8 ELEMENT - 11 METER

MAXIMUM BEAM

M108C

www.macoantennas.net

MACO M108C

PACKING LIST

PART QTY OD SIZE LENGTH DESCRIPTION CHECKLIST

T01 14 ½” .050” 72” ALUMINUM TUBING ____

T04 2 ½” .050” 80.5” ALUMINUM TUBING ____

T11P 8 5/8” .050” 72” ALUM. TUBING SLOTTED BOTH ENDS ____

T36 1 2.875 .125 48” ALUM TUBING ____

T39 2 3” .060 20’ ALUM TUBING ____

PO4P 1 ¼”x6” 18” PLATE 3” BOOM TO 2” MAST ____

V02P 1 1”x1” 36” VERTICAL GUY SUPPORT W/3 HOLES ____

WD3P 1 6/18 50’ STEEL GUY CABLE ____

G01P 1 GAMMA MATCH ____

Z08P 2 GAMMA STRAPS W/COAX CONNECTOR ____

S42 1 FEMALE COAX CONN. W/MOUNTING NUT ____

HARDWARE BAG #1

S01 5 2” PLATED SADDLES ____

S03 13 3” PLATED SADDLES ____

HARDWARE BAG #2 (DOUBLE BAG)

U01 5 2” PLATED U-BOLTS ____

U03 13 3” PLATED U-BOLTS ____

N03 36 5/16” LOCK NUTS ____

HARDWARE BAG #3

BE3P 8 3” BOOM TO ELEMENT MOUNTS ____

HARDWARE BAG #4

EG2 6 EGG INSULATORS ____

W58P 16 5/8” EXTRUDED ALUMINUM CLAMPS ____

S21 21 10-24 ½” MACHINE SCREWS ____

N11 21 10-24 SQUARE NUTS ____

N12 4 #10 LOCK WASHERS ____

S28 1 ½” 3 ½”” HEX BOLT ____

N15 1 ½” HEX NUT ____

N16 1 ½” LOCKWASHER ____

N17 3 ½” FLAT WASHERS ____

N18 2 5/16” EYEBOLTS-W/ 2 NO1 NUTS EACH ____

PL2 16 .437 PLASTIC CAPS – BLACK ____

PL6 1 3” PLASTIC CAP – BLACK ____

PL6R 1 3” PLASTIC CAP – RED ____

Z02 2 GAMMA STRAPS ____

1 TIP SHEET ____

1 WARRANTY SHEET ____

1 INSTRUCTIONS ____

Please note: In an effort to keep the price on Maco Antennas down, we have decided not to clean up all the

burrs and rough edges on the parts. We recommend that you deburr and clean up each part with files,

sandpaper, etc. so that they go together easily. We are aware this needs to be done but have elected not to

do it to save you the money we would have to add to the price of the kit for this service.

Revised 1/09

DIRECTOR

SECOND

DIRECTOR

REFLECTOR

ELEMENT

BLACK PLASTIC

DIRECTOR

THIRD

DIRECTOR

RADIATION

PLASTIC CAP

(PLGR)

SIXTH

DIREC

DIRECTION

OF

/

RADIATION

RED PLASTIC

CAP (PLGR)

P

63

1-k’

HORIZONTAL POLARIATION

REFLECl

DRIVEN

SECOND

DIRECTOR

1

TOR

BLACK

PLASTIC

CAP

P-6)

VERTICAL POLARIATION

FIGURE 1 GENERAL INSTRUCTIONS

This drawing shows a view of the antenna assembled.

M108C

may be used horizontally or

The

vertically. These instructions and FIGURES 2 through 4 show the correct assembly instructions. It is highly

recommended that rope be put in the elements to prolong their life. All hardware should be tightened

securely, and then coated with silicon rubber sealant or similar compound to prevent loosening from wind

vibration.

Take care to locate all parts accurately per dimensions given. Complete each step as instructed before

going on to following steps.

Upon completion of assembly, install the red plastic cap (PL6R) on the director end of the antenna,

and the black plastic cap (PL6) on the reflector end. This will allow you to determine at a glance the direction

of transmit and receive.

M108C

2

3” BOOM

THREAD GUY WIRE THROUGH

EGG INSULATOR AND TWIST END

DIRECTOR

TWIST END OF GUY

HEX NUT

,EYEBOLT

’

y

1” FROM ELEMENT

‘TW:,END

3”

BOOM

OF

2

END OF GUY

,’ ,v”\.

VERTICAL GUY SUPPORT

LOCKWASHERS

HEX NUTS

BOOM

/

NOTE-

THIS CLAMP DOES

-, ,- m,

I I--

NOT ATTACH TO

*Y-F --

'ntrLH't.

PURE

29

FIGURE 2 BOOM ASSEMBLY

(See figure 2A.) First mark the center of the 2.832” O.D. boom coupler (T35P). Slide both of the

20’ sections of 3” O.D. tubing over the ends of the coupler so they both butt at the coupler center.

(See figure 2B.) Mark the center of the boom to mast plate.

Center the plate (P04) on the boom and

secure with four of the 3” U-bolts (U03) and saddles (S03) and eight of the j/16” lockwashers (N02) and

hex nuts (NOl). Avoid over-tightening the U-bolts as doing so may crush and weaken the boom. Now,

reverse a 3” U-bolt so that it points away from the boom to mast plate. Slide on a 3” saddle, followed by

the vertical guy support, then secure with

5/16”

lockwashers and hex nuts.

From the roll of guy cable (WD3), cut two lengths 2’ long. Take the two eyebolts (N18) and pass

one end of the cable through the eye of the bolt and wrap. Pass the opposite end of the cable through the

hole in the egg insulator

egg insulator is

l’,

then wrap the cable. Make two of these, then place the eyebolts onto the guy support with

(EGl)

and adjust so that the length of cable between the eye of the eyebolt and the

one nut inside and the other nut on the outside of the vertical guy support. Tighten only finger tight at this

time.

3

MlOSC

Please

end of this instruction booklet before assembling elements.

I

read the Assembly and Troubleshooting Tips

at

the

I

BE3 CLAMP

\

b-BOLT

ELEMENT

NUTS AND

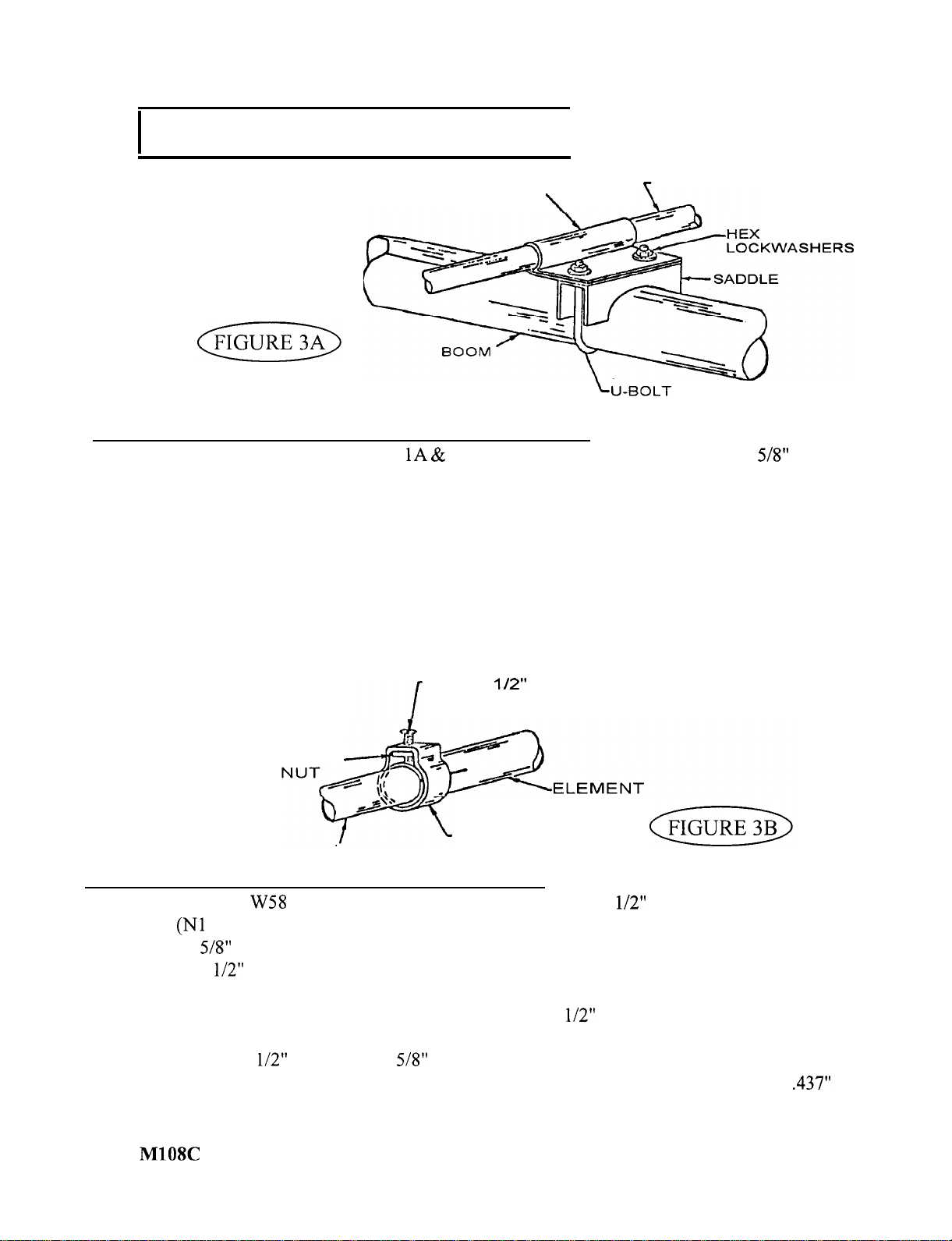

FIGURE 3A ELEMENT CENTER SECTION MOUNTING

Refer to the main sketch (Figures 1A & B) for spacing of the elements. Slide the

5/8”

x 6’ center

sections inside the boom to element mounts. Mount these onto the boom with 3”” U-bolt assemblies as

shown. Refer to Figure 4 (Gamma Match Assembly) before mounting the driven element and note the

position of the coaxial connector assembly. Space the first saddle 1” from the end of the boom. Again,

be careful not to over-tighten the U-bolts. Line up all the sections after mounting with a level or by any

other accurate means. At this time, refer to Figure 2B and complete the boom guy support system.

Allow 6” of cable for the egg insulator wraps and 16” for the wraps around the boom at the boom

to element mounts. Distances shown should be adhered to plus or minus 1”. Pull the sag out of the boom

by tightening the outside nuts on the guy support, then lock the inside nuts against the guy support.

IO-24 x

IO-24 SQUARE

ELEMENT

l/2”

MACHINE

SCREW

W58 CLAMP

FIGURE 3B ELEMENT END SECTION MOUNTING

Assemble the

square nuts

(Nl

position of the

5/8”

W58

clamps as shown in Figure 2B. Thread the l/2” machine screw (S21) into the

1) only slightly at this time. Refer to Figure 4 (Gamma Match Assembly) and note the

metal clamps that will attach the gamma match to the driven position.

Insert the l/2” O.D. x 72” tubing (no slots) into the driven element and director center sections. Slide

on a W58 clamp assembly over each element and tighten slightly.

Assemble the reflector in the same manner by using the l/2” O.D. x 72” slotted one end sections.

At this time, refer to the element length chart on page 7 and set the element lengths. In setting element

lengths, telescope the

telescoped into the next larger size should be 3”. Measure overall element lengths, then push the

l/2”

O.D. into the

5/8”

O.D. by equal amounts. In any case, the minimum length

.437”

plastic caps (PL2) over the ends of the premeasured elements.

black

MlOSC

4

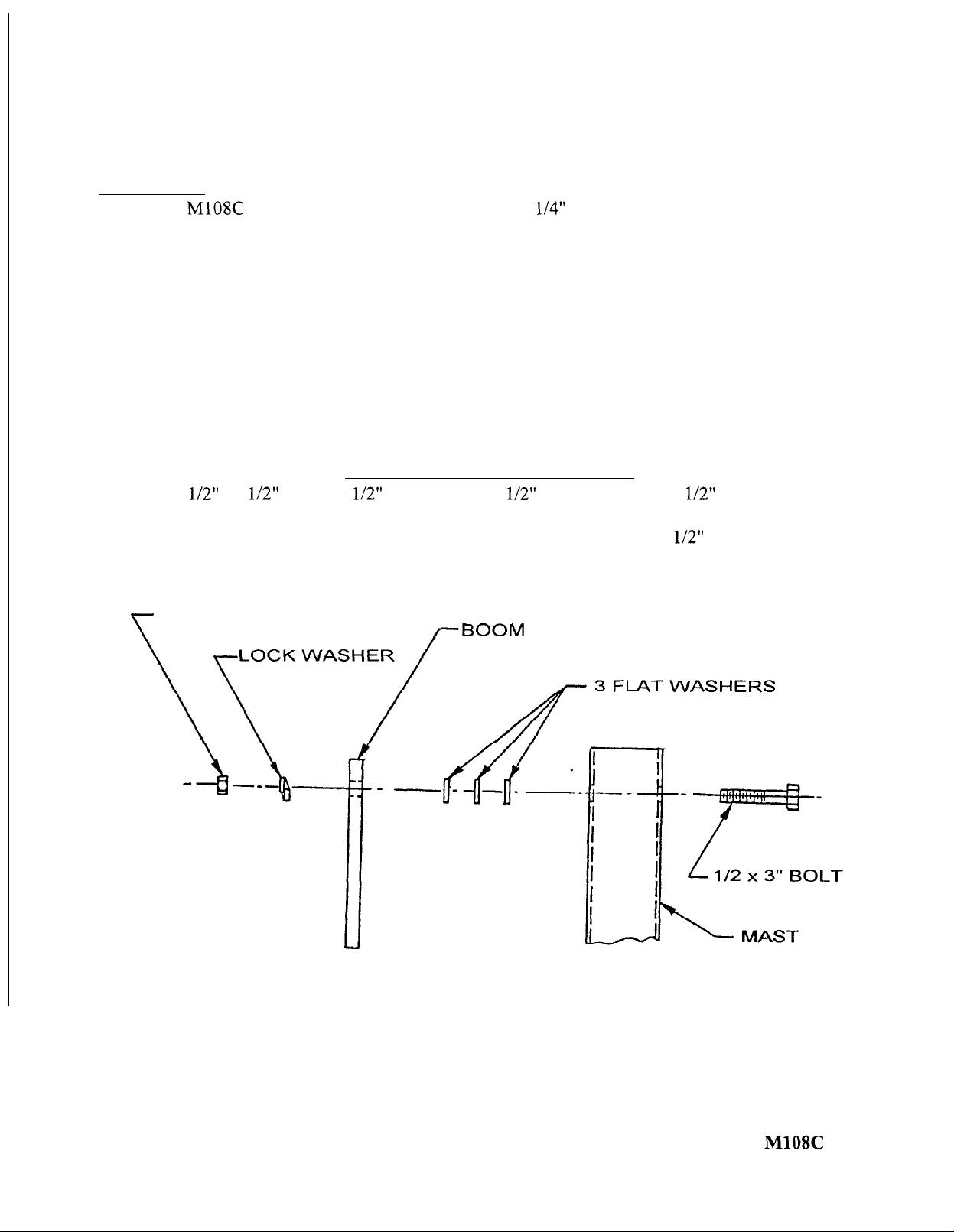

MOUNTING

I

The

M108C

is recommended. If mounted on a guyed tower, break up the guys every 3’ by using egg insulators in the

guy lines for the top 20’ of the guy cables. Also, the guys should be located at least 12’ below the level of

the boom.

of the tower, this should not be attempted unless you are certain that your installation is sturdy enough for

this type of installation.

mounting it 2’ above the top of the tower, or by mounting a rotator so that it lies between the vertical elements.

The first consideration should always be the mechanical stability of the antenna.

to give a tilt feature to the boom, if desired.

Although it may be desirable to mount the antenna on a mast so that the elements clear the top

The l/2” x 3 l/2” hex bolt, l/2” lockwasher, (3) l/2” flat washer cut and l/2” hex nut are provided

A hole will have to be drilled through your mast to accommodate the l/2” bolt.

Place the parts as shown below.

is designed to accept a 2” O.D. mast. A l/4” heavy duty mast designed for this purpose

Experimentation has shown little, if any, effect on the operation of the antenna by

BOOM TO MAST TILT FEATURE

T

NUT

r-BOOM

TO

MAST

PLATE

5

M108C

*

m:

THESE DIMENSONS ARE APPROXIMATE.

REFER TO THE INSTRUCTIONS ON ADJUSTINNG THE

S.W.R. TO DETERMINE EXACT SETTINGS. THERE

ARE2 SEPARATEGAMMA ADJUSTMENTS, 1. CAPACITOR ADJUSTMENT, 2. SLIDER POSITION.

DO NOT MOVE BOTH AT THE SAME TIME. MOVE

THE CAPACITOR FIRST, THEN, IF NECESSARY MOVE

THE SLIDER. AND GO BACK TO THE CAPACITOR.

521,

Nil,

itln-7A Y 1/y SCREWS

., .- -- - .,-

LK.

NUTS

ZO2P

GAMMA STRAPS

(SLIDER)

N12-7

;&SQ.

WSHR5 -

\

DRIVEN

,.N

ELEMENT

318”

24 NUT\

318

STAR-e-(

WASHER

521.

Nil.

‘\

I

I

_

\

-

318

318

#IO-24

LK. WSHRS & SQ.

PLASTIC SHOULDER

WASHER

FLATWASHER

N12

x

I/2”

SCREWS

CABLE

(CUSTOMER

FURNISHED)

-

GO1 P GAMMA MATCH

FIGURE 4 GAMMA MATCH MOUNTING

Mount the gamma match

(GOlP)

to the driven element, using the gamma straps (202,

ZOS)

and attaching

hardware as shown. Attach your 52 ohm coaxial cable to the connector (S42) and dress along boom and down the

mast. The gamma is shown pointing down - this is to let water out.

ADJUSTING THE STANDING WAVE RATIO

(SWR)

Refer to Figure 4. The dimensions given are approximate and should be used as a starting point. * The gamma

match has 2 adjustments. First is the capacitor adjust and second is the slider adjust. Connect a SWR bridge coax

between your transmitter and the antenna and check the SWR. If adjustment is required, loosen the clamp on the

gamma match and the screws holding the slider (gamma straps (202)). Next move the capacitor adjustment first one

direction, then the other until a minimum SWR reading is obtained.

out 2” away from the boom.

Ifthe reading has gone up move the slider

If SWR is not yet satisfactory, move the slider

backto

the original position and

then2”

towards

the boom. Now readjust the capacitor for minimum SWR. You should now be able to determine which direction to

move the slider. Repeat the above procedure moving the slider in smaller increments until a satisfactory SWR is

obtained. Tighten all hardware. Disconnect the SWR bridge and reconnect your coaxial cable.

NOTE!

When assembling for vertical use, set antenna on a pole about 8 to 9 feet above the ground horizontally and

adjust SWR to 1.7. When you turn the antenna vertical and mount it on the tower, etc., the SWR will drop to 1.4 to

1.5. This is good; QUIT! Antenna results best if vertical antenna clears the top of the tower.

7

MlOSC

Installing and rigging towers, masts and antennas require specialized skills and experience. Information

supplied by M

similar products before. No one should attempt to install towers or masts without these knowledgeable skills.

MACO assumes no liability if faulty or dangerous installation practices are used. There are available, trained

and experienced personnel to assist in installation, maintenance, or dissassembly. Contact your local installer if

consultation or assistance is required.

All tower and antenna installations should be throughly inspected at least twice a year by qualified,

experienced, and trained personnel to insure proper performance and safety standards.

An additional warning precaution is given to be careful of surrounding high voltage power wires and other

electrical hazards duing installtion of your tower, rotor, or antenna.

ACO assumes that all products will be installed by personnel having these skills and have installed

Do not erect a tower, rotor, or antenna during an electrical

storm, rainstorm, or when lightning is a possibility.

www.macoantennas.net

(815) 244-3500

MACO Antennas is a Division of Charles Electronics, LLC

Loading...

Loading...