magicpak EWC V Installation Manual

INSTALLATION INSTRUCTIONS

EWC V-Series

This manual must be left with the homeowner for future reference.

This is a safety alert symbol and should never be ignored. When you see this symbol on labels or in manuals, be alert to

the potential for personal injury or death.

WARNING

Improper installation, adjustment, alteration, service

or maintenance can cause property damage, personal

injury or loss of life. Installation and service must be

performed by a licensed professional installer (or

equivalent), service agency or the gas supplier.

TM

Models

Table of Contents

Unit Dimensions ..........................................................2

Installation ...................................................................3

Electrical Connections .................................................4

Operation .....................................................................5

Maintenance ................................................................6

Wiring Diagrams ..........................................................8

WARNING

Installation and servicing of air conditioning equipment

can be hazardous due to internal refrigerant pressure

and live electrical components. Only trained and

qualied service personnel should install or service

this equipment. Installation and service performed by

unqualied persons can result in property damage,

personal injury or death.

Installation shall be made in accordance with the

requirements of the local utility and other authorities

having jurisdiction, or with the National Fuel Gas

Code, ANSI Z223.1 (latest edition) and the National

Electrical Code. Any alteration of internal wiring will void

certication and warranties.

CAUTION

WARNING

For your safety, do not store or use gasoline or other

ammable vapors and liquids in the vicinity of this or any

other appliance. Such actions could result in property

damage, personal injury, or death.

Manufactured By

Allied Air Enterprises LLC

A Lennox International, Inc. Company

215 Metropolitan Drive

West Columbia, SC 29170

Check that equipment complies with all applicable building codes, laws, and regulations for its intended use prior to installation.

507390-02 Issue 2110

These units are not approved for mobile home

applications. Such use could result in property damage,

personal injury, or death.

*P507390-02*

WARNING

(P) 507390-02

Page 1 of 12

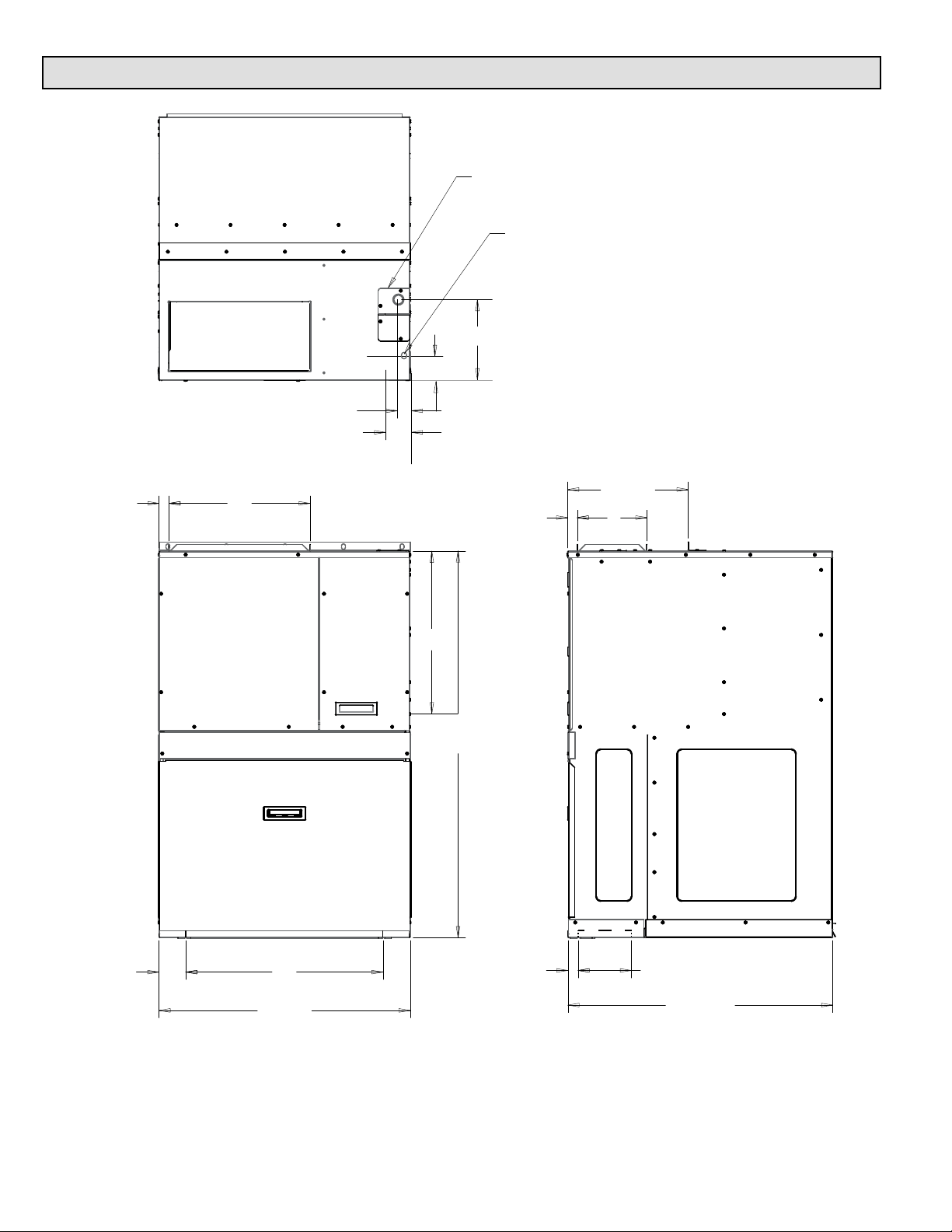

Unit Dimensions

Line Voltage

Connections

Thermostat Wiring

Connections

Supply

161

Supply

1-1/2

2 3/4

1-3/4

18-1/4

43-3/16

8

13-3/8

81

Supply

Return

2-7/8

Page 2 of 12 507390-02Issue 2110

22

27-7/8

61

29-7/16

Installation

Installation shall be made in accordance with local utility

requirements and any other authorities having jurisdiction.

General

The MagicPak All-In-One™ HVAC system model EWC

V-Series™ unit is a self-contained electric heating and

cooling unit. This unit has been examined for compliance

with Canadian Standards Association CAN/CSA-C22.2

No. 236 (latest edition) and Underwriters Laboratories

UL 1995. This unit is also in compliance with A.H.R.I.

Performance Standard 210/240. Any alterations of internal

wiring will void these listings and warranties.

Inspection

This unit is shipped in one package, completely assembled

and wired. The drain tubing is in the cooling compartment

behind the lter access panel.

If any damage is found, proper notation should be made

on the carrier’s freight bill. Damage claims should be led

with the carrier at once. Check the rating plate to conrm

heating and cooling capacities.

NOTE: Be sure to remove the chassis hold down brackets

from the outdoor side of unit before installation. These

brackets are located below the louver panels.

Location

The unit is approved for indoor installation only. It must not

be installed completely outside. Duct connections as well

as service access must be inside the building. The interior

portions of the unit may be surrounded by a closet with

clearances to combustible material held to 0” at sides, 2”

top, and 0” front and plenum. The oor may be combustible.

The grille side of the unit may be ush with, or extend

beyond, the face of the exterior wall, but should not be

recessed more than 2” from the face of the building and

should not be obstructed with trees, landscape materials,

or building structure.

If the unit is to be enclosed, provisions should be made

allowing access to the indoor side of the unit for changing

lters and for inspection. At least 29” of unobstructed space

should be provided in front of the indoor side, whether

enclosed or not, to permit removal of the cooling chassis

should repairs or inspection be required.

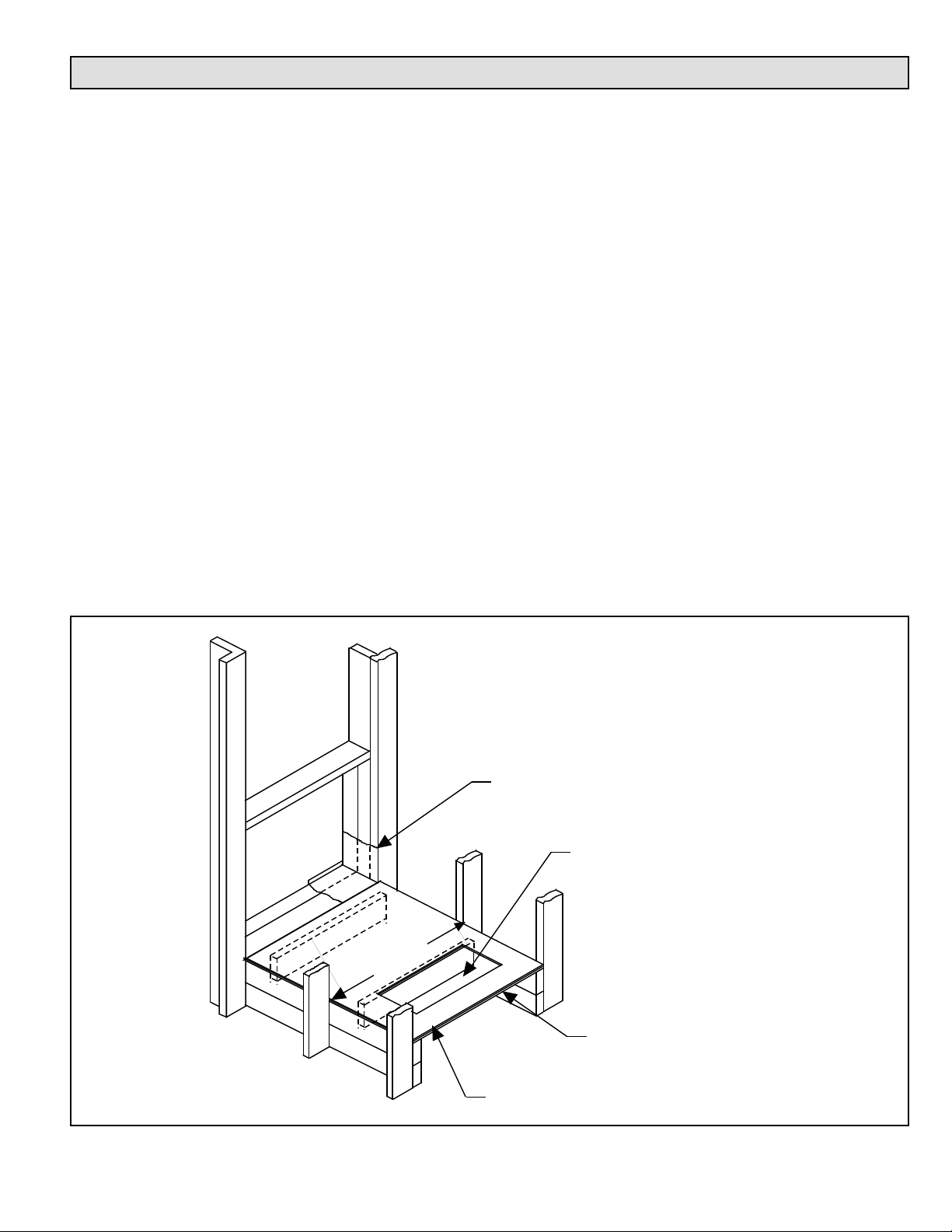

Wall Sleeve

6 x 22 Minimum Opening

""

to Align with Return Air

Opening in Unit.

.

n

" Mi

8

2

Vibration Isolating Material

FLO

O

R

Plywood

Figure 1. EWC Installation

507390-02 Issue 2110 Page 3 of 12

Installing with a Wall Sleeve

Refer to the installation instructions packed with the wall

sleeve and Figure 1 for guidance in assembly and mounting

using a wall sleeve.

• Make sure that the gaskets attached to the sleeve are

not damaged.

• Seal the space between the wall sleeve and the

building opening using non-hardening caulking

compound. This seal must be watertight.

• Assure that the unit is completely seated against the

gaskets on the wall sleeve.

• Slide the unit into the sleeve. When properly nested,

the angle on top of the unit should line up with the top

ange of the sleeve and should almost touch. Fasten

the unit to the sleeve with ve screws furnished with

the sleeve.

CAUTION

The sleeve is not intended as the sole support for the

unit. An additional support must be provided near the

return opening on the unit for adequate support. The

use of vibration isolation material between the unit and

the support is recommended.

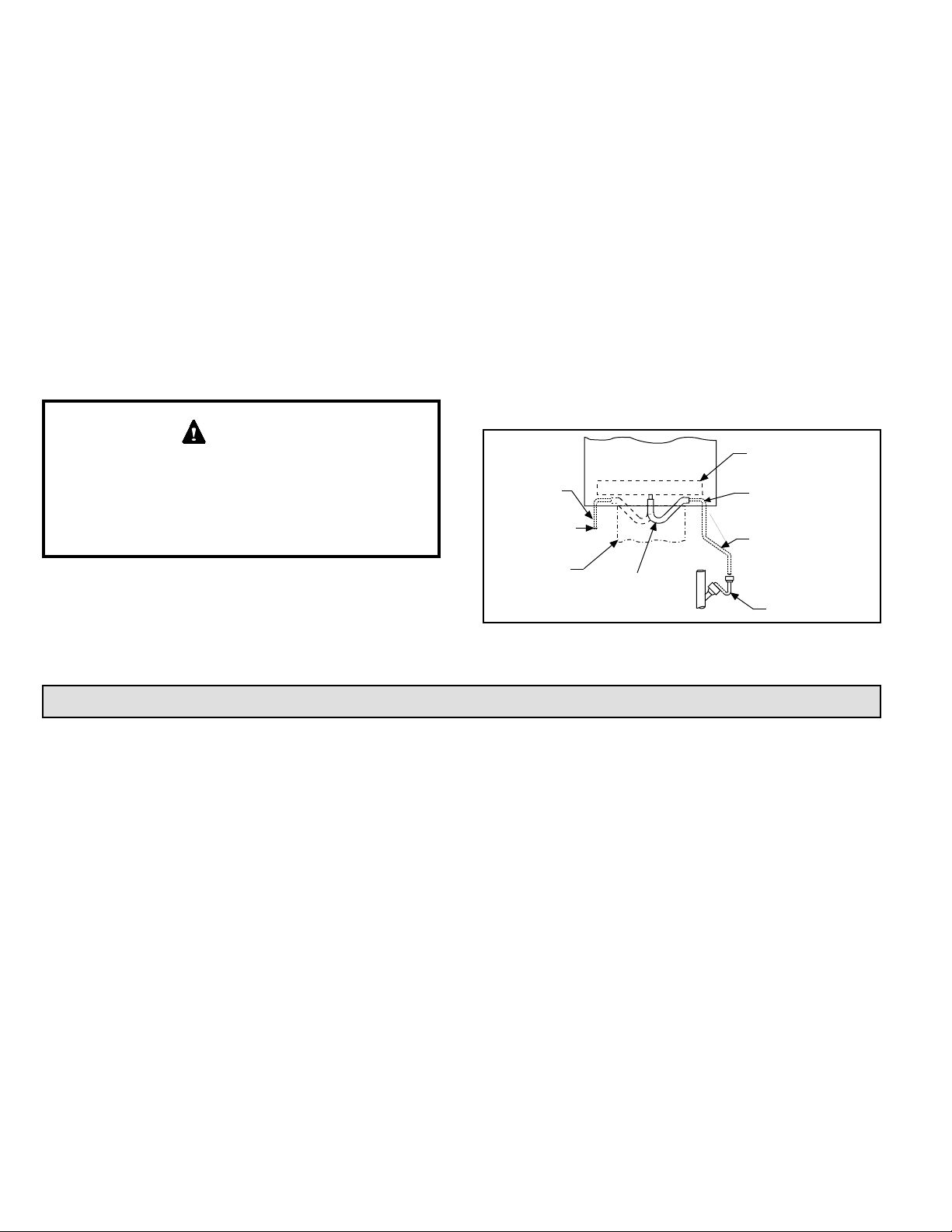

Condensate Drain

To install the condensate line, connect one end of the

plastic tube over the 5/8” O.D. tting in the center of the

condensate pan. Connect the other end to the drain tube

running to the open trap (see Figure 2).

The drain line should pitch gradually downward at least 1”

per 10 feet of horizontal run to the open drain trap.

Be certain that the plastic drain tube has free drainage and

is not crimped or attened at any bend.

Test drainage by pouring water into the drain pan under the

evaporator and see that it is removed rapidly through the

drain tubing.

The plastic drain connection is provided so that it may

be disconnected from the permanent drain tubing in

the building without unsoldering in the event it become

necessary to remove the refrigeration chassis assembly.

Drain Pan

Alternati ve

Method

To Open

Drain Trap

Return

Air Duct

5/8

" I.D.

Plasti c Tube

(Suppli ed)

Top of Drain Tube

Must be Below

Bottom of Drai n Pan

Drain Tube - Pit ch 1"

for every 10 ft.

(Field Suppli ed)

Open Drain Trap

Electrical Connections

All supply wiring should be done in accordance with

the National Electric Code, or with local codes, where

they prevail. Any alternation of internal wiring will void

certication and warranty.

NOTE: Units are factory wired for a 230-volt power supply.

If power supply is 208 volts, it will be necessary to change

a wire connection on unit transformer from 240V terminal

to 208V terminal as shown on the wiring diagram.

The rating plate indicates the operating voltage, phase,

ampacity, and maximum circuit protection. Minimum

operating voltage of the 208-230 volt model is 197 volts.

Units must never be installed where voltage exceeds 10%

of voltage indicated on the rating plate.

Failure of the compressor as a result of operation on

improper voltage voids the compressor replacement

warranty.

Figure 2. EWC Drain Installation

Thermostat

Install the thermostat according to directions furnished with

it. Select a location which will measure true air temperature.

The thermostat must be located on an inside wall where it

will not be aected by drafts, sunlight, or any other heat

producing appliances. Connect the wires to the terminal

block on the unit following the wiring diagram attached to

the unit.

NOTE: For EWC*30 models, a two-stage thermostat is

recommended for reaching highest eciency and full use

of two-stage compressor.

Air Filter

All indoor return air must be ltered before it passes through

the evaporator coil. A permanent-type lter is furnished

with the unit, located directly in front of evaporator coil.

Removing the front panel permits access to the lter.

A separate electric line for each circuit should be run

through a separate fused disconnect, from the main house

panel to the supply terminal block located in the unit.

Page 4 of 12 507390-02Issue 2110

The lter should be cleaned at least once during each of

the heating and cooling seasons and more frequently if

unusual dusty conditions are encountered. To clean the

Loading...

Loading...