Page 1

LCD TV

chassis FL10.9

SERVICE MANUAL

Contents

22” 22ME360B/F7 MAGNAVOX

22” LE220SG1 SYLVANIA

© 2010 Funai Electric Co., Ltd.

All rights reserved. No part of this manual may be reproduced, copied, transmitted, disseminated, transcribed,

downloaded or stored in any storage medium, in any form or for any purpose without the express prior written

consent of Funai. Furthermore, any unauthorized commercial distribution of this manual or any revision hereto

is strictly prohibited.

Information in this document is subject to change without notice. Funai reserves the right to change the content

herein without the obligation to notify any person or organization of such changes.

with the design is a registered trademark of Funai Electric Co., Ltd and may not be used in any way

without the express written consent of Funai. All other trademarks used herein remain the exclusive property of

their respective owners. Nothing contained in this manual should be construed as granting, by implication or

otherwise, any license or right to use any of the trademarks displayed herein. Misuse of any trademarks or any

other content in this manual is strictly prohibited. Funai shall aggressively enforce its intellectual property rights

to the fullest extent of the law.

A017CUH/A017DUH

101004

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

Funai Equipment. The service procedures recommended by Funai and

described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

Funai could not possibly know, evaluate and advice the service trade of all

conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, Funai has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by Funai must first

use all precautions thoroughly so that neither his safety nor the safe

operation of the equipment will be jeopardized by the service method

selected.

The LCD panel is manufactured to provide many years of useful life.

Occasionally a few non active pixels may appear as a tiny spec of color.

This is not to be considered a defect in the LCD screen.

Page 3

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Electrical Adjustment Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

How to Initialize the LCD TV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Page 4

SPECIFICATIONS

< TUNER / NTSC >

ANT. Input ---------------------- 75 Ω Unbal., F type

Description Condition Unit Nominal Limit

1. AFT Pull-In Range --- MHz ±2.3 ±2.1

20

20

23

2. Synchronizing Sens.

TV.ch.4

CA.ch.31

CA.ch.87

dBµ

dBµ

dBµ

18

18

18

< TUNER / ATSC >

Description Condition Unit Nominal Limit

1. Received Freq. Range (-28dBm) --- kHz --- ±100

2. ATSC Dynamic Range (min / max)

ch.4

ch.10

ch.41

dBm

dBm

dBm

---

---

---

-76/0

-76/0

-76/+4

< LCD PANEL >

Description Condition Unit Nominal Limit

1. Native Pixel Resolution

2. Brightness (w / filter) --- cd/m

3. Viewing Angle (CR=10)

Horizontal

Vert ical

Horizontal

Vert ical

pixels

pixels

°

°

1366

768

2

270 ---

-85 to 85

-80 to 80

---

---

---

---

< VIDEO >

Description Condition Unit Nominal Limit

1. Over Scan

2. Color Temperature

3. Resolution (composite video)

Horizontal

Vert ical

--x

y

Horizontal

Vert ical

%

%

°K

---

---

line

line

5

5

12000

0.272

0.278

400

350

5±5

5±5

--±3%

±3%

---

---

< AUDIO >

All items are measured across 8 Ω load at speaker output terminal with L.P.F.

Description Condition Unit Nominal Limit

1. Audio Output Vol. Max

(ATSC 0 dBfs)

2. Audio Distortion (NTSC) 500mW: Lch/Rch % 0.5/0.5 2.0/2.0

3. Audio Freq. Response (NTSC)

Lch/Rch W 3.0/3.0 2.8/2.8

-

6dB: Lch

-

6dB: Rch

Hz

Hz

70 to 10 k

70 to 10 k

---

---

1-1 FL10.9SP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Prior to shipment from the factory, our products are strictly inspected for recognized product safety and electrical

codes of the countries in which they are to be sold. However, in order to maintain such compliance, it is equally

important to implement the following precautions when a set is being serviced.

Safety Precautions for LCD TV

Circuit

1. Before returning an instrument to the

customer, always make a safety check of the

entire instrument, including, but not limited to, the

following items:

a. Be sure that no built-in protective devices are

defective and have been defeated during

servicing. (1) Protective shields are provided

on this chassis to protect both the technician

and the customer. Correctly replace all missing

protective shields, including any removed for

servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the

cabinet, be sure to put back in place all

protective devices, including but not limited to,

nonmetallic control knobs, insulating

fishpapers, adjustment and compartment

covers/shields, and isolation resistor/capacitor

networks. Do not operate this instrument or

permit it to be operated without all

protective devices correctly installed and

functioning. Servicers who defeat safety

features or fail to perform safety checks

may be liable for any resulting damage.

b. Be sure that there are no cabinet openings

through which an adult or child might be able to

insert their fingers and contact a hazardous

voltage. Such openings include, but are not

limited to, (1) spacing between the Liquid

Crystal Panel and the cabinet mask, (2)

excessively wide cabinet ventilation slots, and

(3) an improperly fitted and/or incorrectly

secured cabinet back cover.

c. Antenna Cold Check - With the instrument AC

plug removed from any AC source, connect an

electrical jumper across the two AC plug

prongs. Place the instrument AC switch in the

on position. Connect one lead of an ohmmeter

to the AC plug prongs tied together and touch

the other ohmmeter lead in turn to each tuner

antenna input exposed terminal screw and, if

applicable, to the coaxial connector. If the

measured resistance is less than 1.0 megohm

or greater than 5.2 megohm, an abnormality

exists that must be corrected before the

instrument is returned to the customer. Repeat

this test with the instrument AC switch in the off

position.

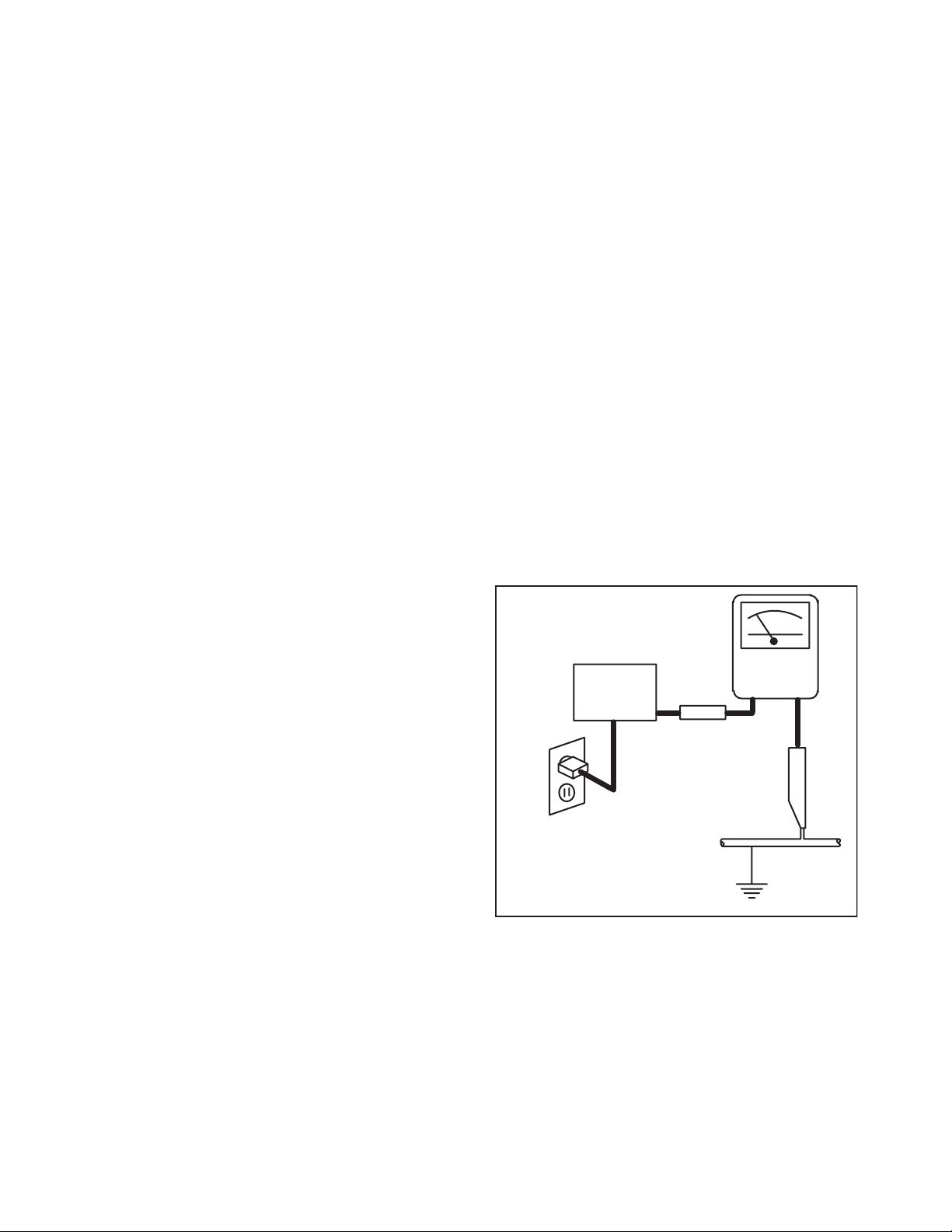

d. Leakage Current Hot Check - With the

instrument completely reassembled, plug the

AC line cord directly into a 120 V AC outlet. (Do

not use an isolation transformer during this

test.) Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI) C101.1

Leakage Current for Appliances and

Underwriters Laboratories (UL) 1410, (50.7).

With the instrument AC switch first in the on

position and then in the off position, measure

from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinet, screw heads, metallic overlays, control

shafts, etc.), especially any exposed metal

parts that offer an electrical return path to the

chassis. Any current measured must not

exceed 0.5 milli-ampere. Reverse the

instrument power cord plug in the outlet and

repeat the test.

READING SHOULD

NOT BE ABOVE 0.5 mA

LEAKAGE

DEVICE

BEING

TESTED

TEST ALL EXPOSED

METAL SURFACES

ALSO TEST WITH

PLUG REVERSED

USING AC

ADAPTER PLUG

AS REQUIRED

ANY MEASUREMENTS NOT WITHIN THE

LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST

BE ELIMINATED BEFORE RETURNING THE

INSTRUMENT TO THE CUSTOMER OR

BEFORE CONNECTING THE ANTENNA OR

ACCESSORIES.

2. Read and comply with all caution and safety-

related notes on or inside the receiver cabinet, on

the receiver chassis, or on the Liquid Crystal

Panel.

CURRENT

TESTER

+

EARTH

GROUND

_

2-1 LTVN_ISP

Page 6

3. Design Alteration Warning - Do not alter or add

to the mechanical or electrical design of this TV

receiver. Design alterations and additions,

including, but not limited to circuit modifications

and the addition of items such as auxiliary audio

and/or video output connections, might alter the

safety characteristics of this receiver and create a

hazard to the user. Any design alterations or

additions will void the manufacturer's warranty and

may make you, the servicer, responsible for

personal injury or property damage resulting

therefrom.

4. Hot Chassis Warning a. Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord and maybe safety-serviced without

an isolation transformer only if the AC power

plug is inserted so that the chassis is

connected to the ground side of the AC power

source. To confirm that the AC power plug is

inserted correctly, with an AC voltmeter,

measure between the chassis and a known

earth ground. If a voltage reading in excess of

1.0 V is obtained, remove and reinsert the AC

power plug in the opposite polarity and again

measure the voltage potential between the

chassis and a known earth ground.

b. Some TV receiver chassis normally have 85V

AC(RMS) between chassis and earth ground

regardless of the AC plug polarity. This chassis

can be safety-serviced only with an isolation

transformer inserted in the power line between

the receiver and the AC power source, for both

personnel and test equipment protection.

c. Some TV receiver chassis have a secondary

ground system in addition to the main chassis

ground. This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulation material that must not be defeated or

altered.

5. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas: a.

near sharp edges, b. near thermally hot parts-be

sure that leads and components do not touch

thermally hot parts, c. the AC supply, d. high

voltage, and, e. antenna wiring. Always inspect in

all areas for pinched, out of place, or frayed wiring.

Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to

have overheated or are otherwise damaged

should be replaced with components, parts, or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

7. Product Safety Notice - Some electrical and

mechanical parts have special safety-related

characteristics which are often not evident from

visual inspection, nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage, wattage, etc.

Parts that have special safety characteristics are

identified by a # on schematics and in parts lists.

Use of a substitute replacement that does not

have the same safety characteristics as the

recommended replacement part might create

shock, fire, and/or other hazards. The product's

safety is under review continuously and new

instructions are issued whenever appropriate.

Prior to shipment from the factory, our products

are strictly inspected to confirm they comply with

the recognized product safety and electrical codes

of the countries in which they are to be sold.

However, in order to maintain such compliance, it

is equally important to implement the following

precautions when a set is being serviced.

2-2 LTVN_ISP

Page 7

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety.

Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation Tape

2) PVC tubing

3) Spacers

4) Insulators for transistors.

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.)

G. Check that replaced wires do not contact sharp

edged or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Use care that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC supply outlet.

L. When installing parts or assembling the cabinet

parts, be sure to use the proper screws and

tighten certainly.

2-3 LTVN_ISP

Page 8

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts and

wires have been returned to original positions. Afterwards, perform the following tests and confirm the specified

values in order to verify compliance with safety standards.

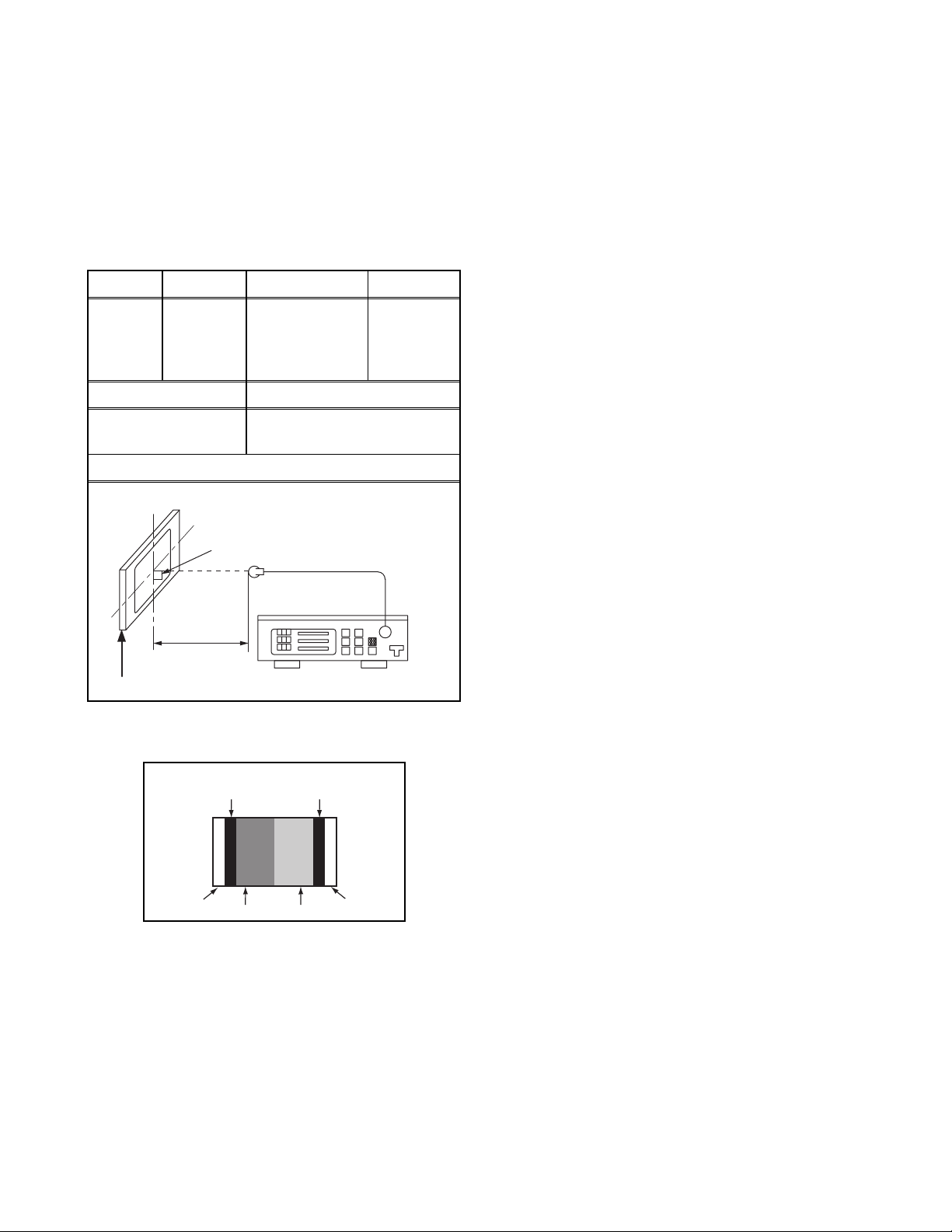

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d') between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Region

110 to 130 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

U.S.A. or

Canada

Clearance

Distance (d), (d’)

≥ 3.2 mm

(0.126 inches)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method: (Power ON)

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across both terminals of load Z.

See Fig. 2 and following table.

d' d

Fig. 1

Exposed Accessible Part

Z

AC Voltmeter

(High Impedance)

Earth Ground

B

Power Cord Plug Prongs

Fig. 2

Table 2: Leakage current ratings for selected areas

AC Line Voltage Region Load Z Leakage Current (i) Earth Ground (B) to:

110 to 130 V

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

U.S.A. or

Canada

0.15 µF CAP. & 1.5 kΩ

RES. Connected in parallel

2-4 LTVN_ISP

i ≤ 0.5 mA rms

Exposed accessible

parts

Page 9

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

To p Vi ew

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

Pb free mark will be found on PCBs which use Pb

free solder. (Refer to figure.) For PCBs with Pb free

mark, be sure to use Pb free solder. For PCBs

without Pb free mark, use standard solder.

Pb free mark

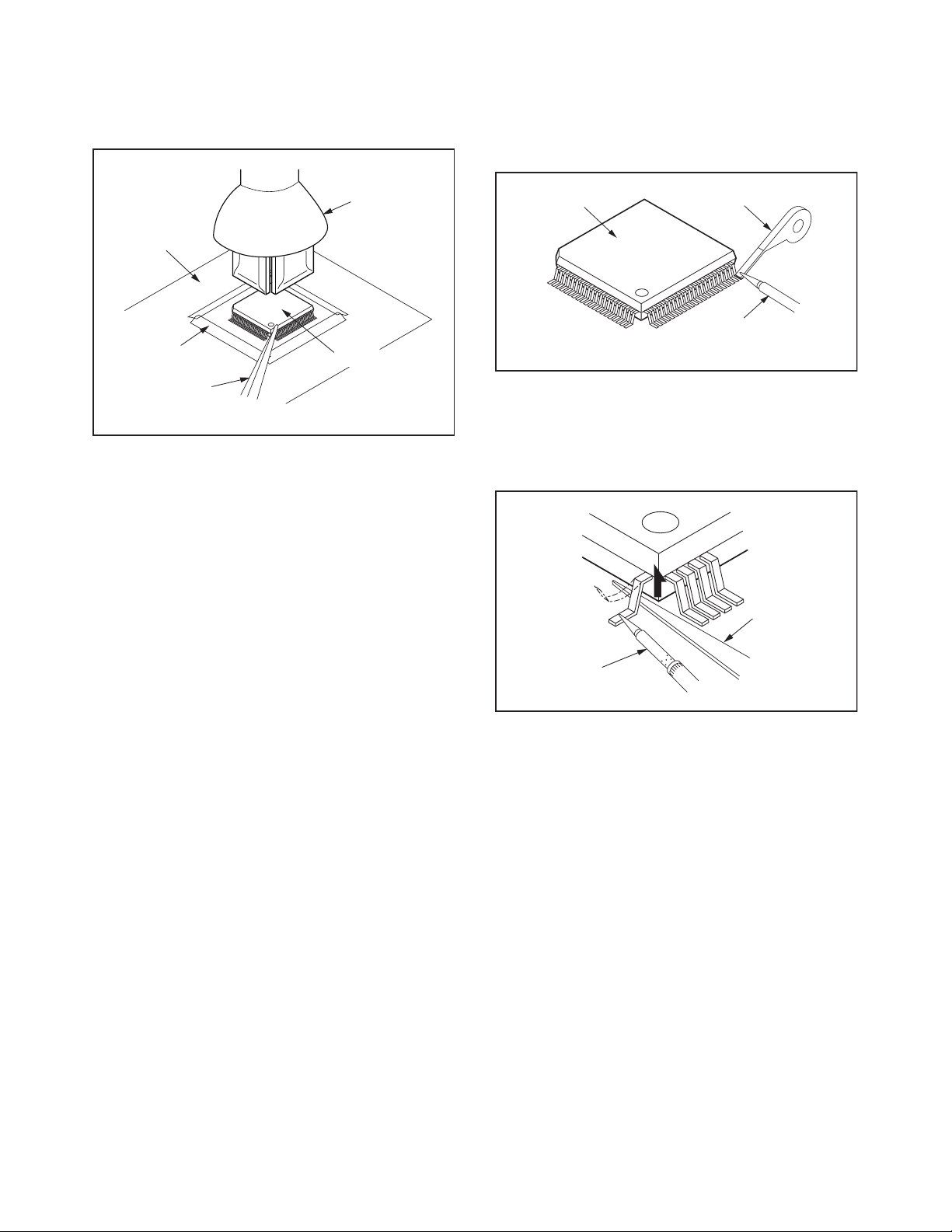

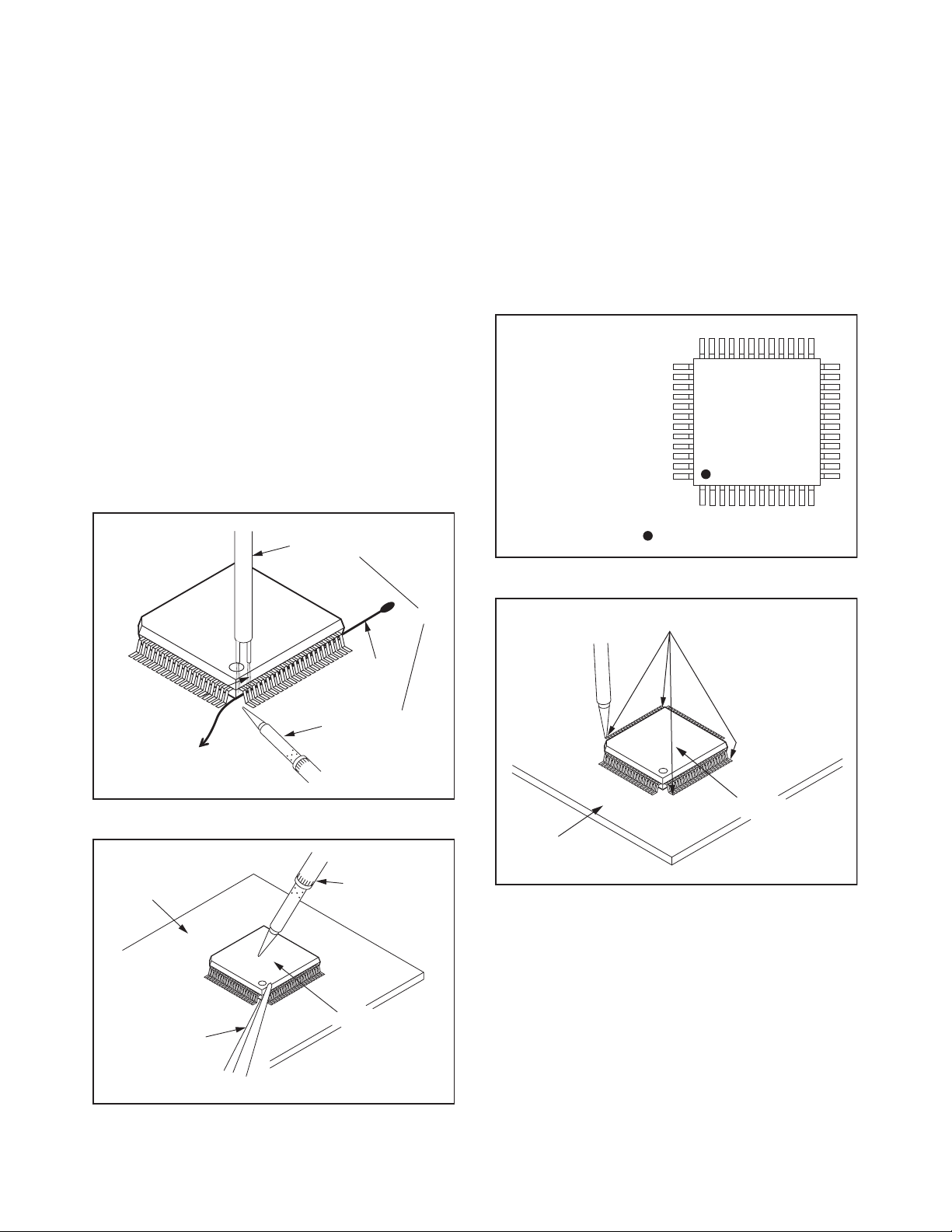

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

3-1 TVN_SN

Page 10

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Ta pe

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

3-2 TVN_SN

Page 11

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

3-3 TVN_SN

Page 12

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

3-4 TVN_SN

Page 13

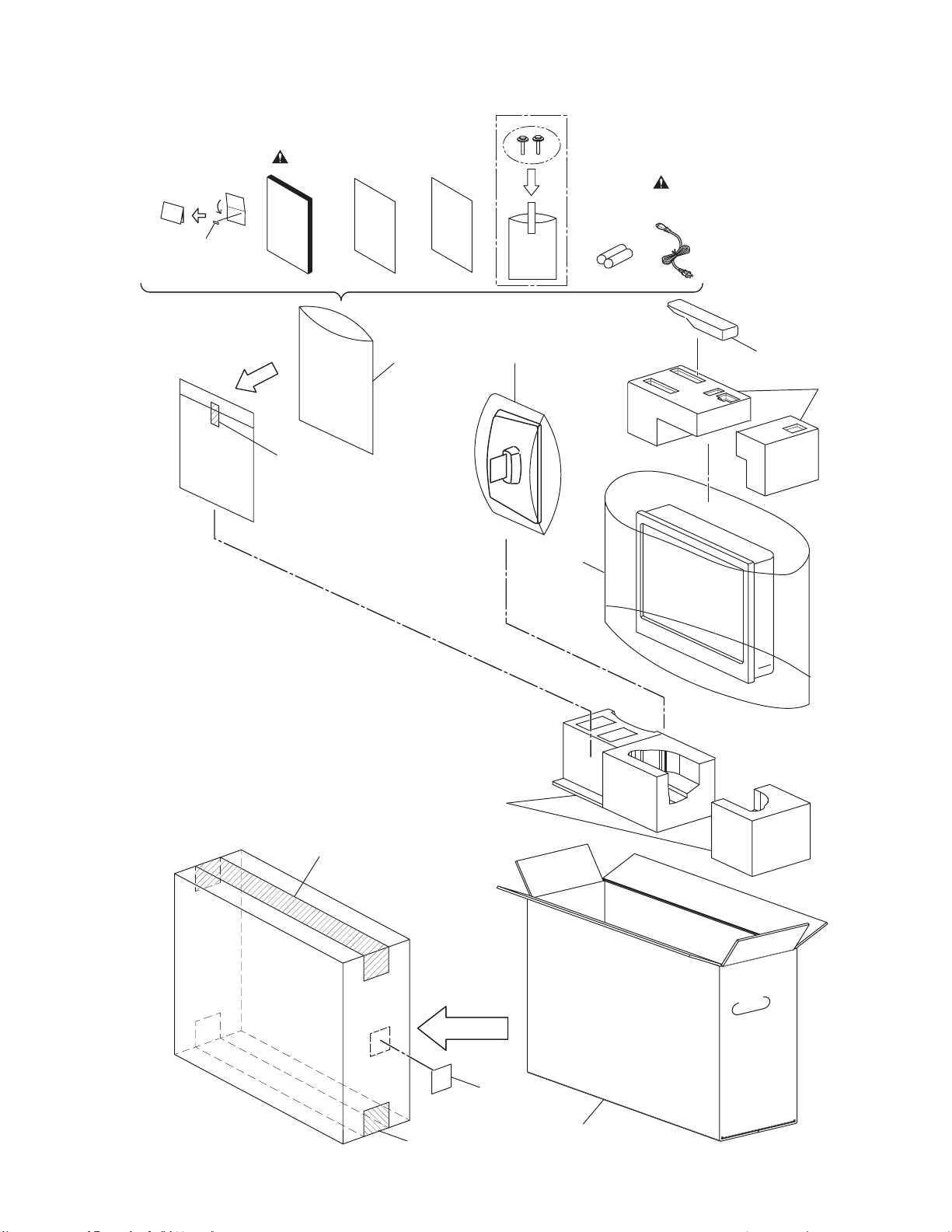

CABINET DISASSEMBLY INSTRUCTIONS

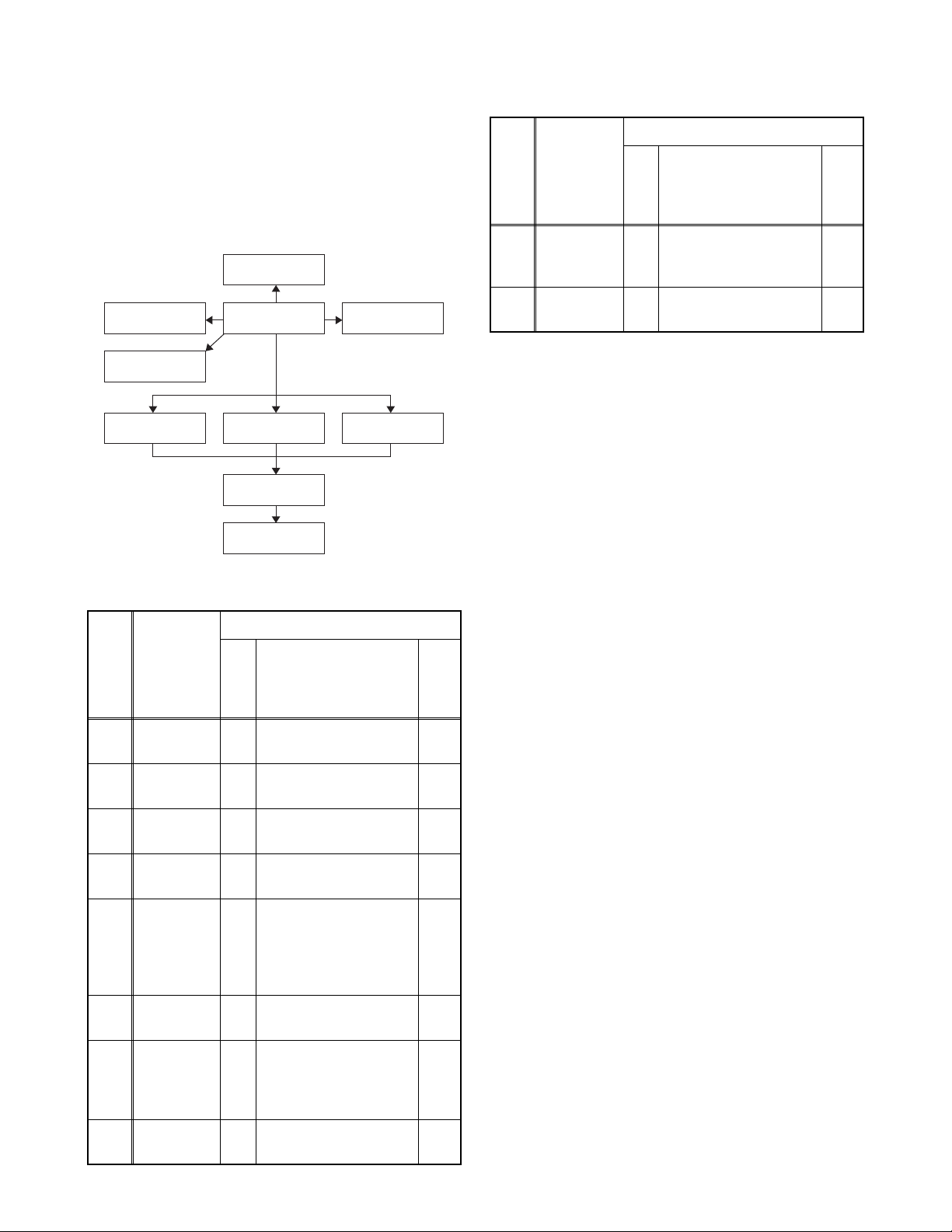

1. Disassembly Flowchart

This flowchart indicates the disassembly steps for the

cabinet parts, and the CBA in order to gain access to

item(s) to be serviced. When reassembling, follow the

steps in reverse order. Bend, route and dress the

cables as they were.

[2] Stand

Assembly

[3] Function

CBA

[8] IR Sensor

CBA

[6] Jack CBA

[1] Rear Cabinet

[5] Main CBA

[9] LCD Module

Assembly

[10] Front

Cabinet

[4] Speaker

[7] Digital Main

CBA Unit

2. Disassembly Method

Removal

Step/

Loc.

No.

[1]

Part

Rear

Cabinet

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Unclamp/

Desolder

9(S-1), 2(S-2), 2(S-3),

D1

8(L-1)

Note

---

Removal

Step/

Loc.

No.

Part

Fig.

Remove/*Unhook/

Unlock/Release/

No.

Unplug/Unclamp/

Note

Desolder

LCD

[9]

Module

D2 --------------- ---

Assembly

Front

[10]

↓

(1)

Cabinet

↓

(2)

D2 --------------- ---

↓

(3)

↓

(4)

↓

(5)

Note:

(1) Order of steps in procedure. When reassembling,

follow the steps in reverse order. These numbers

are also used as the Identification (location) No. of

parts in figures.

(2) Parts to be removed or installed.

(3) Fig. No. showing procedure of part location

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

H = Hex Screw, CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to the following "Reference Notes in the

Table."

Stand

[2]

Assembly

Function

[3]

CBA

[4] Speaker

[5] Main CBA

[6] Jack CBA

Digital Main

[7]

CBA UnitD2D3

IR Sensor

[8]

CBA

D1 2(S-4) ---

D2D32(S-5), *CN101,

Function Knob

D2D3*CN872, *CN2861,

Speaker Holder

---

---

7(S-6), 2(S-7),

*CN102, *CN201,

D2

*CN301, *CN302,

D3

*CN601, *CN702,

---

*CN873, AC Holder

D2

3(S-8), Jack Holder(A) ---

D3

(S-9), 4(S-10),

4(S-11), 2(H-1),

*CN3902, Shield Box,

---

Jack Holder(D)

D2

Sensor LED Lens ---

D3

4-1 FL10.9DC

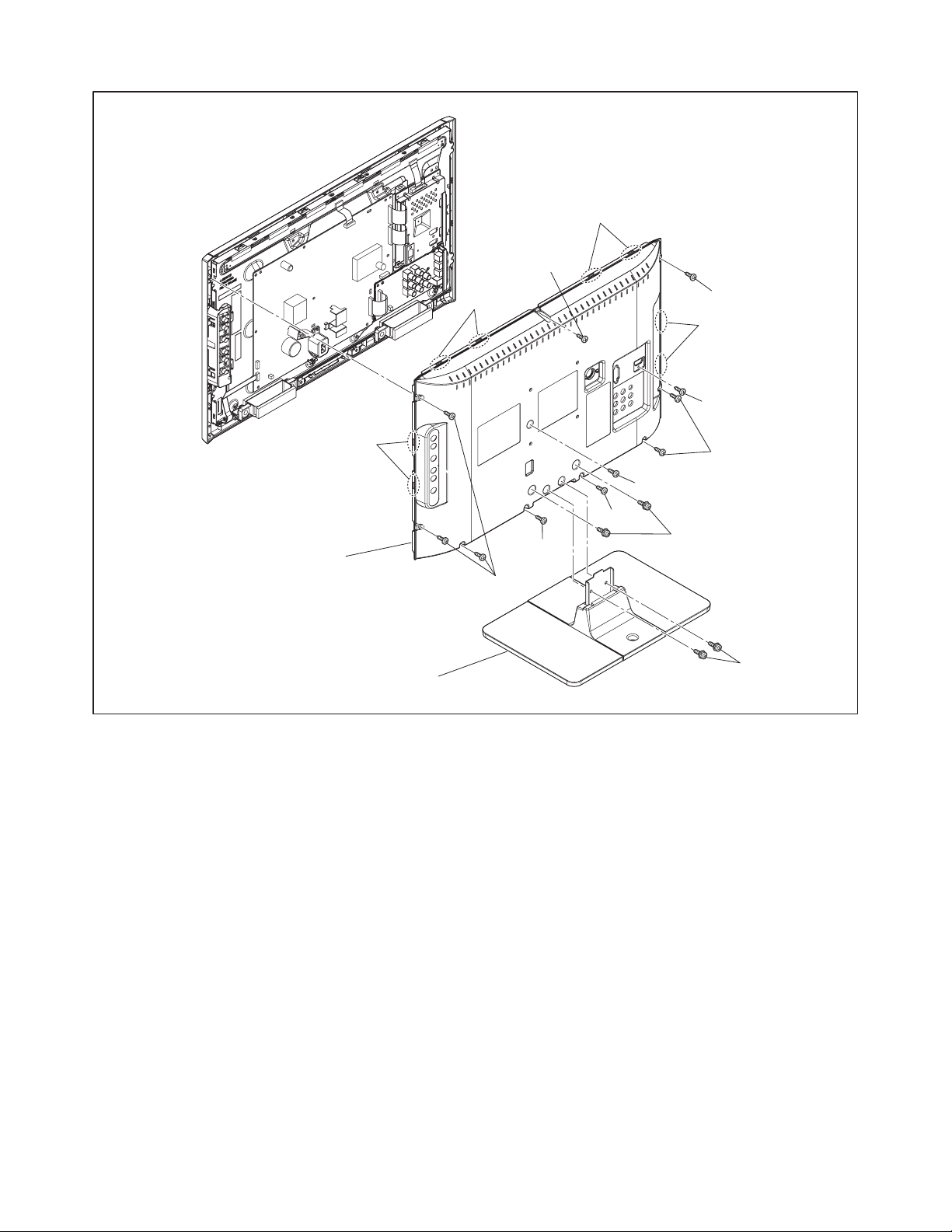

Page 14

(S-1)

(L-1)

[1] Rear Cabinet

[2] Stand Assembly

(L-1)

(L-1)

(S-1)

(L-1)

(S-3)

(S-1)

(S-3)

(S-1)

(S-2)

(S-1)

(S-1)

(S-4)

Fig. D1

4-2 FL10.9DC

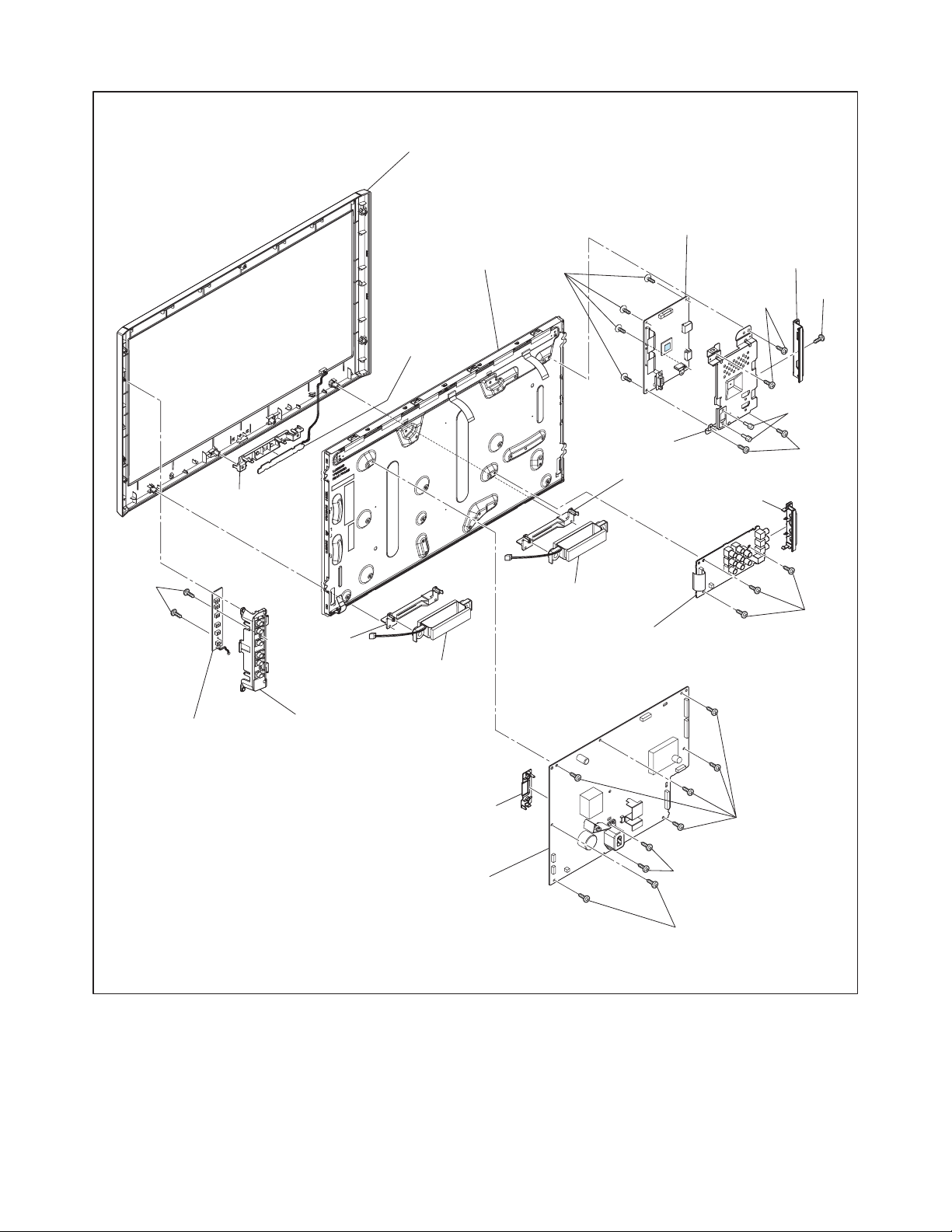

Page 15

[10] Front Cabinet

[9] LCD Module

Assembly

[8] IR Sensor

CBA

(S-11)

[7] Digital Main

CBA Unit

(S-10)

Jack Holder(D)

(S-9)

(H-1)

Sensor LED Lens

(S-5)

[3] Function CBA

Speaker

Holder

Function Knob

[4] Speaker

AC Holder

[5] Main CBA

Speaker Holder

[4] Speaker

[6] Jack CBA

Shield Box

(S-10)

Jack Holder(A)

(S-8)

(S-6)

(S-7)

(S-6)

Fig. D2

4-3 FL10.9DC

Page 16

TV Cable Wiring Diagram

To LCD Module

Assembly

To LCD Module

Assembly

CN101

CN873

CN872

To Speaker

Function

CBA

Main CBA

CN601

To AC cord

CN201

CN702

CN301

CN302

CN102

CN3902

CN3701

CN3702

Digital Main

CBA Unit

Jack CBA

CN2701

CN2681

To Speaker

CN2108

IR Sensor CBA

CN2107

Fig. D3

4-4 FL10.9DC

Page 17

ELECTRICAL ADJUSTMENT INSTRUCTIONS

General Note: “CBA” is abbreviation for

“Circuit Board Assembly.”

Note: Electrical adjustments are required after

replacing circuit components and certain

mechanical parts. It is important to perform

these adjustments only after all repairs and

replacements have been completed.

Also, do not attempt these adjustments unless

the proper equipment is available.

Test Equipment Required

1. NTSC Pattern Generator (Color Bar W/White

Window, Red Color, Dot Pattern, Gray Scale,

Monoscope, Multi-Burst)

2. Remote control unit

3. Color Analyzer

How to set up the service mode:

Service mode:

1. Turn the power on.

2. Press [MENU] button to display Setup menu.

3. Select “Features”.

4. Select “Current Software Info”.

5. Press [0], [4], [2], [5], [7], [4] and [Info] buttons on

the remote control unit in this order. The following

screen appears.

"*" differs depending on the models.

Code :

*******-***-*-*****-****

Pic code :

**-*******-*****-**

MIPS :

Push 0key

Press "POWER" key to exit.

Tuner :

****-*****-****

safety_Non

Safety :

5-1 FL10.3EA

Page 18

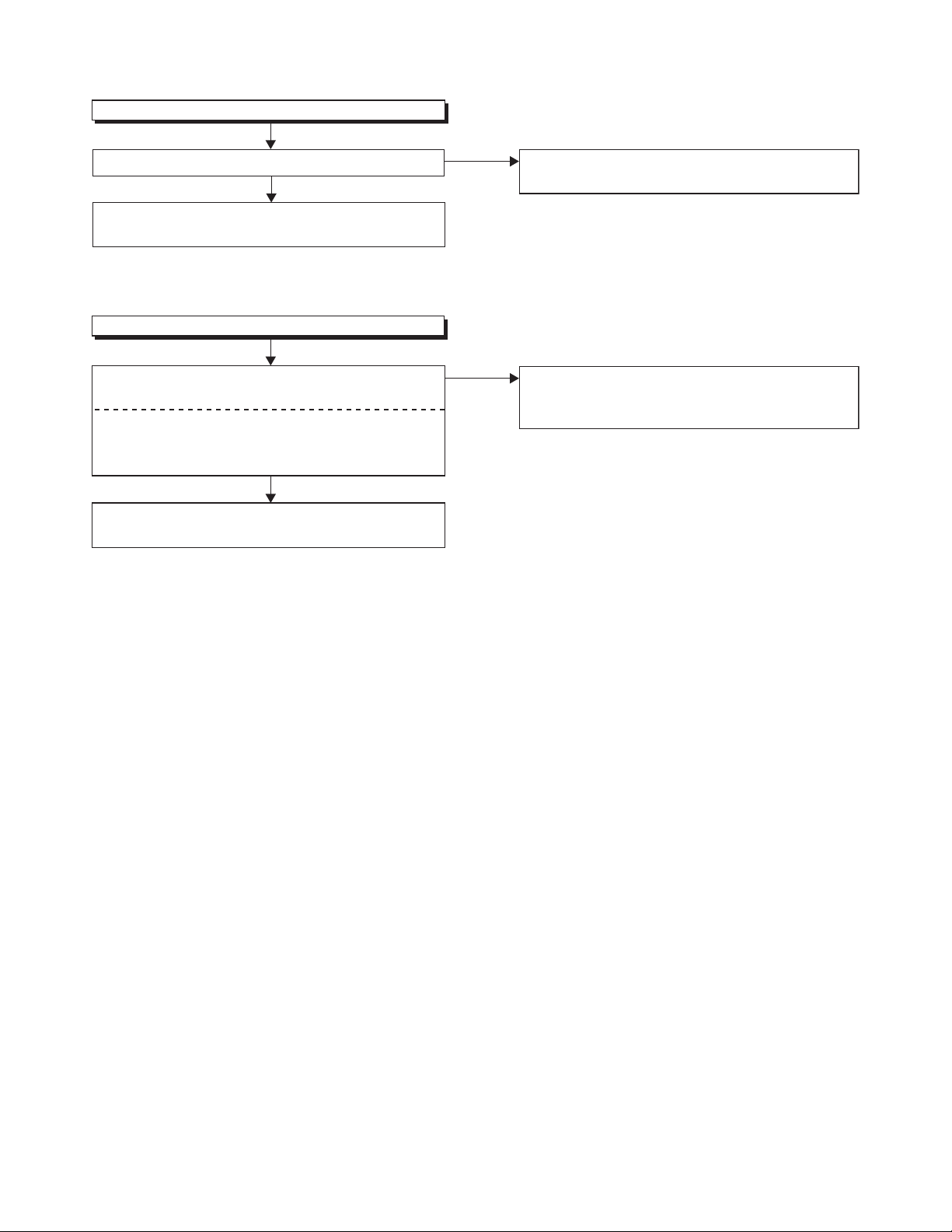

1. Purity Check Mode

2. VCOM Adjustment

This mode cycles through full-screen displays of red,

green, blue, and white to check for non-active pixels.

1. Enter the Service mode.

2. Each time pressing [7] button on the remote

control unit, the display changes as follows.

Purity Check Mode

White mode

[7] button

[7] button

Black mode

[7] button

Red mode

[7] button

Green mode

[7] button

Blue mode

Test Point Adj. Point

Screen

[CHANNEL UP/DOWN ]

buttons

M. EQ. Spec.

Color analyzer See below

Figure

To avoid interference from ambinent

light, this adjustment should be

performed in a dark room.

Perpendicularity

L = 3 cm

Color Analyzer

1. Operate the unit for more than 60 minutes.

2. Set the color analyzer and bring the optical

receptor to the center on the LCD-Panel surface

after zero point calibration as shown above.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

3. Enter the Service mode.

4. Press [3] button on the remote control unit.

5. Press [CHANNEL UP/DOWN] buttons on the

remote control unit so that the color analyzer value

becomes minimum.

6. To cancel or to exit from the VCOM Adjustment,

press [PREV CH] button.

[7] button

White 20% mode

Note:

When entering this mode, the default setting is White mode.

3. To cancel or to exit from the Purity Check Mode,

press [PREV CH] button.

5-2 LC8NEA

Page 19

The White Balance Adjustment should be

performed when replacing the LCD Panel

or Digital Main CBA.

3. White Balance Adjustment

Purpose: To mix red, green and blue beams correctly

for pure white.

Symptom of Misadjustment: White becomes bluish

or reddish.

Test Point

Screen

Adj. Point Mode Input

[VOLUME

DOWN]

button

[VIDEO1]

C/D

M. EQ. Spec.

White Raster

(APL 70%)

or

(APL 40%)

5. [CUTOFF]

Press [1] button to select “COR” for Red Cutoff

adjustment. Press [3] button to select “COB” for

Blue Cutoff adjustment.

[DRIVE]

Press [4] button to select “DR” for Red Drive

adjustment. Press [6] button to select “DB” for Blue

Drive adjustment.

6. In each color mode, press [CHANNEL UP/DOWN]

buttons to adjust the values of color.

7. Adjust Cutoff and Drive so that the color

temperature becomes 12000°K (x

=

0.272 / y

=

0.278 ±0.005).

8. To cancel or to exit from the White Balance

Adjustment, press [PREV CH] button.

Pattern Generator,

Color analyzer

x= 0.272 ± 0.005

y= 0.278 ± 0.005

Figure

To avoid interference from ambinent

light, this adjustment should be

performed in a dark room.

Perpendicularity

L = 3 cm

INPUT: WHITE 70%, 40%

Color Analyzer

1. Operate the unit for more than 60 minutes.

2. Input the White Raster(70%=70IRE, 40%=40IRE).

INPUT SIGNAL

0IRE 0IRE

Low

Hight

Light

Light

100IRE

40%=40IRE

70%=70IRE

100IRE

3. Set the color analyzer to the CHROMA mode and

bring the optical receptor to the center on the

LCD-Panel surface after zero point calibration as

shown above.

Note: The optical receptor must be set

perpendicularly to the LCD Panel surface.

4. Enter the Service mode. Press [VOLUME DOWN]

button on the remote control unit and select “C/D”

mode.

5-3 LC8NEA

Page 20

HOW TO INITIALIZE THE LCD TV

The purpose of initialization is to place the set in a new out of box condition. The customer will be prompted to

select a language and program channels after the set has been initialized.

To put the program back at the factory-default, initialize the LCD TV using the following procedure.

1. Turn the power on.

2. Enter the service mode.

- To cancel the service mode, press [POWER]

button on the remote control unit.

3. Press [INFO] button on the remote control unit to

initialize the LCD television.

4. "INITIALIZED" will appear in the upper right of the

screen. "INITIALIZED" color will change to green

from red when initializing is completed.

6-1 PL10.3INT

Page 21

FIRMWARE RENEWAL MODE

Equipment Required

a. USB storage device

b. Remote Control Unit

Firmware Update Procedure

Note: There are two states (the User Upgrade and

the Factory Upgrade) in firmware update.

User Upgrade Upgrade the firmware only.

The setting values are not

initialized.

Factory upgrade Upgrade the firmware and

initialize the setting values.

The identification of User Upgrade and Factory

Upgrade are done by the filename.

1. Turn the power off and unplug the AC Cord.

2. Insert the USB storage device to the USB port as

shown below.

The USB port “SERVICE TERMINAL” will be

blocked by a cross shaped piece of plastic. Cutoff

both end of the plastic connected to the PCB

Holder as illustrated below.

Rear Cabinet

USB port

Cut

4. The update will start and the following will appear

on the screen.

"*" differs depending on the models.

Software Upgrade

Software upgrade in progress. Please wait.

Do not remove the USB storage device or

turn the TV off while upgrade is in progress.

*1

Current Version:

New Version:

Downloading...

0%

*******-***-*-***-****

*******-***-*-***-****

Note: If the above screen isn’t displayed, repeat from

step 1.

The appearance shown in *1 is described as follows.

Appearance State

Downloading...

Writing...

Downloading the firmware from

the USB storage device.

Writing the downloaded firmware

in flash memory.

Checking... Checking the new firmware.

5. When the firmware update is completed, the

following will appear on the screen.

Software Upgrade

SERVICE

TERMINAL

USB storage

device

3. Plug the AC cord in the wall outlet and turn the

power on.

The software upgrade is completed.

Remove USB storage device, turn TV off then on again.

Remove the USB storage device from the USB

port.

Turn the power off and turn the power on again.

Note:

When the Factory Upgrade is used, after

restarting TV, shift to initial screen menu in service

mode. "INITIALIZED" will appear on the upper

right of the screen. "INITIALIZED" color will

change to green from red when initializing is

completed.

7-1 FL10.9FW

Page 22

[ Power Supply Section ]

FLOW CHART NO.1

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse (F601) normal?

Ye s

Is normal state restored when once unplugged

power cord is plugged again several seconds?

Ye s

Is the +24V line voltage normal?

Ye s

Check each rectifying circuit of the secondary

circuit and service it if de

FLOW CHART NO.2

The fuse blows out.

Check the presence that the primary component

is leaking or shorted and service it if defective.

After servicing, replace the fuse.

FLOW CHART NO.3

When the output voltage fluctuates.

fective.

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check if there is any leak or short-circuiting on the

primary circuit component, and service it if defective.

(D601, D602, D603, D604, Q601, Q603, IC602,

T601)

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondary side,

and service it if defective.

Does the photocoupler circuit on

secondary side operate normally?

Check IC601, IC

peripher

FLOW CHART NO.4

When buzz sound can be heard in the vicinity of power circuit.

Check if there is any short-circuit on the rectif

and service it if defective. (IC201, IC621, IC631, Q210,

FLOW CHART NO.5

+24V is not output.

Is approximately +24V voltage supplied to the

cathode of D632?

Check if there is

circuit, and service it if def

y, circuit and service it if def

602, D615, D616, D617 and their

any leak or short-circuit on the loaded

the

Ye s

ective.

ying diode and the circuit in each rectifying circuit of the seconda

Q634, Q636, Q637, Q641, Q643, D632, D636, D

Ye s

ective.

No

No

Check IC601, D633, D634, D648, Q631 and their

periphery circuit, and service it if defective.

ry side,

641, D643, D1070)

Check C632, C1065, D632, D633 and their

periphery circuit, and service it if defective.

8-1 FL10.9TR

Page 23

FLOW CHART NO.6

VT+32V is not output.

Is approximately +33V voltage supplied to the cathde

of D1070?

Ye s

Check D1071, R1182 and their periphery circuit, and

service it if defective.

FLOW CHART NO.7

P-ON+7V is not output.

Is approximately +7V voltage supplied to the

cathde of D641?

Ye s

Check if there is any leak or s

the loaded circuit, and service it if de

FLOW CHART NO.8

P-ON+5V is not output.

Is approximately +7V voltage supp

collector of Q636?

Is approximately +6V voltage supplied to the

base of Q636?

hort-circuit on

fective.

lied to the

Ye s

Ye s

No

No

No

No

Check C1056, D1070 and

service it if defective.

Check C641, C1067, C1068, D641 and their

periphery circuit, and service it if de

See FLOW CHART No.7 <P-ON+7V is not output.>

Check D659 and their periphery circuit, and service

it if defective.

their periphery circuit, and

fective.

Replace Q636.

FLOW CHART NO.9

TUNER+5V is not output.

Is approximately +

collector of Q637?

Is approximately +6V voltage supp

base of Q637?

Replace Q637.

FLOW CHART NO.10

P-ON+3.3V(P-ON+3V) is not output.

Is approximately +

IC621?

Is the "H" s

Replace IC621.

6.7V voltage supplied to the

Ye s

Ye s

24V voltage supplied to Pin(2) of

Ye s

ignal inputted to Pin(7) of IC621?

Ye s

lied to the

No

No

No

No

See FLOW CHART No.7 <P-ON+7V is not output.>

Check D659 and their periphery circuit, and service

it if defective.

Check C632, C1065, D632 and their p

circuit, and service it if defective.

Check Q402, Q403, Q638, Q639, P-ON-H1 line,

P-ON-H2 line and their periphery circuit, and service

it if defective.

eriphery

8-2 FL10.9TR

Page 24

FLOW CHART NO.11

P-ON+9V is not output.

Is approximately +14V voltage supplied to the

collector of Q641?

Ye s

Is approximately +10V voltage supplied to the

base of Q641?

Ye s

Replace Q641.

FLOW CHART NO.12

AL+3.3V is not output. (P-ON+7V is outputted normally)

Is approximately

IC631?

Replace IC631.

FLOW CHART NO.13

SP+14V is not output.

Is approximately +14V voltage supplied to the cathode

of D643?

+5.8V voltage supplied to Pin(2) of

Ye s

Ye s

No

No

No

No

Check C1069, D643, D644 and their periphery

circuit, and service it if defective.

Check D666 and their periphery circuit, and service

it if defective.

Check D654, D655, R659, R682 and their periphery

circuit, and service it if defective.

Check C1069, D643, D644 and their periphery circuit,

and service it if d

efective.

Check if there is any leak or s

loaded circuit, and service it if defective.

FLOW CHART NO.14

PANEL+12.5V is not output.

Is approximately +24V voltage supplied

Is the "H" s

Replace IC201.

FLOW CHART NO.15

PANEL-5.6V is not output.

Is approximately -8.7V voltage supplied to the emitter

of Q210?

Is approximately -8V voltage supp

Q210?

Check D204, R241, R242

and service it if defective.

ignal inputted to Pin(7) of IC201?

hort-circuit on the

to Pin(2) of IC201?

Ye s

Ye s

Ye s

lied to the base of

Ye s

and their periphery circuit,

No

No

No

No

Check C632, C1065, D632, D633 and their periphery

circuit, and service it if defective.

Check Q202, Q203, P-ON-H1 line and their periphery

circuit, and service it if defective.

Check C636, D636, D637 and their periphery circuit,

and service it if defective.

Check Q202, Q203, D203, P-ON-H1 line and their

periphery circuit, and service it if def

ective.

8-3 FL10.9TR

Page 25

[ Video Signal Section ]

FLOW CHART NO.1

The key operation is not functioning.

Are the contact point and installation state of the key

switches (SW2101~SW2106) nor

Ye s

When pressing each switches (SW2101~SW2106)

do the voltage of Pin(29) of CN302 increase?

Ye s

Replace Digital Main CBA Unit.

FLOW CHART NO.2

No operation is possible from the remote control unit.

Operation is pos

Is 3.3V voltage supp

remote control receiv

Is the "L" pulse sent out Pin(1) terminal of

control receiver (RS2101) when the infrared remote

control is activated?

Is the "L" pulse supplied to Pin(25) of CN301?

Replace Digital Main CBA Unit.

sible from the unit.

lied to Pin(3) terminal of the

er (RS2101)?

Ye s

Ye s

Ye s

mal?

remote

No

No

No

No

No

Re-install the switches (SW2101~SW2106)

correctly or replace the poor switch.

Check the switches (SW2101~SW2106)

and their periphery, and service it if defective.

Check AL+3.3V line and service it if defective.

Replace the remote control receiver(RS2101)

or the remote control unit.

Check the line between Pin(1) terminal of remote

control receiver(RS2101) and Pin(25) of CN301,

and service it if defective.

FLOW CHART NO.3

Picture does not appear normally.(Video input)

Are the video signal inputted to Pin(

Ye s

Replace Digital Main CBA Unit or LCD Module

Assembly.

4) of CN302?

No

Check the line between Pin(4) of CN302 and

JK2752, and service it if def

ective.

8-4 FL10.9TR

Page 26

FLOW CHART NO.4

Picture does not appear normally.(Tuner input)

Are the DIF signal inputted to Pin(26,28) of CN302?

Ye s

Replace Digital Main CBA Unit or LCD Module

Assembly.

FLOW CHART NO.5

Picture does not appear normally.(Y/Pb/Pr input)

Are the video signal inputted to Pin(15, 17, 19)

CN302?

Pin(15): VIDEO-Y

Pin(17): VIDEO-Pb

Pin(19): VIDEO-Pr

Ye s

Replace Digital Main

Assembly.

CBA Unit or LCD Module

of

No

No

Check the line between Pin(26, 28) of CN302 and

TU301, and service it if defective.

Check the line between Pin(15, 17, 19) of CN302

and input terminals(JK2731, JK2732, JK2733), and

service it if defective.

8-5 FL10.9TR

Page 27

[ Audio Signal Section ]

FLOW CHART NO.1

Audio is not outputted normally.(Audio input)

Are the audio(L/R) signals inputted to Pin(2, 15)

of IC2771?

Ye s

Are the audio(L/R) signals inputted to Pin(6, 8) of

CN301?

Ye s

Are the audio(L/R) si

of IC801?

Are the audio(L/R) signals outputted to Pin(4, 6)

of IC801?

Check JK2851, SP801,SP802 and their periphery

circuit, and service it if defective.

FLOW CHART NO.2

Audio is not outputted normally.(Component Audio input)

Are the audio(L/R) signals inputted to Pin(4, 11)

of IC2771?

Are the audio(L/R) signals inputted to Pin(6, 8) of

CN301?

Are the audio(L/R) signals inputted to Pin(1, 9)

of IC801?

Are the audio(L/R) signals outputte

of IC801?

gnals inputted to Pin(1, 9)

Ye s

Ye s

Ye s

Ye s

Ye s

d to Pin(4, 6)

Ye s

No

No

No

No

No

No

No

No

Check the line between Pin(2, 15) of IC2771 and input

terminal(JK2753, JK2754), and service it if defective.

Replace Digital Main CBA Unit.

Check the line b

Pin(1, 9) of IC801, and service it if defective.

Check IC801 and their periphery circuit, and

service it if defective.

Check the line between Pin(4, 11) of IC2771 and input

terminal(JK2741, JK2742), and service it if defective.

Replace Digital Main CBA Unit.

Check the line between Pin(6

Pin(1, 9) of IC801, and s

Check IC801 an

service it if defective.

etween Pin(6, 8) of CN301 and

, 8) of CN301 and

ervice it if defective.

d their periphery circuit, and

Check JK2851, SP801,SP802 and their periphery

circuit, and service it if defective.

8-6 FL10.9TR

Page 28

FLOW CHART NO.3

Audio is not outputted normally.(Tuner input)

Are the DIF signals outputted to Pin(26, 28) of CN302?

Ye s

Are the audio(L/R) signals inputted to Pin(6, 8) of

CN301?

Ye s

Are the audio(L/R) signals inputted to Pin(1, 9)

of IC801?

Ye s

Are the audio(L/R) signals outputted to Pin(4, 6)

of IC801?

Ye s

Check JK2851, SP801,SP802 and their periphery

circuit, and service it if defective.

FLOW CHART NO.4

Audio is not outputted normally.(HDMI Audio input)

Are the audio(L/R) signals inputted to Pin(5, 14)

of IC2771?

Ye s

Are the audio(L/R) signals inputted to Pin(6, 8) of

CN301?

Ye s

Are the audio(L/R) signals inputted to Pin(1, 9)

of IC801?

Ye s

Are the audio(L/R) signals outputte

of IC801?

Ye s

d to Pin(4, 6)

No

No

No

No

No

No

No

No

Check TU301 and their periphery circuit, and service

it if defective.

Replace Digital Main CBA Unit.

Check the line between Pin(6, 8) of CN301 and

Pin(1, 9) of IC801, and service it if defective.

Check IC801 an

service it if defective.

Check the line between Pin(5, 14) of IC2771 and input

terminal(JK2721, JK2722), and service it if defective.

Replace Digital Main CBA Unit.

Check the line between Pin(6

Pin(1, 9) of IC801, and s

Check IC801 an

service it if defective.

d their periphery circuit, and

, 8) of CN301 and

ervice it if defective.

d their periphery circuit, and

Check JK2851, SP801,SP802 and their periphery

circuit, and service it if defective.

8-7 FL10.9TR

Page 29

FLOW CHART NO.5

Audio is not outputted normally.(PC Audio input)

Are the audio(L/R) signals inputted to Pin(1, 12)

of IC2771?

Ye s

Are the audio(L/R) signals inputted to Pin(6, 8) of

CN301?

Ye s

Are the audio(L/R) signals inputted to Pin(1, 9)

of IC801?

Ye s

Are the audio(L/R) signals outputted to Pin(4, 6)

of IC801?

Ye s

Check JK2851, SP801,SP802 and their periphery

circuit, and service it if defective.

No

No

No

No

Check the line between Pin(1, 12) of IC2771 and

input terminal(JK2711), and service it if defective.

Replace Digital Main CBA Unit.

Check the line between Pin(6, 8) of CN301 and

Pin(1, 9) of IC801, and service it if defective.

Check IC801 and their periphery circuit, and

service it if defective.

8-8 FL10.9TR

Page 30

BLOCK DIAGRAMS

System Control Block Diagram

P-ON+5V

LIGHT

D2103

SENSOR

IR SENSOR CBA

KEY SWITCH

FUNCTION CBA

CN210B

REMOTE

RS2101

D2102

POWER

SENSOR

CN2107

TO

P-ON-H2

P-ON-H1

POWER SUPPLY

BLOCK DIAGRAM

PROTECT1

VCOM

TO

LED BACKLIGHT

DRIVE BLOCK

PROTECT3

BACKLIGHT-SW

BACKLIGHT-ADJ

DIAGRAM

LED155

REMOTE22

LIGHT77

CN102

Q171

CN302

KEY-IN129 29

CN3702

L1

KEY-IN1

KEY-IN122

CN101

CN301

P-ON-H199

LED-R13 13

P-ON-H211

Q3704

REMOTE25 25

CN3701

T1

REMOTE

P2

U3

P-ON-H1

P-ON-H2

P3

LED-R

LIGHT11

BUFFER

M3

LIGHT-SENS

CN301

11

PROTECT1

11

CN3701

PROTECT1 L2

5

26

PROTECT3

BACKLIGHT-SW

5

26

M2

PROTECT3

BACKLIGHT-SW E19

DRIVE

IC202,Q211,

29

28

VCOM-PWM

BACKLIGHT-ADJ

29

28

C22BACKLIGHT-ADJ

VCOM-PWM M4

Q212,Q213

Either TU301 is used for Main CBA.

SCL

SDA

TU301 (TUNER UNIT)

*

8

7

CN302

22

21

SCL

SDA

22

21

CN3702

K3

K4

SCL1

SDA1

SCL

SDA

TU301 (TUNER UNIT)

*

4

5

MAIN CBA

IC3301

(MAIN MICRO CONTROLLER)

INPUT0

G19

INPUT0

INPUT1

TO AUDIO

BLOCK

AUDIO-MUTE

INPUT1

P5

G20

AUDIO-MUTE

DIAGRAM

9-1

SCK

K22

SIN

L19

SOUTCSWP

L20

F213

K21

CLKIN-25M

U1

CLKOUT-32K

CLKIN-32K

V1

N2

N1

CLKOUT-25M

DIGITAL MAIN CBA UNIT

25MHz

OSC

652

SI

SO

SCK

IC3101 (MEMORY)

X3101

1

CS

WP

32.768kHz

X3102

OSC

FL10.9BLS

Page 31

Video Block Diagram

AUDIO SIGNAL

TO DIGITAL

SIGNAL PROCESS

BLOCK DIAGRAM

VIDEO SIGNAL

DIGITAL MAIN CBA UNIT

VIDEO-IN

CN3702

CN302

WF1

WF2

COM-VIDEO-Pr-IN

COM-VIDEO-Y-IN

COM-VIDEO-Pb-IN

VIDEO-IN4 4

COM-VIDEO-Y-IN

COM-VIDEO-Pb-IN

COM-VIDEO-Pr-IN

15 15

17 17

19 19

WF4

WF3

VGA-R-IN

1

VGA-G-IN

2

VGA-B-IN

3

VGA-HSYNC

131415

JK3703

PC-RGB

IN

VGA-SCL

VGA-VSYNC

VGA-SDA

12

DIF-OUT1

DIF-OUT2

DIF-OUT126 26

CN302 CN3702

IF-AGC

IF-AGC24 24

DIF-OUT228 28

CN702CN2701

VIDEO-IN 27

3

JK2752

2010

COM-VIDEO-Y-IN

VIDEO-IN

1812

1614

COM-VIDEO-Pb-IN

COM-VIDEO-Pr-IN

COMPONENT

JK2731

-Y-IN

COMPONENT

JK2732

-Pb-IN

JK2733

COMPONENT

-Pr-IN

9-2

MAIN CBA

12

11

10

IF-AGC

DIF-OUT1

DIF-OUT2

9

11

10

IF-AGC

DIF-OUT1

DIF-OUT2

JACK CBA

TU301

*

Either TU301 is used for Main CBA.

(TUNER UNIT)

TU301

(TUNER UNIT)

*

FL10.9BLV

Page 32

Audio Block Diagram

AUDIO SIGNAL

TO

DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

TO

SYSTEM

CONTROL

BLOCK

DIAGRAM

TO

DIGITAL

SIGNAL

PROCESS

BLOCK

DIAGRAM

WF5

AUDIO(L)

CN3702CN302

AUDIO(L)13 13

AUDIO(R)

AUDIO(R)11 11

CN702CN2701

INPUT1

CN3702CN302

INPUT110 10

INPUT0

AUDIO-MUTE

INPUT012 12

SPDIF

AMP(L)-OUT

AMP(R)-OUT

DIGITAL MAIN CBA UNIT

22

CN3701CN301

237

1

CN3702

AUDIO-MUTE 2020

SPDIF

AMP(L)-OUT66

AMP(R)-OUT88

CN302

Q801

8

9

SPDIF

AUDIO(L)17 13

AUDIO(R)15 15

INPUT1624

INPUT0822

DRIVE

DRIVE

IC801 (AUDIO AMP)

BUFFER

Q2773

BUFFER

3

(AUDIO SELECTOR)

IC2771

241

-IN

AUDIO(R)

JK2754

5

151112

-IN

JK2741

JACK CBA

AUDIO(L)

JK2753

13

COMPONENT-

AUDIO(L)-IN

14

COMPONENT-

JK2742

Q2774

CONTROL

AUDIO(R)-IN

LOGIC

PC-AUDIO-IN

JK2711

Q2771

109

HDMI-

JK2721

Q2722

AUDIO(L)-IN

HDMI-

JK2722

JK2841

AUDIO(R)-IN

BUFFER

Q2841

DIGITAL

AUDIO-OUT

(COAXIAL)

4

CN702CN2701

JK2851

HEADPHONE

JACK

MUTE CONTROL

6

3,4

9,10

HEADPHONE(R)

HEADPHONE(L)

SP(R) 1,2

26,27

20,21

28,29

CN2861

SP(L) 1

SP801

SP-GND 2

SPEAKER

L-CH

CN872

SP(R) 1

SP-GND 2

SP802

SPEAKER

MAIN CBA

R-CH

9-3

FL10.9BLA

Page 33

Digital Signal Process Block Diagram

LCD MODULE

ASSEMBLY

LLV1(+)21

LLV1(-)20

LLV0(+)23

LLV0(-)22

LLV2(+)19

LLV2(-)18

LLV3(+)13

LLV3(-)12

LLVCLK(+)16

LLVCLK(-)15

CN3904

AUDIO SIGNAL

VIDEO SIGNAL

IC3201

(DDR2 SDRAM)

B1,B9,C2,C8,

D1,D3,D7,D9,

DATA(0-15)

ADDESS(0-12)

H1,H3,H7,H9

F1,F9,G2,G8,

M2,M3,M7,M8,

N2,N3,N7,N8,

P2,P3,P7,P8,R2

VGA-HSYNC

IC3301 (DIGITAL SIGNAL PROCESS)

C1

VGA-VSYNC

VGA-SCL

VGA-SDA

T3

T2

D1

B9

A9

A10

B10

B11

LVD S TX

F1

K1

G1

B8

A/D

A8

B12

A12

AA7,AA8-10,AA12,AA13,

AA15,AA16,AB7-10,AB12,

AB13,AB15,AB16

Y20,AA1-AA4,AA20-AA22,

AB1-AB3,AB21,AB22

DIGITAL

SIGNAL

PROCESS

HDMI

AUDIO I/F

CONVERTER

DEMODULATOR

SW

F3

E3

K2

H3

G3

/MPEG DECODER

IF-AGC

H2

R1

H1

A2

A3

A6C8B6

AUDIO

DECODER

I/F

P21

P22

N21

N22

M21

M22

26272324202117

HDMI

SW

L21

L22

18

VIDEO

DECODER

A11

E1

VGA-HSYNC

DIGITAL MAIN CBA UNIT

VGA-VSYNC

VGA-SCL

VGA-SDA

VGA-R-IN

VGA-G-IN

TO VIDEO

BLOCK DIAGRAM

VGA-B-IN

VIDEO-IN

COM-VIDEO-Y-IN

COM-VIDEO-Pr-IN

COM-VIDEO-Pb-IN

DIF-OUT1

DIF-OUT2

TO VIDEO

BLOCK DIAGRAM

IC3702 (HDMI SW)

(R)-OUT

AUDIO(R)

AUDIO(L)

IF-AGC

SPDIF

TO AUDIO

BLOCK DIAGRAM

AMP

AMP(L)-OUT

414544484739383637

TMDS-D0(+)

TMDS-D0(-)

TMDS-D1(+)

7 42

94613

TMDS-D1(-)

JK3701

TMDS-CLOCK(+)

TMDS-D2(+)

TMDS-D2(-)

101216

HDMI-IN1

TMDS-CLOCK(-)

SDA

SCL

15

9-4

TMDS-D0(+)

JK3702

8

7

111014

TMDS-D0(-)

TMDS-D1(+)

TMDS-D1(-)

79461

541

13

TMDS-D2(+)

TMDS-D2(-)

TMDS-CLOCK(+)

3

101216

HDMI-IN2

2

TMDS-CLOCK(-)

SDA

SCL

15

FL10.9BLD

Page 34

LED Backlight Drive Block Diagram

+66.2V6

CN873

LCD MODULE

ASSEMBLY

COMP14

COMP23

COMP32

COMP41

Q1032

LED DRIVE

Q1031

1

28

DRIVE1

IC1033(LED BACKLIGHT DRIVER)

LED DRIVE

3

2

DRIVE2

OVP

26

LED DRIVE

Q1033

5

DRIVE3

13

17

4

CONTROL

19

LOGIC

23

LED DRIVE

Q1034

7

DRIVE4

24

Q1028

6

VREF

14

Q1029

MAIN CBA

+24V

Q1035

9-5

BACKLIGHT-ADJ

PROTECT3

BACKLIGHT-SW

TO SYSTEM CONTROL

BLOCK DIAGRAM

FL10.9BLBD

Page 35

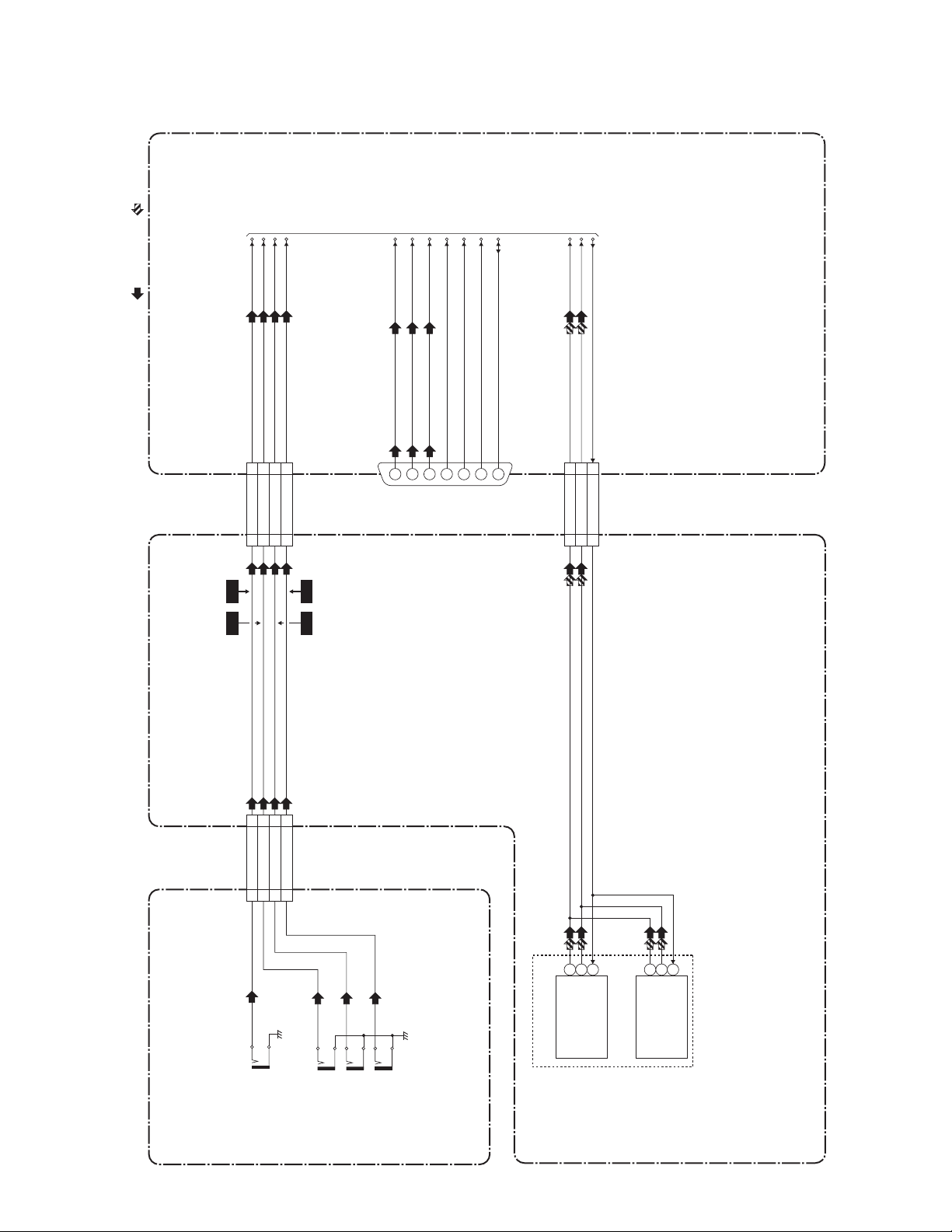

Power Supply Block Diagram

P-ON+7V

AL+3.3V

P-ON+3.3V

P-ON+5V

P-ON+3V

+31V

P-ON+3.3V

+24V

P-ON+9V

P-ON+5V

SP+14V

AL+3.3V

TUNER+5V

VCOM

TO SYSTEM

CONTROL

BLOCK

DIAGRAM

P-ON-H1

P-ON-H2

PROTECT1

LCD MODULE ASSEMBLY

16

10

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

Q204

P-ON+3V10

CN301 CN3701

+3.3V REG.

IC621

P-ON+7V16

PANEL+25.6V4

P-ON+3.3V6,7

PANEL-5.6V8

PANEL+12.5V2,3

VCOM10

CN201

Q215

SW+25.6V

Q206

For continued protection against risk of fire,

replace only with same type 4 A, 125V fuse.

CAUTION ! :

ATTENTION : Utiliser un fusible de rechange de même type de 4A, 125V.

Q205

21,22

AL+3.3V21,22

19,20

P-ON+3.3V19,20

14

P-ON+5V14

IC201

DIGITAL MAIN CBA UNIT

+12.5V REG.

Q641

SW+9V

SWITCHING

Q202,Q203

Q403

Q402

SWITCHING

Q638,Q639

Q643

Q642

SW+3.3V

Q637

SW+5V

Q633

SW+5V

Q635,Q636

IC631

23

+3.3V

REG.

4A/125V

RECTIFIER

FILTER

1

8

5

4A/125V

9

10

4

3

7

6

T601

BRIDGE

D601- D604

LINE

L601

F601

4A/125V

HOT CIRCUIT. BE CAREFUL.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

AC601

AC CORD

2

CN601

9-6

Q634

+5V REG.

SW-8.5V

Q210

Q631

FEED

BACK

IC601

ERROR

VOLTAGE DET

14

3 2

11

12

2

1

HOT COLD

SWITCHING

Q603

8

1

5OUT

2FB3IS6VCC

VH

ZCD

SWITCHING

Q601

SWITCHING

CONTROL

IC602

FL10.9BLP

MAIN CBA

Page 36

SCHEMATIC DIAGRAMS / CBA AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “#” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

6.

This schematic diagrams are masterized version

that should cover the entire FL10.9 chassis models.

Thus some parts in detail illustrated on this

schematic diagrams may vary depend on the

model within the FL10.9 chassis.

Please refer to the parts lists for each models.

7. The Circuit Board layout illustrated on this service

manual is the latest version for this chassis at the

moment of making this service manual.

Depend on the mass production date of each

model, the actual layout of each Board may differ

slightly from this version.

3

, M = 106).

-6

µF).

10-1 FL10.9SC

Page 37

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

r

THE FOLLOWING PAGES:

1. CAUTION:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK OF FIRE, REPLACE ONLY WITH SAME

TYPE_A,_V FUSE.

ATTENTION: UTILISER UN FUSIBLE DE RECHANGE DE MÊME TYPE DE_A,_V.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications on the schematics are as shown below:

Plug the TV power cord into a standard AC outlet.:

2

(Unit: Volt)

1

5.0 5.0

3

Power on mode

5. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line numbe

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

Voltage

Indicates that the voltage

is not consistent here.

3

2

1

AREA D3

1-B1

AREA B1

1-D3

ABCD

10-2 FL10.9SC

Page 38

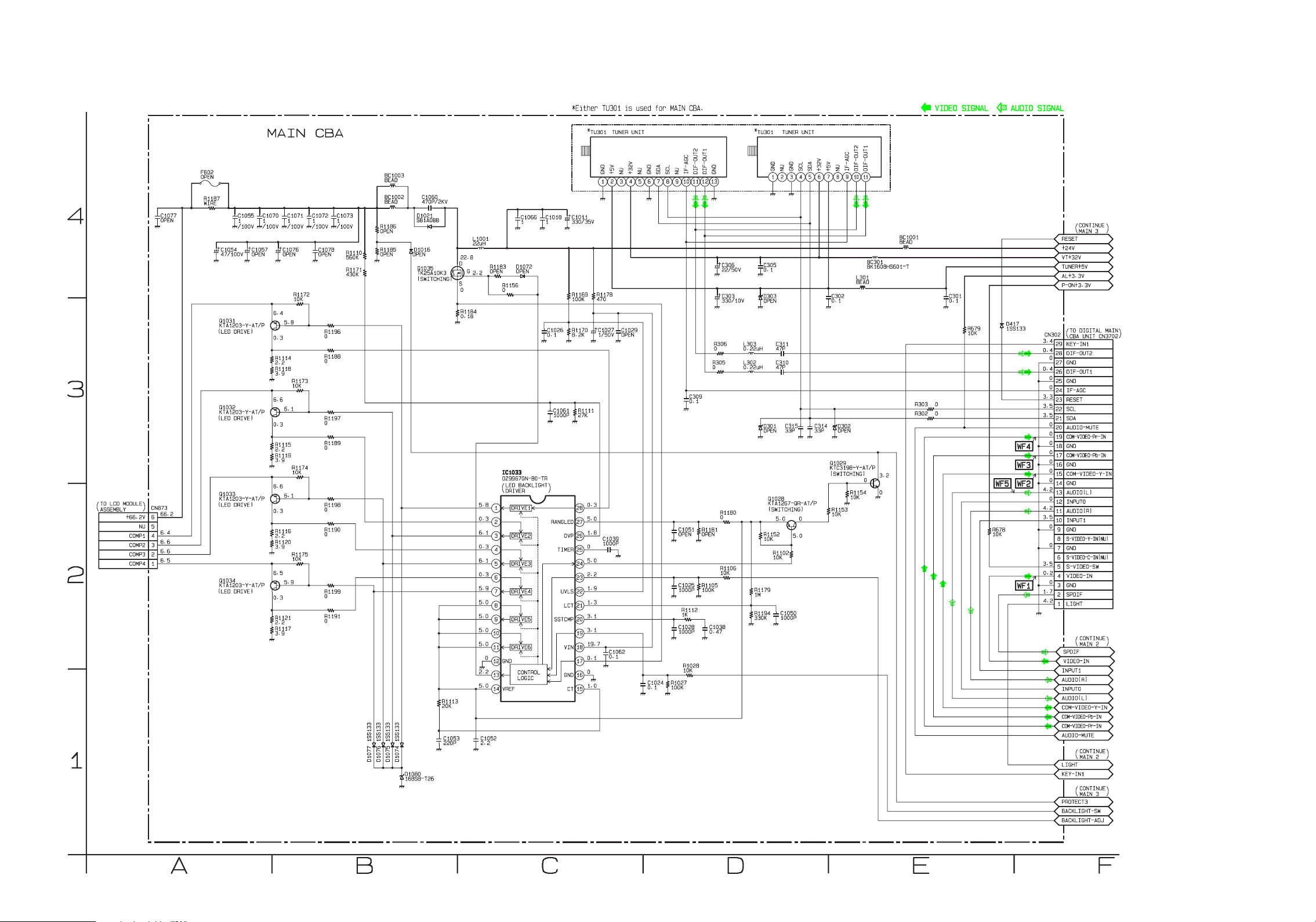

Main 1 Schematic Diagram

10-3

FL10.9SCM1

Page 39

Main 2 Schematic Diagram

10-4

FL10.9SCM2

Page 40

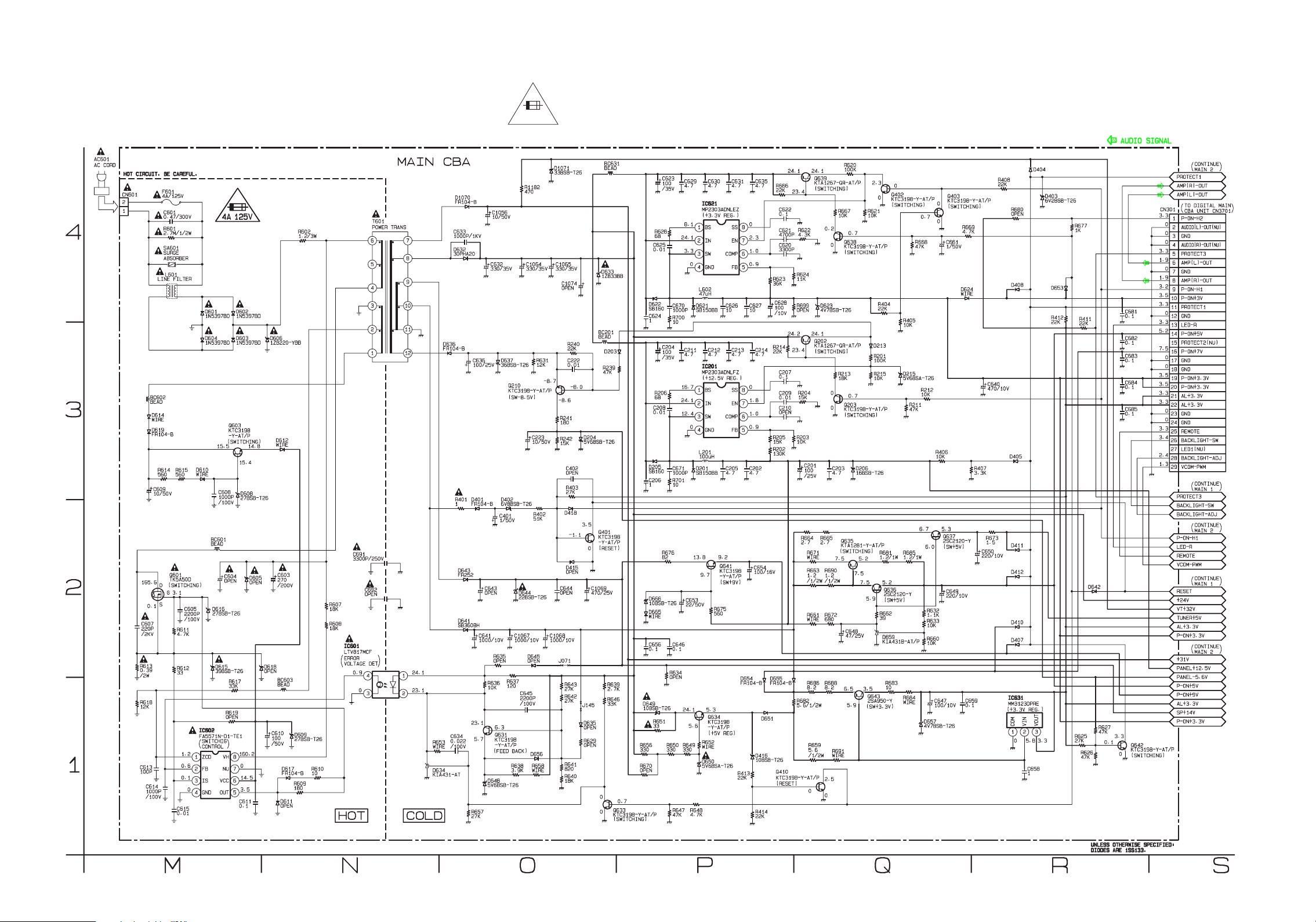

Main 3 Schematic Diagram

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

4A/125V

CAUTION ! :

ATTENTION : Utiliser un fusible de rechange de même type de 4A, 125V.

For continued protection against risk of fire,

replace only with same type 4 A, 125V fuse.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

10-5

FL10.9SCM3

Page 41

Jack Schematic Diagram

10-6

FL10.9SCJ

Page 42

Function Schematic Diagram

10-7

FL10.9SCF

Page 43

IR Sensor Schematic Diagram

10-8

FL10.9SCIR

Page 44

Digital Main 1 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-9

FL10.9SCD1

Page 45

Digital Main 2 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-10

FL10.9SCD2

Page 46

Digital Main 3 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-11

FL10.9SCD3

Page 47

Digital Main 4 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-12

FL10.9SCD4

Page 48

Digital Main 5 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-13

FL10.9SCD5

Page 49

Digital Main 6 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC3301.

IC3301 is divided into five and shown as IC3301 (1/6) ~ IC3301 (6/6) in this Digital Main Schematic Diagram Section.

10-14

FL10.9SCD6

Page 50

Main CBA Top View

Because a hot chassis ground is present in the power supply

circuit, an isolation transformer must be used when repairing.

Also, in order to have the ability to increase the input slowly,

when troubleshooting this type of power supply circuit,

a variable isolation transformer is required.

R1184

J122

J117

+B

J123

PROTECT3

Q1032

J139

R1116

ORV

COMP1

COMP3

J018

J103

J072

Q1033

VIN

ISEN3

J107

2

J087

Q1031

R1118

C692

GNDJ146

ISEN

R1120

C1076

Q1029

J008

C1027

SSTCMP

GND

J173

R1114

D656

CN873-4

J160

J179

GND

GND

C1051

UVLS

C645

R653

GND

C608

HOT

R602

C819

C609

C610

D602

D610

C1026

R1178

R638

Q631

IC601

R614

R615

R619

Q1028

J121

VREF

J113

GND

J100

4

J098

VREF

J076

GND

VREF

+B

J065

D1074

D1076

D1075

J141

D1080

D1077

J043

J102

COMP4

R1115

J140

ISEN4

J052

R1119

CN873-3

3

R1121

Q1034

R1117

R1187

J004

GND

2

COLD

J015

GND

CN101

J142

GND

1

5

J170

J169

GND

2

CN873

6

GND

CN872

1

1

R608

C1054

D1072

GND

J174

C1074

R658

C634

Q633

D648

D634

D608

Q603

D619

D614

D612

D611

D609

J177

VH

R607

C603

D606

D603

RISK OF FIRE REPLACE FUSE AS MARKED

A

C1060

Q1035

J017

J009

ZCD

D601

D637

IC601-1

C614

C611

D604

R637

C636

D636

BC602

C1057

BC1002

+B

J115

D1021

R635

R631

D401

BC603

R617

J012

J157

IC602-OUT

D617

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F601) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

R682

D651

R242

D416

D650

R649

R650

+31V

Q215-C

J048

J153

+24V

J056

C1056

COLD

Q202-C

J011

C632

R659

D654

J192

GND

J156

GND

C661

D666

Q212

D665

R208

D657

R247

C224

R206

BS

J181

D205

R628

J155

IC621 EN

C653

Q641

SP+14V

J025

J126

C623

2

D

Q204

VCOM

1

0

Q203

J073

C813

C812

LCD+12.5V

J129

D215

D402

BS

J182

2

6

D

Q202

C654

R691

J119

R686

R634

J094

J059

J082

+31V

Q215

R231

GND

J137

Q202-C

D655

P-ON-H2

J054

GND

D212

BL-SW

J109

R232

J195

J175

J176

J005

BL-ADJ

J138

J191

GND

J190

GND

J189

GND

+24V

+24V

D213-C

CN902

J027

ALL+3.3V

R688

P-ON-H2

J051

J067

LOW-VOL-SENS

Q639

J097

D211

J148

+24V

GND

GND

AMP-R-SP

KEY-IN1

R683

Q643

J147

Q410

R245

R248

LOW-VOL-SENS

J178

J044

Q204-C

J090

Q205-C

+31V

J095

J089

R667

Q638

J020

P-ON+3.3V

D213

D214

GND

J085

R676

R806

J131

GND

J193

J130

+24V

R675

C204

R666

GND

BC201

BC631

D414

Q205

R807

R684

Q211

+7.0V

+7.0V

C

IS

D645

C401

T601

BC1003

C223

Q210

L1001

GND

J167

Q210-E

J058

D6

R610

43

R609

D

C607

L601

GND

J040

6

32

D641

R612

GND

J042

C1011

Q601

D1016

C641

C1067

D204

R241

D209

BC601

D644

D605

C601

D203

R611

J031

+24V

D208

Q205-C

J180

D615

R

C605

D618

6

1

R220

D635

C1068

D616

3

SA601

Q206

R221

R222

C216

D649

J045

BC1001

+7.0V

J145

J071

C1069

C633

D633

D1070

C691

C604

HOT

1

0

6

H

F

F601

4A/125V

2

0

6

H

F

R601

B

CN904

+24V

SP+14V

TM601TM602

CN601

R230

+24V

J104

GND

J144

R656

C643

R651

J110

GND

C1065

Q634

R652

J154

GND

+24V

J081

R670

C1064

C647

L201

D418

L602

D622

1

J168

LCD+12.5V

D407

D413

J019

P-ON+9.0V

BA0177F0101 2

J128

CN201

-7.1V

J150

J194

GND

C201

LCD+12.5V

J136

GND

J132

C232

R665

LCD+12.5V

J120

IC801

D808

P-ON+3.3V

J135

LCD+12.5V

D415

P-ON-H1

J007

OUT1

J006

Q636

R664

R672

R662

D206

Q401

R1182

C628

IC621 EN

J032

J002

GND

Q213

Q637

C650

J037

LCD+12.5V

D1071

J092

J029

GND

SVRR

J127

R671

R661

D659

J099

P-ON-H1

J084

J091

J063

J062

R699

D623

P-ON+3.3V

J047

J184

J003

OUT2

C648

GND

J111

VCOM-PWM

Q635

ALL+3.3V

RESET

P-ON-H2

VT

J061

P-ON+3.3V

J057

P-ON+3.3V

D412

GND

J010

J151

R685

J023

LCD+12.5V

J069

TU5V

J013

INV2

M/SS

D805

GND

R681

C649

J064

P-ON+5.0V

J172

GND

J185

GND

CN901

J016

P-ON+9.0V

CN903

Q403

P-ON-H1

C834

J171

C7A3 A3

4A/125V

CAUTION ! :

ATTENTION : Utiliser un fusible de rechange de même type de 4A, 125V.

For continued protection against risk of fire,

replace only with same type 4 A, 125V fuse.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

Q642

D405

D207

D410

J134

J079

PROTECT1

R673

D411

J033

ALL+3.3V

J030

S-SW

D809

J133

P-ON+5.0V

R625

+7.0V

D404

J024

Q801

GND

J161

C306

J039

P-ON+5.0V

Q402

AMP-L