Page 1

-,

r------------*----------..,

NAVSHIPS

900,853

INSTRUCTION

BOOK

for

SPEAKER-AMPLIFIER

NAVY

TYPE

CMX

49545

Ma,mfactrtred for

U.

S.

NAVY DEPARTMENT

BUREAU OF SHIPS

6,

THE MAGNAVOX COMPANY

Fort Wayne, Indiana

I--_____

-----*----------~

Page 2

r----------------------*---------------------,

NAVSHIPS

900,853

INSTRUCTION

BOOK

for

SPEAKER

-AMPLIFIER

NAVY

TYPE

CMX

49545

lHallufaClm'ed

for

U.

S.

NAVY

DEPARTMENT

BUREAU

OF

SHIPS

by

THE

MAGNAVOX

COMPANY

Fort

Wayne,

Indiana

L-

_____________________

*

____________________

~

CONTRACT

NXsr

93879

Approved 1

JULY

1946

Page 3

NAV5HIP5

900,853

Front

Matter

A

Page 4

c

,

Front

Matter

NAVSHIPS 900,853

~DDRESG

NAvY DEPARTMENT.

BURPU

OF

SHIpS

NAvY

DEPARTMENT

Section

993-10

0

RD"ER

TO

FlU;:

NO.

BUREAU

OF

51-UPS

WASHINGTON

25.

D.

Co

ORIGINAL

27

June

1946

To,

All

Activities

concerned

with

the

Installation,

Operation

and

Maintenance

of

the

subject

"Equipment.

SUDj'

Instruction

Book

for

Speaker-Amplifier

Navy

Type

CMX-49545 (NAVSRIPS

900,853).

1.

NAVSRIPS

900,853

is

the

instruction

Dook

for

the

sUDje

ct

equipment

and

is

in

effect

upon

receipt.

2.

When

superseded

DY a later

edition,

this

publication

shall

be

destroyed.

3.

Extracts

from

this

pUDlication

may

be

made

to

facilitate

the

preparation

of

other

Navy

instruction

books

and

handbooks.

4.

Copies

of

this

pUDlication

may

be

oDtained

from

the

nearest

ElectronicS

Officer.

E.

L.

cocRIWIE

Chief

of

Bureau

"",,,

BUREAU

OF

sHIPS.

NAVV

DEPARTMENT.

WASHINGTON

2'.

D.

C.

B

Page 5

NAVSHIPS 900,853

Front

Matter

Change

No.

Dale

Signature

of

Officer

Making

Correction

.,

c

Page 6

NAVSHIPS

900,853

TABLE

OF CONTENTS

Paragraph

Contractual Guarantee

Report

of

Failure

SECTION

I - General Description

Suh;ect

Page

. . . . . . . . . . . . . . . . . iii

iv

I-I

1 Function .

..........

.

.....................................

I-I

I-I

I-I

I-I

I-I

2

3

4

5

Reference Data

Equipment Supplied

Equipment

Required But

Not

Supplied

Vacuum Tube Complement

...

SECTION

II-

Theory

of

Operation

I

Theory

of

Operation

SECTION

III

- Installation

and

Initial Adjustments

2

3

Unpacking

Installation

Initial Adjustments

.....

SECTION

IV -Operation

2-0--2-1

.................................

2~

3-0--3-1

4-0

3-0

3-0

3-1

1 Operation .

.............................................

.

4-0

SECTION

V - Maintenance

5-0--5-11-5-12

1 Operators Maintenance

..............

5-1

2

3

Preventive Maintenance

Corrective Maintenance

.......................................................

5-1

5-1

SECTION

VI

- Parts

and

Spare Parts Lists

......................................

6-1----{)-8

Page 7

NA

VSHIPS

900,853

LIST OF ILLUSTRATIONS

Figure

1·1

Speaker.Amplifier CMX·49545

................................................

.

1·0

4-1 Lower Front Panel

...........................................................

.

.w

5·1 Speaker.Amplifier CMX·49545 -

Top

Chassis View

..............................

.

5·2

5·2 Speaker.Amplifier CMX·49545 - Lower Chassis View

............................

.

5'3

5·3 Speaker.Amplifier CMX·49545 - Lower Chassis View

............................

.

5-4

5-7 Parts For Cone Replacement

..................................................

. 5·9

5·8 Completed Cone Replacement

.................................................

. 5·9

LIST OF

DRAWINGS

Figure

Page

2·1 Functional Block

Diagram

....................................................

.

2·1

3·1

Main

Terminal

Board

Diagram

................................................

3·0

5·4

Audio

Frequency Curve

.......................................................

5·5

5·6

5·7

5·5

5·6

5·9

Cable Connection Diagram

Schematic Circuit Diagram

Amplifier

Wiring

Diagram

..............................................

5·11-5·12

LIST OF

TABLES

Table No.

6·1

Major

Unit

.........................................................

.

6·2

6·3

Combined Parts

and

Spare Parts Lists by Symbol Designations

List

of

Parts by

Navy

Numbers

................................................

.

6-4 Applicable Resistor Color Codes

..............................................

.

6·5 Applicable Capacitor Color Codes

.............................................

.

6-6 List

of

Manufacturers

.......................................................

.

Pllge

6-1

6-1

6·4

6·6

6·7

6-8

,

•

•

Page 8

•

•

NAVSHIPS 900,853

CONTRACTUAL

GUARANTEE

The

Contractor

guarantees

that

at

the

time

of

delivery

thetof

the

articles

provided

for

under

this

contract will

be free

from

any defects

in

material

or

workmanship

and

will

conform

to

the

requirements

of

this

contract. Ex-

cept as

to

vacuum tubes, batteries,

rubber

and

material

normally consumed

in

operation,

the

equipment, includ-

ing

all spare parts, is

guaranteed

for a period

of

one

year

from

the

date

of

its delivery

to

and

acceptance

by

the

Government,

with

the

understanding

that

all items

found

to

be defective as

to

material,

workmanship

or

manufacture will be repaired

or

replaced, f.a.b. any

point

within

the

continental

United

States designated

by

the

Government,

without

delay

and

at

no

expense

to

the

Government;

provided,

that

such

guarantee

shall

not

obligate

the

Contractor

to

repair

or

replace any

such defective items unless

the

defect appears

within

the

aforementioned

period

and

the

Contractor

is noti-

fied

within

a reasonable time

and

unless

the

defect

is

not

the

result

of

normal

expected shelf life deteriora-

tion.

This

guarantee

shall

then

continue

as

to

corrected

or

replacing articles

or,

if

only

parts

of

such are cor-

rected

or

replaced,

to

such corrected

or

replacing parts,

until

one year

after

the date

of

redelivery.

To

the

extent

the

equipment,

including

all parts

and

spare parts, as defined above,

is

of

the

Contractor's

de-

sign

or

is

of

a design selected

by

the

Contractor,

it

is

also guaranteed, subject

to

the

foregoing

conditions,

against defects

in

design,

with

the

understanding

that

if

ten percent

or

more

of

the

total

quantity

comprising

such item furnished

under

the

contract

(but

not

less

than

two

thereof)

is

found

to

be

defective as

to

design,

the

entire item

will

be conclusively presumed to

be

of

defective design

and

shall

be

subject

to

one

hundred

percent correction

or

replacement by a suitably rede-

signed

item.

All defective items will be subject

to

ultimate return

to

the

Contractor

except

that

the

exigencies

of

the

naval

service may necessitate expeditious repair

of

certain

items in

order

to

prevent

extended

interruption

of

com-

munications

and

in

such cases

the

return

of

the defec-

tive items

for

examination by

the

Contractor

prior

to

repair

or

replacement shall be mandatory.

The

report

of

a responsible authority, including details

of

the

con-

ditions

surrounding

the

failure,

will

be acceptable as a

basis

for

effecting expeditious

adjustment

under

the

provisions

of

this contractual guarantee.

If

the

Government

does

not

require correction

Or

re-

placement

of

a defective

or

nonconforming

article, the

Contractor,

if

required by the contracting officer within

a reasonable time after

the

notice

of

defect

or

noncon-

formance, shall repay such

portion

of

the

contract price

as

is

equitable

in

the circumstance. Equitable

in

the cir-

cumstance is

to

be determined by mutual agreement be-

tween

the

Contractor

and

the

contracting officer. Failure

to

agree

to

such

adjustment

shall be a dispute concerning

a question

of

fact

within

the

meaning

of

the

section

of

this contract

entitled

"Disputes".

iii

Page 9

iv

NAVSHIPS 900,853

REPORT OF FAILURE

Report

of

failure

of

any

part

of

this equipment,

during

its service life, shall be

made

to

the Bureau

of

Ships

in

accordance

with

current

instructions.

The

report

shall cover all details

of

the

failure and

give

the

date

of

installation

of

the equipment.

For

procedure

in

reporting

failures see

Chapter

67

of

the

Bureau

of

Ships

Manual,

or

superseding instructions.

CONTRACT:

NXsr

93879

DATE

OF

CONTRACf: 2 APRIL

1945

SERIAL

NUMBER

OF

EQUIPMENT

___________________

_

DATE

OF

ACCEPTANCE

BY

THE

NAVY

________________

_

DATE

OF

DELIVERY

TO

CONTRACf

DESTINATION

____________

_

DATE

OF

COMPLETION

OF

INSTALLATION

______________

_

DATE

PLACED

IN

SERVICE

_____________________

_

Blank

spaces

in

this

book

shall

be

filled in at time

of

installation.

Operating

personnel shall also

mark

the

"date

placed

in

service"

on

the

date plate located below

the

model nameplate

on

the

equip.

ment, using suitable methods

and

care

to

avoid

damaging

the equipment.

All requests

or

requisitions

for

replacement material

should

include the

following

data:

1.

Name

of

part

desired.

2.

Navy

stock

number

or,

when

ordering

from

an

Army supply depot,

the

Army stock number.

If

the

Navy

stock

number

has

not

been assigned,

the

requisitions

should

specify the following:

1.

Equipment

model designation.

2.

Name

of

part

and

complete description.

3. Manufacturers designation.

4. Contractors

drawing

and

part

number.

5. A WS,

JAN,

or

Navy

type designation.

SAFETY

NOTICE

The

attention

of

officers

and

operating

personnel

is

directed

to

Chapter

67

of

Bureau

of

Ships Man-

ual

or

superseding instructions

on

the

subject

of

Radio-Safety precautions

to

be observed.

l'

•

Page 10

Page 11

NAVSHIPS

900,853

)

Fi!lure

I-I

5

< •

peaker-Amp/ifier

-

Navy

Type

CMX

49545

1-0

Page 12

r

General

Description

NAVSHIPS

900,853 Section 1

Paragraphs

1-5

SECTION

I

GENERAL

DESCRIPTION

1.

FUNCTION.

The

navy type

CMX·49545

Speaker.Amplifier is de-

signed

for

high-fidelity

reproduction

of

speech

and

music

when

used

with

the

navy

model

RBO

Radio

Receiving

equipment

for

entertainment

purposes

aboard

all types

of

Naval

vessels

or

at

Naval

shore

radio

sta-

nons

or

activities.

2.

REFERENCE

DATA.

a.

Nomenclature-Navy

Type

CMX·49545 Speaker·

Amplifier.

h.

Contract-NXsr

93879

dated 2 April

1945.

c.

Contractor

-

The

Magnavox

Company,

Fort

Wayne,

Indiana.

d.

Cognizant

Naval

Inspector-Inspector

of

Naval

Material,

Detroit,

Michigan.

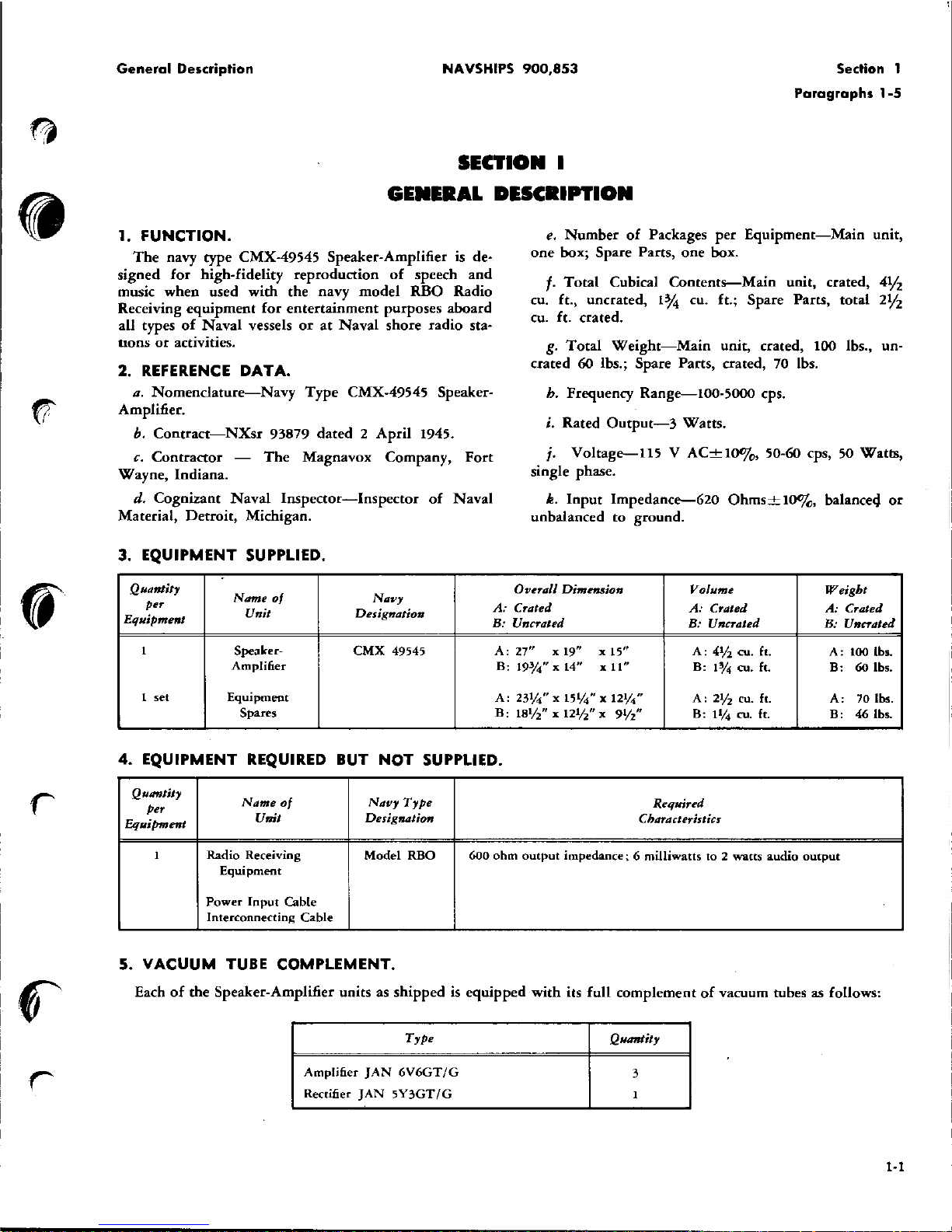

3. EQUIPMENT SUPPLIED.

Quantity

per

Name

0/

Navy

Unit

e.

Number

of

Packages

per

Equipment-Main

unit,

one

box; Spare Parts, one box.

f.

Total

Cubical

Contents-Main

unit, crated,

4Vz

Cll.

ft.,

uDerated,

1%

cu.

ft.;

Spare Parts,

total

2¥2

cu. ft. crated.

g.

Total

Weight-Main

unit, crated, 100 Ibs.,

un-

crated 60 lbs.; Spare Parts, crated, 70 Ibs.

h.

Frequency

Range-100·5000

cps.

i.

Rated

Output-3

Watts.

j.

Voltage-1l5

V

AC±I00/

o

,

50-60 cps, 50

Watts,

single phase.

k.

Input

Impedance-620

Ohms±IO%,

balance4

or

unbalanced

to

ground.

Overall Dimension

Volume

Weight

A:

Crated

A:

Crated

A: Crated

Equipment

Designation

B: Uncrated

B: Uncrated

B: Uncrated

1 Speaker-

CMX

49545

A,

27"

x 19"

xIS"

A:

4%

cu. ft.

A,

100

lb

•.

Amplifier

B:

190/4" x 14"

x 11"

B:

1%

cu. ft.

B,

60 Ibs.

1 set

Equipment

A:

23%"

x 15lj4" x 12lj4"

A:

2%

cu. ft.

A,

70 lbs.

Spares

B:

18lj2" x

12%"

X

9lj2"

B:

11;4

cu. ft.

B,

46

lb

•.

4.

EQUIPMENT REQUIRED BUT

NOT

SUPPLIED.

Qutmtity

Name

0/

Navy

Type

Required

per

Equipment

Unit

Designation

Characteristics

1 Radio Receiving

Model

RBO

600

ohm

output

impedance; 6 milliwaus

to 2 watts

audio

output

Equipment

Power

Input

Cable

Interconnecting

Cable

5.

VACUUM

TUBE COMPLEMENT.

Each

of

the

Speaker. Amplifier units as

shipped

is

equipped

with

its full

complement

of

vacuum tubes as follows:

Type Quantity

Amplifier

JAN

6V6GT/G

3

Rectifier

JAN

SY3GT/G

1

1·1

Page 13

Section 2

Paragraph

1

NAVSHIPS

900,853

Theory

of

Operation

SECTION

II

THEORY OF OPERATION

I.

The

CMX·49545

SPEAKER·AMPLIFIER

consists

of

a two-stage

audio

amplifier

with

power

supply,

and

a magneto-dynamic loudspeaker, all contained

in

a cast

aluminum case.

The

amplifier consists

of

a voltage-amplifier stage

using a

JAN

6V

GGT

/G

vacuum tube; a

push.

pull

class

"AU

power

output

stage using

two

JAN

6V6GT/G

vacuum tubes;

and a power

supply using a JANSY3-

GT

/G

high·vacuum rectifier tube,

and

furnishing

all

filament, plate,

and

grid

voltages necessary

for

opera-

tion

from

115 volt, 60 cps, single phase

alternating

current

power

lines.

Figure 2-1 is a functional block diagram

of

this

equipment.

The

amplifier

unit

is

arranged

to

select

anyone

of

five 600

ohm

input

channels by

the

proper

setting

of

the

channel selector switch (S-102) which is adjustable

from

the

front

of

tbe

panel.

The

unused channels are

terminated

with

resistors

(R-I0l

to

R-I05,

incl.).

The

input

to

the

grid

of

the

voltage-amplifier tube

(V.101)

is

variable by means

of a potentiometer

(R·106)

having a logarithmic taper, which may

be

adjusted

from

the

front

of

the

panel

to

give

the

desired

audio

output.

The

tuned-filter type

tone

control

circuit

is

inserted

2-0

between the voltage amplifier

and

the

power

amplifier

and

the

tone may be regulated by means

of

a potentiom-

eter

(R·112),

adjustable

from

the

front

of

the

panel,

to

give

the

des_ired

audio response.

The

tone

control

circuit

is

composed

of

an

inductance

(L-I02),

three

capacitors

(C-108, C·109,

and

C·ll0),

and

the

potentiometer

(R·112).

The

power

amplifier stage incorporates a negative-

feedback circuit

(R.l13,

R·114, R.115, R·116,

GIll,

and

C-1l2)

to

give a better audio response

and

to

reduce

distortion.

The

power

supply stage

is

a conventional circuit

w-

ing

a high·vacuum rectifier tube

(V·104)

and

a single

PI-section inductance-capacitance

(L-I0l,

C-I07A,

and

C·107B) filter.

The

loudspeaker is a moving coil type speaker using

a

permanent

magnet

to

furnish

the

magnetic flux.

The

moving

coil has

an

impedance

of

3.7 ohms

at

1000

cps,

which

is matched

to

the

load

resistance

of

the

power

amplifier tubes by means

of a transformer

(T·103)

mounted

on

the

amplifier chassis.

The

cast aluminum case,

housing

the

amplifier

and

loudspeaker, forms a vented-bafile type acoustic chamber

for

improved reproduction

of

low-frequency tones.

•

Page 14

':'

~

...

,0.

e:

~

..

•

...

e:

~

~

ir

~

!!.

'"

0-

~

o

ir

~

.,

~

~

r--

...

---

_ ..

-_

..

FROM

G

V-101

...

INPUTS

I

~SOl

:

I i

II I6V6

-

GT

I.

_

1&

\

1_.

INPUT VOLUME

SELECTOR

OONTROL

S-102

R-10e

LEGEND:

ti-

~

STAGE

NS.

r-

L-l02

C-l01

T-l

C-l01

:

C-110

I

I

""---

TONE

OONTROL

R-Ut

r-

3

i.

VARIABLE OONTROLS ARE INDIOATED

BY

A OIROLE AND A DOTTED

LINE

SHOWING

POINT

IN

OIROUIT WHERE

THEY ARE OONNEOTED.

2_

LETTERS

AND

NUMBERS OUTSIDE TUBE

BLOOKS INDIOATE TUBE

ELEMENT

·AND

SOOKET PIN.

3_

HEAVY LINES AND

ARROW

HEADS

INDIOATE DIREOTION

OF

ENERGY

FLOW_

G

POWER

AMPLIFIER

V-102

P

'5

6V6-GT

IT

POWER

AMPLIFIER

G

V-103

P

"'i

eVe-GT

t'3

.,

INVERSE FEEDBAOK

•

.,

01

n

ER

,-

'"101

LS-iOi

~

SPEAKER AMPLIFIER

CMX-49545

FUNCTIONAL BLOCK DIAGRAM

...

:r

CD

0

-<

0

-

0

"

CD

~

Q

::

0

"

z

>

<

.,.

:J:

"

.,.

8

Go

'"

w

.,.

CD

~.

o

"

..

Page 15

Section 3

Paragraphs

1-2

NAVSHIPS 900,853 Installation

and

Initial Adjustments

SECTION

III

INSTALLATION

AND

INITIAL ADJUSTMENTS

1.

UNPACKING.

Each Speaker. Amplifier is shipped

in

completely

moisture·

proof

packing which consists

of

two separate

corrugated cardboard cartons, a moisture·

proof

bag,

desiccant, and

an

outer

wooden box. Care should he

exercised

in

removing

the

unit

from its containers

to

avoid severe jolts which

might

damage the vacuum

tubes installed

in

the unit.

Hooks

or

other

sharp

in·

struments which

might

damage the speaker cone should

not

be used.

2.

INSTALLATION.

This

equipment

is

amenable to either

bulkhead

or

table mounting.

For

bulkhead

mounting,

four

mount-

ing

holes are furnished

in

the back

of

the cabinet.

If

table installation is desired,

four

mounting

holes

may

be

drilled

where

"spotted"

on

the

bottom

of

the

cabinet.

Where

two

or

more units are installed

in

the same

compartment,

it

is

preferred

that

the units be placed

on

the same

bulkhead

and

spaced

in

such a

manner

that

each

unit

covers

an

equal deck area.

NOTE

The

installation

of

the Speaker-Amplifier units

should be limited to enclosed

~paces

offering

some degree

of

protection

from

gun

blast as

this

equipment

is neither

water.proof,

sub-

mergence-proof,

nor

blast.proof.

In

order

to

provide

for

the entrance

of

the

input

and

power

cables, bosses are furnished

on

each side

and

on

top

of

the cabinet in which holes may be drilled to fit

the cables. Side

or

top

entrance should be made ac·

cording

to

the convenience

of

installation.

After

the

input

cable,

containing

the

output

of

from one

to

five

stations from the central radio receiving equipment, has

been introduced

to

the

cabinet, connections should be

made

to

the

input

terminals indicated

in

figure 3·1.

If

the

output

of

the

central radio receiving equipment

incorporates a balanced line, a

jumper

wire should be

placed from terminal

#

12

(input

center

tap)

to

termi-

nal

#7

(ground).

Power connection from a 115 V

AC

line cable is then

made

to

terminals

#)

3

and

# )4.

NOTE

This Speaker. Amplifier is designed

to

operate

ONLY

when connected

to a II

5 volt 60 cps

single phase AC

power

source.

DO

NOT

con·

nect to a

DC

power

source as the line fuses

(F·JO)

and

F·J02)

will

burn

out

under

these

conditions,

and

damage to

the

power

trans-

former

(T.)04)

may result.

A direct lead

from a good

ground

shall be connected

to

terminal #

7,

which serves as the circuit

ground

for

this equipment.

Figure

J-J.

Main Terminal Board Diagram

3·0

Page 16

Installation

and

Initial Adjustments

NAVSHIPS

900,853 Section 3

Paragraphs

2-3

The

equipment

is

so designed

that

no

additional

bonding,

shielding,

or

grounding

is

required except as

noted

in

the

preceding

paragraph.

No

cables

for

the

required external connections be-

tween this

equipment

and

the

power

line,

ground,

and

the

companion

receiver

or

receivers are furnished, either

in assembled form

or

as

bulk

parts.

The

external cabling

should

he installed in

the

most

convenient

manner

commensurate

with

the least pos-

sible

power

loss

or

voltage

drop

in

the lines,

and

mini-

mum

noise pick.up in

the

input

circuit connections.

3.

INITIAL

ADJUSTMENTS.

Adjust

the

output

of

the

companion radio receiver

or

,eceivers

(Navy

Type

RHO

or

equivalent) so

that

the

input

to

any Speaker· Amplifier will be

within

the

range

of

6 milliwatts (1.9 volts across 600

ohms)

to

2 watts (34.7 volts across 600

ohms)

for

proper

operation

of

the

Speaker· Amplifier.

The

input

selector

on

the

outside

of

the

front

panel is adjusted to select

a total

of

five inputs.

1£

less

than

five

input

circuits

are to be used, the switch stop must be adjusted so

that

the

number

of

switch positions will correspond

with

the

number

of

input

circuits connected

to

the

amplifier.

To

reset the

stop

on

the

input

selector

switch, first, remove

knob

from

the

switch shaft; second,

remove

the

switch

mounting

nut

and

pull

switch from

opening

in

panel

(inside);

third,

turn

the

stop plate

(with

stop

pin

attached)

until

placing stop

pin

in locat-

ing

hole will give

the

number

of

input

positions desired;

and

finally, replace switch

in

panel, secure

with

mount-

ing

nut,

and

replace switch knob.

3-1

Page 17

Section 4

Paragraphs

1-2

NAVSHIPS

900,853

Operation

SECTION IV

OPERATION

1.

This

Speaker. Amplifier is designed

to

furnish the

rated three watts

of

audio power to the integral loud-

speaker with a power input--to the amplifier

of

6 milli-

watts (1.9 volts across 600

ohms)

to

2 watts (34.7 volts

across 600 ohms). An input

of

less than 6 milliwatts

may result in insufficient sound output, and

an

input

of

more than 2 watts may result in overloading with

objectionable distortion

of

the sound output. (See para-

graph

III·3)

2.

To

operate

the

Speaker-Amplifier

after

complete

installation has been made, move the "OFF-ON" switch

(figure 4-1)

to

the

"ON"

posItIon

and

set the channel

selector switch to the desired station. The volume con-

trol

on

the

right

side

of

the

panel should then be set

to the desired volume which increases with the scale.

Finally, the

tone

control

on

the left

of

the

"OFF-ON"

switch should be set to give the desired tone.

It

will be

noted that the minimum attenuation

of

the high frequency response occurs with the knob in the most clockwise position.

It

follows that the attenuation

of

the

high frequency response increases

as

the knob

is

turned

counterclockwise.

n,

<~.

•.••. _

_

t"~"

••

~".'''

""_

.-.-

'"'---:.-=

~

~

.

Figure

4-

J.

Lower

front

Panel

4-0

I~

I~

Page 18

~-----.---------.----,-

--=--~-----

Operation

NAVSHIPS

900,853

Section 4

4-1

Page 19

Section 5

NAYSHIPS 900,853

Maintenance

5-0

FAILURE REPORTS

A

FAILURE

REPORT

must

be

filled

out

for

the

failure of

any

part

of

the

equipment

whether

caused

by

defective

or

worn

parts,

improper

operation,

or

external influences.

It

should

be

made

on

Failure

Report, form NBS-

383,

which

has

been

designed

to simplify this

requirement.

The

card

must

be

filled

out

and

forwarded

to

BUSHIPS

in

the

franked

envelope

which

is

provided.

Full

instructions

are

to

be

found

on

each

card.

Use

great

care

in filling

the

card

out

to

make

certain

it carries

adequate

infonnation.

For

example,

under

"Circuit

Symbol"

use

the

proper

circuit identification

taken

from

the

schematic

drawings, such

as

T -803, in

the

case

of a transformer,

or

R-207, for a resistor.

Do

not

substitute

brevity

for clarity. Use

the

back

of

the

card

to

completely describe

the

cause

.u

..... u .....

H

...

W,,",H'.O"".,~,

~.

of

failure

and

attach

an

extra piece

of

paper

if necessary.

The

purpose

of this

report

is to inform B U-

SHIPS of

the

cause

and

rate

of failures.

The

inrormation

is

used

by

the

Bureau

in

the

design

of

future

equipment

and

in

the

maintenance

of

adequate

supplies to keep

the

present

equip-

ment

going.

The

cards you send in,

together

with

those from

hundreds

of

other

ships, fur-

nish a store

of

information

permitting

the

Bureau

to

keep

in

touch

with

the

performance

of

the

equipment

of

your

ship

and

all

other

ships of

the

Navy.

This

report

is

not

a requisition. You

must

re-

quest

the

replacement

of parts

through

your

Officer-in-Charge in

the

usual

manner.

Make

certain you

have a supply

of

Failure

Report

cards

and

envelopes

on

board.

They

may

be

obtained

from

any

Electronics Officer.

.........

>GO

..

,.

............

'.

_

.......

_---

...

-

NAVY

DEPARTMENT

BUREAU

OF

SHIPS

WASHINGTO~!!5.

D.

C

.l

._

19cJd;·lq4~

Sample

Failure

Report

Cards Properly Filled

In

Page 20

r

Maintenance

NAVSHIPS

900,853

Section 5

Paragraphs

1-3a

SECTION

V

MAINTENANCE

1. OPERATORS

MAINTENANCE.

The

only

maintenance

required

of

the

operator

is:

a.

REPLACING

BURNED·OUT

PILOT

LAMP

(REPLACEABLE

FROM

FRONT

OF

PANEL).

(1)

Unscrew

and

remove

the

red

jewel assembly.

(2)

Remove

the

defective

pilot

lamp.

(3)

Insert a new

Mazda

51

or

equivalent

pilot

lamp.

(4)

Replace jewel assembly.

h.

REPLACING

DEFECTIVE

VACUUM

TUBE.

(1)

Throw

"ON·OFF"

switch

to

"OFF"

position.

(2)

Open

the amplifier case.

(3)

Remove

the

defective tube.

Remove

tuhe

with

a

straight,

upward

pull.

DO

NOT

move tube from side

to

side as this may result

in

the base key

breaking

off

and

remaining

in

the socket.

(4)

Replace

with

proper

type tube.

(5)

Close the amplifier case.

IN

ORDER

TO

OBTAIN

FULL

TUBE

LIFE

AND

PROPER

OPERATION,

DO

NOT

USE

TUBES

OF

OTHER

TYPES

THAN

THOSE

HEREIN

SPECIFIED.

ALL

TUBES

FURNISHED

AS

INITIAL

SUPPLY

OR

SPARES

SHALL

BE

USED

PRIOR

TO

EMPLOY·

MENT

OF

TUBES

FROM

GENERAL

STOCK.

e.

REPLACING

BLOWN

FUSES.-DO

NOT

RE·

PLACE

UNTIL

THE

DEFECT

CAUSING

THE

FUSE

TO

BLOW

HAS

BEEN

ISOLATED

AND

COR·

RECTED.

(I)

Throw

"ON·OFF"

switch to

"OFF"

position.

(2)

Open

the amplifier case.

(3)

Remove

blown

fuse

from

fuse

hoard

located

on

back

panel

of

amplifier

case.

CAUTION

Equipment

"On-Off"

switch does

not

remove

the

power

from

the fuses.

The

fuse clips

at

the

top

of

the fuse

board

have a

potential

difference

of

115 volts

AC

between

them

at

all times. Use due

precaution

in

removing

the defective fuse.

(4)

Insert

new fuse

Type

3AG,

1.0 ampere.

(5)

Close

the

amplifier case.

2.

PREVENTIVE

MAINTENANCE.

Operator

shall be

guided

by

Chapter

67

of

the

"Bureau

of

Ships

Manual".

Vacuum

tubes

(V·IOI,

V·102, V·103,

and

V·104)

sh.ll

be checked

on a standard

tube checker

after

every 250

hours

of

operation

or

every three

months,

whichever

comes first. Defective tubes shall be replaced. immediately

for

most

efficient

operation

(See

paragraph

Ib

of

Section

5).

The

dry

electrolytic capacitors (C-101

and

C-102) are

used as cathode

by-pa~s

capacitors,

and,

under

normal

conditions

of

operation,

have sufficient safety factor to

insure a life expectancy equal to

that

of

the entire equip-

ment.

The

balance

of

the

components

in

this

equipment

are

not

subject to

deterioration

due

to

operation,

and

need

to

be checked

only

in

case

of

equipment

failure (See par-

agraph 3 of

Section 5

on

"Corrective

Maintenance").

3.

CORRECTIVE

MAINTENANCE.

If

any

major

repairs

or

replacements become neces-

sary, it is recommended

that

such repairs

or

replace-

ments

be

made

in

a well

equipped

shop

where the

proper

tools,

measuring

equipment,

and

personnel are

available.

Before

making

any repairs

or

adjustments

in

the

Speaker-Amplifier,

it

should

be definitely ascertained

that

the

difficulty

being

experienced is

not

the result

of

external

or

deteriorating

influences such as

worn

out

tubes,

improper

operating

voltages,

blown

fuses,

exterior

noises, etc.

Over-

and

under-chassis views (figures 5-1, 5-2,

and

5-3)

show

the

location

of

tubes

and

other

parts

of

the

Speaker· Amplifier.

Figure 5-4 shows a typical

audio

frequency response

curve,

and

may

be used

in

checking the

over~all

perform-

ance

of

the amplifier if

the

required

audio

oscillator

and

output

meter

is available.

Following

is a suggested systematic procedure

of

"trouble-shooting"

malfunctions

of

the

equipment:

a.

If

the

equipment

does

not

operate

when

the

switch

is

moved

to

the

"ON"

position:

(I)

Check the

power

supply

to

make sure

that

the

source is

11 5 volt

AC

60 cps.

(2)

Check

the

fuses.

(3)

Check

the

circuit

continuity

through

the cables.

(see figures 3·1

and

5·5).

5-1

Page 21

Section 5

NAVSHIPS 900,853

Maintenance

figure

5-1.

Speaker-Amplifier

CMX-49545

Top

Chassis

View

I~

5·2

Page 22

Maintenance

('>II

NAVSHIPS

900,853

RESISTOR BOARD

(SEE

FIG.5-5)

RESISTOR

BOARD

(SEE

FIG.

5-5)

Figure

5·2.

Speaker.

Amplifier

CMX·49545

Lower

Chassis

View

Section 5

5·3

Page 23

Section 5

RESISTOR BOARD

(SEE

FIG.5-5)

NAVSHIPS

900,853

Maintenance

RESISTOR, BOARD

(SEE

FIG.5-5)

Figure

5-3.

Speaker-Amplifier

CMX-49545

Lower

Chassis

View

5-4

•

•

•

Page 24

Maintenance

NAVSHIPS 900,853

Section 5

figure

5-4.

Audio

frequency

Curve

5-5

Page 25

Section 5

NAVSHIPS 900,853

Maintenance

Figure

5-5.

Cable

Connection Diagram

5-6

Page 26

...

cO'

C

~

..

'"

,

~

'"

"

:r

It

ii

D

::-.

"

!:!

~

"

~

to

,i"

CD

~

D

ii

vo

..:..

-,

-"

..

"

~

z

L 2

3

..

"

~

z

..

4

..

..

"

~

;!;

,:,

7

~

f 8

..

•

i

z

..

G

'~

•

"~

GROUND

qa::

..

",

"'-

Go

::~

J

T-104

'-101

6V6-G

V-lOl

5Y3-G

y-t04

-,.

0

1-101

<

o

o

~

•

L-I01

00001

220.1\.

7

2

1

2

-

-

c

1

;)

•

...I

V-l03

6V6-G

.02MFD.

NOTE-

n

C,

VOLTAGES MEASURED BETWEEN

GROUND

AND

INDICATED

TERMINALS,

USING 1000 OHMS/VOLT METER.

FILAMENT

VOLTAGE

MEASURED

BETWEEN

SOCKET TERMINALS

USING

1000 OHMS/VOLT

RECTIFIER

TYPE

A.C.

METER.

VOLTAGES

MEASURED

WITH

115V.

60

CPS

LINE

VOL.TAGE.

RESISTANCE MEASURED WITH EQUIPMENT

-OFF-

a.

EXTERNAL

CABLES

DISCONNECTED.

RESISTANCE

VALUES

DESIGNATED

(6)

DENOTE

RESISTANCE

TO

GROUND

OF

INDICATED POINT.

VOLTAGE a RESISTANCE VALUES MEASURED

WITH

WESTON

MODEL

772

ANALYZER.

3:

D

:r

;;

" D

"

"

..

z

S

X

:;

lit

J

e:

...

¥'

~

o

"

III

Page 27

Section 5

Paragraphs

3a-3b(3)

NAVSHIPS

900,853

Maintenance

(4)

Check the tubes

to

see

that

they light,

and

if

necessary replace

with

known

good

ones.

(5)

Introduce

an

audio signal

to

the

circuit

and

check to see where it stops.

h.

If

the

equipment

operates

but

operates poorly:

(1)

With

equipment switched

"ON"

and

115 volt

single phase

60 cps

AC

applied

to

the

power

terminals,

check

component

voltages against the voltages shown

in

figures 5-6

and

5-9.

(2)

With

equipment

switched

"OFF",

volume

control set at

10,

tone

control set at

10,

and

all external

cables disconnected, check resistance

to

ground

of

com-

ponents

against

the

resistance values

shown

in

figures

5-6

and

5-9.

(3)

Check the loudspeaker

for

poor

connections

and

for

dirty

or

sticky voice coil.

If

the

cone

and

voice coil assembly

is

found

to

be

defective, replace-

ment

may be made by using Cone

and

Voice Coil As-

sembly

#16C50G2,

which

is

furnished

with

the

spare

parts,

and

adhering

to

the

following

instructions:

(a)

Remove the flexible moving coil leads

from

the

terminal strip by

the

application

of a hot

soldering

Iron.

(b)

Cut carefully

around

the edge

of

both

cone

and

corrugated

paper

spider so

that

the

entire moving

structure assembly may

be

removed at once.

(

c)

Im'mediately cover

the

air

gap

with

tape to

prevent

the

entry

of

iron

filings, etc.

(d)

Soften

th~

water-proof

cement which at-

tached

the

cone

and

spider

to

the

housing

with

lacquer

thinner

or

acetone. Use

thinner

liberally

and

in

a few

minutes wipe away all remains

of

the

paper

and

cement.

5-8

(e)

Then

remove all remains

of

the

paper

and

cement from the housing,

after

which remove the tape

and

blow

the

air

gap

with

compressed air

if

available,

or

wipe

out

with

a piece

of

Scotch tape.

(!)

Apply

evenly

an

ample supply

of

some

good

grade, fast drying water-proof cement

to

the hous-

ing

rim

and

in

the circular depression which seats the

spider (see figure 5-7).

Put

the

new assembly lightly in

place

with

the moving coil leads in correct position

to

be properly soldered to

the

terminal strip

and

with the

cone edge in contact

with

the housing rim ail

the

way

around. Immediately

then

slip the

0.006"

paper

spacer

(packed with the replacement cone assembly) curved

to

fit

around

the core between the inside

of

the moving coil

and

steel core.

Next,

apply

an

even coat

of

cement to

the

top

side

of

the

pulpboard

gasket

and

press lightly

in

place (see figure

5-8).

Take

care

not

to slide the cone

one

way

or

another

when

assembling the gasket. Make

certain

that

the

moving coil has entered the air gap

far

enough to place the rim

of

the

spider in good contact

with

the housing, yet

not

so far

as

to

seriously depress

the

spider in its center section.

(g)

Place

the

assembly

on

a smooth, flat surface

(gasket

down)

with

a small weight

on

the back and allow

to

become

thoroughly

dry before proceeding (approxi-

mately 30 minutes).

(

h)

Remove the paper spacers

and

solder the

flexible leads

to

the

terminal strip, allowing just suf-

ficient slack

for

free maximum excursion

of

the moving

coil. Be certain

that

the

flexible leads

do

not

contact the

housing

or

cone at any time while in motion.

(i)

Apply a bead

of

cement

around

the

circum-

ference

of

the felt

dust

cap disc,

and

position the dust

cap centrally over

the

voice coil opening. Press lightly

in

place

and

let dry.

,'\

,

Page 28

."

~

~

:b

~

4IJ

CEMENTING AREAS

VOICE

COIL

FLEXIBLE LEADS

SPIDER

--

__

_

CONE-------------

CONE AND VOICE COIL

ASSEMBLY

figure

5-7.

Parts 'or Cone

Replacement

.J

.-

.I

SHIM

PLACE

CONE

ASSEMBLY

GASKET

Figure

5-8.

Completed

Cone

Replacement,

fReady

for

Drying}

~

c

5'

ii'

=

c

=

"

..

z

,.

<

'"

:J:

...

'"

g

c.

'"

...

'"

..

!l.

0'

=

'"

Page 29

i

VOLTAGE

a RESISTANCE TABLE

TEST

POINT

VOLTAGE

RESISTANCE

TEST

POINT

VOLTAGE

V-lot-267

6.3 AC

V-103-4

2B2

-3

70

-5

-4

25

-B

16.5

-5

1050

V-104-26B

5.0

AC

-B

3

540

-4

V-102-267

63

AC

-6

-3

275

L-101-2

282

-4

282

-1

300

-5

19000

T-104-162

115 V AC

-8

16.5

220

T-103-163

V-t03-267

63

AC

TP-l

-3

275

Maintenance

RESISTANCE

IBOOO

220

140

130

9

430

2700

NAVSHIPS 900,853

Section 5

o NOTES'

o

1.

CHECK

VOLTAGES

WITH

EQUIPMENT

'ON'

t--r-+---'PI--+l......1

AND

115

V.

60'\1

POWER

CONNECTED.

2.

CHECK

RESI~TANCES

WITH EQUIPMENT

'OFF'

AND

ALL

EXTERNAL CABLES

DISCONNECTED.

3.

CHECK

BETWEEN INDICATED TEST POINT

AND

GROUND,

OR

BETWEEN THE TEST

POINTS WHERE

TWO

ARE

LISTED.

4.

MEASUREMENTS

MADE

WITH WESTON

MODEL

772

ANALYZER, USING

1000

OHMS

PER

VOLT

SENSITIVITY

ON

ALL

MEASUREMENTS.

5.

SET VOLUME

AND

TONE CONTROLS

TO

VOLTAGES ARE

DC

UNLESS OTHERWISE INDICATED.

~

;:::::::::::::::::::::::::::::::::::::::::::~'1~~~~~~~~~~~~~~~1.

..

~'I~O'~~BE~F;O:R~E

CHECKING

THE

EQUIPMEN~

~=.:;;'":.~u.o""

TO-R·

JJ

e

==

GJfE~1t

I

~=II

~~;;;::::"""

t...,; r

....

N

~Ol-.L

tOI·/\..

Figure

5-9.

Ampljfier

Wiring Diogram

Pu~/b

OR",I'IQ-e

<.

TO-5-JOt.

5-11-5-12

Page 30

Symbol

Desig.

C-lOl

C-102

C.103

C-104

C-lOS

C-106

C-107

ClO8

C-I09

•

~

.....

""

•..

~.

SECTION

VI

PARTS

AND

SPARE PARTS LISTS

TABLE

6-1

MAJOR

UNIT

Quantity

Navy

Type

Number

Name

of

Maio,. Unit

6382

CMX

49545

Name

0/

Pari

•

nd

Description

Capacitor.

dry

electrolytic;

40

mfd

40

WVDC

Same as

ClOl

Capacitor,

paper;

0.05

mfd ± 10%,

600 V

Capacitor,

paper;

0.5

mfd

±5%,

600 V

Capacitor,

paper;

0.02

mfd

±lO%,

600 V

Same as

C-I05

Capacitor.

paper,

triple

section;

ea

sect

8

mfd

±200/0

500

V;

A,

B,

and

C

denote

sections

1.

2.

and

3 resp.

Capacitor,

mica;

1200

mmfd

±5%.

500 V

Capacitor,

mica;

750

mmfd

±5%.

500 V

Speaker-Amplifier

TABLE

6-2

COMBINED PARTS

AND

SPARE PARTS LIST

For

Speaker-Amplifier CMX-49545

Contract

NXsr

93879

AWS,

JAN

Function

0'

Magnavox

Navy

Type

Drawing No.

Designation

Cathode

by-pass, first

audio

stage

-483949

16B20GI

Cathode

by· pass,

output

stage

-483949

Plate

bloddng,

first

audio

stage

CP26AIEF503K

16A269GI

Screen by-pass, first

audio

stage

-481002-5

16A252GI

Coupling

for

inverse feedback

CN42E203K

16A267Gl

Coupling

for

inverse feedback

CN42E203K

Plate

power

filter

-484591-20

16A1l5G3

Audio

filter,

tone

control

CM30A122}

16A270G4

circuit

Audio

filter,

tone

control

CM3oA751} 16A27oG3

circuit

Mf'·

Mfr. Part No.

Ref·

13

16B20Gl

21

P1l695

20

XTMRTW6·.5-5

15

342YLl4

10

A8587

19

42621

19

60670

Part Designation Group

101

199

Total

No.

Quantity

Quantity

p"

Equip .

Tender

Equip. Spares

Spares

2 2

6

I I

2

I I

2

2 I

3

I I 2

I I 1

I I I

Quantity

Stock

SPares

6

3

3

5

3

I

I

....

D

=

D

"

D.

'"

....

D

;;;

....

D

=

...

;;;-

;:

*

CD

'"

Col

'"

CD

n

=:

o

"

...

Page 31

TABLE

6-2

(Continued)

Symbol

Name

of

Part

AWS,

JAN

and

Function

or

Magnavox

Desig.

Description

Navy

Type

Drawing

No.

Designation

CliO

Capacitor, mica; 6800

mmfd

±1O%,

Audio

filter,

tone

control

CM35A682K

16A270Gl

500 V

circuit

CIIl

Capacitor, mica;

IS

mmfd

±lO%.

High

frequency

by-pass

inverse

CM20AlSOK

16A270G2

SOOv

feedback circuit

C·1I2

Same as

CIIl

High

fre~ency

by-pass inverse

CM20A150K

feedba

circuit

F-lOl

Fuse,

cartridge;

1.0

amp

250

V

Used in

input

line

-28032-1

M600GI

F-102

Same as

F·lOl

Used

in

input

line

·28032·1

1-101

Lamp.

pilot;

6.3 V

Mazda

type 51,

bayonet

base

"ON-OFF"

indicator

M795GI

L-101

Reactor, filter;

DC

resist. 270

ohms;

imped.

2800

ohms @ 60

cps

and

70

rna

DC

load

Smoothing

choke,

plate

power

supply

·304045

16C70GI

L-102

Reactor,

audio;

DC

resist. 370

ohms;

Audio

filter

choke,

tone

control

·303953

16C72GI

inductance

1.035

henries;

impedance

circuit

@ 1000

cps

6400

ohms

LS·101

Loudspeaker,

8"

magneto-dynamic;

voice

coil

DC

resist. 2.9

ohms;

Electro-acoustic

transducer

-491636

16BI9GI

imped.

@ 1000 cps - 3.7

ohms

R-101

Resistor,

fixed

composition;

620

ohms

±5%, 2 watts

Input

channel

load

resistor

RC41BF621j

16A266G2

R-102

Same

as

R-101

Input

channel

load

resistor

RC4lBF621j

R-103

Same

as R-101

Input

channel

load

resistor

RC4lBF621j

R-I04

Same

as R-101

Input

channel

load

resistor

RC41BF621j

R-105

Same

as R-101

Input

channel

load

resistor

RC4

lBF62

Ij

R-loG

Potentiometer;

25000

ohms

±200/0;

Volume

control

.634809-20

16C83GI

taper -4% @ 50%

rotation

R-107

Resistor,

fixed

composition;

270

ohms

Cathode

bias

resistor,

RC21BF271K

16AllOG3

±

10%,

liz

watt

first

audio

stage

R-108

Same

as

R-107

Cathode

bias

resistor,

RC2lBF271K

first

audio

stage

R-109

Resistor,

fixed

composition;

0.47

meg-

Screen

voltage

dropping

resistor,

RCZlBF474K

16AllOG2

ohms

±

~O%,

Y2

watt

first

audio

stage

R·II0

Resistor,

fixed

composition;

33,000

Plate

load

resistor,

RC4lBF333K

16A266G3

ohms ± lOo/(), 2 watt

first

audio

stage

R-Ill

Resis[Qr, fixed

composition;

4700

ohms

±lOo/c, 1 watt

Plate

voltage

dropping

re-

sistor,

first

audio

stage

RC3IBF472K

16A265GI

R-1l2

Potentiometer;

30000

ohms

±20ck ;

linear

taper

Tone

control

-634805-20

16C83G2

R-1l3

Resistor,

fixed

composition;

0.1

ohm ± 10%. 1 watt

meg-

Inverse

feedback

circuit

RC31BF104K

16A265G2

•

Total No.

Mfr.

Mfr. Part

No.

Per

Re/.

Equip.

19

60500

I

19

60519

2

3

3AG·I

2

11

Mazda

51

I

5

9999

I

13

16C72GI

I

13

16BI9Gl

I

12

BT·2

5

6

37W·25000

I

9

504-B

2

7

CY2

I

12

BT-2

I

12

BT-I

I

6

37W·30000

I

12

BT·I

2

•

Quantity

Equip.

Spares

I

I

40

2

I

I

I

3

I

I

I

I

I

I

I

Quantity

Tender

QUdntily

Stock

Spares

Spares

I

I

2

2

80

200

4

6

2

3

2

3

2 2

IS

25

3

5

6 10

3

5

3

5

3

5

3

5

6

10

•

z

~

:1:

"II

'"

g

-."

'"

Col

"II

D

;:

D

:s

...

'"

...

D

0;

"II

D

;:

,..

~

Page 32

•

R·114

Same as R-113

Inverse

feedback

circuit

RC3IBFI04K

R-IIS

Resistor, fixed

composition;

ohms ± 10%,

V2

watt

15000

Inverse

feedback

circuit

RC21BFI53K

R-116

Same as R-115

Inverse feedback circuit

RC2IBFI53K

R-I17

Resistor,

wire-wound;

220

ohms

Cathode

bias resistor,

RU6A221K

± 10%. 2

watts

output

stage

S-lOl

Switch,

toggle;

DPST, 3 amp

125 V

"ON-OFF"

switch

-24001

5-102

Switch,

rotary

wafer;

I-gang

2-circuit.

Selection

of

one

of

five

5-position

input

channels

T-lOl

Transformer,

input;

pei. term. 1 and

3,

DC

resist. 860 ohms; pri.

cr

term.

2; sec. term. 4 and

5,

DC resist.

Couple

input

to

grid

of

first

audio

stage

-304046

1030

ohms;

turns

ratio

1

~1

T-102

Transformer,

interstage;

pei.

term. 1

Couple

output

of

first

audio

-304047

and

2,

DC

resist.

2435

ohms;

sec.

stage

to

grid

of

output

stage

term. 3

and

4,

DC

resist. 3I.4o.Dhms;

sec.

-2

term. 5

and

6,

DC

resist.

3190

ohms;

turns

ratio

pri.

to

either

sec. 1:1.17

T-I03

Transformer,

output;

pri. term. 1

and

Couple

output

to

voice-coil -304048

3,

DC

resist. 410

ohms;

pri.

CT

of

loudspeaker

term.

2;

sec. term. 4

and

5,

DC

re-

sist. 0.170

ohms;

turns

ratio

52:

1

T-104

Transformer,

power;

115 V, 50-60 cps,

Furnish

all

filament voltages,

-304049

input

term. 1

and

2;

6.3 V

output

and

plate

and

screen voltages

term. 3

and

4;

5 V

output

term. 5

and

6;

580 V

output

term. 7

and

9;

CT

high

voltage

sec. term. 8

Y-IOI

Tube,

amplifier

Yoltage

amplifier

JAN

6V6GT/G

Y·102

Same as

V-lOl

Power

amplifier

JAN

6V6GT/G

V-103

Same as Y-lOl

Power

amplifier

JAN

6V6GT/G

V-104

Tube,

rectifier

Furnish

DC

plate

volt

JAN

5Y3GT/G

X-WI

Tube

socket

For

voltage

amplifier tube

-49351

X-102

Same as

X-WI

For

power

amplifier tube

-49351

X-I03

Same as

X·IOI

For

power

amplifier

tube

-49351

X-104

Same as

X-WI

For

rectifier tube

-49351

Cone

and

Voice Coil Assem.

For

replacement in

loudspeaker

Gasket, Vellutex

For

loudspeaker

mounting

Gasket, Vellutex

Equipment

case

vent

seal

Screws,

knurled

Front

panel security

Gasket,

rubber

Front

panel

seal

Lamp socket

assemblr

(includes

hardware)

For

indicator

lamp

Fuse

holders

Holders

for

input

line

fuses

Instruction

book

•

16Al1oG4

9 524

2

16A286GI

12

BW-2

I

16C82GI

2

20902-JB I

16C48G2

14

B1l8118

I

16C7oG2

5

9989

I

16C7oG3

5

9980

I

16C70G4

5

9988

I

16C71GI

5

9990

I

17

6V6GT/G

3

16

5Y3GT/G

I

16AlilGI

I

RN58TM

4

16C50G2

13

16C50G2

I

16A231GI

22 I

16A233GI

22

I

16A24oGi

18 6

16A229GI

4 4143 I

16C8IGI

8 DV88-51 I

SAO-RED

16C61GI

13

16C6IGI

I

16A288GI

23 2

•

I

6

I

3

I

I

I

I

I

2

I

2

I

2

I

2

6

9

2

3

2

2

2

2

I

2

I

2

0

0

I

2

I

I

I

I

10

5

I

I

3

3

3

3

0

0

4

3

4

4

6

4

I

I

...

D

::.

~

D

::J

l>-

II>

-u

D

~

...

D

;-

..-

;;;'

;:

$

..

..

w

II>

CD

~

o

::J

'"

Page 33

Section 6

Quantity

Navy

Type

Number

I

·24001

I

2

-28032·1

I

-;03953

I -304045

I -304046

I

-304047

I -304048

I

-304049

I

JAN

6V6GT/G

I

JAN

6V6GT/G

I

JAN

6V6GT/G

I

JAN

5Y3GT/G

2

CM20Al50K

I

CP26AIEF503K

I

CM30A122J

I CM30A751J

I CM35A682K

2 CN42E203M

I -481002·5

2 -483949

I

-484591-20

6-4

NAVSHIPS

900,853

TABLE

6-3

LIST OF PARTS

BY

NAVY

NUMBERS

(The

quantities

listed

do

not

include

spare

parts)

For

Speaker-Amplifier CMX-49545

Symbol

Des;g.

Description

SWITCHES

(Class 24)

$.101

Toggle;

DP5T. 3 amp,

125 V

5·102 Rotary

Wafer;

l·gang.

2·circuit, 5·position

FUSES (Class 28)

F·lOl,

F·102

Cartridge;

1.0 amp, 250 V

TRANSFORMERS

and

REACTORS

(Class

30)

Parts

and

Spare

Parts

Lists

L·102

Audio;

DC

resistance 370 ohms, inductance 1.035 henries,

imped

@ 1000 cps 6400

ohms

L·101

Filter;

DC

resistance 207 ohms, impedance 2800

ohms

@ 60 cps

and

70 rna.

DC

load

T·lOl

Input;

primary

DC

resistance 860 ohms. sec

DC

resistance 1030 ohms

T·102

Interstage;

primary

DC

resistance 2435 ohms, sec

DC

resistance

3140 ohms

T-103

Output;

primary

DC

resistance 410 ohms, sec

DC

resistance 0.170 ohms

T-104

Power;

115 V, 50·60 cps

VACUUM

TUBES

(Class

38)

V-WI

Amplifier, voltage

Y·102

Amplifier,

power

Y·103

Amplifier,

power

V-Io4

Rectifier

CAPACITORS

(Class

48)

C-llI,

C-1l2

Mica;

15

mmfd ± 100/0,

500 v

C-103

Paper;

0.05

mfd ± 10%.

600 Y

ClO8

Mica;

1200

mmfd

±5"10, 500 V

C-109

Mica;

750

mmfd

±50/(l, 500 Y

C-IlO

Mica;

6800

mmfd ± 10%.

500 V

C-105, C-106

Paper;

0.02

mfd ± 100/(l,

600 Y

C-104

Paper;

0.5

mfd

±50/0.

600 V

C·lOl,

C-102

Electrolytic,

dry;

40

mfd

40

WVDC

C-107

Paper;

8·8-8 mfd ±

20%.

500 V

•

•

t

Page 34

Parts

and

Spare Parts

Lists

Quantity

Navy

Type

Number

4

·49351

•

1 -491636

1

RU6A221K

2 RC21BFI53K

2 RC21BF271F

1

RC2IBF474K

2 RC3IBF104K

1

RC3IBF472K

1 RC41BF333K

5

RC4lBF62IJ

1 -634805-20

1 -634809-20

,

\

NAVSHIPS

900,853

TABLE

6-3

(Continued)

LIST OF PARTS

BY

NAVY

NUMBERS

(The

quantities

listed

do

not

include

spare

parts)

For

Speaker-Amplifier CMX-49545

Symbol Des;g.

Description

VACUUM

TUBE

SOCKETS (Class

49)

X·lOI,

X-102,

X-103, X-104

For

vacuum tubes

JAN

6V6GT/G

and

JAN

5Y3GT/G

LOUDSPEAKER

(Major

Unit

Class

49)

LS-lOl

8"

Magneto-dynamic

RESISTORS

AND

POTENTIOMETERS

(Class

63)

R-1l7

Resistor;

wire

wound,

220

ohms ± 10%, 2 watts

R-llS,

R-1l6

Resistor;

fixed

composition,

15000

ohms

±lO%.

1f2

watt

R-107, R-108

Resistor;

fixed

composition,

270 ohms ±

100/

v

•

112

watt

R-109

Resistor;

fixed composition, 0.47

megohms

±lO%.

Y2

watt

R-113, R-114

Resistor;

fixed composition, 0.1

megohms

±100/0.

1

watt

R-III

Resistor;

fixed

composition,

4700 ohms ±

10%. 1 watt

R-110

Resistor;

fixed composition, 33000 ohms ±

1O%~

2

watts

R-lOI,

R-102, R-103,

Resistor;

fixed composition. 620 ohms ±5o/v. 2

watts

R-104, R-105

R-112

Potentiometer;

30000

ohms

±20o/v.

linear

taper

R-106

Potentiometer;

25000

ohms

±20o/v

Section 6

6-5

Page 35

l

Section 6

Color

Black

Brown

Red

Orange

Yellow

Green

Blue

Violet

Gray

White

Gold

Silver

No

Color

~

~'\'\~

Wll

..

. "

.'

:'-'

...

,'

NAVSHIPS 900,853

Parts

and

Spare

Parts

Lists

TABLE

6-4

APPLICABLE

RESISTOR

COLOR

CODES

AND

MISCELLANEOUS

DATA

FIXED

COMPOSITION

RESISTORS

Significant

Power

of

10

Multiplying

Figure

Value

0

10'

1

1

10'

10

2

10'

100

3

10'

1000

4

10'

10,000

5

10'

100,000

6

lOtl

1,000,000

7

10'

10,000,000

8 10

8

100,000,000

9

10'

1,000,000,000

-

10.

1

0.1

-

10-

2

0.01

- - -

BAND

"A"

indicates first significant figure

of

the

resistance

of

resistor.

BAND

"B"

indicates second significant figure

of

the

resistance

of

resistor.

BAND

"C"

indicates

the

decimal multiplier.

BAND

uD"

indicates

the

tolerance limits

about

the

normal

resistance value .

Tolerance

5%

10%

20%

In

this equipment,

the

nominal resistance values

of

the

fixed composition resistors are indicated by bands

of

color

around

the

body

of

the

resistors

in

accordance

with

the system

shown

above. Also,

the

significant fig-

ures

of

the

resistance values,

the