Magnavox 19MDTR20, 19MDTR17, 27MDTR20S, 27MDTR17S Service Manual

MANUAL 5891 Color TV with Built-In VCR/DVD Player Magnavox 27MDTR20S/17, 19MDTR20/17

Philips Consumer Electronics Company

A Division of Philips Electronics North America Corporation

Technical Service Data

Service Solutions Group

Technical Publications Dept.

P.O. Box 555, 401 E. Old Andrew Johnson Hwy.

Jefferson City,TN 37760

Sec. 1A: Main Section

( 27MDTR20S/17 )

Supplement 1

Sec. 1B: Main Section

( 19MDTR20/17 )

Specifications

Adjustment Procedures

Schematic Diagrams and CBA’s

Exploded Views

Cabinet & Electrical Parts Lists

MANUAL 5891

Sec. 2: Deck Mechanism Section

Color TV with Built-In VCR/DVD Player

Service Manual

MAGNAVOX

Model: 19MDTR20/17

MAGNAVOX

Model: 27MDTR20S/17

Color TV with Built-In VCR/DVD Player

First Issue: 5/03

2003 Philips Consumer Electronics Company

Philips Consumer Electronics Company

A Division of Philips Electronics North America Corporation

Technical Service Data

Service Solutions Group

Technical Publications Dept.

P.O. Box 555, 401 E. Old Andrew Johnson Hwy.

Jefferson City,TN 37760

Supplement 1

Sec. 1B: Main Section

( 19MDTR20/17 )

Specifications

Adjustment Procedures

Schematic Diagrams and CBA’s

Exploded Views

Cabinet & Electrical Parts Lists

MANUAL 5891

Color TV with Built-In VCR/DVD Player

Service Manual

MAGNAVOX

Model: 19MDTR20/17

Color TV with Built-In VCR/DVD Player

First Issue: 5/03

2003 Philips Consumer Electronics Company

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Philips Consumer Electronics Company** Equipment. The service procedures

recommended by Philips and described in this service manual are effective

methods of performing service operations. Some of these service operations

require the use of tools specially designed for the purpose. The special tools

should be used when and as recommended.

It is important to note that this manual contains various CAUTIONS and

NOTICES which should be carefully read in order to minimize the risk of personal injury to service personnel. The possibility exists that improper service

methods may damage the equipment. It also is important to understand that

these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE. Philips could not

possibly know, evaluate and advise the service trade of all conceivable ways

in which service might be done or of the possible hazardous consequences of

each way. Consequently, Philips has not undertaken any such broad evaluation. Accordingly, a servicer who uses a service procedure or tool which is

not recommended by Philips must first satisfy himself thoroughly that neither

his safety nor the safe operation of the equipment will be jeopardized by the

service method selected.

** Hereafter throughout this manual, Philips Consumer Electronics Company

will be referred to as Philips.

WARNING

Critical components having special safety characteristics are identified

with a # by the Ref. No. in the parts list and enclosed within a broken

line* (where several critical components are grouped in one area) along

with the safety symbol # on the schematics or exploded views.

Use of substitute replacement parts which do not have the same specified

safety characteristics may create shock, fire, or other hazards.

Under no circumstances should the original design be modified or altered

without written permission from Philips. Philips assumes no liability,

express or implied, arising out of any unauthorized modification of

design. Servicer assumes all liability.

* Broken Line

Manufactured under license from Dolby Laboratories. "Dolby"

and the double-D symbol are trademarks of Dolby Laboratories.

TABLE OF CONTENTS

Note:

One model, 19MDTR20/17, is covered by Supplement 1. This section only shows what differs between this model and

its base model covered by Section 1A and the Deck Mechanism Section.

[ Main Section ]

Page

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

PREPARATION FOR SERVICING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

CABINET DISASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

ELECTRICAL ADJUSTMENT INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Adjustment Points and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-7

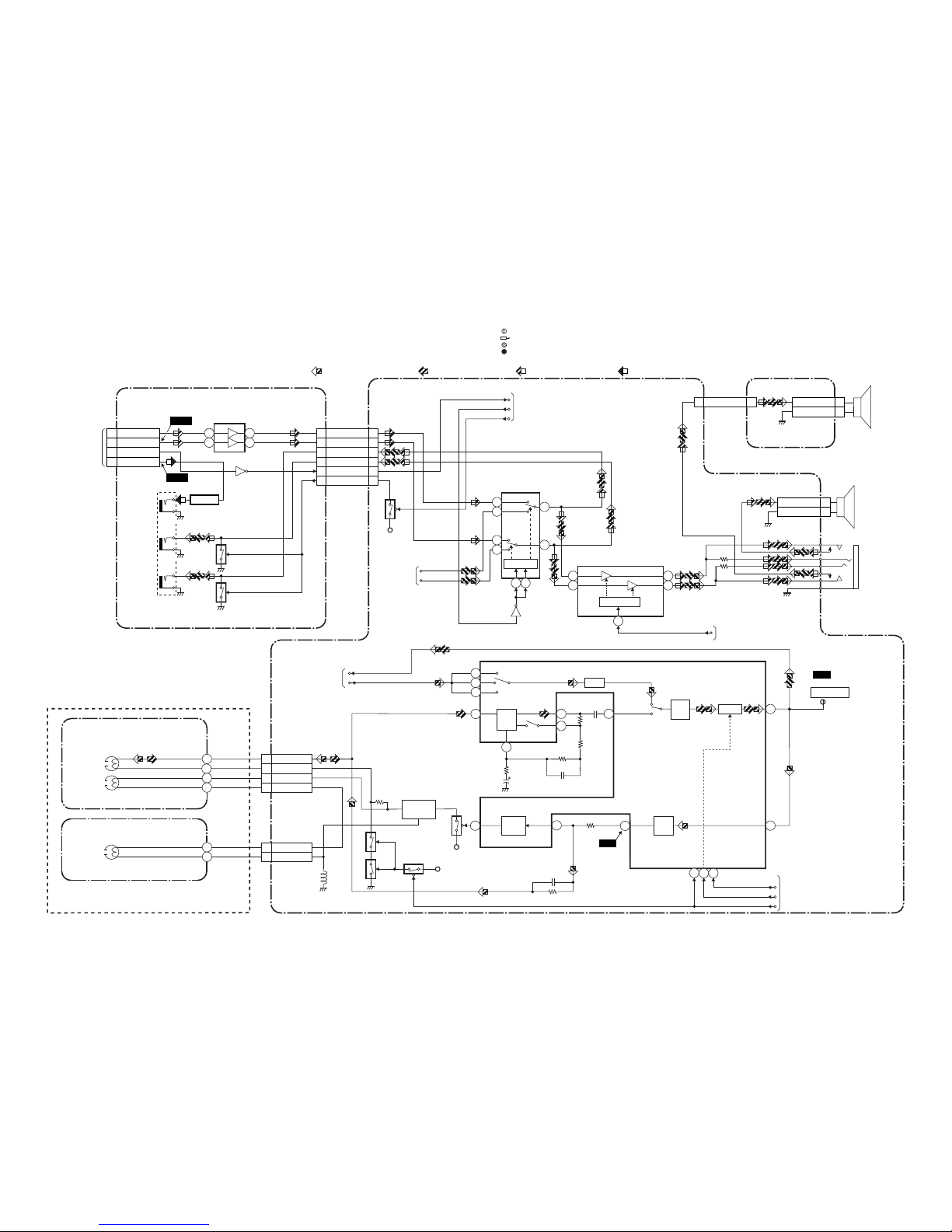

BLOCK DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

Servo/System Control Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

Video Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-3

Audio Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-5

Hi-Fi Audio Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-7

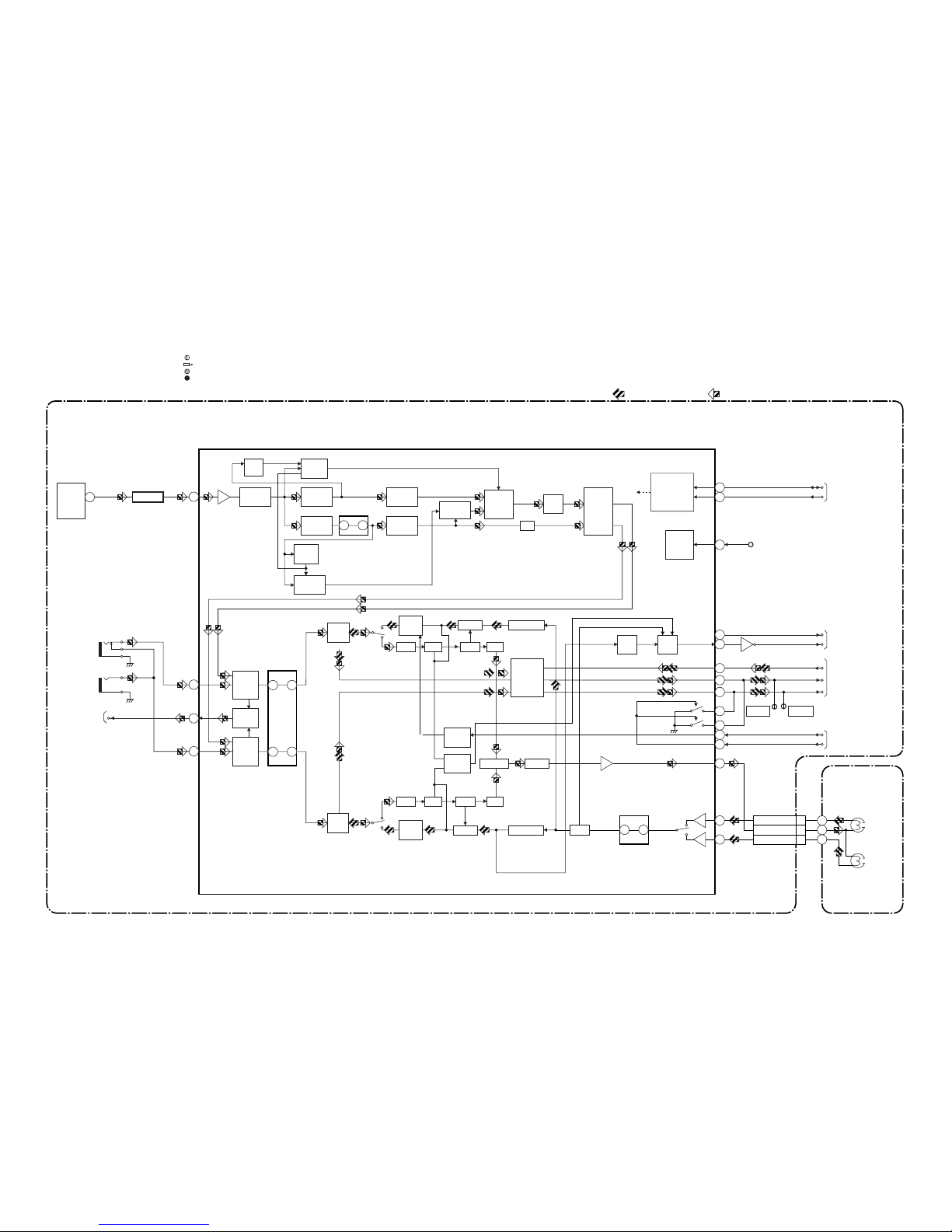

Chroma Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-9

CRT/H.V. Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-11

Power Supply Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-13

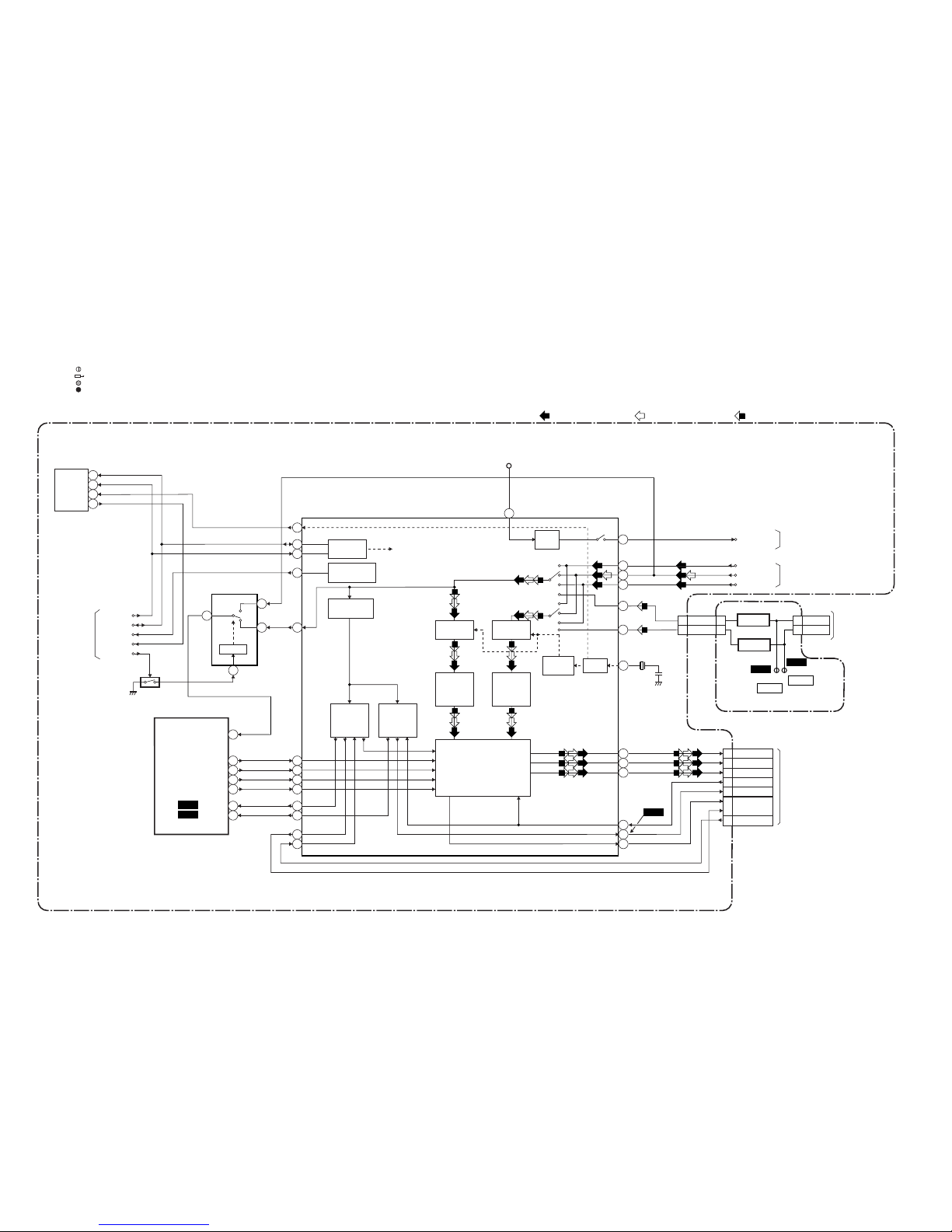

DVD System Control/Servo Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-15

Digital Signal Process Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-17

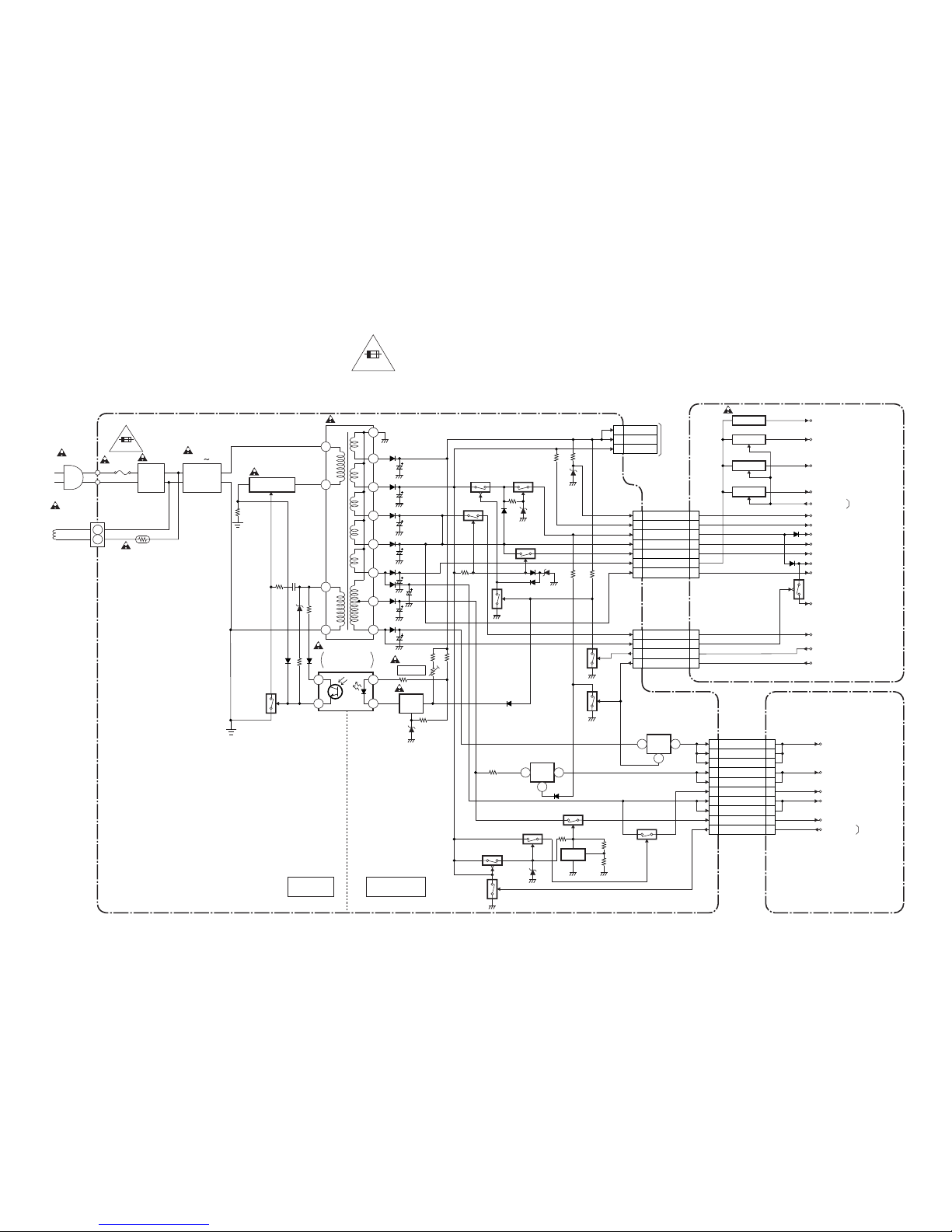

DVD Audio Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-19

SCHEMATIC DIAGRAMS / CBA’S AND TEST POINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

Main 1/5 Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-2

Main 1/5 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-3

Main 2/5 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-5

Main 2/5 Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-7

Main 3/5 Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-8

Main 3/5 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-9

Main 4/5 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-11

Main 4/5 Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-13

Main 5/5 Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-14

Main 5/5 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-15

Main CBA Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-17

Main CBA Top View <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-19

Main CBA Bottom View <TV/VCR SECTION>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-21

Power Supply/AV CBA Top View <TV/VCR SECTION>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-23

Power Supply/AV CBA Bottom View <TV/VCR SECTION>. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-25

Power Supply/AV CBA Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-27

Power Supply/AV 1/2 Schematic Diagram Parts Location Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-29

Power Supply/AV 1/2 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-31

Power Supply/AV 2/2 Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-33

Power Supply/AV 2/2 Schematic Diagram Parts Location Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-35

H.V.Schematic Diagram Parts Location Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-36

H.V. Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-37

Junction A/B CBA Top/Bottom View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-39

H.V. CBA Parts Location Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-40

H.V. CBA Top View <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-41

H.V. CBA Bottom View <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-43

CRT Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-45

Function Schematic Diagram <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-45

CRT CBA Top/Bottom View <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-47

Function CBA Top/Bottom View <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-49

DVD Main 1/3 Schematic Diagram <DVD SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-51

DVD Main 2/3 Schematic Diagram <DVD SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-53

IC101 Voltage Chart. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-55

DVD Main 3/3 Schematic Diagram <DVD SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-57

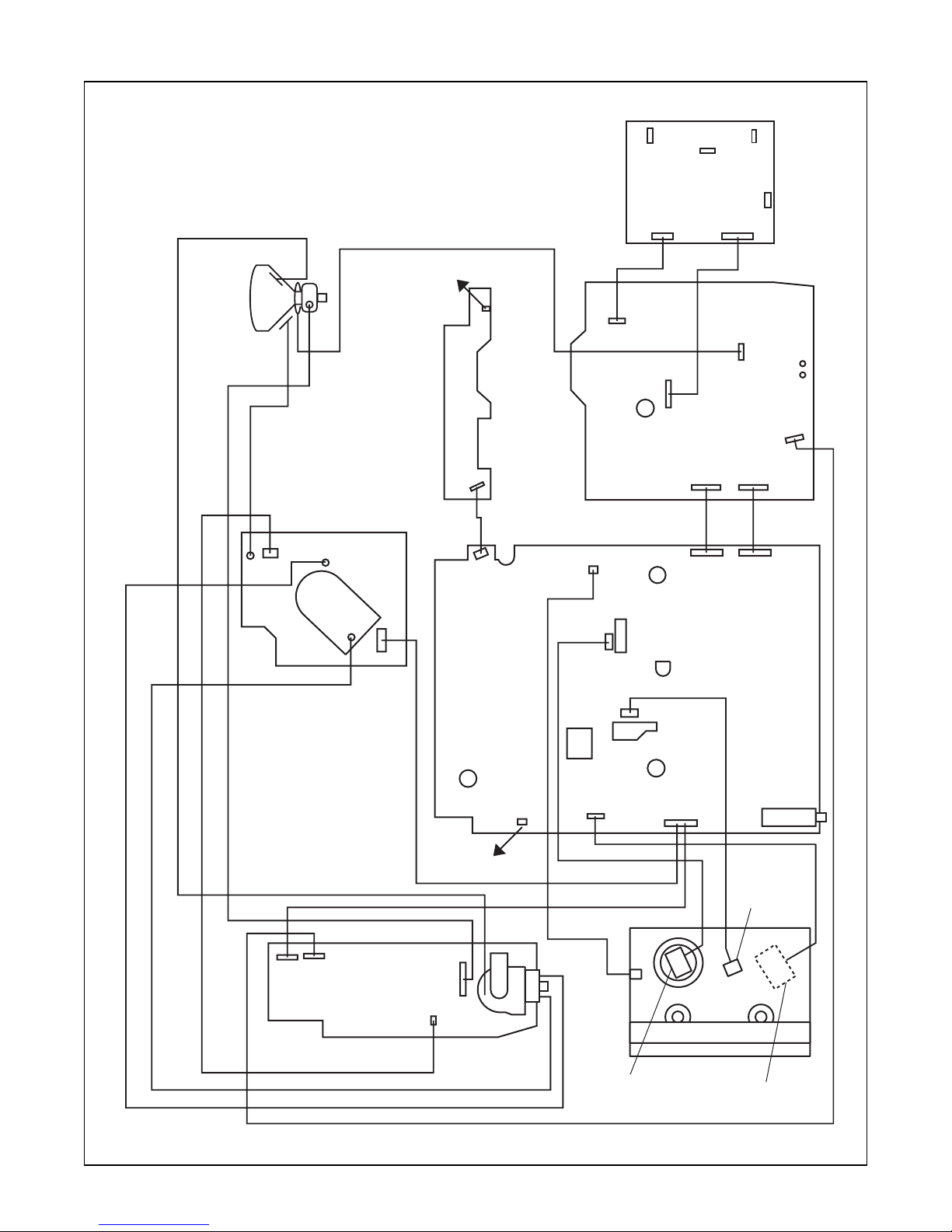

WIRING DIAGRAM <TV/VCR SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

WIRING DIAGRAM <DVD SECTION> . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-3

IC PIN FUNCTION DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

LEAD IDENTIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

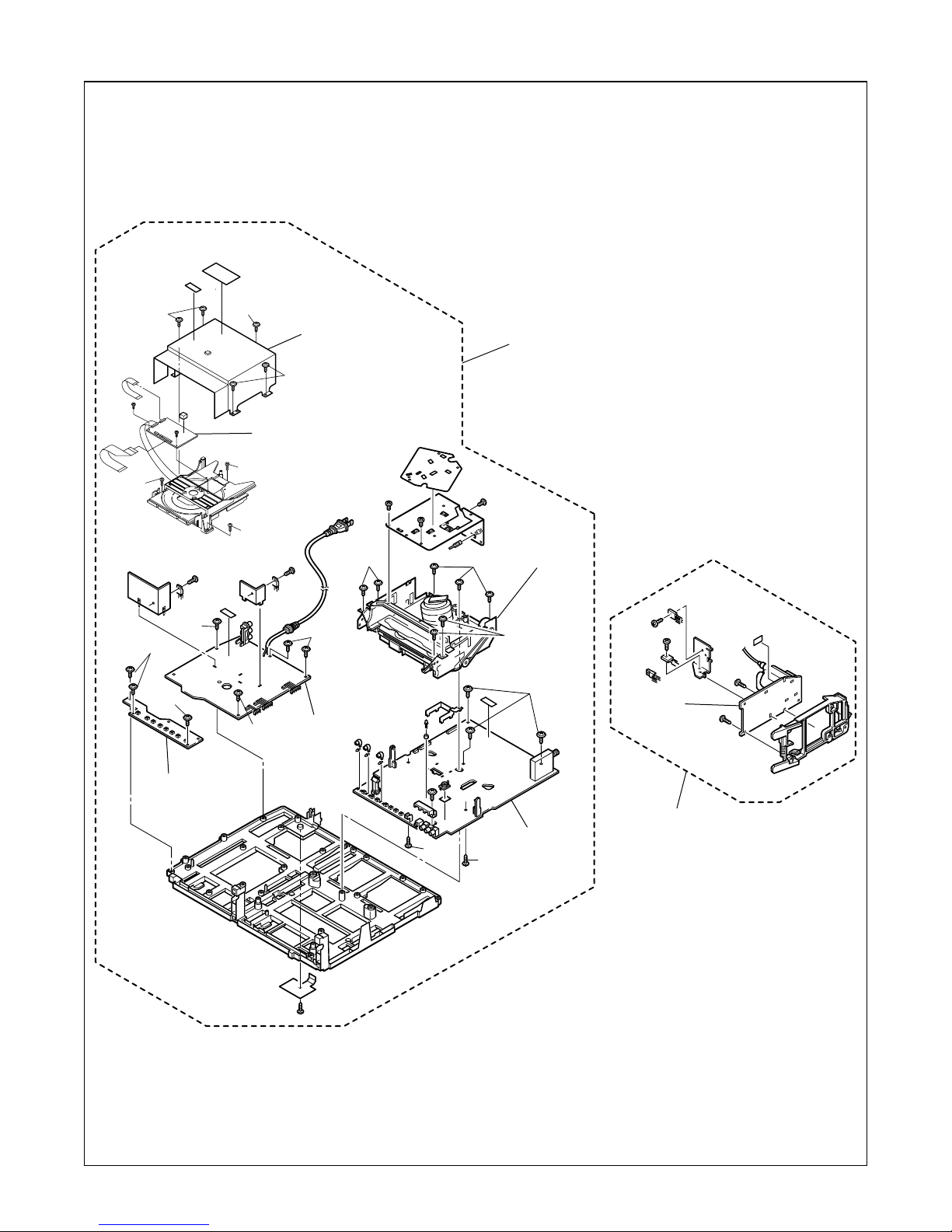

EXPLODED VIEWS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

MECHANICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

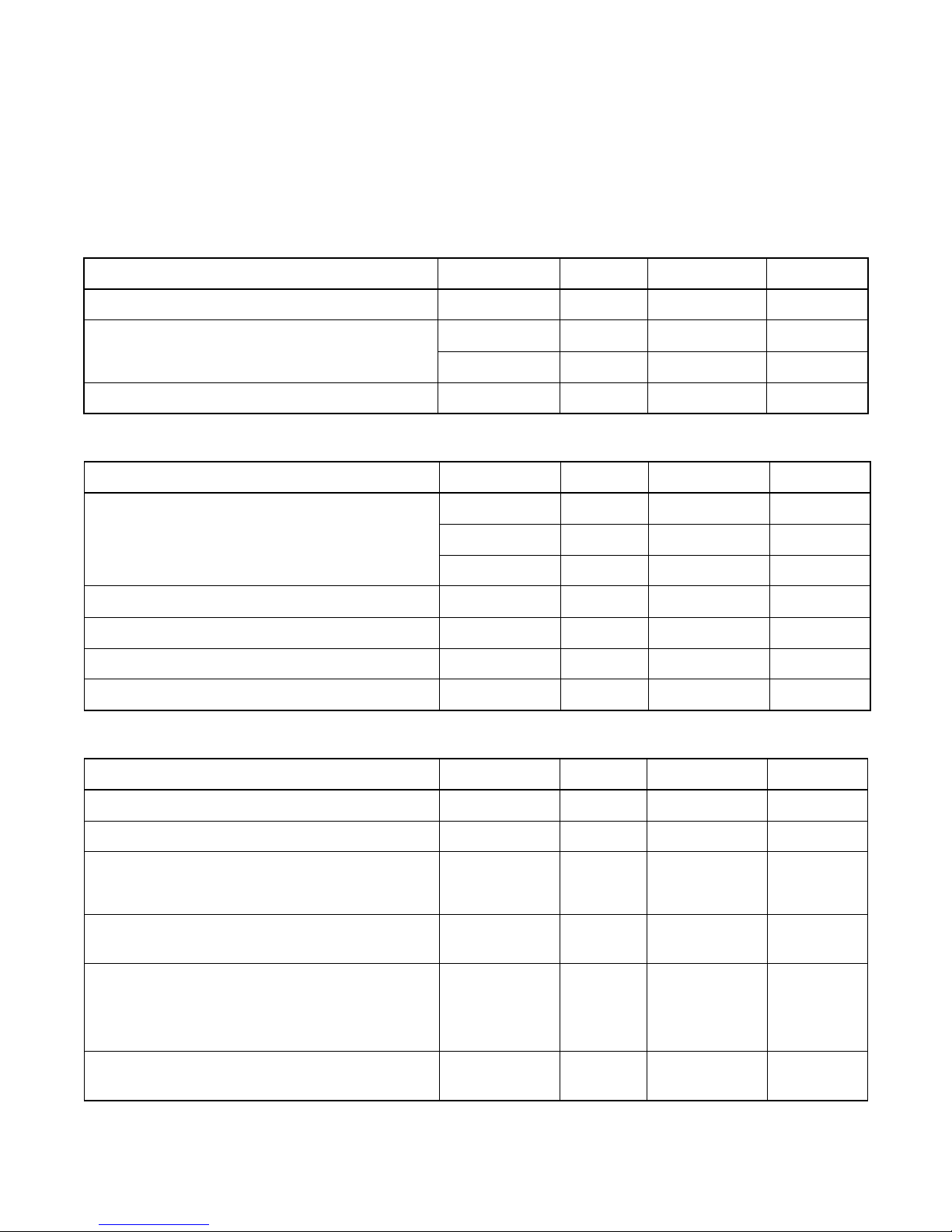

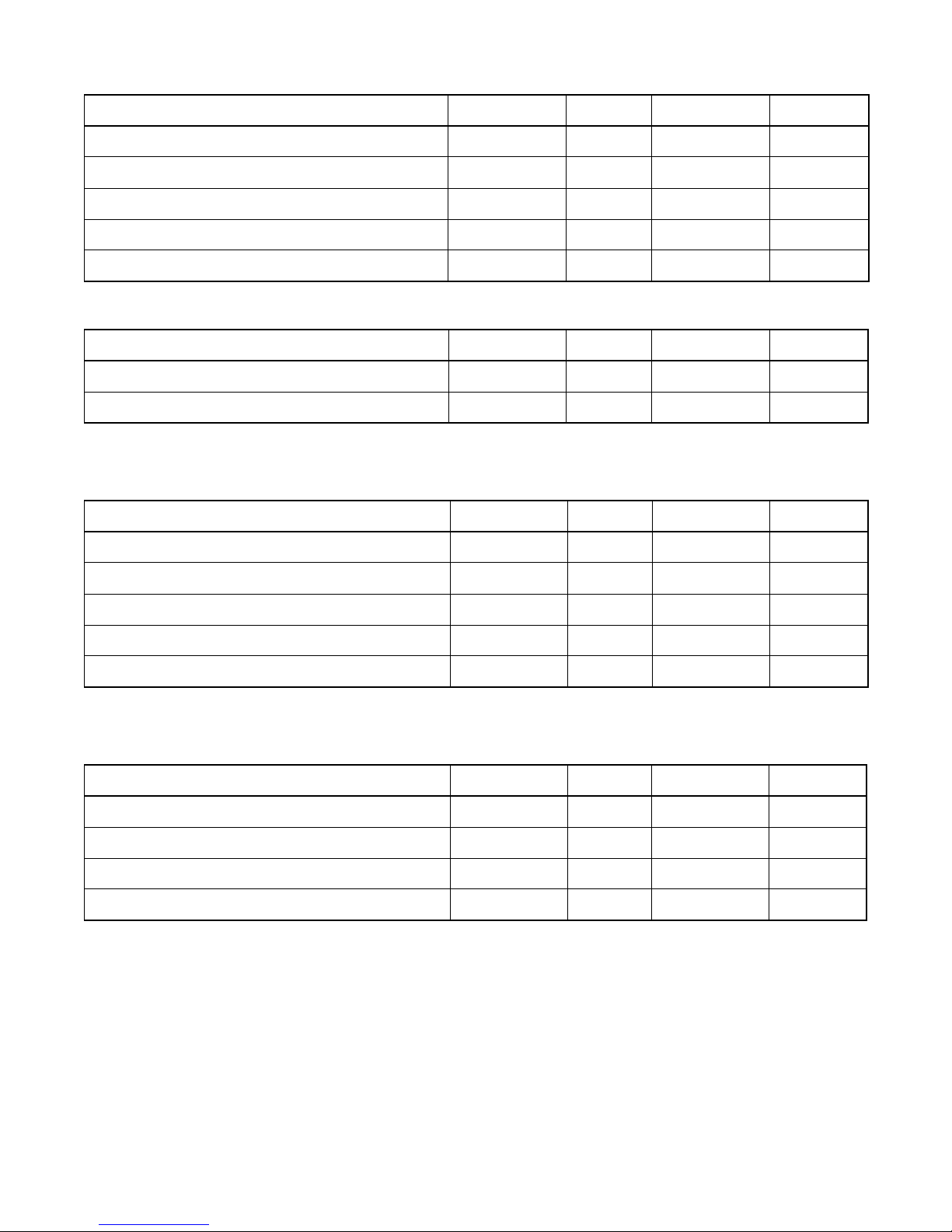

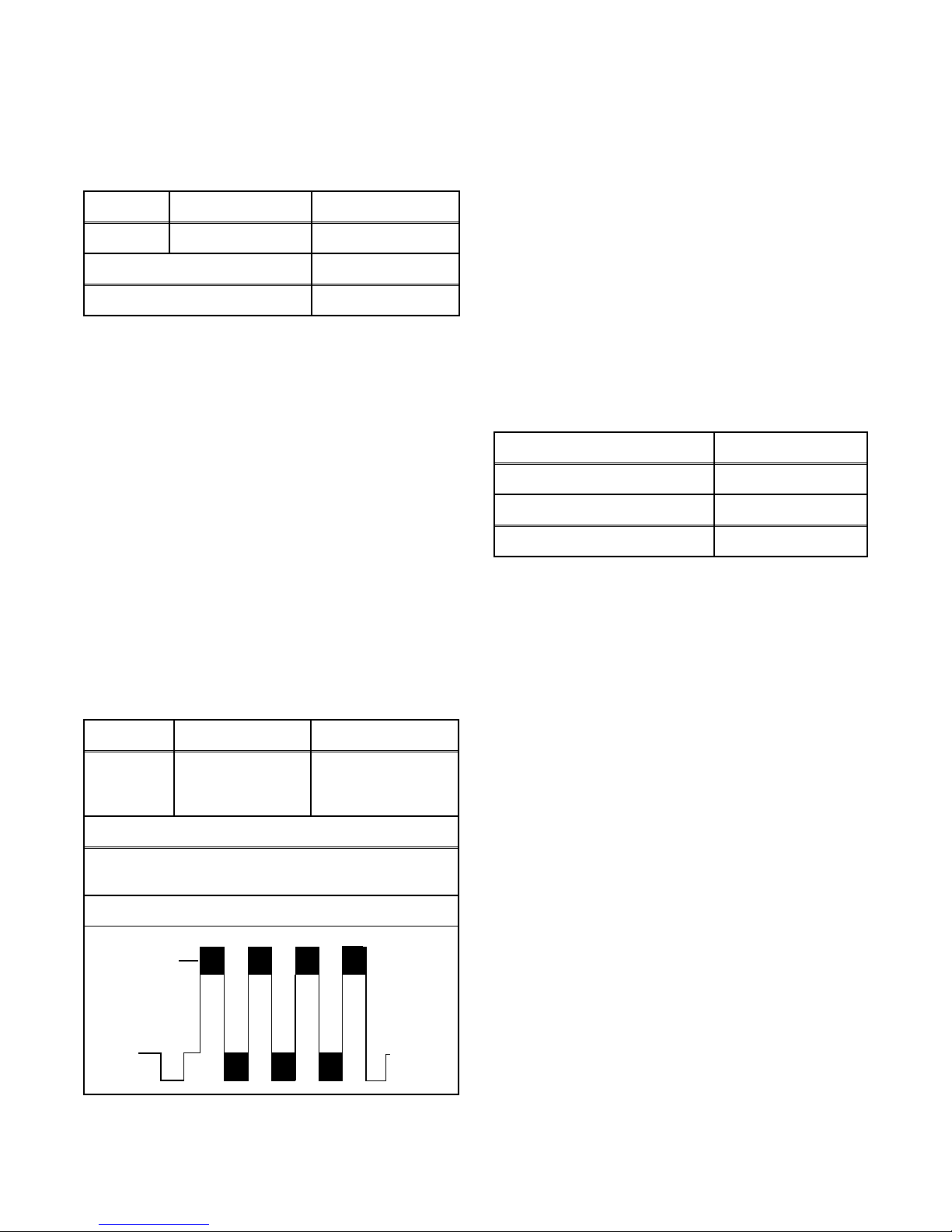

SPECIFICATIONS

*ˆMode---------SP mode unless otherwise specified

*Test input terminal

<Except Tuner>-------------Video input (1Vp-p)

Audio input (-10dB)

<Tuner>-----------------------Ant. input (80dBµV) Video: 87.5%

Audio: 25kHz dev (1kHz Sin)

<DEFLECTION>

Description Condition Unit Nominal Limit

1. Over Scan — % 90 —

2. Linearity

3. High Voltage — kV 25 —

Horizontal % — 15

Vertical % — 10

<VIDEO & CHROMA>

Description Condition Unit Nominal Limit

Center m/m — 0.4

1. Misconvergence

2. Tint Control Range — deg ±30 —

3. Contrast Control Range — dB 6 2

4. Brightness (100% White Full Field) Contrast: Max ft-L 35 24

5. Color Temperature — K 9200 —

Corner m/m — 2.5

Side m/m — 1.5

<DVD>

Description Condition Unit Nominal Limit

1. Horizontal Resolution (TDV-540 TIT.2 CHP.16) — Line 330 320

2. Video S/N at CN3400 (TDV-540 TIT.2 CHP.6) — dB 60 55

3. S/N Chroma at CN3400 AM — dB 58 53

(TDV-540 TIT.2 CHP.17) PM — dB 58 53

4. Audio Distortion (LPCM 48 kHz, W/LPF)

(PTD 1-NOR TIT.1 CHP.1)

5. Audio freq. response (LPCM 48kHz)

(PTD 1-NOR TIT.1 CHP.5 -- 10)

6. Audio S/N (LPCM 48KHz,W/LPF,A-WTD)

(PTD 1-NOR TIT.1 CHP.1 -- 2)

L

R

L, 20 Hz

R, 20 Hz

L, 20 kHz

R, 20 kHz

L

R

1-1-1 TD851SP

%

dB 0 +4/-5

dB 85 75

0.03

0.03

0.07

0.07

<VCR>

Description Condition Unit Nominal Limit

1. Horizontal Resolution (R/P, SP) Line 230 200

2. Jitter (Low) (R/P, SP) µS0.1 0.2

3. S/N Chroma AM(SP) (R/P, SP) dB 38 33

PM(SP) (R/P, SP) dB 38 33

4. Wow & Flutter (JIS, UNWTD) (R/P, SP) % 0.25 0.5

<TUNER>

Description Condition Unit Nominal Limit

1. Video S/N (80dBµV, TV4ch) — dB 45 40

2. Audio S/N (W/LPF) — dB 45 40

<NORMAL AUDIO>

All items are measured across 8Ω resistor at speaker output terminal.

Description Condition Unit Nominal Limit

1. Audio Output Power (R/P, SP) W 1.0 0.8

2. Audio S/N (W/LPF) (R/P, SP) dB 40 36

3. Audio distortion (W/LPF,-10dB 1kHz IN) (R/P, SP) % 3.0 5.0

4. Audio Freq. Response (-10dB 1kHz IN) 200 Hz (R/P, SP) dB -2.0 -2.0±5.0

8 kHz (R/P, SP) dB 0 0±6.0

<Hi-Fi AUDIO>

All items are measured at TP1701 and TP1702.

Description Condition Unit Nominal Limit

1. Output Level (-10dB 1kHz IN) (R/P, SP) dB -8.0 -8±4

2. Audio Distortion (-10dB 1kHz IN) (R/P, SP) % 0.5 1.0

3. Freq. Response (-15dB 1kHz IN) 20 Hz (R/P, SP) dB 0 ±4

20 kHz (R/P, SP) dB 0 ±4

Note: Nominal specifications represent the design specifications. All units should be able to approximate these.

Some will exceed and some may drop slightly below these specifications. Limit specifications represent the absolute worst condition that still might be considered acceptable. In no case should a unit fail to meet limit specifications.

1-1-2 TD851SP

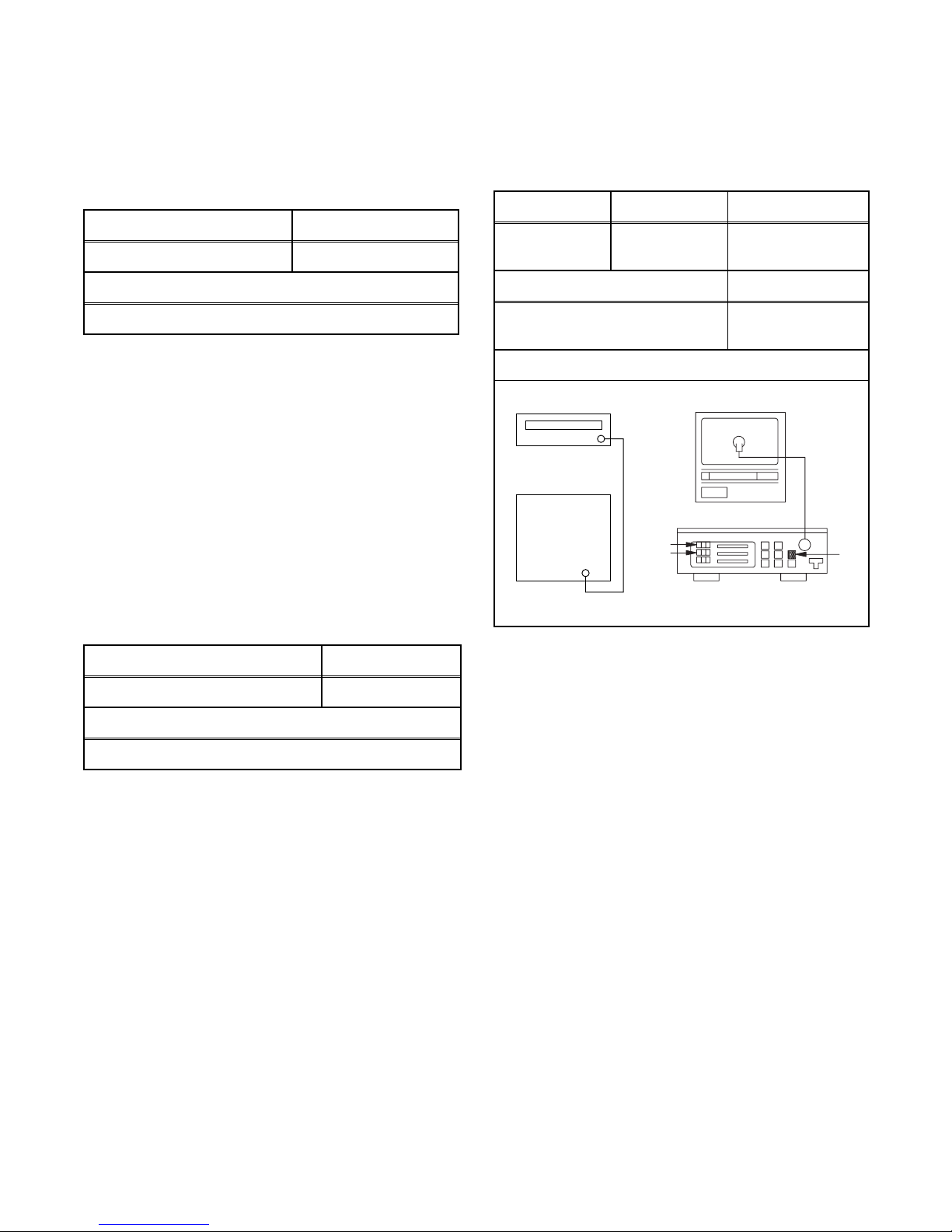

PREPARATION FOR SERVICING

How to Enter the Service Mode

Caution: 1

1. Optical sensors system are used for Tape Start and

End Sensor on this equipment. Read this page

carefully and prepare as described on this page

before starting to service; otherwise, the unit may

operate unexpectedly.

Preparing: 1

1. Cover Q202 (START SENSOR) and Q201 (END

SENSOR) with Insulation Tape or enter the service

mode to activate Sensor Inhibition automatically.

Note: Avoid playing, rewinding or fast forwarding the

tape to its beginning or end, because both Tape End

Sensors are not active.

How to Enter the Service Mode

1. Turn power on.

2. Use service remote control unit and press DISC

MENU key. (See page 1-4-1)

3. When entering the service mode, one of the number (1, 2 or 4) will display at corners of the screen.

4. During the service mode, electrical adjustment

mode can be selected by remote control key. (Service remote control unit).

Details are as follows.

Key Adjustment Mode

8

9

VOL p Cut-off Adjustment 1-4-3.

Caution: 2

1. The deck mechanism assembly is mounted on the

Main CBA directly, and SW1211 (REC-SAFETY

SW) is mounted on the Main CBA. When deck

mechanism assembly is removed from the Main

CBA due to servicing, this switch can not be operated automatically.

H. Shift adjustment mode: See adjustment instructions page 1-4-3.

V.size/V. shift adjustment: See adjustment instructions pages 1-4-2 and

1-4-3.

Preparing: 2

1. To eject the tape, press the STOP/EJECT button

on the unit (or Remote Control).

2. When you want to record during the Service mode,

press the Rec button while depressing SW1211

(REC-SAFETY SW) on the Main CBA.

Q201

(END SENSOR)

Q202

(START SENSOR)

Key Adjustment Mode

Picture adjustment mode: Press the

MENU button to change from BRT

(Bright), *CNT (Contrast),

MENU

0 No need to use.

1 No need to use.

2

3 No need to use.

4

5

6 No need to use.

7

*COL(Color), *TNT(Tint) and *V-T.

Press CH UP/DOWN key to adjust Initial Value. *Marked items are not necessary to adjust normally.

H adjustment mode: See adjustment

instructions page 1-4-2.

Auto record mode: Perform recording

(15 Sec.)-->Stop-->Rewind (Zero

return) automatically.

Head switching point adjustment

mode: See adjustment instructions

page 1-4-5.

Purity check mode: Shows Red,

Green, Blue or White cyclically on the

screen each time the “7” key is

pressed.

SW1211

(REC-SAFETY SW)

MAIN CBA

1-2-1 TD857PFS

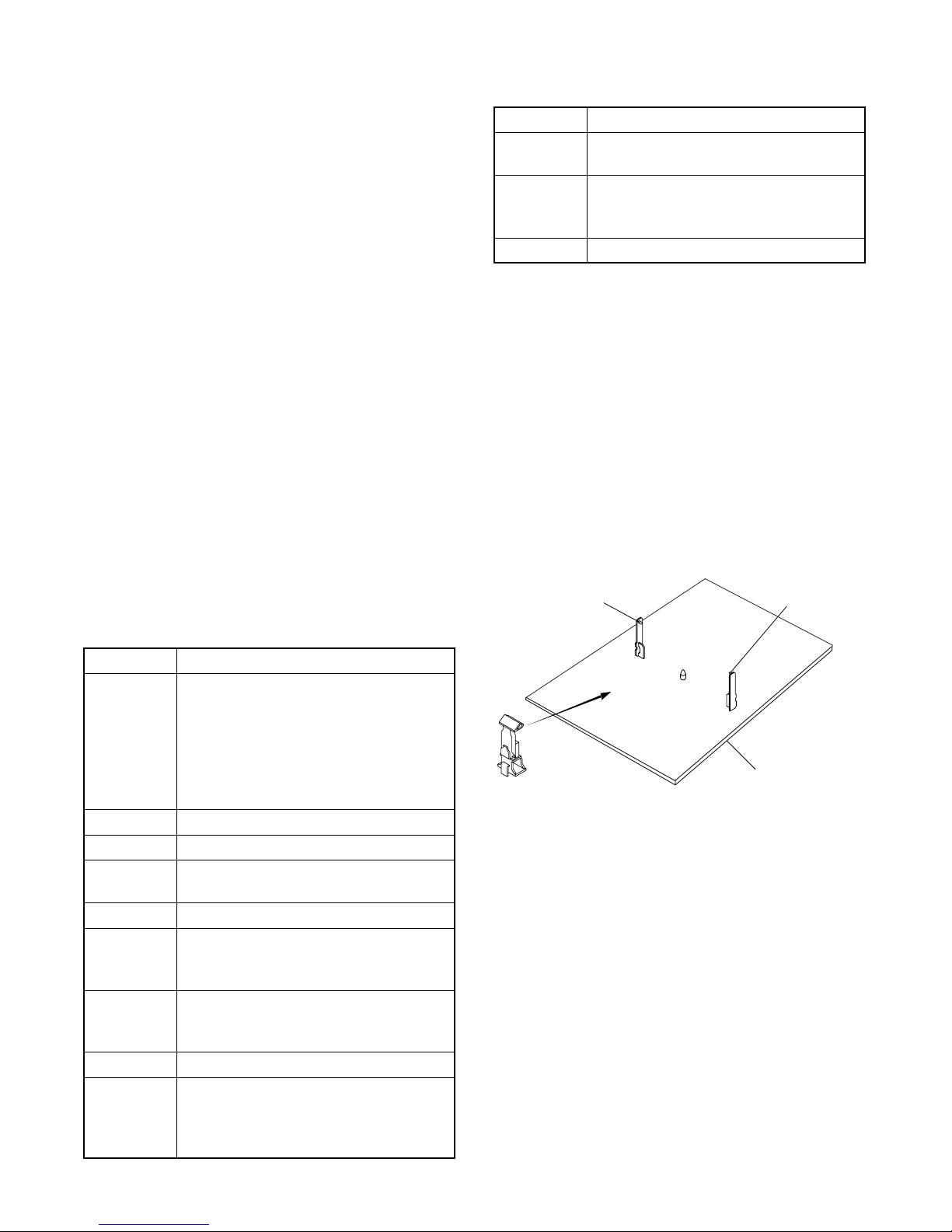

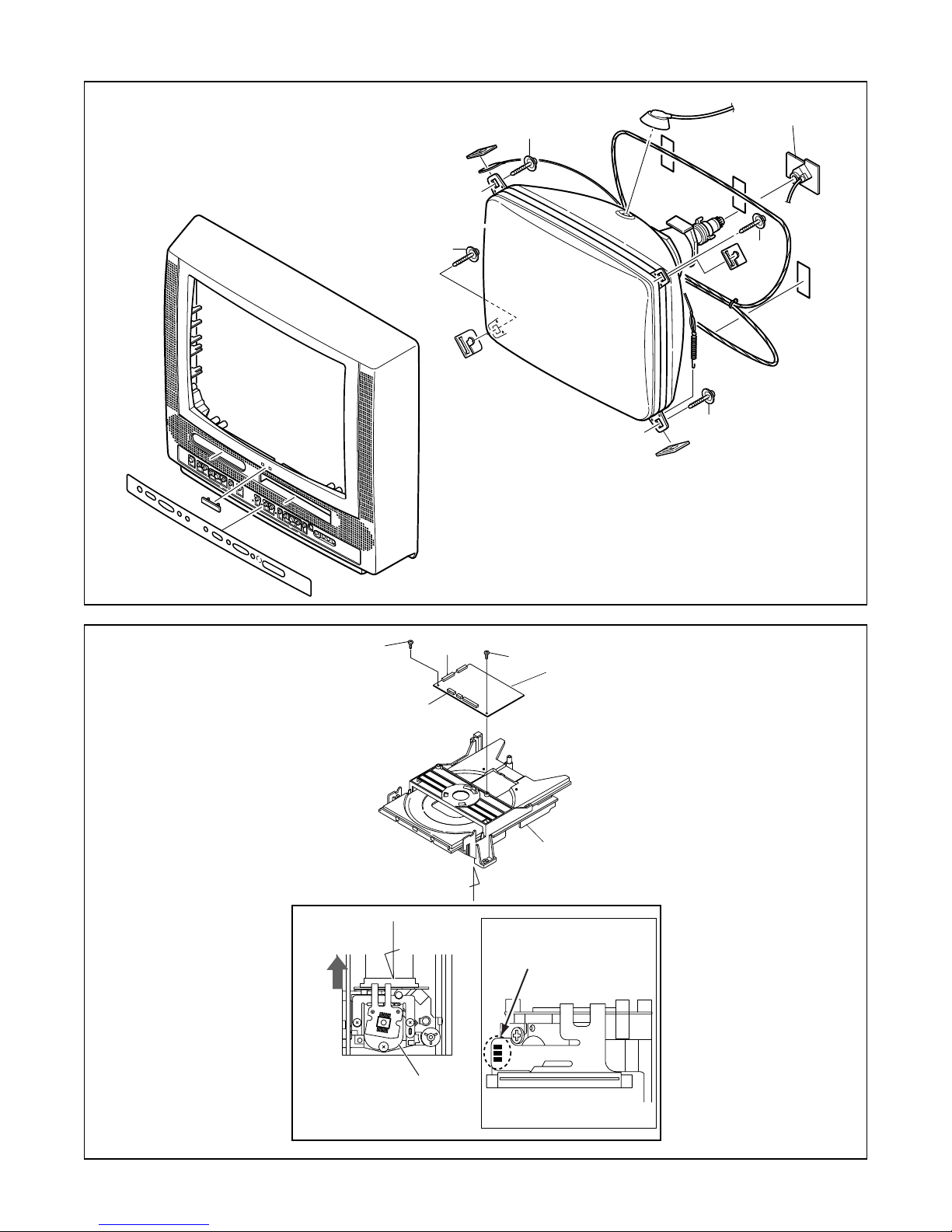

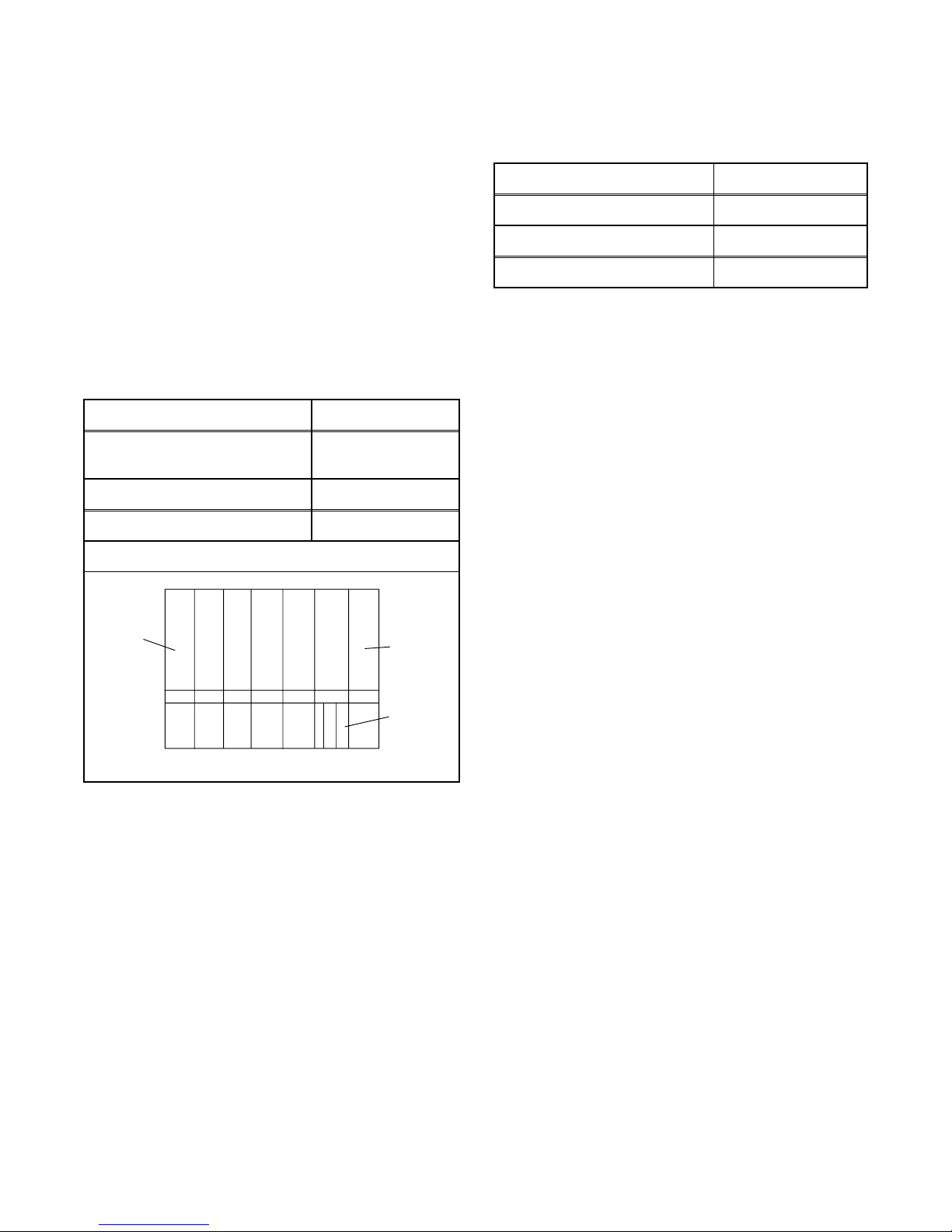

CABINET DISASSEMBLY INSTRUCTIONS

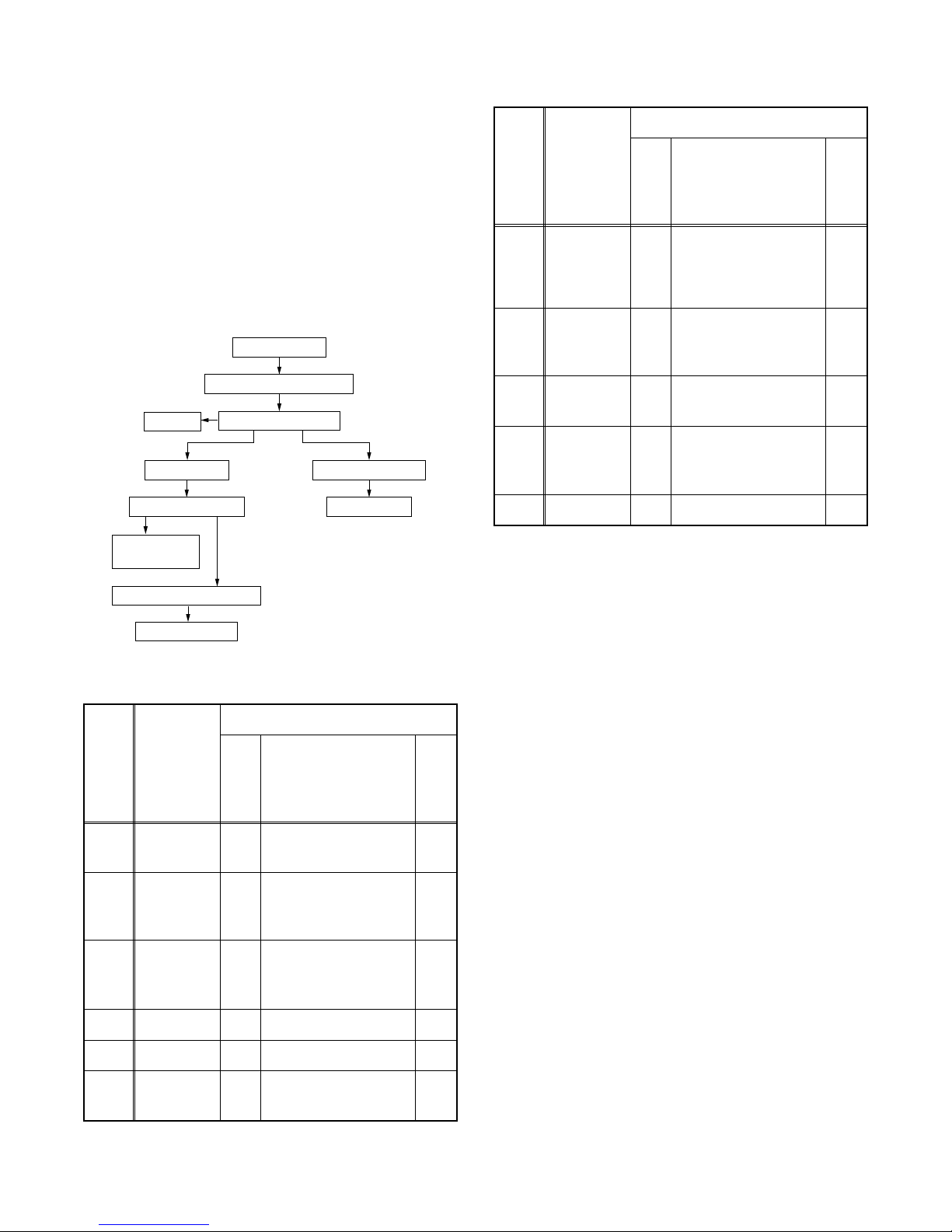

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

Caution !

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

[1] Rear Cabinet

[2] H.V. CBA (with Holder)

[4] CRT

[5] Shield Box

[6] DVD Mechanism

[7] DVD Main

CBA Unit

[3] Tray Chassis Unit

[10] Deck Assembly

[11] Main CBA

REMOVAL

ID/

LOC.

No.

PAR T

REMOVE/

*UNHOOK/UNLOCK/

Fig.

No.

RELEASE/UNPLUG/

DESOLDER

[7]

[8]

[9]

[10]

DVD Main

CBA Unit

Power

Supply/AV

CBA

Function

CBA

Deck

Assembly

2(S-7), CN201,

5

CN301

4(S-8), CN2803,

3, 6

CN2804

3 3(S-9) -

7(S-10), 2(S-11),

3, 6

CL1201, CL1401,

CL1402, CL1403

[11] Main CBA 3 3(S-12) -

↓

(1)

↓

(2)

↓

(3)

↓

(4)

Note

2-1

2-2

2-3

3

-

4

↓

(5)

[8] Power Supply/AV CBA

[9] Function CBA

2. Disassembly Method

REMOVAL

ID/

LOC.

PART

No.

Rear

[1]

Cabinet

H.V. CBA

[2]

(With

Holder)

Tr ay

[3]

Chassis

Unit

[4] CRT 4 4(S-4) -

REMOVE/

*UNHOOK/UNLOCK/

Fig.

No.

RELEASE/UNPLUG/

DESOLDER

1, 2 6(S-1), 1(S-2), 1(S-3) -

Anode Cap, CN501,

3, 4,

CRT CBA, CN571,

6

CN1301, CN2602

CN1802, CN2801,

3, 6

CN2601

Note

1

-

(1): Order of steps in Procedure. When reassembling,

follow the steps in reverse order.These numbers

are also used as the Identification (location) No. of

parts in Figures.

(2): Parts to be removed or installed.

(3): Fig. No. showing Procedure of Part Location.

(4): Identification of part to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

S=Screw, P=Spring, L=Locking Tab, CN=Connec-

tor, *=Unhook, Unlock, Release, Unplug, or

Desolder

2(S-2) = two Screw (S-2)

(5): Refer to the following "Reference Notes in the

Table."

[5] Shield Box 3 5(S-5) -

DVD

[6]

Mechanism

CN2401, CN2402,

3, 6

3(S-6)

-

1-3-1 TD857DC

Reference Notes in the Table

Caution !

When removing the CRT, be sure to discharge the

Anode Lead of the CRT with the CRT Ground Wire

before removing the Anode Cap.

Reference Notes in the Table

CAUTION 1: Discharge the Anode Lead of the CRT

with the CRT Ground Wire before removing the Anode

Cap.

1. Disconnect the following: Anode Cap, CN501, CRT

CBA, CN571, CN2602, and CN1301.

Then remove H.V. CBA (with Holder).

CAUTION 2: Electrostatic breakdown of the laser

diode in the optical system block may occur as a

potential difference caused by electrostatic charge

accumulated on cloth, human body etc., during

unpacking or repair work.

To avoid damage of pickup follow these procedures.

2-1. Slide out the pickup unit as shown in Fig. 5.

2-2. Short the three short lands of FPC cable with sol-

der before removing the FFC cable (CN201) from

it. If you disconnect the FFC cable (CN201), the

laser diode of pickup will be destroyed. (Fig. 5)

2-3. Disconnect connector (CN301). Remove two

screws (S-7) and lift the DVD Main CBA Unit.

(Fig. 5)

CAUTION 3: When reassembling, confirm the FFC

cable (CN201) is connected completely. Then remove

the solder from the three short lands of FPC cable.

(Fig. 5)

4. Remove screws 7(S-10) and 2(S-11). Then, desolder connectors (CL1201, C1401, CL1402, CL1403)

and lift up the Deck Assembly.

1-3-2 TD857DC

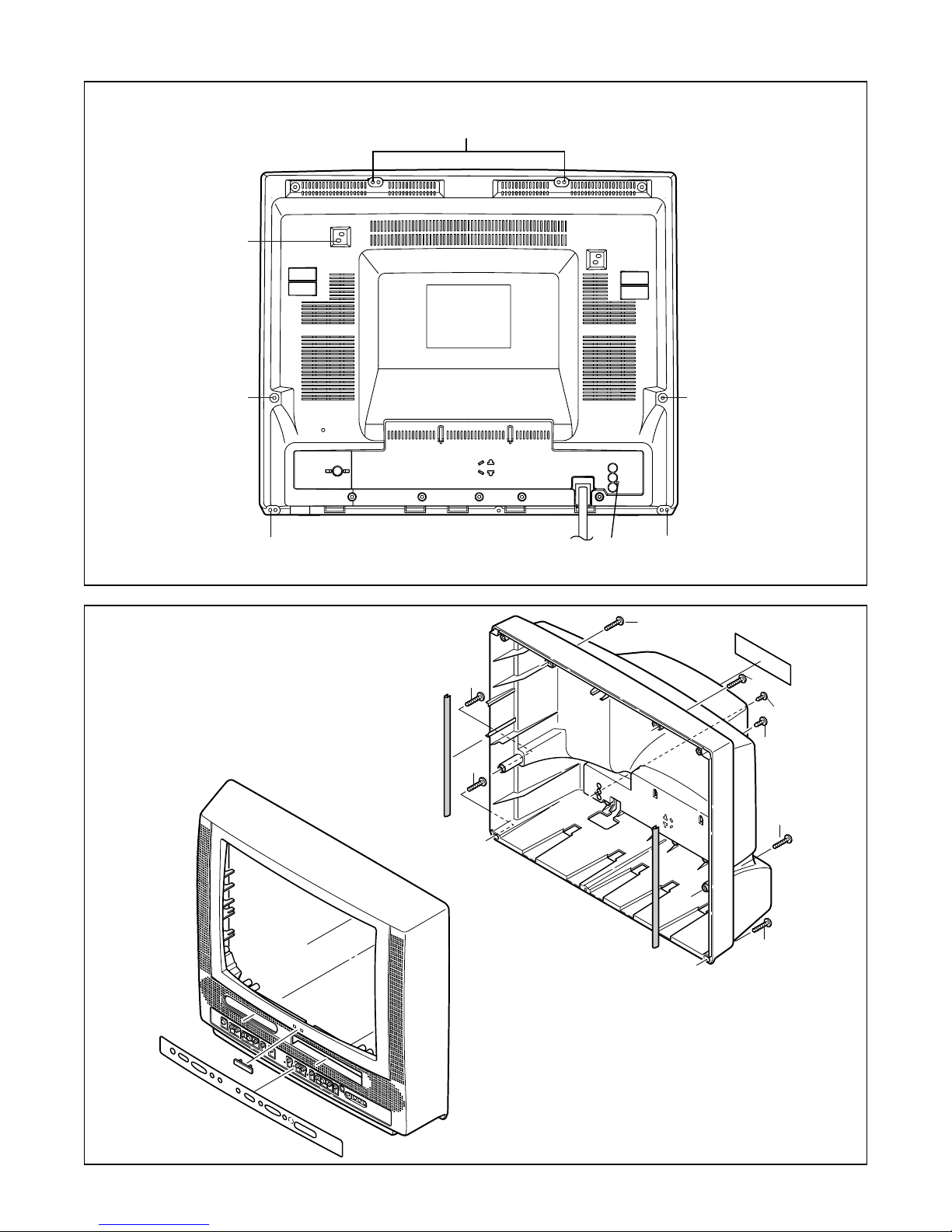

S-2

S-1

[1] REAR CABINET

S-1

S-1

S-1

S-1

S-3

S-1

S-1

Fig. 1

S-1

S-1

S-3

S-2

S-1

S-1

[1] REAR CABINET

Fig. 2

1-3-3 TD857DC

S-6

S-5

S-5

[5] Shield Box

[3] Tray Chassis Unit

S-5

[6] DVD

Mechanism

S-6

S-8

S-9

S-9

[9] Function

CBA

S-6

S-8

S-8

[8] Power

Supply/

AV CBA

S-10

S-11

S-10

S-11

[10] Deck

Assembly

S-10

S-12

[11] Main

CBA

H.V. CBA

[2] H.V. CBA

(wih Holder)

Fig. 3

1-3-4 TD857DC

S-4

Anode Cap

CRT CBA

S-7

CN301

S-4

CN201

[4] CRT

S-7

[7] DVD Main

CBA Unit

S-4

S-4

Fig. 4

Slide

B

Pickup Unit

View for A

DVD Mechanism

A

Short the three short

lands by soldering

View for B

Fig. 5

1-3-5 TD857DC

DVD MAIN CBA

FACTORY USE

ONLY

ANODE

CRT

GND

CL501

CN501

FUNCTION CBA

CRT CBA

SCREEN

FOCUS

CL504A

TO SPEAKER

CN2801

CN2805

CN1805

CN2401

MAIN CBA

CL1403

CL1401

CN601

CN2402

CN401

CN2601

AC CORD

POWER SUPPLY/

AV CBA

CN2803

CN1804

CN2602

CN2804

CN1803

CL503A

CL502A

CL501A

H.V. CBA

TO SPEAKER

CN571

CN1802

CL1201

FE HEAD

CYLINDER

ASSEMBLY

CL1402

CN1301

AC HEAD

ASSEMBLY

DECK ASSEMBLY

CAPSTAN

MOTOR

TUNER

Fig. 6

1-3-6 TD857DC

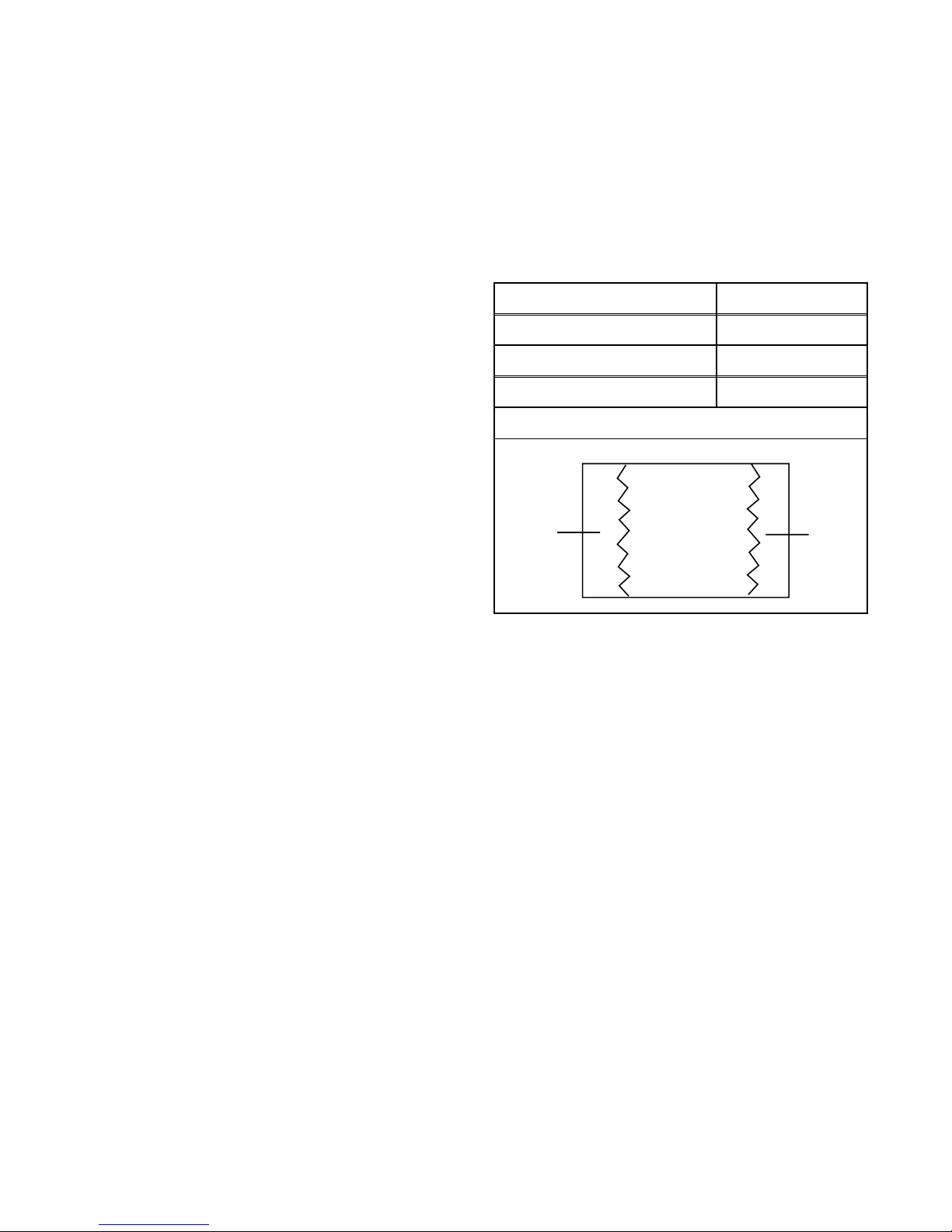

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note:

"CBA" is abbreviation for "Circuit Board

Assembly."

NOTE:

Electrical adjustments are required after replacing

circuit components and certain mechanical parts.

It is important to perform these adjustments only

after all repairs and replacements have been completed.

Also, do not attempt these adjustments unless the

proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator (Color Bar W/White Window, Red Color, Dot Pattern, Gray Scale, Monoscope, Multi-Burst)

2. AC Milli Voltmeter (RMS)

3. Alignment Tape (VFMS0001H6), Blank Tape

4. DC Voltmeter

5. Oscilloscope: Dual-trace with 10:1 probe,

V-Range: 0.001~50V/Div,

F-Range: DC~AC-60MHz

6. Frequency Counter

7. Plastic Tip Driver

8. Color Analyzer

How to make service remote control

unit:

1. Prepare remote control unit (ID No. NE206UD, Part

No. 4835 218 37345). Remove 4 screws from the

back lid (Fig. 1-1).

SCREW

How to Set Up the Service Mode:

1. Turn the power on. (Use main power on the TV

unit.)

2. To enter the TV mode, press "CH o" or "CH p"

button on the TV unit.

3. Press "DISC MENU" button on the service remote

control unit. (Version of micro computer will display

on the CRT. (Ex: 057-001)

X-Ray Protection Test

X-Ray protection test should be done when replacing

any parts of this chassis.

1. Short test points J551 and J552 (on H.V. CBA).

2. Confirm that the main power turns off.

3. If the main power does not turn off, then replace

the following parts (D591, Q591, R592, R593,

R594 and IC1201).

4. Perform steps 1 to 3 again.

1. DC 114V (+B) Adjustment

Purpose: To obtain correct operation.

Symptom of Misadjustment: The picture is dark and

unit does not operate correctly.

Test Point Adj. Point

J553(+B)

HEAT SINK (on H.V. CBA)

(GND)

M. EQ. Spec.

DC Voltmeter +114±0.5V DC

Notes: J553(+B), HEAT SINK --- H.V. CBA

VR2601 --- Power Supply/AV CBA

1. Connect the unit to AC power outlet.

2. Connect DC Volt Meter to J553(+B) and HEAT

SINK (on H.V. CBA) (GND).

3. Adjust VR2601 so that the voltage of J553(+B)

becomes +114±0.5V DC.

VR2601

Remote control unit (Bottom)

2. Cut off pin 10 of the remote control microprocessor

and short circuit pins 10 and 17 of the microprocessor with a jumper wire.

Fig. 1-1

1-4-1 TD857EA

2. H Adjustment

Purpose: To get correct horizontal position and size of

screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Test Point Adj. Point Mode

R583 CH o / p buttons Video

M. EQ. Spec.

1. Connect Oscilloscope to D1304 (Cathode).

2. Input a color bar signal from RF input.

Enter the Service mode. (See page 1-4-1.)

3. Press "0" button on the service remote control unit

and select C-TRAP Mode.

4. Press CH o / p buttons on the service remote

control unit so that the carrier leakage B-Out

(3.58MHz) value becomes minimum on the oscilloscope.

5. Turn the power off and on again.

Frequency Counter 15.734kHz±300Hz

Note: R583 --- H.V. CBA

1. Connect frequency counter to R583.

2. Operate the unit for at least 20 minutes.

3. Enter the Service mode. (See page 1-4-1.) Press

"2" button on the service remote control unit and

select H-ADJ mode.

4. Press "CH o / p" buttons on the service remote

control unit so that the display will change "0" to

"7." At this moment, choose display "0" to "7" when

the frequency counter display is closest to

15.734kHz±300Hz.

5. Turn the power off and on again.

3. C-Trap Adjustment

Purpose: To get minimum leakage of the color signal

carrier.

Symptom of Misadjustment: If C-Trap Adjustment is

incorrect, stripes will appear on the screen.

Test Point Adj. Point Input

4. V. Size Adjustment

Purpose: To obtain correct vertical height of screen

image.

Symptom of Misadjustment: If V. Size is incorrect,

vertical height of image on the screen may not be

properly displayed.

Adj. Point Input

CH o / p buttons Monoscope

M. EQ. Spec.

Pattern Generator 90±5%

1. Enter the Service mode. (See page 1-4-1.)

Press "9" button on the service remote control unit

and select V-S mode. (Press "9" button then display will change to V-P and V-S).

2. Input monoscope pattern.

3. Press "CH o / p" buttons on the service remote

control unit so that the monoscope pattern is

90±5% of display size and the circle is round.

D1304

(Cathode)

(B-OUT)

minimum

Note: D1304 (Cathode) (B-Out)--- Main CBA

CH o / p

buttons

M. EQ.

Oscilloscope,

Pattern Generator

Figure

Color Bar

Fig. 2

1-4-2 TD857EA

5. V. Shift Adjustment

7. Cut-off Adjustment

Purpose: To obtain correct vertical position of screen

image.

Symptom of Misadjustment: If V. shift is incorrect,

vertical position of image on the screen may not be

properly displayed.

Adj. Point Input

CH o / p buttons Monoscope

M. EQ.

Pattern Generator

1. Enter the Service mode. (See page 1-4-1.)

Press "9" button on the service remote control unit

and select V-P mode. (Press "9" button then display will change to V-P and V-S).

2. Input monoscope pattern.

3. Press "CH o / p" buttons on the service remote

control unit so that the top and bottom of the monoscope pattern are equal to each other.

6. H. Shift Adjustment

Purpose: To adjust the beam current of R, G, B, and

screen voltage.

Symptom of Misadjustment: White color may be

reddish, greenish or bluish.

Adj. Point Mode Input

Screen-Control Ext.

M. EQ. Spec.

Pattern Generator

Color Analyzer

Figure

PATTERN

GENERATOR

Black Raster /

White Raster

See Reference

Notes below

Purpose: To obtain correct horizontal position and

size of screen image.

Symptom of Misadjustment: Horizontal position and

size of screen image may not be properly displayed.

Adj. Point Input

CH o / p buttons Monoscope

M. EQ.

Pattern Generator

1. Enter the Service mode. (See page 1-4-1.)

Press "8" button on the service remote control unit

and select H-P mode.

2. Input monoscope pattern.

3. Press "CH o / p" buttons on the service remote

control unit so that the left and right side of the

monoscope pattern are equal to each other.

4. Turn the power off and on again.

EXT. INPUT

Color Analyzer

Fig. 3

Notes: Screen Control FBT --- H.V. CBA

FBT= Fly Back Transformer

Use the service remote control unit

1. Degauss the CRT and allow CRT to operate for 20

minutes before starting the alignment.

2. Input the Black raster signal from EXT. input.

3. Enter the Service mode. (See page 1-4-1.)

4. Press the "VOL p" button.

(Press "VOL p" then display will change CUT OFF/

DRIVE, 7Fh adjustment and DVD-KEY).

5. Choose CUT OFF/DRIVE mode then press "1" button. This adjustment mode is CUT OFF (R).

6. Increase the screen control so that the horizontal

line just appears on the CRT.

7. Press the "CH o / p" button until the horizontal line

becomes white.

8. Choose CUT OFF/DRIVE mode then press "2" button. This adjustment mode is CUT OFF (G). Press

"CH o / p" until the horizontal line becomes white.

9. Choose CUT OFF/DRIVE mode then press "3" button. This adjustment mode is CUT OFF (B). Press

"CH o / p" until the horizontal line becomes white.

10.Choose CUT OFF/DRIVE mode then press "4" button.

11.Input the White Raster Signal from Video In.

1-4-3 TD857EA

12.Set the color analyzer to the CHROMA mode and

after zero point calibration, bring the optical receptor to the center on the tube surface (CRT).

13.Adjust the RED DRIVE as needed with the CH o /

p buttons to get the following value, X= 286, Y=

294.

14.Choose CUT OFF/DRIVE mode then press "5."

Adjust the BLUE DRIVE as needed with the CH o /

p buttons to get the following value, X= 286.

15.Turn the power off and on again.

8. Sub-Brightness Adjustment

Purpose: To get proper brightness.

Symptom of Misadjustment: If Sub-Brightness is

incorrect, proper brightness cannot be obtained by

adjusting the Brightness Control.

Adj. Point Input

CH o / p

buttons

M. EQ. Spec.

Pattern Generator See below

Figure

SMPTE 7.5IRE

9. Focus Adjustment

Purpose: Set the optimum Focus.

Symptom of Misadjustment: If Focus Adjustment is

incorrect, blurred images are shown on the display.

Adj. Point Input

Focus Control Monoscope

M. EQ. Spec.

Pattern Generator See below.

Notes: Focus VR (FBT) --- H.V. CBA

FBT= Fly Back Transformer

1. Operate the unit more than 30 minutes.

2. Face the unit to the East and degauss the CRT

using a degaussing coil.

3. Input the monoscope pattern.

4. Adjust the Focus Control on the FBT to obtain a

clear picture.

10. SIF Adjustment

Purpose: To set the SIF (Sound Intermediate Fre-

quency).

Symptom of Misadjustment: Audio may not sound

correctly.

Note: This adjustment automatically done by the

chrominance IC (IC1301).

White

Note: SMPTE Setup level --- 7.5 IRE

1. Enter the Service mode. (See page 1-4-1.)

Then input SMPTE signal from RF input.

2. Press "PICTURE" button. (Press "PICTURE" button then display will change B R T, C N T, COL, T N

T and V-T ). Select BRT and press "CH o / p" buttons so that the bar is just visible (See above figure).

3. Turn the power off and on again.

Black

This bar

just

visible

Fig. 4

11. CCS Text Box Location

Note: This adjustment automatically done by the

microcomputer.

1-4-4 TD857EA

12. Head Switching Position Adjustment

Purpose: Determine the Head Switching Point during

Playback.

Symptom of Misadjustment: May cause Head

Switching Noise or Vertical Jitter in the picture.

Note: Unit reads Head Switching Position automati-

cally and displays it on the screen (Upper Left Corner).

1. Playback test tape (VFMS0001H6).

2. Enter the Service mode. (See page 1-4-1.)

Then press the "5" button on the service remote

control unit.

3. The Head Switching position will display on the

screen; if adjustment is necessary follow step 4.

6.5H(412.7µs) is preferable.

4. Press "CH o" or "CH p" button on the service

remote control unit if necessary. The value will be

changed in 0.5H steps up or down. Adjustable

range is up to 9.5H. If the value is beyond adjustable range, the display will change as:

Lower out of range: 0.0H

Upper out of range: -.-H

5. Turn the power off and on again.

The following 2 adjustments normally are not

attempted in the field. They should be done

only when replacing the CRT, then adjust as a

preparation.

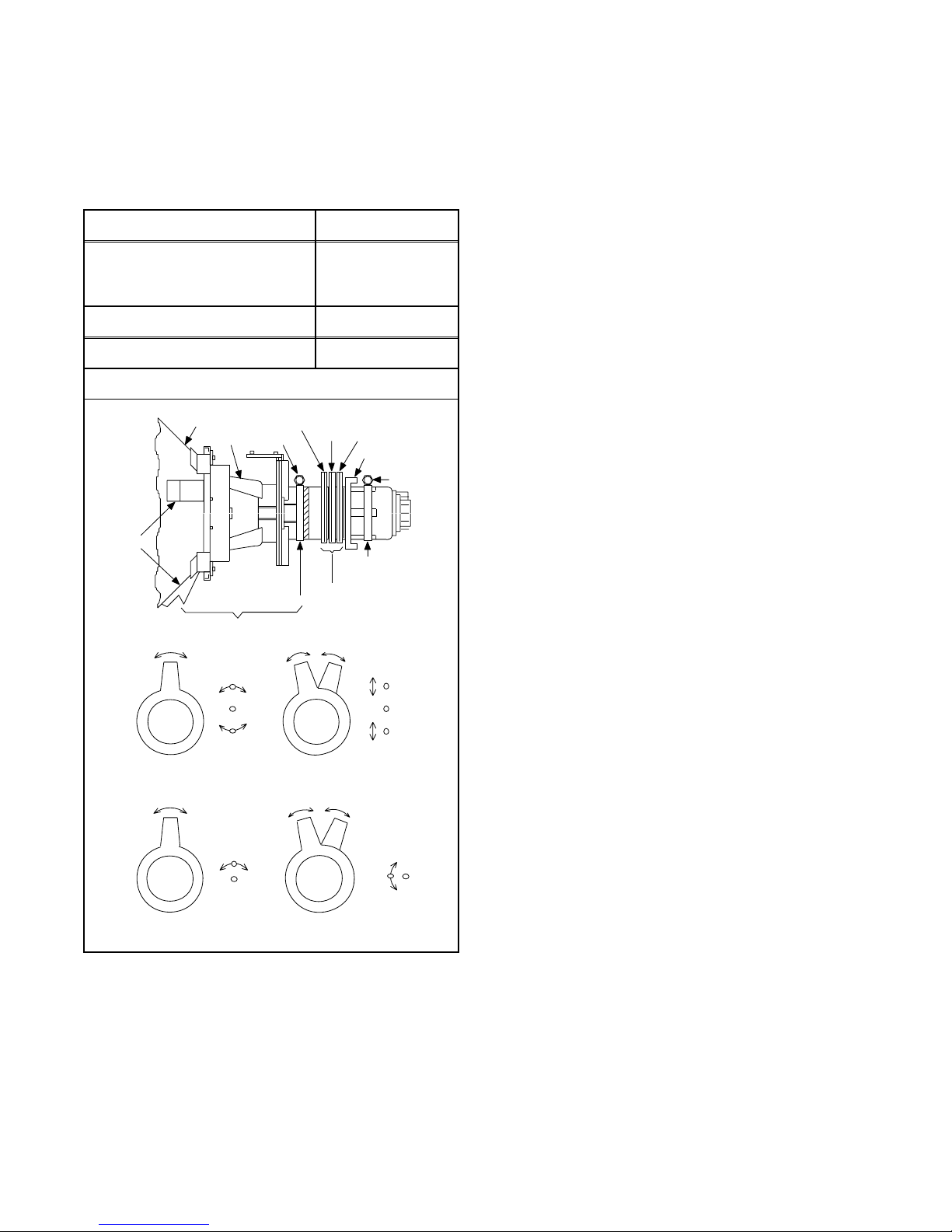

13. Purity Adjustment

Purpose: To obtain pure color.

Symptom of Misadjustment: If Color Purity Adjust-

ment is incorrect, large areas of color may not be

properly displayed.

Adj. Point Input

Deflection Yoke Purity Magnet Red Color

M. EQ. Spec.

Pattern Generator See below.

Figure

GREEN

RED

BLUE

Fig. 5

1. Set the unit facing East.

2. Operate the unit for over 30 minutes before adjusting.

3. Fully degauss the unit using an external degaussing coil.

4. Set the unit to the AUX mode, which is located

before CH2, then input a red raster from video in.

5. Loosen the screw on the Deflection Yoke Clamper

and pull the Deflection Yoke back away from the

screen. (See Fig. 6.)

6. Loosen the Ring Lock and adjust the Purity Magnets so that a red field is obtained at the center of

the screen. Tighten Ring Lock. (See Fig. 5,6.)

7. Slowly push the Deflection Yoke toward the bell of

the CRT and set it where a uniform red field is

obtained.

8. Tighten the clamp screw on the Deflection Yoke.

1-4-5 TD857EA

14. Convergence Adjustment

Purpose: To obtain proper convergence of red, green

and blue beams.

Symptom of Misadjustment: If Convergence Adjust-

ment is incorrect, the edge of white letters may have

color edges.

Adj. Point Input

5. Remove the DY Wedges and slightly tilt the Deflection Yoke horizontally and vertically to obtain the

best overall convergence.

6. Fix the Deflection Yoke by carefully inserting the

DY Wedges between CRT and Deflection Yoke.

C.P. Magnet (RB),

C.P. Magnet (RB-G),

Dot Pattern or

Deflection Yoke

M. EQ. Spec.

Pattern Generator See below.

Figure

CRT

COIL

DY WEDGE

COIL CLAMPER

DEFLECTION YOKE

PURITY

SCREW

RB

C.P. MAGNET

CLAMPER

C.P. MAGNET

C.P. MAGNET (RB)

R

Crosshatch

RB-G

RING LOCK

SCREW

Fig. 6

R

G

B

G

B

Fig. 7

C.P. MAGNET (RB-G)

RB

RB

G

G

Fig. 8

1. Set the unit to the AUX mode which is located

before CH2, then input a dot or crosshatch pattern.

2. Loosen the Ring Lock and align red with blue dots

or crosshatch at the center of the screen by rotating (RB) C.P. Magnets. (See Fig. 7.)

3. Align red / blue with green dots at the center of the

screen by rotating (RB-G) C.P. Magnet.

(See Fig. 8.)

4. Fix the C.P. Magnets by tightening the Ring Lock.

1-4-6 TD857EA

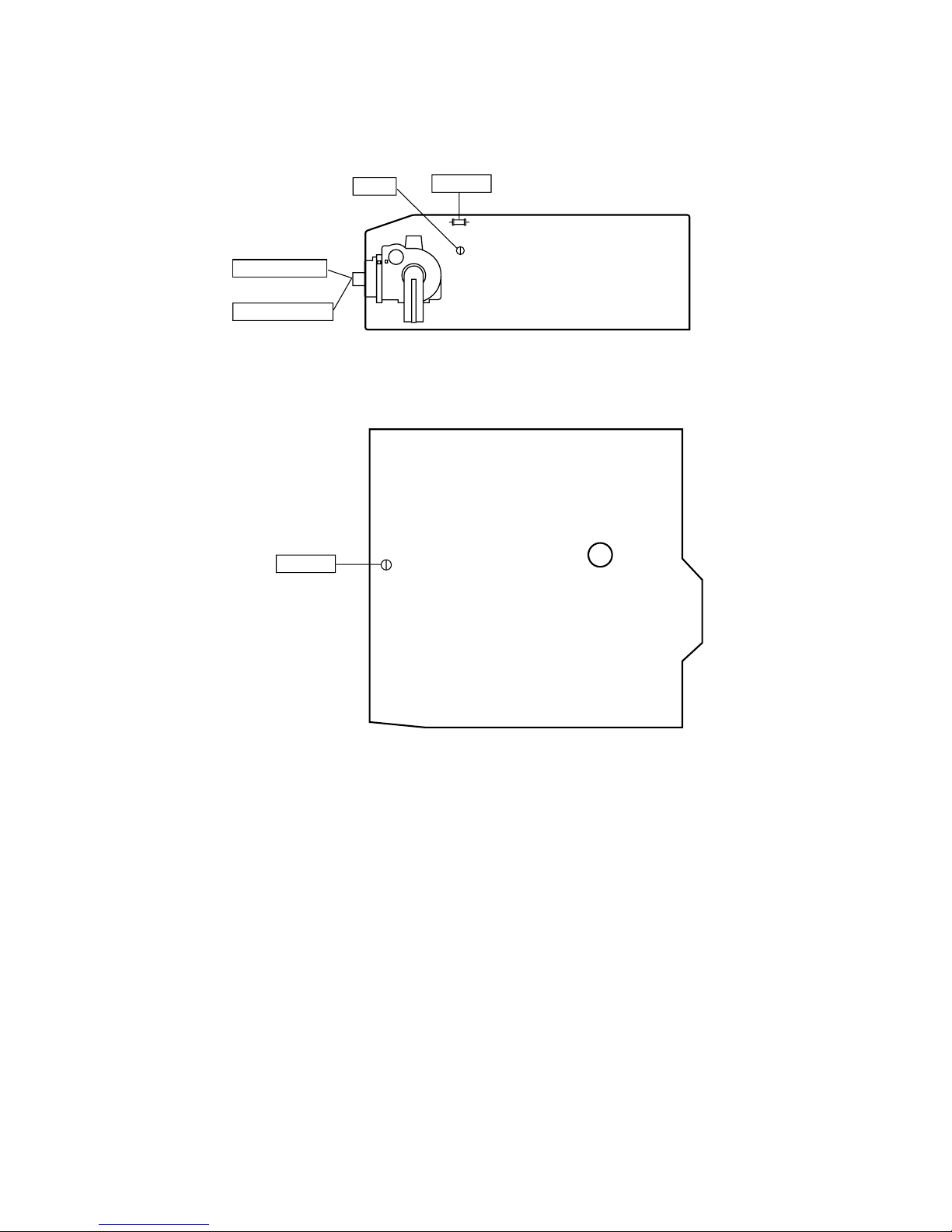

Adjustment Points and Test Points

H.V. CBA

UPPER

FOCUS VR

LOWER

SCREEN VR

VR2601

+B ADJ

J553

+B

R583

H ADJ.

Power Supply/AV CBA

1-4-7 TD857EA

CONTROL

HEAD

CL1402

AC HEAD ASSEMBLY

MAIN CBA

POWER SUPPLY / AV CBA

RF-SW

T-REEL

DV-SYNC

C-SYNC

C-SYNC

V-ENV

CTL(+)

D1224 S-LED

D1204 REC

D1216 DVD

D1217

TV/VCR

Q1210

Q1211

Q1207

P-ON+5V

REC-LED

KEY0

RS1201

REMOTE

SENSOR

KEY1

DVD-H

TV/VCR-LED

RESET

ROTA

D-REC-H

D-REC-H

REC-SAFETY

A-MUTE

SCL

REMOTE

SDA

A-MUTE

CTL(-)

RF-SW

DV-SYNC

V-ENV

ROTA

IC1201

(SERVO/SYSTEM CONTROL)

AL+5V

AL+5V

94

95

80

34

18

15

10

13

74

33

8

44

65

72

CTL-AMP-OUT

DVD-REMOTE

97

CTL-AMP-OUT

TP1201

(DECK ASSEMBLY)

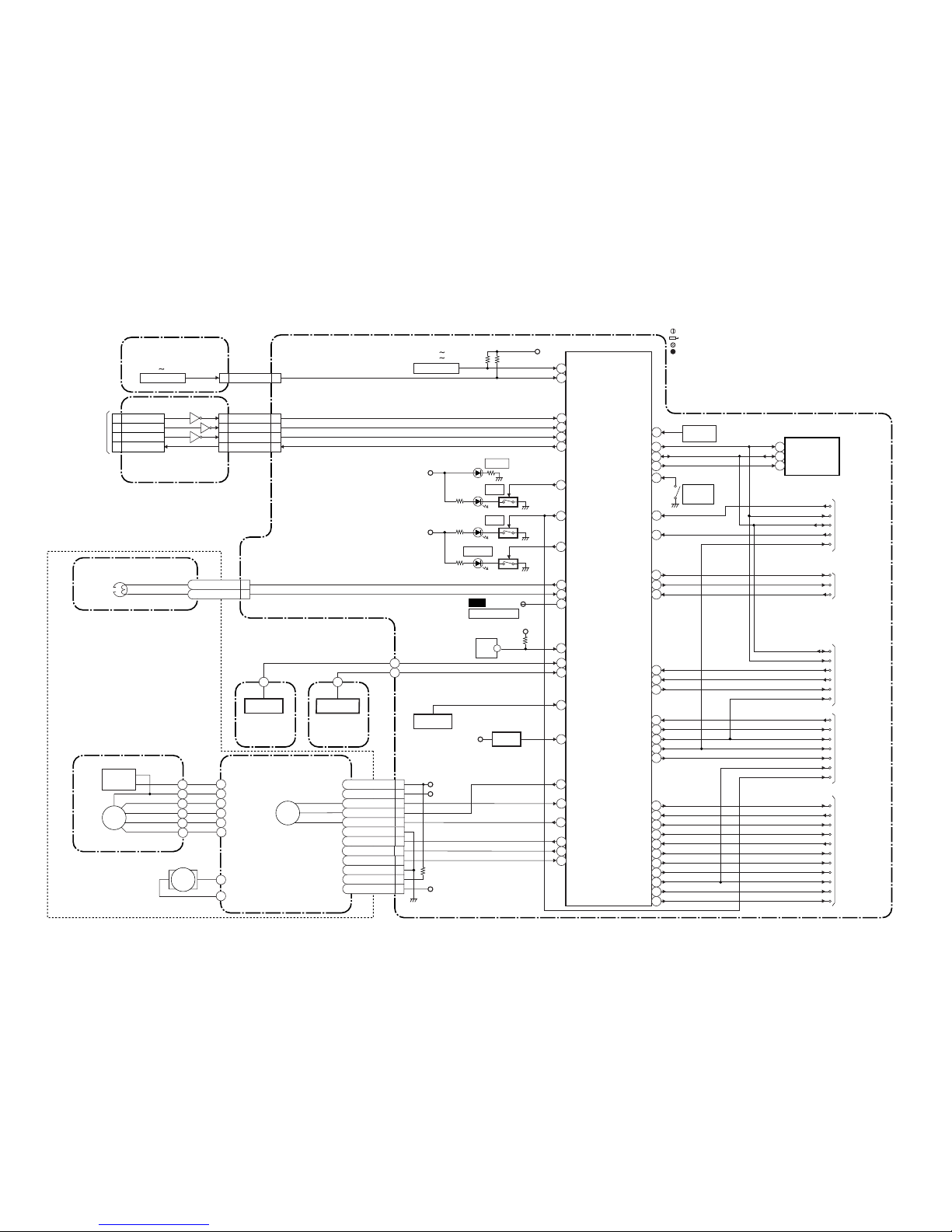

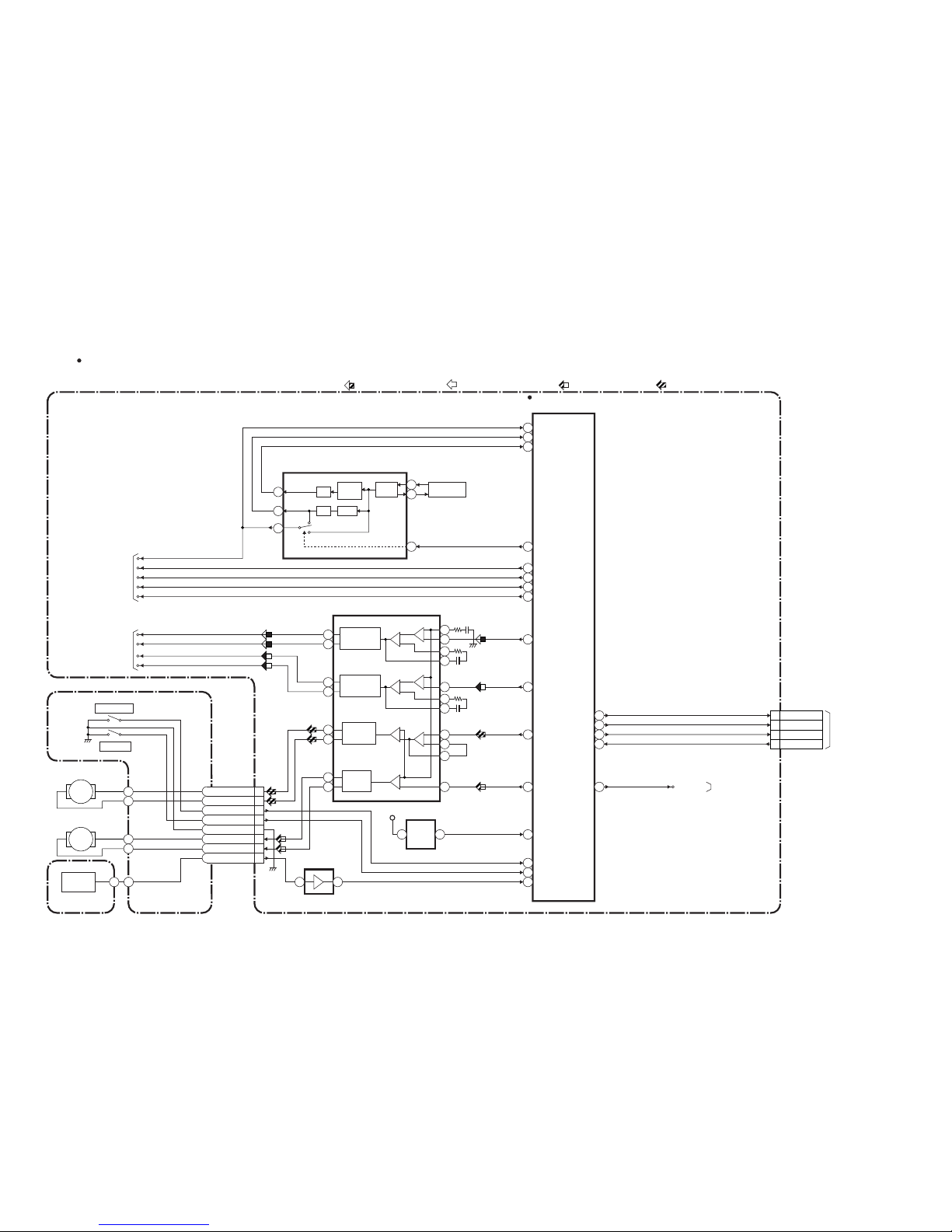

Servo/System Control Block Diagram

BLOCK DIAGRAMS <TV/VCR Section>

T-REEL

Q1206

Q1205

RESET

TIMER+5V

ST/SAP-MODE

4

NORMAL-H

22

28

EXT-H

29

RENTAL

30

SPL-PLAY

SP/LP/SLP

EXT-H

RENTAL

SPL-PLAY

32

REC/EE/PB

REC/EE/PB

27

VOL-CONT

VOL-CONT

11

EXT-H

A-MUTE

JACK-MUTE

JACK-MUTE

DVD-MAIN-POWER

67

SW1211

REC

SAFETY

FROM/TO

VIDEO BLOCK

FROM/TO

AUDIO BLOCK

FROM/TO

Hi-Fi AUDIO

BLOCK

1-5-1 1-5-2 TD857BLS

SCL

(MEMORY)

SDA

6

5

P-DOWN

84

P-ON-H

P-DOWN

P-ON-H

31

LD-SW1

I2C-OPEN

45

71

AL+5V

SW1212

LD-SW

CS7

FROM/TO

POWER

SUPPLY BLOCK

SDA

SCL

FROM/TO

CHROMA

BLOCK

IC1202

WF3

ENV-DET

17

V-H-SW

ENV-DET

V-H-SW

16

SDA

SCL

Hi-Fi-H-SW

ST/SAP-IN

NORMAL-H

DVD-MAIN-POWER

Hi-Fi-H-SW

19

26

48

21

DVD-H

DVD-A-MUTE

42

5

KEY SWITCH

SW1201 SW1203,

SW1206 SW1210

5 5KEY1

CN2805

CN2803

CN1805

KEY SWITCH

SW2401 SW2408

14

25

12SDATA

1220 SDATA

FROM/TO

DVD SYSTEM

CONTROL

/SERVO BLOCK

<DVD SECTION>

CN401

CN2402

6

CN1804

13SCLK

14CS

15

DVD-REMOTE

M

1P-ON+12V

5C-CONT

6

FG-GND

7LD-CONT

CAPSTAN

MOTOR

CAPSTAN MOTOR

P-ON+5V

D/L+15V

P-ON+12V

10M-GND

11D/L+12V

9D-PFG

12D/L+15V

END-SENS.

Q201

SENSOR CBA

(END-SENSOR)

ST-SENS.

Q202

SENSOR CBA

(ST-SENSOR)

21 SCLK

18 CS

22

DVD-REMOTE

52

51

50

SDATA

SCLK

CS

69

DVD-A-MUTE

5CTL(+)

6CTL(-)

8D-CONT

4

C-F/R

3C-FG

2P-ON+5V(3)

66

87

76

82

77

90

C-F/R

C-FG

C-CONT

LD-CONT

D-CONT

D-PFG

CL1201

M

LOADING

MOTOR

CYLINDER ASSEMBLY

M

DRUM

MOTOR

PG

SENSOR

9

7

ST-SENS.

END-SENS.

13

14

15

AFT

AFT

D-REC-H

SP/LP/SLP

FUNCTION CBA

Q2621

Q2622

Q2623

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

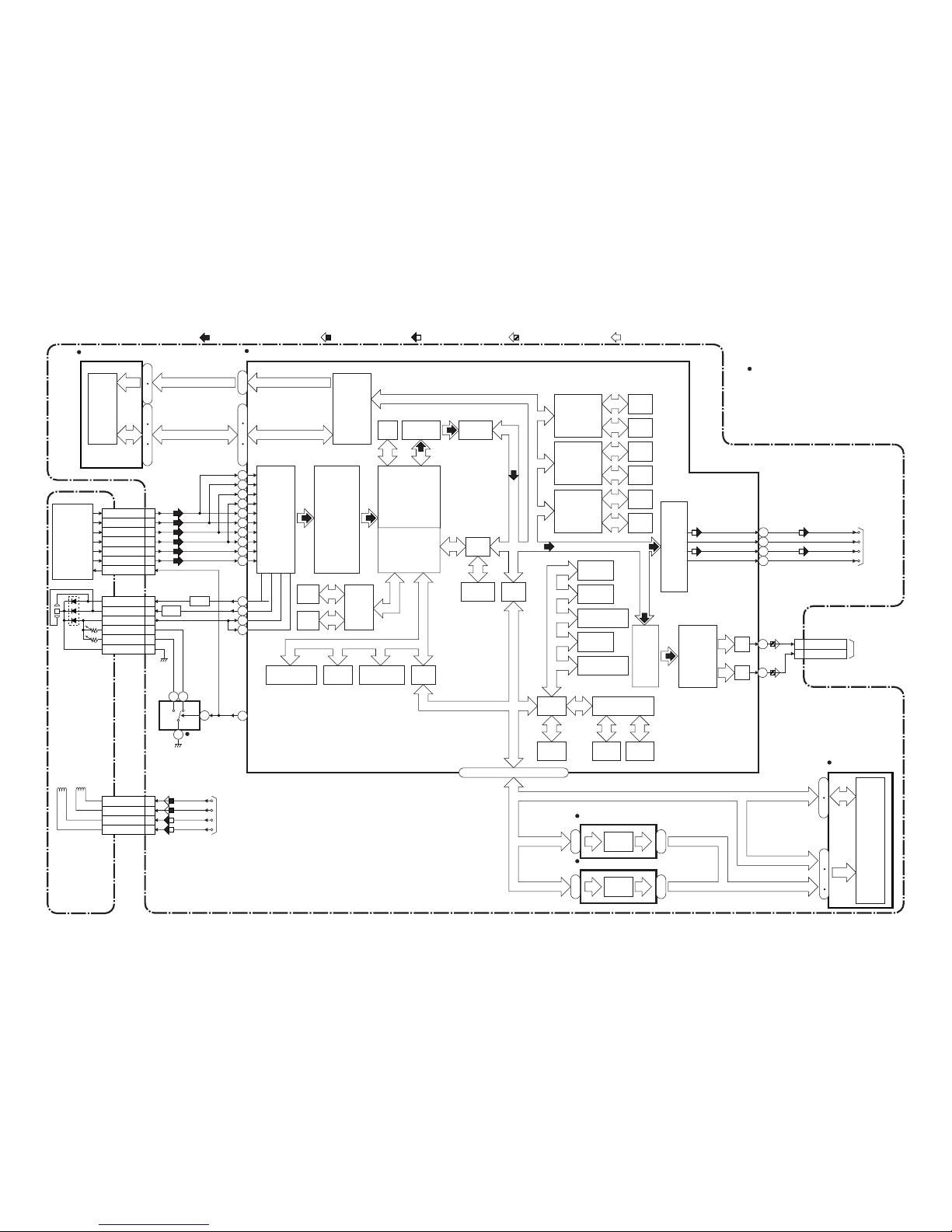

Video Block Diagram

1-5-3 1-5-4 TD857BLV

REC VIDEO SIGNAL PB VIDEO SIGNAL MODE: SP/REC

LUMINANCE

SIGNAL PROCESS

MAIN CBA

CL1401

Q1401

TP1402

V-OUT

V-AGC

R P

FBC

Y/C

MIX

CCD 1H

DELAY

R

P

DOC YNR Y/C COMB

CHROMINANCE

SIGNAL PROCESS

IC1401

VIDEO/AUDIO

SIGNAL PROCESS

35

42

38

17

CHARA

MIX

6dB

AMP

VXO

ENV

DET

AGC

AMP

HPF

FROM

SERVO/SYSTEM

CONTROL BLOCK

RF-SW

TP1401

WF1

TP1403

HA-MONITOR

BUFFER

DV-SYNC

SP/LP/SLP

ROTA

DV-SYNC

ROTA

14

36

16

71

39

59

73

SPL-PLAY

REC/EE/PB

RENTAL

SPL-PLAY

REC/EE/PB

RENTAL

42

EXT-H

74

45 47 49 44

Q1402

WF6

WF5

WF4

WF2

L

R

VIDEO (R)-1 HEAD

VIDEO (L)-1 HEAD

(DECK ASSEMBLY)

V(R)-1

V-COM

V(L)-1

9

8

7

V(L)-2

V-COM

V(R)-2

6

5

4

13

88

89

90

91

FROM/TO

SERVO/SYSTEM

CONTROL BLOCK

CYLINDER ASSEMBLY

R

L

RF-SW

93

V-ENV

V-H-SW

ENV-DET

ENV-DET

VIDEO (L)-2 HEAD

VIDEO (R)-2 HEAD

15

94

82

83

84

85

SP

EP

TO

CHROMA

BLOCK

62 61

X1401

3.58MHz

VIDEO

V-OUT

TVEXT-V-IN

VIDEO

TU1001

(TUNER UNIT)

JK1701

VIDEO-IN

SP/LP/SLP

BUFFER

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

Audio Block Diagram

BLOCK DIAGRAM FOR SECTION 2 (DECK MECHANISM)

MAIN CBA

POWER SUPPLY / AV CBA

PB-AUDIO SIGNAL

DVD AUDIO SIGNAL

REC-AUDIO SIGNAL

1-5-5

IC1401

TD857BLA1-5-6

BIAS

OSC

Q1872

P-ON+5V

P-ON+5V

Q1871

Q1873

Q1874

Q1875

(AUDIO PROCESS)

N-A-IN

N-A-OUT

TP1802

NA-IN-YCA

AUDIO

HEAD

AC HEAD ASSEMBLY

A-COM

A-PB/REC

CL1402

CN1804CN2803

AUDIO

ERASE

HEAD

AE-H

AE-H/FE-H

1

2

FE-H

FE-H GND

FULL

ERASE

HEAD

CN1403

4

3

1

2

FE HEAD UNIT

REC

AMP

7

98

6

AUTO

BIAS

99

LINE

AMP

MUTE

96

P

R

ALC

7112

D-REC-H

D-REC-H

EXT-H

A-MUTE

EXT-H

FROM SERVO/SYSTEM

CONTROL BLOCK

4

78

11

WF7

WF8

FROM/TO SERVO/SYSTEM

CONTROL BLOCK

3

1

EQ

AMP

100

SP/LP-ON

2

IC1802

(OUTPUT SELECT)

IC2201

(OP AMP)

JK1801

HEADPHONE

JACK

SPEAKER

R-CH

CN1802

CN1805

SP1802

FROM/TO

Hi-Fi AUDIO

BLOCK

FROM DVD

AUDIO BLOCK

<DVD SECITON>

CN601

FROM

Hi-Fi AUDIO

BLOCK

SW CTL.

Q2204

Q1803

CN2401

Q2202

JK2201

DIGITAL

A-OUT

(COXIAL)

A-OUT(L)

A-OUT(R)

A-OUT(R)

A-OUT(L)

2

1

12

13

14

15

1110

6

2 1

7

Q2205

BUFFER

IC1801

(AUDIO AMP)

DC VOL.

5

2 12

7

6

Q2207

76

80

7

DVD-A-MUTE

1 SPDIF

4 DVD-A(R)

6 DVD-A(L)

8 8DVD-A(R)

7 7DVD-A(L)

11 11JACK-MUTE

10 10

DVD-A-MUTE

5 5

JACK-OUT(R)

4 4

JACK-OUT(L)

FUNCTION CBA

SPEAKER

L-CH

CN2801CN2805

SP2801

SP-R

1

SP-GND 2

SP-L

1

SP-GND 2

2 2SP-L

DVD-A-MUTE

CL1802

CL2801

FROM SERVO/SYSTEM

CONTROL BLOCK

VOL-CONT

Q1212

DVD-H

JACK-MUTE

AL+5V

WF19

WF20

DATA(AUDIO) SIGNAL

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

57

7

48 47

13 14

69

6

7

R-CH

INSEL

L-CH

INSEL

NOR

SW

SERIAL

DATA

DECODER

OUTPUT

SELECT

VCO

LPF

L-CH BPF

R-CH

PNR

PILOT

DET

CONT

STEREO

PLL

STEREO

FILTER

SAP

FILTER

SAP

DET

SIF

DEMOD

SAP

DEMOD

L-R

DEMOD

ST/SAP

SW

MATRIX

L-CH

PNR

LIM DEV

COMP

SW

NOISE

VCO

LPF

LIM DEV

COMP

COMP

DC

SW

NOISE

dBX

DEC

ENV

DET

MODE

OUT

RIPPLE

FILTER

DO

DET

MATRIX

R-CH BPF

P

R

R

L

P

R

HOLD

PULSE

NOISE

DET

34 33

23

4

80

78

37

38

54

77

1

39

26

24

27

N-A-OUT

LIM

49

A-OUT (L)

A-OUT (R)

N-A-IN

Hi-Fi-H-SW

A-MUTE

NORMAL-H

40

ST/SAP-MODE

FROM/TO AUDIO

BLOCK

SCL

P-ON+9V

TO SERVO/SYSTEM

CONTROL BLOCK

Hi-Fi

AUDIO

(R) HEAD

Hi-Fi

AUDIO

(L) HEAD

CYLINDER

ASSEMBLY

MAIN CBA

Hi-Fi-A(R) 3

Hi-Fi-COM 2

Hi-Fi-A(L) 1

CL1401

IC1751(MTS/ SAP/ Hi-Fi AUDIO PROCESS/ Hi-Fi HEAD AMP)

Hi-Fi Audio Block Diagram

TD857BLH1-5-7 1-5-8

REC-AUDIO SIGNALPB-AUDIO SIGNAL

PILOT

CANCEL

TO

AUDIO BLOCK

FROM/TO

SERVO/ SYSTEM

CONTROL BLOCK

FROM

SERVO/SYSTEM

CONTROL BLOCK

62 63

JK1702

AUDIO-IN(L)

JK1703

AUDIO-IN(R)

BUFFER

Q1010

SIF

TU1001

(TUNER UNIT)

Q1701

TP1701

TP1702

SDA

Hi-Fi-L Hi-Fi-R

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

TD857BLC

X1301

3.58MHz

CN1301

IC1301

(VIDEO/AUDIO/CHROMA/DEFLECTION)

SDA

SCL

FSC

10

9

13

16

IC1201 (OSD)

V-SYNC

H-SYNC

OSD-R

OSD-G

OSD-B

59

58

60

62

63

64

OSD-BLK

EXT-V-IN

FROM

VIDEO BLOCK

V-OUT

FROM/TO

CRT/H.V. BLOCK

CN503

12

GREEN11

BLUE

FBP3

H-DRIVE4

ACL/ABL

V-DRIVE8

V-RAMP-FB

Chroma Block Diagram

SDA

AFT

SCL

FROM/TO

SERVO/

SYSTEM

CONTROL

BLOCK

REC VIDEO SIGNAL

PB VIDEO SIGNAL

DVD VIDEO SIGNAL

WF16

WF15

WF9

56

CV-IN

10

18

28

29

34

35

8

9

31

13

10

11

12

15

14

4

5

3

2

40

41

16

6

20

25

23

CHROMA

TRAP

SERIAL

I/F

INTELLIGENT

MONITORING

CHROMA

BPF

SYNC

SEPARATION

LUMA

SIGNAL

PROCESS

CIRCUIT

CHROMA

SIGNAL

PROCESS

CIRCUIT

H-SYNC

PROCESS

CIRCUIT

V-SYNC

PROCESS

CIRCUIT

OSD MIX/RBG MATRIX/

BLIGHT/DRIVE AMP/

HV BLANKING

TUNER

TUNER

FILTER

TUNING

VXCO

C-SYNC

LINE

VCR

VCR

LINE

RED

AFT

TU1001

(TUNER UNIT)

1-5-9

SWCTL

IC1802

(OUTPUT SELECT)

Q1806

D-REC-H

S-C

S-Y

DVD-Y12

DVD-C10

BUFFER

BUFFER

CN1803

CN2804

Q2210

Q2211

CN2401

DVD-C

TP2204

DVD-Y

TP2203

POWER SUPPLY/AV CBA

TV-VIDEO

7

5

FROM DIGITAL

SIGNAL PROCESS

BLOCK

<DVD SECTION>

CN601

1-5-10

5

3

9

4

VCR

DVD

MAIN CBA

WF17

WF18

+5.7V

REG.

27 +5V CTRL

TO POWER

SUPPLY BLOCK

30

+8V

14 14DVD-Y

15 15DVD-C

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

PULSE

UP

AMP

THERMAL

PROTECTION

3

6

7

1

5

V-DRIVE

8

H-DRIVE

4

8

10

7

9

6

GREEN AMP

BLUE AMP

Q501

Q502

Q503

H.DRIVE

Q572

Q571

T572

TD857BLCRT

FBP

ACL/ABL

CRT/H.V. Block Diagram

VDRIVE

HDRIVE

D.Y.

L551

IC551 (V-DEFLECTION CONTROL)

T571 F.B.T.

ANODE

FOCUS

SCREEN

3

5

CL503A

7

H.V. CBA

CRT CBA

CL504A

R

G

B

HEATER

ANODE

GND

V501

CRT

GND

FOCUS

SCREEN

JK501

HEATER 11

CN501

CL501BCL501A

REC VIDEO SIGNAL PB VIDEO SIGNAL

CN571

+180V 33

11

S

F

HV

FOCUS VR

SCREEN VR

1-5-121-5-11

+B5

CL502A

2

3

4 RED

GREEN

BLUE

6 +B

3 DEF+B

H.OUTPUT

V-RAMP-FB

1

3

5

4

5

4

3

1

WF13WF12

WF14

WF10

WF11

RED AMP

J553

+B

J563

GND

5

FROM

POWER

SUPPLY

BLOCK

CN2602

CN502

CL502B

CN503

CL503B

CN503 CL504B

JUNCTION-B

CBA

JUNCTION-A

CBA

3

7

4

8

2

3

4

5

6

3

V-DRIVE

8

H-DRIVE

4

FBP

ACL/ABL

3

5

7

RED

12

GREEN

11

BLUE

10

V-RAMP-FB

FROM

CHROMA

BLOCK

CN1301

5 +B

6 +B

3 DEF+B

DVD VIDEO SIGNAL

FROM/TO

CHROMA

BLOCK

CN1301

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

TEST POINT INFORMATION

:INDICATES A TEST POINT WITH A JUMPER WIRE ACROSS A HOLE IN THE PCB.

:USED TO INDICATE A TEST POINT WITH A COMPONENT LEAD ON FOIL SIDE.

:USED TO INDICATE A TEST POINT WITH NO TEST PIN.

:USED TO INDICATE A TEST POINT WITH A TEST PIN.

Power Supply Block Diagram

LINE

FILTER

BRIDGE

RECTIFIER

T2601

IC2601

ERROR

VOLTAGE DET

W2601

F2601

4A/125V

L2601

D2603 D2606

TD857BLP

DEGAUSSING

COIL

CN2601

PS2601

HOT

COLD

1-5-141-5-13

POWER SUPPLY/AV CBA

MAIN CBA

DVD MAIN CBA UNIT

NOTE :

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

Fixed voltage power supply circuit is used in this unit.

If Main Fuse (F2601) is blown, check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

4A 125V

SWITCHING

Q2601

IC1602

P-DOWN

(TO PIN84 OF IC1201)

Q2604

IC2603

IC2604

VR2601

Q2602

+5V REG.

+B ADJ

5 +B

6 +B

3 DEF+B

Q1608

SW+5V

Q1611

SW+5V

Q1613

SW+5V

P-ON+5V

P-ON+5V

P-ON+5V

T+5V

P-ON+9V

P-ON+12V

AL+5V

P-ON+12V

Q1612

AL+33V

D/L+15V

P-ON+5V

+5V-CTRL

P-ON-H

(FROM PIN31 OF IC1201)

DVD-MAIN-POWER

(FROM PIN42 OF IC1201)

CN2602 TO CN502

TO

CRT/H.V.

BLOCK

CN2804 CN1803

CN2803 CN1804

CN2402 CN401

DVD-ON+3.3V

1

23

4

13 13DVD-ON+5V

16 16

DVD-MAIN-POWER

9 9P-ON-H

2 2P-ON+9V(3)

19 19AC-DOWN

19 19D/L+15V

4 4P-ON+9V(1)

10 10P-ON+12V

18 18P-ON+12V

9 9AL+33V

8 8AL+5.7V

6 6P-ON+9V(2)

3 3EV+1.5V

2 2EV+1.5V

1 1EV+1.5V

4 4EV+3.3V

5 5EV+3.3V

17 17DVD-ON+3.3V

14 14AL+9V

15 15AL+9V

19 19PWRCON

DVD-ON+5V

EV+3.3V

EV+1.5V

AL+9V

12

16

15

14

11

13

10

92

3

5

7

FEED

BACK

+3.3V

REG.

REG.

Q2606

Q2614

Q2607

Q2613

Q2609

Q2605

Q2615

Q2617

1 2

4

IC2602

+1.5V

REG.

1 2

4

Q2611

Q2610

Q2612

Q2608

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE ONLY WITH SAME TYPE 4 A, 125V FUSE.

CAUTION:

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE 4A, 125V.

4A 125V

FROM CHROMA

BLOCK

P-ON+9V

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

PWRCON

FROM DVD SYSTEM

CONTROL

/SERVO BLOCK

<DVD SECTION>

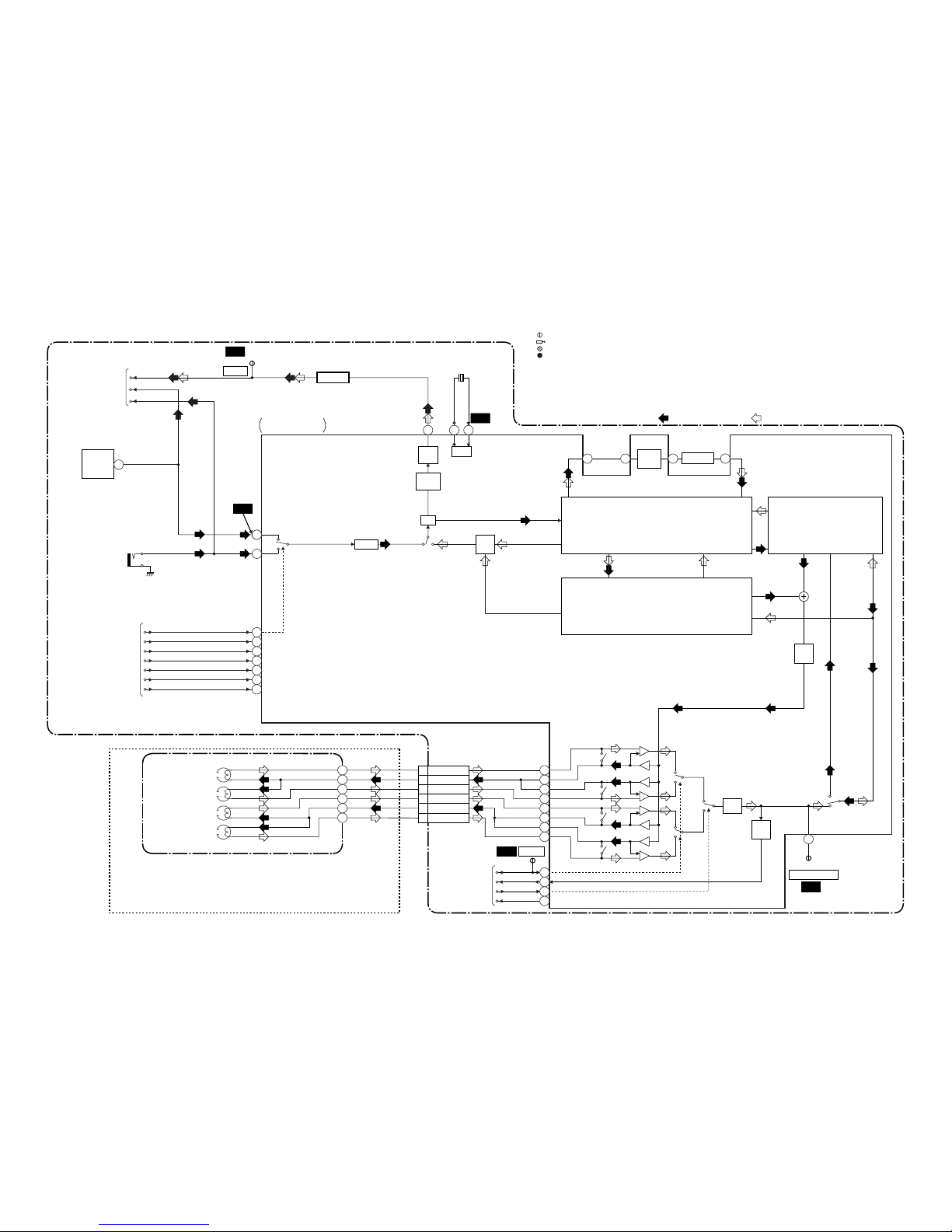

DVD System Control/Servo Block Diagram

TD857BLDS

27

7

8

3

15

10

14

26

1

2

3

4

6

23

5

17

18

12

11

14

13

15

16

25

24

54CS

55

SDATA

61

REMOTE

PWRCON PWRCON

53

SCLK

CN401

DVD MAIN CBA UNIT

DRIVE CBA

IC301

(SERVO DRIVE)

IC451

(CLOCK GENERATOR)

BLOCK DIAGRAMS < DVD Section >

IC202

(OP AMP)

12 14

CN301

FG CBA

FG

SENSOR

M

SLED

MOTOR

M

SPINDLE

MOTOR

IC101

(MICRO CONTROLLER)

+

-+

-

+

-

+

-

+

-

+

-

+

-

SLED

MOTOR

DRIVE

FOCUS

ACTUATOR

DRIVE

1/4

1/4

PLL2

X451

MULTI

PLL

X'TAL

OSC

36.864MHz

OSC

SPINDLE

MOTOR

DRIVE

TRACKING

ACTUATOR

DRIVE

EXT CLOCK

CLK33M

BE CLOCK

172

170

150

TRAY-OUT

TRAY-IN

FG-IN

97

SLD70

SPDL71

TRACKING

DRIVE

152

FOCUS DRIVE

60

66

TO DIGITAL SIGNAL

PROCESS BLOCK

FS(+)

FS(-)

TS(+)

TS(-)

TO DVD/ AUDIO

BLOCK

51

ADAC-MD

50 ADAC-MC

96 ADAC-ML

ADAC-MC

ADAC-ML

PCM-SCLK

95

A-MUTE

ADAC-MD

A-MUTE

1792FSEL

RESET68

RESET

IC461

5 4

+3.3V

TRAY-OUT

TRAY-IN

FOCUS SERVO SIGNAL TRACKING SERVO SIGNAL

SLED SERVO SIGNAL SPINDLE SERVO SIGNAL

3SP(+)

4SP(-)

5TRAY-OUT

6TRAY-IN

7GND

8SL(-)

9SL(+)

1FG-IN

18 CS

20 SDATA

21 SCLK

22

DVD-REMOTE

FROM/TO SERVO

/SYSTEM CONTROL

BLOCK

<TV/VCR SECTION>

CN2402

63

TO POWER

SUPPLY BLOCK

<TV/VCR SECTION>

1-5-161-5-15

DVD-

" " = SMD

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

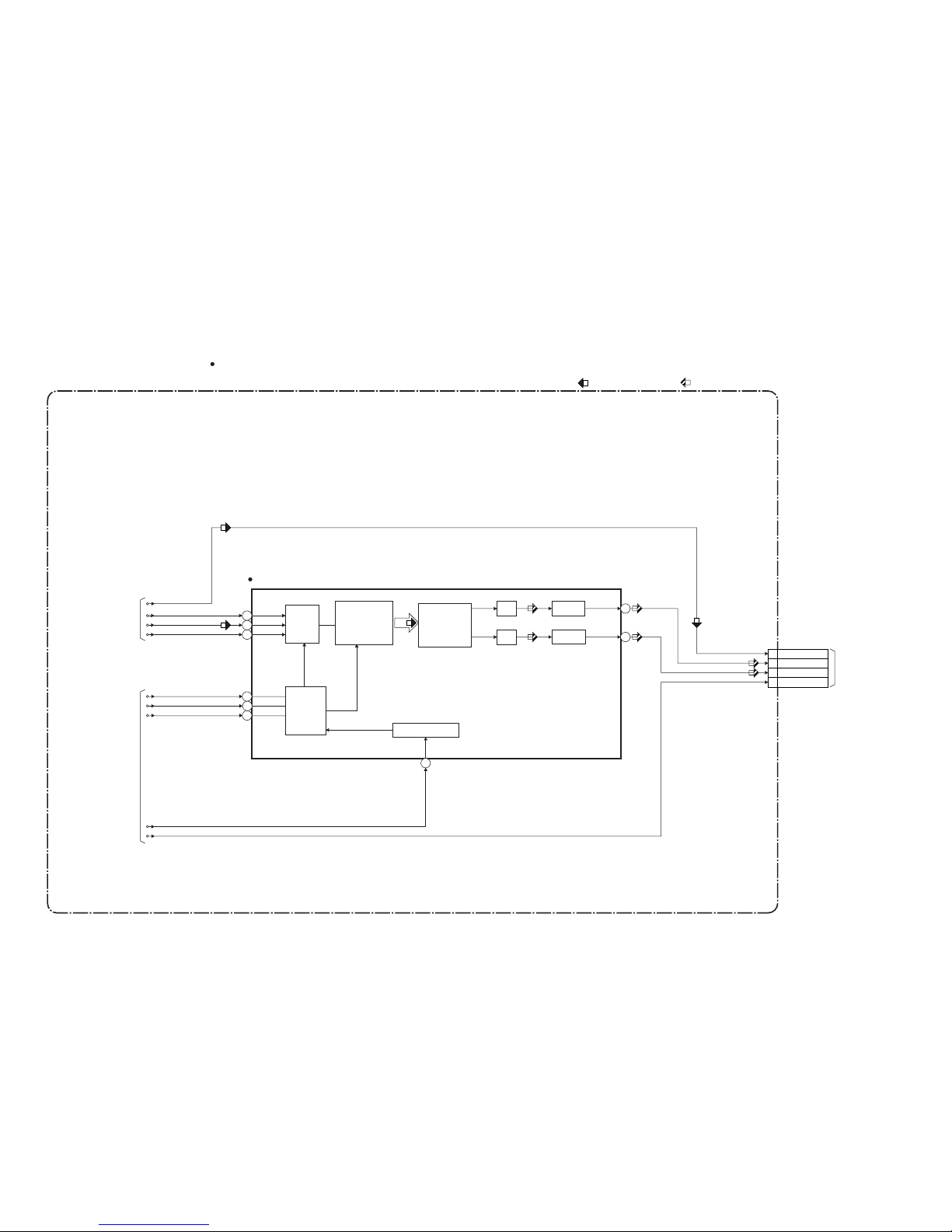

Digital Signal Process Block Diagram

TD857BLD

C 6

D 7

A 8

B 5

F 10

E 2

DVD-LD 14

CD-LD 12

PD-MONI 13

FS(+) 18

FS(-) 19

TS(+) 20

TS(-) 17

CN201

CN201

CN201

IC201

(SW)

IC105 (LATCH)

IC102 (SDRAM) IC101 (MICRO CONTROLLER)

FS

FS(+)

CD/DVD

FS(-)

TS(+)

TS(-)

TS

PICK-UP

UNIT

DETECTOR

CD/DVD 9

Q251,Q252

CD DVD

AMP

Q253,Q254

AMP

4

1 3

6

GND(DVD-PD)

15

GND(CD-PD)

16

GND(LD)

11

FROM DVD SYSTEM

CONTROL/SERVO

BLOCK

RF

SIGNAL

PROCESS

CIRCUIT

DVD/CD

FORMATTER

AUDIO

I/F

VIDEO

I/F

NTSC/PAL

ENCODER

DMA

BCU

INST.

ROM

32BIT

CPU

DATA

ROM

INTERRUPT

CONTROLLER

WATCH DOG

TIMER

CPU

I/F

TIMER

DECODER

I/F

CPU

I/F

READ

MEMORY

DATA

ROM

DSP

DECODER

PIXEL

OPERATION

I/O

PROCESSOR

INST.

ROM

DATA

ROM

INST.

ROM

DATA

ROM

INST.

ROM

SERIAL

D/A

GENERAL

I/O

INTERRUPT

CONTROLLER

TIMER

WATCH DOG

TIMER

32BIT CPU

STREAM

I/F

EXTERNAL

MEMORY

I/F

SDRAM

ECC

UMAC

124

125

122

123

128

129

126

127

131

130

135

133

132

134

78

DEBUG

BCU

INST

CACHE

D TYPE

LATCH

DATA

CACHE

D/A

TO CHROMA

BLOCK

CN2401

158

164

Y

CN601

C

TO DVD

AUDIO

BLOCK

181

SPDIF

175

PCM-BCK

176

PCM-DATA0

174

PCM-LRCLK

EXADT (0-15), EXADR (16-19)

EXADT (0-15), EXADR (16-19)

EXADT (0-7)

EXADT (8-15)

EXADR (0-7)

EXADR (0-15)

EXADR (8-15)

SDRAM DATA(0-31)SDRAM DATA(0-31)

SDRAM ADDRESS(0-10)SDRAM ADDRESS(0-10)

2

9

~

12

19

~

210

235

~

IC104 (LATCH)

D TYPE

LATCH

2

9

~

12

19

~

2

13

184

205

247

256

~~~

2

13

31

56

74

85

~~~

IC103 (FLASH ROM)

FLASH

ROM

29

36

38

45

~

~

DVD MAIN CBA UNIT

DATA(VIDEO/AUDIO) SIGNAL DVD VIDEO SIGNAL

DATA(AUDIO) SIGNAL

FOCUS SERVO SIGNAL TRACKING SERVO SIGNAL

24

27

60

66

~~

EXADT (0-15)

EXADR (16-19)

~

1

9

16

25

48

~

1 DVD-Y

3 DVD-C

1-5-181-5-17

<TV/VCR SECTION>

" " = SMD

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

DVD Audio Block Diagram

TD857BLAD

IC601 (AUDIO DAC)

7

8

CN601

1

2

3

13

14

15

16

FROM

DVD SYSTEM

CONTROL

/SERVO

BLOCK

FROM

DIGITAL

SIGNAL

PROCESS

BLOCK

SERIAL

PORT

SERIAL

CONTROL

4X/8X

OVERSAMPLING

DIGITAL FILTER

/FUNCTION

CONTROLLER

ENHANCED

MULTI-LEVEL

DELTA-SIGMA

MODULATOR

DAC

LPF+AMP

L-CH

R-CH

LPF+AMP

DAC

SYSTEM CLOCK

PCM-BCK

SPDIF

PCM-DATA0

PCM-LRCLK

ADAC-MD

ADAC-MC

ADAC-ML

PCM-SCLK

DVD MAIN CBA UNIT

DATA(AUDIO) SIGNAL

A-MUTE

12 SPDIF

7 DVD-A(L)

9 DVD-A(R)

6 DVD-A-MUTE

TO AUDIO BLOCK

<TV/VCR SECTION>

CN2401

DVD AUDIO SIGNAL

1-5-201-5-19

" " = SMD

NOTE FOR WIRE CONNECTORS:

1. PREFIX SYMBOL "CN" MEANS CONNECTOR.

(CAN DISCONNECT AND RECONNECT.)

2. PREFIX SYMBOL "CL" MEANS WIRE-SOLDER

HOLES OF THE PCB.

(WIRE IS SOLDERED DIRECTLY.)

Loading...

Loading...