder shield is not to be

connected at the encoder end. On

the drive side of the cable a portion

of PVC material 1inch [25mm]

should be removed approximately

12inches [300mm] from the

connection to the customer

interface PCB (A6) to expose the

shield material. This point is

required to be secured under a

clamp located under the control

tray. Do not connect the shield to

any other point. Refer to the EMC

Compliance on page 97.

2. Motor frame

a. The motor frame is required to be

grounded. The bond wire should be

returned to the common ground point

located in the Quattro enclosure (PE).

3. Three phase power

a. The three phase wires must be run

with a ground wire. This ground wire,

which is connected back to the utility

ground, is required to be connected to

the Quattro ground (PE).

4. Control power, 230VAC

a. The neutral side of the control power is

required to be grounded at the Quattro

ground (PE).

Initial adjustments after power up

Encoder Set-up

Electrical interference and mechanical speed

modulations are common problems that can

result in improper speed feedback getting to

the drive. To help avoid these common

Quattro DC Startup Guide

problems, the following electrical and

mechanical considerations are suggested.

IMPORTANT

Proper encoder speed feedback is essential

for a drive to provide proper motor control.

Electrical Requirements:

− Insulate both the encoder case and shaft

from the motor

− Incremental encoder type

− Use twisted pair cable with shield tied to

chassis ground at drive end

− Use limited slew rate differential line

drivers

− Do not allow capacitors from internal

encoder electronics to case

− Do not exceed the operating specification

of the encoder/drive (300Khz @ rated

motor speed maximum)

− Use the proper encoder supply voltage

and use the highest possible voltage

available. The Quattro DC provides both

5VDC and 12VDC. Magnetek

recommends using the 12VDC for the

encoder supply.

Mechanical Considerations:

− Use direct motor mounting without

couplings

− Use hub or hollow shaft encoder with

concentric motor stub shaft

− If possible, use a mechanical protective

cover for exposed encoders

− It is not advisable to use friction wheels

Enter / Verify the encoder pulses entered in

the ENCODER PULSES (A1) parameter

matches the encoder’s nameplate.

Motor Parameter Set-up

Enter / Verify the following from the motor’s

nameplate:

1. Motor Current (RATED MTR CURRENT

(A6))

2. Motor Voltage (RATED ARM VOLTS (A6))

3. Motor field amps, forcing (FULL FLD

AMPS (A6))

4. Motor field amps, running (WEAK FLD

AMPS (A6))

5. Motor field amps, standing (STNDBY

FIELD (A6))

Hoist way Parameter Set-up

Enter / Verify the hoist way parameters:

1. CONTRACT CAR SPD (A1) parameter

programs the elevator contract speed in

ft/min or m/s.

13

Quattro DC Startup Guide

2. CONTRACT MTR SPD (A1) parameter

programs the motor speed at elevator

contract speed in RPM.

Line voltage setup

Enter / Verify the line voltage parameter:

1. INPUT L-L VOLTS (A5) parameter

programs the line voltage level

Auto tune Procedure

Refer to page 95 on how to implement Auto

tune if desired. Auto tune will automatically

measure the motor’s armature inductance,

armature resistance including cable resistance,

field resistance, and field time constant. Auto

tune will also calculate the armature resistance

voltage drop at motor rated current and the

armature and field regulation gains.

(C1, C2, C3, C4) configuration setup

It will be required to adjust the configuration

menus to operate the Quattro as the elevator

manufacturer has specified to interact with the

car controller. Magnetek does not supply this

data.

Low speed inspection mode

Run the drive in low speed inspection mode

and…

1. Verify encoder polarity, the motor rotation

should match the encoder phasing. The

equivalent of swapping A and /A can be

done with the ENCODER CONNECT (C1)

parameter.

2. Verify proper hoist way direction. This can

be reversed with the MOTOR ROTATION

(C1) parameter.

If using an external speed regulator, which

produces an analog torque command to

Quattro (SPEED REG TYPE (C1) =

external reg and EXT TORQ CMD SRC

(C1) = analog input), it is imperative that

the encoder polarity matches the armature

voltage. To verify polarity, insert a torque

command into the analog input. Check

ENCODER SPD (D2) against ARMATURE

VOLTAGE (D2). Verify they are the same

polarity. If not, swap A and /A or change

the ENCODER CONNECT (C1) parameter.

WARNING

Verify that the Safety Chain / Emergency Stop

works.

14

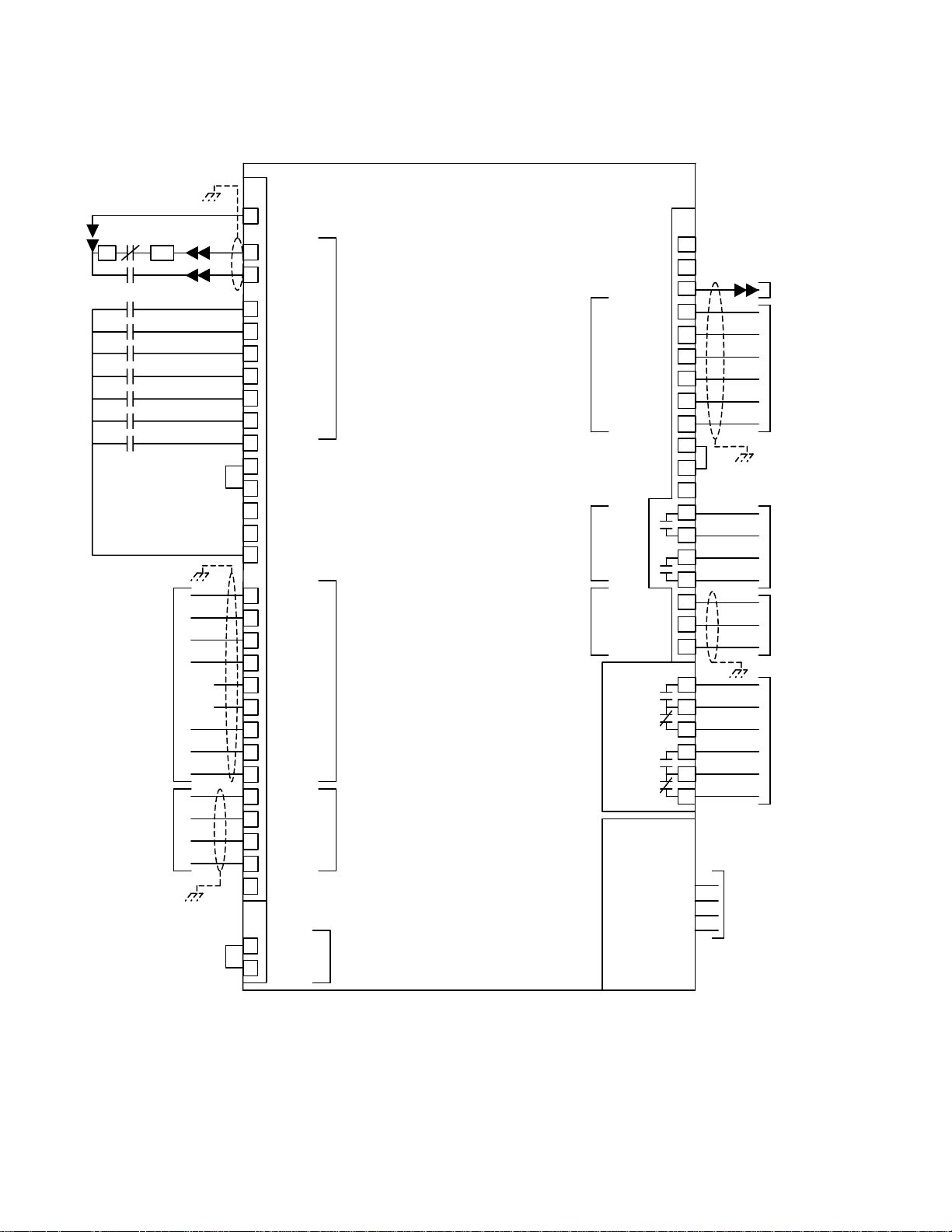

Interconnections

–

A

Z

A

A

A

A

A

A

A

O

O

A

A02AC

A

A

A

A

A

A

A

A

A

A

-

-

9JCC1-4

Contact

Cfirm

5*

CTR PWR Sense

*Located on A9TB1

To/ From

Encoder, Use

+5 or +12 Volt

supply power

From Customer

nalog Outputs

9JCC1-2

6*

9JCC1-1

TB1

11

1

2

3

4

5

6

7

8

9

10

43

44

45

46

34

35

36

37

38

39

40

41

42

15

16

18

19

17

TB2

7

14

+24 VISO

LI1

LI2

LI3

LI4

LI5

LI6

LI7

LI8

LI9

LIB

C_24VISO

C_24VISO

C_24VISO

+24 VISO

/A

/B

B

/Z

C_ISO

+5VISO

+12VISO

IN1+

IN1-

IN2+

IN2-

COM

BB_1

BB_2

QUATTRO SIGNAL

CONNECTIONS

Logic

Inputs

To / From

Encoder,

Use +5 or +12

volt Supply Power

s Required.

+/- 10V

nalog Inputs

Base Enable

Jumper

A6

Open Collector

Outputs, 24 VDC,

15mA Max

Solid State

Relay Outputs,

50V AC/DC

Max 150 mA

nalog Outputs,

+/- 10 VDC,

+/- 4mA

Relays,

230VAC 1A or

30VDC 2A

Quattro DC Interconnections

TB1

LO1

LO2

LO3

LO4

LO5

LO6

LO7

LOC

01

-RTS

+CTS

TXRX+

TXRX

RX

RX+

47

48

25

26

27

28

29

30

31

32

33

45

21

22

23

24

12

13

14

1

3

5

8

10

12

1

6

2

7

3

8

4

9

5

9JCC1-3

To contactor

pickup Relay K on

9

Open collector

Outputs, 30VDC,

150mA max

Solid State relay

Outputs,

50V AC/DC

Max 150mA Max

nalog Outputs,

+/- 10 VDC,

+/- 4mA

Relays, 230 VAC

1A or 30VDC 2A

RS422

Customer

Serial Link

+24VISO

+24VISO

C_24VIS

C_24VIS

SSR1

SSR2

TB2

Relay 1

Relay 2

JC4

+5V_SA

COM_SA

Figure 1: Interconnection Diagram

15

Quattro DC Interconnections

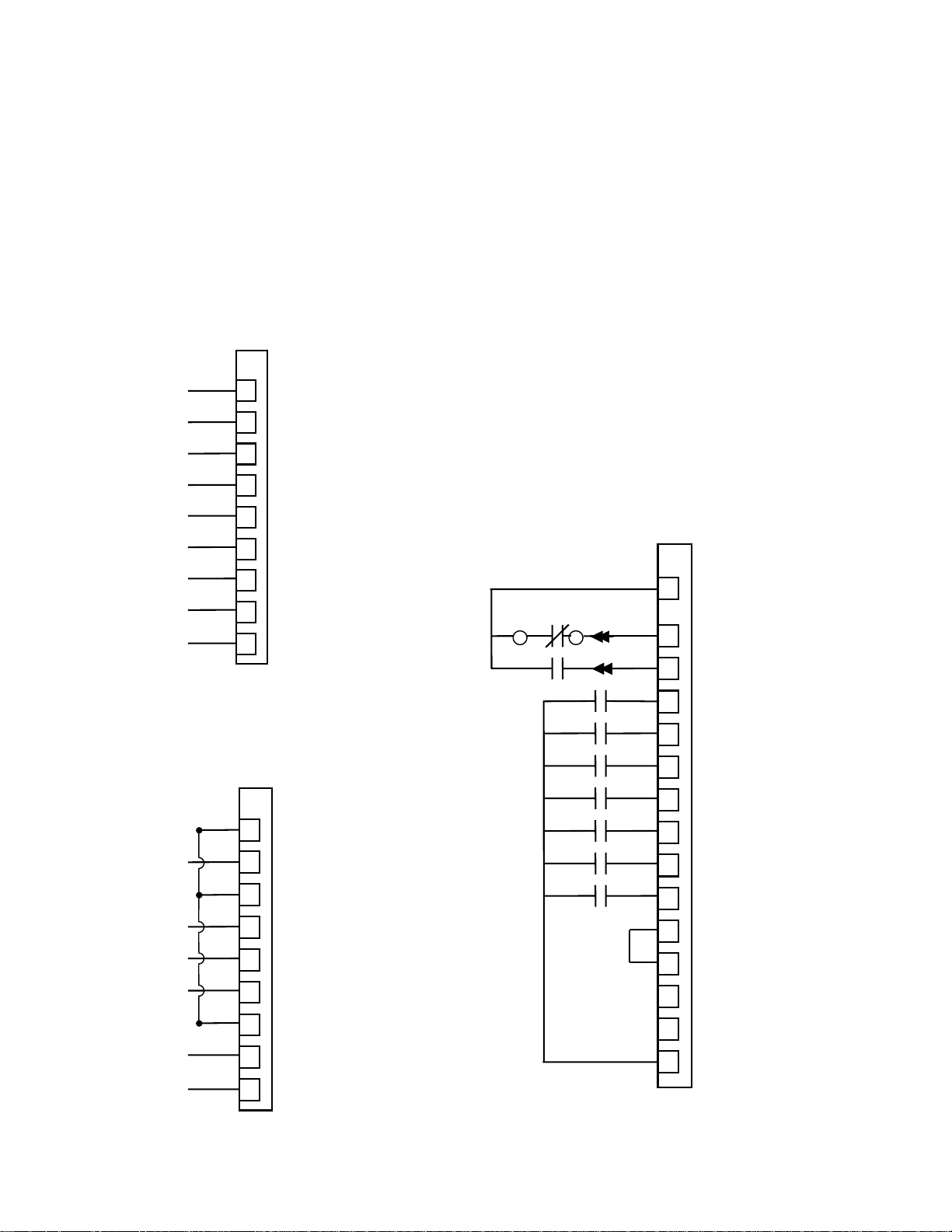

)

2

A

)

E

E

A

EMEME

* Note 1

* Note 1

H(X) H(1)

Provided for

the Primary

side of the

230V control

power

transformer

GND

L(1) L(2) L(3

To Quattro Drive

Internal Control

Power

F1

F2

TB1

24

SWout (+)

Motor Fi eld Contr ol

DCout (-)

Safety Chai n

3

Control Power

230VAC hi 230VAC lo

* Note 1

Motor Shunt Field

M

TB1K1 K1 TB1 ME TB1 TB1

4

3

Located on A9

Not es:

(F1)(F2

* Note 1

1. * indi cates components

not suppli ed by Magnetek

2 1

Safety Chain

* Note 1

(21) (22) (13) (14) (43) (44)

Motor Contactor Auxiliaries

ME

(4) (3)

K1

Part of A9

M

(5) (6)

M

(2) (1)

Figure 2: Quattro DC Power Connections

DBR

DBR

1-4

5-8

(A1)

* Note 1

Hoi st Motor

(A2)

Encoder to

6TB1

16

Quattro DC Interconnections

A

A

A

A

A

Encoder Connections

The Quattro DC has connections for an

incremental two-channel quadrature encoder.

The Quattro DC requires the use of an encoder

coupled to the motor shaft. The encoder power

can be either a +5VDC or +12VDC.

The encoder pulses per revolution must be

entered in the ENCODER PULSES parameter

in the A1 submenu.

Figure 3 shows the encoder connection

terminals for non-single ended applications.

TB1

34

35

36

37

38

/A

/B

B

/Z

39

40

41

42

Z

C_ISO

+5V_ISO

+12V_ISO

Figure 3: Encoder Connections

Below shows the connection for the encoder

option card, if they are configured to be single

ended. This configuration is not recommended,

since, the Quattro DC encoder noise immunity

circuitry is not in effect.

TB1

34

35

/A

36

37

38

39

40

/B

B

/Z

Z

C_ISO

41

42

+5V_ISO

+12V_ISO

Figure 4: Encoder Connections (Single-

Ended)

Logic Inputs

The Quattro DC’s nine programmable logic

inputs are opto-isolated.

For more information

on programming logic inputs, see Logic Inputs

C2 submenu on page 61.

The inputs become

“true” by closing contacts or switches between

the logic input terminal and voltage source

common (or voltage source). The inputs are

sourcing inputs – nominally sitting at common

and when the contacts or switches are closed,

turning “true” at 24VDC. The voltage supply for

the logic inputs is 24VDC.

IMPORTANT

Internal 24VDC power supply has a capacity of

100 mA

Note: Logic input 1 and 2 are reserved and prewired for CONTACT CFIRM and CTR PWR

SENSE respectively.

The choices for the voltage source common (or

voltage source) depend on if the user is using

an external voltage supply or using the internal

voltage supply. See Figure 5 for internal supply

example and Figure 6 for external supply

example.

Contact

Cfirm

9TB1

5

CTR PWR Sense

6

9JCC1-2

9JCC1-1

TB1

11

+24VDC isolated

1

logic input 1

2

logic input 2

3

logic input 3

4

logic input 4

5

logic input 5

6

logic input 6

7

logic input 7

8

logic input 8

9

logic input 9

10

logic input common

43

+24VDC iso. common

44

+24VDC iso. common

45

+24VDC iso. common

46

+24VDC isolated

Figure 5: Logic Input Diagram (Internal

Supply)

17

Quattro DC Interconnections

A

A

A

+

Contact

Cfirm

9TB1

5

CTR PWR Sense

9JCC1-2

6

9JCC1-1

+24V external

supply

Figure 6: Logic Inputs (External Supply)

Analog Inputs

The Quattro DC has two non-programmable

differential analog input channels.

• Analog input channel 1 is reserved for the

speed command (if used).

• Analog input channel 2 is reserved for the

pre-torque command (if used) or torque

command source (if used).

The analog input channels are bipolar and have

a voltage range of ±10VDC.

Available with the analog channels is multiplier

gain parameters (SPD COMMAND MULT and

EXT TORQUE MULT) and bias parameters

(SPD COMMAND BIAS and EXT TORQUE

BIAS). These parameters are used to scale the

user’s analog command to the proper range for

the drive software. The formula below shows

the scaling effects of these two parameters.

analog

⎛

⎜

channel

⎜

input

⎜

voltage

⎝

−

⎞

⎟

⎟

⎟

⎠

TB1

+24VDC isolated

11

1

logic input 1

2

logic input 2

3

logic input 3

4

logic input 4

5

logic input 5

6

logic input 6

7

logic input 7

8

logic input 8

9

logic input 9

10

logic input common

43

C_24VISO

44

C24VISO

45

C24VISO

46

+24VDC isolated

MULTBIAS

=×

signal

drive

software

uses

For more on the multiplier gain or bias

parameters, see Drive A1 submenu on page 30.

The scaling of the analog input signals, with

BIAS set to 0.00 and MULT set to 1.0 follows:

• Speed Command

+10VDC = positive contract speed

-10VDC = negative contract speed

• Pre Torque Command

+10VDC = positive rated pre-torque of motor

-10VDC =

negative rated pre-torque of motor

• Torque Command

+10VDC = positive rated torque of motor

-10VDC =

negative rated torque of motor

NOTE: The drive cannot recognize voltages

outside of the

±10VDC on its analog input

channels.

The Quattro DC provides common mode noise

rejection with the differential analog inputs. The

connection of these two differential inputs is

shown in Figure 7.

Speed Cmd

±10V

PreTorque

Cmd, ±10V

or Torque

Command, ±10V

TB1

analog input 1+

15

analog input 1-

16

analog input common

17

analog input 2+

18

analog input 2-

19

Figure 7: Analog Inputs (Differential)

Figure 8 shows the connection for the analog

inputs if they are configured for single-ended

connection. In this configuration, the Quattro

DC noise immunity circuitry is not in effect.

Note: For prevention of ground noise

interference, a twisted shielded pair must be run

to the source and not connected at the board.

Speed Cmd

±10V

PreTorque

Cmd, ±10V

or Torque

Command, ±10V

TB1

analog input 1+

15

analog input 1-

16

analog input common

17

analog input 2+

18

analog input 2-

19

Figure 8: Analog Inputs (Single Ended)

18

Quattro DC Interconnections

A

Logic Outputs

The Quattro DC’s seven programmable logic

outputs are opto-isolated, open collector. The

outputs are normally open and can withstand an

applied maximum voltage of 30VDC. When the

outputs become “true”, the output closes and is

capable of sinking up to 150mA between the

logic output terminal and the logic output

common (TB1-32). Figure 9: Logic Outputs

shows the logic output terminals.

Note: Logic Output 1 is prewired for CLOSE

CONTACT.

logic output common

+24V iso. common

+24V iso. common

+24V iso.

+24V iso.

logic output 1

logic output 2

logic output 3

logic output 4

logic output 5

logic output 6

logic output 7

TB1

47

48

25

26

27

28

29

30

31

32

33

45

9JCC1-3

Figure 9: Logic Outputs

For more information on programming the logic

outputs, see Logic Outputs C3 submenu on

page 63.

Relay Outputs

The Quattro DC’s two programmable relay logic

outputs are Form-C relays. The have both

normally open and normally closed contacts.

The specifications for each relay are as follows:

Relay 1

• 2A at 30VDC or 1A at 230VAC

Relay 2

• 2A at 30VDC or 1A at 230VAC

Figure 10: Relay Outputs shows the logic output

terminals.

TB2

1

relay 1

relay 2

3

5

8

10

12

Figure 10: Relay Outputs

For more information on programming the relay

outputs, see Logic Outputs C3 submenu on

page 63.

Solid State Relay Outputs

The Quattro DC has two programmable solidstate relays. They have a 30 VDC max with

150mA load capability.

Figure 11: Solid State Relay Outputs shows the

relay output connections.

TB1

solid state relay 1

solid state relay 2

21

22

23

24

Figure 11: Solid State Relay Outputs

For more information on programming the solidstate relays, see Logic Outputs C3 submenu on

page 63.

19

Quattro DC Interconnections

Analog Outputs

The Quattro DC has two programmable

differential analog output channels. The two

analog output channels were designed for

diagnostic help.

programming the analog output channels, see

Analog Outputs C4 submenu on page 65.

The analog output channels are bipolar and

have a voltage range of

draw of +/- 4mA.

Available with the analog channels is multiplier

gain parameters (ANA 1 OUT GAIN and ANA 2

OUT GAIN) and a bias or offset parameters

(ANA 1 OUT OFFSET and ANA 2 OUT

OFFSET). These parameters are used to scale

the user’s analog outputs to the proper range

for the drive software. The formula below

shows the scaling effects of these two

parameters.

signal

⎛

⎜

drive

⎜

software

⎜

creates

⎝

−

For more information on

±10VDC and current

=×

analog

channel

output

voltage

⎞

⎟

GAINOFFSET

⎟

⎟

⎠

For more on the gain or offset parameters, see

section Drive A1 submenu on page 30.

The connection of these two outputs is shown in

Figure 12: Analog Outputs.

TB1

analog output 1

analog output 2

analog output com

12

13

14

Figure 12: Analog Outputs

For more information on programming the

Analog Outputs, see Analog Outputs C4

submenu on page 65.

20

Quattro DC Drive Sequencing

Drive Sequencing

NORMAL operating sequence

1. Motor field current is at Stand-By during

drive idle. The No Faults relay is active.

Full-Field and Run command signals are

OFF. Motor contactor Safety circuits may

be open or closed. The DC bus will

remain charged with regulated voltage as

long as the drive is providing motor field

current.

2. A Field Enable Command, programmable

by FLD ENA SRC (C1), is sent to the

drive. If the DC bus is not pre-charged, a

pre-charge cycle will be completed before

motor field current is restored. See

Quattro Pre-Charge on page 22 for timing

information of the Pre-Charge circuit.

Motor field current will go to the Full-Field

value in preparation to produce motor

torque.

Field Enable

Motor Field

Stndy Fld

FLUX CFRM

(logic output)

Drive Enable

Run

3. Pre-Torque command value is sent to the

drive. It must be available before a run

command is given. If the Pre-Torque

Latch is used, see Pre-Torque Latch (C1),

it can be placed inactive depending on the

settings of Pre-Torque Latch Clk (C1). If

latching is not used, it must remain active

until the SPD REG RLS output is active.

Safety circuit relays are closed making

power available to the contactor coil

circuit.

Pre-Torque

Run

Safety Chain

CONTACT

CFRM (input)

SPD REG RLS

(output)

Full Fld

Field Enable (input)

Stand-by On

Pre-charge

Pre-charge Cnfrm

Boost On

Flux Confirm

Drive Enable

Run Command

(input)

(input)

LATCH

Pick Contactor

Speed Reg Release

No Faults

Contact Cfirm

4. Once the regulators are released, motor

current starts at pre-torque amperes. The

velocity regulator starts at zero speed. (All

conditions of 3. must be present and motor

field current must be greater that the

sensing threshold before the drive will Start.

This is noted by the output Flux Confirm

(programmable by Flux Cnfrm Level (A6)).

5. Drive activates elevator Brake relays, if

programmed to do so (or the car controller

does it externally).

6. Drive follows the external or internal

velocity profile via the programmed

accel/decel rate as programmed during the

remainder of the elevator run cycle.

7. When at the next landing...the Drive (or

car controller) de-activates elevator Brake.

8. After the Brake has set, the Run command

is removed causing...

9. Reference speed to be clamped to zero.

10. Motor torque ramps down to zero, then the

Motor contactor is opened.

Brake Relay

Run

SPD REG RLS (logic output)

Torque

Motor Contactor

11. While idle, motor field current reference will

drop to Stand-By, after the Full-Field timer

expires. Safety circuit relays may (or may

not) open to remove contactor-actuating

power.

12. A DSPR time-out may occur while field

current is at stand-by. In that case motor

field current goes to zero and the AC main

power contactor to the drive is opened. A

pre-charge cycle and power on recovery

will occur on the next command to reestablish motor field current.

21

Boost On Confirm

Field

Control

On

Speed Ref

Release

Brake Release

Quattro DC Drive Sequencing

ABNORMAL Operation Sequence

1. If a Drive or Drive Sequence Fault occurs

the Drive will immediately open the motor

contactor, de-energize the Brake Pick,

Brake Hold, and Drive OK Relays if so

programmed. May be caused by:

a. “Fatal Error” drive Faults including loss

of serial communications

b. Opening of the contactor power Safety

circuit while the contactor is pulled in

c. Loss of correct motor contactor or

Brake Relay feedback.

2. If an Alarm occurs, the drive will signal an

Alarm but continue to run. May be caused

by:

a. Drive Alarms including motor overload,

drive over temp warning

b. Loss of correct feedback from Brake

Hold relay or Brake Switches

c. Open motor thermostat circuit

d. Speed command is held at zero due to

conflict with the analog speed

command polarity and the run up/ run

down logic

e. Encoder Fault (C1) set to disabled

f. The drive is or was being limited by

the motor torque limit setting (Hit

Torque Limit)

g. Speed feedback is failing to properly

track the speed reference (Speed Dev)

h. DC bus voltage drops below user

specified percent of the input line to

line voltage

Quattro Pre-Charge

When power is first applied to the Quattro

drive, or after it has shut itself down via a

DSPR time-out, the internal DC bus must be

pre-charged before operation can resume.

The following sequence will occur:

1. Power is applied to the Quattro drive

a. Control power may be applied before or

after 3-phase main power

b. Some OEM drive versions may have a

built-in control transformer

c. Drive controls should become active

but no contactors should operate

2. Quattro drive receives command to

‘energize’

a. This command may be from serial link

software or hardware logic command to

deliver motor field current in

preparation to start.

b. AC input voltage from mains is

measured and verified to be adequate

according to the setting of the VACinput adjustment parameter.

c. Pre-charge contactor PCM is then

pulled in. This provides resistor limited

inrush current to DC bus capacitors

from AC mains and separate rectifier.

3. DC bus is Pre-Charged

a. With pre-charge contactor PCM closed,

separate resistor and rectifier circuits

limit capacitor charging inrush current.

b. Bus voltage is monitored during pre-

charge to verify proper voltage build-up.

(See 6.a. below)

c. Target bus voltage is nominal input

VAC (INPUT L-L VOLTS (A5)) X √2.

4. Mains contactor is closed

a. As measured DC bus voltage nears

target value main utility power contactor

UTM closes.

b. Aux contact feedback from UTM

indicates to controls that main utility

contactor is closed.

c. Then Pre-charge contactor PCM is

opened. (See 6.b. below)

5. Boost converter is turned ON.

a. DC bus voltage is boosted to a higher

level as programmed by the Boost

Level parameter setting in order to

achieve near unity power factor and low

harmonic content of the Quattro drive.

b. Motor field controls also turn ON to

begin regulating motor field current

and/or operate main motor armature

circuits.

c. The boost converter will remain ON as

long as any field or armature current is

being provided to the motor. (See 6.c.

below) Time-out of the DSPR (Drive

Stand-by Power Reduction) feature or

other command may turn the Boost

converter OFF when drive is idle

although standby field will still be

present. In that case as new precharge cycle must occur before drive

re-start.

6. Problem prevention

a. If DC bus voltage does not rise at the

expected rate to the expected voltage

level during pre-charge a “Charge

Fault” is declared.

b. UTM and PCM are interlocked with aux

contacts such that UTM cannot be

picked unless PCM is already closed.

Once picked, an aux contact of UTM

seals the same circuit allowing PCM to

be dropped with UTM remaining ON.

c. In the event of a major drive Fault, UTM

will be opened to disconnect utility lines

from main power devices of Quattro.

22

Quattro DC Drive Operation and Feature Overview

Drive Operation and Feature Overview

The Quattro DC drive is a velocity and torque

regulated motor drive designed specifically for

operating elevators. Many of the features

described below can be selectively

programmed to customize an individual

application.

Analog Velocity Follower

The elevator car controller provides an analog

velocity reference to the drive at A6TB1-15

and A6TB1-16. The signal may be bi-polar +/10 VDC to indicate speed and travel direction,

or a positive only unipolar signal with the

direction of travel selected by logic commands.

In most cases the signal profile will be adjusted

by the car controller for precise landing

positioning. The velocity reference passes

directly to the closed loop velocity controller,

except for an internal rate limiter to buffer any

unexpected electrical noise. Start and Stop

commands are via 24VDC logic inputs.

Calibration of the analog velocity reference

signal may be adjusted with separate gain and

offset parameters. To set the Analog Velocity

Follower, the user must set SPD COMMAND

SRC (C1) to Analog Input.

Preset Speed & Profile Generator

An alternate method of speed control is that

the elevator car controller provides 24VDC

logic input commands to select one of 15 predetermined running speeds. The drive

generates a smooth S-Curve acceleration

profile to transition between speed selections.

Either of three separately adjustable ramp

times may be selected. The direction of travel

may be determined by either a Run command

with an Up/Down command signal or by

separate Run-Up / Run-Down logic

commands. To set the Analog Velocity

Follower, the user must set SPD COMMAND

SRC (C1) to Multi-Step, then adjusting MultiStep Speed Commands in the Multi-Step

Submenu A3.

Serial Link Follower

The elevator car controller provides the

equivalent of an analog reference command

over a digital serial link. The drive returns

operating status conditions and messages.

Primary run command are 24VDC logic for

redundant safety if wanted. The speed

sensitivity of the serial velocity reference is

adjustable. Enabling the serial link follower

requires SPD COMMAND SRC (C1) to be set

to SERIAL.

Pre-Torque

When enabled, the speed error integrator will

be pre-conditioned by the supplied pre-torque

signal before starting the regulator. This will

cause motor armature current to begin at a

magnitude proportional to the pre-torque

command to prevent elevator motion or

rollback when the elevator brake is released.

The pre-torque signal will be from either an

analog (wired at A6TB1-18 and A6TB1-19) or

serial link digital source as selected by

programming PRETORQUE SOURCE (C1). If

Pre-Torque is not used, leave PRETORQUE

SOURCE (C1) at the defaulted value of none.

An EXT TORQUE BIAS (A1) and an EXT

TORQUE MULT (A1) are available to scale the

pre-torque signal. Ten volts = rated motor

current with a multiplier of 1 and a bias of zero.

Torque Feed Forward

Some car controllers may calculate an

accurate demand for motor torque as required

to accelerate the connected load as well as

hold it against gravity. The torque demand

signal can be programmed to directly drive the

torque control part of Quattro from either an

analog or serial link input. EXT TORQ CMD

SRC (C1) must be set to either analog input or

serial and SPEED REG TYPE (C1) must be

set to either pi speed reg, elev spd reg, or

external reg. The connections for an analog

external torque command source are A6TB118 and A6TB1-19. With an accurate torque

compensating signal, the gain of the PI

regulator can be reduced, to better ignore and

not amplify mechanical vibrations of the hoist

way. Separate adjustments are provided for

torque signal gain and offset. An EXT

TORQUE BIAS (A1) and an EXT TORQUE

MULT (A1) are available to scale the torque

signal. Ten volts = rated motor current with a

multiplier of 1 and a bias of zero.

Torque/Current Ramp-Down

When the drive is told to cease operation by

removal of the Run logic command, (and after

Brake Drop time if that function is engaged)

the armature current reference ramps down to

zero at a constant rate. This allows the

mechanical Brake to gently assume elevator

holding torque, reducing the tendency to

‘thump’ the brake. When armature current

ramp-down is complete, the contactor will be

opened. In the event that the contactor opens

unexpectedly, as reported by the feedback

contact or in the event of a severe drive fault,

23

Quattro DC Drive Operation and Feature Overview

there will be no timed delay for current rampdown. This time may be adjusted by the

function RAMPED STOP TIME (A1).

Motor Field Current Control and Field weakening

DC elevator motors have a separately excited

shunt field. Adjustments include Stand-By

Current, Full-Field Current and Weak-Field

Current, all programmed in amperes, and a

Flux Confirm Level, programmed as a % of

Full-Field. With no active Full-Field or drive

Run command motor field current would

normally be at Stand-By amps. An active

command to provide Full Field causes field

current to increase to the Full Field setting.

When Field current is greater than the FullField threshold setting (and there are no other

faults) the DC motor contactor will be enabled

to pull in when told to do so by an active drive

Run command. When the motor contactor is

acknowledged as being closed, the motor

armature current regulator is released to follow

the commanded torque reference current

signal. Motor field current will remain at the

Full-Field value as long as the per unit (pu)

reference or measured speed (whichever is

greater) is less than the pu ratio of WF/FF

amps. Above that speed motor field current

will automatically follow the constant CEMF

profile of WF/FF X 1/spd, where speed is again

the greater active value of reference or

measured speed. When motor speed reduces

from high speed, motor field current

automatically increases according to the

constant CEMF calculated profile. However,

field current will not increase to be more than

the Full field ampere setting.

DSPR

While the drive is idle with Stand-By Current

being applied to the motor field, a second timer

for Drive Stand-by Power Reduction (DSPR)

will be running. When/If the DPSR timer

times-out, motor field current will turn

completely Off and the main 3-phase power to

the drive will be removed. This helps save

electrical energy during long periods of nonuse. Recovery of this condition will be

automatic upon the receipt of the next “FullField” or “Run” command. At that time,

recovery from a DSPR power OFF condition

may take several seconds. DSPR TIME can

be set in the Drive A1 Submenu.

Over-Speed Test

A reference speed multiplier is provided to help

testing of the elevator governor over-speed

trip. This feature will automatically return to

normal at the completion of each elevator run.

However, to ensure that the drive Over-Speed

Trip does not interfere with the governor test,

one must temporarily raise the value set for the

Drive Over-Speed Trip point to a value higher

than that of the governor.

Fault & Alarm Reset

An external Fault Reset command signal from

the car controller may be applied to a logic

input or from a serial command link. Or, an

automatic Fault Reset will occur 5 seconds

after a drive fault occurs, when enabled to do

so. Either method may be used to enable the

car controller to quickly recover from a resettable fault. One Fault will be subtracted

from a fault count accumulation every 20

minutes. The maximum number of AutoResets that can be accumulated is 5. The

Auto-Reset function will then require a power

Off/On cycle in order to recover. Faults &

Alarms may also be cleared by use of the

Magnetek Operator.

Electronic Motor Over-Load

An electronic motor over-load function is

provided to take the place of heater type power

components. Motor armature current is

continuously monitored and the heating effect

is calculated over time. A motor overload trip

will not automatically stop the drive, but is an

important alarm signal to elevator car controller

to help prevent equipment damage.

Armature Voltage Feedback

This is a temporary ‘construction’ or trial mode

for proving out direction orientation of the

motor and operation of the encoder. Motor

speed regulation is controlled by armature

voltage feedback with IR compensation.

Precise speed regulation is not possible.

Operation above base speed of the motor is

not possible since the field weakening is

inhibited. However, it is still possible to

monitor the feedback from the encoder

although it will not used for speed regulation.

Successful operation in this mode may require

reduced gain settings. This is selectable by

setting SPD REG TYPE (C1) to CEMF REG.

24

Quattro DC Drive Operation and Feature Overview

Status Indicator Lights

Five status indicator lamps are provided on the

front panel of the drive.

READY – (GRN) Power is applied to the drive,

there are no drive Faults and drive is

ready to Run when requested. The Run

light will blink slowly when it is in DSPR

(Drive Standby Power Reduction) Mode