Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Gas 20-inch Wide Conventional

Free-standing Ranges

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

CLEARANCE DIMENSIONS

Range may be installed with zero inches clearance

Only qualified personnel should

install or service this range.

Read "Safety Instructions" in the

Use & Care book before using

range.

adjacent to (against) combustible construction at the rear

and on the sides below the cooktop. For complete

information in regard to the installation of wall cabinets

above the range and clearances to combustible wall

above the cooking top see the installation drawings. For

SAFETY CONSIDERATIONS do not install a range in any

combustible cabinetry which is not in accord with the

installation drawings.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

• CAN TIP AND

INJURIES TO PER-

=

• INSTALL ANTI-TIP DEVICES

PACKEDWITH RANGE.

• FOLLOW ALL INSTALLATION

INSTRUCTIONS.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the cabinets.

* NOTE: The 30-inch dimension may be reduced to not

less than 24-inches when the wall cabinets in a domestic

home are protected with fireproof materials in accordance

with American National Standards - National Fuel Gas

Code or in mobile homes when they are protected with

fireproof materials in accordance with the Federal

Standard for Mobile Home Construction and Safety.

CAUTION: SOME CABINETS AND BUILDING

MATERIALS ARE NOT DESIGNED TO WITHSTAND

THE HEAT PRODUCED BY THE NORMAL SAFE

OPERATION OF A LISTED APPLIANCE. DIS-

COLOATION OR DAMAGE, SUCH AS DELAMINA-

TION, MAY OCCUR.

Your range may not be equipped With some of the features referred to in this manual:

8101 P634-60

(02-04-00)

Page 2

INSTALLATION

Check the range model number plate to see if the range is

approved for installation in mobile homes and/or

recreational park trailers. If approved the following items

are applicable.

MOBILE HOMES

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, Part 280) or, when

such standard is not applicable, the Standard for

Manufactured Home Installations ANSI A225.1/NFPA

501A, or with local codes.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1 and Section Z240.4.1 - Installation

Requirements for Gas Burning Appliances in Mobile

Homes (CSA Standard CAN/CSA - Z240MH).

RECREATIONAL PARK TRAILERS

The installation of a range designed for recreational park

trailers must conform with state or other codes or, in the

absence of such codes, with the Standard for

Recreational Park Trailers, ANSI A119.5-latest addition.

In Canada the range must be installed in accordance with

Section C22.2 No. 148/CAN/CSA- Z240.6.2 - Electrical

Requirements for R.V.'s (CSA Standard CAN/CSA - Z240

RV Series) and Section Z240.4.2 - Installation

Requirements for Propane Appliances and Equipment in

R.V.'s (CSA Standard CAN/CSA - Z240 RV Series).

REMOVAL OF SHIPPING & PACKING

a. Using carton corner posts (4), folded flat and stacked

two high to protect floor, lay range on its back.

Remove the four screws which attach skid to base of

range.

b. Stand range upright.

c. Remove all packing material, tape and protective film

on some chrome plated or stainless steel parts before

range is installed.

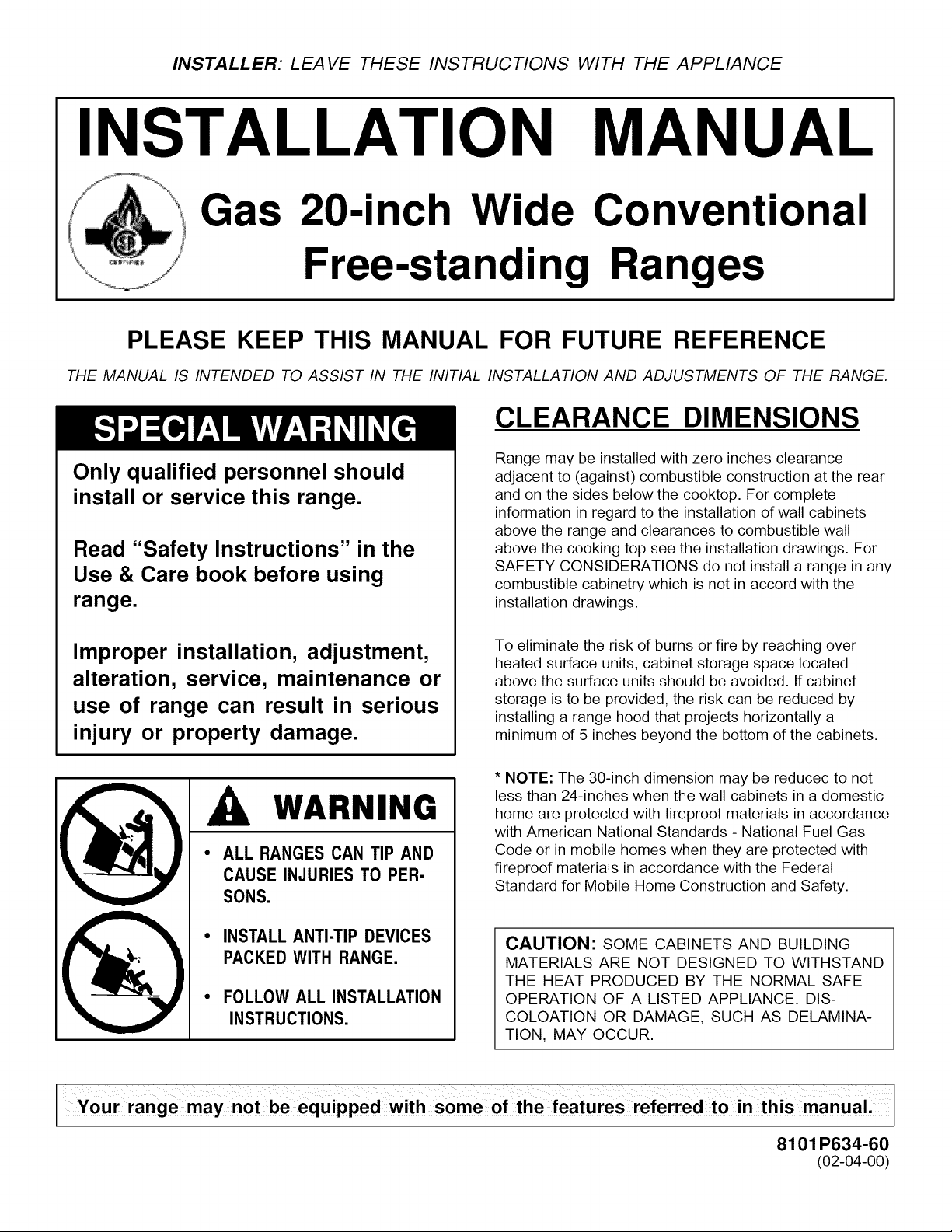

INSTALLATION DRAWINGS

36" HEIGHT

OF CAB I NET

TOP / _

I ./- 20 1/8" CAB I NET

18

1/4" -NDED GAS LINE

•,_ LOCATION.

DE FOR 120 VOLT

GROUNDED ELECTRICAL

OUTLET IN THIS AREA.

OUTLET MUST BE FLUSH

25" NORMAL

16

24" CABINET

DEPTH.

TOP DEPTH

CAB INET

-2-

Page 3

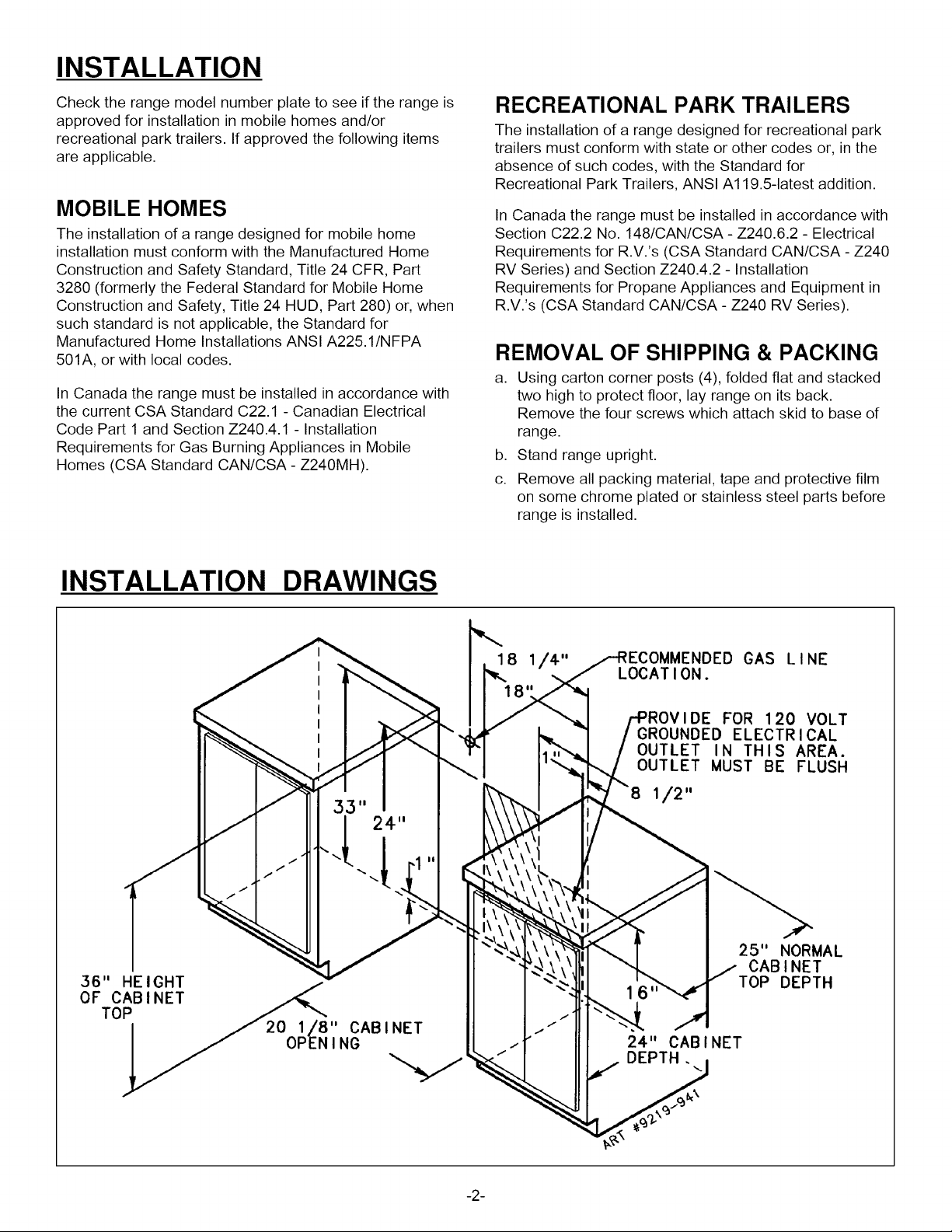

INSTALLATION DRAWINGS

m

ANY COMBUSTIBLE

SURFACE

I L,

"_ 20" 3 ,, pAG'_DF___J

.....

O0 0 O0

| i

! I

BACKGUARD INSTALLATION

(if not installed)

The backguard fits on the range as shown in figure 1 and

is secured with a bracket, 2 bolts and nuts on each side.

Set the backguard on the rear of the range. Bolt the

backguard to the end panel flanges.

13" MAX. DEPTH

OF CABINETS

ABOVE COOK TOP

MIN. _._._

36"

ART #9219-94-0

_L:;;_-- 0" CLEARANCE

"--'- BETWEEN ADJACENT

COMBUSTIBLE

CONSTRUCTION AND

THE BACK AND SIDES

OF THE RANGE

BELOW THE COOKING

SURFACE,

WARNING

DISCONNECT ELECTRICAL POWER TO

AVOID SHOCK HAZARD.

CLEARANCE DIMENSIONS

All free-standing ranges can be installed with the back

against (0 inches) a vertical combustible wall, and the

sides below the cooking surface against (0 inches)

combustible base cabinets. For complete information in

regard to the installation of wall cabinets above the range

and clearances to combustible surfaces see the

installation drawings and/or the model number plate on

the range. For SAFETY CONSIDERATIONS do not install

a range in any combustible cabinetry which is not in

accord with the installation drawings and the clearance

given on the range Model Number Plate.

FIGURE 1

LOCATING THE RANGE

Do not set range over holes in the floor or other locations

where it may be subject to strong drafts. Any opening in

the wall behind the range and in the floor under the range

should be sealed. Make sure the flow of

cooling/ventilation air is not obstructed below the range.

NOTE: A range should NOT be installed directly over

kitchen carpeting.

-3-

Page 4

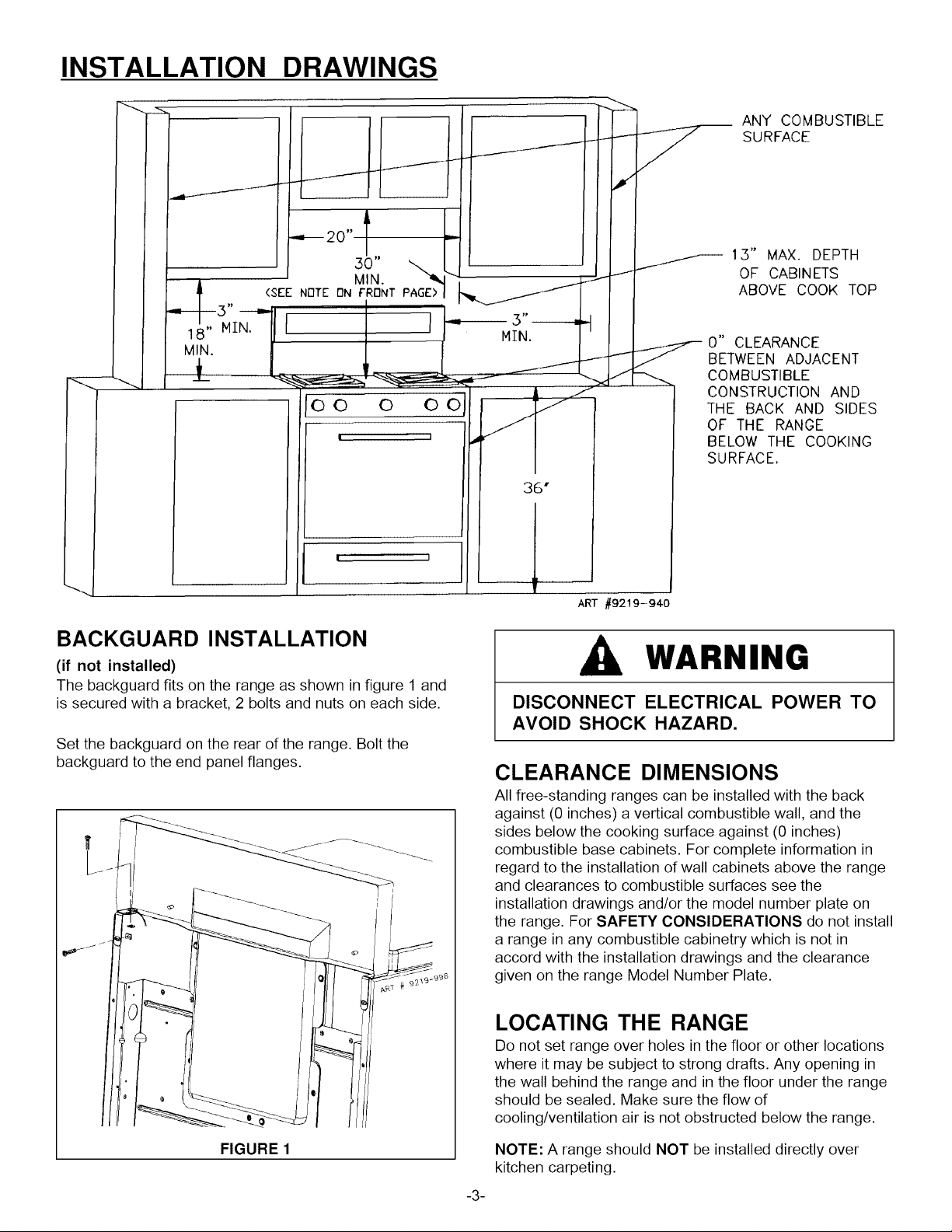

WARNING

THISPRODUCTSHOULDNOTBEINSTALLED

BELOWAVENTILATIONTYPEHOODSYSTEM

THATDIRECTSAIRINA DOWNWARDDIRECTION.

(SEEFIGURE)

THESESYSTEMSMAYCAUSEIGNITIONAND

COMBUSTIONPROBLEMSWITHTHEGAS

BURNERSRESULTINGIN PERSONALINJURYAND

MAYAFFECTTHECOOKINGPERFORMANCEOF

THEUNIT.

NOTE:THEFIGUREMAYNOTACCURATELY

REPRESENTYOURRANGEOR COOKTOP;

HOWEVER,THISWARNINGAPPLIESTOALL GAS

ART# 9_15-Z5_

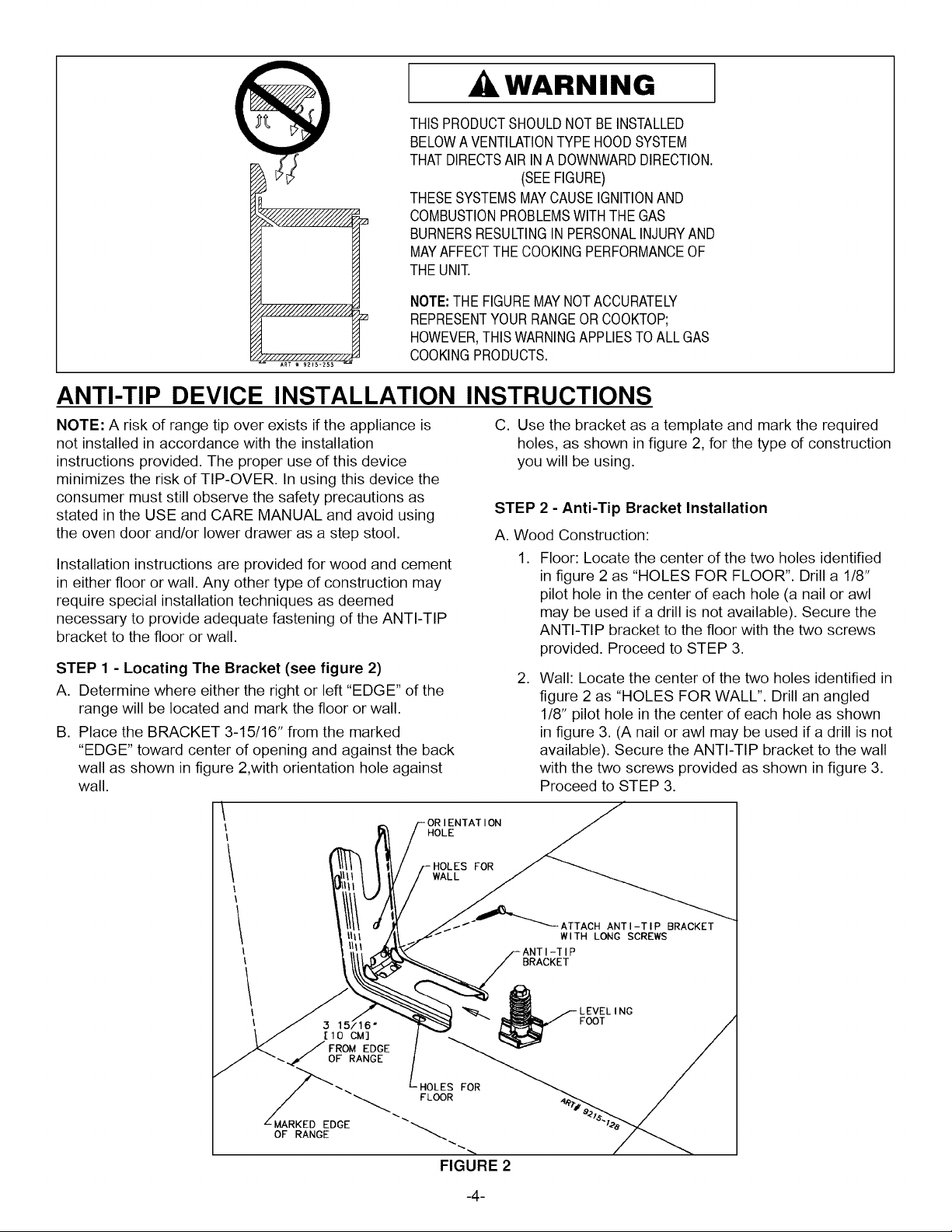

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

COOKINGPRODUCTS.

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the installation

instructions provided. The proper use of this device

minimizes the risk of TIP-OVER. In using this device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven door and/or lower drawer as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall.

STEP 1 - Locating The Bracket (see figure 2)

A. Determine where either the right or left "EDGE" of the

range will be located and mark the floor or wall.

B. Place the BRACKET 3-15/16" from the marked

"EDGE" toward center of opening and against the back

wall as shown in figure 2,with orientation hole against

wall.

HOLE

WALL

C. Use the bracket as a template and mark the required

holes, as shown in figure 2, for the type of construction

you will be using.

STEP 2 - Anti-Tip Bracket Installation

A. Wood Construction:

, Floor: Locate the center of the two holes identified

in figure 2 as "HOLES FOR FLOOR". Drill a 1/8"

pilot hole in the center of each hole (a nail or awl

may be used if a drill is not available). Secure the

ANTI-TIP bracket to the floor with the two screws

provided. Proceed to STEP 3.

, Wall: Locate the center of the two holes identified in

figure 2 as "HOLES FOR WALL". Drill an angled

1/8" pilot hole in the center of each hole as shown

in figure 3. (A nail or awl may be used if a drill is not

available). Secure the ANTI-TIP bracket to the wall

with the two screws provided as shown in figure 3.

Proceed to STEP 3.

ENTATION

FOR

OF RANGE

[10 CM]

FROM EDGE

OF RANGE

EDGE

HOLES FOR

FLOOR

FIGURE 2

-4-

ATTACH ANTI-TIP BRACKET

WITH LONG SCREWS

-TIP

BRACKET

___-LEVELINGFooT

Page 5

B.CementorConcreteConstruction:

1. Suitablescrewsforconcreteconstructioncanbe

obtainedatthehardwarestore.Drilltherequired

sizeholeforthescrewsobtainedintotheconcrete

atthecenteroftheholesidentifiedinfigure2 as

"HOLESFORFLOOR".SecuretheANTI-TIP

brackettothefloor.ProceedtoSTEP3.

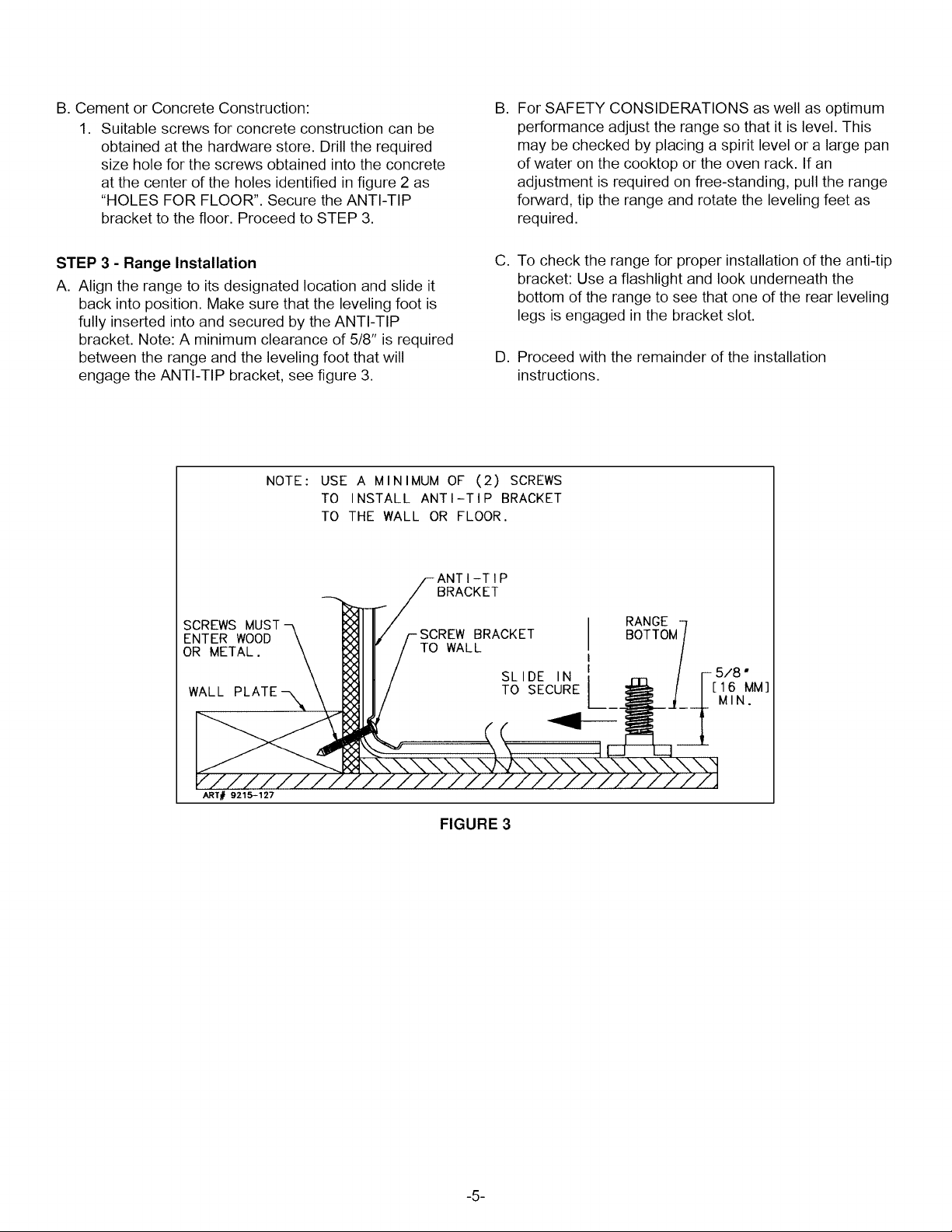

STEP3-RangeInstallation

A. Aligntherangetoitsdesignatedlocationandslideit

backintoposition.Makesurethatthelevelingfootis

fullyinsertedintoandsecuredbytheANTI-TIP

bracket.Note:Aminimumclearanceof 5/8"isrequired

betweentherangeandthelevelingfootthatwill

engagetheANTI-TIPbracket,seefigure3.

NOTE: USE A MINIMUM OF (2) SCREWS

TO INSTALL ANTI-TIP BRACKET

TO THE WALL OR FLOOR.

B,

For SAFETY CONSIDERATIONS as well as optimum

performance adjust the range so that it is level. This

may be checked by placing a spirit level or a large pan

of water on the cooktop or the oven rack. If an

adjustment is required on free-standing, pull the range

forward, tip the range and rotate the leveling feet as

required.

C,

To check the range for proper installation of the anti-tip

bracket: Use a flashlight and look underneath the

bottom of the range to see that one of the rear leveling

legs is engaged in the bracket slot.

D,

Proceed with the remainder of the installation

instructions.

SCREWS MUST

ENTER WOOD

OR METAL.

WALL PLATE

ARTI_ 9215-127

I-TIP

BRACKET

BRACKET

FIGURE 3

SLIDE IN

TO SECURE

RANGE -

BOTTOM

[16 MM]

MIN.

-5-

Page 6

CONNECTING THE RANGE

Electric Supply

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1.

ELECTRICAL SUPPLY CONNECTION:

The range requires 120 volts, 60 cycle alternating current

from an outlet capable of supplying 15 amperes.

User may experience occasional circuit tripping if Ground

Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

WARNING

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock hazard

and should be plugged directly into a properly grounded

receptacle. Do not cut or remove the grounding prong

from this plug.

WARNING

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

Gas Supply

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223. l-latest edition.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA-B149 -Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A "T" handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

GAS SUPPLY CONNECTION: (see figure 4)

A QUALIFIED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED

PETROLEUM (L.P.)/PROPANE GAS SUPPLY LINE

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN

RESULT IN A GAS LEAK.

a. A GAS CUTOFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNING OFF GAS SUPPLY. If range is to be

connected to house piping with flexible or semi-rigid

metal connectors for gas appliance, CONNECTOR

NUTS MUST NOT BE CONNECTED DIRECTLY TO

PIPE THREADS. THE CONNECTOR MUST BE

INSTALLED WITH ADAPTORS PROVIDED WITH

THE CONNECTOR.

b. The house piping and/or range connector used to

connect the range to the main gas supply must be

clean, free of metal shavings, rust, dirt and liquids (oil

or water). Dirt, etc. in the supply lines can work its way

into the range manifold and in turn cause failure of the

gas valves or controls and clog burners and/or pilot

orifices.

-6-

Page 7

CAUTION: DO NOT LIFT OR MOVE RANGE BY

DOOR HANDLES, OR BACKGUARD.

CAUTION: NEVER CHECK FOR LEAKS WITH A

FLAME.

c. Turn off all pilots and main gas valve of other gas

appliances.

d. Turn off main gas valve at meter.

e. Before connecting range, apply pipe thread compound

approved for LPG to all threads.

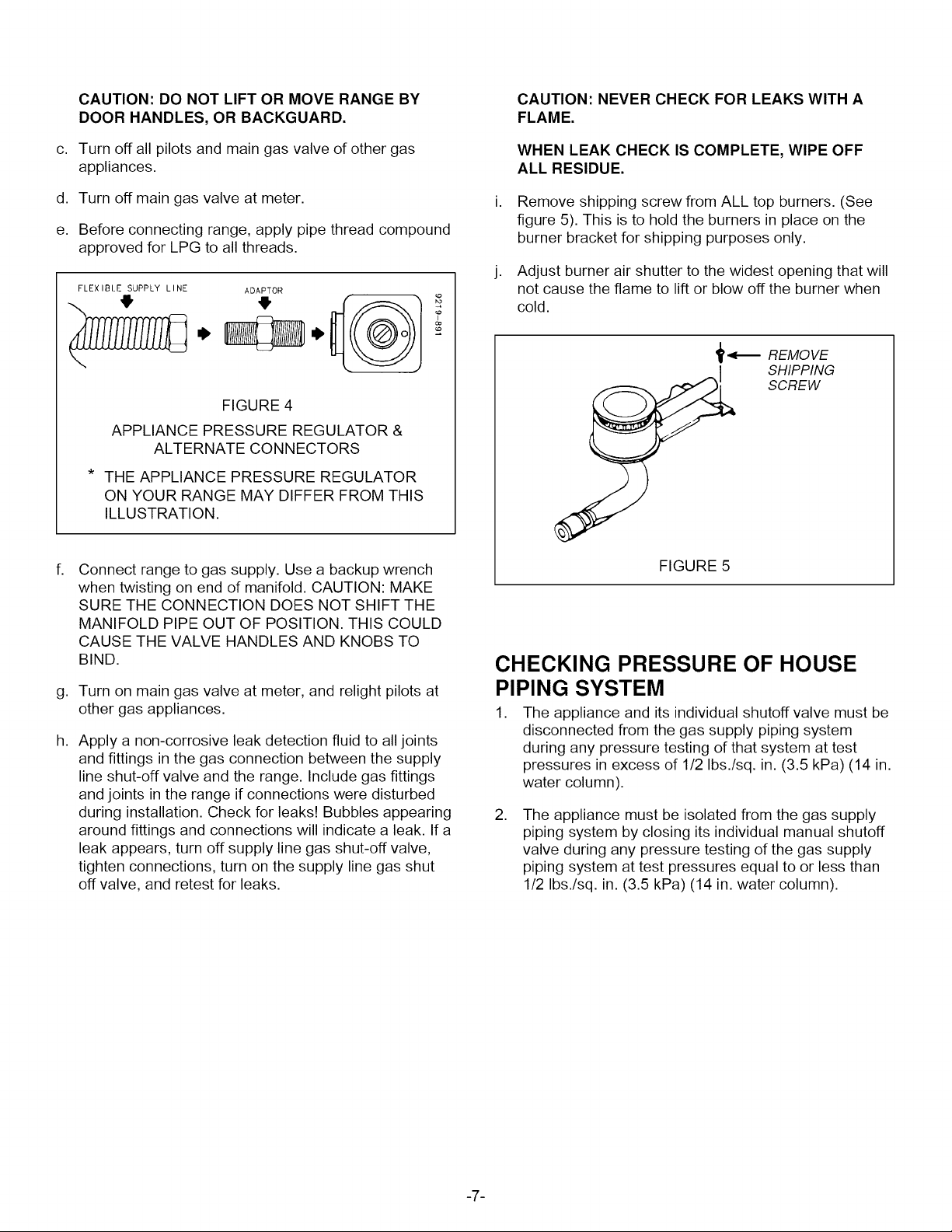

FLEXIBLE SUPPLY LINE ADAPTOR

t t

FIGURE 4

APPLIANCE PRESSURE REGULATOR &

ALTERNATE CONNECTORS

THE APPLIANCE PRESSURE REGULATOR

ON YOUR RANGE MAY DIFFER FROM THIS

ILLUSTRATION.

f,

Connect range to gas supply. Use a backup wrench

when twisting on end of manifold. CAUTION: MAKE

SURE THE CONNECTION DOES NOT SHIFT THE

MANIFOLD PIPE OUT OF POSITION. THIS COULD

CAUSE THE VALVE HANDLES AND KNOBS TO

BIND.

g,

Turn on main gas valve at meter, and relight pilots at

other gas appliances.

h,

Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fittings

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles appearing

around fittings and connections will indicate a leak. If a

leak appears, turn off supply line gas shut-off valve,

tighten connections, turn on the supply line gas shut

off valve, and retest for leaks.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF

ALL RESIDUE.

Remove shipping screw from ALL top burners. (See

figure 5). This is to hold the burners in place on the

burner bracket for shipping purposes only.

Adjust burner air shutter to the widest opening that will

not cause the flame to lift or blow off the burner when

cold.

_ _ REMOVE

SHIPPING

SCREW

FIGURE 5

CHECKING PRESSURE OF HOUSE

PIPING SYSTEM

1. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system

during any pressure testing of that system at test

pressures in excess of 1/2 Ibs./sq. in. (3.5 kPa) (14 in.

water column).

,

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 Ibs./sq. in. (3.5 kPa) (14 in. water column).

-7-

Page 8

RANGE ADJUSTMENTS

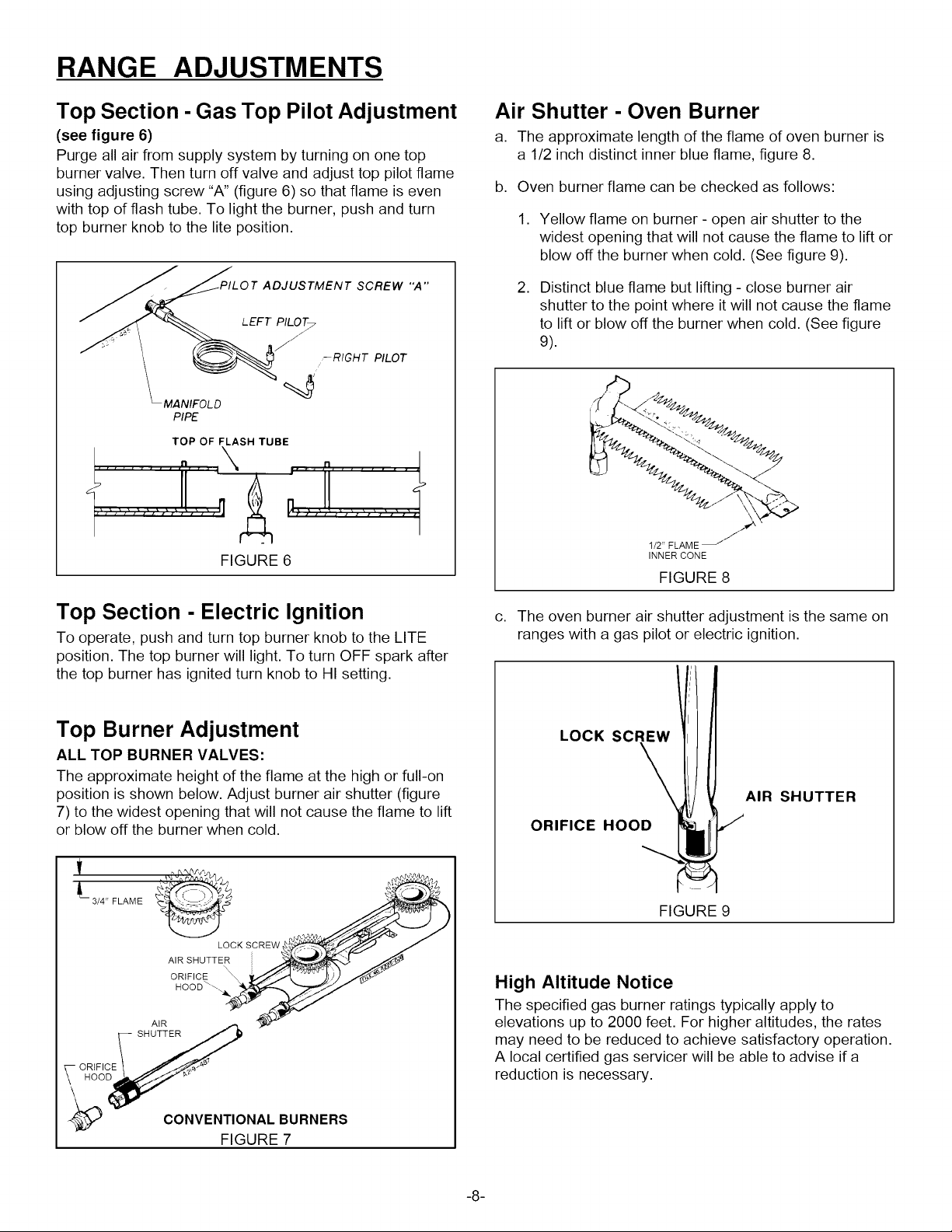

Top Section - Gas Top Pilot Adjustment

(see figure 6)

Purge all air from supply system by turning on one top

burner valve. Then turn off valve and adjust top pilot flame

using adjusting screw "A" (figure 6) so that flame is even

with top of flash tube. To light the burner, push and turn

top burner knob to the lite position.

ADJUSTMENT SCREW '_"

LEFT PILOT7

/

--RIGHT PILOT

MANIFOLD

PIPE

TOP OF FLASH TUBE

FIGURE 6

Air Shutter - Oven Burner

a. The approximate length of the flame of oven burner is

a 1/2 inch distinct inner blue flame, figure 8.

b. Oven burner flame can be checked as follows:

1. Yellow flame on burner - open air shutter to the

widest opening that will not cause the flame to lift or

blow off the burner when cold. (See figure 9).

,

Distinct blue flame but lifting - close burner air

shutter to the point where it will not cause the flame

to lift or blow off the burner when cold. (See figure

9).

I/2" FLAME

INNER CONE

FIGURE 8

f

Top Section - Electric Ignition

To operate, push and turn top burner knob to the LITE

position. The top burner will light. To turn OFF spark after

the top burner has ignited turn knob to HI setting.

Top Burner Adjustment

ALL TOP BURNER VALVES:

The approximate height of the flame at the high or full-on

position is shown below. Adjust burner air shutter (figure

7) to the widest opening that will not cause the flame to lift

or blow off the burner when cold.

/

!_ 3/4"FLAME :L_::

_,_s_o_ _ _

ORIFICE_ _ .-:4_'_ Yd /b,_*'Y'

HOOD"'--\ _ ,,,.....>_// v

AIR _

\ _ooo__-

C,

The oven burner air shutter adjustment is the same on

ranges with a gas pilot or electric ignition.

LOCK SCREW

AIR SHUTTER

ORIFICE HOOD

FIGURE 9

High Altitude Notice

The specified gas burner ratings typically apply to

elevations up to 2000 feet. For higher altitudes, the rates

may need to be reduced to achieve satisfactory operation.

A local certified gas servicer will be able to advise if a

reduction is necessary.

CONVENTIONAL BURNERS

FIGURE 7

-8-

Page 9

GAS CONVERSION

General

All ranges are equipped with fixed orifices and with a

convertible appliance pressure regulator. The unit model

number plate states which gas it was adjusted for at the

factory. To convert the unit to either Natural gas or LP gas

will require the replacement of orifice hoods, adjustment

of the air shutters on the burners and adjustment of the

appliance pressure regulator converter cap.

SEE INSTRUCTIONS FOR GAS CONVERSION

LOCATED ON THE BACK OF THE RANGE.

HOW TO REMOVE RANGE

FOR SERVICING

Follow these procedures to remove appliance for

servicing:

1. Shut off gas supply to appliance.

2. Disconnect electrical supply to appliance, if equipped.

3. Disconnect gas supply tubing to appliance.

4. Slide range forward to disengage range from the

anti-tip bracket. (See page 4).

5. Reverse procedure to reinstall. If gas line has been

disconnected, check for gas leaks after reconnection.

Inlet pressure to the appliance pressure regulator should

be as follows for both operation and checking of appliance

pressure regulator setting:

INLET PRESSURE IN NATURAL LP

INCHES OF WATER COLUMN GAS GAS

Minimum 5 11

Maximum 14 14

NOTE: A qualified servicer should disconnect and

reconnect the gas supply.

The servicer MUST follow installation instructions

provided with the gas appliance connector and the

warning label attached to the connector.

,

To prevent range from accidentally tipping, range must

be secured to the floor by sliding rear leveling leg into

the anti-tip bracket.

SERVICE - PARTS INFORMATION

WHEN YOUR RANGE REQUIRES SERVICE OR

REPLACEMENT PARTS, CONTACT YOUR DEALER

OR AUTHORIZED SERVICE AGENCY. PLEASE GIVE

THE COMPLETE MODEL AND SERIAL NUMBERS OF

THE RANGE WHICH IS LOCATED ON THE RANGE

MODEL NUMBER PLATE.

-9-

Page 10

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL ELECTRODOME-STICO

MANUAL DE INSTALACION

Estufas de gas independientes

convencionales

de 20 pulgadas (50,8 cm) de ancho

CONSERVE ESTE MANUAL COMO REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE A YUDARLE EN LA INSTALACION Y LOS AJUSTES INICIALES DE LA ESTUFA.

DIMENSIONES DEL

ESPACIO LIBRE

Solamente el personal calificado

debera instalar o dar servicio a esta

estufa.

Lea las "lnstrucciones de seguridad"

en el libro de Uso y cuidado antes de

usar la estufa.

La instalacion, el ajuste, la alteracion,

el servicio, el mantenimiento o el uso

incorrectos de la estufa pueden

causar lesiones graves o da_os

materiales.

ADVERTENCIA

TODAS LAS ESTUFAS PUEDEN

i V

VOLTEARSE Y CAUSAR

LESIONES A LAS PERSONAS.

INSTALE LOS DISPOSITIVOS

ESTABILIZADORES

EMPACADOS CON LA ESTUFA.

SIGA TODAS LAS

INSTRUCCIONES DE

INSTALAClON.

La estufa puede instalarse con un espacio libre de cero

pulgadas adyacente (contra)la construcci6n combustible

en la parte posterior y lateral debajo de la superficie para

cocinar. Para obtener la informaci6n completa

relacionada con la instalaci6n de gabinetes de pared

encima de la estufa y los espacios libres a las paredes

combustibles por encima de la parte superior de la

superficie para cocinar, vea los dibujos de instalacidn. Por

MOTIVOS DE SEGURIDAD no instale la estufa en ningQn

gabinete combustible que no est6 de acuerdo con los

dibujos de instalaci6n.

Para eliminar el riesgo de quemaduras o incendios al

atravesarse por encima de las unidades calientes de la

superficie, debe evitarse el almacenaje en los gabinetes

por encima de las unidades de la superficie. Si se va a

proporcionar almacenaje, puede reducirse el riesgo

instalando una campana de estufa que sobresalga

horizontalmente cuando menos 5 pulgadas (12.7 cm) de

la parte inferior de los gabinetes.

* NOTA: La dimensi6n de 30 pulgadas ( 76.2 cm) no

puede reducirse a menos de 24 pulgadas (61 cm) cuando

los gabinetes de pared en una casa est_n protegidos con

materiales contra incendios de acuerdo con las Normas

Nacionales Estadounidenses _6digo Nacional de Gas

Combustible o en casas m6viles cuando est_n protegidas

con materiales contra incendios de acuerdo con la Norma

Federal para Construcci6n y Seguridad de Casas

M6viles.

PRECAUCION: ALGUNOS GABINETES Y

MATERIALES DE CONSTRUCCION NO ESTAN

DISENADOS PARA SOPORTAR EL CALOR QUE SE

PRODUCE DURANTE LA OPERACION NORMAL

SEGURA DE UN ELECTRODOMESTICO INDICADO.

PODRJA OCURRIR DECOLORACION O DANOS,

TALES COMO LA PERDIDA DEL LAMINADO.

Su estufa p0dria no estar equipada con algunas de las caracteristicas mencionadas en este manual:

Page 11

INSTALACION

Lea la placa del nOmero de modelo de la estufa para ver

si est_ aprobada la instalaci6n en casas m6viles o

vehiculos recreativos. Si est_ aprobada, se aplicarSn los

puntos siguientes:

CASAS MOVILES

La instalaci6n de una estufa dise_ada para instalarse en

una casa m6vil debe estar en conformidad con la Norma

de Construcci6n y Seguridad de Casas Prefabricadas,

Titulo 24 CFR, Parte 3280 (anteriormente la Norma

Federal para Construcci6n y Seguridad de Casas

M6viles, Titulo 24 HUD, Parte 280) o, cuando dicha

norma no corresponda, con la Norma para Instalaciones

de Casas Prefabricadas ANSI A225.1/NFPA 501A, o con

los c6digos locales.

En Canad_ la estufa debe instalarse de acuerdo con la

norma actual de CSA C22.1 _6digo EI6ctrico

Canadiense Parte 1y Secci6n Z240.4.1 _equisitos de

Instalaci6n para Electrodom6sticos que Consumen Gas

en Casas M6viles (Norma CSA CAN/CSA _240MH).

DIBUJOS DE INSTALACION

VEHICULOS RECREATIVOS

La instalaci6n de una estufa dise_ada para vehiculos

recreativos debe estar en conformidad con los c6digos

estatales u otros similares, en caso de no existir dichos

c6digos, entonces con la Qltima edici6n de la Norma para

Vehiculos Recreativos, ANSI A119.5.

En Canad_ la estufa debe estar instalada de acuerdo con

la Secci6n C22.2 No. 148/CAN/CSA- Z240.6.2 -de los

Requisitos EI6ctricos para Vehiculos Recreativos (Norma

CSA CAN/CSA _erie Z240 RV) y con la Secci6n

Z240.4.2. _equisitos de Instalaci6n para

Electrodom6sticos y Equipo de Propano en Vehiculos

Recreativos (Norma CSA CAN/CSA --

Serie Z240 RV).

PARA QUITAR DE LOS MATERIALES

DE EMBALAJE Y EMBARQUE

a. Usando los postes (4) esquineros de la caja, doblados

horizontalmente y apilados en dos para proteger el

piso, coloque la estufa sobre la parte posterior. Quite

los cuatro tornillos que sujetan el larguero a la base de

la estufa.

b. Coloque la estufa verticalmente.

c. Quite todos los materiales de embalaje, la cinta y

pelicula protectora que hayan en algunas partes

cromadas o de acero inoxidable antes de instalar la

estufa.

36" (91.4 CM) DE

ALTURA DE LA

PARTE SUPERIOR

DEL G_

33"

(83.8 CM) 24"

(61 CM)

20 1/8" (51.1 CM) DE

ABERTURA DEL

GABINETE

18 1/4"

(46.4 CM)

18"

(45.7CM)

UBICACION

RECOMENDADA PARA

LA TUBERIA DE GAS.

PROVEA UN TOMACORRIENTES

CONECTADO A TIERRA DE

120 VOLTIOS EN ESTA AREA.

EL TOMACORRIENTE DEBE

ESTAR AL RAS

8 1/2"

(21.6 CM)

25" (63.5 CM) DE

PROFUNDIDAD

16"

(40.6 CM)

NORMAL DE LA

PARTE SUPERIOR

DEL GABINETE

24" (61 CM) DE PROFUNDIDAD

DEL GABINETE

-2-

Page 12

DIBUJOS DE INSTALACION

i__,_.___ ! _ CUALQUIER

LA NOTA EN COCINAR

|..... I_ (_i_O_ 1tl .....I' (7 3"CM) 0" DE ESPACIO LIBRE

' -- .... ._ ADYACENTE Y LA

O O O O O _J_"'_ PARTE POSTERIOR Y

Ii SUPERFICIE PARA

' ' DEBAJO DE LA

SUPERFICIE

COMBUSTIBLE

PROFUNDIDAD PARA

LOS GABINETES

ENCIMA DE LA

13,330 , Ax o E

CONSTRUCCION

COMBUSTIBLE

LATERAL DE LA ESTUFA

SUPERFICIE PARA

36" COCINAR.

(91.4 CM)

!

INSTALACION DEL PROTECTOR

POSTERIOR

(si no est_i instalado)

El protector posterior se ajusta a la estufa como se

muestra en la figura 1 y se asegura con un soporte,

2 pernos y 2 tuercas en cada lado.

Coloque el protector en la parte posterior de la estufa.

Atornille el protector alas pesta_as del panel final.

ART #9219-94-0

ADVERTENCIA

DESCONECTE LA ENERGJA EL¢:CTRICA

PARA EVITAR EL RIESGO DE DESCARGAS

EL¢:CTRICAS.

DIMENSIONES DEL ESPAClO LIBRE

Todas las estufas independientes pueden instalarse con

la parte posterior contra una (0") la pared combustible

vertical, y los lados debajo de la superficie para cocinar

contra (0") los gabinetes combustibles de la base. Para

obtener la informaci6n completa relacionada con la

instalaci6n de los gabinetes de pared por encima de la

estufa y los espacios libres alas superficies combustibles,

vea los dibujos de instalaci6n y la placa del nQmero de

modelo de la estufa. Por MOTIVOS DE SEGURIDAD no

instale una estufa en ningQn gabinete combustible que no

est6 de acuerdo con los dibujos de instalaci6n y los

espacios libres indicados en la placa del nQmero de

modelo.

FIGURA 1

UBICACION DE LA ESTUFA

No coloque la estufa sobre agujeros del piso ni en otros

lugares en donde est6 sujeta a corrientes fuertes de aire.

Las aberturas en la pared por detrSs de la estufa yen el

piso por debajo de la estufa deben sellarse. AsegQrese

de que el flujo de aire de enfriamiento o ventilaci6n por

debajo de la estufa no est6 obstruido.

NOTA: Una estufa NO debe instalarse directamente

sobre alfombras de cocina.

-3-

Page 13

[ ADVERTENClA

ESTEPRODUCTONODEBEINSTALARSEDEBAJODE

UNACAMPANADEVENTILACIONQUEDIRIJAELAIRE

ENUNADIRECCIONHACIAABAJO.

(VEALAFIGURA)

ESTOSSISTEMASDEVENTILACIONPUEDENCAUSAR

PROBLEMASDEIGNICIONY DECOMBUSTIONCONLOS

QUEMADORESA GASRESULTANDOEN LESIONES

PERSONALESY PUEDENAFECTARLAMANERADE

COCINARDE LAUNIDAD.

NOTA:ESPOSIBLEQUELAFIGURANOSEAUNA

REPRESENTACIONEXACTADESUESTUFA0 DESU

SUPERFICIEPARRCOCINAR;SINEMBARGO,ESTA

ADVERTENCIASEAPLICAA TODOSLOS

ELECTRODOMt_STICOSDECOCINAAGAS.

INSTRUCCIONES DE INSTALACION DEL DISPOSITIVO ESTABILIZADOR

NOTA: Existe el riesgo de que la estufa se voltee si el

electrodom6stico no est_ instalado de acuerdo con las

instrucciones de instalaci6n provistas. El uso correcto de

este dispositivo reduce el riesgo de VOLTEO. Cuando se

use este dispositivo, el propietario debe aun observar las

precauciones de seguridad segen se indican en el

MANUAL DE USO Y CUIDADO y evitar usar la puerta del

horno o el caj6n inferior como banquillo.

Se proporcionan las instrucciones de instalaci6n para

madera y cemento tanto para piso como para pared.

Cualquier otro tipo de construcci6n podria requerir

t6cnicas de instalaci6n especiales segen se determine

necesario para proporcionar un anclaje adecuado del

soporte ESTABILIZADOR al piso o a la pared.

PASO 1 - Ubicaci6n del soporte (yea la figura 2)

A. Determine en d6nde estar_ ubicado el "BORDE"

derecho o izquierdo de la estufa y marque el piso o

la pared.

B. Coloque el SOPORTE de 3 15/16" (10 cm) del

"BORDE" marcado hacia el centro del hueco y contra

la pared posterior, segOn se muestra en la flgura 2,

con el orificio orientado contra la pared.

\

\

I

I

\

I

ORIFICIO DE /

ORIENTACION

ORIFIClOS

PARR LA /

PARED

C. Use el soporte como plantilla y marque los orificios

necesarios, segOn se muestra en la figura 2, para el

tipo de construcci6n que usar&

PASO 2 - Instalaci6n del soporte estabilizador

A. Construcci6n de madera:

1. Piso: Ubique el centro de los dos orificios que se

identifican en la figura 2 como "ORIFICIOS PARA

EL PISO". Taladre un orificio piloto con una broca

de 118"en el centro de cada orificio (puede usar un

clavo o un punz6n si no tiene un taladro

disponible). Asegure el soporte ESTABILIZADOR

al piso con los dos tornillos provistos. ContinQe

con el PASO 3.

2. Pared: Ubique el centro de los dos orificios que se

identifican en la figura 2 como "ORIFICIOS PARA

LA PARED". Taladre un orificio piloto en 8ngulo

con una broca de 1/8" en el centro de cada orificio

como se muestra en la figura 3. (Puede usar un

clavo o un punz6n si no tiene disponible un

taladro). Asegure el soporte ESTABILIZADOR a la

pared con los dos tornillos provistos segQn se

muestra en la figura 4. ContinOe con el PASO 3.

FIJE EL SOPORTE -._

ESTABILIZADOR CON

TORNILLOS LARGOS

SOPORTE

ESTABILIZADOR

I

I

L BORDE MARCADO ""

DE LA ESTUFA _...

3 15/16"

(10 CM)

DEL BORDE

DE LA ESTUFA

"_ PARA EL PISO

'--. L ORIFICIOS

_ PATA

-4-

NIVELADORA

FIGURA 2

Page 14

B.Construcci6ndecementooconcreto:

1. Puedenobtenersetornillosapropiadosparala

construcci6ndeconcretoenunaferreteria.

Taladreelorificiodeltama_orequeridoparalos

tornillosquehayaobtenido,enelconcreto,enel

centrodelosorificiosidentificadosenlafigura2

como"ORIFICIOSPARAELPISO"Asegureel

soporteESTABILIZADORalpiso.Contin[3econel

PASO3.

PASO 3 - Instalaci6n de la estufa

A. Alinee la estufa en su ubicaci6n final y deslicela hacia

atr_s en su lugar. Aseg@ese de que la pata

niveladora est6 completamente insertada y asegurada

en el soporte ESTABILIZADOR. Nota: Se requiere un

espacio libre de cuando menos 5/8"(1.58 cm) entre la

estufa y la pata niveladora que se enganchar8 al

soporte ESTABILIZADOR, vea la figura 3.

B,

Por CONSIDERACIONES DE SEGURIDAD asi como

para obtener el mejor rendimiento, ajuste la estufa de

manera que quede bien nivelada. Esto puede

revisarse colocando un nivel de burbuja de aire o un

recipiente grande de agua en la superficie para

cocinar o en la parrilla del homo. Si es necesario

realizar un ajuste en una estufa independiente, j_lela

hacia delante, incline la estufa y gire la pata niveladora

seg[3n sea necesario.

C,

Para comprobar que el soporte estabilizador est6

correctamente instalado en la estufa: Use una lintema

y vea por debajo de la parte inferior de la estufa para

comprobar que una de las patas niveladoras

posteriores est6 enganchada en la ranura del soporte.

D,

Proceda con el resto de las instrucciones de

instalaci6n.

NOTA: USE CUANDO MENOS DOS

LOS TORNILLOS

DEBEN ENTRAR EN

MADERA O METAL

PLACA DE

PARED

ARTS 9215-127

TORNILLOS PARA INSTALAR EL

SOPORTE ESTABILIZADOR A LA

PARED O AL PISO.

SOPORTE

ESTABILIZADOR

DESLICE

PARA

SUJETAR

FIGURA 3

FONDO DE

LA ESTUFA

5/8"

(16MM)

MINIMOS

-5-

Page 15

CONEXION DE LA ESTUFA

Suministro de energia electrica

El electrodom6stico, cuando se instala, debe conectarse

a tierra de acuerdo con los c6digos locales o, si 6stos no

existieran, entonces con el C6digo Nacional EI6ctrico,

ANSI/NFPA 70.

En Canad_ la estufa debe instalarse de acuerdo con la

Norma actual C22.1 de CSA _6digo EI6ctrico

Canadiense Parte 1.

CONEXION DEL SUMINISTRO EL#CTRICO:

La estufa requiere una corriente alterna de 60 ciclos,

120 voltios de un tomacorriente capaz de suministrar

15 amperios.

El usuario puede experimentar la desconexi6n ocasional

del circuito si est_ en uso el interruptor accionado por

corriente de p6rdida a tierra del circuito (GFCI).

ADVERTENCIA

Instrucciones electricas de conexion

a tierra

Este electrodom6stico est_ equipado con una clavija de

conexi6n a tierra (de tres puntas) para protegerlo contra

el riesgo de descargas el6ctricas y debe conectarse

directamente en un recept_culo debidamente conectado

a tierra. No corte ni quite la punta de conexi6n a tierra de

esta clavija.

ADVERTENCIA

DESCONECTE EL SUMINISTRO

EL#CTRICO ANTES DE DAR SERVICIO

AL ELECTRODOM#STICO.

Suministro de gas

La instalaci6n de esta estufa debe estar en conformidad

con los c6digos locales o, 6stos si no existieran, entonces

con la Qltima edici6n del C6digo Nacional de Gas

Combustible, ANSI Z223.1

En Canad_ la estufa debe instalarse de acuerdo con la

Norma actual CAN/CGA-B149 de CGA _6digos de

instalaci6n para electrodom6sticos y equipos que queman

gas y con los c6digos locales.

En la Commonwealth de Massachusetts

Este producto debe instalarse por un plomero o un

instalador de gas certificado cuando est& instalado

dentro de la Commonwealth de Massachusetts.

Debe instalarse en el electrodom6stico una v_lvula de

gas tipo "T" manual en la tuberia del suministro de gas.

Cuando se utiliza un conector flexible de gas, no debe

exceder una Iongitud de tres (3) pies o 36 pulgadas

(91,4 cm).

CONEXION DEL SUMINISTRO DE GAS: (vea la figura 4)

LA CONEXION DE GAS DEBE REALIZARLA UN

T#CNICO CALIFICADO DE SERVICIO O UN

INSTALADOR DE ELECTRODOM#STICOS DE GAS. Las

pruebas de fugas del electrodomestico debe realizarlas

el instalador de acuerdo con las instrucciones que

aparecen en la seccion h.

LA TUBERiA DE SUMINISTRO DE GAS DEBE TENER UN

REGULADOR DE SERVlCIO DE GAS NATURAL. LA

PRESION DE ENTRADA A ESTE ELECTRODOMI_STICO

DEBE REDUCIRSE A UN M/_,XlMO DE 14 PULGADAS DE

COLUMNA DE AGUA (0.5 LIBRAS POR PULGADA

CUADRADA [PSI]). LA TUBERiA DE SUMINISTRO DE

PETROLEO LICUADO (LP) O GAS PROPANO DEBE

TENER UN REGULADOR DE PRESION PARA GAS LP.

LA PRESION DE ENTRADA A ESTE

ELECTRODOMI_STICO DEBE REDUCIRSE A UN

MAXlMO DE 14 PULGADAS DE COLUMNA DE AGUA (0.5

PSI). LAS PRESIONES DE ENTRADA SUPERIORES A 0.5

PSI PUEDEN DANAR EL REGULADOR DE PRESION Y

OTROS COMPONENTES DE GAS DEL

ELECTRODOMI_STICO Y PUEDEN CAUSAR FUGAS DE

GAS.

DEBE INSTALARSE UNA VALVULA DE CIERRE DE

a,

GAS EN UN LUGAR ACCESIBLE EN LA TUBERiA DE

SUMINISTRO M/_,SADELANTE DE LA ESTUFA, PARA

CERRAR Y ABRIR EL SUMINISTRO DE GAS. Si la

estufa se conectar_ a la tuberia de la casa con

conectores flexibles o semirrigidos de metal para el

electrodom6stico de gas, LAS TUERCAS DE

CONEXION NO DEBEN CONECTARSE

DIRECTAMENTE EN LAS ROSCAS DE LA TUBERiA.

EL CONECTOR DEBE INSTALARSE CON LOS

ADAPTADORES PROVlSTOS CON EL CONECTOR.

b,

La tuberia de la casa y el conector de la estufa que se

use para conectar la estufa al suministro principal de

gas, deben estar limpios, sin desechos de metal, sin

corrosi6n, tierra ni liquidos (aceite o agua). La tierra y

demos en las tuberias de suministro pueden Ilegar hasta

el mQItiple de la estufa y causar fallas en las v_lvulas de

gas o en los controles y obstruir los quemadores o los

orificios de los pilotos.

-6-

Page 16

PRECAUCION: NO LEVANTE NI MUEVA LA

ESTUFA SOSTENIC:NDOLA DE LAS ASAS DE LA

PUERTA NI DEL PROTECTOR POSTERIOR.

C,

Apague todos los pilotos y la vSIvula principal de gas

de los demos electrodom6sticos de gas.

d,

Cierre la vSIvula principal de gas en el medidor.

e.

Antes de conectar la estufa, aplique compuesto para

roscas de tuberias que est6 aprobado para todas las

roscas de gas LP.

PRECAUCION: NUNCA REVISE SI EXISTEN

FUGAS CON LLAMAS.

CUANDO TERMINE DE REVISAR QUE NO FUGAS,

LIMPIE TODOS LOS RESIDUOS.

Quite el tornillo de embarque de TODOS los

quemadores superiores. (Vea la figura 5.) Esto s61o es

con el fin de mantener los quemadores en su lugar en

el soporte de los quemadores durante el embarque.

TUBERJAFLEXIBLEDE SUMINISTR0 ADAPTADOR

t

FIGURA 4

REGULADOR DE PRESION Y CONECTORES

ALTERNATIVOS DEL ELECTRODOMI_STICO

* EL REGULADOR DE PRESION DE SU

ESTUFA PODRJA SER DISTINTO AL DE LA

ILUSTRACION.

f,

Conecte la estufa al suministro de gas. Use una Ilave

de respaldo cuando tuerza el extremo del multiple.

PRECAUCl0N: ASEGORESE DE QUE LA

CONEXION NO SE MUEVA DE LUGAR EN LA

TUBERJA DEL MOLTIPLE. ESTO PUEDE CAUSAR

QUE LAS PERILLAS Y LAS ASAS DE LA V/_,LVULA

SE PEGUEN.

g,

Abra la vSIvula principal de gas al medidor, y vuelva a

encender los pilotos de los otros electrodom6sticos

de gas.

h,

Aplique un liquido de detecci6n de fugas que sea

anticorrosivo en todas las uniones y accesorios de la

conexi6n de gas entre la vSIvula de cierre de la tuberia

de suministro y la estufa. Incluya los accesorios y las

uniones de gas de la estufa si se alteraron las

conexiones durante la instalaci6n, iRevise si existen

fugas! Si aparecen burbujas alrededor de los

accesorios y las conexiones significar_ que hay una

fuga. Si aparece una fuga, cierre la v_lvula de

suministro de la tuberia de gas, apriete las

conexiones, abra la v_lvula de cierre de la tuberia de

suministro de gas y vuelva a revisar si hay fugas.

Ajuste el obturador de aire del quemador a la posici6n

m_s abierta que no haga que se levante o apague la

llama cuando el quemador est6 frio.

._._ UITE EL

TORNILLO DE

EMBARQUE

FIGURA 5

REVISE LA PRESION DEL SISTEMA

DE TUBERIAS DE LA CASA

1. El electrodom6stico y su v_lvula de cierre individual

deben estar desconectados del sistema de suministro

de gas durante las pruebas de presi6n de ese

sistema a presiones que sobrepasen 1/2 libra por

pulgada cuadrada (3.5 kPa) (14 pulgadas de columna

de agua).

, El electrodom6stico debe estar aislado del sistema de

suministro de gas cerrando la vSIvula de cierre

individual durante las pruebas de presi6n de ese

sistema a presiones iguales o menores de 1/2 libra

por pulgada cuadrada (3.5 kPa) (14 pulgadas de

columna de agua).

-7-

Page 17

AJUSTES DE LA ESTUFA

Seccion superior- ajuste del piloto

superior de gas (vea la figura 6)

Purgue todo el aire del sistema de suministro abriendo la

v_lvula de un quemador superior. Despu6s cierre la

v&lvula y ajuste la llama del piloto usando el tornillo de

ajuste "A" (figura 6) hasta que la llama quede uniforme

con la parte superior del tubo cubrellamas. Para encender

el quemador, empuje y gire la perilla del quemador

superior a la posici6n de encendido "lite".

f

TORNILLO "A" DE AJUSTE

DEL PILOTO

PILOTO IZQUIERDO

TUBERfA DEL

MUL TIPLE

PARTE SUPERIOR DEL

FIGURA 6

/Z

J

PILOTO DERECHO

Obturador de aire - Quemador

del horno

a. La Iongitud aproximada de la llama del quemador del

horno es de 1/2 pulgada, y debe ser con el interior

azul, bien definida, figura 8.

b. La llama del quemador del horno puede revisarse de

la manera siguiente:

,

Llama amarilla en el quemador- abra el obturador

de aire a la posici6n m_s abierta que no haga que

se levante o apague la llama cuando el quemador

est6 frio. (Vea la figura 9.)

,

Llama azul bien definida pero se levanta - cierre el

obturador de aire hasta el punto en donde no

cause que se levante o apague la llama cuando el

quemador est6 frio. (Vea la figura 9.)

CONO INTERIOR

DE LA LLAMA

DE I/2"

/

Seccion superior- Encendido

electrico

Para que funcione, empuje y gire la perilla del quemador

superior a la posici6n de encender "LITE". El quemador

superior se encender& Para APAGAR la chispa despu6s

de que se haya encendido el quemador superior, gire la

perilla al ajuste alto "HI".

Ajuste del .quemador superior

TODAS LAS VALVULAS DE LOS QUEMADORES

SUPERIORES:

La altura aproximada de la llama en la posici6n alta o

completa se muestra abajo. Ajuste el obturador de aire

del quemador (figura 7) a la )osici6n m_s abierta que no

haga que se levante o apague la llama cuando el

quemador est6 frio.

.b',,hs¢ _,

L 3/4" LLAMA L_::

TORNILLO DE __ _ J_

SUJECION ._S__ _-_ J

OBTURADOR DE AIRE _J

OAMPANAOEOR,F, O

OBTURADOR " "_

CAMPA.AOE OE

QUEMADORES CONVENCIONALES

FIGURA 7

FIGURA 8

c. El ajuste del obturador de aire del quemador del horno

es el mismo en las estufas con pilotos de gas o de

encendido el6ctrico.

TORNILLO DE

SUJECION

\

CAMPANA DE ORIFICIO

FIGURA 9

OBTURADOR

DE AIRE

Aviso de altitud

Las capacidades de funcionamiento especificadas del

quemador de gas por Io general corresponden a

elevaciones de hasta 609.6 metros (2000 pies). Cuando

la altitudes mayor, podria ser necesario reducir las

capacidades de funcionamiento para Iograr un

funcionamiento satisfactorio.

Un t6cnico local, certificado en servicios de gas, podr8

aconsejarle si es necesaria la reducci6n.

-8-

Page 18

CONVERSION DE GAS

General

Todas las estufas est_n equipadas con oriflcios fijos y con

un regulador de presi6n convertible para

electrodom6sticos. La placa del modelo de la unidad

marca para qu6 tipo de gas est_ ajustada de f_brica. Para

convertir la unidad a gas natural o LP se tendrSn que

cambiar las campanas de orificio, ajustar los obturadores

de aire de los quemadores y ajustar la tapa convertidora

del regulador de presi6n del electrodom6stico.

CONSULTE LAS INSTRUCCIONES PARA LA

CONVERSION DE GAS QUE SE ENCUENTRA

EN LA PARTE POSTERIOR DE LA ESTUFA.

COMO QUITAR LA ESTUFA

PARA DARLE SERVIClO

Siga estos procedimientos para quitar el

electrodomestico para darle servicio:

1. Cierre el suministro de gas al electrodom6stico.

2. Desconecte el suministro el6ctrico al electrodom6stico,

si est_ equipado con uno.

3. Desconecte la tuberia de gas al electrodom6stico.

4. Deslice la estufa hacia adelante para desengancharla

del soporte estabilizador. (Vea la pSgina 4).

5. Invierta el procedimiento para volver a instalarlos. Si se

desconect6 la tuberia de gas, revise si tiene fugas de

gas despu6s de reconectarla.

La presi6n de entrada al regulador de presi6n deber8 ser

del modo siguiente para establecer el ajuste de

funcionamiento y la revisi6n del regulador de presi6n del

electrodom6stico:

PRESIC)N DE ENTRADA NATURAL LP

PULG. DE COLUMNA DE AGUA GAS GAS

Minima 5 11

Maxima 14 14

NOT, A: El suministro de gas debe desconectarlo y

volver a conectarlo un t6cnico calificado de servicio.

El t6cnico DEBE seguir las instrucciones de

instalaci6n provistas con el conector del

electrodom6stico de gas y las de la etiqueta de

advertencia adherida al conector.

,

Para evitar que la estufa se voltee accidentalmente,

6sta debe estar asegurada al piso deslizando la pata

niveladora posterior dentro del soporte estabilizador.

SERVICIO -INFORMACION SOBRE

PIEZAS

CUANDO SU ESTUFA REQUIERA SERVICIO O

PIEZAS DE REPUESTO, COMUNJQUESE CON EL

PROVEEDOR O AGENCIA AUTORIZADA DE

SERVlCIO. PROPORCIONE LOS NOMEROS DE

MODELO Y SERIE COMPLETOS DE LA ESTUFA,

QUE SE ENCUENTRAN EN LA PLACA DEL NOMERO

DE MODELO DE LA ESTUFA.

-9-

Page 19

INSTALLATEUFI: VEUILLEZ LAISSER CES INSTRUCTIONS A VEC L'APPAREIL

MANUEL DE MISE EN SERVICE

Cuisiniere a gaz amovible de

20 pouces a four traditionnel

VEUILLEZ CONSERVER CE MANUEL POUR RC:FC:RENCE ULTC:RIEURE

CE MANUEL EST DESTIN'_ ,A FACILITER LA MISE EN SERVICE ET LE R'_GLAGE INITIAUX DE LA CUISINI'_RE.

DI GAGEMENT NI CESSAIRE

La cuisini@e peut avoir un d6gagement nul (0 po/cm) par

La mise en service et le depannage de

cette cuisiniere doivent _tre realises

uniquement par du personnel qualifi&

Lire les " Mesures de securite " dans

le manuel de I'utilisateur avant

d'utiliser la cuisiniere.

Une mauvaise realisation de la mise

en place, du reglage, de toutes

modifications ou reparations ou de

I'entretien de la cuisiniere ou son

usage incorrect peuvent entrainer

des blessures ou des deg&ts graves.

rapport aux parois en mat@iaux combustibles _ I'arri@e et

sur les c6t6s au-dessous de la surface de cuisson (elle

peut _tre contre ces parois). Pour tous renseignements

concernant la pose d'armoires murales au-dessus de la

cuisini@e et des d6gagements _ respecter par rapport

aux parois combustibles se trouvant au-dessus de la

surface de cuisson, se reporter aux sch6mas

d'installation. Pour des RAISONS DE SECURIT¢:, ne pas

monter la cuisini@e dans une armoire en mat@iau

combustible qui ne soit pas conforme aux sch6mas

d'installation.

Pour 61iminer tout risque de brQlure ou d'incendie en

essayant d'atteindre un objet plac6 au-dessus d'616ments

brQlants, 6viter d'avoir un espace de rangement

au-dessus de la surface de cuisson. S'il doit y avoir des

armoires au-dessus de la surface de cuisson, les risques

peuvent _tre r6duits en posant une hotte qui d6passe d'un

minimum de 5 po (12,7 cm) du bas des armoires.

* REMARQUE : La dimension de 30 po (76,2 cm) peut

6tre r6duite _ 24 po (61 cm) minimum si les armoires

murales d'un Iogement sont prot6g_es par des mat@iaux

ininflammables conform_ment aux normes American

National Standards - National Fuel Gaz Code ou, dans le

PEUVENT BASCULER ET

PROVOQUER DES BLESSURES.

POSER LES DISPOSITIFS DE

STABILISATION FOURNIS AVEC

CETTE CUlSINII_RE.

SUIVRE TOUTES LES

CONSIGNES DE MISE EN

SERVICE.

votre cuisiniere peut ne pas _tre dotee de toutes les fonctions mentionnees dans ce manuel

cas de maisons mobiles, si les armoires murales sont

protegees par des mat@iaux ininflammables

conform_ment aux r_glements du Federal Standard for

Mobile Home Construction and Safety.

ATTENTION : CERTAINES ARMOIRES ET

CERTAINS MATERIAUX DE CONSTRUCTION NE

SONT PAS CONOUS POUR SUPPORTER LA

CHALEUR PRODUITE LORS DU

FONCTIONNEMENT NORMAL D'UN APPAREIL.

UNE DECOLORATION OU DES DEG,_,TS TELS

QUE LA DELAMINATION PEUVENT SE PRODUIRE.

Page 20

MISE EN SERVICE

V6rifier sur la plaque signal6tique de la cuisini_re si elle

est homologu6e pour la mise en service dans une maison

mobile et/ou une roulotte de parc. Si la plaque de cuisson

est homologu6e pour cet usage, les points suivants

s'appliquent.

MAISONS MOBILES

La mise en service d'une cuisini_re pr6vue pour les

maisons mobiles doit _tre conforme aux normes

" Manufactured Home Construction and Safety Standard ",

titre 24 CFR, partie 3280 (pr6c6demment" Federal

Standard for Mobile Home Construction and Safety ", titre

24 HUD, partie 280) ou, Iorsque ces normes ne sont pas

applicables, les normes "Standard for Manufactured

Home Installations ", ANSI A225.1/NFPA 501A, ou les

codes de la construction Iocaux.

Au Canada, la mise en service de la cuisini_re doit se a.

faire conform6ment aux normes ACNOR C22.1 du code

d'61ectricit6 canadien les plus r6centes, partie 1 et section

Z240-4.1 relative aux caract6ristiques techniques exig6es

pour les appareils _ gaz utilis6s dans les maisons mobiles b.

(norme CAN/ACNOR - Z240MH).

ROULOTTES DE PARC

La mise en service d'une cuisini_re pr6vue pour les

roulottes de parc doit _tre conforme aux codes

provinciaux et autres codes ou, en leur absence, _ la

derni_re 6dition de la norme ANSI A119.5 relative aux

roulottes de parc.

Au Canada, la mise en service de la cuisini_re doit _tre

r6alis6e conform6ment _ I'article C22.2 alin6a 148

CAN/ACNOR - s6rie Z240.6.2 relatif aux caract6ristiques

exig6es pour I'installation 61ectrique dans les v6hicules de

parc (norme CAN/ACN s6rie Z240 RV) et _ I'article

Z240.4.2 relatif aux caract6ristiques techniques exig6es

pour les appareils et le mat6riel fonctionnant au propane

dans les v6hicules de parc (norme CAN/ACNOR s6rie

Z240 RV).

DEBALLAGE

Prot6ger le plancher _ I'aide des 4 montants d'angle

du carton empil6s _ plat par deux et coucher la

cuisini_re dessus. Enlever les quatre vis qui fixent le

socle en bois sur la cuisini_re.

Remettre la cuisini_re debout.

C.

Enlever tous mat6riaux d'emballage, ruban adh6sif et

pellicule protectrice de certains composants chrom6s

ou en acier inoxydable avant de mettre la cuisini_re

en place.

SCHI MAS DE MISE EN SERVICE

_" 18 1/4 PO

(46,4 CM)

(45,7CM)

PO (2,5 CM)

33 PO

(83,8 CM/

(61 CM)

36 PO (91,4 CM)

DE HAUTEUR DE

DESSUS

D'ARMOIRE

_ 24 PO

OUVERTURE DE

20 1/8 PO (51,1 CM)

DANS L'ARMOIRE

1 PO (2,5 CM) \

18P0

EMPLACEMENT RECOMMAND#

POUR LA CONDUITE DE GAZ.

PR#VOIR UNE PRISE DE 120 V

RELI#E h, LA TERRE DANS

CETTE ZONE. LA PRISE DOlT

#TRE ENCASTR¢:E

8 1/2 PO

(21,6 CM)

25 PO (63,5 CM)

DE PROFONDEUR

16 PO

(40,6 CM)

OUVERTURE DE 24 PO (61

CM) DANS L'ARMOIRE

NORMALE

D'ARMOIRE

-2-

Page 21

SCHI MAS DE MISE EN SERVICE

36 PO

(91,4 CM)

TOUTE SURFACE:

COMBUSTIBLE

13 PO (33 CM) MAX.

DE PROFONDEUR

lJ_'-- D'ARMOIRE

AU-DESSUS DE LA

SURFACE DE

CUISSON

Dt_GAGEMENT DE 0

PO/CM ENTRE LES

PAROIS COMBUSTIBLES

ADJACENTES ET

L'ARRI#RE ET LES

COTI_S DE LA

CUISINI#RE

AU-DESSOUS DE LA

SURFACE DE CUISSON.

!

I

POSE DU DOSSERET

(s'il n'est pas en place)

Le dosseret se place sur la cuisiniere tel qu'indiqu6 a la

figure 1 et il est fix6 en place a I'aide d'un support et de 2

boulons et 6crous de chaque cSt&

Placer le dosseret sur I'arri_re de la cuisini_re. Le fixer sur

les flasques d'extr6mit6 des panneaux.

FIGURE 1

ART #9219-94-0

AVERTISSEMENT

D#BRANCHER OU COUPER DU SECTEUR POUR

#VlTER LES RISQUES D'#LECTROCUTION.

D#GAGEMENT N#CESSAIRE

Toutes les cuisini_res amovibles peuvent _tre install6es

directement contre un mur ou une cloison en mat6riau

combustible (espace libre de 0 cm/po) et plac6es avec

leurs cSt6s contre des armoires en mat6riau combustible

(espace libre de 0 cm/po). Pour tous renseignements

concernant la pose d'armoires murales au-dessus de la

cuisiniere et des d6gagements a respecter par rapport aux

parois combustibles, se reporter aux sch6mas d'installation

et/ou a la plaque portant le num6ro de mod61e qui se

trouve sur la cuisini6re. Pour des RAISONS DE

SI_CURITI_, ne pas installer la cuisini_re dans une armoire

en mat6riau combustible qui ne soit pas conforme aux

sch6mas d'installation et ne respecte pas les espaces de

d6gagement indiqu6s sur la plaque de num6ro de mod61e

de la cuisini_re.

EMPLACEMENT DE LA CUISINII RE

Ne pas placer la cuisini_re au-dessus de trous dans le

plancher ou en tout autre endroit oQelle sera expos6e a de

forts courants d'air. Toute ouverture dans lemur a I'arri_re

de la cuisini_re et dans le plancher sous la cuisini6re doit

_tre bouch6e. S'assurer que le passage de I'air de

refroidissement/ventilation sous la cuisini_re n'est pas

entrav&

REMARQUE : Une cuisini_re ne doit PAS _tre plac6e sur

de la moquette.

-3-

Page 22

AVERTISSEMENT

CETAPPAREILNEDOlTPASI_TREINSTALLI2AU-DESSOUS

D'UNEHOTTEDEVENTILATIONQUIDIRIGEL'AIRDAMSUNE

DIRECTIONDEHAUTENBAS.

(VOIRLAFIGURE)

CESSYSTEMESD'I_VACUATIONPEUVENTPOSERDES

PROBLEMESD'ALLUMAGEET DECOMBUSTIONAVECDES

BRULEURS,&,GAZAYANTPOURRt_SULTATDESBLESSURESET

PEUVENTAFFECTERLAFA(_ONDECUIREDEL'APPAREIL.

NOTE:IL ESTPOSSIBLEQUELAFIGURENESOITPASUNE

REPRt_SENTATIONEXACTEDEVOTRECUISINIEREOUDE

VOTREPLAQUEDECUISSON;POURTANT,CETAVERTISSEMENT

"///////////////////,f

ART # 9215-252.

MISE EN PLACE DU DISPOSITIF DE STABILISATION

S'APPLIQUE,&,TOUTAPPAREILDECUISSON,&,GAZ.

REMARQUE • La cuisini@e risque de basculer si elle

n'est pas mise en place conform6ment aux instructions

fournies. Si le dispositif de stabilisation est utilis6

correctement, il r6duit le risque que la cuisini@e ne

BASCULE. M6me si le dispositif est utilis6 correctement,

le consommateur doit observer les pr6cautions indiqu6es

dans le MANUEL D'UTILISATION ET D'ENTRETIEN et

6viter d'utiliser la porte du four et/ou le tiroir inf6rieur

comme un tabouret.

Les instructions sont pr6vues pour un plancher ou un mur

en bois ou en ciment. Un autre mat_riau pourra requ6rir

des techniques sp6ciales, qu'il conviendra de d6terminer,

pour assurer la fixation du SUPPORT DE

STABILISATION au mur ou au plancher.

I_TAPE 1 - Emplacement du support (voir figure 2)

A. D6terminer oQ le " BORD" gauche ou droit de la

cuisini@e se trouvera une fois celle-ci en place et le

marquer d'un rep@e sur le plancher.

B. Placer le SUPPORT _ 3 15/16 po (10 cm) de la

marque " BORD " en allant vers le centre de

I'ouverture et contre lemur arri@e tel qu'indiqu6 _ la

figure 2, le trou d'orientation 6tant contre le mur.

\

\

C. Utiliser le support comme gabarit et marquer

I'emplacement de tousles trous pour le type de

mat@iau sur lequel le support doit 6tre fix6, tel

qu'indiqu6 _ la figure 2.

I_TAPE 2 - Pose du support de stabilisation

A. Bois:

1. Plancher : D6terminer le centre des deux trous

identifi6s par" TROUS POUR PLANCHER" _ la

figure 2. Percer un trou de positionnement de 1/8

po (3 mm) au centre de chaque trou (un clou ou un

poingon peut 6galement 6tre utilis6 si une perceuse

n'est pas disponible). Fixer le support de

STABILISATION au plancher _ I'aide des deux vis

fournies. Passer _ I'ETAPE 3.

, Mur : D6terminer le centre des deux trous identifi6s

par" TROUS POUR MUR" _ la figure 2. Percer un

trou de positionnement en biais de 1/8 po (3 mm)

au centre de chaque trou (un clou ou un poingon

peut 6galement _tre utilis6 si une perceuse n'est

pas disponible) tel qu'indiqu6 _ la figure 3. Fixer le

support de STABILISATION au mur _ I'aide des

deux vis fournies tel qu'indiqu6 _ la figure 3. Passer

I'I_TAPE 3.

\

\

REPt_RE DU BORD_

DE LA CUISINII_RE

FIGURE 2

-4-

Page 23

B.Cimentoub6ton:

1. Ontrouvedesvisconvenantaucimentouaub6ton

danslesquincailleries.Percerlestrousde

positionnementdelagrandeurcorrespondante

celledesvisobtenuesenquincaillerieaucentre

destrousidentifi6s"TROUSPOURPLANCHER"

lafigure2.Fixerlesup.portdeSTABILISATION

auplancher.Passer_I'ETAPE3.

B,

Pour des RAISONS DE SI_CURITI_ et pour obtenir des

r6sultats optimums _ la cuisson, r6gler la cuisini@e de

fagon _ ce qu'elle soit de niveau. Pour v@ifier le

niveau, mettre un niveau _ bulle ou une grande

casserole d'eau sur la surface de cuisson ou sur la

grille du four. Si la cuisini@e amovible doit _tre mise

de niveau, la tirer vers soi, la faire basculer 16g_rement

et faire tourner le pied de mise _ niveau autant que

n6cessaire.

€:TAPE 3 - Mise en place de la cuisiniere

A. Placer la cuisini@e de fagon _ ce qu'elle puisse entrer

dans I'ouverture oO elle sera encastr6e et la pousser

en place. S'assurer que le pied de r6glage est ins@6

fond dans le support de STABILISATION et que

celui-ci le retient bien. Remarque : Un d6gagement

minimum de 5/8 po (16 mm) est exig6 entre la

cuisini@e et le pied de mise _ niveau qui va s'ins@er

dans le support de STABILISATION (voir figure 3).

REMARQUE UTILISER UN MINIMUM DE

DEUX (2) VIS POUR FIXER LE

SUPPORT AU MUR OU AU

PLANCHER.

LES VlS

DOIVENT

P¢:N¢:TRER

BOIS OU LE

DANS LE --_

M¢:TAL

PLAQUE MURALE

C,

Pour v@ifier si le support de stabilisation est bien en

place : Regarder sous la cuisini@e _ I'aide d'une

lampe 61ectrique et v@ifier que I'un des pieds de mise

niveau arri@e est bien ins@6 dans la fente du

support.

D,

Finir la mise en service de la cuisini@e tel qu'indiqu6

dans les instructions de mise en service.

SUPPORT DE

STABILISATION

GLISSER DANS LE s

SUPPORT POUR [

STABILISER ____

BAS DE LA

CUISINII_RE

I

5/8 PO

(16aM)

MIN.

ARTI_ 9215-127

FIGURE 3

-5-

Page 24

RACCORDEMENT DE LA CUISINII RE

Alimentation electrique

Une fois en place, I'appareil doit _tre reli6 _ la terre

conform6ment aux codes Iocaux ou, en I'absence de codes

Iocaux, aux normes ANSI/NFPA 70 du National Electrical

Code.

Au Canada, le raccordement de la cuisini@e doit _tre

conforme _ la norme ACN C22.1 du Code d'61ectricit6

canadien partie 1.

II pourra occasionnellement se produire une coupure de

courant si le disjoncteur de fuite _ la terre (GFCI) est en

service.

RACCORDEMENT .&.L'ALIMENTATION #LECTRIQUE :

La cuisini@e exige une alimentation en courant alternatif

120 Vet 60 Hz par prise de courant murale capable

d'assurer 15 A.

AVERTISSEMENT

Mise a la terre

Cet appareil est muni d'une fiche _ trois broches avec

mise _ la terre pour assurer la protection contre les

risques d'61ectrocution et doit _tre branch6 directement

dans une prise de courant correctement reli6e _ la terre.

Ne pas enlever ni couper la broche de terre de cette fiche

61ectrique.

AVERTISSEMENT

D#BRANCHER L'APPAREIL DE

L'ALIMENTATION #LECTRIQUE AVANT

TOUT D#PANNAGE.

Alimentation en gaz

La mise en service de cette cuisini@e doit _tre conforme

aux codes Iocaux ou, en I'absence de tels codes, _ la

norme ANSI Z223.1, derni@e 6dition, du National Fuel Gas

Code.

Au Canada, la mise en service de la cuisini@e doit _tre

conforme _ la norme ACG CAN/ACG-B149 en vigueur

relative aux codes de mise en service d'appareils _ gaz

et/ou aux codes Iocaux.

Dans le Commonwealth du Massachusetts

Ce produit doit 6tre mis en service par un plombier ou

un monteur d'installations au gaz d6tenteur d'une

licence quand install6 dans le Commonwealth du

Massachusetts.

Un robinet d'arr6t de gaz manuel de type _ poign6e en

"T" doit 6tre pos6 sur la conduite de gaz de cet appareil.

Quand un raccord flexible de gas est utilis6, il ne doit

pas exc6der une Iongueur de trois (3) pieds / 36 pouces

(91,4 cm).

RACCORDEMENT .&.L'ALIMENTATION EN GAZ :

(voir figure 4).

LE RACCORDEMENT AU GAZ DOlT I_TRE EFFECTU#

PAR UN TECHNICIEN QUALIFI# OU PAR UN

INSTALLATEUR D'APPAREILS .&.GAZ. La verification

de I'absence de fuites sera effectuee par I'installateur

conformement aux directives fournies a la section h.

LA CONDUITE DE GAZ NATUREL DOlT FtTRE t_QUIPt_E

D'UN DI_TENDEUR POUR GAZ NATUREL. LA PRESSION

_, L'ARRIVt_E DE CET APPAREIL DOlT PTRE DI_TENDUE

DE FAOON _,NE PAS t_TRE SUPI_RIEURE _, 14 PO DE

COLONNE D'EAU (0,5 LB/PO 2 / 3,5 KPA) DANS LE CAS

DE GPL / LA CONDUITE DE GAZ PROPANE DOlT AVOIR

UN DI_TENDEUR POUR GAZ GPL. LA PRESSION _,

L'ARRIVt_E DE CET APPAREIL DOlT ETRE DI_TENDUE

DE FA_ON _,NE PAS t_TRE SUPI_RIEURE _, 14 PO DE

COLONNE D'EAU (0,5 LB/PO 2 / 3,5 KPA), UNE

PRESSION _, L'ARRIVEE SUPt_RIEURE A 0,5 LB/PO2 (3,5

KPA) PEUT ENDOMMAGER LE DI_TENDEUR DE

L'APPAREIL ET LES AUTRES COMPOSANTS DE CET

APPAREIL ET POURRAIT PROVOQUER DES FUITES DE

GAZ.

a. UN ROBINET D'ARRET DEVRA ETRE POSt_ DANS UN

ENDROIT ACCESSIBLE DE LA CONDUITE DE GAZ

EN AMONT DE LA CUISINIC:RE POUR PERMETTRE

D'OUVRIR ET DE FERMER L'ALIMENTATION EN

GAZ. Si la cuisini@e doit 6tre raccord6e _ des conduites

I'aide de raccords m6talligues flexibles ou semi-rigides

pour appareils _ gaz, LES ECROUS DES RACCORDS

NE DOIVENT PAS ETRE VlSSI_S DIRECTEMENT SUR

LE FILETAGE DES CONDUITES. LES RACCORDS

DOIVENT FtTRE RACCORDt_S _, LA CONDUITE _,

L'AIDE DES ADAPTATEURS FOURNIS.

b,

La conduite de gaz du Iogis et/ou le raccord de la

cuisini@e _ gaz utilis6s pour raccorder la cuisini@e

I'alimentation en gaz doivent _tre propres, libres de

toutes rognures de m_tal, rouille ou salet_ et de tout

liquide (huile ou eau). La salet_ qui se trouve dans les

conduites peut se trouver emport_e vers la rampe _ gaz

et entrafner des probl_mes au niveau des robinets de

gaz ou des commandes et boucher les orifices des

brOleurs et/ou des veilleuses.

-6-

Page 25

ATTENTION : NE PAS SOULEVER NI DISPLACER

LA CUISINIERE EN LA PRENANT PAR LES

POIGNC:ES DE PORTE OU LE DOSSERET.

t_teindre toutes les veilleuses et le robinet d'arr6t de

C,

tous autres appareils _ gaz.

d,

Fermer le gaz au robinet principal du compteur de gaz.

e.

Avant de raccorder la cuisini_re au gaz, enduire tous

les filetages de pate _ filetage convenant au GPL.

CONDUITED'AUMENTATIONFLEXIBLE ADAPTATEUR

t t

ATTENTION : NE JAMAIS VC:RIFIER LA PRC:SENCE

DE FUITES .&.L'AIDE D'UNE FLAMME.

UNE FOIS LA VC:RIFICATION DE LA PRC:SENCE DE

FUITES TERMINC:E, ESSUYER TOUT RC:SIDU DE

PRODUIT.

Enlever les vis d'exp6dition de TOUS les br01eurs de

la surface de cuisson (voir la figure 5). Ces vis servent

maintenir les br01eurs en place sur le support pour

I'exp6dition seulement.

R6gler I'obturateur d'air afin d'assurer son ouverture

maximum tout en ayant une flamme qui ne se soul_ve

pas du br01eur ou qui s'6teigne Iorsque le br01eur est

froid.

FIGURE 4

DI_TENDEUR POUR APPAREIL Mt_NAGER ET

AUTRES OPTIONS DE RACCORDS

* LE DI_TENDEUR DE VOTRE APPAREIL

PEUT FtTRE DIFFt_RENT DE CELUI

ILLUSTRt _.

f,

Raccorder la cuisini_re _ I'alimentation en gaz. Utiliser

une deuxi_me cl6 pour I'extr6mit6 de la rampe _ gaz.

ATTENTION : VEILLER _, CE QU'EN EFFECTUANT

LE RACCORDEMENT, LA POSITION DE LA

CONDUITE DE LA RAMPE _, GAZ NE SE TROUVE

PAS MODIFIt_E CAR LES POIGNt_ES DU ROBINET

ET LES BOUTONS DE COMMANDES POURRAIENT

SE TROUVER BLOQUt_S.

g,

Ouvrir le robinet de gaz au niveau du compteur et

rallumer la veilleuse de tous autres appareils _ gaz.

h,

Appliquer du liquide de d6tection de fuites non corrosif

sur tousles joints et raccords entre le robinet de la

conduite de gaz et la cuisini_re. Inclure les joints et

raccords de I'appareil si ceux-ci ont pu se trouver

desserr6s pendant la mise en service. V6rifier les

fuites ! Si des bulles apparaissent autour des joints et

des raccords, il y a une fuite. En cas de fuite, fermer le

robinet d'alimentation de gaz, serrer les raccords,

ouvrir le robinet de gaz et rev6rifier s'il y a des fuites.

._._ NLEVER LES

VIS

D'EXPEDITION

FIGURE 5

VITRIFICATION DE LA PRESSION DE

L'ALIMENTATION EN GAZ DE LA

MAISON

1. L'appareil _ gaz et son robinet d'alimentation doivent

_tre d6solidaris6s des conduites de gaz pendant toute

v6rification de la pression _ des pressions

sup6rieures _ 0,5 Ib/po2 (3,5 kPa) (14 po de colonne

d'eau).

,

L'appareil _ gaz doit _tre coup6 des conduites de gaz

en fermant son robinet de gaz individuel pendant

toute v6rification de la pression dans les conduites de

gaz _ des pressions 6gales ou inf6rieures _ 0,5 Ib/po 2

(3,5 kPa) (14 po de colonne d'eau).

-7-

Page 26

RI GLAGES DE LA CUISINII RE

Partie superieure - Reglage de la veilleuse

de la surface de cuisson (voirfigure 6)

I_liminer I'air des conduites de gaz en allumant un des

brOleurs. L'6teindre, puis r6gler, a I'aide de la vis de

r6glage A (figure 6), la flamme de la veilleuse de fa(_on ace

que le haut de la flamme arrive au niveau du haut de la

tubulure. Pour allumer le brOleur, pousser sur le bouton de

commande correspondant et le mettre sur la position

d'allumage.

_/IS A DE REGLAGE DE LA

VEILLEUSE

VEILLEUSE

GAUCHE

/

VEILLEUSE

DROITE

CONDUITE, DE LA

RAMPE A GAZ

HAUT DE LA TUBULURE

FIGURE 6

Partie superieure - Allumage electrique

Pour allumer un brOleur de la surface de cuisson, pousser

sur le bouton de commande correspondant et le mettre sur

la position LITE. Le brQleur s'allume. Pour CESSER la

production d'6tincelles une fois le brQleur allum6, tourner le

bouton sur le r6glage HI.

Obturateur d'air - BrOleur du four

a. La hauteur approximative de la flamme d'un brOleur du

four doit pr6senter une partie bleue distincte de 1/2 po

(13 mm) (voir la figure 8).

b. Pour v6rifier la flamme du brOleur du four •

,

Flamme jaune - ouvrir I'obturateur d'air afin

d'assurer son ouverture maximum tout en ayant

une flamme qui ne se soul_ve pas du brOleur ou

qui s'6teigne Iorsque le brOleur est froid. (Voir la

figure 9).

,

Flamme avec partie bleue distincte mais qui se

soul_ve du brOleur - fermer I'obturateur d'air

jusqu'_ ce qu'il produise une flamme qui ne se

soul_ve pas du brOleur ou s'_teigne Iorsque le

brQleur est froid. (voir la figure 9).

FLAMME DE 1/2 PQ (13 MIVt__/

CONE INTERIEUR

C,

Le r_glage de I'obturateur d'air du brOleur du four est le

meme pour les cuisinieres a allumage par veilleuse

ou _lectrique.

/

FIGURE 8

Reglage des br01eurs de la surface

de cuisson

TOUS BRULEURS DE LA SURFACE DE CUISSON :

La hauteur approximative de la flamme en position <<plein

feu >>est indiqu6e ci-dessous. R6gler I'obturateur d'air

(figure 7) a I'ouverture maximum qui produise une flamme

qui ne se soul6ve pas du brQleurou s'6teigne Iorsque le

brQleur est froid.

LFLAMME DE t-_E._¢'1_'_ _-_,'_ _._"_: _

BLOCAGE ._._Y__''_"Y'_-_

OBTURATEUR D'AIR ii _J

CAPUCHON_ ._'_ _j

T D'ORIFIC_ ....

BRULEURS TRADITIONNELS

FIGURE 7

VIS DE

BLOCAGE

\

CAPUCHON

D'ORIFICE

OBTURATEUR

D'AIR

FIGURE 9

Utilisation en haute altitude

Les valeurs nominales indiqu_es pour les brQleurs

s'appliquent en g_n_ral aux _l_vations de 600 m (2 000

pi) maximum. Pour des altitudes plus _lev_es, ces

chiffres pourront devoir _tre r_duits pour assurer un

fonctionnement correct.

Un prestataire de service agr_ local sp_cialiste du gaz

sera en mesure de vous conseiller.

-8-

Page 27

CONVERSION A UN GAZ

DIFFI RENT

Questions d'ordre general

Toutes les cuisini@es sont 6quip6es d'orifices fixes et

d'un d6tendeur pour appareil _ gaz convertible. La

plaque signal6tique indiquant le num6ro de module

signale 6galement _ quel type de gaz I'appareil a 6t6

r6g16 en usine. Pour convertir I'appareil au gaz naturel ou

au gaz de p6trole liqu6fi6 (GPL), il faut remplacer les

capuchons d'orifice et r6gler les obturateurs d'air des

br01eurs, ainsi que le capuchon de conversion du

d6tendeur.

VOIR LES CONSIGNES DE CONVERSION .&,

UN TYPE DE GAZ DIFFC:RENT ._, L'ARRII_RE

DE LA CUISINII_RE.

La pression d'arriv6e de gaz au d6tendeur d'un appareil

m6nager doit _tre la suivante Iors du fonctionnement de

I'appareil et Iors de la v@ification du r6glage du

d6tendeur :

PRESSION D'ARRIVI_E DE GAZ

EN POUCES DE COLONNE D'EAU

Minimum

Maximum

GAZ GAZ

NATUREL GPL

5 11

14 14

DI=PLACEMENT DE LA CUISINII RE

POUR LA DI=PANNER

Suivre les indications ci-dessous pour deplacer

I'appareil afin de le depanner.

1. Fermer I'alimentation en gaz _ I'appareil.

2. D6brancher I'appareil de I'alimentation 61ectrique s'il est

branch6.

,

D6solidariser la conduite d'alimentation en gaz de

I'appareil.

,

Faire glisser la cuisini@e vers I'avant pour la d6gager

du dispositif de stabilisation. (Voir page 4.)

,

Proc6der inversement pour la remettre en place. Si la

conduite de gaz a 6t6 d6solidaris6e de I'appareil,

v@ifier qu'il n'y a pas de fuites une fois le raccordement

effectu6.

REMARQUE : II est fortement recommand6 que

I'appareil soit d6solidaris6 de I'alimentation en gaz et

raccord6 _ nouveau par un technicien de service

apr_s-vente qualifi6.

La personne effectuant le d6pannage DOlT suivre

les instructions de mise en service fournies avec le

raccord _ gaz de I'appareil ainsi que 1'6tiquette de

mise en garde fix6e au raccord.

,

Pour 6viter que la cuisini@e ne bascule

accidentellement, il faut la bloquer en glissant le pied

de mise _ niveau arri@e dans le dispositif de

stabilisation.

INFORMATIONS SUR LES PII CES ET

LE SERVICE APRI S-VENTE

POUR TOUTES PIC:CES DE RECHANGE ET TOUT

SERVICE APRC:S-VENTE, CONTACTER LE

REVENDEUR OU UN PRESTATAIRE DE SERVICE

APRC:S-VENTE AGRI_I_. PRIC:RE DE DONNER LE

NUMI_RO DE MODC:LE ET LES NUMI_ROS DE SI_RIE

COMPLETS DE LA CUISINIC:RE, QUI SE TROUVENT

SUR LA PLAQUE SIGNALI_TIQUE DE L'APPAREIL.

-9-

Loading...

Loading...