Magic Chef MGS5870ADB, MGS5770ADW, MGS5770ADQ, MGS5770ADC, MGS5770ADB Installation Instructions

...Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE

INSTALLATION MANUAL

Gas 30-inch

Free -standing and Slide-in

PLEASE KEEP THIS MANUAL FOR FUTURE REFERENCE

THE MANUAL IS INTENDED TO ASSIST IN THE INITIAL INSTALLATION AND ADJUSTMENTS OF THE RANGE.

SPECIAL WARNING

Only qualified personnel should

install or service this range.

Read “Safety Instructions” in the

Use & Care book before using

range.

Improper installation, adjustment,

alteration, service, maintenance or

use of range can result in serious

injury or property damage.

· ALL RANGES CAN TIP AND

CAUSE INJURIES TO

PERSONS.

· INSTALL ANTI-TIP DEVICES

PACKED WITH RANGE.

· FOLLOW ALL INSTALLATION

INSTRUCTIONS.

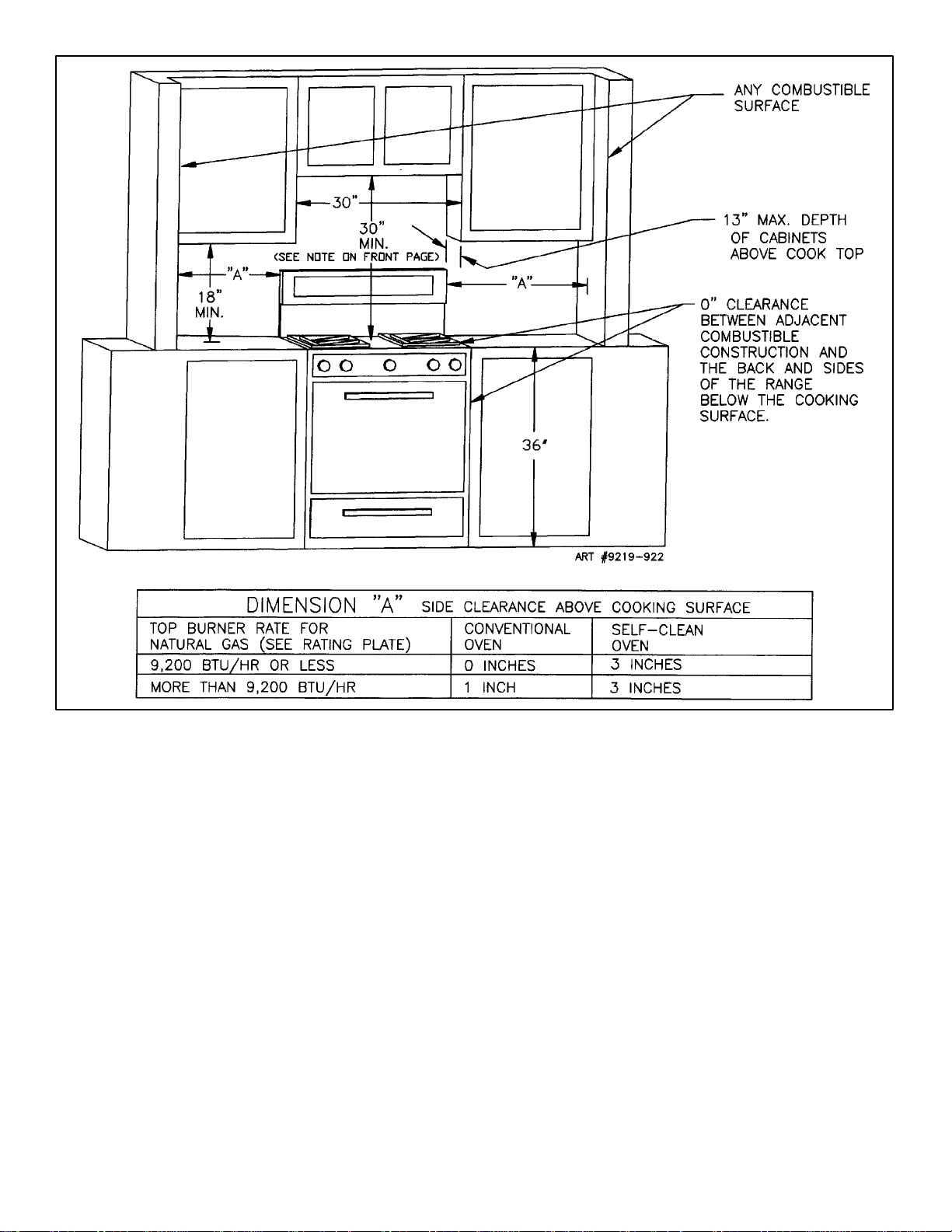

CLEARANCE DIMENSIONS

Range may be installed with zero inches clearance

adjacent to (against) combustible construction at the rear

and on the sides below the cooktop. For complete

information in regard to the installation of wall cabinets

above the range and clearances to combustible wall

above the cooking top see the installation drawings. For

SAFETY CONSIDERATIONS do not install a range in any

combustible cabinetry which is not in accord with the

installation drawings.

*NOTE:30 inch dimension between cooking top and wall

cabinet shown on illustration does not apply to ranges

with an elevated oven. The 30 inch dimension may be

reduced to not less than 24 inches when the wall cabinets

in a domestic home are protected with fireproof materials

in accordance with American National Standards National Fuel Gas Code or in mobile homes when they

are protected with fireproof materials in accordance with

the Federal Standard for Mobile Home Construction and

Safety.

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located

above the surface units should be avoided. If cabinet

storage is to be provided, the risk can be reduced by

installing a range hood that projects horizontally a

minimum of 5 inches beyond the bottom of the cabinets.

Your range may not be equipped

with some of the features referred

to in this manual.

CAUTION: Some cabinets and building materials

are not designed to withstand the heat produced by the

normal safe operation of a listed appliance.

Discoloration or damage, such as delamination, may

occur.

8101P592-60

(05-04-00)

Page 2

INSTALLATION DRAWINGS

FREE-STANDING

SLIDE-IN

*23 1/4²

CUT DEPTH

51/2²

EACH SIDE

10²

36² HEIGHT

OF CABINET

30² CABINET

CAUTION:

SOME WHITE EUROPEAN STYLE CABINETS ARE EQUIPPED WITH DELICATE

WHITE VINYL DRAWER AND DOOR FRONTS. THE VINYL MAY NOT BE

DESIGNED TO WITHSTAND THE HEAT PRODUCED BY THE NORMAL SAFE

OPERATION OF A SELF-CLEAN RANGE. DISCOLORATION OR DELAMINATION

MAY OCCUR. TO AVOID POSSIBLE DAMAGE, WE RECOMMEND INCREASING

THE 30² CABINET OPENING TO 31 1/4² MINIMUM AND USING HEAT SHIELD

KIT-CABKIT V. THE COUNTERTOP CUT-OUT MUST REMAIN 30².

21/4²

RECOMMENDED GAS

OPENING

30²

PROVIDE FOR 120 VOLT

GROUNDED ELECTRICAL

OUTLET IN THIS AREA.

OUTLET MUST BE FLUSH.

23 5/8²

FLAT AREA

24² CABINET

DEPTH

NOTE:

ON CABINET TOPS WITH

FORMED FRONT EDGE, SHAVE

RAISED SECTION TO CLEAR TOP.

25² MINIMUM

CABINET

TOP DEPTH

* When replacing an existing unit, a maximum of 23 1/2² is acceptable. If the cut depth exceeds 23 1/2², use filler kit (K70 Fill).

-2-

Page 3

Check the range model number plate to see if the range is

approved for installation in mobile homes and/or

recreational vehicles. If approved the following items are

applicable.

MOBILE HOMES

The installation of a range designed for mobile home

installation must conform with the Manufactured Home

Construction and Safety Standard, Title 24 CFR, Part

3280 [formerly the Federal Standard for Mobile Home

Construction and Safety, Title 24 HUD, (Part 280)] or,

when such standard is not applicable, the Standard for

Manufactured Home Installations, ANSI A225.1/NFPA

501A, or with local codes.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1 and Section Z240.4.1 - Installation

Requirements for Gas Burning Appliances in Mobile

Homes (CSA Standard CAN/CSA - Z240MH).

RECREATIONAL VEHICLES

The installation of a range designed for recreational

vehicles must conform with state or other codes or, in the

absence of such codes, with the Standard for

Recreational Vehicles, ANSI A119.2-latest edition.

In Canada the range must be installed in accordance with

CAN/CSA - Z240.6.2 - Electrical Requirements for R.V.’s

(CSA Standard CAN/CSA - Z240 RV Series) and Section

Z240.4.2 - Installation Requirements for Propane

Appliances and Equipment in R.V.’s (CSA Standard

CAN/CSA - Z240 RV Series).

LOCATING THE RANGE

Do not set range over holes in the floor or other locations

where it may be subject to strong drafts. Any opening in

the wall behind the range and in the floor under the range

should be sealed. Make sure the flow of cooling/

ventilation air is not obstructed below the range.

NOTE: A range should NOT be installed over kitchen

carpeting.

-3-

Page 4

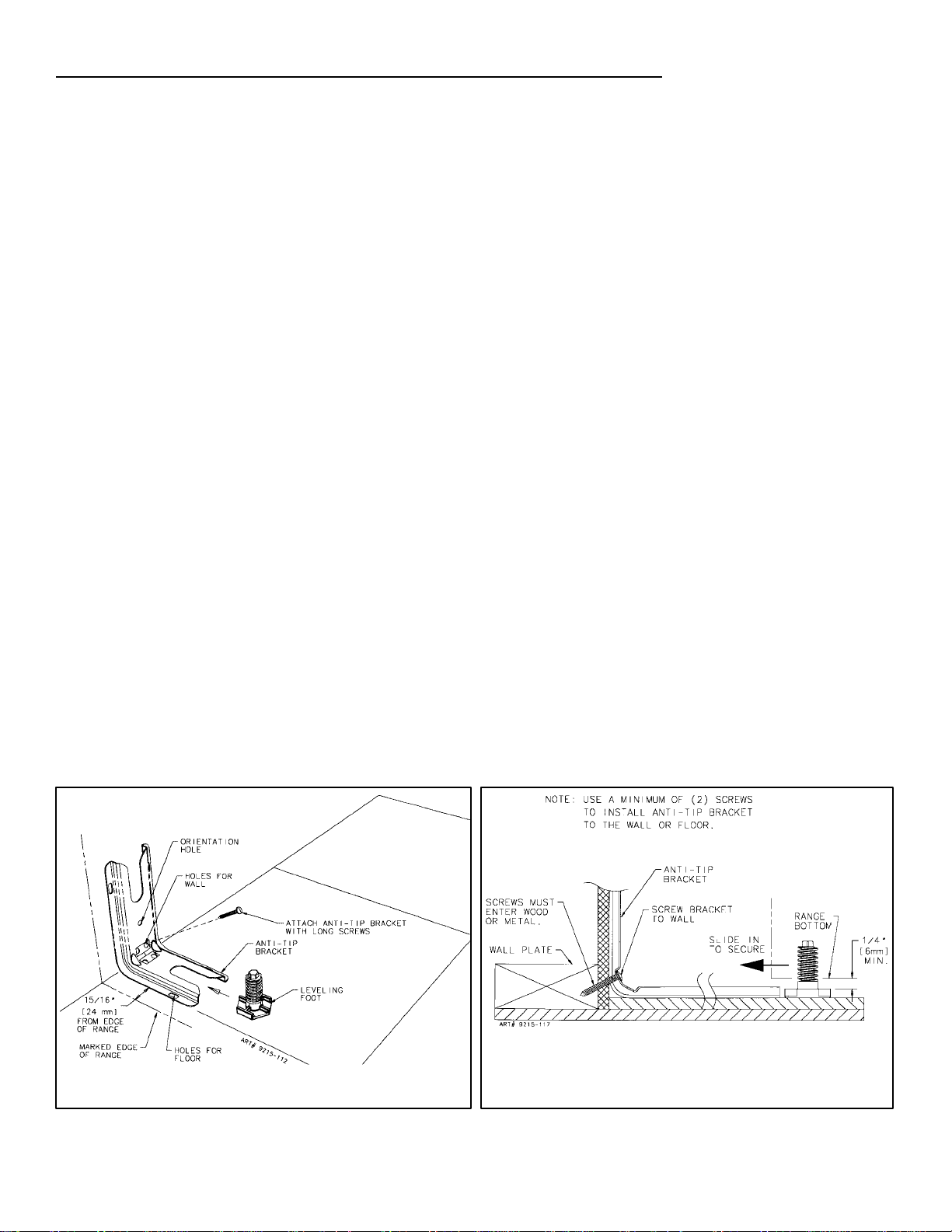

ANTI-TIP DEVICE INSTALLATION INSTRUCTIONS

NOTE: A risk of range tip over exists if the appliance is

not installed in accordance with the installation

instructions provided. The proper use of this device

minimizes the risk of TIP-OVER. In using this device the

consumer must still observe the safety precautions as

stated in the USE and CARE MANUAL and avoid using

the oven door and/or lower drawer as a step stool.

Installation instructions are provided for wood and cement

in either floor or wall. Any other type of construction may

require special installation techniques as deemed

necessary to provide adequate fastening of the ANTI-TIP

bracket to the floor or wall.

STEP 1 - Locating The Bracket (see figure 1)

A. Determine where either the right or left rear “edge” of

the range will be located and mark the floor or wall.

B. Place the BRACKET 15/16² from the marked “EDGE”

toward center of opening and against the back wall as

shown in figure 1, with orientation hole against wall.

C. Use the bracket as a template and mark the required

holes, as shown in figure 1 for the type of construction

you will be using.

STEP 2 - Anti-Tip Bracket Installation

A. Wood Construction:

1. Floor: Locate the center of the two holes identified

in figure 1 as “HOLES FOR FLOOR”. Drill a 1/8²

pilot hole in the center of each hole (a nail or awl

may be used if a drill is not available). Secure the

ANTI-TIP bracket to the floor with the two screws

provided. Proceed to STEP 3.

2. Wall: Locate the center of the two holes identified

in figure 1 as “HOLES FOR WALL. Drill an angled

1/8² pilot hole in the center of each hole as shown

in figure 2. (A nail or awl may be used if a drill is

not available). Secure the ANTI-TIP bracket to the

wall with the two screws provided as shown in

figure 2. Proceed to STEP 3.

B. Cement or Concrete Construction:

1. Suitable screws for concrete construction can be

obtained at a hardware store. Drill the required

size hole for the screws obtained into the

concrete at the center of the holes identified in

figure 1 as “HOLES FOR FLOOR”. Secure the

ANTI-TIP bracket to the floor. Proceed to STEP 3.

STEP 3 - Range Installation

A. Align the range to its designated location and slide it

back into position. Make sure that the leveling foot is

fully inserted into and secured by the ANTI-TIP

bracket. Note: A minimum clearance of 1/4² is

required between the range and the leveling foot that

will engage the ANTI-TIP bracket, see figure 2.

B. For safety considerations as well as optimum

performance adjust the range so that it is level. This

may be checked by placing a spirit level or a large

pan of water on the cooktop or the oven rack. If an

adjustment is required on free-standing, pull the range

forward, tip the range and rotate the leveling feet as

required. Slide-in ranges require total removal from

cabinet before an adjustment can be made.

C. To check the range for proper installation of the

anti-tip bracket: Use a flashlight and look underneath

the bottom of the range to see that one of the rear

leveling legs is engaged in the bracket slot.

D. Proceed with the remainder of the installation

instructions.

FIGURE 1 FIGURE 2

-4-

Page 5

CONNECTING THE RANGE

ELECTRIC SUPPLY

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical Code,

ANSI/NFPA 70.

In Canada the range must be installed in accordance with

the current CSA Standard C22.1 - Canadian Electrical

Code Part 1.

ELECTRICAL SUPPLY CONNECTION:

The range requires 120 volts, 60 cycle alternating current

from an outlet. See serial plate for rating.

User may experience occasional circuit tripping if Ground

Fault Circuit Interrupter (GFCI) outlet or breaker is in use.

Electrical Grounding Instructions

This appliance is equipped with a (three-prong)

grounding plug for your protection against shock

hazard and should be plugged directly into a

properlygroundedreceptacle. Donot cutor remove

the grounding prong from this plug.

GAS SUPPLY CONNECTION: (See figure 4)

A QUALIFIED SERVICEMAN OR GAS APPLIANCE

INSTALLER MUST MAKE THE GAS SUPPLY

CONNECTION. Leak testing of the appliance shall be

conducted by the installer according to the

instructions given in section h.

NATURAL GAS SUPPLY LINE MUST HAVE A NATURAL

GAS SERVICE REGULATOR. INLET PRESSURE TO

THIS APPLIANCE SHOULD BE REDUCED TO A

MAXIMUM OF 14 INCHES WATER COLUMN (0.5

POUNDS PER SQUARE INCH (P.S.I.) LIQUEFIED

PETROLEUM (L.P.)

MUST HAVE A L.P. GAS PRESSURE REGULATOR.

INLET PRESSURE TO THIS APPLIANCE SHOULD BE

REDUCED TO A MAXIMUM OF 14 INCHES WATER

COLUMN (0.5 P.S.I.). INLET PRESSURES IN EXCESS

OF 0.5 P.S.I. CAN DAMAGE THE APPLIANCE

PRESSURE REGULATOR AND OTHER GAS

COMPONENTS IN THIS APPLIANCE AND CAN

RESULT IN A GAS LEAK.

a. A GAS CUTOFF VALVE SHOULD BE PUT IN AN

ACCESSIBLE LOCATION IN THE SUPPLY LINE

AHEAD OF THE RANGE, FOR TURNING ON AND

TURNING OFF GAS SUPPLY. If range is to be

connected to house piping with flexible or semi-rigid

metal connectors for gas appliances, CONNECTOR

NUTS MUST NOT BE CONNECTED DIRECTLY TO

PIPE THREADS. THE CONNECTORS MUST BE

INSTALLED WITH ADAPTORS PROVIDED WITH

THE CONNECTOR.

/PROPANE GAS SUPPLY LINE

DISCONNECT ELECTRICAL SUPPLY

BEFORE SERVICING THE APPLIANCE.

GAS SUPPLY

Installation of this range must conform with local codes or,

in the absence of local codes, with the National Fuel Gas

Code, ANSI Z223.1-latest edition.

In Canada the range must be installed in accordance with

the current CGA Standard CAN/CGA-B149 - Installation

Codes for Gas Burning Appliances and Equipment and/or

local codes.

In The Commonwealth Of Massachusetts

This product must be installed by a licensed plumber or

gas fitter when installed within the Commonwealth of

Massachusetts.

A “T” handle type manual gas valve must be installed in

the gas supply line to this appliance.

A flexible gas connector, when used, must not exceed a

length of three (3) feet / 36 inches.

b. The house piping and/or range connector used to

connect the range to the main gas supply must be

clean, free of metal shavings, rust, dirt and liquids (oil

or water). Dirt, etc. in the supply lines can work its

way into the range manifold and in turn cause failure

of the gas valves or controls and clog burners and/or

pilot orifices.

CAUTION: DO NOT LIFT OR MOVE RANGE BY

DOOR HANDLES, OR BACKGUARD.

c. Turn off all pilots and main gas valve of other gas

appliances.

d. Turn off main gas valve at meter.

e. Before connecting range, apply pipe thread

compound approved for LPG to all threads.

f. Connect range to gas supply at appliance pressure

regulator using adaptors supplied with flexible

connector. Rigid pipe may also be used. See rating

plate for type of gas range has been manufactured

for.

g. Turn on main gas valve at meter, and relight pilots at

other gas appliances.

-5-

Page 6

Gas Supply Connections For Ranges With

Appliance Pressure Regulator

Located In The Bottom Of Range

h. Apply a non-corrosive leak detection fluid to all joints

and fittings in the gas connection between the supply

line shut-off valve and the range. Include gas fittings

and joints in the range if connections were disturbed

during installation. Check for leaks! Bubbles

appearing around fittings and connections will indicate

a leak. If a leak appears, turn off supply line gas

shut-off valve, tighten connections, turn on the supply

line gas shut off valve, and retest for leaks.

CAUTION: NEVER CHECK FOR LEAKS WITH A

FLAME.

WHEN LEAK CHECK IS COMPLETE, WIPE OFF

ALL RESIDUE.

i. Remove shipping screw from ALL top burners.

(Conventional top burner models only). This is to hold

the burners in place on the burner bracket for shipping

purposes only. (See figure 5).

j. Adjust burner air shutter to the widest opening that will

not cause the flame to lift or blow off the burner when

cold.

TO CONNECT GAS SUPPLY TO 1/2I N.P.T. MALE INLET

TO CONNECT GAS SUPPLY TO 1/2I N.P.T. FEMALE INLET

WHEN THE INSTALLER HAS COMPLETED INSTALLATION

OF THE APPLIANCE, LEAVE THE APPLIANCE PRESSURE

REGULATOR SHUT-OFF VALVE IN THE “ON”

POSITION.

Gas Supply Connection For Ranges With

Appliance Pressure Regulator

Located Under Main Top Of Range

NOTE: Correctly adjusted sealed burners, can have

flames that will lift or blow off without a pot over the

burner. These should be adjusted with a pot in place.

FIGURE 5

CHECKING PRESSURE OF HOUSE PIPING

SYSTEM

1. The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water

column).

FIGURE 4

Appliance Pressure Regulator

& Alternate Connectors

* The appliance pressure regulator on your range may

differ from this illustration.

2. The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than

1/2 lbs./sq. in. (3.5 kPa) (13.8 in. water column).

-6-

Page 7

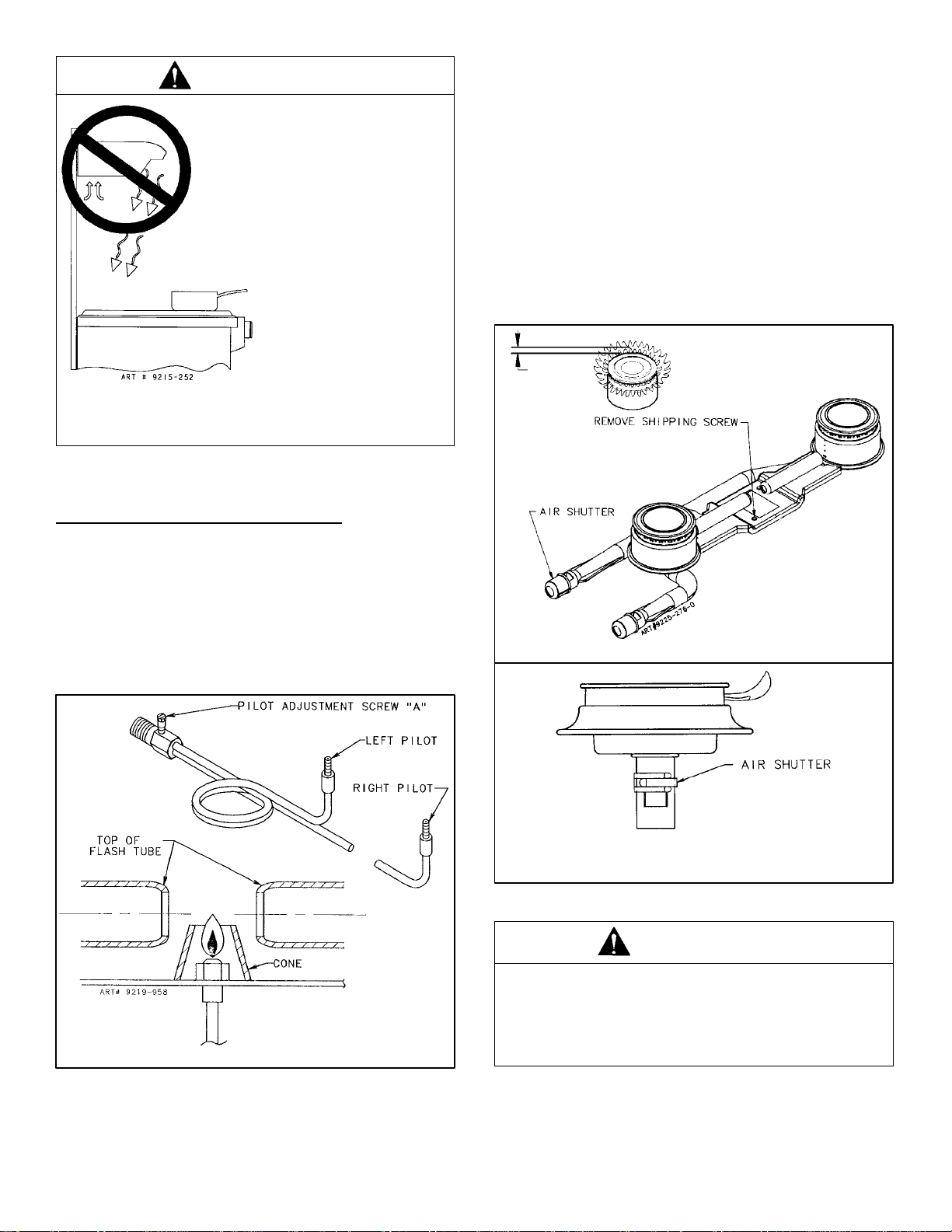

WARNING

THIS PRODUCT SHOULD NOT

BE INSTALLED BELOW A

VENTILATION TYPE HOOD

SYSTEM THAT DIRECTS AIR IN

A DOWNWARD DIRECTION.

(SEE FIGURE)

THESE SYSTEMS MAY CAUSE

IGNITION AND COMBUSTION

PROBLEMS WITH THE GAS

BURNERS RESULTING IN

PERSONAL INJURY AND MAY

AFFECT THE COOKING

PERFORMANCE OF THE UNIT.

NOTE: THE FIGURE MAY NOT ACCURATELY REPRESENT YOUR

RANGE OR COOKTOP; HOWEVER, THIS WARNING APPLIES TO

ALL GAS COOKING PRODUCTS.

Top Section - Electric Ignition

To operate, push and turn top burner knob to the LITE

position. The top burner will light. To turn OFF spark after

the top burner has ignited turn knob to HI setting.

Top Burner Adjustment

All Top Burner Valves: The approximate height of the

flame at the high or full-on position is shown below.

Adjust burner air shutter to the widest opening that will not

cause the flame to lift or blow off the burner when cold.

NOTE: Correctly adjusted sealed burners, can have

flames that will lift or blow off without a pot over the

burner. These should be adjusted with a pot in place.

3/4² FLAME

RANGE ADJUSTMENTS

Top Section - Gas Top Pilot Adjustment

(See figure 6)

Purge all air from supply system by turning on one top

burner valve. Then turn off valve and adjust top pilot flame

using adjusting screw “A” (figure 6) so that flame is even

with top of flash tube. To light the burner, push and turn

top burner knob to the lite position. NOTE: Some models

have ONLY one pilot adjustment at the manifold pipe.

CONVENTIONAL BURNERS

SEALED BURNERS

FIGURE 7

WARNING

FIGURE 6

Gas leaks may occur in your system and result in a

dangerous situation. Gas leaks may not be detected by

smell alone.Gas suppliers recommendyou purchase and

install an UL approved gas detector. Install and use in

accordance with the manufacturer’s instructions.

-7-

Page 8

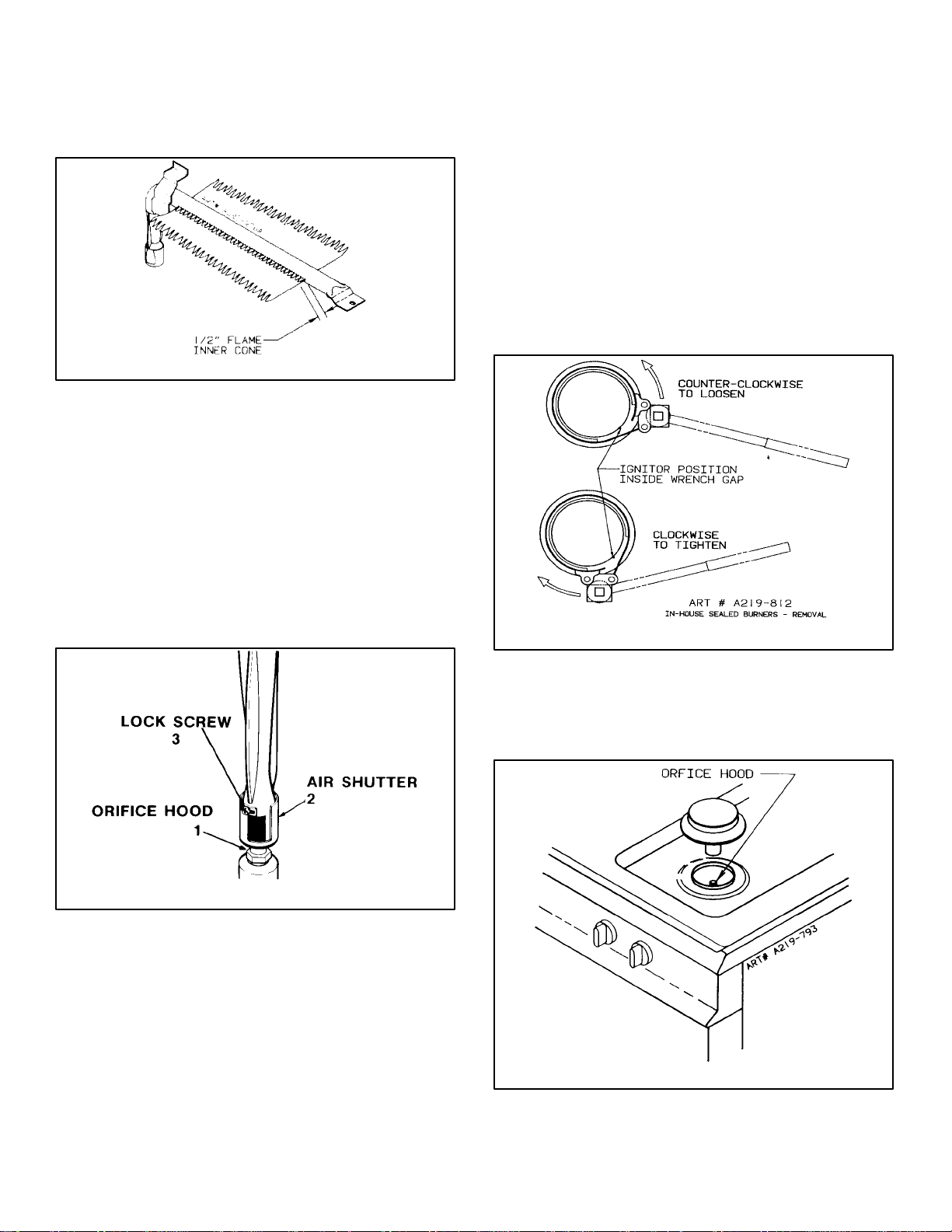

Air Shutter - Oven Burner

a. The approximate length of the flame of oven burner is

a 1/2 inch distinct inner blue flame, figure 8.

FIGURE 8

b. Oven burner flame can be checked as follows:

1. Yellow flame on burner - open burner air shutter

to the widest opening that will not cause the flame

to lift or blow off the burner when cold. (See #2 on

figure 9).

2. Distinct blue flame but lifting - close burner air

shutter to the point where it will not cause the

flame to lift or blow off the burner when cold. (See

#2 on figure 9).

Removing Sealed Burner For Adjustment Or

Service:

Mark ignitor location relative to main top with pencil. This

mark on the main top is used as a reference point when

replacing the burner assembly to insure that the burner is

tightened to its original position.

Place burner wrench (part no. 8312D075-60, available

from your dealer or authorized service agency) over

surface burner assembly with ignitor positioned inside gap

in wrench ring (figure 10). This prevents ignitor from being

crushed when wrench tightens on burner assembly.

Rotate burner assembly approximately one-eighth turn

counter-clockwise and lift from main top (figure 11).

c. The oven burner air shutter adjustment is the same on

ranges with a gas pilot or electric ignition.

FIGURE 9

High Altitude Notice

The specified gas burner ratings typically apply to

elevations up to 2000 feet. For higher altitudes, the rates

may need to be reduced to achieve satisfactory operation.

A local certified gas servicer will be able to advise if a

reduction is necessary.

FIGURE 10

To Reassemble: Replace burner assembly in main top

and rotate approximately one-eighth turn clockwise using

burner wrench until burner locks into position with ignitor

aligned with reference mark on main top.

-8-

FIGURE 11

Page 9

GAS CONVERSION

General

All ranges and cooktops are equipped with double coaxial

(universal) orifices and with a convertible appliance

pressure regulator. The unit model number plate states

which gas it was adjusted for at the factory. To convert the

unit to either Natural gas or LP gas will require adjustment

of the orifice hoods, air shutters on the burners and

adjustment of the appliance pressure regulator converter

cap.

Inlet pressure to the appliance pressure regulator should

be as follows for both operation and checking of appliance

pressure regulator setting:

INLET PRESSURE IN NATURAL LP

INCHES OF WATER COLUMN

Minimum 5 11

Maximum 14 14

GAS GAS

Appliance Pressure Regulator Conversion

The unit appliance pressure regulator must be set to

match the type gas supply used. If converting from natural

gas to LP gas, the appliance pressure regulator must be

converted to regulate LP gas. If converting from LP gas to

natural gas, the appliance pressure regulator must be

converted to regulate natural gas.

To convert the appliance pressure regulator from one gas

to another, do either (1), (2) or (3) below: Your unit will be

equipped with one of the three appliance pressure

regulator types shown below.

1. Remove the cap, push down and turn

counter-clockwise. Turn the cap over and reinstall

(figure 12).

NOTE: The gas type you are converting to must be

visible on the top of the installed appliance pressure

regulator cap.

2. Remove plastic dust cover from cap nut on top of

appliance pressure regulator. Remove cap nut from

appliance pressure regulator (plastic dust cover comes

off with nut). “IMPORTANT” remove plastic dust cover

from cap nut and reinstall on opposite side of cap nut.

Reinstall cap nut to appliance pressure regulator and

replace dust cover. “CAUTION” be sure marking for

the type of gas to which appliance pressure regulator

has just been converted is visible in top of cap nut

before replacing plastic dust cover. (See figure 13).

3. Remove cap and forcibly snap out plastic plunger from

bottom of cap. Turn plunger over and forcibly snap

back in original location (figure 14).

NOTE: Plunger MUST

you are converting to must be visible on lower side of

plunger.

snap into position; the gas type

FIGURE 12 FIGURE 13 FIGURE 14

-9-

Page 10

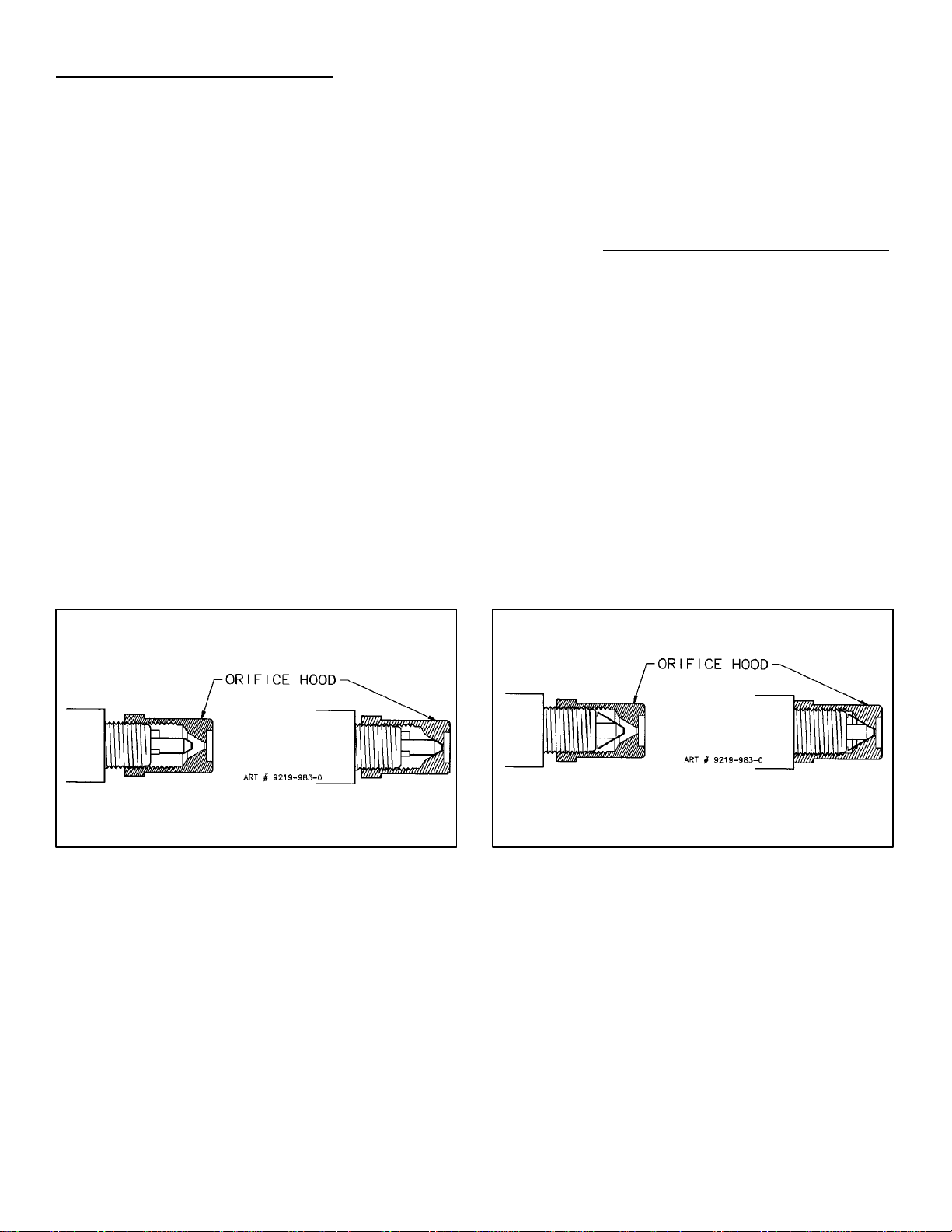

ORIFICE CONVERSION

1. From Natural Gas To LP/Propane Gas:

a. Change the appliance pressure regulator from

natural to LP setting. (See figure 12, 13 or 14).

b. Screw the burner orifice hoods down tight against

the pins. (See figure 15B). Use care to not over

tighten. Over tightening can damage the coaxial

pin inside the orifice hood.

NOTE: On units using Eaton Oven Safety Valve

screw the valve orifice hood down tight against

the valve body. (See figure 15D). It is important

that the hood be turned down as far as it can go

to insure that complete conversion has occurred.

c. Models with standing pilots: Adjust burner pilots.

(See figure 6). Turn the selector switch on the

face of the thermostat to the LP position.

d. Adjust burner air shutter to the widest opening

that will not cause the flame to lift or blow off the

burner when cold.

NOTE: Correctly adjusted sealed burners, can

have flames that will lift or blow without a pot over

the burner. These should be adjusted with a pot

in place.

2. From LP/Propane Gas To Natural Gas:

a. Change the appliance pressure regulator from LP

to natural setting. (See figure 12, 13 or 14).

b. Screw the burner orifice hoods away from the

pins. (See figure 15A). Approximately 1 1/2 to 2

turns.

NOTE: On units using Eaton Oven Safety Valve

screw the burner orifice hoods away from pin (see

,

figure 15C). Approximately 1 1/2 to 2 turns.

c. Models with standing pilots: Adjust top burner

pilots. (See figure 6). Turn the selector switch on

the face of the thermostat to the Nat. position.

d. Adjust burner air shutter to the widest opening

that will not cause the flame to lift or blow off the

burner when cold.

NOTE: Correctly adjusted sealed burners, the

flame will lift or blow without a pot over the

burner. These should be adjusted with a pot in

place.

,

FOR ALL TOP BURNER AND

OVEN SAFETY VALVE CONVERSION

(EXCEPT EATON VALVE)

FIGURE 15A

NATURAL GAS

SETTING

FIGURE 15B

SETTING

LP GAS

FOR EATON

OVEN SAFETY VALVE CONVERSION

FIGURE 15C

NATURAL GAS

SETTING

FIGURE 15D

LP GAS

SETTING

-10-

Page 11

HOW TO REMOVE RANGE

FOR

Follow these procedures to remove appliance for

servicing:

1. Shut off gas supply to appliance.

2. Disconnect electrical supply to appliance, if equipped.

3. Disconnect gas supply tubing to appliance.

4. Slide range forward to disengage range from the

5. Reverse procedure to reinstall. If gas line has been

SERVICING

anti-tip bracket. (See page 4).

disconnected, check for gas leaks after reconnection.

NOTE: A qualified servicer should disconnect and

reconnect the gas supply.

The servicer MUST

provided with the gas appliance connector and the

warning label attached to the connector.

6. To prevent range from accidentally tipping, range must

be secured to the floor by sliding rear leveling leg into

the anti-tip bracket.

follow installation instructions

SERVICE-PARTS INFORMATION

When your range requires service or replacement parts,

contact your dealer or authorized service agency. Please

give the complete model and serial numbers of the range

which is located on the range model number plate.

-11-

Page 12

INSTALADOR: DEJE ESTAS INSTRUCCIONES CON EL ELECTRODOMÉSTICO

MANUAL DE INSTALACIÓN

Estufadegasde76.2cm

(30 pulgadas) independiente y

deslizable

CONSERVE ESTE MANUAL COMO REFERENCIA FUTURA

EL MANUAL TIENE LA FINALIDAD DE AYUDARLE EN LA INSTALACIÓN Y LOS AJUSTES INICIALES

DE LA ESTUFA.

ADVERTENCIA ESPECIAL

Solamente el personal calificado

deberá instalar o dar servicio a esta

estufa.

Lea las “Instrucciones de seguridad”

en el libro de Uso y cuidado antes de

usar la estufa.

La instalación, el ajuste, la alteración,

el servicio, el mantenimiento o el uso

incorrectos de la estufa pueden

causar lesiones graves o daños

materiales.

ADVERTENCIA

· TODAS LAS ESTUFAS PUEDEN

VOLTEARSE Y CAUSAR

LESIONES A LAS PERSONAS.

· INSTALE LOS DISPOSITIVOS

EST ABILIZADORES EMPACADOS

CON LA ESTUFA.

· SIGA TODAS LAS

INSTRUCCIONES DE

INSTALACIÓN.

DIMENSIONES DEL ESPACIO LIBRE

La estufa puede instalarse con un espacio libre de cero

pulgadas adyacente (contra) la construcción combustible

en la parte posterior y lateral debajo de la superficie para

cocinar. Para obtener información completa relacionada

con la instalación de gabinetes de pared encima de la

estufa y los espacios libres a las paredes combustibles

por encima de la parte superior de la superficie para

cocinar, vea los dibujos de instalación. Por MOTIVOS DE

SEGURIDAD no instale la estufa en ningún gabinete

combustible que no esté de acuerdo a los dibujos de

instalación.

*NOTA: La dimensión de 76.2 cm (30 pulg) entre la

superficie de cocinar y el gabinete de la pared que se

muestra en la ilustración no corresponde a las estufas

con el horno elevado. La dimensión de 76.2 cm

(30 pulgadas) no puede reducirse a menos de 61 cm

(24 pulgadas) cuando los gabinetes de pared en una casa

están protegidos con materiales a contra de incendios de

acuerdo con las Normas Nacionales Estadounidenses —

Código Nacional de Gas Combustible o en casas móviles

cuando están protegidas con materiales contra incendios

de acuerdo con la Norma Federal para Construcción y

Seguridad de Casas Móviles.

Para eliminar el riesgo de quemaduras o incendios al

atravesarse por encima de las unidades calientes de la

superficie, debe evitarse el almacenaje en los gabinetes

por encima de las unidades de la superficie. Si se va a

proporcionar almacenaje, puede reducirse el riesgo

instalando una campana de estufa que sobresalga

horizontalmente cuando menos 5 pulgadas más que los

gabinetes inferiores.

Su estufa podría no estar equipada

con algunas de las características

mencionadas en este manual.

PRECAUCIÓN: Algunos gabinetes y materiales de

construcción no están diseñados para soportar el calor

producido por el funcionamiento normal seguro del

electrodoméstico indicado. Podría ocurrir decoloración

o daños tales como la pérdida del laminado.

Page 13

DIBUJOS DE INSTALACIÓN

INDEPENDIENTE

83.8 CM (33 PULG)

96.5 CM (36 PULG)

ALTURA DEL GABINETE

2.54 CM

(1 PULG)

5.7 CM

(2 1/4

PULG)

27.94 CM

(11 PULG)*

8.24 CM

(3 1/4

PULG)

2.54 CM

(1 PULG)

UBICACIÓN RECOMENDADA

DE LA TUBERÍA DE GAS PARA

LOS MODELOS QUE NO SON

DE LIMPIEZA AUTOMÁTICA.

PROVEA UN TOMACORRIENTE ELÉCTRICO

DE 120 V CONECTADO A TIERRA EN ESTA

ÁREA. EL TOMACORRIENTE DEBE ESTAR AL

RAS. EL ÁREA ES DE 33 CM (13 PULG)

ANCHO X 22.86 CM (9 PULG) DE ALTO.

UBICADO A 23.55 CM (9 3/8 PULG) POR

ENCIMA DEL PISO Y A 3.8 CM (1 1/2 PULG)

DE LA PARED DERECHA

63.5 CM (25 PULG) PROFUNDIDAD

NORMAL DE LA PARTE SUPERIOR

DEL GABINETE

UBICACIÓN RECOMENDADA PARA LA

TUBERÍA DE GAS EN LOS MODELOS

DE LIMPIEZA AUTOMÁTICA.

DESLIZABLE

76.2 CM (30 PULG)

ABERTURA DEL GABINETE

*DE DÉCOUPE DE

59 CM (23 1/4 PULG)

PROFUNDIDAD DEL

CORTE DEL HUECO

91.4 CM (36 PULG)

ALTURA DEL

GABINETE

(2 1/4 PPULG)

76.2 CM

(30 PULG)

76.2 CM (30 PULG)

14 CM

(5 1/2 PULG)

EN CADA LADO

25.4 CM

(10 PULG)

5.7 CM

GAS RECOMENDADO

60.96 CM (24 PULG)

PROFUNDIDAD DEL GABINETE

* 45.7 CM (18 PULG) PERMITIDOS

PARA LOS MODELOS QUE NO SON

DE CONVECCIÓN

NOTA: EN LOS MOSTRADORES

DE LOS GABINETES QUE

TENGAN EL BORDE FORMADO,

REBAJE LA SECCIÓN REALZADA

PARA LIBRAR LA SUPERFICIE.

PROPORCIONE UN TOMACORRIENTE

ELÉCTRICO CONECTADO A TIERRA DE

120 VOLTIOS EN ESTA ÁREA. EL

TOMACORRIENTE DEBE ESTAR AL RAS.

59.2 CM (23 5/8 PULG)

ÁREA PLANA

63.5 CM (25 PULG)

PROFUNDIDAD

61 CM (24 PULG)

PROFUNDIDAD

DEL GABINETE

MÍNIMA DE LA PARTE

SUPERIOR DEL

GABINETE

ABERTURA

DEL GABINETE

PRECAUCIÓN:

ALGUNOS GABINETES BLANCOS DE ESTILO EUROPEO ESTÁN EQUIPADOS CON FRENTES DE VINILO BLANCO

DELICADO EN EL CAJÓN Y LAS PUERTAS. EL VINILO PODRÍA NO ESTAR DISEÑADO PARA SOPORTAR EL CALOR QUE

SE PRODUCE DURANTE LA OPERACIÓN NORMAL SEGURA DE UNA ESTUFA DE LIMPIEZA AUTOMÁTICA. PODRÍA

OCURRIR DECOLORACIÓN O DAÑOS AL LAMINADO. PARA EVITAR POSIBLES DAÑOS, SE RECOMIENDA AUMENTAR LA

ABERTURA DEL GABINETE DE 76 CM (30 PULG) A 79 CM (31 1/4 PULG) CUANDO MENOS Y USAR EL JUEGO DE

GABINETE DE CORAZA CONTRA EL CALOR. EL CORTE DEL MOSTRADOR DEBE PERMANECER DE 76 CM (30 PULG).

**Cuando reemplace una unidad existente, es aceptable un máximo de 60 cm (23 1/2 pulg). Si el corte de profundidad excede 60 cm

(23 1/2 pulg), use el juego de relleno (K70 Fill).

-2-

Page 14

76.2 CM (30 PULG)

76.2 CM

(30 PULG)

(VEA LA NOTADE LA PÁGINA DELANTERA)

CUALQUIER

SUPERFICIE

COMBUSTIBLE

33 CM (13 PULG)

MÁX. PROFUNDIDAD

DE LOS GABINETES

QUE ESTÁN POR

ENCIMA DE LA

SUPERFICIE PARA

COCINAR

45.7 CM

(18 PULG) MÍN.

DIMENSIÓN ”A” ESPACIO LIBRE LATERAL POR ENCIMA DE LA SUPERFICIE PARA COCINAR

CLASIFICACIÓN DEL QUEMADOR

SUPERIOR PARA EL GAS NATURAL

(VEA LA PLACA DE DATOS)

9,200 BTU/HORA O MENOS

MÁS DE 9.200 BTU/HORA

Lea la placa de datos de la estufa para ver si está

aprobada la instalación en casas móviles o vehículos

recreativos. Si está aprobada, se aplicarán los puntos

siguientes:

CASAS MÓVILES

La instalación de una estufa diseñada para instalarse en

una casa móvil debe estar en conformidad con la Norma

de Construcción y Seguridad de Casas Prefabricadas,

Título 24 CFR, Parte 3280 (anteriormente la Norma

Federal para Construcción y Seguridad de Casas

Móviles, Título 24 HUD, Parte 280) o, cuando dicha

norma no corresponda, la Norma para Instalaciones de

Casas Prefabricadas 1982 (Standard for Manufactured

Home Installations), ANSI A225.1/NFPA 501A - Última

edición, o con los códigos locales.

En Canadá la estufa debe instalarse de acuerdo con la

norma actual de CSA C22.1 — Código Eléctrico

Canadiense Parte 1 y Sección Z240.4.1 — Requisitos de

Instalación para Electrodomésticos que Consumen Gas

en Casas Móviles (Norma CSA CAN/CSA — Z240MH).

91.4 CM (36 PULG)

HORNO

CONVENCIONAL

0CM(0PULG)

2.54 CM (1 PULG)

VEHÍCULOS RECREATIVOS

La instalación de una estufa diseñada para vehículos

recreativos debe estar en conformidad con los códigos

estatales y similares, en caso de no existir dichos

códigos, con la última edición de la Norma para Vehículos

Recreativos, ANSI A119.2.

En Canadá la estufa debe estar instalada de acuerdo con

los Requisitos Eléctricos CAN/CSA — Z240.6.2 — para

Vehículos Recreativos (Norma CSA CAN/CSA —

Serie Z240 RV) y con la Sección Z240.4.2 — Requisitos

de Instalación para Electrodomésticos y Equipo de

Propano en Vehículos Recreativos (Norma CSA

CAN/CSA — Serie Z240 RV).

UBICACIÓN DE LA ESTUFA

No coloque la estufa sobre agujeros del piso ni en otros

lugares en donde esté sujeta a corrientes fuertes de aire.

Las aberturas en la pared por detrás de la estufa y en el

piso por debajo de la estufa deben sellarse. Asegúrese

de que el flujo de aire de enfriamiento o ventilación por

debajo de la estufa no esté obstruido.

NOTA: Una estufa NO debe instalarse directamente

sobre alfombra de cocina.

0CM(0PULG)DE

ESPACIO LIBRE ENTRE LA

CONSTRUCCIÓN

COMBUSTIBLE

ADYACENTE Y LA PARTE

POSTERIOR Y LOS LADOS

DE LA ESTUFA DEBAJO

DE LA SUPERFICIE PARA

COCINAR

HORNO DE LIMPIEZA

AUTOMÁTICA

7.62 CM (3 PULG)

7.6CM(3PULG)

-3-

Page 15

INSTRUCCIONES DE INSTALACIÓN DEL DISPOSITIVO ESTABILIZADOR

NOTA: Existe el riesgo de que la estufa se voltee si el

electrodoméstico no está instalado de acuerdo con las

instrucciones de instalación provistas. El uso correcto de

este dispositivo reduce el riesgo de VOLTEO. Cuando

use este dispositivo el propietario, de la misma manera

debe observar las precauciones de seguridad según se

indican en el MANUAL DE USO Y CUIDADO y evitar usar

la puerta del horno o el cajón inferior como banquillo.

Se proporcionan las instrucciones para madera y

cemento tanto para piso como para pared. Cualquier otro

tipo de construcción podría requerir técnicas de

instalación especiales según se determine necesario para

proporcionar un anclaje adecuado del soporte

ESTABILIZADORalpisooalapared.

PASO 1 — Ubicación del soporte (vea la figura 1)

A. Determine en dónde estará ubicado el “borde”

derecho o izquierdo de la estufa y marque el piso o la

pared.

B. Coloque el SOPORTE a 15/16” del “BORDE”

marcado hacia el centro del hueco y contra la pared

posterior, según se muestra en la figura 1, con el

orificio orientado contra la pared.

C. Use el soporte como plantilla y marque los orificios

necesarios, según se muestra en la figura 1, para el

tipo de construcción que usará.

PASO 2 — Instalación del soporte estabilizador

A. Construcción de madera:

1. Piso: Ubique el centro de los dos orificios que se

identifican en la figura 1 como “ORIFICIOS PARA

ELPISO”. Taladreunorificiopilotoconuna

broca de 1/8” en el centro de cada orificio (puede

usar un clavo o un punzón si no tiene un taladro

disponible). Asegure el soporte ESTABILIZADOR

al piso con los dos tornillos provistos. Continúe

conelpaso3.

2. Pared: Ubique el centro de los dos orificios que

se identifican en la figura 1 como “ORIFICIOS

PARA LA PARED”. Taladre un orificio piloto en

ángulo con una broca de 1/8” en el centro de

cada orificio como se muestra en la figura 2.

(Puede usar un clavo o un punzón si no tiene

disponible un taladro). Asegure el soporte

ESTABILIZADOR a la pared con los dos tornillos

provistos según se muestra en la figura 2.

Continúe con el PASO 3.

B. Construcción de cemento o concreto:

1. Pueden obtenerse tornillos apropiados para la

construcción de concreto en una ferretería. Con

el taladro haga el orificio del tamaño requerido

para los tornillos que haya obtenido, en el

concreto, en el centro de los orificios identificados

en la figura 1 como “ORIFICIOS PARA EL PISO”.

Asegure el soporte ESTABILIZADOR al piso.

Continúe con el PASO 3.

PASO 3 — Instalación de la estufa

A. Alinee la estufa en su ubicación final y deslícela hacia

atrás en su lugar. Asegúrese de que la pata niveladora esté completamente insertada y asegurada en el

soporte ESTABILIZADOR. Nota: Se requiere un

espacio libre de cuando menos 1/4 pulg. entre la

estufa y la pata niveladora que se enganchará al

soporte ESTABILIZADOR, vea la figura 2.

B. Por razones de seguridad así como para obtener el

mejor rendimiento, ajuste la estufa para que quede

bien nivelada. Esto puede revisarse colocando un

nivel de burbuja de aire o un recipiente grande de

agua en la superficie para cocinar o en la parrilla del

horno. Si es necesario realizar un ajuste en una

estufa independiente, jálela hacia delante, incline la

estufa y gire la pata niveladora según sea necesario.

Las estufas deslizables necesitan sacarse

completamente del gabinete antes de realizar algún

ajuste.

C. Para verificar que el soporte estabilizador esté

correctamente instalado a la estufa: Use una linterna

y vea por debajo de la parte inferior de la estufa para

comprobar que una de las patas niveladoras

posteriores esté enganchada en la ranura del soporte.

D. Proceda con el resto de las instrucciones de

instalación.

2.37 CM

(15/16

PULG) DEL

BORDE DE

LA ESTUFA

BORDE

MARCADO

PARA LA

ESTUFA

ORIFICIO DE

ORIENTACIÓN

ORIFICIOS

PARA LA

PARED

ORIFICIOS

PARA EL PISO

FIGURA 1 FIGURA 2

SUJETE EL SOPORTE

ESTABILIZADOR CON

TORNILLOS LARGOS

SOPORTE

ESTABILIZADO

R

PATAS

NIVELADORAS

-4-

LOS

TORNILLOS

DEBEN

ENTRAR EN

LA MADERA

OEL

METAL.

PLACA DE

LA PARED

NOTA: U SE CUANDO MENOS DOS (2) TORNILLOS

PARA INSTALAR EL SOPORTE

ESTABILIZADOR A LA PARED O AL PISO.

SOPORTE

ESTABILIZADO

R

ATORNILLE EL

SOPORTE A LA PARED

DESLÍCELO PARA

ASEGURARLO

PARTE

INFERIOR

DE LA

ESTUFA

0.6 CM

(1/4

PULG)

MÍN.

Page 16

CONEXIÓN DE LA ESTUFA

SUMINISTRO ELÉCTRICO

El electrodoméstico, cuando se instala, debe conectarse

a tierra de acuerdo con los códigos locales o, si no existieran, con el Código Nacional Eléctrico, ANSI/NFPA 70.

En Canadá la estufa debe instalarse de acuerdo con la

Norma actual C22.1 de CSA — Código Eléctrico

Canadiense Parte 1.

CONEXIÓN DEL SUMINISTRO ELÉCTRICO:

La estufa requiere 120 voltios de corriente alterna de 60

ciclos de un tomacorriente. Vea la placa de datos para

encontrar la clasificación.

El usuario podría experimentar la desconexión ocasional

del tomacorriente del interruptor del circuito contra fallas

de conexión a tierra (GFCI) o del disyuntor que se esté

usando.

ADVERTENCIA

Instrucciones eléctricas de conexión

a tierra

Este electrodoméstico está equipado con una clavija de

conexión a tierra (de tres puntas) para protegerlo contra

el peligro de descargas eléctricas y debe conectarse

directamente en unreceptáculo debidamente conectado

a tierra. No corte niquite lapunta deconexión a tierra de

esta clavija.

ADVERTENCIA

DESCONECTE EL SUMINISTRO

ELÉCTRICO ANTES DE DAR SERVICIO AL

ELECTRODOMÉSTICO.

SUMINISTRO DE GAS

La instalación de esta estufa debe estar en conformidad

con los códigos locales o, si no existieran, con la última

edición del Código Nacional de Gas Combustible,

ANSI Z223.1.

CONEXIÓN DEL SUMINISTRO DE GAS:

(Vea la figura 4)

LA CONEXIÓN DE GAS DEBE REALIZARLA UN

TÉCNICO CALIFICADO DE SERVICIO O UN

INSTALADOR DE ELECTRODOMÉSTICOS DE GAS.

Las pruebas de fugas del electrodoméstico debe

realizarlas el instalador de acuerdo a las

instrucciones indicadas en la sección h.

LA TUBERÍA DE SUMINISTRO DE GAS DEBE TENER

UN REGULADOR DE SERVICIO DE GAS NATURAL. LA

PRESIÓN DE ENTRADA A ESTE

ELECTRODOMÉSTICO DEBE REDUCIRSE A UN

MÁXIMO DE 14 PULGADAS DE COLUMNA DE AGUA

(0.5 LIBRAS POR PULGADA CUADRADA [PSI]). LA

TUBERÍA DE SUMINISTRO DE PETRÓLEO LÍCUADO

(LP) O GAS PROPANO DEBE TENER UN REGULADOR

DE PRESIÓN PARA GAS LP. LA PRESIÓN DE

ENTRADA A ESTE ELECTRODOMÉSTICO DEBE

REDUCIRSE A UN MÁXIMO DE 14 PULGADAS DE

COLUMNADEAGUA(0.5PSI).LASPRESIONESDE

ENTRADA SUPERIORES A 0.5 PSI PUEDEN DAÑAR EL

REGULADOR DE PRESIÓN Y OTROS COMPONENTES

DE GAS DEL ELECTRODOMÉSTICO Y PUEDEN

CAUSAR FUGAS DE GAS.

a. DEBE INSTALARSE UNA VÁLVULA DE CIERRE DE

GAS EN UN LUGAR ACCESIBLE EN LA TUBERÍA

DE SUMINISTRO MÁS ADELANTE DE LA ESTUFA,

PARA CERRAR Y ABRIR EL SUMINISTRO DE GAS.

Si la estufa se conectará a la tubería de la casa con

conectores flexibles o semirígidos de metal para el

electrodoméstico de gas, LAS TUERCAS DE

CONEXIÓN NO DEBEN CONECTARSE

DIRECTAMENTE EN LAS ROSCAS DE LA

TUBERÍA. LOS CONECTORES DEBEN

INSTALARSE CON LOS ADAPTADORES

PROVISTOS CON EL CONECTOR.

b. La tubería de la casa y el conector de la estufa que se

use para conectar la estufa al suministro principal de

gas, deben estar limpios, sin desechos de metal, sin

corrosión, tierra ni líquidos (aceite o agua). La tierra y

demás en las tuberías de suministro pueden llegar

hasta el múltiple de la estufa y causar fallas en las

válvulas de gas o en los controles y obstruir los

quemadores o los orificios de los pilotos.

PRECAUCIÓN: NO LEVANTE NI MUEVA LA

ESTUFAPORLASASASDELAPUERTANIPOR

EL PROTECTOR POSTERIOR.

En Canadá la estufa debe instalarse de acuerdo con la

Norma actual CAN/CGA-B149 de CGA — Códigos de

instalación para electrodomésticos y equipos que queman

gas y/o con los códigos locales.

En la Comunidad de Massachusetts

Este producto debe instalarlo un plomero certificado o

un ajustador de gas cuando se instale dentro de la

Comunidad de Massachusetts.

Debe instalarse una válvula manual con asa tipo “T” en

la tubería de suministro de gas al electrodoméstico.

Los conectores flexibles de gas, cuando se usen, no

deben sobrepasar una longitud de 90 cm (36 pulg).

c. Apague todos los pilotos y la válvula principal de gas

de los demás electrodomésticos de gas.

d. Cierre la válvula principal de gas en el medidor.

e. Antes de conectar la estufa, aplique compuesto para

roscas de tuberías que esté aprobado para todas las

roscas de gas LP.

f. Conecte la estufa al suministro de gas en el regulador

de presión usando los adaptadores provistos con el

conector flexible. También puede usarse tubería

rígida. Vea la placa de clasificación para encontrar el

tipo de gas para el que se fabricó la estufa.

g. Abra la válvula principal de gas al medidor, y vuelva a

encender los pilotos de los otros electrodomésticos

de gas.

-5-

Page 17

Conexiones del suministro de gas para las

estufas con el regulador de presión ubicado

en la parte inferior de la estufa

TUBERÍA FLEXIBLE

DE SUMINISTRO

CODO HEMBRA

ADAPTADOR

* REGULADOR DE

PRESIÓN DEL

ELECTRODOMÉSTICO

PARA CONECTAR EL SUMINISTRO DE GAS A UNA ENTRADA

EXTERIOR DE 1/2 PULG NPT

DE 1/2 NPT

ENCENDIDO

(ON)

APAGADO (OFF)

VÁLVULA DE

CIERRE DEL

HORNO INFERIOR

h. Aplique un líquido de detección de fugas que sea

anticorrosivo en todas las uniones y accesorios de la

conexión de gas entre la válvula de cierre de la

tubería de suministro y la estufa. Incluya los

accesorios y las uniones de gas en la estufa si se

tocaron de alguna manera las conexiones durante la

instalación. ¡Revise si existen fugas! Si aparecen

burbujas alrededor de los accesorios y las conexiones

significará que hay una fuga. Si aparece una fuga,

cierre la válvula de suministro de la tubería de gas,

apriete las conexiones, abra la válvula de cierre de la

tubería de suministro de gas y vuelva a revisar las

fugas.

PRECAUCIÓN: NUNCA REVISE SI EXISTEN

FUGAS CON LLAMAS.

CUANDO TERMINE DE REVISAR LAS FUGAS,

LIMPIE TODOS LOS RESIDUOS.

i. Quite el tornillo de embarque de TODOS los

quemadores superiores. (Sólo los modelos de

quemador superior convencional.) Esto es para

mantener los quemadores en su lugar en el soporte

de los quemadores solamente con fines de

embarque. (Vea la figura 5.)

j. Ajuste el obturador de aire del quemador a la posición

más abierta que no haga que se levante o apaga la

llama cuando el quemador esté frío.

ADAPTADO

R

CODO DE PISO

DE 1/2 NPT

APAGADO (OFF)

(ON)

VÁLVULA DE

CIERRE DEL

HORNO INFERIOR

* REGULADOR DE

PRESIÓN DEL

ELECTRODOMÉSTICO

ENCENDIDO

PARA CONECTAR EL SUMINISTRO DE GAS A UNA ENTRADA

INTERIOR DE 1/2 PULG NPT

CUANDO EL INSTALADOR HAYA TERMINADO LA

INSTALACIÓN DEL ELECTRODOMÉSTICO, DEJE LA

VÁLVULA DE CIERRE DEL REGULADOR DE PRESIÓN EN

LA POSICIÓN ABIERTA “ON” (ENCEDIDO).

La conexión del suministro de gas para las

estufas con el regulador de presión ubicado

debajo de la superficie principal de la estufa

TUBERÍA FLEXIBLE

DE SUMINISTRO

Regulador de presión y conectores

alternativos del electrodoméstico

* El regulador de presión de su estufa podría ser distinto

al de la ilustración.

ADAPTADO

R

FIGURA 4

NOTA: Los quemadores sellados ajustados

correctamente pueden tener llamas que se levantan o

apagan si no tienen un recipiente encima del

quemador. Estos deben ajustarse con un recipiente

en su lugar.

QUITE EL TORNILLO DE EMBARQUE

OBTURADOR

DE AIRE

FIGURA 5

REVISE LA PRESIÓN DEL SISTEMA DE

PRESIÓN DE LA CASA

1. El electrodoméstico y su válvula de cierre individual

deben estar desconectados del sistema de suministro

de gas durante cualquier prueba de presión de ese

sistema a presiones que sobrepasen 1/2 libra por

pulgada cuadrada (3.5 kPa) (13.8 pulgadas de

columna de agua).

2. El electrodoméstico debe estar aislado del sistema de

suministro de gas cerrando la válvula de cierre

individual durante cualquier prueba de presión de ese

sistema a presiones iguales o menores de 1/2 libra por

pulgada cuadrada (3.5 kPa) (13.8 pulgadas de

columna de agua).

-6-

Page 18

ADVERTENCIA

ESTE PRODUCTO NO DEBE

INSTALARSE DEBAJO DE UNA

CAMPANA DE VENTILACIÓN

QUE DIRIJA EL AIRE EN UNA

DIRECCIÓN HACIA ABAJO.

(VEA LA FIGURA)

ESTOS SISTEMAS DE

VENTILACIÓN PUEDEN

CAUSAR PROBLEMAS DE

IGNICIÓN Y DE COMBUSTIÓN

CON LOS QUEMADORES A

GAS RESULTANDO EN

LESIONES PERSONALES Y

PUEDEN AFECTAR LA

MANERA DE COCINAR DE LA

UNIDAD.

NOTA: ES POSIBLE QUE LA FIGURA NO SEA UNA REPRESENTACIÓN EXACTA DE SU ESTUFA O DE SU SUPERFICIE PARA

COCINAR; SIN EMBARGO, ESTA ADVERTENCIA SE APLICA A

TODOS LOS ELECTRODOMÉSTICOS DE COCINA A GAS.

Sección superior — Encendido electrónico

Para que funcione, empuje y gire la perilla del quemador

superior a la posición de encender “LITE” (ENCIENDER).

El quemador superior se encenderá. Para APAGAR la

chispa después de que se haya encendido el quemador

superior, gire la perilla al ajuste alto “HI” (ALTO).

Ajuste del quemador superior

Todas las válvulas de los quemadores superiores: La

altura aproximada de la llama en la posición alta o

completa se muestra a continuación.

Ajuste el obturador de aire del quemador a la posición

más abierta que no haga que se levante o apaga la llama

cuando el quemador esté frío. NOTA: Los quemadores

sellados ajustados correctamente, pueden tener llamas

que se levantan o apagan si no tienen un recipiente

encima del quemador. Estos deben ajustarse con un

recipiente en su lugar.

LLAMA DE

1.9 CM

(1/4 PULG)

QUITE EL TORNILLO DE EMBARQUE

AJUSTES DE LA ESTUFA

Ajuste del piloto superior de gas de la

sección superior

(Vea la figura 6)

Purgue todo el aire del sistema de suministro abriendo la

válvula de un quemador superior. Después cierre la

válvula y ajuste la llama del piloto usando el tornillo “A”

(figura 6) de ajuste para que la llama esté uniforme con la

parte superior del tubo de cremalleras. Para encender el

quemador, empuje y gire la perilla del quemador superior

a la posición baja. NOTA: Algunos modelos SOLAMENTE

tienen un ajuste de piloto en la tubería del múltiple.

TORNILLO “A” DE AJUSTE DEL PILOTO

PILOTO

IZQUIERDO

PILOTO

DERECHO

PARTE SUPERIOR

DEL TUBO

DESTELLANTE

OBTURADOR

DE AIRE

QUEMADORES CONVENCIONALES

QUEMADORES SELLADOS

FIGURA 7

OBTURADOR

DE AIRE

FIGURA 6

CONO

ADVERTENCIA

Puede ocurrir un escape de gas en su sistema y provocar

una situación peligrosa. Los escapes de gas no pueden

ser detectadospor el olor solamente. Los proveedores de

gas recomiendan quecompre einstale undetector degas

aprobado por el laboratorio UL. Inst lelo y úselo de

acuerdo con las instrucciones de fabricante.

-7-

Page 19

Obturador de aire — Quemador del horno

a. La longitud aproximada de la llama del quemador del

horno es una llama cónica con el interior azul, bien

definida de 1/2 pulgada, figura 8.

LLAMA DE 1.27 CM

(1/2 PULG) DEL

CONO INTERIOR

FIGURA 8

Retiro del quemador sellado para ajustarlo o

darle servicio:

Marque con un lápiz la ubicación del encendedor en

relación a la parte superior principal. Esta marca en la

parte superior principal se usará como punto de

referencia cuando reemplace el quemador para asegurar

que el quemador esté apretado en su posición original.

Coloque la llave del quemador (pieza núm. 8312D075-60,

disponible a través del distribuidor o agencia autorizada

de servicio) sobre el quemador de la superficie con el

encendedor colocado dentro del espacio en el anillo de la

llave (figura 10). Esto evita que el encendedor se aplaste

cuando la llave apriete el quemador. Gire el quemador

aproximadamente un octavo de vuelta en sentido

contrario al de las manecillas del reloj y levántelo de la

superficie principal (figura 11).

b. La llama del quemador del horno puede revisarse de

la manera siguiente:

1. Llama amarilla en el quemador — abra el

obturador de aire del quemador a la posición más

abierta que no cause que se apague ni levante la

llama cuando el quemador esté frío. (Vea el

número2delafigura9.)

2. Llama azul bien definida pero se levanta - cierre

el obturador de aire hasta el punto en donde que

no cause que se levante o apague la llama

cuando el quemador esté frío. (Vea el número 2

de la figura 9.)

c. El ajuste del obturador de aire del quemador del

horno es el mismo en las estufas con pilotos de gas o

de encendido electrónico.

TORNILLO DE TRABADO

OBTURADOR DE AIRE

CAMPANA DE ORIFICIO

EN SENTIDO CONTRARIO AL

DE LAS MANECILLAS DEL

RELOJ PARA AFLOJAR

COLOCACIÓN DEL ENCENDEDOR

DENTRO DE LA TAPA DE LA LLAVE

EN EL SENTIDO DE

LAS MANECILLAS

DEL RELOJ PARA

APRETAR

FIGURA 10

Para volver a ensamblarlo: Coloque de nuevo el

quemador en la parte superior principal y gírelo

aproximadamente un octavo de vuelta en el sentido de

las manecillas del reloj usando la llave del quemador

hasta que se trabe en su lugar con el encendedor

alineado en referencia a la marca de la parte superior

principal.

CAMPANADEORIFICIO

FIGURA 9

Aviso de altitud

Las capacidades de funcionamiento especificadas del

quemador de gas por lo general corresponden a

elevaciones de hasta 609.6 metros (2000 pies). Cuando

la altitud es mayor, podría ser necesario reducir las

capacidades de funcionamiento para lograr un

funcionamiento satisfactorio.

Un técnico local, certificado en servicios de gas, podrá

aconsejarle si es necesaria la reducción.

FIGURA 11

-8-

Page 20

CONVERSIÓN DE GAS

General

Todas las estufas están equipadas con orificios coaxiales

dobles (universales) y con un regulador de presión

convertible de electrodoméstico. La placa del número del

modelo de la unidad indica para qué tipo de gas está

ajustada de fábrica. Para convertir la unidad a gas

natural o LP se necesitará el ajuste de las campanas de

orificio, los obturadores de aire de los quemadores y el

ajuste de la tapa del convertidor del regulador de presión

del electrodoméstico.

La presión de entrada al regulador de presión deberá

estar del modo siguiente para el ajuste de funcionamiento

y la revisión del electrodoméstico:

PRESIÓN DE ENTRADA

PULGADAS DE COLUMNA NATURAL LP

DE AGUA

Mínima 5 11

Máxima 14 14

GAS GAS

Conversión del regulador de presión del

electrodoméstico

El regulador de presión de la unidad debe estar ajustado

para el tipo de gas que se suministrará. Si se convertirá el

gas natural a gas LP, el regulador de presión debe

convertirse para que regule el gas LP. Si se convertirá de

gas LP a gas natural, el regulador de presión debe

convertirse para que regule el gas natural.

Para convertir el regulador de presión de un gas a otro,

realice los pasos (1), (2) o bien (3) siguientes: Su unidad

estará equipada con uno de los tres tipos de reguladores

de presión que se muestran a continuación.

1. Quite la tapa, empuje hacia abajo y gire en el sentido

contrario al de las manecillas del reloj. Voltee la tapa y

vuelva a instalarla (figura 12).

NOTA: El tipo de gas al que esté convirtiendo el

regulador debe estar a la vista en la parte superior de

la tapa del regulador de presión instalado.

2. Quite la cubierta plástica contra polvo de la tuerca de la

tapa en la parte superior del regulador de presión.

Quite la tuerca de la tapa del regulador de presión (la

cubierta plástica contra polvo se sale con la tuerca).

“IMPORTANTE” quite la cuberita plástica contra polvo

de la tuerca de la tapa y vuelva a instalar en la tuera de

la tapa del lado opuesto.

Instale de nuevo el regulador de presión y coloque otra

vez la cubierta contra polvo. “PRECAUCIÓN”

asegúrese de que la marca del tipo de gas al que se

acaba de convertir el regulador de presión esté a la

vista en la parte superior de la tuerca de la tapa antes

de volver a colocar la cubierta plástica contra polvo.

(Vea la figura 13.)

3. Quite la tapa y saque a presión el pestillo de plástico

de la parte inferior de la tapa. Voltee el pestillo y

colóquelo a presión en su lugar original (figura 14).

NOTA: El pestillo DEBE

tipode gas alque estáhaciendo laconversión debe estar

a la vista en el lado inferior del pestillo.

entrar a presión en su lugar; el

GAS LP

Tapa

del

convertidor

GAS

NATURAL

POSICIÓN LP

POSICIÓN GAS NATURAL

GAS LP

EMPAQUE

FIGURA 12 FIGURA 13 FIGURA 14

-9-

GAS

NATURAL

Page 21

CONVERSIÓN DEL ORIFICIO

1. De gas natural a gas propano/LP:

a. Cambie el ajuste del regulador de presión del

electrodoméstico de gas natural a LP. (Vea la

figura 12, 13 ó 14.)

b. Atornille las campanas de orificio de los

quemadores ajustadamente contra los

pasadores. (Vea la figura 15B.) Tenga cuidado de

no apretarlo demasiado. Hacerlo puede dañar el

pasador coaxial que se encuentra adentro de la

campana de orificio.

NOTA: En las unidades que usen válvulas

de seguridad para hornos

de orificio de la válvula ajustadamente contra el

cuerpo de la válvula. (Vea la figura 15D.) Es

importante que la campana esté hacia abajo

tanto como sea posible para garantizar la

conversión completa.

c. Modelos con pilotos verticales: Ajuste los pilotos

de los quemadores. (Vea la figura 6.) Gire el

interruptor del selector de la cara del termostato a

la posición LP.

d. Ajuste el obturador de aire del quemador a la

posición más abierta que no haga que se levante

o apaga la llama cuando el quemador esté frío.

NOTA: Los quemadores sellados ajustados

correctamente, pueden tener llamas que se

levantan o apagan si no tienen un recipiente

encima del quemador. Estos deben ajustarse con

un recipiente en su lugar.

, atornille la campana

Eaton

2. De gas propano/LP a g as natural:

a. Cambie el ajuste del regulador de presión del

electrodoméstico de gas LP a natural. (Vea la

figura 12, 13 ó 14.)

b. Destornille las campanas de orificio de los

quemadores para sacarlas de los pasadores.

(Vealafigura15A.)11/2a2vueltas

aproximadamente.

NOTA: En las unidades que usen válvulas

seguridad Eaton para hornos

campanas de orificio del quemador para sacarlas

del pasador (vea la figura 15C.) 1 1/2a2vueltas

aproximadamente.

c. Modelos con pilotos verticales: Ajuste los pilotos

de los quemadores superiores. (Vea la figura 6.)

Gire el interruptor del selector de la cara del

termostato a la posición de gas natural.

d. Ajuste el obturador de aire del quemador a la

posición más abierta que no haga que se levante

o apaga la llama cuando el quemador esté frío.

NOTA: Los quemadores sellados ajustados

correctamente pueden tener llamas que se

levantan o apagan si no tienen un recipiente

encima del quemador. Estos deben ajustarse con

un recipiente en su lugar.

, destornille las

de

PARA TODAS LAS CONVERSIONES DE

VÁLVULAS DE SEGURIDAD PARA HORNOS Y

QUEMADORES SUPERIORES (EXCEPTO LA

VÁLVULA EATON)

CAMPANA DE

ORIFICIO

FIGURA 15A

AJUSTE DE

GAS NATURAL

FIGURA 15B

AJUSTE DE

GAS LP

PARA LA CONVERSIÓN DE LA VÁLVULA EATON

DE SEGURIDAD PARA HORNOS

CAMPANA DE

ORIFICIO

FIGURA 15C

AJUSTE DE

GAS NATURAL

FIGURA 15D

AJUSTE DE

GAS LP

-10-

Page 22

CÓMO QUITAR LA ESTUFA

SERVICIO — INFORMACIÓN DE

PARA DARLE

Siga estos procedimientos para quitar el

electrodoméstico para darle servicio:

1. Cierre el suministro de gas al electrodoméstico.

2. Desconecte el suministro eléctrico al electrodoméstico,

si está equipado.

3. Desconecte la tubería de gas al electrodoméstico.

4. Deslice la estufa hacia delante para desgancharla del

soporte estabilizador. (Vea la figura 4.)

5. Invierta el procedimiento para volver a instalarlos. Si se

desconectó la tubería de gas, revise si tiene fugas de

gas después de reconectarla.

SERVICIO

NOTA: El suministro de gas debe desconectarlo y

volver a conectarlo un técnico calificado de servicio.

El técnico DEBE

instalación provistas con el conector del

electrodoméstico de gas y la etiqueta de advertencia

sujeta al conector.

6. Para evitar que la estufa se voltee accidentalmente,

ésta debe estar asegurada al piso deslizando la pata

niveladora posterior dentro del soporte estabilizador.

seguir las instrucciones de

LAS

Cuando la estufa requiera servicio o piezas de repuesto,

comuníquese con el proveedor o la agencia autorizada de

servicio. Proporcione los números completos de modelo y

serie de la estufa que se encuentran localizados en la

placa de datos de la estufa.

PIEZAS

-11-

Page 23

INSTALLATEUR: VEUILLEZ LAISSER CES INSTRUCTIONS AVEC L’APPAREIL

MANUEL DE MISE EN SERVICE

Cuisinière à gaz de 76,2 cm

(30 po) amovible et encastrée

VEUILLEZ CONSERVER CE MANUEL POUR RÉFÉRENCE ULTÉRIEURE

CE MANUEL EST DESTINÉ À FACILITER LA MISE EN SERVICE ET LE RÉGLAGE INITIAUX DE

LA CUISINIÈRE.

AVERTISSEMENT SPÉCIAL

La mise en service et le dépannage de

cette cuisinière doivent être réalisés

uniquement par du personnel qualifié.

Lire les « Mesures de sécurité » dans le

manuel de l’utilisateur avant d e l’utiliser.

Une mauvaise réalisation de la mise en

place, du réglage, de toutes

modifications ou réparations ou de

l’entretien de la cuisinière ou son

usage incorrect peuvent entraîner des

blessures ou des dégâts graves.

AVERTISSEMENT

· TOUTES LES CUISINIÈRES

PEUVENT BASCULER ET

PROVOQUER DES BLESSURES.

· POSER LES DISPOSITIFS DE

STABILISATION FOURNIS AVEC

CETTE CUISINIÈRE.

· SUIVRE TOUTES LES CONSIGNES

DE MISE EN SERVICE.

DÉGAGEMENT NÉCESSAIRE

La cuisinière peut avoir un dégagement nul (0 cm/po) par

rapport aux parois en matériaux combustibles à l’arrière et

sur les côtés au-dessous de la surface de cuisson (elle

peut être contre ces parois). Pour tous renseignements

concernant la pose d’armoires murales au-dessus de la

cuisinière et des dégagements à respecter par rapport

aux parois combustibles se trouvant au-dessus de la

surface de cuisson, se reporter aux schémas

d’installation. Pour des RAISONS DE SÉCURITÉ, ne pas

monter la cuisinière dans une armoire en matériau

combustible qui ne soit pas conforme aux schémas

d’installation.

*REMARQUE : La dimension de 76,2 cm (30 po) entre la

surface de cuisson et l’armoire murale montrée sur

l’illustration ne s’applique pas aux cuisinières ayant un

four en hauteur. La dimension de 76,2 cm (30 po) peut

être réduite à 61 cm (24 po) si les armoires murales d’un

logement sont protégées par des matériaux

ininflammables conformément aux normes American

National Standards - National Fuel Gaz Code ou, dans le

cas de maisons mobiles, si les armoires murales sont

protégées par des matériaux ininflammables

conformément aux règlements du Federal Standard for

Mobile Home Construction and Safety.

Pour éliminer tout risque de brûlure ou d’incendie en

essayant d’atteindre un objet placé au-dessus d’éléments

brûlants, éviter d’avoir un espace de rangement

au-dessus de la surface de cuisson. S’il doit y avoir des

armoires au-dessus de la surface de cuisson, les risques

peuvent être réduits en posant une hotte qui dépasse d’un

minimum de 12,7 cm (5 po) du bas des armoires.

Votre cuisinière peut ne pas être

dotée de toutes les fonctions

mentionnées dans ce manuel.

ATTENTION : Certaines armoires et certains

matériaux de construction ne sont pas conçus pour

supporter la chaleur produite pendant le

fonctionnement normal d’un appareil électroménager

de la liste. Il peut se produire une décoloration ou des

dommages tels que le délaminage.

Page 24

SCHÉMASDEMISEENSERVICE

AMOVIBLE

HAUTEUR D’ARMOIRE

DE 91,4 CM (36 PO)

OUVERTURE DANS

L’ARMOIRE DE 76,2 CM (30 PO)

EMPLACEMENT RECOMMANDÉ

POUR LA CONDUITE DE GAZ,

MODÈLES À FOUR AUTONETTOYANT.

2,54 CM

(1 PO)

83,8 CM

(33 PO)

5,7 CM

(2 1/4 PO)

27,9 CM*

(11 PO)

8,3 CM

(3 1/4 PO)

2,54 CM

(1 PO)

EMPLACEMENT RECOMMANDÉ

POUR LA CONDUITE DE GAZ,

MODÈLES À FOUR NON

AUTONETTOYANT.

PRÉVOIR UNE PRISE DE 120 V

RELIÉE À LA TERRE DANS CETTE

ZONE. LA PRISE DOIT ÊTRE

ENCASTRÉE. CETTE ZONE A POUR

DIMENSIONS 33 (L) X 22,9 (H) CM

(13 PO X 9 PO) ET SE TROUVE À

23,8 CM (9 3/8 PO) AU--DESSUS DU

PLANCHER ET À 3,8 CM (1 1/2 PO) DE

LA CLOISON DE DROITE.

PROFONDEUR DE

COMPTOIR NORMALE

DE 63,5 CM (25 PO)

OUVERTURE DANS

L’ARMOIREDE61CM(24PO)

*-- 45,7 CM (18 PO) PRÉVUS POUR LES

MODÈLES NON À CHALEUR TOURNANTE.

ENCASTRÉE

*PROFONDEUR

DE DÉCOUPE DE

59 CM (23 1/4 PO)

14 CM (5 1/2 PO)

DE CHAQUE

CÔTÉ

25,4 CM (10 PO)

HAUTEUR

D’ARMOIRE DE

5,7 CM

(2 1/4 PO)

91,4 CM (36 PO)

GAZ RECOMMANDÉ

OUVERTURE

DANS

L’ARMOIRE DE

76,2 CM (30 PO)

ATTENTION :

CERT AINES ARMOIRES BLANCHES DE STYLE EUROPÉEN SONT MUNIES D’UN TIROIR ET DE DEVANTS DE PORTE EN VINYLE

BLANC FRAGILE. LE VINYLE PEUT NE PAS ÊTRE CONÇU POUR SUPPORTER LA CHALEUR PRODUITE LORS DU

FONCTIONNEMENT NORMAL D’UNE CUISINIÈRE À FOUR AUTONETTOYANT. IL PEUT SE PRODUIRE UNE DÉCOLORATION OU UNE

DÉLAMINATION. POUR ÉVITER TOUTE POSSIBILITÉ DE DOMMAGES, IL EST RECOMMANDÉ DE PRÉVOIR UNE OUVERTURE DE

79,4 CM (31 1/4 PO) MINIMUM DANS L’ARMOIRE, AU LIEU DES 76,2 CM (30 PO) NORMALEMENT RECOMMANDÉS, ET D’UTILISER UN

NÉCESSAIRE DE PROTECTION THERMIQUE-CABKIT V. LA DÉCOUPE DANS LE COMPTOIR DOIT RESTER DE 76,2 CM (30 PO).

PRÉVOIR UNE PRISE MURALE DE

120VRELIÉEÀLATERREDANS

CETTE ZONE. LA PRISE DOIT ÊTRE

ENCASTRÉE.

59,2 CM (23 5/8 PO)

ZONE PLATE

PROFONDEUR

D’ARMOIRE DE

61 CM (24 PO)

REMARQUE :

DANS LE CAS DE HAUTS D’ARMOIRE

AVEC UN REBORD AVANT EN RELIEF,

ROGNER LA PARTIE REHAUSSÉE

POUR DÉGAGER LE HAUT.

PROFONDEUR DE

COMPTOIR MINIMUM

DE 63,5 CM (25 PO)

* Lors du remplacement d’un appareil existant, un maximum de 59,7 cm (23 1/2 po) est acceptable. Si la profondeur de la découpe est supérieure

à 59,7 cm (23 1/2 po), utiliser un nécessaire de garniture (K70 Fill).

-2-

Page 25

TOUTE PAROI

COMBUSTIBLE

76,2 CM (30 PO)

76,2 CM

(30 PO) MIN.

(VOIR REMARQUE EN PREMIÈRE PAGE)

45.7 CM

(18 PO) MÍN.

DIMENSION A DÉGAGEMENT LATÉRAL AU-DESSUS DE LA SURFACE DE CUISSON

PRODUCTION DES BRÛLEURS DE LA

SURFACE DE CUISSON POUR LE GAZ

NATUREL (VOIR LA PLAQUE SIGNALÉTIQUE)

9.200 BTU/H OU MOINS

PLUS DE 9.200 BTU/H

91,4 CM

(36 PO)

FOUR TRADITIONNEL

0CM(0PO)

2,54 CM (1 PO)

ARMOIRES D’UNE

PROFONDEUR MAX.

DE 33 CM (13 PO)

AU-DESSUS DE LA

SURFACE DE CUISSON

DÉGAGEMENT NUL (0

CM/PO) ENTRE TOUTE

PAROI EN MATÉRIAU

COMBUSTIBLE

ADJACENTE SE

TROUVANT AU-DESSOUS

DE LA SURFACE DE

CUISSON ET L’ARRIÈRE

ET LES DEUX CÔTÉS DE

LA CUISINIÈRE.

FOUR AUTONETTOYANT

7,6CM(3PO)

7,6CM(3PO)

Vérifier la plaque portant le numéro de modèle de la

cuisinière pour voir si elle est homologuée pour mise en

service dans une maison mobile et/ou un véhicule de

plaisance. Si elle est homologuée pour cet usage, les

points suivants s’appliquent.

MAISONS MOBILES

La mise en service d’une cuisinière prévue pour les

maisons mobiles doit être conforme aux normes

« Manufactured Home Construction and Safety

Standard », titre 24 CFR, partie 3280 (précédemment

« Federal Standard for Mobile Home Construction and

Safety », titre 24 HUD [partie 280]) ou, lorsque ces

normes ne sont pas applicables, les normes « Standard

for Manufactured Home Installations », ANSI

A225.1/NFPA 501A, ou les codes de la construction

locaux.

Au Canada, la mise en service de la cuisinière doit se

faire conformément aux normes CSA C22.1 du code

d’électricité canadien les plus récentes, partie 1 et section

Z240-4.1 relative aux caractéristiques techniques exigées

pour les appareils à gaz utilisés dans les maisons mobiles

(norme CAN/CSA - Z240MH).

VÉHICULES DE PLAISANCE

La mise en service d’une cuisinière prévue pour les

véhicules de plaisance doit être conforme aux codes

provinciaux et autres ou, en l’absence de tels codes, avec

la norme ANSI A119.2 relative aux véhicules de

plaisance, dernière édition.

Au Canada, la mise en service de la cuisinière doit être

réalisée conformément à la norme CAN/CSA - série

Z240.6.2 relative aux caractéristiques exigées pour

l’installation électrique dans les véhicules de plaisance

(norme CAN/CSA - série Z240 RV) et à la section

Z240.4.2 relative aux caractéristiques techniques exigées

pour les appareils et le matériel fonctionnant au propane

dans les véhicules de plaisance (norme CAN/CSA série

Z240 RV).

EMPLACEMENT DE LA CUISINIÈRE

Ne pas placer la cuisinière au-dessus de trous dans le

plancher ou en tout autre endroit où elle sera exposée à

de forts courants d’air. Toute ouverture dans le mur à

l’arrière de la cuisinière et dans le plancher sous la

cuisinière doit être bouchée. S’assurer que le passage de

l’air de refroidissement/ventilation sous la cuisinière n’est

pas entravé.

REMARQUE : Une cuisinière ne doit PAS être placée sur

de la moquette.

-3-

Page 26

ANTI-MISE EN PLACE DU SUPPORT DE STABILISATION

REMARQUE : La cuisinière risque de basculer si elle

n’est pas mise en place conformément aux instructions

fournies. Si le dispositif de stabilisation est utilisé

correctement, il réduit le risque que la cuisinière ne

BASCULE. Même si le dispositif est utilisé correctement,

le consommateur doit observer les précautions indiquées

dans le MANUEL D’UTILISATION ET D’ENTRETIEN et

éviter d’utiliser la porte du four et/ou le tiroir inférieur

comme un tabouret.

Les instructions sont prévues pour un plancher ou un mur

en bois ou en ciment. Un autre matériau pourra requérir

des techniques spéciales, qu’il conviendra de déterminer,

pour assurer la fixation du SUPPORT DE

STABILISATION au mur ou au plancher.

ÉTAPE 1 - Emplacement du support (voir figure 1)

A. Déterminer où le « bord » gauche ou droit de la

cuisinière se trouvera une fois celle-ci en place et le

marquer d’un repère sur le plancher.

B. Placer le SUPPORT à 24 mm (15/16 po) de la

marque « BORD » en allant vers le centre de

l’ouverture et contre le mur arrière tel qu’indiqué à la

figure 1, le trou d’orientation étant contre le mur.

C. Utiliser le support comme gabarit et marquer

l’emplacement de tous les trous pour le type de

matériau sur lequel le support doit être fixé, tel

qu’indiqué à la figure 1.

ÉTAPE 2 - Pose du support de stabilisation

A. Bois :

1. Plancher : Déterminer le centre des deux trous

identifiés par « TROUS POUR PLANCHER » à la

figure 1. Percer un trou de positionnement de

3 mm (1/8 po) au centre de chaque trou (un clou

ou un poinçon peut également être utilisé si une

perceuse n’est pas disponible). Fixer le support

de STABILISATION au plancher à l’aide des deux

vis fournies. Passer à l’ÉTAPE 3.

2. Mur : Déterminer le centre des deux trous

identifiés par « TROUS POUR MUR » à la figure

1. Percer un trou de positionnement en biais de

3 mm (1/8 po) au centre de chaque trou (un clou

ou un poinçon peut également être utilisé si une

perceuse n’est pas disponible) tel qu’indiqué à la

figure 2. Fixer le support de STABILISATION au

mur à l’aide des deux vis fournies tel qu’indiqué à

la figure 2. Passer à l’ÉTAPE 3.

B. Ciment ou béton :

1. On trouve des vis convenant au ciment ou au

béton dans les quincailleries. Percer les trous de

positionnement de la grandeur correspondante à

celle des vis obtenues en quincaillerie au centre

des trous identifiés « TROUS POUR PLANCHER » à la figure 1. Fixer le support de STABILISATION au plancher. Passer à l’ÉTAPE 3.

ÉTAPE 3 - Mise en place de la cuisinière

A. Placer la cuisinière de façon à ce qu’elle puisse entrer

dans l’ouverture où elle sera encastrée et la pousser

en place. S’assurer que le pied de réglage est inséré

à fond dans le support de STABILISATION et que

celui-ci le retient bien. Remarque : Un dégagement

minimum de 6 mm (1/4 po) est exigé entre la

cuisinière et le pied de mise à niveau qui va s’insérer

dans le support de STABILISATION (voir figure 2).

B. Pour des RAISONS DE SÉCURITÉ et pour obtenir

des résultats optimums à la cuisson, régler la

cuisinière de façon à ce qu’elle soit de niveau. Pour

vérifier le niveau, mettre un niveau à bulle ou une

grande casserole d’eau sur la surface de cuisson ou

sur la grille du four. Si la cuisinière amovible doit être

mise de niveau, la tirer vers soi, la faire basculer

légèrement et faire tourner le pied de mise à niveau

autant que nécessaire. La cuisinière encastrée doit

être complètement retirée de l’ouverture dans

l’armoire avant que le réglage ne puisse être fait.

C. Pour vérifier si le support de stabilisation est bien en

place : Regarder sous la cuisinière à l’aide d’une

lampe électrique et vérifier que l’un des pieds arrière

de mise à niveau est bien inséré dans la fente du

support.

D. Finir la mise en service de la cuisinière tel qu’indiqué

dans les instructions de mise en service.

24 MM

(15/16 PO) DU

BORD DE LA

CUISINIÈRE

REPÈRE DU

BORD DE LA

CUISINIÈRE

TROU

D’ORIENTATIO

N

TROUS

POUR MUR

TROUS POUR

PLANCHER

FIGURE 1 FIGURE 2

FIXER LE SUPPORT DE

STABILISATION EN PLACE

AVEC DES VIS LONGUES

SUPPORT DE

STABILISATION

PIED DE

RÉGLAGE

LES VIS

DOIVENT

PÉNÉTRER

DANS LE BOIS

OU LE MÉTAL

-4-

REMARQUE : UTILISER UN MINIMUM DE DEUX (2)

PLAQUE

MURALE

VIS POUR FIXER LE SUPPORTAU

MUR OU AU PLANCHER.

SUPPORT DE

STABILISATION

FIXER LE SUPPORT

AU MUR

GLISSER DANS LE

SUPPORT POUR

STABILISER

BAS DE LA

CUISINIÈRE

0,6 CM

(1/4

PO)

MÍN.

Page 27

RACCORDEMENT DE LA CUISINIÈRE

ALIMENTATION ÉLECTRIQUE

Une fois en place, l’appareil doit être relié à la terre

conformément aux codes locaux ou, en l’absence de

codes locaux, aux normes ANSI/NFPA 70 du National

Electrical Code.

Au Canada, le raccordement de la cuisinière doit être

conforme à la norme ACN C22.1 du Code d’électricité

canadien partie 1.

RACCORDEMENT À L’ALIMENTATION

ÉLECTRIQUE :

La cuisinière exige une alimentation en courant alternatif

120 V et 60 Hz par prise de courant murale. Voir la plaque

signalétique pour déterminer la puissance électrique de

l’appareil.

L’utilisateur pourra occasionnellement avoir des

problèmes de panne de courant si une prise avec

disjoncteur de prise à la terre ou un disjoncteur sont

utilisés.

AVERTISSEMENT