Page 1

SCOPE

:

This specification applies to the Pb Free high current type SMD inductors for

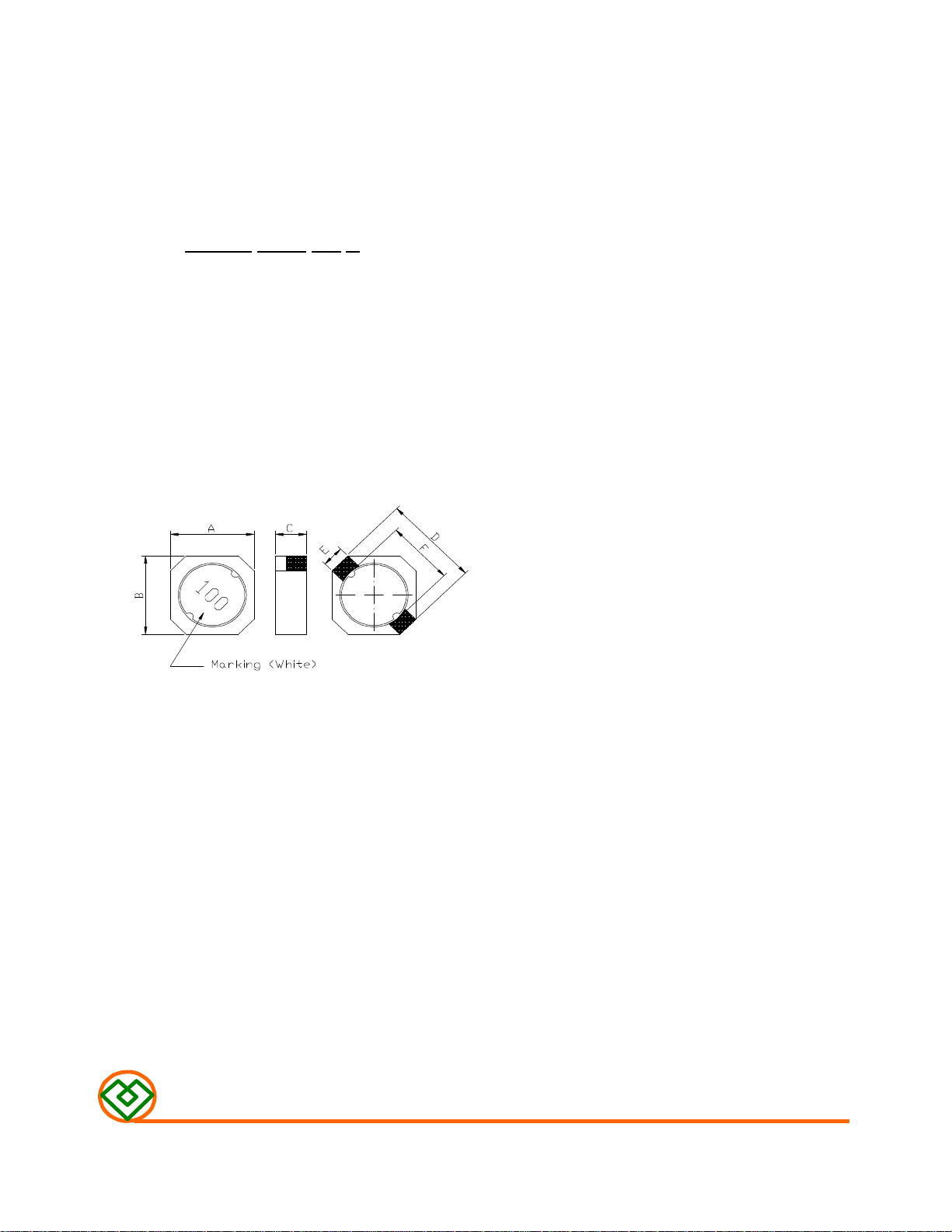

(1) SHAPES AND DIMENSIONS

(2) ELECTRICAL SPECIFICATIONS

(3) CHARACTERISTICS

MSCDRI-5020F-SERIES

PRODUCT INDENTIFICATION

MSCDRI-5020F-100 M

① ② ③ ④

① Product Code

② Dimensions Code

③ Inductance Code

④ Tolerance Code

A: 5.30Max. mm

B: 5.30Max. mm

C: 2.00Max. mm

D: 5.80±0.3 mm

E: 1.70Typ. mm

F: 4.20Typ. mm

SEE TABLE 1

TEST INSTRUMENTS

L : HP 4284A PRECISION LCR METER (or equivalent)

RDC : CHROMA MODEL 16502 MILLIOHMMETER (or equivalent)

(3)-1 Ambient temperature ……......... +60℃ Max.

(3)-2 Operate temperature range ...... -40℃~+125℃

(Including self temp. rise)

(3)-3 Storage temperature range ...... -40℃~+125℃

MAG.LAYERS

MSCDRI-5020F-SERIES Page 1/8

Page 2

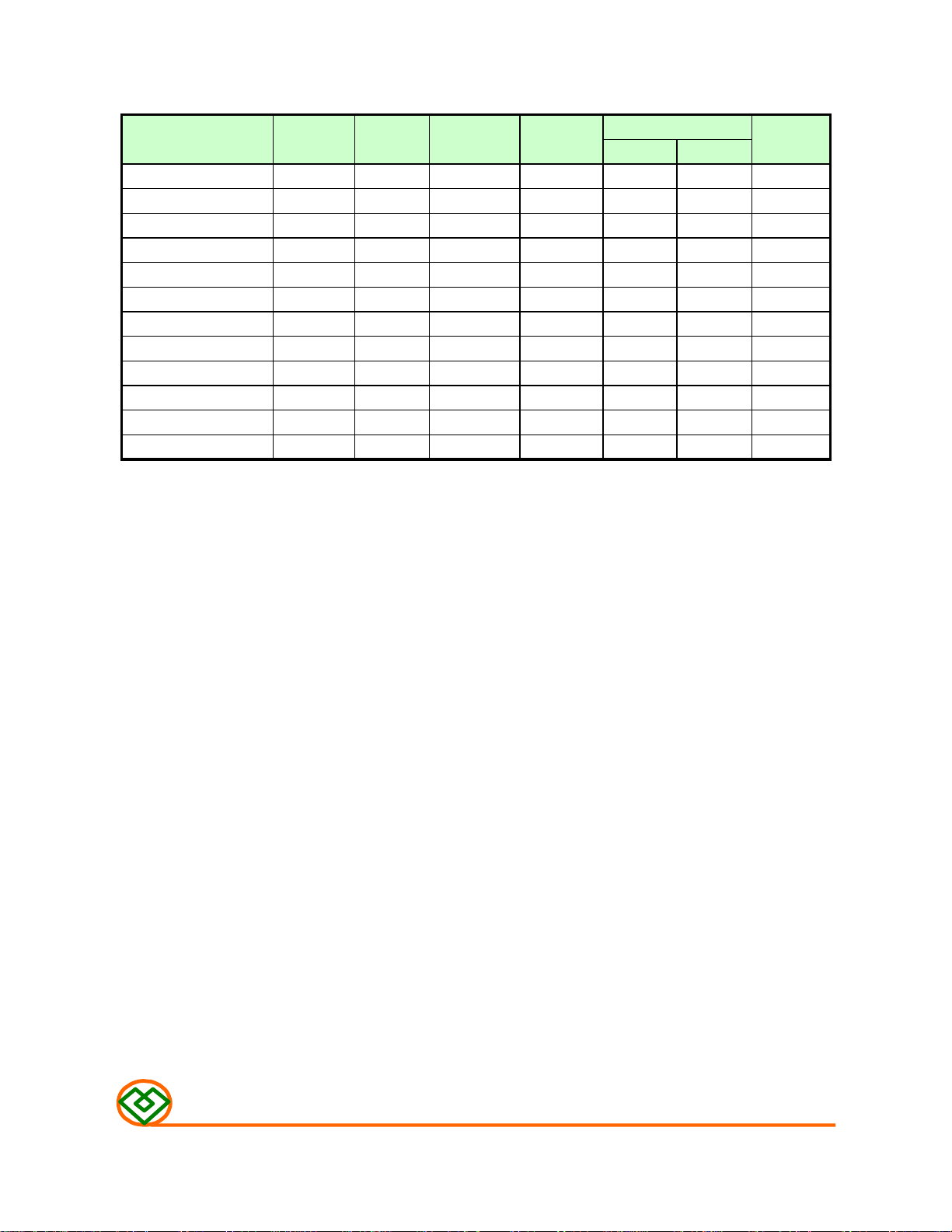

TABLE 1

※

MAGLAYERS

PT/NO.

MSCDRI-5020F-1R2□

MSCDRI-5020F-2R2□

MSCDRI-5020F-3R5□

MSCDRI-5020F-4R7□

MSCDRI-5020F-6R8□

MSCDRI-5020F-100□

MSCDRI-5020F-150□

MSCDRI-5020F-220□

MSCDRI-5020F-330□

MSCDRI-5020F-470□

MSCDRI-5020F-680□

MSCDRI-5020F-101□

※ □ specify the inductance tolerance,M(±20%),N(±30%)

※ IDC1: Based on inductance change (△L/Lo: drop 30% max)

IDC2: Based on temperature rise (△T: 40℃ TYP.)

Rated DC Current: The less value which is IDC1 or IDC2.

Inductance Percent Test Resistance Rated DC Current

L(μH) Tolerance Frequency RDC(Ω)Max. IDC1(A) IDC2(A)

1.2 N 100kHz,025V 44m 2.15 2.87 1R2

2.2 N 100kHz,025V 59m 1.63 2.06 2R2

3.5 N 100kHz,025V 73m 1.34 1.82 3R5

4.7 M,N 100kHz,025V 87m 1.14 1.54 4R7

6.8 N 100kHz,025V 0.105 0.95 1.38 6R8

10 M,N 100kHz,025V 0.150 0.76 1.10 100

15 M,N 100kHz,025V 0.210 0.63 0.91 150

22 M,N 100kHz,025V 0.275 0.56 0.83 220

33 M,N 100kHz,025V 0.455 0.44 0.61 330

47 M,N 100kHz,025V 0.730 0.36 0.45 470

68 M,N 100kHz,025V 0.935 0.30 0.42 680

100 M,N 100kHz,025V 1.500 0.23 0.31 101

Marking

MAG.LAYERS

MSCDRI-5020F-SERIES Page-2/8

Page 3

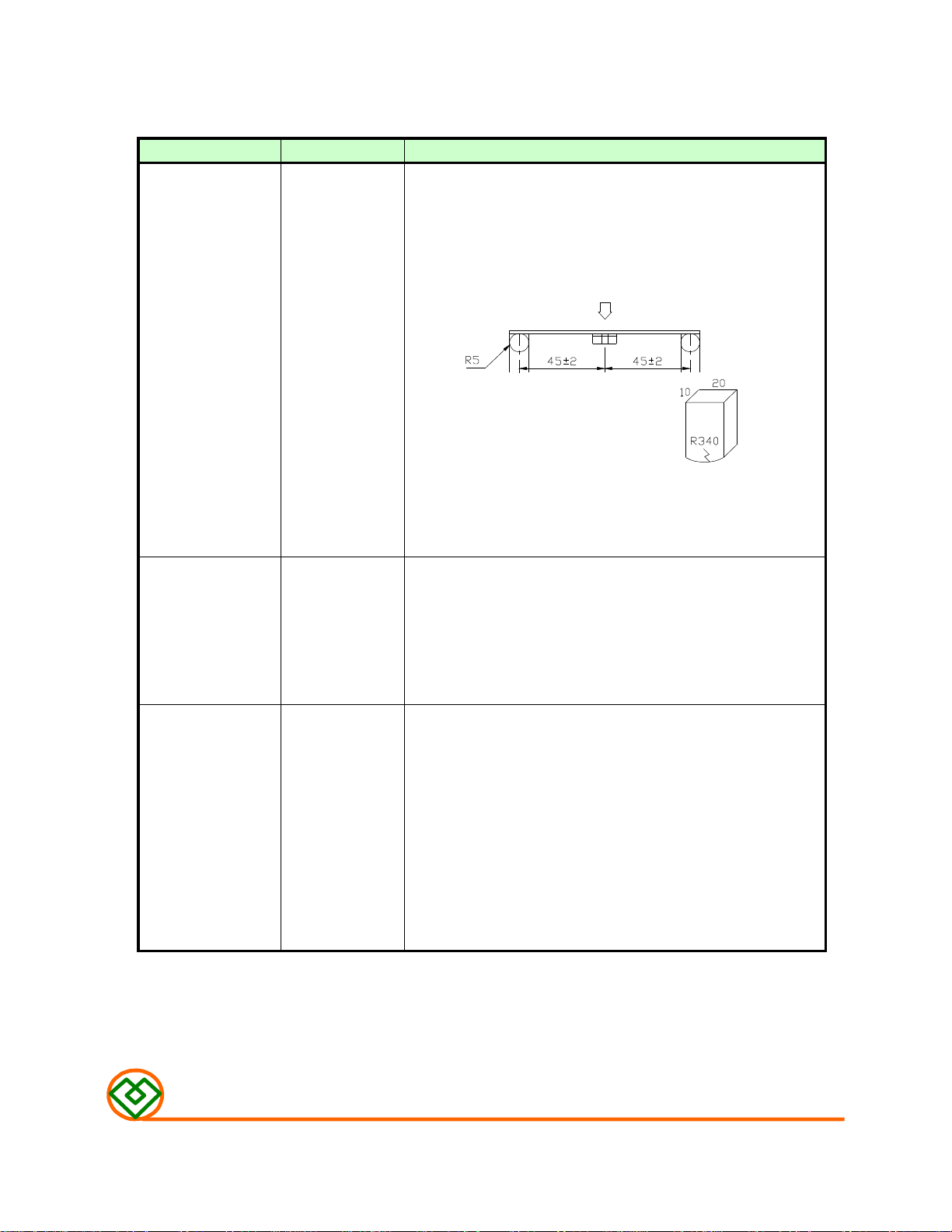

(4) RELIABILITY TEST METHOD

MECHANICAL

TEST ITEM SPECIFICATION TEST DETAILS

Substrate bending

△L/Lo≦±5%

There shall be direction is made approximately 3mm.(keep time 30 seconds)

no mechanical PCB dimension shall the page 7/9

damage or elec- F(Pressurization)

trical damege.

The sample shall be soldered onto the printed circuit board

in figure 1 and a load applied unitil the figure in the arrow

PRESSURE ROD

figure-1

Vibration

Solderability

△L/Lo≦ ±5%

There shall be and a frequency of from 10 to 55Hz/1 minute repeated should

no mechanical be applied to the 3 directions (X,Y,Z) for 2 hours each.

damage. (A total of 6 hours)

New solder Flux (rosin, isopropyl alcohol{JIS-K-1522}) shall be coated

More than 90% over the whole of the sample before hard, the sample shall

The sample shall be soldered onto the printed circuit board

and when a vibration having an amplitude of 1.52mm

then be preheated for about 2 minutes in a temperature of

130~150℃ and after it has been immersed to a depth 0.5mm

below for 3±0.2 seconds fully in molten solder M705 with

a temperature of 245±5℃.

More than 90% of the electrode sections shall be couered

with new solder smoothly when the sample is taken out of

the solder bath.

MAG.LAYERS

MSCDRI-5020F-SERIES

Page-3/8

Page 4

MECHANICAL

Sodering temperature (℃)

(230

℃)

2 min

TEST ITEM SPECIFICATION

Resistance to There shall be Temperature profile of reflow soldering

Soldering heat no damage or

(reflow soldering) problems.

300

250

soldering

(Peak temperature 260±3℃ 10 sec

200

150

100

50

Pre-heating

150 ~ 180℃

30 sec Min

+0

10

sec.

Slow cooling

(Stored at room

temperature)

2 min. or more

The specimen shall be passed through the reflow oven with the

condition shown in the above profile for 1 time.

The specimen shall be stored at standard atmospheric conditions

for 1 hour, after which the measurement shall be made.

ELECTRICAL

TEST ITEM SPECIFICATION TEST DETAILS

Insulation There shall be DC 100V voltage shall be applied across this sample of top

resistance no other surface and the terminal.

damage or

problems.

Dielectric There shall be AC 100V voltage shall be applied for 1 minute acrosset the top

withstand no other surface and the terminal of this sample

voltage damage or

problems.

Temperature

characteristics

△L/L20℃≦±10%

0~2000 ppm/℃ an ambient temperature of -20 to +85℃ ,and the value

The insulation resistance shall be more than 1 × 108 Ω.

The test shall be performed after the sample has stabilized in

calculated based on the value applicable in a normal

MAG.LAYERS

temperature and narmal humidity shall be △L/L20℃≦±10%.

MSCDRI-5020F-SERIES

Page-4/8

Page 5

ENVIROMENT CHARACTERISTICS

TEST ITEM SPECIFICATION

High temperature

storage

△L/Lo≦±5%

There shall be Upon completion of the measurement shall be made after the

no mechanical sample has been left in a normal temperature and normal

damage. humidity for 1 hour.

The sample shall be left for 96±4 hours in an atmospere with

a temperature of 85±2℃ and a normal humidity.

Low temperature

storage

Change of

temperature in the table 2 below and then it shall be subjected to standard

△L/Lo≦±5%

There shall be Upon completion of the test, the measurement shall be made

no mechanical after the sample has been left in a normal temperature and

damage. normal humidity for 1 hour.

△L/Lo≦±5%

There shall be stmospheric conditions for 1 hour, after which measurement

no other dama- shall be made.

ge of problems

The sample shall be left for 96±4 hours in an atmosphere with

a temperature of -25±3℃.

The sample shall be subject to 5 continuos cycles, such as shown

table 2

Temperature Duration

1

2

3

4

-25±3℃

(Themostat No.1)

Standard

atmospheric

85±2℃

(Themostat No.2)

Standard

atmospheric

30 min.

No.1→No.2

30 min.

No.2→No.1

Moisture storage

Test conditions:

The sample shall be reflow soldered onto the printed circuit board in every test.

△L/Lo≦±5%

There shall be Upon completion of the test, the measurement shall be made

no mechanical after the sample has been left in a normal temperature and

damage. normal humidity more than 1 hour.

MAG.LAYERS

The sample shall be left for 96±4 hours in a temperature of

40±2℃ and a humidity(RH) of 90~95%.

MSCDRI-5020F-SERIES

Page-5/8

Page 6

(5) LAND DIMENSION (Ref.)

PCB: GLASS EPOXY t=1.6mm

(5)-1 LAND PATTERN DIMENSIONS

(STANDARD PATTERN)

(5)-2 SUBSTRATE BENDING TEST BENDING TEST BOARD

MAG.LAYERS

MSCDRI-5020F-SERIES

Page-6/8

Page 7

(6) PACKAGING

(6)-1 CARRIER TAPE DIMENSIONS (mm)

(6)-2 TAPING DIMENSIONS (mm)

Unreeling

Direction

MAG.LAYERS

MSCDRI-5020F-SERIES

Page-7/8

Page 8

(6)-3 REEL DIMENSIONS (mm)

Tape width

(6)-4 QUANTITY

3500pcs/Reel

The products are packaged so that no damage will be sustained.

:12

MAG.LAYERS

MSCDRI-5020F-SERIES

Page-8/8

Loading...

Loading...