Page 1

SERVICE MANUAL

Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

When servicing the deck

mechanism, refer to MK14 Deck

Mechanism Section.

Deck Mechanism Part No.:

N2440FL, N2460FL

DVD PLAYER &

VIDEO CASSETTE RECORDER

DVC840F

MWD2205 DVC865F

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

Funai could not possibly know, evaluate and advice the service trade of all

conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Funai has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by Funai must first

use all precautions thoroughly so that neither his safety nor the safe

operation of the equipment will be jeopardized by the service method

selected.

Manufactured under license from Dolby Laboratories.

“Dolby” and the double-D symbol are trademarks of Dolby Laboratories.

Page 3

MAIN SECTION

DVD PLAYER &

VIDEO CASSETTE RECORDER

DVC840F/MWD2205/

DVC865F

Main Section

I Specifications

I Preparation for Servicing

I Adjustment Procedures

I Schematic Diagrams

I CBA’s

I Exploded Views

I Parts List

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4-1

Preparation for Servicing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

How to Initialize the DVD Player & VCR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Function Indicator Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11-1

Schematic Diagrams / CBA’s and Test Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

Wiring Diagram < VCR Section > . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

Wiring Diagram < DVD Section > . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14-2

System Control Timing Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15-1

IC Pin Function Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16-1

Lead Identifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-18-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20-1

Page 4

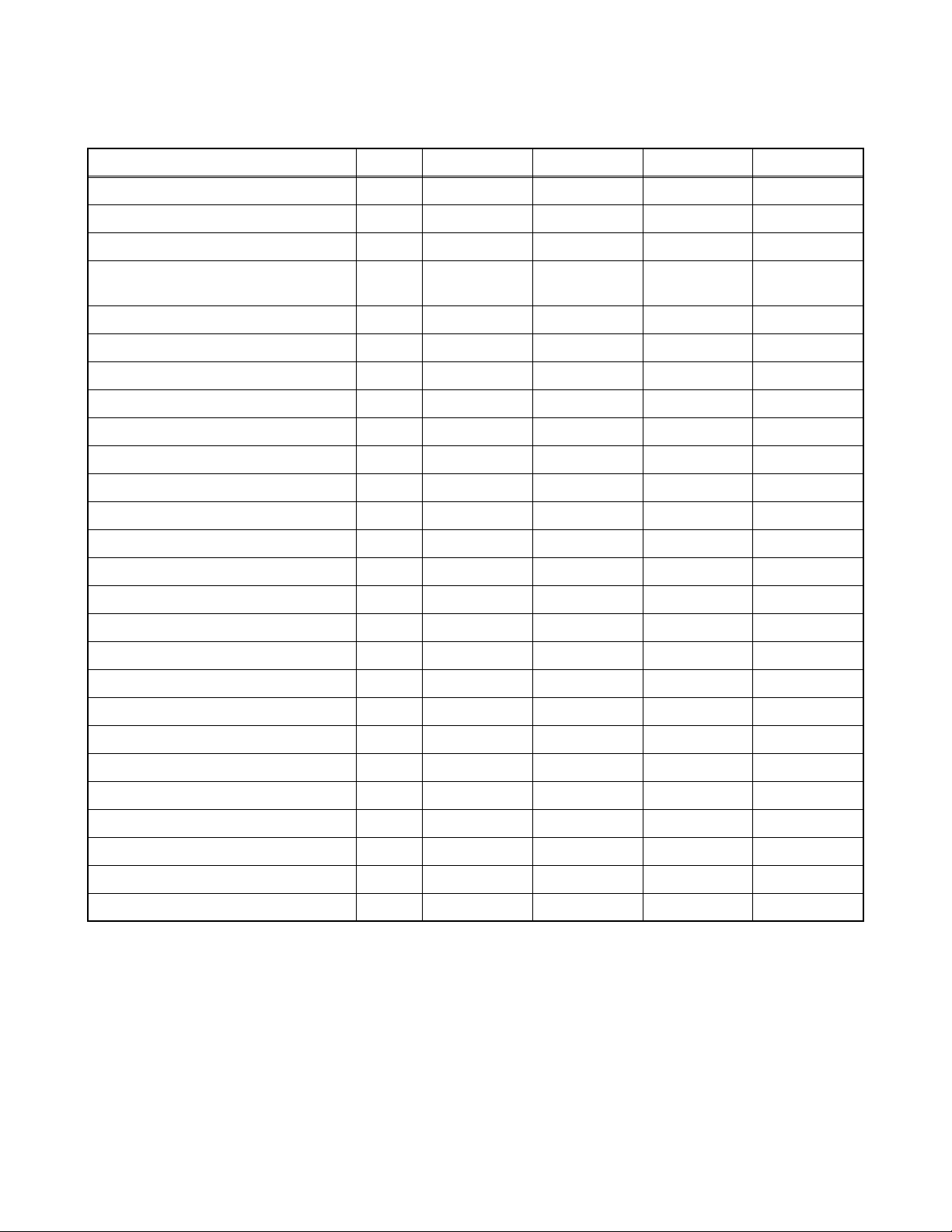

SPECIFICATIONS

< VCR Section >

Description Unit Minimum Nominal Maximum Remark

1. Video

1-1. Video Output (PB) Vp-p 0.8 1.0 1.2 SP Mode

1-2. Video Output (R/P) Vp-p 0.8 1.0 1.2

1-3. Video S/N Y (R/P) dB 40 45

1-4. Video Color S/N AM (R/P) dB 35 41 SP Mode

1-5. Video Color S/N PM (R/P) dB 33 36 SP Mode

1-6. Resolution (PB) Line 230 245 SP Mode

2. Servo

2-1. Jitter Low µsec 0.07 0.12 SP Mode

2-2. Wow & Flutter % 0.3 0.5 SP Mode

3. Normal Audio

3-1. Output (PB) dBV -9 -6 -3 SP Mode

3-2. Output (R/P) dBV -9 -6 -1.5 SP Mode

3-3. S/N (R/P) dB 36 41 SP Mode

3-4. Distortion (R/P) % 1.0 4.0 SP Mode

3-5. Freq. resp (R/P) at 200 Hz dB -11 -4 SP Mode

(-20 dB ref. 1 kHz) at 8 kHz dB -14 -4 SP Mode

4. Tuner

4-1. Video output Vp-p 0.8 1.0 1.2 E-E Mode

SP Mode,

W/O Burst

4-2. Video S/N dB 39 42 E-E Mode

4-3. Audio output dB -10 -6 -2 E-E Mode

4-4. Audio S/N dB 40 46 E-E Mode

5. Hi-Fi Audio [ DVC865F ]

5-1. Output dBV -12 -8 -4 SP Mode

5-2. Dynamic Range dB 70 80 SP Mode

5-3. Freq. resp (6 dB B.W) Hz 20 ~ 20 k SP Mode

Note: Nominal specs represent the design specs. All units should be able to approximate these – some will

exceed and some may drop slightly below these specs. Limit specs represent the absolute worst condition

that still might be considered acceptable; In no case should a unit fail to meet limit specs.

1-1-1 H9801SP

Page 5

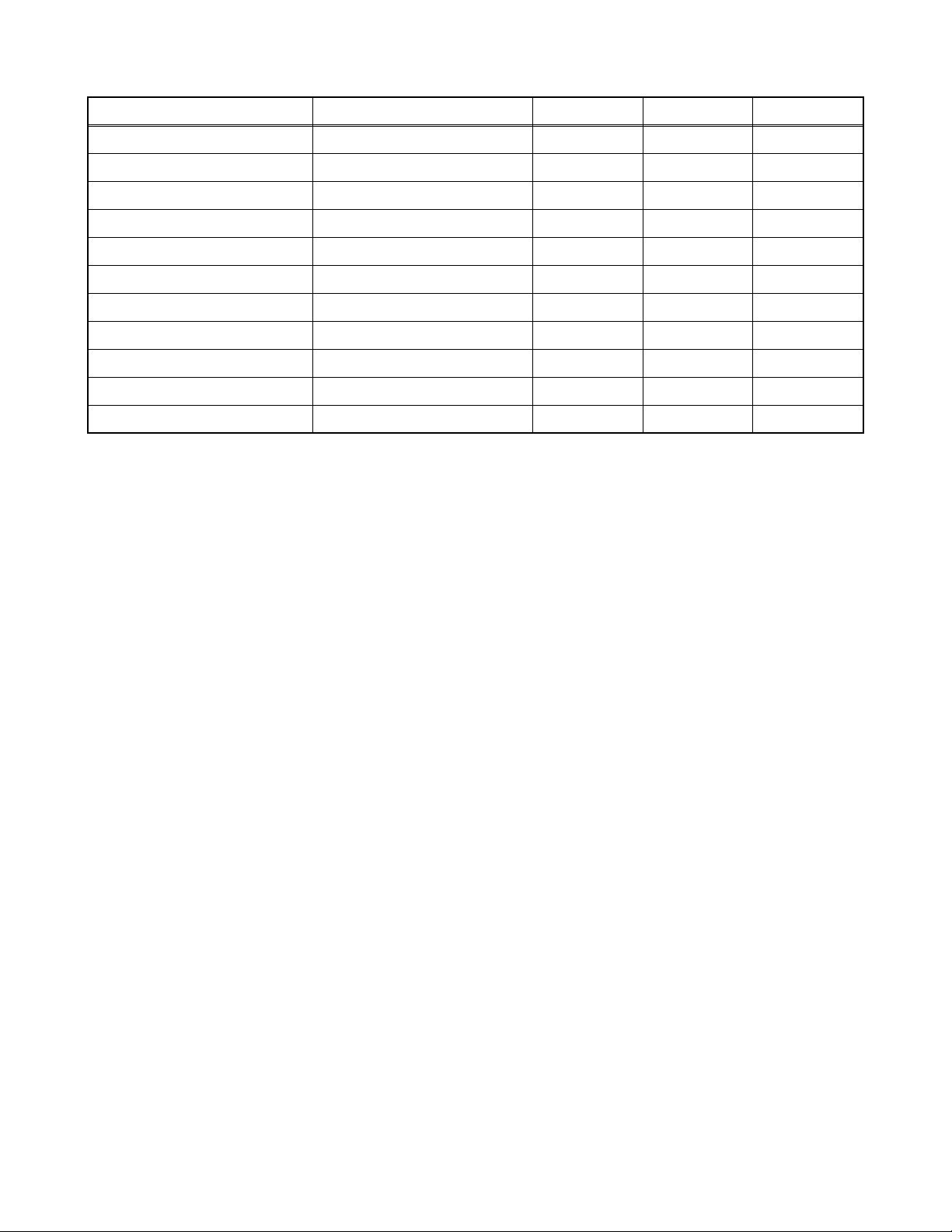

< DVD Section >

Item Conditions Unit Nominal Limit

1. Video Output 75 Ω load Vpp 1.0 ± 0.1

2. Coaxial Digital Out 75 Ω load mVpp 500 ± 50

3. Audio (PCM)

3-1. Output Level 1 kHz, 0 dB Vrms 2.0

3-2. S/N dB 100

3-3. Freq. Response

DVD fs = 48 kHz ± 0.5 dB Hz 20 ~ 22 k

CD fs = 44.1 kHz ± 0.5 dB Hz 20 ~ 20 k

3-4. THD+N

DVD 1 kHz, 0 dB % 0.01

CD 1 kHz, 0 dB % 0.01

Notes:

1. All Items are measured without pre-emphasis unless otherwise specified.

2. Power supply: AC 120 V, 60 Hz

3. Load imp.: 100 kΩ

4. Ambient Temperature: +25 °C

1-1-2 H9801SP

Page 6

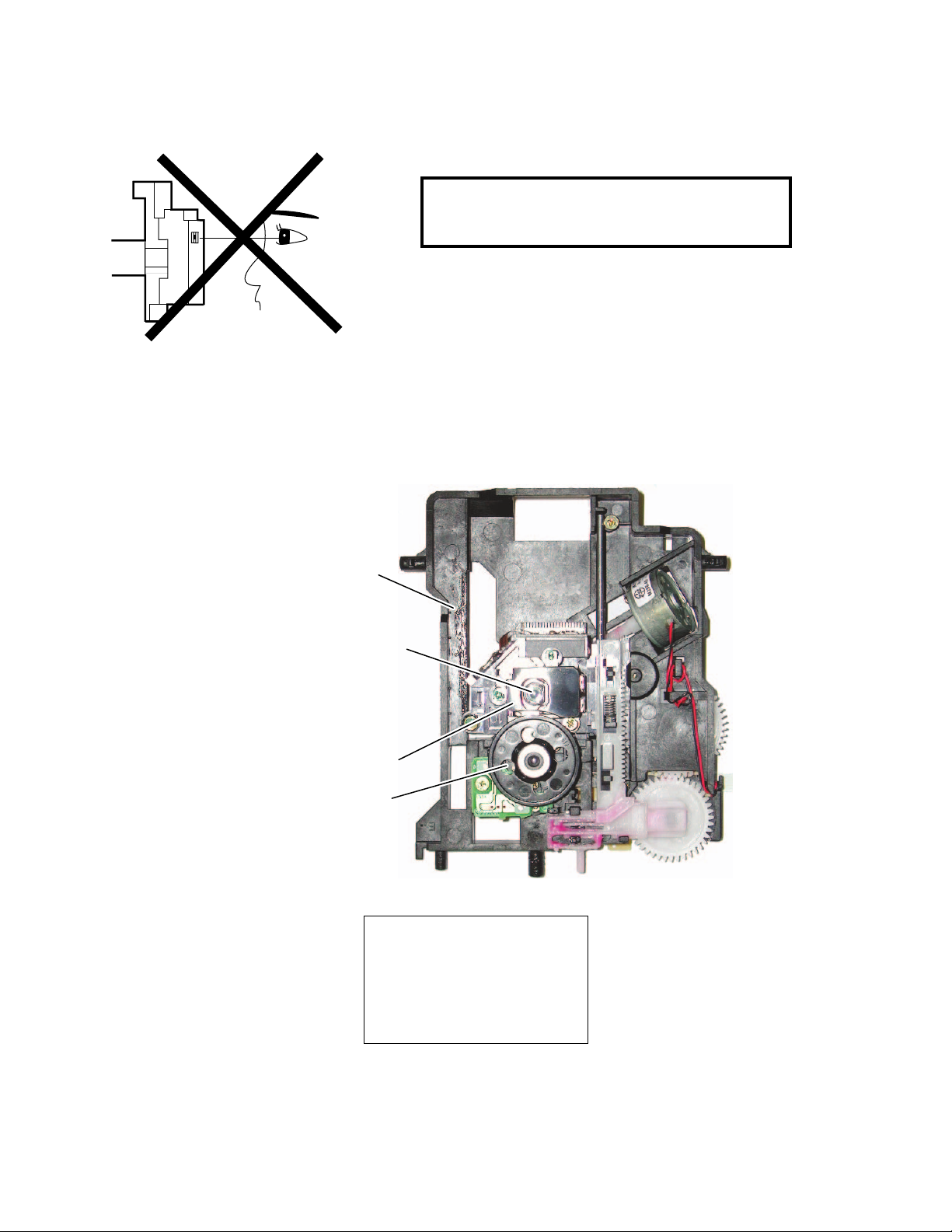

LASER BEAM SAFETY PRECAUTIONS

This DVD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mecha Assembly

Laser Beam Radiation

Laser Pickup

Turntable

CAUTION

LASER RADIATION

WHEN OPEN. DO NOT

STARE INTO BEAM.

Location: Top of DVD mechanism.

1-2-1 E6NLSP

Page 7

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. Crimp type wire connector

The power transformer uses crimp type

connectors which connect the power cord and the

primary side of the transformer. When replacing

the transformer, follow these steps carefully and

precisely to prevent shock hazards.

Replacement procedure

1) Remove the old connector by cutting the wires

at a point close to the connector.

Important: Do not re-use a connector.

(Discard it.)

2) Strip about 15 mm of the insulation from the

ends of the wires. If the wires are stranded,

twist the strands to avoid frayed conductors.

3) Align the lengths of the wires to be connected.

Insert the wires fully into the connector.

4) Use a crimping tool to crimp the metal sleeve at

its center. Be sure to crimp fully to the complete

closure of the tool.

L. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

1-3-1 DVDN_ISP

Page 8

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

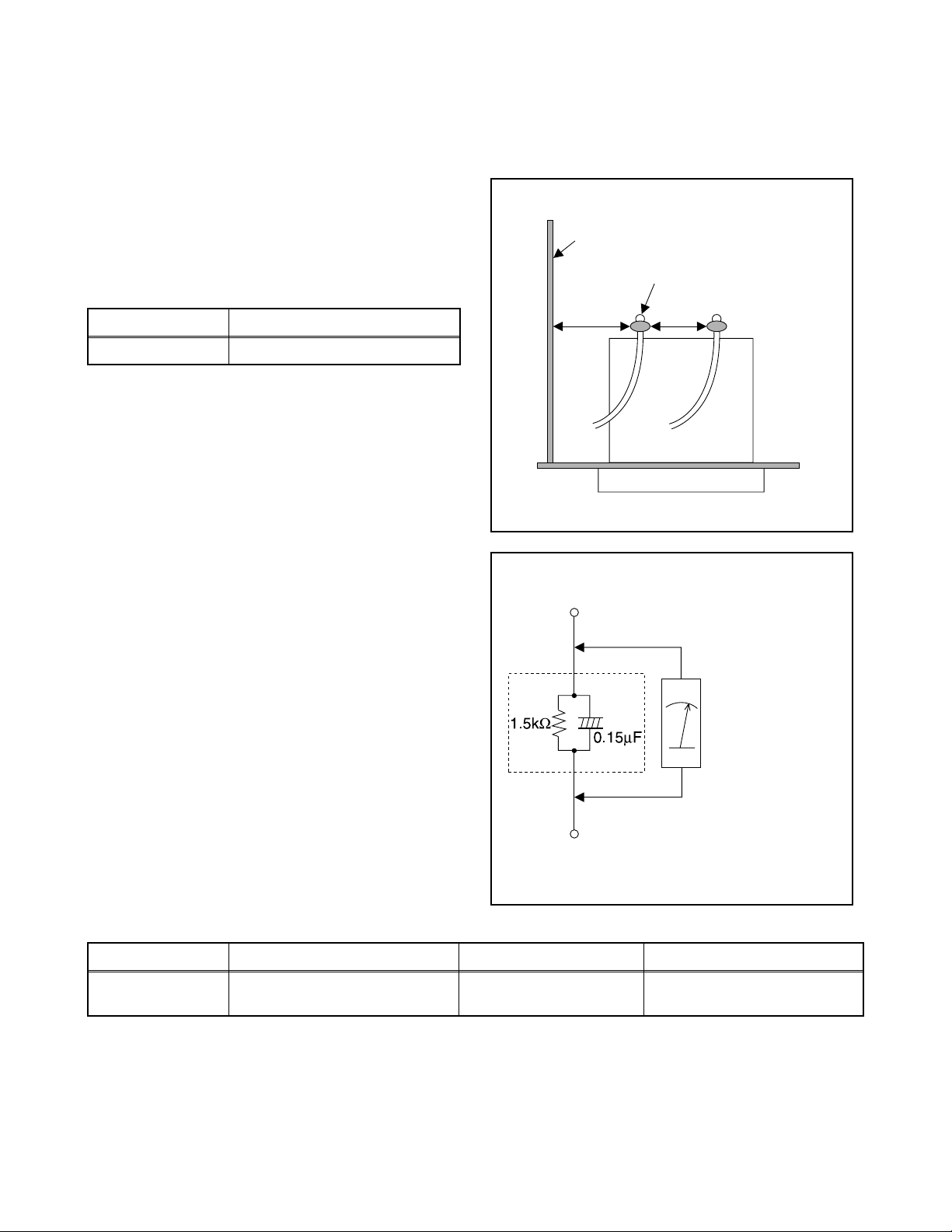

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit Terminals

AC Line Voltage Clearance Distance (d), (d’)

120 V ≥ 3.2 mm (0.126 inches)

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

dd'

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i) Earth Ground (B) to:

120 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

0.15 µF CAP. & 1.5 kΩ RES.

Connected in parallel

i ≤ 0.5 mA Peak Exposed accessible parts

1-3-2 DVDN_ISP

Fig. 2

Page 9

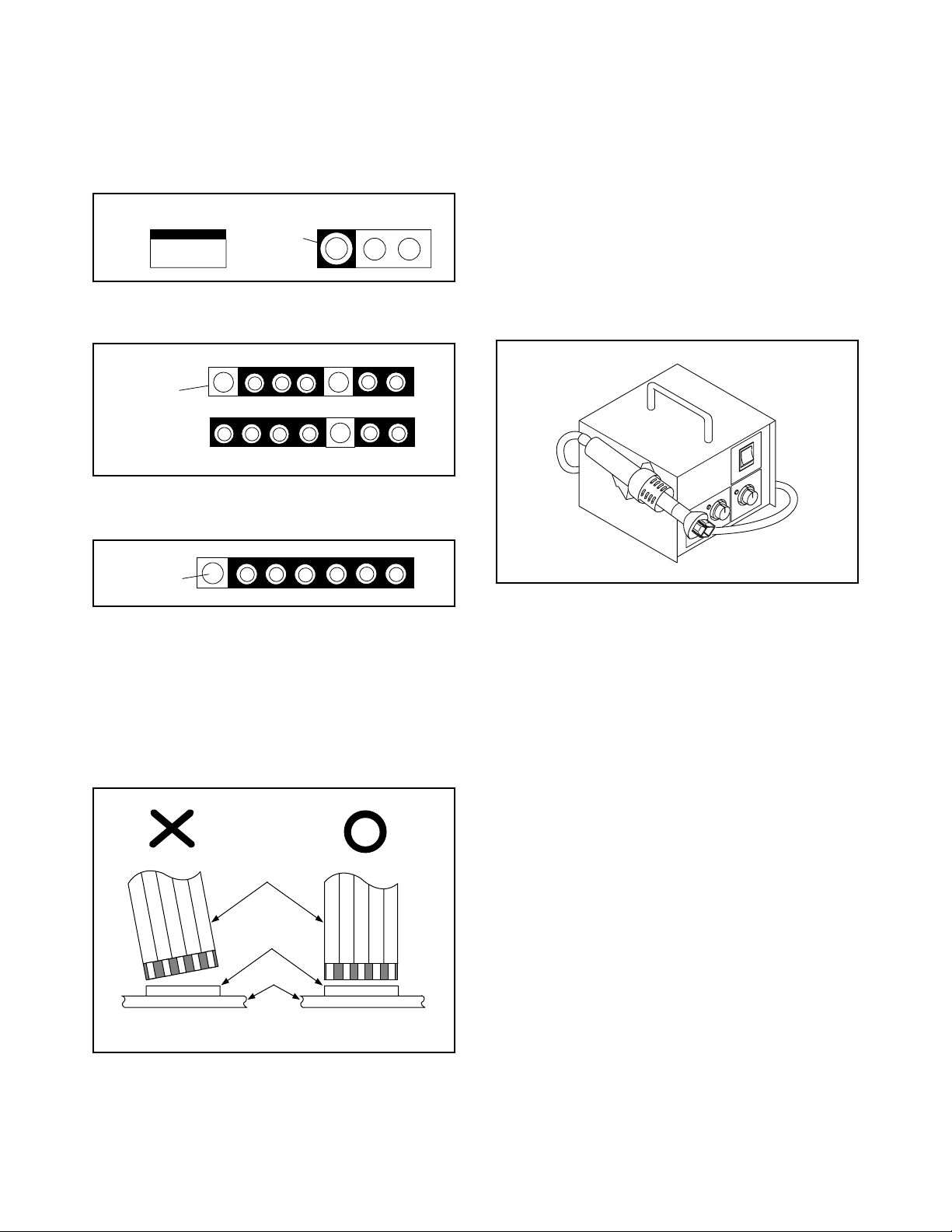

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

Top View

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

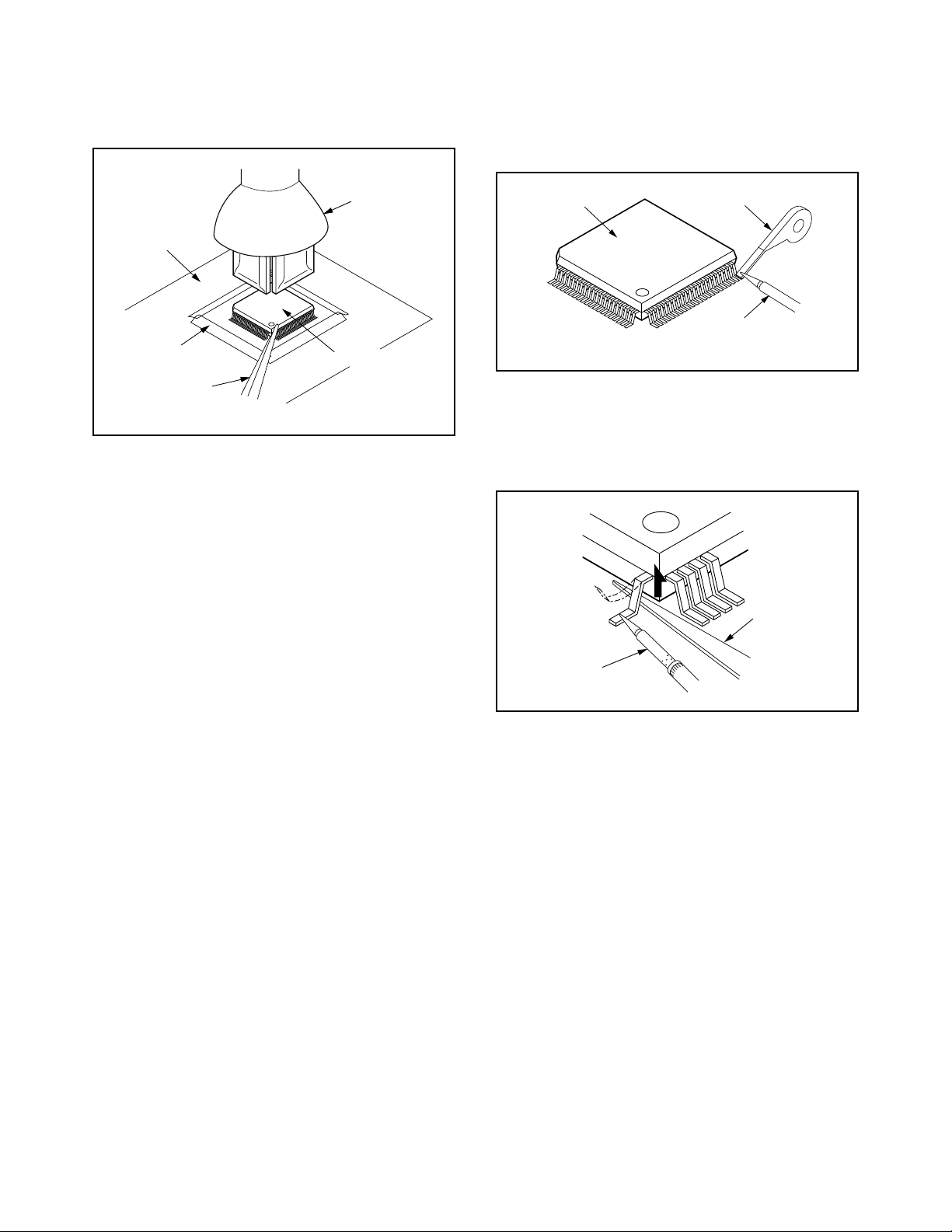

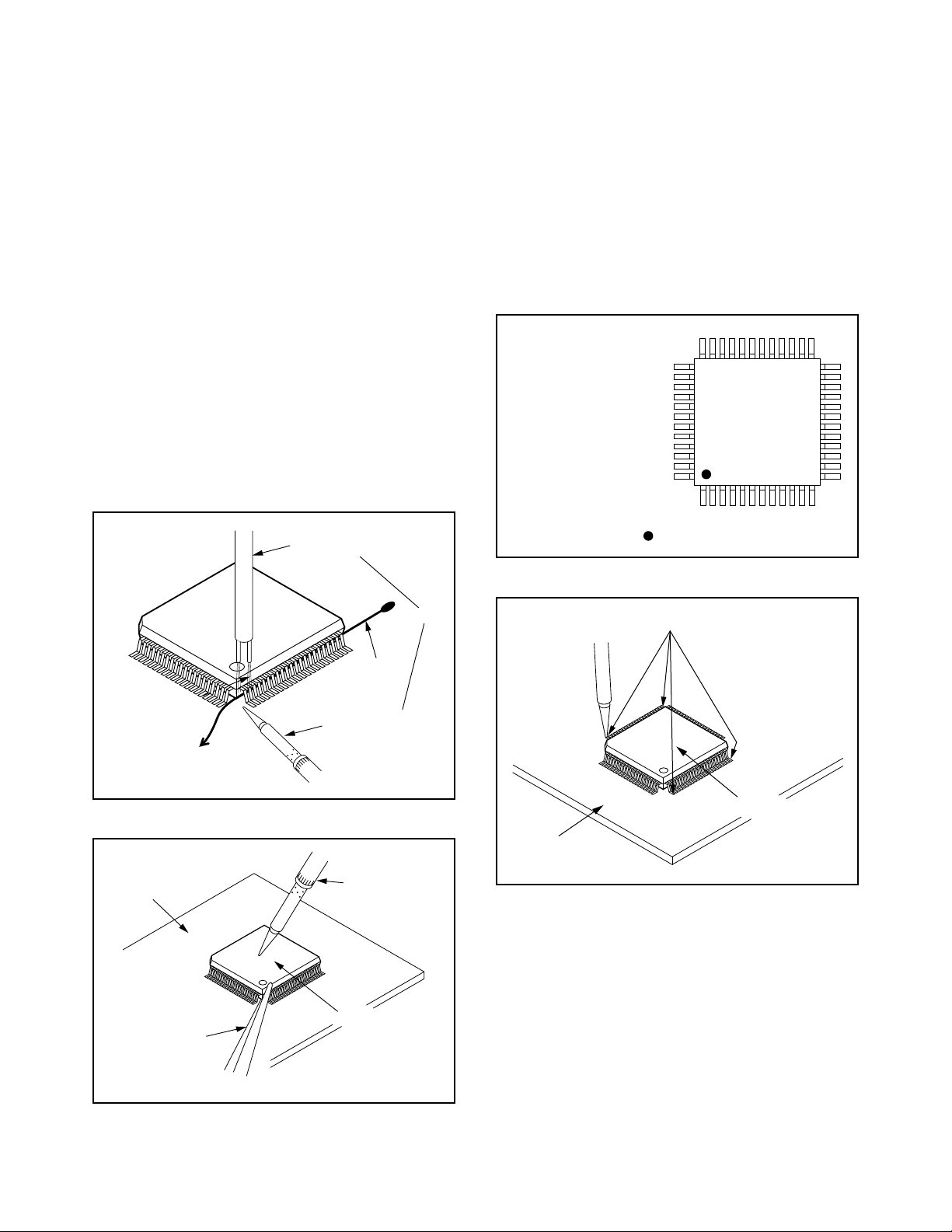

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 DVDN_SN

Page 10

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Tape

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 DVDN_SN

Page 11

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “●” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the 1

on the PCB when positioning for installation. Then

presolder the four corners of the flat pack-IC. (See

Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 DVDN_SN

Page 12

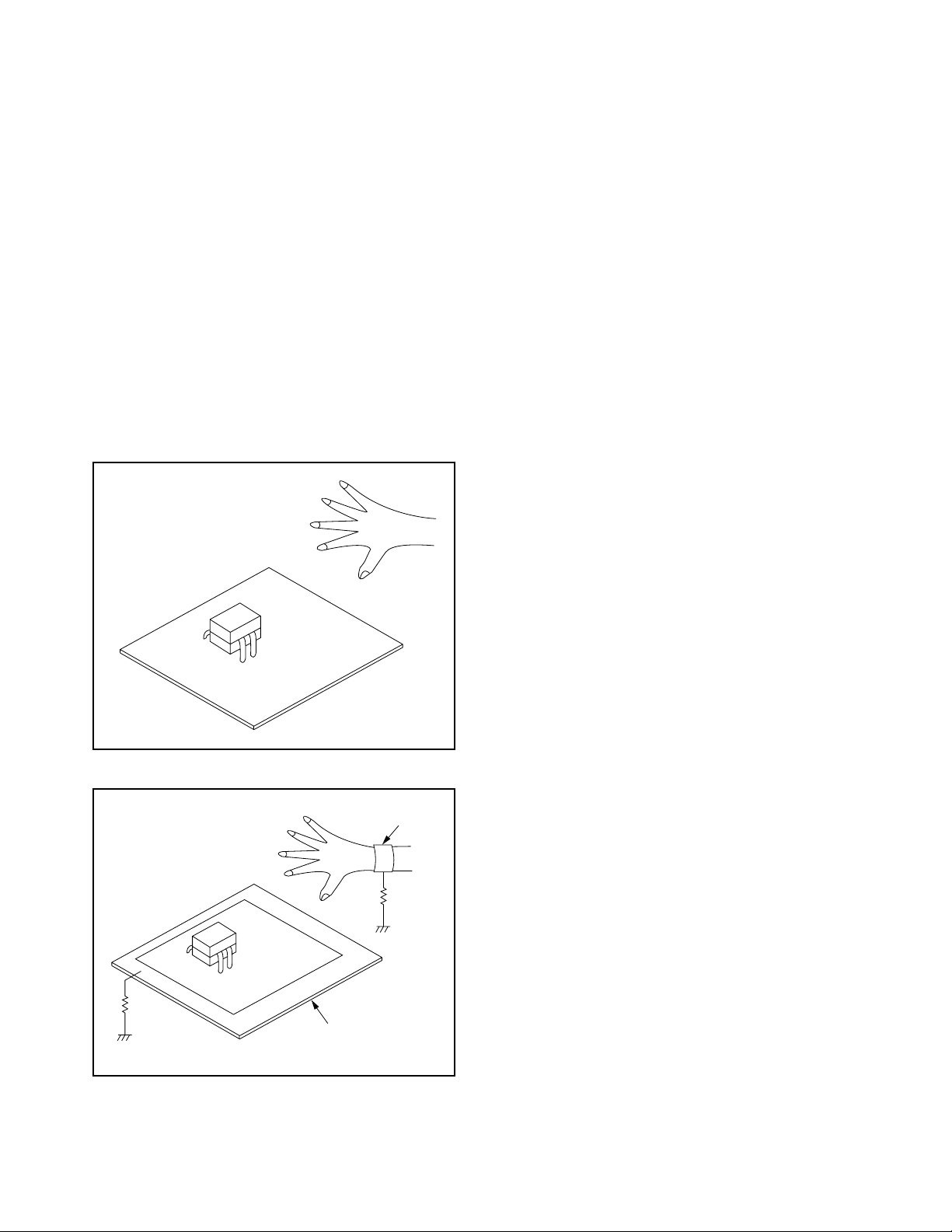

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 DVDN_SN

Page 13

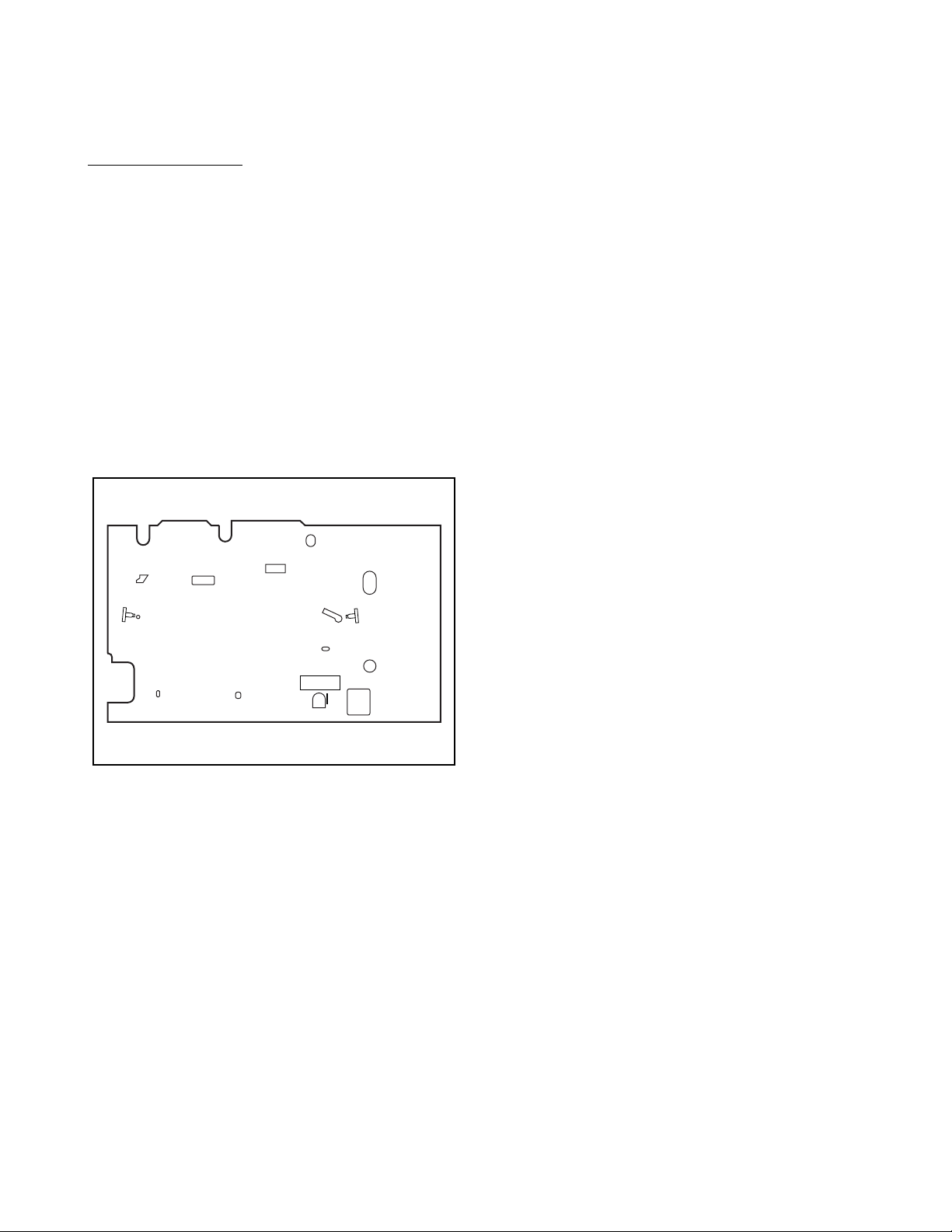

PREPARATION FOR SERVICING

How to Enter the Service Mode

About Optical Sensors

Caution:

An optical sensor system is used for the Tape Start

and End Sensors on this equipment. Carefully read

and follow the instructions below. Otherwise the unit

may operate erratically.

What to do for preparation

Insert a tape into the Deck Mechanism Assembly and

press the [PLAY] button. The tape will be loaded into

the Deck Mechanism Assembly. Make sure the power

is on, connect TP502 (S-INH) to GND. This will stop

the function of Tape Start Sensor, Tape End Sensor

and Reel Sensors. (If these TPs are connected before

plugging in the unit, the function of the sensors will

stay valid.) See Fig. 1.

Q503

Q504

TP502

S-INH

Fig. 1

Note: Because the Tape End Sensors are inactive,

do not run a tape all the way to the start or the

end of the tape to avoid tape damage.

1-5-1 H9801PFS

Page 14

CABINET DISASSEMBLY INSTRUCTIONS

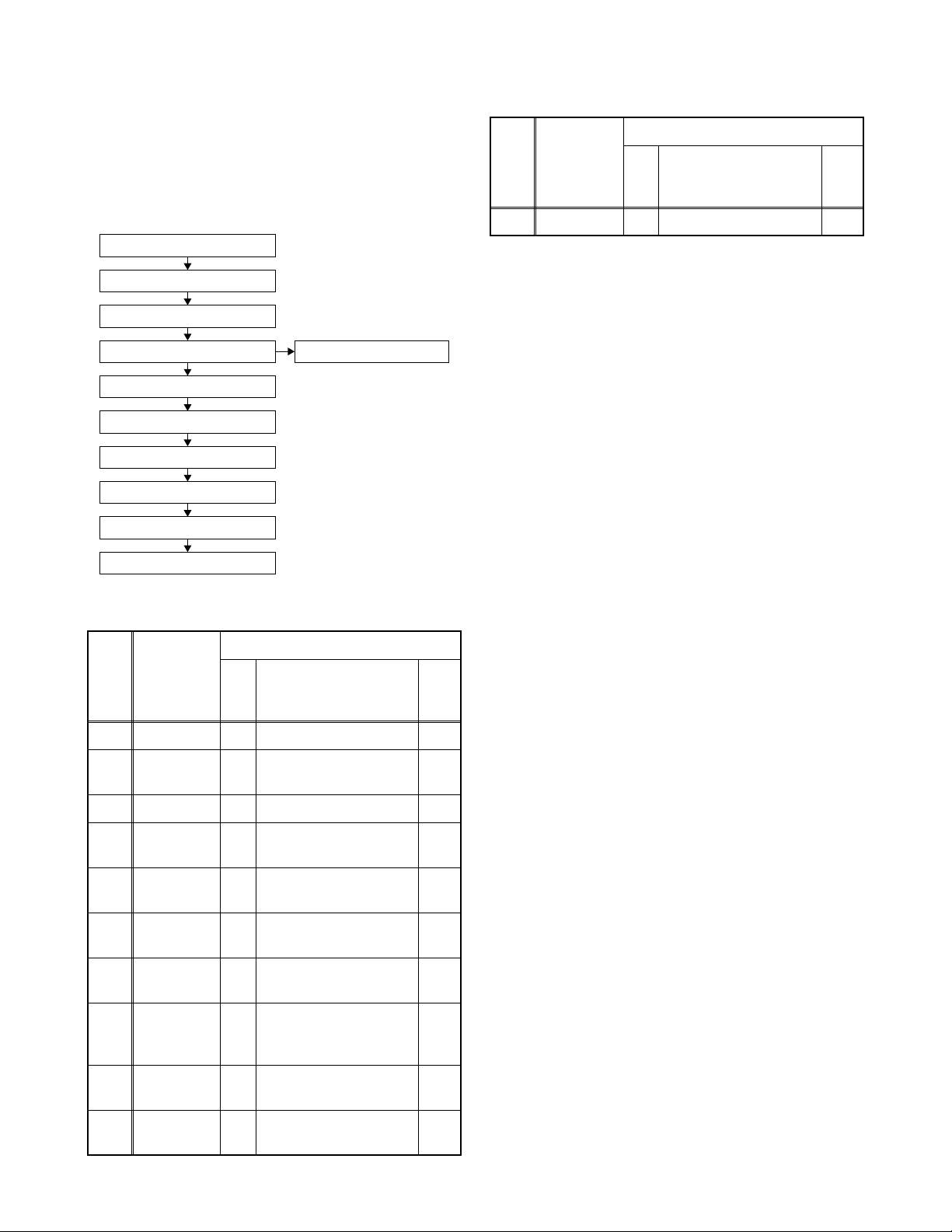

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

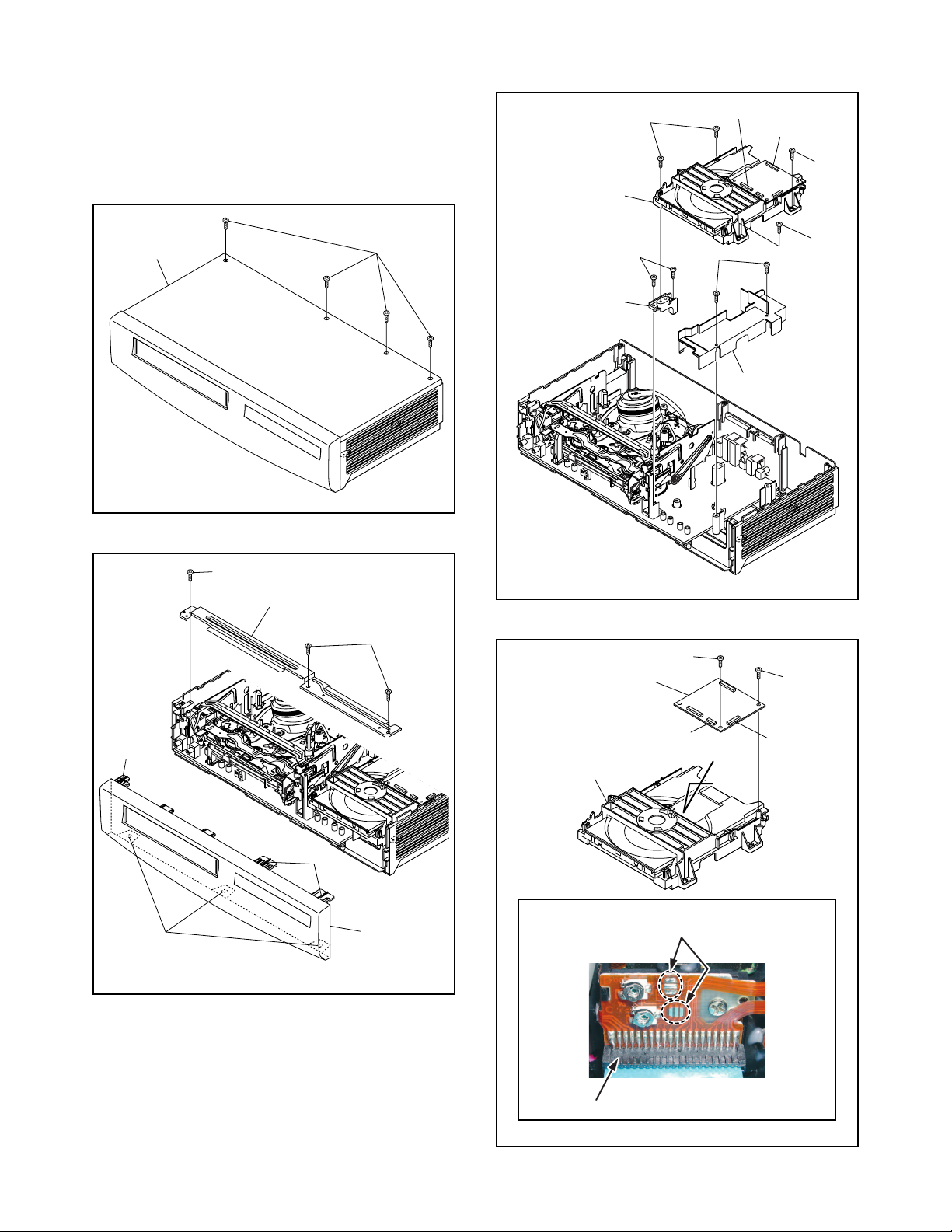

[1] Top Case

[2] Front Assembly

[3] Top Bracket

[4] DVD Mecha Assembly [7] DVD Main CBA Unit

[5] Partition Plate

[6] Loader Holder

[8] VCR Chassis Unit

[9] Deck Assembly

[10] DVD Open/Close CBA

[11] Main CBA

2. Disassembly Method

ID/

Loc.

No.

[1] Top Case D1 4(S-1) ---

[2]

[3] Top Bracket D2 3(S-2) ---

[4]

[5]

[6]

[7]

[8]

[9]

Part

Front

Assembly

DVD Mecha

Assembly

Partition

Plate

Loader

Holder

DVD Main

CBA Unit

VCR

Chassis

Unit

Deck

Assembly

Fig.

No.

D2 *3(L-1), *3(L-2) 1

4(S-3), *CN401,

D3

*CN601

D3 2(S-4) ---

D3 2(S-5) ---

(S-6), *CN201,

D4

*CN301

D5 5(S-7), (S-8) -

Desolder,

D6

(S-9), (S-10), (S-11)

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

---

2, 3

4, 5

ID/

Loc.

No.

[11] Main CBA D6 ---------- ---

↓

(1)

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to “Reference Notes.”

Part

↓

(2)

Fig.

No.

↓

(3)

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

↓

(4)

Note

↓

(5)

Reference Notes

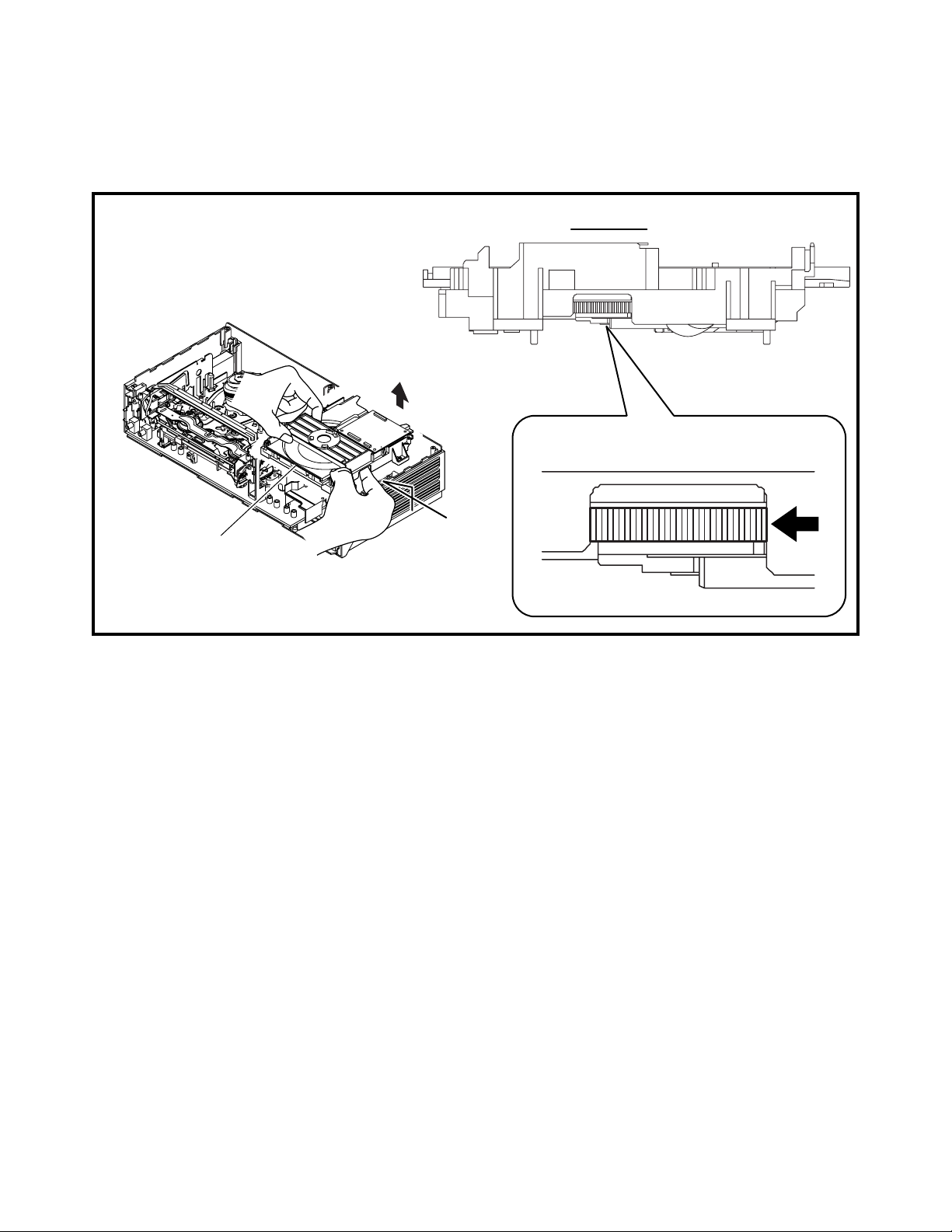

1. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

1) Release three Locking Tabs (L-1).

2) Release three Locking Tabs (L-2), then remove

the Front Assembly.

2. CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc, during

unpacking or repair work.

To avoid damage of pickup follow next procedures.

1) Disconnect Connector (CN301). Remove a

Screw (S-6) and lift the DVD Main CBA Unit.

(Fig. D4)

2) Short the three short lands of FPC cable with

solder before removing the FFC cable (CN201)

from it. If you disconnect the FFC cable

(CN201), the laser diode of pickup will be

destroyed. (Fig. D4)

3. CAUTION 3: When reassembling, confirm the

FFC cable (CN201) is connected completely. Then

remove the solder from the three short lands of

FPC cable. (Fig. D4)

4. When reassembling, solder wire jumpers as

shown in Fig. D6.

[10]

DVD Open/

Close CBA

D6 Desolder ---

1-6-1 H9801DC

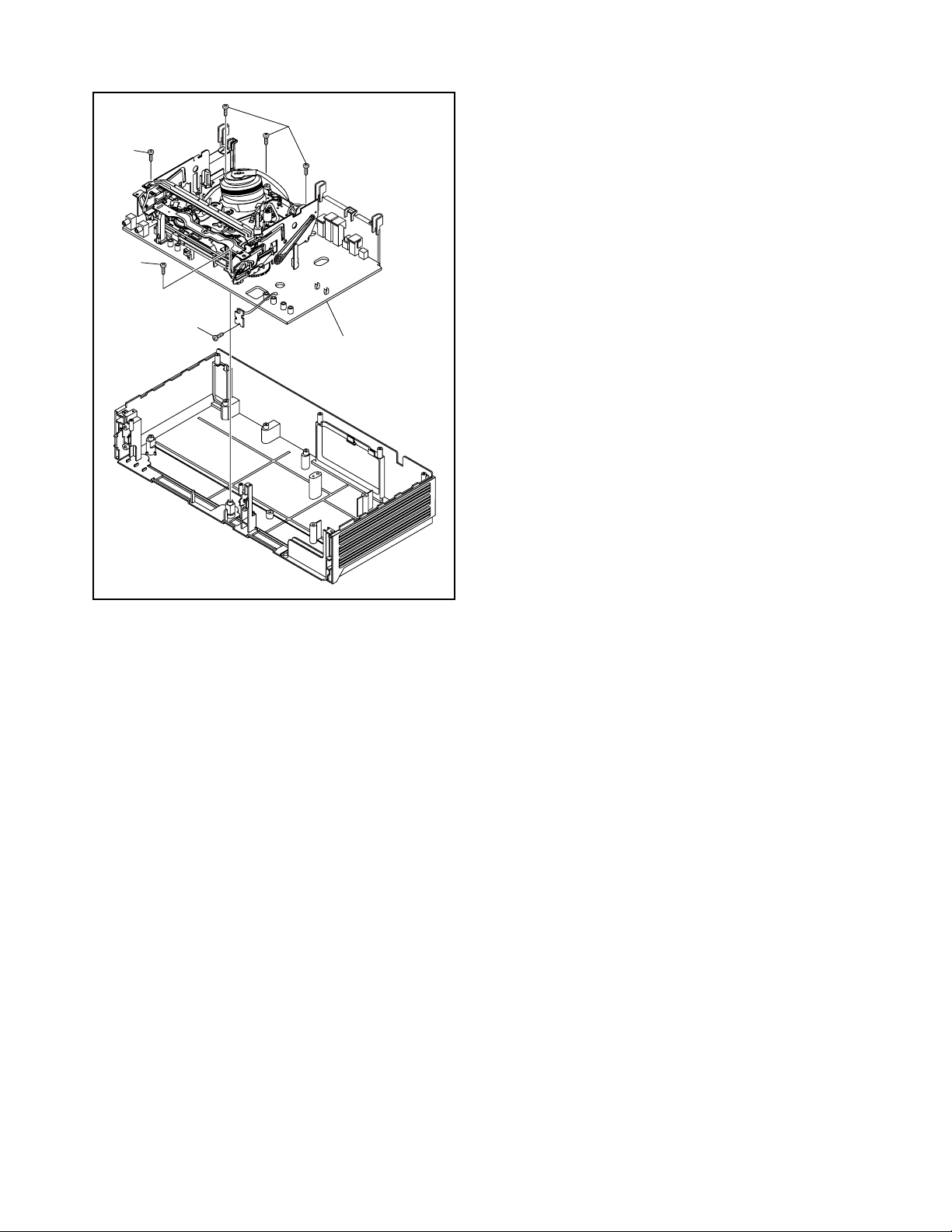

Page 15

5. Before installing the Deck Assembly, be sure to

place the pin of LD-SW on Main CBA as shown in

Fig. D6. Then, install the Deck Assembly while

aligning the hole of Cam Gear with the pin of LDSW, the shaft of Cam Gear with the hole of LD-SW

as shown in Fig. D6.

[4] DVD Mecha

Assembly

(S-3)

CN401

CN601

(S-3)

[1] Top Case

(S-2)

[3] Top Bracket

(S-1)

(S-2)

Fig. D1

(S-5)

[6] Loader

Holder

[7] DVD Main

CBA Unit

(S-3)

(S-4)

[5] Partition Plate

Fig. D3

(S-6)

(S-6)

(L-1)

(L-2)

(L-1)

[2] Front

Assembly

Fig. D2

CN301

A

DVD Mecha

Short the three short lands by soldering.

(Either of two places.)

Connector

View for A

CN201

Fig. D4

1-6-2 H9801DC

Page 16

(S-7)

(S-7)

(S-7)

(S-8)

[8] VCR Chassis Unit

Fig. D5

1-6-3 H9801DC

Page 17

FE Head

Cylinder

Assembly

ACE Head

Assembly

Pin

(S-9)

[10] DVD

Open/Close CBA

[9] Deck Assembly

(S-11)

[11] Main CBA

(S-10)

Desolder

Lead with

blue stripe

From

ACE Head

Assembly

Lead with

blue stripe

[11] Main CBA

[9] Deck Assembly

Shaft

Hole

LD-SW

From

Cylinder

Lead with

blue stripe

Assembly

From

FE Head

SW512

LD-SW

Cam Gear

Hole

Pin

[11] Main CBA

Desolder

Lead with

red stripe

Desolder

Printing side

From

Capstan

Motor

Assembly

Desolder

BOTTOM VIEW

Lead connections of Deck Assembly and Main CBA

1-6-4 H9801DC

Fig. D6

Page 18

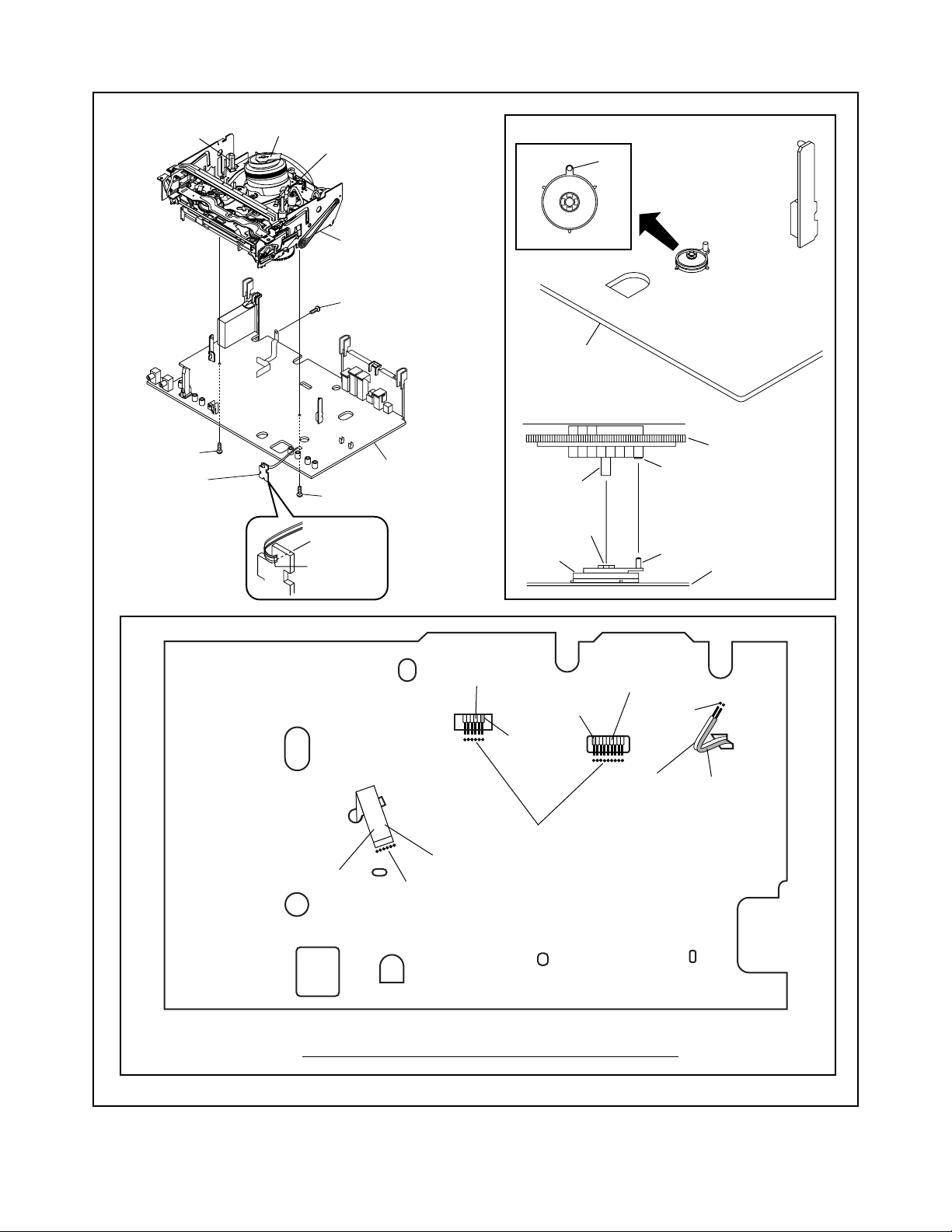

3. HOW TO EJECT MANUALLY

1. Remove the Top Case, Front Assembly and Top Bracket.

2. Remove four Screws (S-3) in Fig. D3. Do not disconnect connectors.

3. While lifting up the DVD Mecha, rotate the roulette in the direction of the arrow as shown below.

4. Pull the tray slowly with a hand.

View for A

Rotate this roulette in

the direction of the arrow

A

DVD Mecha

1-6-5 H9801DC

Page 19

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: “CBA” is abbreviation for

“Circuit Board Assembly.”

NOTE:

1. Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to do these adjustments only after

all repairs and replacements have been

completed. Also, do not attempt these adjustments

unless the proper equipment is available.

2. To perform these alignment / confirmation

procedures, make sure that the tracking control is

set in the center position: Press either [CHANNEL

L] or [CHANNEL K] button on the front panel first,

then the [PLAY] button on the front panel.

Test Equipment Required

1. Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50 V/Div.,

F-Range: DC~AC-20 MHz

2. Alignment Tape (FL8A)

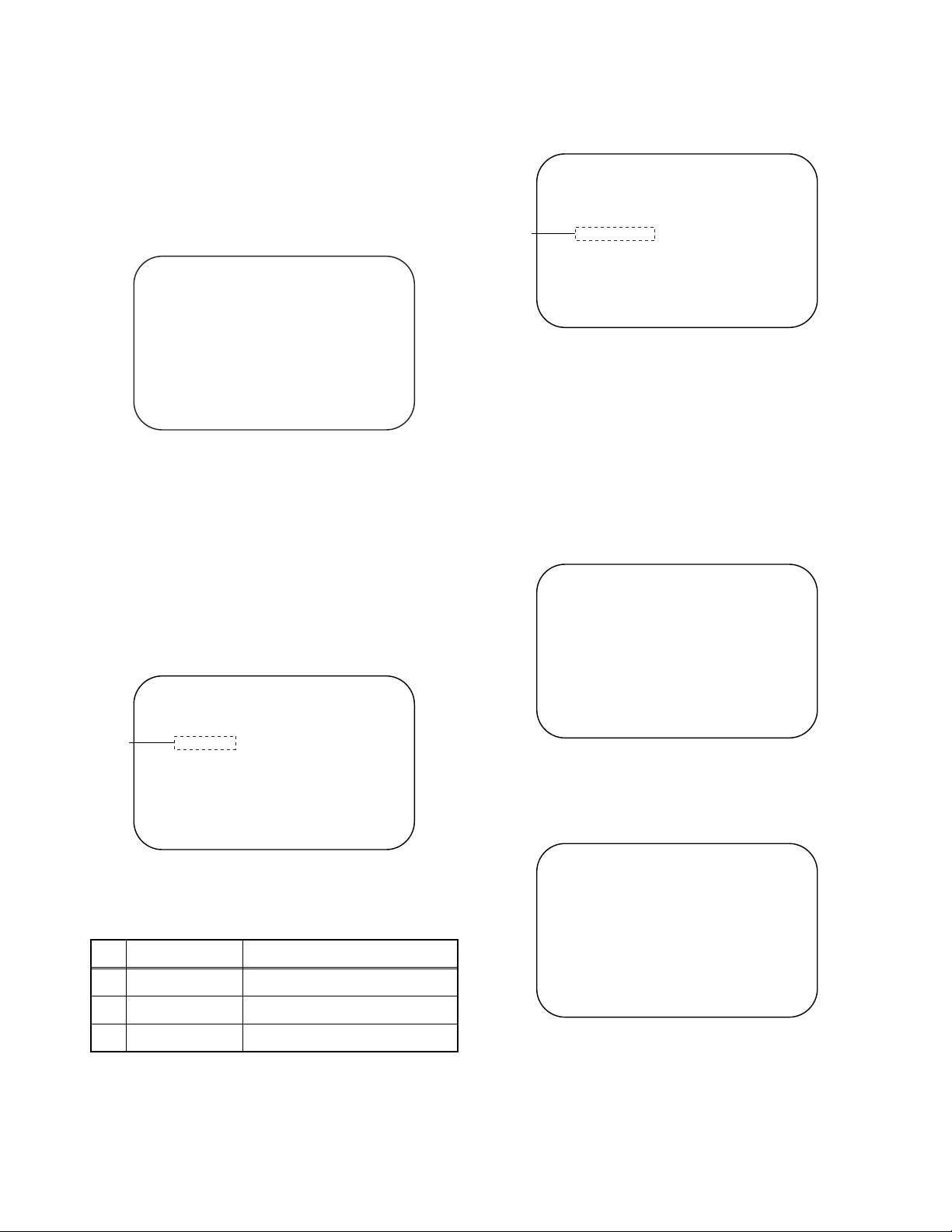

Head Switching Position

Adjustment

Purpose: To determine the Head Switching position

during playback.

Symptom of Misadjustment: May cause Head

Switching noise or vertical jitter in the picture.

Test point Adj. Point Mode Input

TP751(V-OUT)

TP302(RF-SW)

GND

Tape

FL8A Oscilloscope

Connections of Measurement Equipment

Main CBA

VR501

(Switching Point)

Measurement

Equipment

TP751

GND

TP302

PLAY

(SP)

6.5H ± 1H

(412.7µs±63.5µs)

Oscilloscope

-----

Spec.

CH1 CH2

Trig. (+)

Figure 1

EXT. Syncronize Trigger Point

CH1

CH2

Note: TP751(V-OUT), TP302(RF-SW),

Reference Notes:

Playback the Alignment tape and adjust VR501 so that

the V-sync front edge of the CH1 video output

waveform is at the 6.5H ± 1H (412.7 µs ± 63.5 µs)

delayed position from the rising edge of the CH2 head

switching pulse waveform.

1.0H

6.5H±1H (412.7µs±63.5µs)

Switching Pulse

VR501(Switching Point) --- Main CBA

0.5H

V-Sync

1-7-1 H9801EA

Page 20

HOW TO INITIALIZE THE DVD PLAYER & VCR

To put the program back at the factory-default,

initialize the DVD player & VCR as the following

procedure.

< DVD Section >

1. Press [DVD], [1], [2], [3], [4], and [DISPLAY]

buttons on the remote control unit in that order.

Fig. a appears on the screen.

"

" differ depending on the models.

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

Fig. a

"

" differ depending on the models.

*******

2. Press [CLEAR/C.RESET] button on the remote

control unit.

Fig. b appears on the screen.

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

EEPROM CLEAR : OK

Fig. b

When “OK” appears on the screen, the factory

default will be set. Then the firmware renewal

mode is complete.

3. To exit this mode, press [POWER] or [STANDBYON] button.

1-8-1 H9801INT

Page 21

FIRMWARE RENEWAL MODE

1. Turn the power on and remove the disc on the tray.

2. To put the DVD player into version up mode, press

[DVD], [9], [8], [7], [6], and [SEARCH MODE]

buttons on the remote control unit in that order.

The tray will open automatically.

Fig. a appears on the screen.

"

" differ depending on the models.

*******

F/W Version Up Mode Model No : *******

Please insert a DISC

for F/W Version Up.

VERSION : *.**

EXIT: POWER

Fig. a Version Up Mode Screen

The DVD player can also enter the version up

mode with the tray open. In this case, Fig. a will be

shown on the screen while the tray is open.

3. Load the disc for version up.

4. The DVD player enters the F/W version up mode

automatically. Fig. c appears on the screen. If you

enter the F/W for different models, “Disc Error” will

appear on the screen, then the tray will open

automatically.

"

" differ depending on the models.

*******

the checksum in (*2) of Fig. e.

"

" differ depending on the models.

*******

(*2)

F/W Version Up Mode

VERSION : ************.ab6

Completed

SUM : 7ABC

Model No : *******

VERSION : *.**

Fig. e Completed Program Mode Screen

At this time, no buttons are available.

6. Remove the disc on the tray.

7. Unplug the AC cord from the AC outlet. Then plug

it again.

8. Turn the power on by pressing the [POWER] or

[STANDBY-ON] button and the tray will close.

9. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. g appears on the screen.

"

" differ depending on the models.

*******

MODEL : *******

Version

Region

: *.**

: *

(*1)

F/W Version Up Mode Model No : *******

VERSION : ************.ab6

Reading...

VERSION : *.**

Fig. c Programming Mode Screen

The appearance shown in (*1) of Fig. c is

described as follows:

No. Appearance State

1 Reading... Sending files into the memory

2 Erasing... Erasing previous version data

3 Programming... Writing new version data

5. After programming is finished, the tray opens

automatically. Fig. e appears on the screen and

EXIT: POWEREEPROM CLEAR : CLEAR

Fig. g

10. Press [CLEAR/C.RESET] button on the remote

control unit.

Fig. h appears on the screen.

"

" differ depending on the models.

*******

MODEL : *******

Version

Region

: *.**

: *

EXIT: POWEREEPROM CLEAR : CLEAR

EEPROM CLEAR : OK

Fig. h

When “OK” appears on the screen, the factory

default will be set. Then the firmware renewal

mode is complete.

11. To exit this mode, press [POWER] or [STANDBYON] button.

1-9-1 H9801FW

Page 22

FUNCTION INDICATOR SYMBOLS

Note: If a mechanical malfunction occurs, the power is turned off. When the power comes on again after that by

pressing [POWER] or [STANDBY-ON] button, an error message is displayed on the TV screen for 5

seconds.

Cause Indicator Active

When reel or capstan mechanism is not

functioning correctly

When tape loading mechanism is not

functioning correctly

When cassette loading mechanism is not

functioning correctly

When the drum is not working properly “EJECT A D” is displayed on a TV screen. (Refer to Fig. 4.)

“EJECT A R” is displayed on a TV screen. (Refer to Fig. 1.)

“EJECT A T” is displayed on a TV screen. (Refer to Fig. 2.)

“EJECT A C” is displayed on a TV screen. (Refer to Fig. 3.)

TV screen

When reel or capstan mechanism is not functioning

correctly

EJECT A R

Fig. 1

When tape loading mechanism is not functioning

correctly

When cassette loading mechanism is not functioning

correctly

EJECT A C

When the drum is not working properly

Fig. 3

EJECT A T

Fig. 2

EJECT A D

Fig. 4

1-10-1 H9801FIS

Page 23

BLOCK DIAGRAMS <VCR SECTION>

Servo / System Control Block Diagram

Q566

Q567

S-INH

TP502

KEY SWITCH

KEY SWITCH

66

67

D565 REC

AL+5V

Q565

D564 TIMER

72

D566 VCR

Q563

75

D571 POWER

D567 DVD

71

70

CLOCK

TU701(TUNER UNIT)

11

WF12

P-ON+9V

DATA

12

WF13

DVC865F

VCR/TV

5

77

TO Hi-Fi AUDIO

BLOCK

Hi-Fi-H-SW

NORMAL-L

IIC-BUS SCL

IIC-BUS SDA

12

13

25

DIAGRAM

ST/SAP-MODE

AUDIO-MUTE-H

AUDIO-MUTE-H

61

59

TO AUDIO

BLOCK DIAGRAM

D-REC-H

YCA-SCL

OUTPUT-SELECT

7

24

YCA-CS

YCA-SDA

YCA-CS

C-SYNC

YCA-SCL

YCA-SDA

OUTPUT-SELECT

41

46

14

15

16

TO VIDEO

BLOCK DIAGRAM

V-ENV

RF-SW

H-A-SW

C-ROTA

D-V SYNC

18

786419

H-A-COMP

79

80

KEY- 2

KEY- 1

REMOTE-VIDEO

DVD-POWER

IC501

(SERVO/SYSTEM CONTROL)

5

26

REMOTE-VIDEO

DVD-POWER

TO DVD SYSTEM

CONTROL BLOCK

DIAGRAM

<DVD SECTION>

AL+5V

D555

MAIN CBA

S-LED

TP513

CTL

REC-IND

CTL58CTL(-)

CTL(+)

56

57

CN504

5 CTL(+)

6 CTL(-)

TIMER-IND

AL+5V

SW512

LD-SW

TP507

TP506 TP505

DVD-L IND

LD-SW

68

END-S

T-REEL

ST-S

Q504

DVD-H IND

ST-S

END-S

69

62

ST-S

T-REEL

3

T-REEL

Q506

Q503

SENSOR CBA

Q501

END-S

RESET

20

RESET

TIMER+5V

VCR/TV

IIC-BUS SCL

IIC-BUS SDA

PG-DELAY

65

AL+5V

VR501

SW-POINT

SENSOR CBA

D-REC-H

ST/SAP-IN

Hi-Fi-H-SW

Hi-Fi/NOR-IN

AUDIO-MUTE-H

REC-

SAF-SW

C-FG

2

AL+5V

C-F/R

49

27

REC SW

SW511

P-ON+5V

AL+12V(1)

CN502

AL+12V(1)2P-ON+5V3C-FG4C-F/R5C-CONT6GND7LM-FWD/REV

1

CAPSTAN MOTOR

C-CONT

28

MOTOR

YCA-SCL

OUTPUT-SELECT

LM-FWD/REV

D-CONT

D-PFG

29

47

21

D-CONT9D-PFG10GND11AL+12V

8

DRIVE

CIRCUIT

M

CAPSTAN

MOTOR

YCA-CS

C-SYNC

YCA-SDA

AL+12V

AL+18V

AL+18V

12

V-ENV

C-ROTA

D-V SYNC

RF-SW

H-A-SW

H-A-COMP

P-ON-L

P-DOWN-L

1

22

P-ON-L

P-DOWN-L

TO POWER

SUPPLY

BLOCK DIAGRAM

AC HEAD ASSEMBLY

(DECK ASSEMBLY)

CONTROL

HEAD

1-11-1

M

PG

SENSOR

DRUM

CYLINDER ASSEMBLY

MOTOR

M

LOADING

MOTOR

H9801BLS

Page 24

Video Block Diagram

P

R

MAIN CBA

REC VIDEO SIGNAL PB VIDEO SIGNAL DVD VIDEO SIGNAL MODE: SP/REC

(OSD)

OSD CHARACTER

IC501

38

1

2

VCR

DVD

(OUTPUT SELECT)

SW CTL

IC751

15

40

MIX

WF6

9 10 11

OUTPUT-SELECT

LUMINANCE

SIGNAL PROCESS

CLAMP

Q301

BUFFER

DELAY

CCD 1H

36 37 39 34

VCA

26

6dB

AMP

QV/QH

TUNER

IC301

(VIDEO SIGNAL PROCESS/ HEAD AMP)

32

YNR/COMB FILTER

FBC

Y/C

VIDEO

REAR

28

MIX

AGC

RP

CHROMINANCE

SIGNAL PROCESS

I/F

SERIAL

FRONT

30

54

R

69

SYNC

P

SEPA

D-V SYNC

255324

EP

EP

HEAD

AMP

65

66

67

VIDEO-COM

VIDEO(R)-2

14

TP302

70

SP

SP

HEAD

AMP

727374

VIDEO-COM

VIDEO(R)-1

VIDEO(L)-1

VIDEO(L)-2

CN253

456

123

RF-SW

WF2

C-PB

TP301

C-ROTA/RF-SW

57

C-ROTA

RF-SW

TO

WF3

H-A-COMP

ENV-DET

59

58

60

V-ENV

H-A-SW

H-A-COMP

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

Q391

WF1

TP751 V-OUT

BUFFER

JK751

VIDEO

-OUT

REAR

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

WF11

6

18

VIDEO IN

TU701

VIDEO OUT

(TUNER UNIT)

WF15

DVD-VIDEO

TO

DVD VIDEO/AUDIO

BLOCK DIAGRAM

<DVD SECTION>

JK752

VIDEO

-IN

REAR

JK753

VIDEO

FRONT

1-11-2

YCA-SCL

YCA-SDA55YCA-CS

TO SERVO/SYSTEM

CONTROL BLOCK

-IN

D-V SYNC

C-SYNC

DIAGRAM

VIDEO (L)-1 HEAD

VIDEO (R)-1 HEAD

(DECK ASSEMBLY)

VIDEO (L)-2 HEAD

VIDEO (R)-2 HEAD

CYLINDER ASSEMBLY

H9801BLV

Page 25

Audio Block Diagram ( DVC840F, MWD2205 )

TO

DVD VIDEO/AUDIO

BLOCK DIAGRAM

DVD AUDIO SIGNAL

DVD-AUDIO(L)

DVD-AUDIO(R)

<DVD SECTION>

10

MUTE

LINE

AMP

SERIAL

I/F

TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

YCA-CS

D-REC-H

YCA-SCL

YCA-SDA

AUDIO-MUTE-H

58 55 53 54

PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC

MAIN CBA

5

3

DVD

VCR

IC751

(OUTPUT SELECT)

4

TP753

A-OUT (R)

LPF

ALC

TUNER

LINE 2

LINE 1

(AUDIO PROCESS) 7680

IC301

12

13

DVD

VCR

TO SERVO/SYSTEM

9 10 11

SW CTL

14

TP754

A-OUT (L)

OUTPUT-SELECT

CONTOL BLOCK

DIAGRAM

78

P

R

4

3 2

SP/LP-ON

5

EQ

AMP

6

CN504

BIAS

OSC

Q422

AUDIO-PB/REC

4

3 A-COM

1 AE-H

REC

AMP

9

8

AUTO

BIAS

11

Q421

2 AE-H/FE-H

P-ON+5V

Q426

(PB=ON)

P-ON+5V

SWITCHING

D-REC OFF

Q425

CN501

1 FE-H

2 FE-H-GND

WF14

14

AUDIO OUT

TU701

(TUNER UNIT)

BUFFER

Q763

WF10

BUFFER

+

2

AUDIO IN

Q762

JK751

AUDIO(R)

-OUT

AUDIO(L)

-OUT

JK756

AUDIO(R)

-OUT

REAR

AUDIO(L)

-OUT

JK752

AUDIO

-IN

1-11-3

JK755

AUDIO

-IN

FRONT

AC HEAD ASSEMBLY

AUDIO

HEAD

AUDIO

ERASE

(DECK ASSEMBLY)

HEAD

FE HEAD

FULL

ERASE

HEAD

H9801BLA

Page 26

Audio Block Diagram ( DVC865F )

TO Hi-Fi AUDIO

SIF

AUDIO(L)-IN-F

AUDIO(R)-IN-F

BLOCK DIAGRAM

AUDIO(L)-IN

AUDIO(R)-IN

AUDIO(L)-OUT

AUDIO(R)-OUT

N-A-IN

N-A-OUT

DVD-AUDIO(R)

DVD AUDIO SIGNAL

TO Hi-Fi AUDIO

BLOCK DIAGRAM

DVD-AUDIO(L)

TO

DVD VIDEO/AUDIO

DVD-AUDIO(R)

BLOCK DIAGRAM

DVD-AUDIO(L)

<DVD SECTION>

MOD-AUDIO

LINE

10

MUTE

AMP

SERIAL

I/F

TO

SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

YCA-CS

D-REC-H

YCA-SCL

YCA-SDA

AUDIO-MUTE-H

58 55 53 54

PB-AUDIO SIGNAL REC-AUDIO SIGNAL Mode : SP/REC

MAIN CBA

5

3

DVD

VCR

IC751

(OUTPUT SELECT)

4

TP753

A-OUT (R)

LPF

ALC

TUNER

LINE 2

LINE 1

80

(AUDIO PROCESS) 76

IC301

12

13

DVD

VCR

TO SERVO/SYSTEM

9 10 11

SW CTL

14

TP754

A-OUT (L)

OUTPUT-SELECT

CONTOL BLOCK

DIAGRAM

78

P

R

4

3 2

SP/LP-ON

5

EQ

AMP

6

CN504

BIAS

OSC

Q422

AUDIO-PB/REC

4

3 A-COM

1 AE-H

2 AE-H/FE-H

REC

AUTO

9

8

11

AMP

BIAS

Q421

P-ON+5V

Q426

(PB=ON)

P-ON+5V

SWITCHING

D-REC OFF

Q425

CN501

1 FE-H

2 FE-H-GND

15

SIF OUT

TU701

(TUNER UNIT)

WF10

2

AUDIO IN

JK751

AUDIO(R)

-OUT

AUDIO(L)

-OUT

JK756

AUDIO(R)

-OUT

REAR

AUDIO(L)

-OUT

JK752

AUDIO(R)

1-11-4

-IN

AUDIO(L)

-IN

JK754

AUDIO(L)

-IN

FRONT

JK755

AUDIO(R)

-IN

AC HEAD ASSEMBLY

AUDIO

(DECK ASSEMBLY)

HEAD

AUDIO

ERASE

HEAD

FE HEAD

FULL

ERASE

HEAD

H9802BLA

Page 27

Hi-Fi Audio Block Diagram ( DVC865F )

TO SERVO/ SYSTEM

CONTROL BLOCK

DIAGRAM

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

TO AUDIO

BLOCK DIAGRAM

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

Hi-Fi

CYLINDER

ASSEMBLY

AUDIO

(R) HEAD

Hi-Fi

AUDIO

(L) HEAD

DVD AUDIO SIGNAL

REC-AUDIO SIGNALPB-AUDIO SIGNAL Mode : SP/REC

MAIN CBA

IIC-BUS SCL

IIC-BUS SDA

37

38

SERIAL

DATA

DECODER

MATRIX

dBX

DEC

ST/SAP

SW

L-R

DC

DEMOD

P-ON+9V

54

RIPPLE

FILTER

NORMAL-L

ST/SAP-MODE

23

40

MODE

OUT

ENV

DO

R-CH BPF

LPF

VCO

COMP

N-A-IN

4802

DET

DET

AUDIO(L)-OUT

AUDIO(R)-OUT

MOD-AUDIO

78

MUTE

ALC

OUTPUT

SELECT

Hi-Fi-H-SW

77139

AUDIO-MUTE-H

26

49

COMP

MATRIX

HOLD

PULSE

NOISE

(DECK ASSEMBLY)

LPF

VCO

DET

7

CN253

AUDIO(R)

Hi-Fi-

24

R

9

AUDIO(L)

Hi-Fi-COM 8

Hi-Fi-

27

L

34 33

LIM

L-CH BPF

COMP

PILOT

CANCEL

SAP

DEMOD

62 63

STEREO

FILTER

SAP

FILTER

CONT

SAP

DET

SIF

DEMOD

IC451 (MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP)

57

SIF

PILOT

DET

STEREO

PLL

SW

P

NOISE

R-CH

PNR

LIM DEV

R

TO AUDIO

BLOCK

R-CH

DIAGRAM

48 47

INSEL

69

71

AUDIO(R)-IN

AUDIO(R)-IN-F

NOR

SW

6

N-A-OUT

13 14

L-CH

INSEL

7

9

AUDIO(L)-IN

AUDIO(L)-IN-F

DVD-AUDIO(L)

LIM DEV

R

74

12

DVD-AUDIO(R)

L-CH

SW

PNR

NOISE

P

1-11-5

H9802BLH

Page 28

Power Supply Block Diagram

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

"Ce symbole reprèsente un fusible à fusion rapide."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

A V

F

P-ON+9V

AL+12V

TIMER+5V

AL+5V

P-ON+5V

AL-30V

EV+3.3V

AL+33V

AL+18V

DVD-P-ON+12V

DVD-P-ON+3.3V

DVD-P-ON+5V

TO DVD MAIN

CBA UNIT

CN401

Q055

Q057

Q052

Q056

Q1006

Q1005

+3.3V REG.

IC1004

1 EV+1.2V

CN1001

+1.2V REG.

IC1002

2 EV+1.2V

3 EV+3.3V

4 EV+3.3V

5 EV+3.3V

Q1004

DVD-P-ON+3.3V

7 DVD-P-ON+5V

8 EV+10V

9 EV+10V

6

Q1011

17 PWRCON

TO

SERVO/SYSTEM

CONTROL

BLOCK DIAGRAM

P-ON-L

P-DOWN-L

MAIN CBA

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse(F1001)is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

20

T001

2

BRIDGE

RECTIFIER

D1001 - D1004

LINE

FILTER

L1001

F1001

1A 250V

HOT CIRCUIT. BE CAREFUL.

AC1001

19

F

18

4

A V

Q031

17

16

15

14

13

12

11

1

4

IC1001

ERROR

VOLTAGE DET

8

7

23

HOT COLD

Q1001

Q1003

Q1008

1-11-6

H9801BLP

Page 29

BLOCK DIAGRAMS <DVD SECTION>

DVD System Control / Servo Block Diagram

DVD-OPEN/CLOSE

DVD OPEN/CLOSE CBA

AL+5V

SW2001

1

2

CN2002CN2003

DVD-OPEN/CLOSE

1 EV+3.3V

2

EV+3.3V

D2002

D2001

PLAY

DISCIN-L

Q2002 Q2013

REMOTE

RM2001

EV+3.3V

SENSOR

SW2002 STOP

SW2005 SKIP-UP

SW2003 PLAY

SW2006 SKIP-DOWN

23

20212122192018

24

TO SERVO/SYSTEM

CONTROL BLOCK

DIAGRAM

<VCR SECTION>

DVD-POWER

REMOTE-VIDEO

MAIN CBA

IC101

(MICRO CONTROLLER)

ADAC-MD

AUDIO-MUTE

PCM-SCLK

57

88

163

56 ADAC-MC

86 ADAC-ML

IC462

+3.3V

IC461

+3.3V

RESET73

RESET

1 3

RESET

2 1

VREF

IC301

(SERVO DRIVE)

FOCUS DRIVE

FD-OFST

148

146

25

27

26

-

+

-

+

FOCUS

ACTUATOR

DRIVE

15

16

24

CN401 CN1001

TRACKING

DRIVE

TD-OFST

147

139

-

+

-

+

TRACKING

ACTUATOR

DRIVE

14

13

DVD-STOP 2627DVD-POWER

DVD-PLAY 25

DVD-OPEN/CLOSE

24

25

26

53546568826061

DVD-PLAY

DVD-STOP

DVD-POWER

OPEN/CLOSE

SPDL

76

312

+

SPINDLE

MOTOR

12

SKIP-UP

DISCIN-L

SKIP-UP

DISCIN-L

-

+

-

DRIVE

11

SKIP-DOWN

PLAY

REMOTE 22

19

23

67

59

PLAY

REMOTE

SKIP-DOWN

SLD

75

645

23

-

+

SLED

MOTOR

DRIVE

17

18

IC202

(OP AMP)

SP-ROT

143

1

2

3

CN301

5

3SP(+)

7

4SP(-)

6

5TRAY-IN

+3.3V

6GND

SL-AMP

/TRAY-OUT

81

14

13

12

7SL(-)

8SL(+)

TRAY-IN

66

DVD MAIN CBA UNITDRIVE CBA

FS(+)

FS(-)

TS(+)

ADAC-MC

AUDIO-MUTE

ADAC-ML

ADAC-MD

PCM-SCLK

TO DVD

VIDEO/ AUDIO

BLOCK DIAGRAM

1 NOTE:

Either IC461 or IC462 is used for DVD MAIN CBA UNIT.

TS(-)

TO DIGITAL SIGNAL

PROCESS BLOCK

DIAGRAM

1-11-7

TRAY-IN

SPINDLE

MOTOR

M

SLED

MOTOR

M

H9801BLSD

Page 30

Digital Signal Process Block Diagram

TO DVD

VIDEO

/AUDIO

BLOCK

DIAGRAM

TO DVD

VIDEO

/AUDIO

BLOCK

DIAGRAM

FLASH

ROM

DATA(AUDIO) SIGNAL

DATA(VIDEO/AUDIO) SIGNAL DVD VIDEO SIGNAL

DATA

RAM

DSP

INST.

ROM

DECODER

STREAM

I/F

DATA

RAM

I/O

INST.

ROM

PROCESSOR

SPDIF

PCM-BCK

177

170

PCM-DATA

171

AUDI O

I/F

UMAC

PCM-LRCLK

169

SERIAL

GENERAL

I/O

CPU

I/F

READ

MEMORY

VIDEO-Y(I/P)

Y(I/P)

INTERRUPT

CONTROLLER

149

D/A

TIMER

VIDEO-C

158

C

D/A

NTSC/PAL

VIDEO

WATCH DOG

TIMER

VIDEO-Pr/Cr

VIDEO-Pb/Cb

152

Pr/Cr

Pb/Cb

D/A

ENCODER

I/F

REMOTE

CONTROL

151

D/A

32BIT CPU

BCU

DATA

INST

DEBUG

RAM

RAM

IC103 (FLASH ROM)

23~51

~

1

~

9

162548

FADR (0-19)

~

293638

FDQ (0-15)

~

45

SDRAM ADDRESS(0-10)

~

217

238

SDRAM ADDRESS(0-10)

~~

202427

IC501, IC502 (SDRAM) IC101 (MICRO CONTROLLER)

EXTERNAL

MEMORY

I/F

1

2

32

SDRAM

DECODER

I/F

ECC

SDRAM DATA(0-15)

~~

18

252

SDRAM DATA(0-15)

~~

123949

256

114

115

DMA

116

RF

117

CN201

DVD/CD

FORMATTER

SIGNAL

PROCESS

132

131

C16

D18

CIRCUIT

134

133

A17

B15

DETECTOR

BCU

129

E14

130

F12

CD/DVD 19

32BIT

CPU

INST.

ROM

126

AMP

Q253,Q254

CN201

CD-LD 10

DATA

RAM

124

125

Q251,Q252

AMP

DVD-LD 8

PD-MONI 7

123

6

5

9

GND(LD)

GND(CD-PD)

GND(DVD-PD)

CPU

I/F

WATCH DOG

TIMER

TIMER

INTERRUPT

CONTROLLER

192~212

CD/DVD

83

TO DVD SYSTEM

CONTROL/SERVO

BLOCK DIAGRAM

6

IC201

(SW)

4

1 3

CD DVD

FS

TS

FS(+)

CN201

FS(+) 2

FS(-)

FS(-) 3

TS(+)

TS(+) 1

TS(-)

DVD MAIN CBA UNIT

TS(-) 4

PICK-UP

UNIT

1-11-8

H9801BLD

Page 31

DVD Video / Audio Block Diagram

DVD AUDIO SIGNALDATA(AUDIO) SIGNAL

JK1401

DVD VIDEO SIGNAL

2

1

3 4

S-VIDEO OUT

YC

13

14

DRIVER

15

TO VIDEO

BLOCK DIAGRAM

<VCR SECTION>

DVD-VIDEO

JK1403

11

VIDEO-Y

OUT

10

VIDEO-Pb/Cb

OUT

VIDEO-Pr/Cr

OUT

JK1202

Q1351

BUFFER

DIGITAL

AUDIO OUT

WF9

(AMP)

IC1201

WF7

CN601 CN1601

TO

AUDI O

DVD-AUDIO(L)

1

2

3

18

DVD-AUDIO(L)

SPDIF

13 13

18

BLOCK

DIAGRAM

<VCR

SECTION>

DVD-AUDIO(R)

675

WF8

15

DVD-AUDIO(R)

DVD-AUDIO(R)-MUTE

15

14 14

+5V

Q1202

Q1204

MAIN CBADVD MAIN CBA UNIT

Q1201

+3.3V

2dB

AMP

2dB

LPF DRIVER

4dB

AMP

IC1402 (VIDEO DRIVER)

3

WF4

AMP

WF5

2dB

AMP

2dB

AMP

2dB

AMP

LPF DRIVER

LPF DRIVER

LPF DRIVER

4dB

AMP

4dB

4dB

AMP

1

CN1601

88VIDEO-Y(I/P)

CN601

VIDEO-Y(I/P)

VIDEO-C

TO DIGITAL

AMP

6

8

VIDEO-Pb/Cb

66

44VIDEO-Pr/Cr

10 10VIDEO-C

VIDEO-Pb/Cb

VIDEO-Pr/Cr

SIGNAL PROCESS

BLOCK DIAGRAM

IC601 (AUDIO DAC)

15

L-CH

LPF+AMP

DAC

ENPHANCED

MULTI-LEVEL

DELTA-SIGMA

4X/8X

/FUNCTION

DIGITAL FILTER

OVERSAMPLING

PORT

SERIAL

768

14

R-CH

LPF+AMP

DAC

MODULATOR

CONTROLLER

16

ZERO DETECT

432

SERIAL

CONTROL

5

SYSTEM CLOCK

1-11-9

SPDIF

TO DIGITAL

SIGNAL

PCM-BCK

PCM-DATA

PCM-LRCLK

PROCESS

BLOCK

DIAGRAM

ADAC-MD

ADAC-MC

ADAC-ML

TO DVD

SYSTEM

CONTROL

/SERVO

BLOCK

DIAGRAM

PCM-SCLK

AUDIO-MUTE

H9801BLVD

Page 32

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “#” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

3

, M = 106).

-6

µF).

1-12-1 D6N_SC

Page 33

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE

F

A V

SAME TYPE FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D'INCELE N'UTILISER

QUE DES FUSIBLE DE MÊME TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

This symbol means fast operating fuse.

Ce symbole represente un fusible a fusion rapide.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Mode: SP/REC

5. Voltage indications for PLAY and REC modes on the schematics are as shown below:

< DVD Section >

5.0

The same voltage for

both PLAY & STOP modes

5.0

(2.5)

PLAY mode

STOP mode

231

Indicates that the voltage

is not consistent here.

The same voltage for

both PLAY, REC & DVD

modes

< VCR Section >

231

5.0

5.0

(2.5)

< >

Indicates that the voltage

is not consistent here.

PLAY mode

REC mode

DVD mode

Unit: Volts

6. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

3

1-B1

AREA D3

2

AREA B1

Examples:

1. "1-D3" means that line number "1" goes to area "D3".

2. "1-B1" means that line number "1" goes to area "B1".

1

1-D3

ABCD

7. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

1-12-2 D6N_SC

Page 34

Main 1/8 Schematic Diagram < VCR Section >

MAIN 1/8

Ref No. Position

IC501 C-3

Q501 D-1

Q506 A-2

CN501 A-4

CN502 F-4

CN504 A-4

VR501 B-4

TP505 B-2

TP513 B-4

IC

CONNECTORS

TEST POINTS

VARIABLE RESISTOR

TRANSISTORS

1-12-3

H9801SCM1

Page 35

Main 2/8 & Sensor Schematic Diagram < VCR Section >

MAIN 2/8

Ref No. Position

Q563 H-3

Q565 H-3

Q566 H-2

Q567 I-2

TP502 I-4

TP506 K-1

TP507 K-1

TEST POINTS

TRANSISTORS

1-12-4

H9801SCM2

Page 36

Main 3/8 Schematic Diagram < VCR Section >

MAIN 3/8

Ref No. Position

IC301 O-2

Q301 Q-3

Q302 Q-4

Q303 Q-4

Q421 N-1

Q422 N-1

Q425 N-1

Q426 N-1

CN253 M-4

TP301 P-1

TP302 O-4

CONNECTOR

TEST POINTS

IC

TRANSISTORS

1-12-5

H9801SCM3

Page 37

Main 4/8 Schematic Diagram < VCR Section >

MAIN 4/8

Ref No. Position

IC1201 T-1

IC1402 U-3

Q1201 U-1

Q1202 U-1

Q1204 U-1

Q1351 V-1

Q1385 S-2

CN1601 S-3

CONNECTOR

TRANSISTORS

ICS

1-12-6

H9801SCM4

Page 38

Main 5/8 Schematic Diagram < VCR Section >

MAIN 5/8

Ref No. Position

IC751 Z-3

Q391 AA-3

Q762 Z-2

Q763 Z-2

TP751 AA-2

TP753 AA-2

TP754 AA-2

IC

TRANSISTORS

TEST POINTS

1-12-7

H9801SCM5

Page 39

Main 6/8 & DVD Open/Close Schematic Diagram < VCR Section >

MAIN 6/8

Ref No. Position

IC1002 AD-4

IC1004 AD-3

Q052 AG-4

Q055 AF-3

Q056 AG-3

Q057 AE-3

Q1004 AE-2

Q1005 AF-2

Q1006 AG-2

Q1011 AD-2

Q2002 AF-1

Q2013 AD-1

CN1001 AC-3

CN2003 AG-1

CONNECTORS

TRANSISTORS

ICS

1-12-8

H9801SCM6

Page 40

Main 7/8 Schematic Diagram < VCR Section >

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

MAIN 7/8

Ref No. Position

IC1001 AK-1

Q031 AL-1

Q1001 AK-3

Q1003 AJ-3

Q1008 AJ-1

TRANSISTORS

IC

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse(F1001)is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

F

A V

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

1-12-9

H9801SCM7

Page 41

Main 8/8 Schematic Diagram < VCR Section > ( DVC865F )

1-12-10

H9802SCM8

Page 42

DVD Main 1/3 Schematic Diagram < DVD Section >

DVD MAIN 1/3

Ref No. Position

IC201 C-1

IC202 D-4

IC301 D-3

IC461 F-1

IC462 E-1

Q251 C-2

Q252 B-2

Q253 C-2

Q254 B-2

CN201 A-3

CN301 A-1

CN401 F-3

TRANSISTORS

CONNECTORS

ICS

1 NOTE:

Either IC461 or IC462 is used for DVD MAIN CBA UNIT.

1-12-11

H9801SCD1

Page 43

DVD Main 2/3 Schematic Diagram < DVD Section >

DVD MAIN 2/3

Ref No. Position

IC101 H-4

CN702 G-2

IC

CONNECTOR

1-12-12

H9801SCD2

Page 44

IC101 Voltage Chart

PIN.NO PLAY STOP PIN.NO PLAY STOP PIN.NO PLAY STOP PIN.NO PLAY STOP

129 2.3 2.3 161 3.4 3.4 193 ~ ~ 225 3.4 3.4

130 2.3 2.3 162 0 0 194 ~ ~ 226 ~ ~

131 2.3 2.3 163 1.8 1.8 195 ~ ~ 227 ~ ~

132 2.4 2.3 164 0 0 196 3.4 3.4 228 ~ ~

133 2.4 2.4 165 1.7 1.8 197 ~ ~ 229 0 0

134 2.4 2.4 166 1.7 1.7 198 ~ ~ 230 ~ ~

135 2.3 2.3 167 3.4 3.4 199 ~ ~ 231 3.4 3.4

136 2.3 2.3 168 0 0 200 ~ ~ 232 1.3 1.6

137 2.3 2.3 169 1.8 1.8 201 0 0 233 ~ ~

138 2.3 2.3 170 1.7 1.7 202 3.4 3.4 234 1.9 2.3

139 1.7 1.7 171 1.3 0.1 203 ~ ~ 235 0 0

140 1.7 1.7 172 1.3 1.3 204 ~ ~ 236 1.3 1.3

141 3.4 3.4 173 0 0 205 0 0 237 ----- ----142 1.3 1.3 174 ----- ----- 206 ~ ~ 238 ~ ~

143 2.1 1.7 175 ----- ----- 207 ~ ~ 239 3.4 3.4

144 2.2 2.2 176 ----- ----- 208 ~ ~ 240 3.4 3.3

145 0 0 177 1.8 1.7 209 3.4 3.4 241 1.9 1.9

146 1.7 1.7 178 3.4 3.5 210 ~ ~ 242 0 0

147 1.8 1.7 179 0 0 211 ~ ~ 243 1.9 1.9

148 1.7 1.7 180 3.5 3.4 212 ~ ~ 244 3.4 3.3

149 0.6 0.5 181 0 0 213 0 0 245 3.4 3.4

150 3.4 3.4 182 3.5 3.5 214 2.5 3.0 246 3.4 3.4

151 0.5 0.6 90 3.5 3.5 215 2.5 3.0 247 0 0

152 0.5 0.4 184 0 0 216 3.4 3.4 248 3.3 3.4

153 1.4 1.3 185 0 0 217 ~ ~ 249 3.2 3

154 1.4 1.3 186 0 0 218 0 0 250 0 0

155 2.4 2.4 187 0 0 219 1.3 1.3 251 3.2 3.0

156 ----- ----- 188 0 0 220 ~ ~ 252 ~ ~

157 0 0 189 0 0 221 ~ ~ 253 0 0

158 0.9 0.9 190 3.4 3.5 222 0 0 254 ~ ~

159 3.4 3.4 191 0 0 223 ~ ~ 255 3.4 3.4

160 0 0 192 ~ ~ 224 ~ ~ 256 ~ ~

~ : Voltage is not consistent ----- : Not used Unit : Volts

PIN.NO PLAY STOP PIN.NO PLAY STOP PIN.NO PLAY STOP PIN.NO PLAY STOP

1 ~ ~ 33 ~ ~ 65 0 0 97 ----- ----2 ~ ~ 343.43.4663.43.5983.43.4

3 0 0 35 0 0 673.23.2990.90.8

4 ~ ~36~ ~680 01000 0

5 ~ ~ 37 ~ ~ 69 ----- ----- 101 2.4 2.4

6 3.4 3.4 38 0.4 0.3 70 3.4 3.4 102 2.2 2.2

7 ~ ~ 39 ~ ~ 71 ----- ----- 103 1.9 1.9

8 ~ ~ 40 ~ ~ 72 1.4 2.7 104 0.4 0.3

9 0 0 41 ~ ~ 73 3.4 3.4 105 0 0

10 ~ ~ 42 ~ ~ 74 0 0 106 1.7 1.7

11 ~ ~ 43 ~ ~ 75 1.7 1.8 107 3.4 3.4

12 3.4 3.4 44 1.3 1.3 76 2.3 1.8 108 ----- ----13 ~ ~ 45 ~ ~ 77 ----- ----- 109 ----- ----14 ~ ~ 46 ~ ~ 78 ----- ----- 110 1.9 1.9

15 ~ ~ 47 ~ ~ 79 ----- ----- 111 1.9 1.9

16 0 0 48 3.4 3.4 80 3.4 0.1 112 1.7 1.7

17 ~ ~ 49 0 0 81 0.1 0.1 113 1.7 1.7

18 ~ ~ 50 ~ ~ 82 0 0 114 1.7 1.7

19 3.4 3.4 51 ~ ~ 83 0.1 0.1 115 1.7 1.7

20 0 0 52 0.8 0.8 84 3.4 3.4 116 1.7 1.7

21 ----- ----- 53 0 0 85 0.1 0.1 117 1.7 1.7

22 3.5 3.5 54 0 0 86 3.6 3.4 118 3.4 3.4

23 ~ ~ 55 ----- ----- 87 0 0 119 2.0 2.0

24 ~ ~ 56 3.4 3.4 88 3.5 0.1 120 1.7 1.7

25 ~ ~ 57 3.5 3.5 89 1.3 1.3 121 1.5 1.5

26 1.3 1.3 58 ----- ----- 90 ----- ----- 122 0 0

27 ~ ~ 59 0.6 3.4 91 ----- ----- 123 0.3 0.1

28 3.4 3.4 60 0 0 92 ----- ----- 124 1.2 0.1

29 0 0 61 0 0 93 0 0 125 0.3 0.1

30 ~ ~

31 ~ ~

32 ~ ~

62 3.4 3.4

63 0 0

64 0 0

94 ----- ----- 126 0.1 0.1

95 ----- ----- 127 2.3 2.3

96 ----- ----- 128 1.7 1.7

1-12-13

Page 45

DVD Main 3/3 Schematic Diagram < DVD Section >

DVD MAIN 3/3

Ref No. Position

IC103 N-3

IC501 O-4

IC502 Q-4

IC601 P-1

CN601 R-1

ICS

CONNECTOR

1-12-14

H9801SCD3

Page 46

Main CBA Top View

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse(F1001)is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

Sensor CBA Top View

BHF300F01011A

BHF300F01011B

TO SENSOR CBA

(END-SENSOR)

F

A V

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

TO SENSOR CBA

(START-SENSOR)

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

WF1

TP751

V-OUT

DVD Open/Close

CBA Top View

BH9800F01011C

WF2

TP302

RF-SW

WF3

TP301

C-PB

TP513

CTL

VR501

SW-P

TP502

S-INH

1-12-15

BH9800F01011A

Page 47

Main CBA Bottom View

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

MAIN CBA

Ref No. Position

IC301 C-4

IC451 B-4

IC501 C-1

IC751 B-5

IC1001 F-5

IC1002 G-2

IC1004 G-2

IC1201 C-5

IC1402 E-4

Q031 F-5

Q052 F-3

Q055 F-2

Q056 F-2

Q057 F-2

Q301 C-3

Q302 C-3

Q303 B-3

Q391 D-5

Q421 D-4

Q422 C-4

Q425 D-4

Q426 D-4

Q501 B-1

Q506 C-3

Q563 B-1

Q565 B-1

Q566 F-1

Q567 E-1

Q762 A-5

Q763 B-5

Q1001 G-4

Q1003 G-4

Q1004 G-3

Q1005 G-1

Q1006 G-1

Q1008 G-5

Q1011 G-3

Q1201 F-5

Q1202 F-5

Q1204 D-5

Q1351 G-5

Q1385 D-5

Q2002 G-1

Q2013 G-1

CN253 C-4

CN501 A-5

CN502 E-3

CN504 D-4

CN1001 G-1

CN1601 E-4

CN2003 G-1

VR501 A-2

TP301 A-3

TP302 A-3

TP502 E-1

TP505 A-3

TP506 F-3

TP507 A-3

TP513 A-2

TP751 F-5

TEST POINTS

ICS

TRANSISTORS

CONNECTORS

VARIABLE RESISTOR

CAUTION !

Fixed voltage ( or Auto voltage selectable ) power supply circuit is used in this unit.

If Main Fuse(F1001)is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

PIN 18 OF

CN1601

PIN 15 OF

CN1601

WF7

WF7

PIN 13 OF

CN1601

F

A V

WF5

WF5

PIN 10 OF

CN1601

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

"Ce symbole reprèsente un fusible à fusion rapide."

WF6

WF4WF8WF9

WF4WF8

PIN 8 OF

CN1601

WF6

PIN 2 OF

IC751

1-12-16

Because a hot chassis ground is present in the power

supply circut, an isolation transformer must be used.

Also, in order to have the ability to increase the input

slowly, when troubleshooting this type power supply

circuit, a variable isolation transformer is required.

WF10

PIN 2 OF

TU701

WF11

PIN 6 OF

TU701

WF12

PIN 11 OF

TU701

WF13

PIN 12 OF

TU701

WF14

PIN 14 OF

TU701

WF15

PIN 18 OF

TU701

BH9800F01011A

Page 48

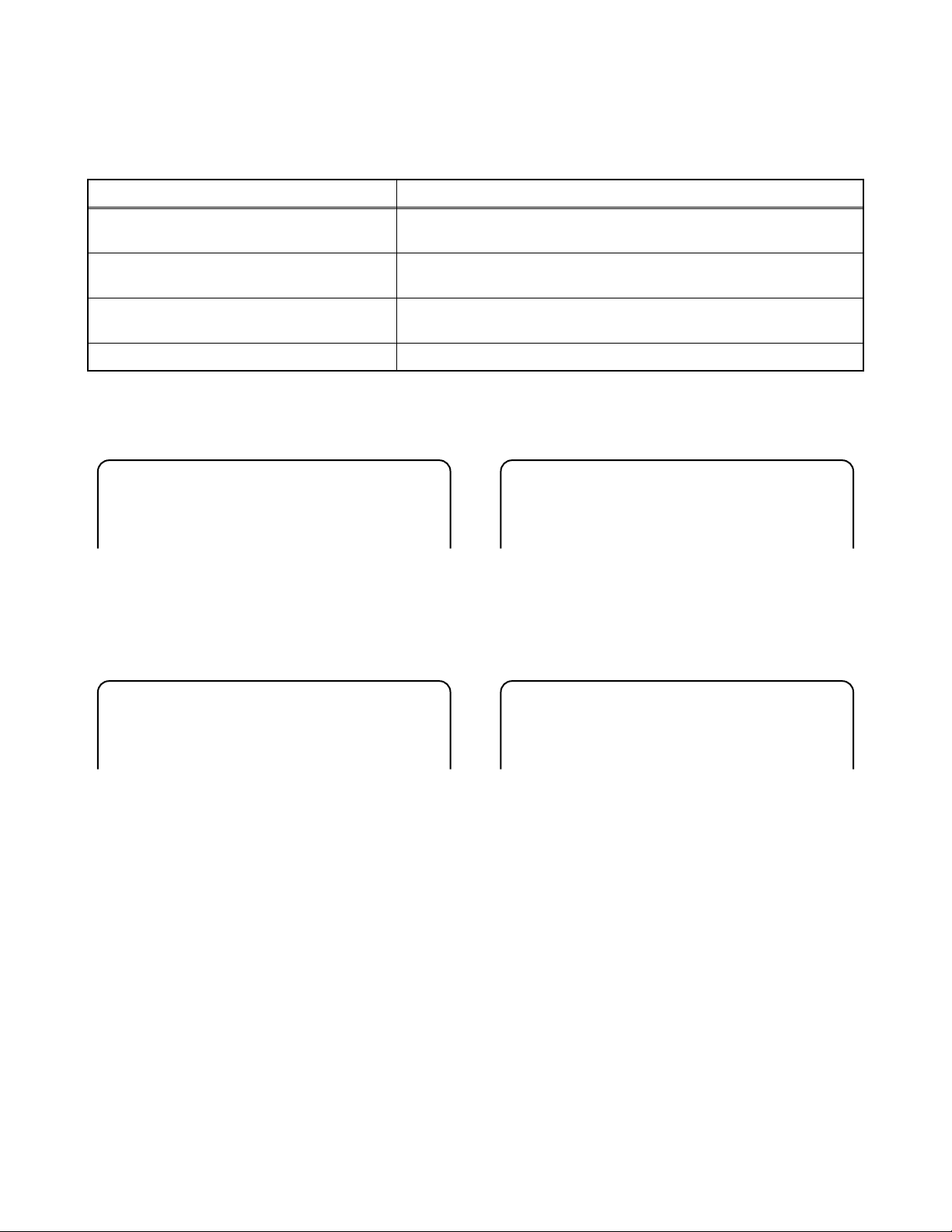

WAVEFORMS

VIDEO-Y

0.2V2020

VIDEO-C

0.2V2020

VIDEO-CVBS

0.5V2020

s

AUDIO-L

1V

0.5ms

AUDIO-R

1V

SPDIF

1V

0.1

s

0.5ms

V-OUT E-E

0.2V2020

V-OUT

10V

C-PB

RF-SW

0.2V5m5m

RF-SW

0.5V

10V

NOTE:

Input

VCR: COLOR BAR SIGNAL (WITH 1KHz AUDIO SIGNAL)

(WF1~WF3, WF10~WF15)

DVD: POWER ON (STOP) MODE

(WF4~WF6)

CD: 1kHz PLAY

(WF7~WF9)

WF1

V-OUT E-E

WF1

WF2

TP751

UPPER

LOWER

0.2V

TP751

TP302

µs

WF4

Pin 8 of CN1601

VIDEO-Y

WF5

Pin 10 of CN1601

0.2V

µs

WF7

Pin 13 of CN1601

AUDIO-L

WF8

Pin 15 of CN1601

1V

0.5ms

WF3

WF2

V-OUT

RF-SW

UPPER

LOWER

C-PB

RF-SW

10V

0.5V

TP301

TP302

10V

0.2V

5050µs

s

VIDEO-C

WF6

Pin 2 of IC751

VIDEO-CVBS

0.2V

0.5V

1-13-1

µs

µs

AUDIO-R

WF9

Pin 18 of CN1601

SPDIF

1V

1V

0.5ms

0.1

µs

H9801WF

Page 49

NOTE:

Input

VCR: COLOR BAR SIGNAL (WITH 1KHz AUDIO SIGNAL)

(WF1~WF3, WF10~WF15)

DVD: POWER ON (STOP) MODE

(WF4~WF6)

CD: 1kHz PLAY

(WF7~WF9)

WF10

Pin 2 of TU701

WF13

Pin 12 of TU701

MOD-A 0.5V 0.2ms

WF11

Pin 6 of TU701

MOD-V 0.5V 20

WF12

Pin 11 of TU701

PLL-DATA 2V 2ms

WF14

µs

WF15

Pin 14 of TU701

TU AUDIO 0.5V 0.2ms

Pin 18 of TU701

PLL-CLK 2V 2ms

1-13-2

TU VIDEO 0.2V 20

µs

H9801WF

Page 50

WIRING DIAGRAM < VCR SECTION >

TO WIRING

DIAGRAM

<DVD SECTION>

REAR

DIGITAL

AUDIO OUT

VIDEO

-Pb/Cb

VIDEO

-Y

VIDEO

-Pr/Cr

AUDIO(L)

-OUT

AUDIO(R)

-OUT

VIDEO

-OUT

AUDIO(L)

-IN

AUDIO(R)

-IN

VIDEO

-IN

ANT-IN

DVC865F

ANT-OUT

123456789

CN1001

EV+1.2V

EV+3.3V

EV+1.2V

MAIN CBA

EV+3.3V

EV+3.3V

DVD-P-ON+3.3V

10

GND

EV+10V

EV+10V

DVD-P-ON+5V

(W002)

TO DVD

MAIN CBA

UNIT CN401

111213141516171819

GND

GND

GND

GND

GND

GND

PLAY

PWRCON

AC CORD

20

SKIP-DOWN

21

SKIP-UP

DISCIN-L

24

25

22

23

REMOTE

DVD-PLAY

DVD-POWER

DVD-OPEN/CLOSE

SENSOR CBA

26

DVD-STOP

2

3

NU

I/P-SW

CN1601

DVC840F,

DVC865F

SENSOR CBA

TO DVD

MAIN CBA

789

456

GND

GND

VIDEO-Pb/Cb

VODEO-Pr/Cr

(W004)

(W006)

DVC840F,

DVC865F

UNIT CN601

VIDEO-Y(I/P)

GND

101112

GND

VIDEO-C

MWD2205

1314151617

GND

AUDIO+5V

DVD-AUDIO(L)

DVD-AUDIO(R)

DVD-AUDIO(R)-MUTE

AUDIO+5V

DVD OPEN/CLOSE CBA

CN2002

W011

EV+3.3V

DVD-OPEN/CLOSE

11

22

CN2003

18

SPDIF

AUDIO(L)

-OUT

AUDIO(R)

-OUT

S-VIDEO

OUT

AUDIO(L)

-IN

FRONT

AUDIO(R)

-IN

VIDEO

-IN

(DECK ASSEMBLY)

DVC865F

AE-H1

AE-H/FE-H2

A-COM3

AUDIO-PB/REC4

AUDIO

AUDIO HEAD

ERASE HEAD

CTL(+)5

CONTROL HEAD

CN504

AC HEAD ASSEMBLY

DVC865F

FE-H1

FE-H-GND2

CN501

M

CAPSTAN

MOTOR

CTL(-)6

CAPSTAN MOTOR

CN502

1 AL+12V(1)

C-F/R

P-ON+5V

2

3 C-FG

4

C-CONT5

MOTOR

D-CONT8

LM-FWD/REV

GND

6

7

DRIVE

CIRCUIT

GND

D-PFG9

AL+18V12

AL+12V

10

11

CN253

VIDEO(R)-11

VIDEO-COM2

3 VIDEO(L)-1

VIDEO-COM5

VIDEO(R)-26

VIDEO(L)-2

4

Hi-Fi-AUDIO(R)7

Hi-Fi-COM8

Hi-Fi-AUDIO(L)9

M

FE HEAD

FULL

ERASE HEAD

LOADING

MOTOR

1-14-1

CYLINDER ASSEMBLY

PG

SENSOR

M

DRUM

MOTOR

VIDEO

(R)1

HEAD

VIDEO

(L)1

HEAD

VIDEO

(L)2

HEAD

VIDEO

(R)2

HEAD

Hi-Fi AUDIO

(R) HEAD

Hi-Fi AUDIO

(L) HEAD

H9801WI

Page 51

WIRING DIAGRAM < DVD SECTION >

TO WIRING

DIAGRAM

<VCR SECTION>

(W002)

TO MAIN CBA

2345678

CN401

EV+3.3V

EV+1.2V

EV+3.3V

EV+1.2V

9

EV+10V

EV+3.3V

DVD-P-ON+5V

DVD-P-ON+3.3V

CN1001

121314151617181920

10

11

GND

GND

GND

GND

GND

EV+10V

GND

GND

PWRCON

25

23

SKIP-UP

REMOTE

24

DVD-POWER

26

27

DVD-PLAY

DVD-STOP

DVD-OPEN/CLOSE

21

22

PLAY

DISCIN-L

SKIP-DOWN

2

CN601

I/P-SW

DVC840F,

3

456

NU

VODEO-Pr/Cr

DVC865F

TO MAIN CBA

CN1601

789

GND

GND

VIDEO-Pb/Cb

VIDEO-Y(I/P)

(W004)

DVC840F,

GND

(W006)

DVC865F

101112

GND

VIDEO-C

GND

MWD2205

1314151617

AUDIO+5V

DVD-AUDIO(L)

DVD-AUDIO(R)