Magnetek Telemotive TR12 inteleSmart Instruction Manual

Telemotive

TR12 inteleSmart™ Receiver

Radio Control Equipment

Instruction Manual

TCTR12-PDA Rev. J March 2007

Part Num

©Copyright 2007 Magnetek Material Handling

ber 30033T

Table of Contents

Service Information.....................................................................................................1

Radio Controlled Crane Safety...............................................................................2-8

General System Information.......................................................................................9

Installation............................................................................................................10-12

Operation.......................................................See Appropriate Transmitter Manual

Wiring................................................................................................................... 14-39

Programming........................................................................................................40-53

Servicing................................................................................................................53-57

Spare Parts .................................................................................................................58

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 1 – Service Information

Your New Radio Receiver

Thank you for your purchase of Magnetek’s Telemotive® brand TR 12 inteleSmart Receiver. Magnetek

has set a whole new standard in radio-remote performance, dependability, and value with this unique line

of products. Without a doubt, our Telemotive TR 12 inteleSmart Receiver is the ultimate solution for

having precise, undeterred, and safe control of your material.

If your product ever needs modification or service, please contact one of our representatives at the

following locations:

U.S. Service Information

For questions regarding service or technical information, contact 1-866-MAG-SERV

(1-866-624-7378).

Magnetek Material Handling

N49 W13650 Campbell Drive

Menomonee Falls, WI 53051

Telephone: 800-288-8178

Website: www.magnetekmh.com

e-mail: info@magnetekmh.com

Fax Numbers

Main: 800-298-3503

Sales: 262-783-3510

Service: 262-783-3508

For Canada Service Information Contact Berlet Electronics:

Phone: 1-905-564-2710

Fax: 1-905-564-2755

1

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety

Telemotive Industrial Control trademarks:

Boommate, GateMate, 10K, inteleSmart,

Telemotive, telePilot, telePendant, Laser Guard,

Teledrive, Teltec, and TeleMotion are either

trademarks or registered trademarks of Telemotive

Industrial Controls.

Third-party trademarks: All other trademarks, trade

names or company names referenced herein are used

for identification only and are the property of their

respective owners.

CAUTION

ONLY TRAINED QUALIFIED INDIV ID UALS

SHOULD DO SERVICING.

STRICT ANTI-STATIC HANDLING

PROCEDURES MUST BE FOLLOWED.

FAILURE TO FOLLOW THIS CAUTION COULD

RESULT IN SERIOUS DAMAGE TO EQUIPMENT AND/OR VOID THE WARRANTY.

Warnings, Cautions And Notes.

Throughout this document WARNING, CAUTION

and NOTE statements have been deliberately placed

to highlight items critical to the protection of

personnel and equipment.

WARNING – A warning highlights an essential

operating or maintenance procedure, practice, etc.

which if not strictly observed, could result in injury

or death of personnel, or long term physical hazards.

Warnings are highlighted as shown below:

NOTE

WARNINGS, CAUTIONS AND NOTES SHOULD

NEVER BE DISREGARDED.

The safety rules in this section are not

intended to replace any rules or regulations

of any applicable local, state, or federal

governing organizations. The following

information is intended to be used in

conjunction with other rules or regulations

already in existence. It is important to read

all of the safety information contained in this

section before installing or operating the

Radio Control System.

2-1. Critical Installation Considerations.

WARNING

ALL EQUIPMENT MUST HAVE A MAINLINE

CONTACTOR INSTALLED AND ALL TRACKED

CRANES AND SIMILAR EQUIPMENT MUST

HAVE A BRAKE INSTALLED. FAILURE TO

FOLLOW THIS WARNING COULD RESULT IN

SERIOUS INJURY OR DEATH AND DAMAGE

TO EQUIPMENT.

WARNING

CAUTION – A caution highlights an essential

operating or maintenance procedure, practice, etc.

which if not strictly observed, could result in damage

to, or destruction of equipment, or loss of functional

effectiveness. Cautions are highlighted as shown

below:

CAUTION

NOTE – A not

maintenance procedure, condition or statement. Notes

are shown as below:

e highlights an essential operating or

2

WARNING

ON ALL REMOTE CONTROLLED CRANES AN

AUDIBLE AND/OR VISUAL WARNING MEANS

MUST BE PROVIDED. THESE AUDIBLE

AND/OR VISUAL WARNING DEVICES MUST

MEET ALL GOVERNMENTAL REQUIREMENTS. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN SERIOUS INJURY OR

DEATH AND DAMAGE TO EQUIPMENT.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety (continued)

WARNING

REMOVE ALL ELECTRICAL POWER FROM

THE CRANE OR MACHINERY BEFORE ATTEMPTING ANY INSTALLATION PROCEDURES. DE-ENERGIZE AND TAG OUT ALL

SOURCES OF ELECTRICAL POWER BEFORE

TOUCH TESTING ANY EQUIPMENT. FAILURE

TO FOLLOW THIS WARNING COULD RESULT

IN SERIOUS INJURY OR DEATH AND DAMAGE TO EQUIPMENT.

WARNING

THE DIRECT OUTPUTS OF THIS PRODUCT

ARE NOT DESIGNED TO INTERFACE DIRECTLY TO TWO STATE SAFETY CRITICAL

MAINTAINED FUNCTIONS, I.E., MAGNETS,

VACUUM LIFTS, PUMPS, EMERGENCY

EQUIPMENT, ETC. A MECHANICALLY LOCKING INTERMEDIATE RELAY SYSTEM WITH

SEPARATE POWER CONSIDERATIONS MUST

BE PROVIDED. FAILURE TO FOLLOW THIS

WARNING COULD RESULT IN SERIOUS INJURY OR DEATH AND DAMAGE TO EQUIPMENT.

2-2. General.

2-3. Persons Authorized To Operate Radio

Controlled Cranes.

Only properly trained persons designated by

management should be permitted to operate radiocontrolled cranes.

Radio controlled cranes should not be operated by

any person who cannot read or understand signs,

notices and operating instructions that pertain to the

crane.

Radio controlled cranes should not be operated by

any person with insufficient eyesight or hearing or by

any person who may be suffering from a disorder or

illness or is taking any medication that may cause

loss of crane control.

2-4. Training Checklist For Crane Operators.

Anyone being trained to operate a radio-controlled

crane should possess as a minimum the following

knowledge and skills before operating the crane:

The operator should have knowledge of hazards

peculiar to crane operation.

The operator should have knowledge of the safety

rules for radio-controlled cranes.

The operator should have the ability to judge distance

or moving objects.

The operator should have knowledge of the radio

transmitter.

The operator should know the limit switch test

procedure.

Radio controlled overhead cranes and other material

handling equipment operate in several directions.

They are large, bulky pieces of equipment that handle

heavy loads efficiently at high speeds. Quite

frequently, the equipment is operated in areas where

people are working on the floor below. The crane

operator must exercise extreme caution at all times.

Workers must constantly be alert to avoid accidents.

The following rules have been included to indicate

how your careful and thoughtful action s may prevent

injuries, damage to equipment, or even save a life. If

radio controlled material-handling equipment is

operated from the cab, special care must be taken to

secure the transmitter. Refer to section titled Section

2-9. Boarding The Crane for specific safety rules.

3

The operator should know, where authorized,

instructions for plugging motions.

The operator should have knowledge of the use of

crane warning lights and alarms.

The operator should have knowledge of observing

crane signal lights.

The operator should be trained to avoid striking any

obstructions.

The operator should have knowledge of the proper

clearance of lifts or hooks before moving bridge or

trolley.

The operator should have knowledge of the proper

storage space for radio transmitter when not in use.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety (continued)

The operator should be trained in transferring radio

transmitter to another person.

The operator should be trained how and when to

report unsafe or unusual operating conditions.

The operator should be trained how to exhibit caution

in approaching bridge or trolley bumpers.

Before putting the transmitter in service the

transmitter unit should be inspected for any damage

or excessive wear. Units with, but not limited to, any

of the following: broken housings, switches or

handles, missing battery doors, switch boots or

switch knobs should be repaired before putting into

service.

2-7. Operating The Crane.

The operator should know equipment capacity.

The operator should be trained in making lifts below

floor level.

The operator should be trained in making side pulls.

The operator should know how to keep himself and

other people clear of lifts and to avoid "pinch" points.

The operator should know cable and hook inspection

procedures.

The operator should know procedures for testing

hoist, trolley, and bridge brakes.

2-5. Operating Area.

Aisles between equipment, stock, etc., should be free

of obstructions so the crane operator can move freely.

These aisles should be a minimum of three feet (one

meter) wide, or meet local regulations.

Crane operators should always position themselves

for the best view of the crane they are controlling.

The crane should never be operated blindly. The

operator should stay as close to the crane load as

possible. Operators should never position themselves

in a "pinch" point.

2-6. Transmitter Unit.

Transmitter switches should never be mechanically

blocked ON or OFF for any crane motion. When not

in use turn the transmitter OFF. A secure storage

space should be provided for the transmitter unit and

the transmitter unit should always be placed there

when not in use. This precaution will prevent

unauthorized people from operating the crane.

2-7.1. Pre-operation Test.

At the start of each work shift, or when a new operator takes control of the crane, operators shall do as

a minimum the following steps before making lifts

with any crane or hoist:

Test the upper-limit switch. Slowly raise the

unloaded hook block until the limit switch trips.

When checking limit switches the hoist should be

centered over an area free of personnel and

equipment.

Visually inspect the hook, load lines, trolley, and

bridge as much as possible from the operator's

station; in most instances, this will be the floor of the

building.

The bridge and trolley brakes should be tested. On

transmitter units equipped with two or more speeds,

use the "lowest" speed when testing braking devices.

When lifting maximum loads, the crane operator

should test the hoist brakes by raising the load a few

inches from the floor. If the brakes do not hold, the

load should immediately be lowered to the floor.

If provided, test the lower-limit switch.

Test all warning devices.

Test all direction and speed controls for both bridge

and trolley travel.

Test all bridge and trolley limit switches, where

provided, if operation will bring the equipment in

close proximity to the limit switches.

Test the transmitter emergency stop.

Spare transmitters should be stored in a secure

storage space and only removed from the storage

space after the current transmitter in use has been

turned OFF, taken out of the service area and

secured.

4

Test the hoist brake to verify there is no drift without

a load.

If any crane or hoist fails any of the above tests notify

the supervisor and lock out and tag for repair.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety (continued)

2-7.2. General Rules For Operation.

Consult the crane manufacturer, local and

governmental regulations for complete rules of

operation. In general the following rules apply to

remotely controlled cranes:

The limit switches should never be used as a

regular stopping device. They are intended to be

protective devices.

When moving the crane, the crane operator should

be sure that the hook block and attachments or

cables would not catch on nearby equipment.

Slings, chains, or cables should never be dragged

along the floor.

Unless required for operator safety, gloves should

not be worn when operating the transmitter unit.

All loose materials or parts should be removed

from the load before starting the lift.

Do not make lifts in excess of the equipment rated

capacity.

The bridge and trolley should be centered directly

over the load when the load is raised to prevent

swinging when making lifts.

A crane designed for this purpose and only with

supervisor permission should make side pulls.

When a lift is being made, the crane operator

should not be positioned in the line of travel. The

crane or hoist should be operated from a position

either to the side or opposite from the direction of

travel.

When raising or lowering a load, proceed slowly

and make certain the load is under control. Tag

lines should be used for handling unusual lengths

or bulky loads. Remove slack from chains or slings

gradually. Make certain all personnel are clear

before making a lift.

The crane operator should keep all body parts away

from the lift and should never be positioned under

the lift.

Do not make a lift or move a load if anyone is in a

location where they could be struck by the crane or

the load.

If the crane operator is being helped, the crane

should not be moved until the helper signals they

are clear of the crane and its load.

When a load is hanging from the crane hook and

the crane is being moved, the crane operator should

sound all warning devices frequently .

The crane operator should always hoist lifts high

enough to clear all equipment and workers.

The crane operator should never permit anyone to

ride on the load or hook except when authorized by

the supervisor.

When another crane on the same runway is stationary with a load hanging, the crane operator

should maintain a safe distance between the stationary crane and the one under their control.

Never leave suspended loads unattended. In an

emergency, if the crane is inoperative and a load

suspended, notify the supervisor immediately,

barricade and post signs on the floor beneath crane

and load.

If power to the crane is removed, the crane operator should turn the transmitter unit OFF and

keep it OFF until power is restored.

If the crane fails to respond properly, the crane

operator should stop operation, turn the transmitter

unit OFF and immediately report the condition to

their supervisor.

Outdoor cranes, which are subject to movement by

wind, should be securely anchored when left

unattended. If the crane is equipped with bridge

brakes, the parking brake should be set immediately.

2-8. Boarding The Crane.

The crane should not be boarded without permission of the supervisor.

Loads should not be carried over workers heads. If

a worker is in the path of crane travel, the crane

operator should stop the crane and clear the area

before proceeding.

Runway stops or other cranes should never be

bumped into.

5

The crane operator should turn off the transmitter

and take it with them when boarding the crane.

If more than one person is boarding the crane, one

person should be made responsible for ensuring all

personnel are off the crane before the system is

returned to operation.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety (continued)

2-9. Crane Maintenance And Repair.

Qualified personnel must maintain a regularly, i.e.,

such as monthly, scheduled crane inspection.

During this crane inspection the functionality and

safety of the crane remote control must also be

tested. The inspection shall include, but be not

limited to items listed in Section 2-12 Condition Of

The Radio Controlled Crane. Consult crane

manufacturer, local and governmental regulations

for recommended inspection intervals and proper

inspection procedures. Problems noted during this

inspection must be repaired before using the crane

or the remote control.

Minor repairs include routine maintenance and

repairs such as greasing, cleaning and control

troubleshooting. All other repairs should be considered major. If the repair crew consists of more

than one person, one person should be designated

as the repair crew leader with the following

responsibilities. If the repair crew consists of only

one person, that person has the following

responsibilities:

For minor repairs warning signs should be placed

on the floor beneath the crane or suspended from

the crane. For major repairs, the floor area below

the crane should be roped off.

When major repairs are to take place, all persons

operating other cranes on the same or adjacent

runways, if any, must be notified prior to starting

repairs. Notification should include the nature of

the repair, safeguards provided, and movement

limitations while repairs are in progress.

When practical, radio controlled cranes which

cannot be moved during repairs must be protected

against being bumped by other cranes on the

runway. Bumpers should be installed on the

exposed side or sides of the crane under repair.

They should be placed as far away as possible. The

location of these bumpers should be indicated by

red lights placed so that they are clearly visible to

other crane operators traveling on the same runway.

When it is not possible to use bumpers, red lights

must be placed so they are clearly visible to other

crane operators traveling on the same runway to

indicate the restricted travel zone. All crane operators on the same runway must be informed of the

repair effort and thoroughly instructed to what their

operations are limited to and informed they will be

notified when repairs are completed.

If any hazard involving the repairperson exists

when there is a runway adjacent to the crane under

repair, the adjacent runway should be blocked off

as described above. When it is necessary to

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

6

continue crane operation on the adjacent runways

warning lights must be installed and be visible to

operators of cranes on those runways. All cranes

should come to a complete stop prior to entering

the restricted area and should proceed through this

area only after receiving permission from a signal

person designated for this purpose. Access of

persons to and from the crane being repaired should

be under control of the repair crew leader.

When boarding the crane, the transmitter should be

turned OFF and the transmitter should remain with

the repair crew leader. The leader should board the

crane first, open and lock out the main switch, and

then signal the other members of the crew it is safe

to board the crane.

If work on the crane is to be done in areas not

protected by standard handrails, the repair crew

should wear approved safety belts.

All tools and equipment should be moved onto the

crane by the use of hand lines. The tools and

equipment should be adequately secured to the

hand lines.

If it is necessary to have the crane control circuits

energized, all power circuits for crane movement

must be opened prior to energizing the control

circuits.

All personnel and tools should be moved to a safe

spot before moving the crane during repairs.

Headroom is at a minimum in some crane cabs and

on some crane walkways. Caution should be

exercised when boarding or working on cranes.

Hard hats should be worn whenever possible.

When repairs are finished, all personnel, tools and

repair equipment should be removed before

energizing the crane circuits.

2-10. Using The Crane As A Work Platform.

When the crane is to be used as a stationary work

platform, follow all rules provided in Section 2-8

Crane Maintenance and Repair. When it is

necessary for the crane to be moved from time to

time, the crane operator should board the crane

with the transmitter unit. The crane operator should

ensure all personnel working on the crane are in a

secure position before moving the crane to the next

workstation. It should also be the crane operators

responsibility to ensure the main switch is open and

locked down before work is resumed.

Section 2 - Radio Controlled Crane Safety (continued)

Broken, cracked, or chipped rails on trolley or

runway.

WARNING

THE CRANE OPERATOR SHOULD NOT

ATTEMPT TO REPAIR ANY OF THE ITEMS

STATED BELOW. THE CRANE CONDITION

SHOULD BE REPORTED TO THE

SUPERVSOR. FAILURE TO FOLLOW THIS

WARNING COULD RESULT IN SERIOUS

INJURY OR DEATH AND DAMAGE TO

EQUIPMENT.

2-11. Condition Of The Radio Controlled Crane.

If the crane fails to respond properly, the crane

operator(s) should notify their supervisor. When

serious conditions are noticed (conditions that

make the crane unsafe to operate), the crane should

be shut down immediately and the supervisor

notified. The following is a list of some of the items

that should be included in the report. (See the crane

manufacturer for specifics and possible additional

items):

Condition of hoisting cable and hook block (broken

strands, clipped sheave wheels, etc.).

Condition of brakes (hoist, trolley, and bridge). (No

bluing, rivets on shoes showing, glazing, etc.).

Condition of limit switches.

Condition of electrical and mechanical control

(electrical or mechanical defects which cause faulty

operation such as un-commanded stopping or

starting of any crane motions, warning devices,

lights, or auxiliary functions).

Condition of gears (grinding or squealing may

indicate foreign materials in gear teeth or a lack of

lubrication.

All controls especially ESTOPs are in place and in

working order.

Frequent relay tripping of power circuits.

Mechanical parts loosened by vibration (loose

rivets, covers, bolts, etc.).

Uneven riding (worn or damaged wheels) .

Condition of collector shoes or bars.

Condition of warning or signal lights and horns.

(Burned out or broken).

2-12. Batteries

Condition of trolley and rail stops.

Condition of bridge structure.

Condition of festoon system.

Broken welds in any part of the crane structure.

Proper fluid levels and lubrication.

Condition of bridge and trolley stops.

Carbon dust or signs burning on the covers of

motors.

Indication of fluid, oil or grease leaks.

Condition of rail sweeps.

Walkways required handrails and ladders are in

place, sturdy and not loose.

Protective guards are in place for all moving parts.

Alignment of bridge (screeching or squealing

wheels indicate bridge is out of line).

WARNING

KNOW AND FOLLOW PROPER BATTERY

HANDLING, CHARGING AND DISPOSAL

PROCEDURES. IMPROPER BATTERY PROCEDURES CAN CAUSE BATTERIES TO

EXPLODE OR DO OTHER SERIOUS DAMAGE.

FAILURE TO FOLLOW THIS WARNING

COULD RESULT IN SERIOUS INJURY OR

DEATH AND DAMAGE TO EQUIPMENT.

2-12.1. Battery Handling.

Use only batteries approved by Telemotive for the

specific product.

Do not dispose of a battery pack in fire; it may

explode.

Do not attempt to open the battery pack.

7

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 2 - Radio Controlled Crane Safety (continued)

Do not short circuit battery.

Do not attempt to use a battery that is leaking,

swollen or corroded.

For intrinsically safe environments only use

specified Telemotive intrinsically safe batteries.

Keep the battery pack environment cool during

charging operation and storage, (i.e., not in direct

sunlight or close to a heating source).

Do not attempt to charge non-rechargeable battery

packs.

Avoid charging the battery pack for more than 24

hours.

Do not charge batteries in a hazardous

environment.

Do not short the charger.

2-12.2. Battery Charging.

For those transmitters equipped with battery

chargers, please familiarize all users with the

instructions of the charger before attempting to use.

Use only Telemotive approved chargers for the

appropriate battery pack.

Do not attempt to charge a damaged battery.

Charger units are not intended for outdoor use. Use

only indoors.

2-12.3. Battery Disposal.

Before disposing of batteries consult local and

governmental regulatory requirements for proper

disposal procedures.

8

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 3 - General System Information

3-1. General System Information.

The Telemotive Radio Control System (system)

provides remote control of overhead cranes using

radio signals. The system consists of a hand held

portable battery operated transmitter unit and a

fixed station receiver unit.

A unique 16-bit code (Access Code) for each

system is preset in every transmitter and receiver.

The receiver considers any received signal, which

does not match the receiver access code setting,

invalid. The Access Code is made up of 16-bits

(65,000 combinations) and no two similar codes are

assigned to any two Telemotive systems.

Up to four systems may be used with the same

frequency in a 600-foot area (220 meters). Each

transmitter operating on the same frequency may be

operated in close proximity, not less than six feet

(1.9 meters) to each other.

3-2. TMS Low Power Signaling.

TMS (Time Multiplexed Signaling) is a Telemotive

proprietary high-speed packet data system. The

system software is structured to minimize "on the

air" transmission time of any transmitter. This

allows for multiple transmitters to share a common

frequency. The TMS system is designed so that a

transmitter will send a signal for a predetermined

ON time, and then will turn OFF. The length of

transmitter ON time is referred to as data burst or

packet. The packet length is a function of the

quantity of data to be sent, and the data rate (baud).

Once the packet is sent, the transmitter will turn

OFF. This allows for other transmitters to timeshare the same frequency when a transmitter has

turned OFF. The TMS system software determines

the OFF period and repetition rate of the ON

period. Since each system has its own access code,

up to 4 transmitters can share and have equal access

to the same frequency. TMS also allows for

reduced battery consumption and extended battery

life.

These systems have low power pulsed signaling,

FCC certified under Part 15 Telecommunications

Code of Regulations, no license is required. The

transmitter unit is frequency modulated, low power

and is certified under the appropriate regulations. A

license is not required for the transmitter or

operator. Modifications to the RF section of this

system are not permitted and could void FCC

certification.

3-3. Channel Designations:

Indicator Channel Actual

Count Designator Frequency

01. AK01 439.8 MHz

02. AK02 439.6 MHz

03. AK03 439.4 MHz

04. AK04 439.2 MHz

05. AK05 439.0 MHz

06. AK06 438.8 MHz

07. AK07 438.6 MHz

08. AK08 438.4 MHz

09. AK09 438.2 MHz

10. AK10 438.0 MHz

11. AK11 437.8 MHz

12. AK12 437.6 MHz

13. AK13 437.4 MHz

14. AK14 437.2 MHz

15. AK15 437.0 MHz

16. AK16 436.8 MHz

Indicator Channel Actual

17. AK17 436.6 MHz

18. AK18 436.4 MHz

19. AK19 436.2 MHz

20. AK20 436.0 MHz

21. AKA00 433.125 MHz

22. AKA01 433.325 MHz

23. AKA02 433.525 MHz

24. AKA03 433.725 MHz

25. AKA04 433.925 MHz

26. AKA05 434.125 MHz

27. AKA06 434.325 MHz

28. AKA07 434.525 MHz

29. AKA08 434.725 MHz

30. AK38 432.4 MHz

31. AK50 430.0 MHz

3-4. Receiver Specifications.

Receiver housing: NEMA 4X, IP67

Operating Temperature: –22° F to +158° F (-30

degrees C to +70 degrees C) ambient.

Humidity: up to 95 % (non-condensing).

Typical Operating Range: 300 feet (91 meters).

Relays are rated for 16 Amps 277VAC/24VDC, 1

HP 240VAC for maximum life and surge

protection, they are fused with 2AG Slow Blo fuses

and protected with MOV’s.

3-5. Receiver Unit.

The receiver unit consists of a synthesized RF

module, antenna, integral power supply,

microprocessor controlled output motor control and

auxiliary function relays and mainline contactor

relay. The receiver unit contains circuitry, which

matches the frequency and access code of the

transmitter.

9

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 4 - Installation

4-1. Pre-Installation Considerations.

To ensure reliable and safe operation of the system,

the following items must be considered before

installing the receiver unit.

WARNING

THE RECEIVER UNIT OR RELAYS ARE NOT

RATED AS EXPLOSION PROOF. THE

RECEIVER UNIT MUST NOT BE INSTALLED

IN EXPLOSIVE ENVIRONMENTS UNLESS

APPROPRIATE SECONDARY ENCLOSURE

MEASURES ARE TAKEN. FAILURE TO

FOLLOW THIS WARNING COULD RESULT IN

SERIOUS INJURY OR DEATH AND DAMAGE

TO EQUIPMENT.

4-2. Receiver Unit Mounting Location

Considerations.

Ensure the mounting location is as far as possible

from exposed trolley wires and sources of

electromagnetic or radiated noise

The receiver cabinet is approximately 8" (20 cm)

wide by 12" (30 cm) high. A depth of at least 13"

(35 cm) must be provided to allow the cabinet door

to open.

The mounting surface must be smooth and

continuous. Mounting the cabinet on uneven

surfaces could cause warpage or stress internal

components.

The receiver unit may be mounted in any position.

The greatest radio control range is obtained when

the receiver unit is mounted with the antenna at the

top.

4-4. Line Input Considerations.

WARNING

THE UNIT MUST BE WIRED TO THE CORRECT VOLTAGE, AND BE CONNECTED TO

THE CORRECT TERMINAL AS REQUIRED BY

THE ACTUAL LINE VOLTAGE. FAILURE

FOLLOW THIS WARNING COULD RESULT IN

SERIOUS INJURY OR DEATH AND DAMAGE

TO EQUIPMENT.

The receiver unit has direct connect provisions for

operation from 115 VAC (nominal), 60 Hz power.

For applications where the line voltage is not

between 95-130 VAC or if 260 VAC or 440 VAC

power is used, a step up or step down transformer

must be used.

NOTE

THE RECEIVER UNIT SHOULD NOT BE CONNECTED TO LINES CONTAINING EXCESSIVE

POWER UP TRANSIENTS OR CONTINUOUS

COMMUTATOR NOISE. A LINE

CONDITIONER MAY BE NECESSARY IN

SOME INSTALLATIONS.

4-5. Wiring Considerations.

1. Read this manual before installation.

2. Please observe appropriate local and National

Electrical Codes when wiring electrical devices.

3. Do not connect or disconnect wiring, or

perform circuit checks while the power is turned

on.

If possible, avoid installing receiver unit to a

surface where high vibration or shock is present. If

this cannot be avoided, use appropriate shock

mounts.

4-3. Antenna Mounting Considerations.

It is best to mount the antenna so that it is visible to

the operator. Usually, this is accomplished by

mounting the antenna under the crane and pointed

down. You should always try and avoid power

sources, motors, drives, brakes, etc. If necessary

we offer an external antenna kit.

10

4. The motor wiring should be in a separate

metal conduit from the power wiring, which should

also be in metal conduit.

5. Low voltage wires shall be wired with proper

low voltage class wiring procedures.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 4 – Installation (continued)

6. Control wiring as well as antenna wiring

shall be in separate conduit and shall be kept as

short as possible.

7. All terminals shall be tightened to sp ecified

terminal torque 4.4 IN-LBS (.5 N·m). Unless

otherwise specified.

8. Remove excess metal screws, metal filings

and wire clippings from inside of unit.

9. Inspect to make sure no exposed wire has

contact with any other wiring or termi nals.

10. Suppressors are strongly recommended on

all contactors.

4-6. Receiver/Equipment Interface

Considerations.

All output relay contacts are rated for 16 Amps

277VAC/24VDC, 1 HP 240VAC for maximum

life and surge protection, they are fused with

2AG Slow Blo fuses and protected with MOV’s.

Connection to equipment or contactors with

higher voltage or current requirements will

require intermediate relays.

All relay outputs are normally open, momentary

contact. Since a relay closure is only active while

the transmitter unit key is pressed and held,

devices such as lights or lifting magnet must use

a mechanical auxiliary latching relay.

4-7. Receiver Unit Cabinet Mounting.

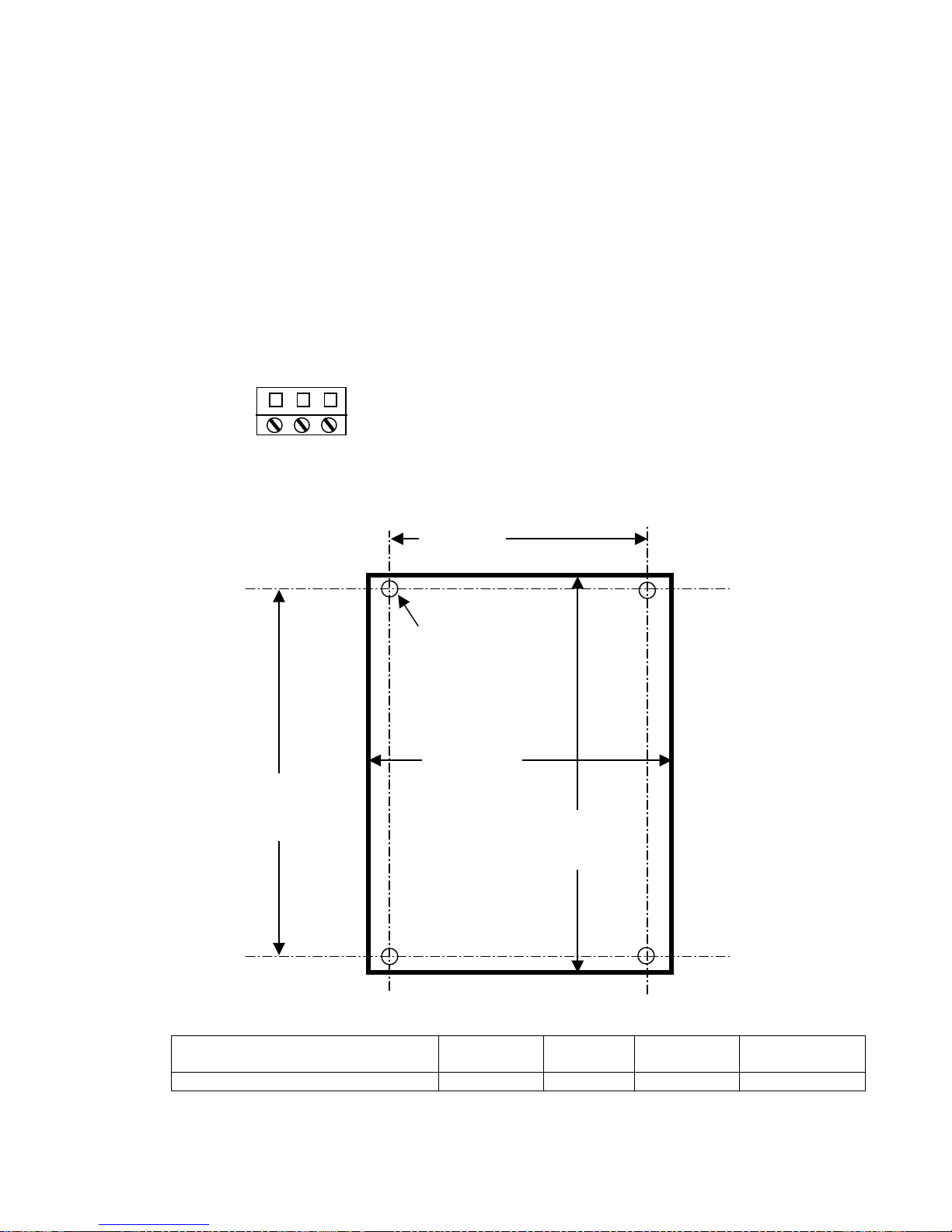

See next page Figure 4-2. Receiver Mounting

Details. Allow room in mounting the receiver for

the door to swing open

Mount receiver unit cabinet securely to mounting

surface. Actual cabinet mounting dimensions are

shown on next page Figure 4-2. Receiver

Mounting Details.

4-8. Receiver Installation.

NOTE

CONNECTING OUTPUTS TO DRIVES.

MOV’S (TRANSIENT PROTECTORS) ARE

ON ALL THE OUTPUT RELAYS TO

PROTECT THE RELAYS FROM POWER

SURGES. MOV’S ALLOW A SMALL

LEAKAGE CURRENT THAT CAN AFFECT

SOME HIGH IMPEDANCE CIRCUITS.

WHEN CONNECTING OUTPUT RELAYS TO

DRIVES, IT MAY BE REQUIRED TO

REMOVE THE MOV TO PREVENT THE

LEAKAGE CURRENT THROUGH THE MOV

FROM HOLDING IN THE DRIVE. SEE

FIGURE 8-1. RECEIVER LAYOUT FOR THE

LOCATION OF THE MOV'S. THE MOV’S

ARE NEXT TO THE RELAYS THEY

PROTECT. THE MOV’S CAN BE CUT OUT

OF THE CIRCUIT WITH A WIRE CUTTER.

REMEMBER TO DO THIS WITH ALL

POWER OFF ON THE CRANE AND ALL

ASSOCIATED CONTROLS.

1. Normally it should not be necessary to

set the Access Codes, they are preset. If

special field programming is needed.

Power the unit up on the bench and preprogram the unit for any special crane

configurations or other parameters, if

desired, see Section 7 - Programming

for details. The unit can be reprogrammed after it is installed also.

2. Position the receiver. Locate as far as

possible from exposed trolley wire and

sources of electromagnetic or radiated

noise. Cabinet mounting dimensions

and mounting template is on next page

see Figure 4-2. Receiver Mounting

Details. Antenna should be kept as clear

as possible of any metal object.

3. Mount the receiver. The four deep

mounting holes in corners of the

receiver use quantity four #10-24

combo drive round head screws 1.5 “ in

length, four #10 lock washers and four

#10-24 hex nuts to mount. Lock

washers should be used in front of hex

nuts.

4. Wire the unit using the appropriate

electrical drawings for the specific

transmitter and crane orientation

selected, see Section 6 - Wiring. If you

need to remove the main board (4

screws) the antenna unplugs from the

RF Receiver, be sure to dress the

antenna cable on the RF Receiver when

reinstalling the antenna cable.

5. Wire the power to J1 input power

connector. The connections are Ground

(GND), Neutral (N) and 115 VAC 60

Hz (115V).

Connections.

See Figure 4-1. Input Power

11

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 4 – Installation (continued)

m

6. Wiring of the system should now be

complete. Install antenna.

7. Turn switch SW2 OFF (MR relay

control) and SW1 ON (main power

switch). Stand clear of the crane and

apply AC power to receiver unit. Check

to see if at least the three green LEDs

DS1, DS2 and DS3 are ON, as well the

red RF Receiver ON LED (other LEDs

may be ON also). If none are lit check

AC power and power switch SW1. See

Figure 8-1. Receiver Layout for switch

and LED locations.

Figure 4-1. Input Power Connections.

1

120V N GRN

J1

11.02”

279.9 mm

7.09”

180 m

.30” DIA.

7.5 mm

hole 4 places

7.87”

200 mm

WHEN FIRST APPLING POWER TO THE

UNIT YOU MUST WAIT 10 SECONDS FOR

THE RECEIVER TO GO THROUGH THE

PROGRAMMING MODE.

8. Wait 10 seconds and turn the

transmitter ON. Check to see if the red

LEDs DS30 and DS32 are now ON. At

this point the MR relay is disabled; the

functions of the transmitter can be

checked by noting the turning ON of the

appropriate red LEDs next to the

control relays (K1-K12). After checking

out the functions, turn switch SW2 ON

to enable the MR relay (red LED DS31

should now turn ON), check function

and direction by jogging each motion.

Installation should now be complete.

9. If there are any problems see Section 8 Servicing.

11.81”

300 mm

NOTE

Drawing not to scale.

Overall Cabinet Depth With door

closed inches

Cabinet 5.26 13

With door

closed mm

3.60 12.12 307.98

With door

open inches

With door open

mm

Figure 4-2. Receiver Mounting Details

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

12

Section 5

See Appropriate Transmitter Manual

13

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

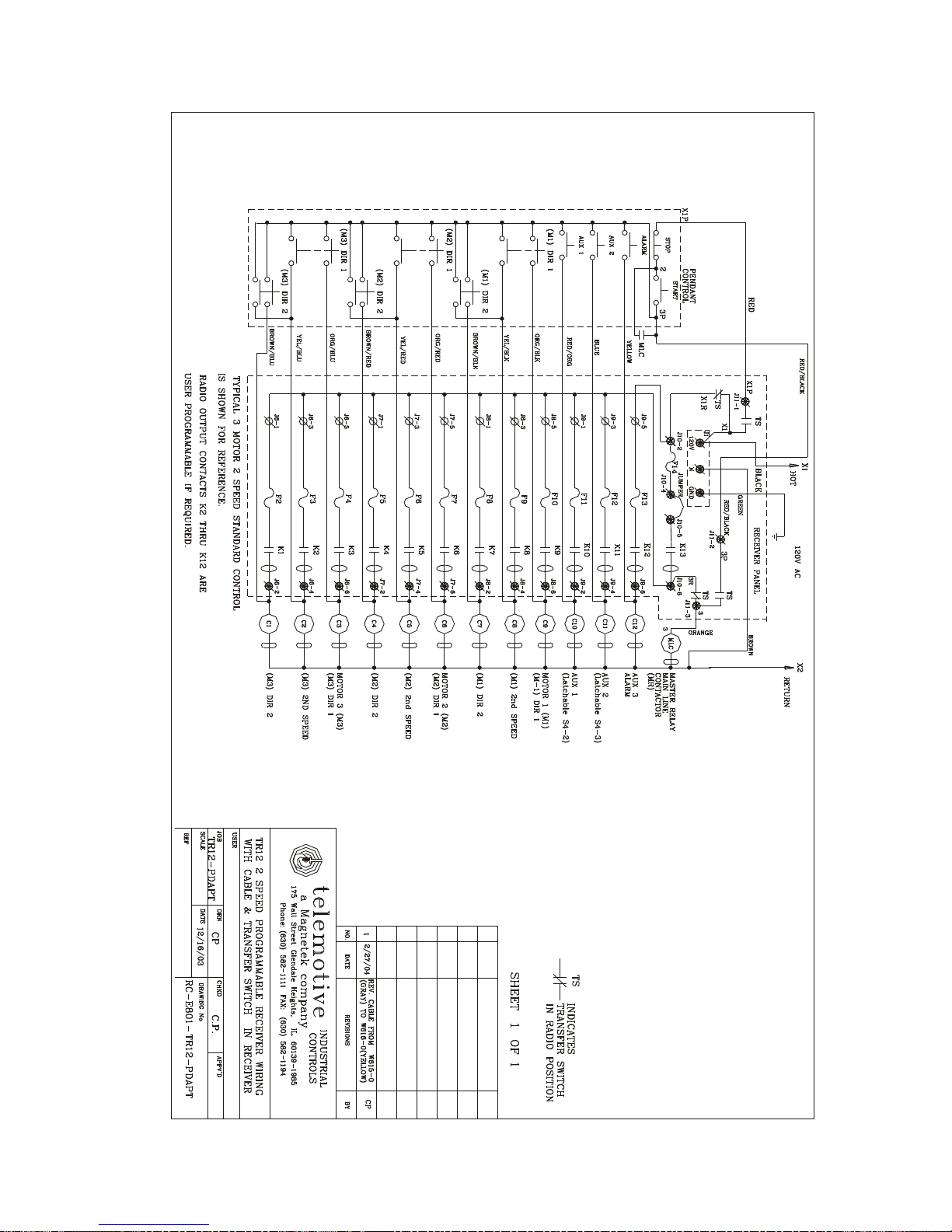

Section 6 - Wiring

6-1. Wiring Diagrams.

The system comes pre-programmed; the

following pages in this section have individual

wiring diagrams for different crane

configurations. Find the appropriate wiring

diagram and if necessary program the receiver

and transmitter switch settings shown for the

appropriate diagram. Terminal designators are

marked on the wiring diagram corresponding to

designators found on the Receiver Board. For

terminal locations see Figure 8-1. Receiver

Layout. After selecting the appropriate motors

for each function remember to place the

appropriate label on your transmitter for

describing the appropriate command.

Typically in the following wiring diagrams, the

Hoist is shown as Motor 1, Trolley as Motor 2

and Bridge is shown as Motor 3. Make sure the

transmitter is labeled with the correct functions.

Stick on or movable button labels are provided

with the transmitter for proper labeling.

6-2. Installation.

Follow the procedure in Section 4 - Installation

for installing the receiver.

6-3. Alarms And Horns.

Make sure that the installation includes the

proper alarms, horns, indicator lights and their

associated controls as required by local and

governmental regulations.

6-4. Relay Sequencing.

The Diagrams in this section show actual relay

sequencing. Typically the directional stays in

when the second and third speed is actuated.

6-5. Alarm After ESTOP.

When connecting output relays to drives, it may

be required to remove the MOV to prevent the

leakage current through the MOV from holding

in the drive. See Figure 8-1. Receiver Layout for

the location of the MOV's. The MOV’s are next

to the relays they protect. The MOV’s can be cut

out of the circuit with a wire cutter. Remember

to do this with ALL power OFF on the crane and

all associated controls.

6-7. Single-Speed Transmitter Wiring.

For a Single-Speed Transmitter the only wiring

configuration is the diagram in Section 6 Wiring. Table 1, Single-Speed Standard

Configuration Hoist, Trolley and Bridge.

6-8. 2-Speed and 3-Speed telePendant

operation.

A 3-Speed telePendant will work on a 2-Speed

receiver; the 3

the motion buttons will not activate any

functions or speed changes. To use a 3-Speed

telePendant on a 2-Speed receiver the

particular transmitter Bank to be used must have

matching frequency, Access Codes and its Tx

Type” set to “3 SPD telePendant”. For the 3Speed telePendant transmitter there are no

configuration switches to set, the default for the

configuration switches is all OFF. The number of

Motors must be selected.

6-9. Commons.

Each receiver relay output (normally open) is

independent (floating) both input and output.

Relay commons (Hot) are not wired together on

the Receiver Board nor connected to the input

power. Relay common wiring must be provided.

This is to give total flexibility. Different motors

and/or functions can use different phases or

independent (even DC) power sources.

rd

speed position (switch detent) on

This is only for wiring configurations where the

Aux 3 (relay K12, output J8-6) is being used for

the Alarm function, placing a jumper on JU1 on

the Receiver Board will allow the alarm to

function after an ESTOP command. See Figure

8-1. Receiver Layout for jumper location.

6-6. Connecting Outputs To Drives.

MOV’s (transient protectors) are on all the

output relays to protect the relays from power

surges. MOV’s allow a small leakage current

that can affect some high impedance circuits.

14

6-10. Power or Hot routing.

The Diagrams in this Section show independent

power “HOT” routed to each relay. An alternate

way of routing power is to route all power to

each function from the MR (Master Relay) relay.

This wiring can only be used if the total current

does not exceed the MR relay ratings.

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Section 6 - Wiring (Continued)

H

B

H

*

B

6-11. Legend.

The following is the legend for the wiring diagrams below:

#

An input with the terminal

number # matching the connector in the receiver.

Auxiliary

Controls

AUX 1

AUX 2

AUX 3

ON/

OFF

K#

Matching relay contacts

in radio receiver panel

by number.

ON/OFF & Low Battery Indicators

Figure 6-1. Legend.

Motor 1

Dir 1

Dir 2

Motor 2

Dir 1

Dir 2

Motor 3

Dir 1

Dir 2

OIST*

TROLLE

RIDGE

ON/

OFF

Y

A B

AUX 1

AUX 2

AUX 3

AUX 4

AUX 5

AUX 6

Aux

Controls

#

An output with the terminal

number # matching the connector in the receiver.

iliary

C#

Customer supplied

contactor coil with arc

suppressor in parallel.

Motor 1

Dir 1

Dir 2

Motor 2

Dir 1

Dir 2

Motor 3

Dir 1

OIST*

TROLLE

RIDGE*

Dir 2

Y

TX12M-2

A B

Optional

4th Motor or Select Indicators

2-Speed telePilot

*

NOTE: Hoist, Trolley and Bridge are listed here as traditional configurations,

the installer may choose to define the motors differently.

Figure 6-2. telePilot and telePendant, Output Controls

15

E-STOP

E-STOP

Programmable

Motor Control and Select Indicators

2-Speed telePendant

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

Wiring for Internal Transfer Switch using Optional Pigtail.

Section 6 - Wiring (continued)

Telemotive TR12 inteleSmart Receiver Instruction Manual – 03/01/07

16

Loading...

Loading...