INSTALLATION INSTRUCTIONS

HWC8 V-Series

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in manuals, be alert to

the potential for personal injury or death.

TM

Models

Table of Contents

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional installer (or

equivalent), service agency or the gas supplier.

WARNING

Do not store combustible materials near the furnace or

warm air ducts. The material may ignite by spontaneous

combustion creating a re hazard.

WARNING

Unit Dimensions ..........................................................2

Installation ...................................................................3

Electrical Connections .................................................7

Start-Up .....................................................................11

Operation ...................................................................12

Maintenance ..............................................................14

Wiring Diagrams ........................................................17

WARNING

For your safety, do not store or use gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance. Such actions could result in property

damage, personal injury, or death.

These units are not approved for mobile home

applications. Such use could result in property damage,

personal injury, or death.

Installation shall be made in accordance with the

requirements of the local utility and other authorities

CAUTION

If these instructions are not followed exactly, a re

or explosion may result causing property damage,

personal injury, or loss of life.

Manufactured By

Allied Air Enterprises LLC

A Lennox International, Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

Check that equipment complies with all applicable building codes, laws, and regulations for its intended use prior to installation.

507388-03 Issue 2110

having jurisdiction, or with the National Fuel Gas

Code, ANSI Z223.1 (latest edition) and the National

Electrical Code. Any alteration of internal wiring will void

certication and warranties.

*P507388-03*

CAUTION

(P) 507388-03

Page 1 of 19

27-7/8

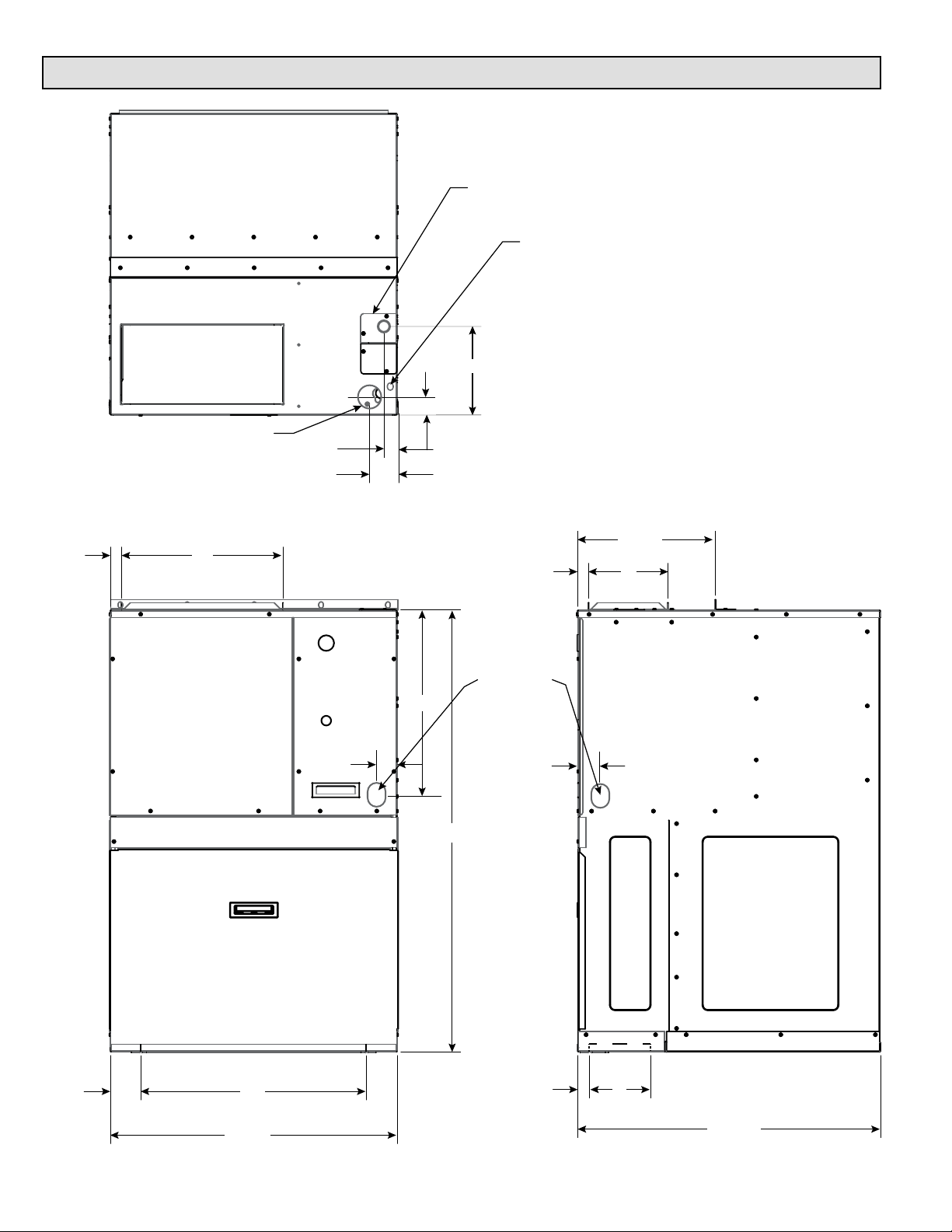

Unit Dimensions

Line Voltage

Box

Low

Voltage

Supply

1/2 Gas Inlet

161

Supply

1-1/2

2-3/4

1-3/4

8

13-3/8

81

Supply

Condensate

18-1/4

2

Drain

(HWC9 Only)

2

43-3/16

Return

2-7/8

Page 2 of 19 507388-03Issue 2110

22

61

Return

29-7/16

Installation

General

These instructions must be hung on or near the furnace in

a conspicuous place.

The MagicPak All-In-One™ HVAC system model HWC8

V-Series™ units are self-contained, gas-red heating

with electric cooling models. The unit design has been

certied by Intertek Testing Services for compliance with

the latest edition of the American National Standard ANSI

Z21.47 for direct vent central furnaces. The HWC8 models

are certied to be in compliance with the latest edition of

A.H.R.I. Standard 210/240. All models are design certied

for heating operation when red with natural or propane

gas.

These installation instructions are intended as a general

guide only, for use by an experienced, qualied contractor.

Inspection

The unit is shipped in one package, completely assembled

and wired. The Evaporator drain tubing is in the cooling

compartment behind the lter access panel.

If any damage is found, proper notation should be made on

the carrier’s freight bill. Damage claims should be led with

the carrier as quickly as possible.

Check the rating plate to conrm heating and cooling

capacities. The unit should be operated only with the type

of gas and electrical supply noted on the rating plate.

WARNING

In the State of Massachusetts:

This product must be installed by a licensed Plumber

or Gas Fitter. When exible connectors are used, the

maximum length shall not exceed 36”. When lever-type

gas shutos are used, they shall be T-handle type.

NOTE: Remove the chassis hold down shipping bracket

before installation. These brackets are located on the

outdoor side of the unit below the louver panels.

The grille side of the unit may be ush with, or extend

beyond, the face of the exterior wall, but should not be

recessed more than 2” from the face of the building and

should not be obstructed with trees, landscape materials,

or building structure.

There is no minimum clearance required on locating the

unit to an interior corner of a building.

If the unit is to be enclosed, provisions should be made

allowing access to the indoor side of the unit for changing

lters and for inspection. At least 29” of unobstructed space

should be provided in front of the indoor side, whether

enclosed or not, to permit removal of the cooling chassis

should repairs or inspection be required.

If the unit is installed in a residential garage, it must be

located or protected to avoid physical damage by vehicles.

Unit must be installed so the burners and ignition source

are not less than 18” (457 mm) above the oor. This unit

must be installed so that no electrical components are

exposed to water.

This appliance should be installed in a location such that

the vent outlet is located in the following manner:

1. Distances to windows that open, building openings, or

public walkways should be consistent with the National

Fuel Gas Code Z223.1.

2. For U.S. installations, the vent system shall terminate

a minimum horizontal clearance of 4’ from electric

meters, regulators, and relief equipment.

3. Flue products will not cause degradation to building

materials.

This furnace design is not listed for installation in mobile

homes, recreational vehicles, or outdoors.

Use of Furnace as a Construction Heater

Allied Air does not recommended the use of these units

as a construction heater during any phase of construction.

Very low return air temperature, harmful vapors and

operation of the unit with clogged or misplaced lters will

damage the unit.

Location

The design is certied for indoor installation only. The

interior portions of the unit may be surrounded by a closet

with minimum clearances to combustible material held

to 0” sides, 2” top, and 1” front and plenum. Adequate

clearance must be provided to install gas line union and

manual shuto valve as well as providing accessibility for

eld wiring. Do not install directly on carpeting, tile, or other

combustible material other than wood ooring.

507388-03 Issue 2110 Page 3 of 19

Units may be used for heating of buildings or structures

under construction, if the following conditions are met:

• The unit must be permanently installed per these

installation instructions.

• A room thermostat must control the furnace. The use

of xed jumpers that will provide continuous heating is

not allowed.

• The return air duct must be provided and sealed to the

furnace.

• Return air temperature range between 60°F (16°C)

and 80°F (27°C) must be maintained.

• Air lters must be installed in the system and must be

maintained during construction.

• Air lters must be replaced upon construction

completion.

• The input rate and temperature rise must be set per

the furnace rating plate.

• One hundred percent (100%) outdoor air must be

provided for combustion air requirements during

construction.

• The furnace heat exchanger, components, duct

system, air lters and evaporator coils must be

thoroughly cleaned following nal construction clean-

up.

• All furnace operating conditions (including ignition,

input rate, temperature rise and venting) must be

veried according to these installation instructions.

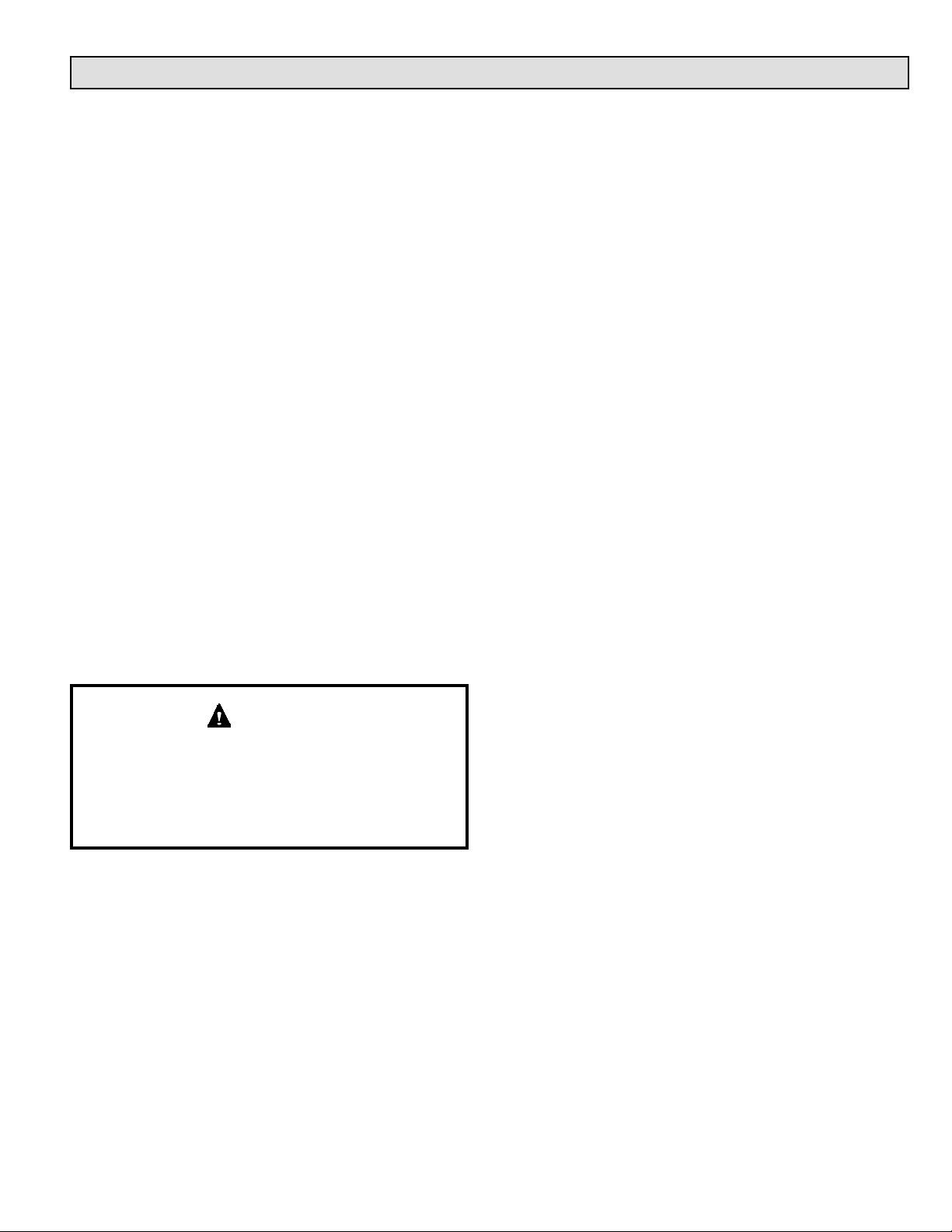

Installing With a Wall Sleeve

Refer to the installation instructions packed with the wall

sleeve and Figure 2 for guidance in assembly and mounting

using a wall sleeve.

The drain line should pitch gradually downward at least 1”

per 10’ of horizontal run to the open drain trap.

Be certain that the plastic drain tube has free drainage and

is not crimped or attened at any bend.

Drain Pan

Alternati ve

Method

To Open

Drain Trap

Return

Air Duc t

5/8

" I . D.

Plasti c Tube

(Suppli ed)

Top of Drain Tube

Must be Below

Bottom of Drai n Pan

Drain Tube - Pitch 1"

for every 10 ft.

(Field Suppli ed)

Open Drain Trap

Figure 1. HWC Evaporator Condensate Drain

Installation

Wall Sleeve

• Make sure the gaskets attached to the sleeve are not

damaged.

• Seal the space between the wall sleeve and the building

opening with non-hardening caulking compound. The

seal must be weather-tight to prevent entrance of

moisture and water into the building.

• Assure that the unit is completely seated against the

gaskets on the wall sleeve.

• Slide the unit into the sleeve. When properly nested,

the angle on top of the unit should line up with the top

ange of the sleeve and should almost touch. Fasten

the unit to the sleeve with ve screws furnished with

the sleeve.

CAUTION

The sleeve is not intended as the sole support for the

unit. An additional support must be provided near the

return opening on the unit for adequate support. The

use of vibration isolation material between the unit and

the support is recommended.

.

n

" Mi

8

2

F

L

O

O

R

Figure 2. HWC Installation

Plywood

6 x 22 Minimum Opening

""

to Ali gn with Return Ai r

Opening in Uni t.

Vibrat ion Isolat ing Material

Evaporator Condensate Drain

Install the plastic drain tube (furnished) over the 5/8” O.D.

tting in the center of the Evaporator condensate pan.

Connect other end of the drain tube to the open trap (see

Figure 1). The plastic drain connection is provided so that

it may be disconnected from the permanent drain tubing in

the building in the event it becomes necessary to remove

the cooling chassis assembly.

Page 4 of 19 507388-03Issue 2110

WARNING

Insucient combustion air can cause headaches,

nausea, dizziness or asphyxiation. It will also cause

excess water in the heat exchanger resulting in rusting

and premature heat exchanger failure. Excessive

exposure to contaminated combustion air will result

in safety and performance related problems. Avoid

exposure to the following substances in the combustion

air supply:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine base swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

Combustion Air

This unit is a direct - vent furnace which obtains all air

needed for combustion from outdoors.

Venting

The venting system is an integral part of the appliance.

The venting system must not be modied or added on

to.

The unit contains a combustion inducer. The inducer

draws the combustion products out of the heat exchanger

together with dilution air and forces the mixture from the

unit to the outside. No special provisions are required for

supplying air for combustion, nor is a chimney required.

1. Seal any unused openings in the common venting

system.

2. Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage

or restriction, leakage, corrosion, or other deciencies

which could cause an unsafe condition.

3. Insofar as is practical, close all building doors and

windows between the space in which the appliances

remaining connected to the common venting system

are located and other spaces in the building. Turn on

clothes dryers and any appliance not connected to the

common venting system. Turn on exhaust fans, such

as range hoods and bathroom exhausts, so they will

operate at maximum speed. Do not operate a summer

exhaust fan. Close replace dampers.

4. Following the lighting instructions, place the unit being

inspected in operation. Adjust the thermostat so the

appliance will operate continuously.

5. Test for spillage at the draft control relief opening after

5 minutes of main burner operation. Use the ame of

a match or candle.

6. Follow the preceding steps for each appliance

connected to the common venting system.

7. After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, replace dampers,

and any other fuel burning appliance to their previous

condition of use.

8. If improper venting is observed during any of the above

tests, the common venting system must be corrected.

See National Fuel Gas Code, ANSI Z223.1 (latest

edition) to correct improper operation of common

venting system.

Gas Connections

The gas line to the unit should be adequately sized to

prevent undue pressure drop and should never be smaller

than the manual valve used. Consult the local utility or

National Fuel Gas Code for complete details on special

requirements in sizing gas piping.

The vent outlet must not be altered or extended.

The venting system is designed for proper operation under

all weather conditions and for winds up to 31 m.p.h.

The units supplied for operation with natural gas contain

a gas regulator which must be operated with inlet gas

pressures specied on the rating plate. If gas line pressure

exceeds this gure, an additional high pressure regulator

must be installed to reduce this pressure.

Removal of Unit from Common Venting System

When an existing furnace is removed from a common

venting system serving other appliances, the venting

system is likely to be too large to properly vent the

remaining attached appliances. The following test

should be conducted with each appliance while the other

appliances connected to the common venting system are

not in operation.

507388-03 Issue 2110 Page 5 of 19

Units for operation with propane must be converted with a

kit supplied by the manufacturer and require for operation

an inlet pressure of 11” W.C. minimum and 13” W.C.

maximum. A regulator is also required on the propane tank.

If local codes allow use of a exible gas connector, a new

listed connector must be used. Do not use a connector

which has previously serviced another gas appliance.

CAUTION

If a exible gas connector is required or allowed by

the authority that has jurisdiction, black iron pipe shall

be installed at the gas valve and extend outside the

furnace cabinet. The exible connector can then be

added between the black iron pipe and the gas supply

line.

IMPORTANT

Compounds used on threaded joints of gas piping must

be resistant to the actions of liqueed petroleum gases.

Figure 3. Gas Supply Piping

CAUTION

Never use a ame to check for gas leaks. Explosion

causing injury or death may occur.

A manual shuto valve must be located outside the unit.

The use of a union located upstream of the controls is

recommended, between the controls, and the manual

shuto valve. This will facilitate removal of controls and

manifold. See Figure 3 for recommended placement of the

union.

Provide a drip leg in the supply piping located exterior

to the unit. Piping connections must be sealed with nonhardening pipe joint compound resistant to propane.

WARNING

The furnace must be isolated from the gas supply piping

system by closing the individual manual shuto valve

during any pressure testing of gas supply piping system

at test pressures equal to or less than 1/2 psig or 14”

W.C. If the piping system is to be tested at pressures in

excess of 1/2 psig, the furnace and its individual shuto

valve must be disconnected from the gas supply piping

system. The gas valve supplied with this furnace is

rated at 1/2 psig. Any higher pressure may rupture the

pressure regulator diaphragm which will cause over-

ring of the burners and improper burner operation.

This action may produce a high concentration of carbon

monoxide which can result in asphyxiation.

Leak Check

After gas piping is completed, carefully check all piping

connections (factory and eld installed) for gas leaks. Use

a leak detecting solution or other preferred means.

NOTE: If emergency shuto is necessary, shut o the main

manual gas valve and disconnect the main power to the

furnace. The installer should properly label these devices.

CAUTION

Some soaps used for leak detection are corrosive to

certain metals. Carefully rinse piping thoroughly after

leak test has been completed. Do not use matches,

candles, ame or other sources of ignition to check for

gas leaks.

Page 6 of 19 507388-03Issue 2110

Electrical Connections

All wiring must be done in accordance with the National

Electrical Code, ANSI/NFPA No. 70 (latest edition); or local

codes, where they prevail. Any alteration of internal wiring

will void certication and warranty.

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can aect electronic components.

Take precautions during furnace installation and service

to protect the furnace’s electronic controls. Precautions

will help to avoid control exposure to electrostatic

discharge by putting the furnace, the control and

the technician at the same electrostatic potential.

Neutralize electrostatic charge by touching hand and

all tools on an unpainted unit surface, such as the gas

valve or vestibule panel, before performing any service

procedure.

The rating plate indicates the operating voltage, phase,

minimum circuit ampacity, maximum fuse size, and

minimum voltage. Units must never be installed where

voltage exceeds 10% over the voltage indicated on the

rating plate.

Units are factory wired for a 230 volt power supply. If power

supply is 208 volts, it will be necessary to change a wire

connection on unit transformer from 240 volt terminal to

208 volt terminal as shown on the wiring diagram.

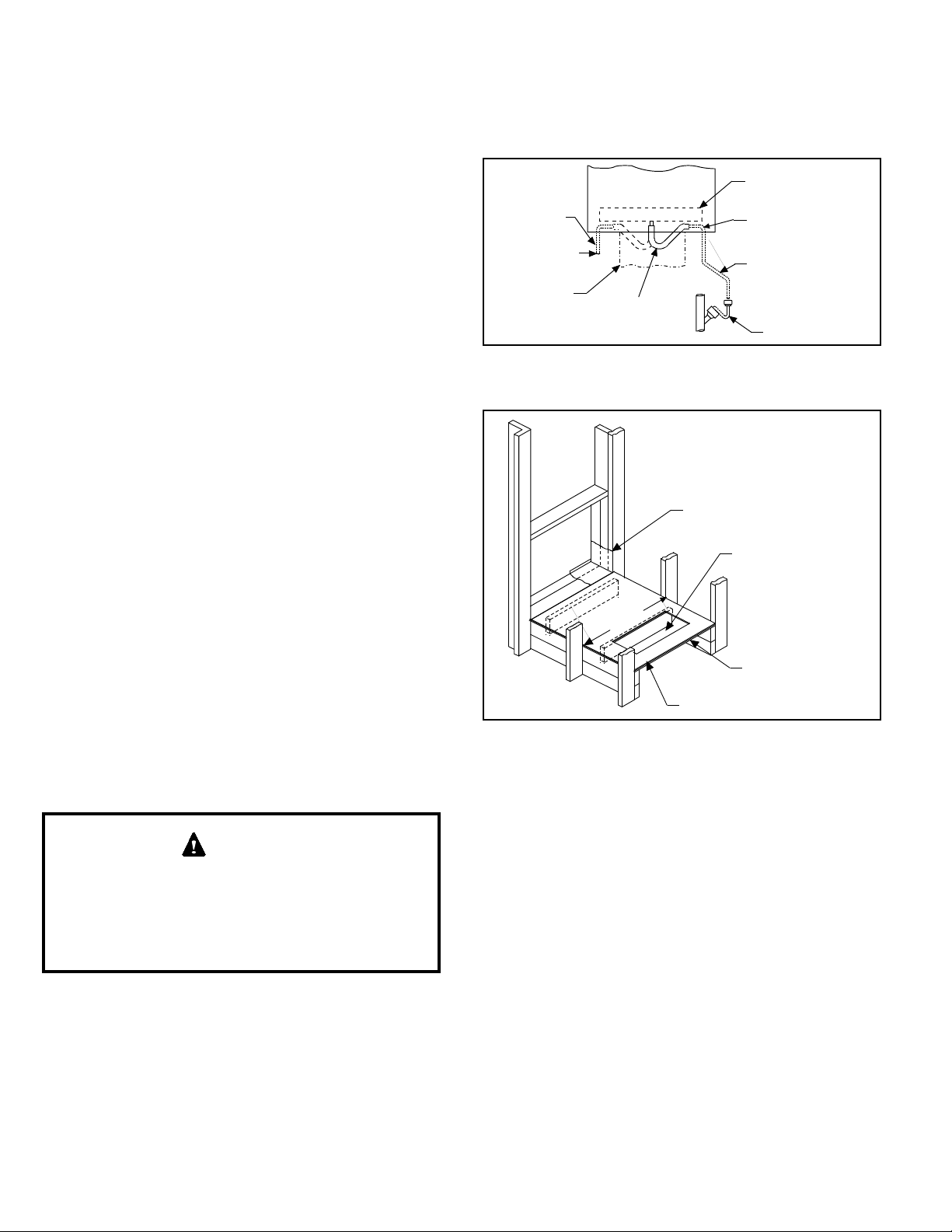

Exterior Junction Box and Switch

If local codes allow, a eld supplied junction box and

optional switch may be installed on the top panel to provide

an exterior electrical wiring point and disconnect. A suitable

junction box cover must be used. If a switch is used it must

meet or exceed the electrical specications shown on the

unit rating plate. The junction box, cover, and (if used)

switch are standard items that are locally available.

Installing an Exterior Junction Box

1. Remove the two screws that secure the factorysupplied cover over the rear half of the internal junction

box. Keep the front cover in place. See Figure 4.

2. Position a 4x4 junction box over the opening as shown

in Figure 5. Make sure the junction box is pulled up

against the front cover so that there is no gap. Remove

a knock-out in the box to allow the unit wiring leads

to extend into the bottom of the box. Pull the leads

through the knock-out and into the box. Remove a

knock-out for the main power supply leads.

3. Secure the junction box to the top panel using screws.

4. Connect the unit wiring leads to the main power supply

or the switch as desired. Securely attach the cover to

the junction box. When complete, the junction box

should be as shown in Figure 6.

5. The rear cover that was removed in Step 1 is not used

and may be discarded.

Rear Cover

Failure of the compressor as a result of operation on

improper voltage voids the compressor replacement

warranty.

A separate electric line with wire having a temperature rating

of 60°C should be run directly from the main supply panel

to the leads in the unit. Refer to the rating plate located on

the unit for proper fuse or breaker size. Make sure the unit

is electrically grounded in accordance with local codes or,

in the absence of local codes, with the National Electrical

Code, ANSI/NFPA No. 70 (latest edition) for installations

in the U.S.

See rating plate for minimum wire ampacity and size wire

accordingly.

507388-03 Issue 2110 Page 7 of 19

Front Cover

(Leave in place)

Figure 4.

Junction Box

Use Screws to secure

Junction box

No Gap

Remove Knock-out over opening, pull unit wiring leads through

Figure 5.

Thermostat

Install the thermostat according to the directions furnished

with it. The thermostat must be located on an inside wall

where it will not be aected by drafts, sunlight, or any other

heat producing appliances. Connect the thermostat wires

to the low voltage leads on top of the unit following the

wiring diagram attached to the unit. The heat anticipator

setting is 0.50 amp.

NOTE: For HWC8*30 models, a two-stage thermostat is

recommended for reaching highest eciency and full use

of two-stage compressor.

Air Filter

All indoor return air must be ltered. A permanent-type

lter is furnished with the unit, located directly behind the

access panel. Removing the panel permits access to the

lter. See Figure 3.

If an installation is made in which it is more desirable to

mount the lter exterior to the unit, in the return duct work

or elsewhere, the permanent lter can be used or replaced

with a disposable lter. If a disposable lter is used, refer

to the information provided in Table 1 when sizing the

disposable lter.

Figure 6.

Model Number

HWC8*12 300

HWC8*18 480

HWC8*24 480

HWC8*30 480

Filter Area

(sq. in.)

Table 1. Minimum Required Surface Area for

Disposable Filters

Supply and Return Duct(s)

Provide duct(s) sized suciently to handle the larger of the

air volumes for heating or cooling provided by this model.

Connect the supply duct to the top of the unit using canvas

connections or other exible connections to prevent noise

transmission into the duct system.

To connect the return duct to the system, use a straight

piece of duct 22” wide by 6” deep. Insert the duct into the

return opening in the bottom of the unit and ange the

duct over the existing anges around the opening inside

the unit. Make sure that all sides of the duct are anged

over to permit removal of the cooling chassis if required.

Use a exible connection to attach the remainder of the

return duct. The return duct should be sealed to the unit

casing and must terminate outside the space containing

the furnace.

Page 8 of 19 507388-03Issue 2110

Adjustments – Heating Section

Temperature Rise

At time of installation, the temperature rise must be

adjusted to be within the range specied on the unit rating

plate. See Table 2. Select a lower blower speed to increase

rise. Select a higher blower speed to reduce rise.

Pressure Regulator

The gas input must not exceed the gures shown on the

rating plate. The unit is equipped for rated inputs with

manifold pressures of: 3.5” W.C. for natural gas and 10.5”

W.C. for propane.

Blower

The unit contains a direct-drive, multispeed blower. The

proper speeds have been preset at the factory for heating

and cooling. Refer to the wiring diagram or Table 2 for

recommended heating/cooling speeds for specic models.

Direct-drive blower motors are permanently lubricated and

do not require oiling.

Limit Control

A xed temperature limit control is provided which will shut

o the gas to the main burners if the unit is overheated for

any reason. The control must not be adjusted or relocated.

The manifold pressure can be measured by removing the

pipe plug in the automatic gas valve. Connect a water

manometer and measure the pressure. See Figure 9.

Only small variations in gas input may be made by adjusting

the regulator. In no case should the nal manifold

pressure vary more than 0.3” W.C. for natural gas or

0.7” W.C. for propane.

To adjust the regulator, turn the adjusting screw on the

regulator clockwise to increase pressure and input or

counterclockwise to decrease pressure and input. See

Figure 9.

For natural gas installations, check the burner rate by

observing the gas meter (making sure that all other gas

appliances are turned o). The test hand on the meter

should be timed for at least one revolution. Note the

number of seconds for one revolution.

Cubic Feet per

BTU/HR

Input

=

Revolution

# Seconds per

Revolution

x 3600 x

Heating

Value

Adjustments – Cooling Section (HWC models)

No adjustments are required or should be attempted

regarding any of the components of the cooling chassis.

The chassis should be checked to see that none of the

wiring is loose or missing.

High Altitude Adjustments (U.S. Installations)

Ratings shown on the rating plate are for elevations up to

2000 feet. For elevations above 2000 feet, ratings should

be reduced at a rate of 4% for each 1000’ above sea level.

Refer to the National Fuel Gas Code Z223.1 (latest edition)

for further explanation.

Installation and Operation in Extremely Cold

Weather Areas

In areas where extremely cold (below – 20°F) outdoor

temperatures can be expected, some additional installation

and operating precautions should be taken. The following

precautions are taken to prevent possible vent system

ice blockage that could result in safety shutdown of the

burners:

1. Adjust to the highest achievable temperature rise

within the rise and static pressure ranges specied

on the rating plate. Depending on specic model, it

may be possible to change to a lower heating blower

speed tap to get a higher temperature rise. This also

increases comfort.

2. Make sure there are no leaks of outside air into the

return air system.

3. Keep the outside louver grille as free as possible of

any ice that may form and obstruct the ue outlet.

Cooling chassis is charged with R410A refrigerant.

507388-03 Issue 2110 Page 9 of 19

Model

HWC8N2412P12A 25 - 55 40

HWC8N3612P12A 35 - 65 50

HWC8N3612P18A 25 - 55 40

HWC8N4812P18A 35 - 65 50

HWC8N6012P18A 45 - 75 60

HWC8N3612P24A 25 - 55 40

HWC8N4812P24A 35 - 65 50

HWC8N6012P24A 45 - 75 60

N/A: Do not operate unit in heating mode using this blower speed at this external static pressure outside of the proper temperature rise range.

NOTE: HWC**30A models shipped with Low and High stage Cooling taps connected for use of the two-stage system.

* As shipped speed for Heating operation

† As shipped speed for Cooling operation

Rise

Range

(°F)

Mid

Rise

(°F)

TAP 1 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 2 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 1 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 2 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 3 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 1 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 2 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

TAP 3 (HEAT) *

TAP 4 (COOL) †

TAP 5 (COOL)

Indoor Blower

Speed

TAP 2 (HEAT)

TAP 3 (HEAT)

TAP 1 (HEAT)

TAP 3 (HEAT)

TAP 2 (HEAT)

TAP 3 (HEAT)

TAP 1 (HEAT)

TAP 3 (HEAT)

TAP 1 (HEAT)

TAP 2 (HEAT)

TAP 2 (HEAT)

TAP 3 (HEAT)

TAP 1 (HEAT)

TAP 3 (HEAT)

TAP 1 (HEAT)

TAP 2 (HEAT)

Unit Voltage

(V)

208 or 230 455 39 415 43 385 46 355 50

208 or 230 570 31 540 33 510 35 485 37

208 or 230 655 27 625 28 595 30 575 31

208 or 230 480 460 440 415

208 or 230 530 505 485 460

208 or 230 455 59 415 N/A 385 N/A 355 N/A

208 or 230 570 47 540 50 510 53 485 55

208 or 230 655 41 625 43 595 45 575 47

208 or 230 480 460 440 415

208 or 230 530 505 485 460

208 or 230 630 42 600 44 570 47 550 48

208 or 230 770 35 740 36 715 37 690 39

208 or 230 885 30 855 31 830 32 810 33

208 or 230 560 540 520 500

208 or 230 610 580 560 535

208 or 230 630 56 600 59 570 62 550 N/A

208 or 230 770 46 740 48 715 50 690 52

208 or 230 885 40 855 42 830 43 810 44

208 or 230 560 540 520 500

208 or 230 610 580 560 535

208 or 230 630 71 600 N/A 570 N/A 550 N/A

208 or 230 770 58 740 60 715 62 690 64

208 or 230 885 50 855 52 830 54 810 55

208 or 230 560 540 520 500

208 or 230 610 580 560 535

208 or 230 630 42 600 44 570 47 550 48

208 or 230 770 35 740 36 715 37 690 39

208 or 230 885 30 855 31 830 32 810 33

208 or 230 770 750 730 710

208 or 230 820 790 770 750

208 or 230 645 55 615 58 590 60 565 63

208 or 230 780 46 755 47 730 49 710 50

208 or 230 900 40 875 41 855 42 835 43

208 or 230 770 750 730 710

208 or 230 820 790 770 750

208 or 230 645 69 615 72 590 N/A 565 N/A

208 or 230 780 57 755 59 730 61 710 63

208 or 230 900 49 875 51 855 52 835 53

208 or 230 770 750 730 710

208 or 230 820 790 770 750

0.1“ w.c. 0.2“ w.c. 0.3“ w.c. 0.4“ w.c.

SCFM

Temp

Rise

(°F)

SCFM

Table 2. Supply Airow Performance (SCFM) as a Function of External Static Pressure

Temp

Rise

(°F)

SCFM

Temp

Rise

(°F)

SCFM

Temp

Rise

(°F)

Page 10 of 19 507388-03Issue 2110

Model

HWC8N4812P30A 30-60 45

HWC8N6012P30A 45 - 75 60

N/A: Do not operate unit in heating mode using this blower speed at this external static pressure outside of the proper temperature rise range.

NOTE: HWC**30A models shipped with Low and High stage Cooling taps connected for use of the two-stage system.

* As shipped speed for Heating operation

† As shipped speed for Cooling operation

Rise

Range

(°F)

Mid

Rise

(°F)

TAP 1 (HEAT) *

TAP 3 (COOL) †

TAP 4 (COOL)

TAP 5 (COOL) †

TAP 2 (HEAT) *

TAP 3 (COOL) †

TAP 4 (COOL)

TAP 5 (COOL) †

Indoor Blower

Speed

TAP 2 (HEAT)

TAP 1 (HEAT)

Unit Voltage

(V)

208 or 230 780 46 755 47 730 49 710 50

208 or 230 900 40 875 41 855 42 835 43

208 or 230 530 510 490 465

208 or 230 570 545 530 505

208 or 230 950 920 900 885

208 or 230 780 57 755 59 730 61 710 63

208 or 230 900 49 875 51 855 52 835 53

208 or 230 530 510 490 465

208 or 230 570 545 530 505

208 or 230 950 920 900 885

0.1“ w.c. 0.2“ w.c. 0.3“ w.c. 0.4“ w.c.

SCFM

Temp

Rise

(°F)

SCFM

Table 2. Supply Airow Performance (SCFM) as a Function of External Static Pressure

Temp

Rise

(°F)

SCFM

Temp

Rise

(°F)

SCFM

Temp

Rise

(°F)

Start-Up

For Your Safety Read Before Lighting

WARNING

If you do not follow these instructions exactly, a re

or explosion may result causing property damage,

personal injury, or loss of life.

CAUTION

This furnace is equipped with a direct ignition control.

Do not attempt to manually light the burners.

To Light Main Burners

1. Turn o electrical power to unit.

2. Turn the thermostat to lowest setting.

3. Move the gas valve ON/OFF switch to the “ON”

position (Figure 7).

4. Turn on electrical power to the unit.

5. Set the room thermostat to the desired temperature.

(If the thermostat “set” temperature is above room

temperature after the pre-purge time expires, main

burners will light.)

To Shut Down Main Burners

1. Turn o electrical power to unit.

2. Move the ON/OFF switch to the “OFF” position (Figure

7).

Gas Inlet

Gas Inlet

Pressure Test

Tap

ON/OFF

Switch

Gas Manifold

Pressure Test

Tap

Figure 7. Gas Valve

Regulator Adjustment

Screw

(Under Cap)

507388-03 Issue 2110 Page 11 of 19

Operation

Operation of the unit is automatic and will provide heating

and cooling depending on the setting of the thermostat.

Heating

1. Turn on main power supply.

2. Open manual gas shuto valve.

3. Set thermostat system to “HEAT”.

4. Set thermostat to temperature desired.

Cooling

1. Turn on main power supply.

2. Set thermostat system switch to “COOL”.

3. Set thermostat to temperature desired.

Heating Sequence of Operation

1. Thermostat calls for heat.

2. Combustion blower starts and proper air ow is proven

by the pressure switch closing.

3. Blower continues to operate for 30 seconds prior to

the burners lighting.

4. Ignition control begins spark and opens gas valve. The

burners are lit. Ignition is proved through the ame

sensor.

5. Circulating air blower starts 30 seconds after the

burners light.

6. When the thermostat is satised, the burners and

combustion blower shut o.

7. Circulating air blower will shut o 120 seconds later.

Blower Control

The blower will start approximately 30 seconds after the

burners ignite and will stop approximately 120 seconds

after the thermostat is satised. The time delay is preset at

the factory and timing can not be adjusted.

Cooling Sequence of Operation

When the thermostat system switch is set for “COOL”, the

blower will start 5 seconds after the thermostat calls for

cooling and will stop 90 seconds after the thermostat is

satised.

Continuous Fan Operation

Continuous operation of the air handling blower will be

obtained if the thermostat fan switch is set to “ON”. With

the thermostat fan switch set to “AUTO”, the air handling

blower will cycle corresponding with the thermostat cycling.

To Shut Down Unit

For temporary or short periods of shutdown, set the

thermostat system switch to “OFF”. For a prolonged period

of shutdown, set the thermostat system switch to “OFF”

and turn o the electrical power supply and the gas supply

to the unit.

If the burners should fail to ignite, the ignition control will

try to ignite the burners a total of three times. Should the

burners fail to ignite within the three trials for ignition, the

ignition control will lock out for 1 hour before beginning

another ignition cycle. To reset the control, turn the

thermostat down or o for 10 seconds and then set to

desired setting. At this time, the ignition sequence will try

again.

Page 12 of 19 507388-03Issue 2110

Flue Collector Box

Combustion

Inducer

Remove these screws

to remove Combustion

inducer

Loosen these screws to

remove control board

mounting bracket

Ignition Control

Board

Remove these screws

to remove Burner

Assembly

Igniter

Gas Valve

Primary Limit

(Mounted to Vest panel)

Inducer prover

switch

Gas Manifold

Flame sensor

(mounted to top of

Burner Assembly)

Rollout switch

Burner & Manifold

Assembly

Figure 8. Component Layout

507388-03 Issue 2110 Page 13 of 19

Step 7

Mounting Brackets

Step 8

Step 9

Step 10

Figure 9. Burner & Manifold Assembly Removal

Maintenance

WARNING

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could result in

dangerous operation, Serious injury, death or property

damage.

Improper servicing could result in dangerous operation,

Serious injury, death or property damage

• Before servicing, disconnect all electrical power to

furnace

• When servicing controls, label all wires prior to

disconnecting reconnect wires correctly.

• Any disassembly of components containing ue

or vent gases shall be done by a qualied service

agency.

• Verify proper operation after servicing.

Burner & Manifold

Assembly

Refer to Figure 8 for heating compartment component

layout.

It is recommended that the furnace be inspected annually

by a qualied service person.

Burner & Manifold Assembly

To remove the burner & manifold assembly:

1. Disconnect electrical service and turn o gas to the

appliance.

2. Loosen the pipe union external to the unit and remove

the gas line to the gas valve.

3. Disconnect the orange high voltage spark wire at the

ignition control board.

4. Disconnect the white ame sensor wire at the ame

sensor on top of the burner assembly.

5. Disconnect the orange and yellow wires at the rollout

switch.

Page 14 of 19 507388-03Issue 2110

6. Disconnect the red and blue wires at the gas valve.

7. Refer to Figure 9. Remove the two screws on the

burner assembly that secure it to the mounting

brackets. The mounting brackets contain pins to locate

the assembly and hold it in place after the screws are

removed. The mounting brackets are hidden until the

burner assembly is removed.

8. First, carefully pull the burner assembly toward you

until it is clear of the locating pins in the mounting

brackets.

9. Then move the assembly away from the vest panel.

10. Finally, pull the assembly from the unit.

11. Once the burner assembly is removed, the burners

can be cleaned using a bottle brush.

12. For reassembly, follow the above steps in reverse

order.

Control Board Mounting Bracket

The control board mounting bracket is designed to be

removed to allow component access for some service

procedures. The ignition control board and the inducer

prover switch are mounted to the bracket.

1. Disconnect electrical service and turn o gas to the

appliance.

2. Loosen the two screws securing the control mounting

bracket (it is not necessary to completely remove

them).

3. Lift the bracket clear of the screws and carefully lower

the bracket and ignition board to the bottom of the

compartment.

4. It may be necessary to remove the inducer prover

switch tubing at the switch.

5. For reassembly, follow the above steps in reverse

order.

Igniter

The igniter can be accessed from the front of the unit

without removing any other components. To remove the

igniter:

1. Disconnect electrical service and turn o gas to the

appliance.

2. Disconnect the orange high voltage spark wire at the

ignition control board.

3. Remove the screw and pull the igniter out of the burner

assembly.

4. For reassembly, follow the above steps in reverse

order.

Rollout Switch

If for any reason the heat exchanger becomes blocked

the temperature-sensitive rollout switch located beside the

burners will open and the ignition control will turn o the

burners. After investigating and correcting the problem,

the rollout switch must be manually reset by pressing the

button on top of it.

The rollout switch can be accessed from the front of the

unit without removing any other components. To remove

the rollout switch:

1. Disconnect electrical service and turn o gas to the

appliance.

2. Disconnect the orange and yellow wires at the rollout

switch.

3. Remove the screw and slip the rollout switch from

beneath the lanced tab on the burner assembly.

4. For reassembly, follow the above steps in reverse

order.

Flame Sensor

1. Remove the control board mounting bracket as

described previously.

2. Remove the screw and pull the ame sensor from the

top of burner assembly.

3. For reassembly, follow the above steps in reverse

order.

Primary Limit Switch

The primary limit will shut down the unit in case of

overheating and automatically resets when temperature

falls to an acceptable level. It is not eld adjustable

1. Remove the control board mounting bracket as

described previously.

2. Disconnect the two orange and yellow wires at the

primary limit switch.

3. Remove the three screws securing the primary limit

switch to the vest panel.

4. For reassembly, follow the above steps in reverse

order.

Inducer Prover Switch

1. Remove the control board mounting bracket as

described previously.

2. Disconnect the two purple leads at the inducer prover

switch.

3. If the tubing is in place, remove it.

4. Remove the screw securing the switch to the bracket

and slip the strap end out of the hole in the bracket.

5. For reassembly, follow the above steps in reverse

order.

507388-03 Issue 2110 Page 15 of 19

Burner Orices

Orices are threaded into the gas manifold. To remove

them:

1. Remove the burner & manifold assembly as described

previously.

2. Remove the four screws securing the gas manifold to

the burner assembly.

3. Remove the orices by unscrewing them. Do not use

any pipe thread sealant during reassembly.

4. For reassembly, follow the above steps in reverse

order.

Combustion Inducer

The combustion inducer can be removed for inspection,

replacement, or to access the heat exchanger and ue

tube extension for cleaning. To remove the combustion

inducer:

1. Remove the control board mounting bracket as

described previously.

2. Disconnect the black inducer motor leads.

3. Disconnect the inducer prover switch tubing at the

switch.

4. Remove the two screws on the combustion inducer

plate.

5. Pull the combustion inducer and plate toward you until

it is free of the dilution air box that supports it. Lower

the inducer and plate and rotate to pull the assembly

out of the compartment.

6. The ue tube extension can be cleaned if necessary.

Leave it in place; do not remove it from the unit.

7. For reassembly, follow the above steps in reverse

order.

Heat Exchanger

The heat exchanger should be inspected periodically and

cleaned if necessary. When cleaning use a sti brush with

a wire handle to remove scale and soot. To access the

heat exchanger tubes for cleaning:

1. Remove the burner & manifold assembly as described

previously.

2. Remove the combustion inducer as described

previously.

3. Remove the four screws securing the dilution air box

to the ue collector box.

4. Remove the nine or twelve screws (depending on

model) securing the ue collector box to the vest panel.

5. Using the wire brush, brush out the inside of each heat

exchanger tube from the burner assembly end and

from the ue collector box end.

6. Brush out the inside of the ue collector box.

7. Brush out the inside of the ue tube extension.

8. If soot buildup is excessive, clean the combustion

inducer wheel and housing.

9. When brushing is complete, blow all brushed areas

with air. Vacuum as needed.

10. For reassembly, follow the above steps in reverse

order.

Cooling Chassis

The refrigeration system contained in the cooling chassis

normally requires no maintenance since it is a closed,

self-contained system. System is charged with R410A

refrigerant. Periodic maintenance is limited to:

• Cleaning the air lter. Follow directions noted on the

lter and label attached to the access panel.

• Cleaning the condenser coil if covered with any foreign

material, lint, leaves, or other obstructions.

If servicing or major repairs are required, the complete

chassis can be removed from the unit. To remove the

chassis:

1. Shut o the main power supply.

2. Remove lter access panel and panel covering cooling

controls.

3. Remove drain hose from the drain pan.

4. Disconnect the plug-in electrical connections.

5. Disconnect two power leads at contactor (leads come

from grommet in unit partition).

6. Remove screws from panel directly in front of blower

and remove panel. Also remove additional screws

located near top edge of control panel.

7. Drape power wires and wire harnesses out of cabinet

and tape to upper panel.

8. Slide out the chassis, being careful not to damage any

seals or parts. Particular care should be taken to insure

wiring is not damaged during removal/reinstallation

process.

NOTE: Tubing is not to be used as a handle.

To reinstall the chassis, reverse the procedure outlined

above. Be sure that the chassis is inserted as far back as

it will go before replacing the screws. Side anges on the

chassis must be engaged with sealing strips on the unit

sides to prevent water and air leakage. Reconnect the

wire harness, reconnect the power leads, and replace both

access panels before turning on the main electrical power.

Page 16 of 19 507388-03Issue 2110

Wiring Diagrams

Figure 10. Wiring Diagram - HWC*12,18

507388-03 Issue 2110 Page 17 of 19

Figure 11. Wiring Diagram - HWC*24

Page 18 of 19 507388-03Issue 2110

Figure 12. Wiring Diagram - HWC*30

507388-03 Issue 2110 Page 19 of 19

Loading...

Loading...