Page 1

INSTALLATION INSTRUCTIONS

HOOD MODELS – LOH36, LOH48 & LOH60

IMPORTANT SAFETY INSTRUCTIONS

PLEASE READ ENTIRE INSTRUCTION BEFORE PROCEEDING.

INSTALLATIONS MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector's use.

INSTALLER: Please leave these Installation Instructions with this unit for owner.

OWNER: Please retain these Instructions for future reference

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK, OR INJURY TO PERSONS, HOODS

SHOULD BE INSTALLED WITH VENTILATORS APPROVED FOR USE WITH THE HOOD. SEE TABLE – 1 ON

THIS PAGE FOR APPROVED VENTILATORS.

WARNING - TO REDUCE THE RISK

OF FIRE, ELECTRIC SHOCK, OR

INJURY TO PERSONS, OBSERVE

THE FOLLOWING:

A. Installation work and Electrical Wiring

Must Be Done By Qualified Person(s) In

Accordance With All Applicable Codes

& Standards. Including Fire-Rated

Construction. “WARNING” To Reduce

The Risk Of Fire, Use Only Metal Duct

Work.

B. Sufficient air is needed for proper

combustion and exhausting of gases

CAUTION - TO REDUCE THE RISK OF FIRE AND TO PROPERLY EXHAUST AIR, BE SURE TO DUCT AIR

OUTSIDE FOR DUCTED FANS – DO NOT VENT EXHAUST AIR INTO SPACE WITHIN WALLS OR CEILING

OR INTO ATTICS, CRAWL SPACES OR GARAGES.

Read this instruction completely before starting installation. Planning the complete installation before starting any work is

highly recommended. This includes all aspects of the installation including hood location, ducting, electrical requirements, and

adequacy of mounting surfaces.

TABLE - 1

Model LOHI = Internal ventilator

Model LOHE = Remote ventilator

DUCTING: Use a minimum 10" round duct for LOHI and LOHE installations. See Page – 3. A standard starting transition

(33895) is included with the Hood.

SAFTY WARNING:

Turn off power circuit at the service entrance and lockout panel before wiring the range hood.

through the flue (chimney) of fuel

burning equipment to prevent

backdrafting. Follow the heating

equipment manufactures guideline and

safety standard such as those published

by the National Fire Protection

Association (NFPA) and the American

Society for Heating, Refrigeration and

Air Conditioning Engineers (ASHRAE),

and the local code authorities.

C. When cutting or drilling into wall or

ceiling, do not damage electrical wiring

and other hidden utilities.

This hood series has been designed to be used with the ventilators shown in Table – 1. Before

cutting into cabinets, it is necessary to confirm that the correct ventilator is being used. Your

dealer should have reviewed your needs prior to your purchase. Be sure you have the correct

ventilation system.

CAUTION: To Reduce The Risk Of Fire And Electrical Shock, Install This

Rangehood Only With Blowers Manufactured By Lynx Professional Grills.

D. Ducted fans must always be vented to the

outdoors.

E. Before Servicing or Cleaning Unit,

Switch Power off At Service Panel And

Lock Service Disconnecting Means to

Prevent Power From Being Switched On

Accidentally. When The Service

Disconnecting Means Cannot be Locked,

securely Fasten A Prominent Warning

Device, Such As A Tag, To The Service

Panel

NOTE: Unit must be vented

to the outside of the building.

Page 1 of 8 P/N 11857.00 Rev A

Page 2

BEFORE STARTING INSTALLATION, YOU MUST IDENTIFY THE VENTILATOR MODEL BEING USED AND

IF A TOP OR REAR EXHAUST IS TO BE USED.

Prepare cabinet and/or wall for mounting either top (Fig - 1)

or rear (Fig 6 & 7) exhaust. Use furring strips to level cabinet

mounting surface with any cabinet trims.

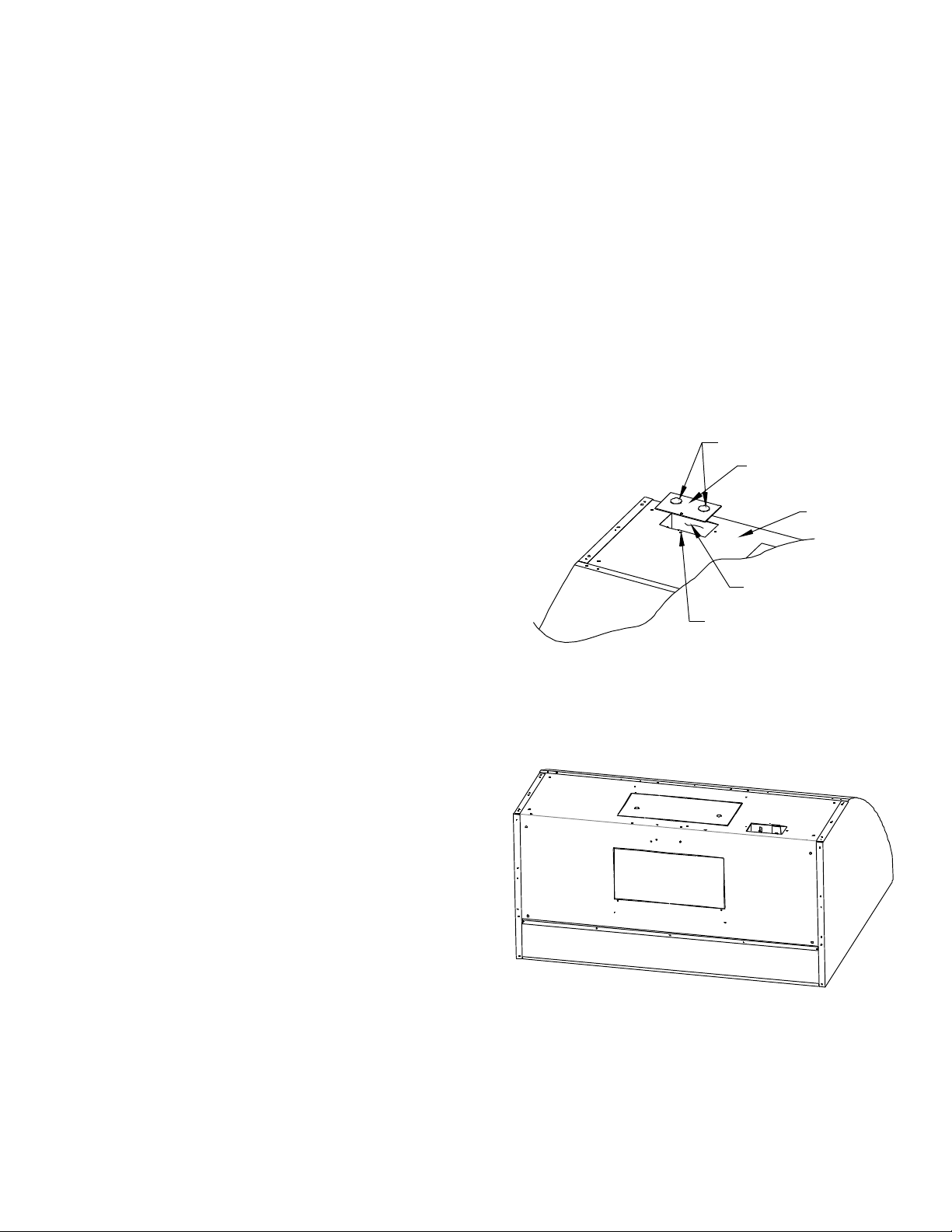

For knock out removal see Fig- B

Ventilator Model

Knock out

Remove

Transition

#

#

See

Fig

LOHI Top Exhaust 1 33895 1,2,3

LOHE Top Exhaust 1 33895 1,2,3

LOHI Rear Exhaust 2 33895 4,5,6,7

LOHE Rear Exhaust 2 33895 5,6,7

LOHE ventilator will require revision of some wiring in the

hood receptacle box - See LOHE instructions.

NOTE: LOHE requires a dedicated 20 AMP Power

Supply. All other ventilators require a dedicated

15 AMP Power Supply

CAUTION: The hood is of sufficient weight that two

installers are recommended to prevent injury or damage to the

hood in handling.

Turn the power on at the service entrance and check the

operation of the controls.

NOTE: be sure that all dampers are operating properly and

are free to open.

Break the metal webs by placing a screwdriver at one corner

of the plate and hitting screwdriver sharply with a hammer.

After breaking a second web the plate can be flexed to break

other webs.

Wear eye protection when using tools.

RECEPTACLE BOX COVER

Knock Outs

Cover

Caution: When knock outs are removed the edges will be

sharp! Sharp Edges should be Filed or Covered with

Hood Top

Metal Tape.

Attach and secure the transition to the hood with #6x3/8 sheet

metal screws and tape all joints prior to installing the hood.

Attach hood to cabinet using #10 wood screws. Holes are

located in the back panel and top panel of the hood for

mounting. Use a minimum of four #10x3/4 wood screws to

Hood Wiring Access

Mounting Screw

mount the hood. Longer screws are required if wall board or

other nonstructural surfaces are used between the hood and

main mounting surface which should be a minimum of 3/4”

thick. When using rear holes for additional mounting use

appropriate anchors if not engaging the wood structure.

HINT: If you find vibration noise is present because of

Remove Appropriate Knock Outs and Connect Wiring

According to Hood and Blower Installation Instructions.

CAUTION: Always Install Receptacle Box Cover.

Fig – A

cabinet structure use additional screws, in holes available, to

make the mounting more ridged.

Connect 120 volt, 60 Hz power through the conduit hole in

1

top of hood, connecting to pigtail in hood junction box, white

to white, black to black and connect green ground wire to the

power supply ground wire per local codes. See Fig – A.

2

NOTE: Recommended height over BBQ Grills = 36

inches.

Hood is recommended for use over domestic gas or electric

appliances. Not recommended for use over solid fuel fired

appliances.

Fig - B

After installing the hood, install the internal blower (Top

Exhaust See Fig 2; Rear Exhaust See Fig - 4) unit by

positioning the blower onto bracket-A, notched blower

bracket will center blower. Rotate into position against hood

and secure Bracket – B to Hood with #8 sheet metal screws.

If the remote ventilator is used see related instructions. The

Page 2 of 8 P/N 11857.00 Rev A

Page 3

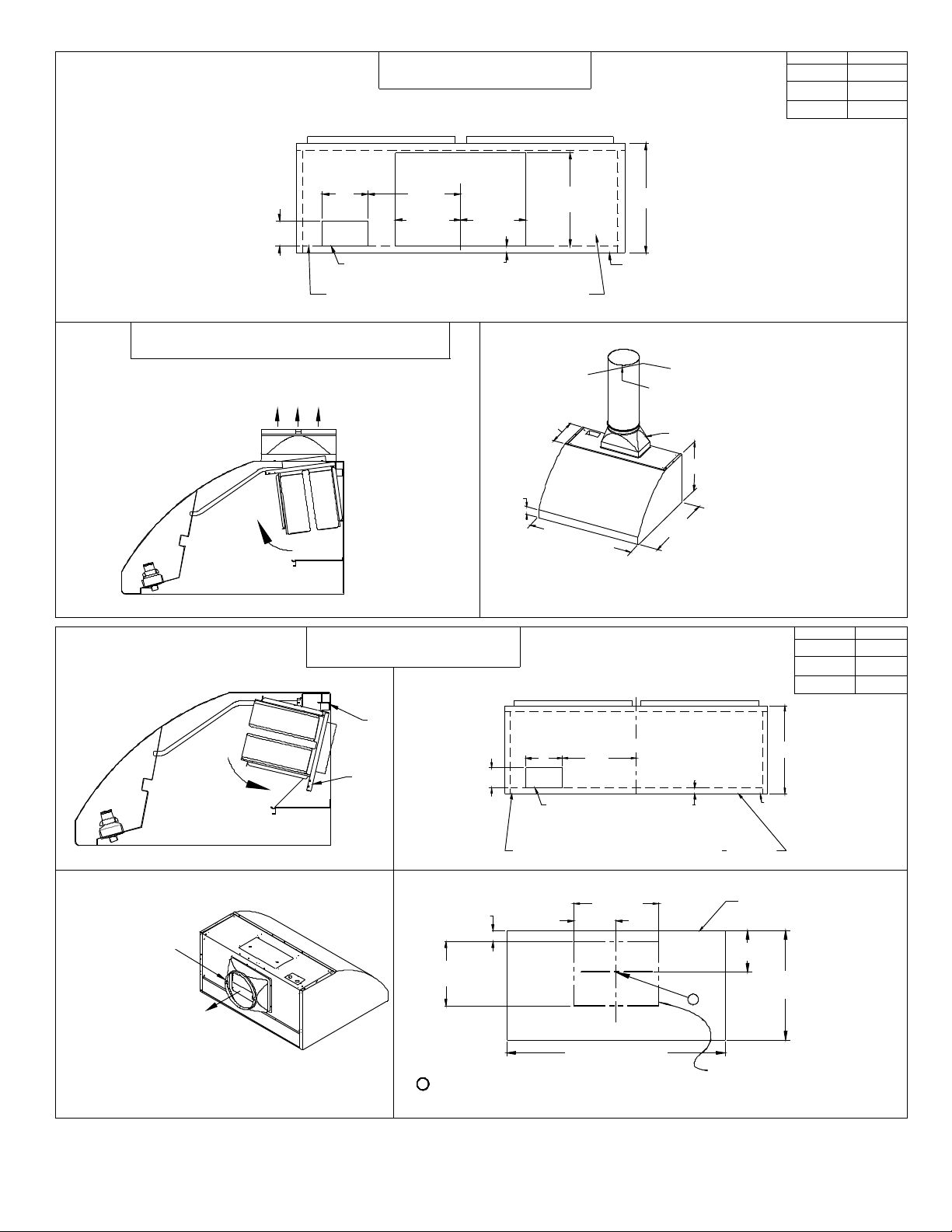

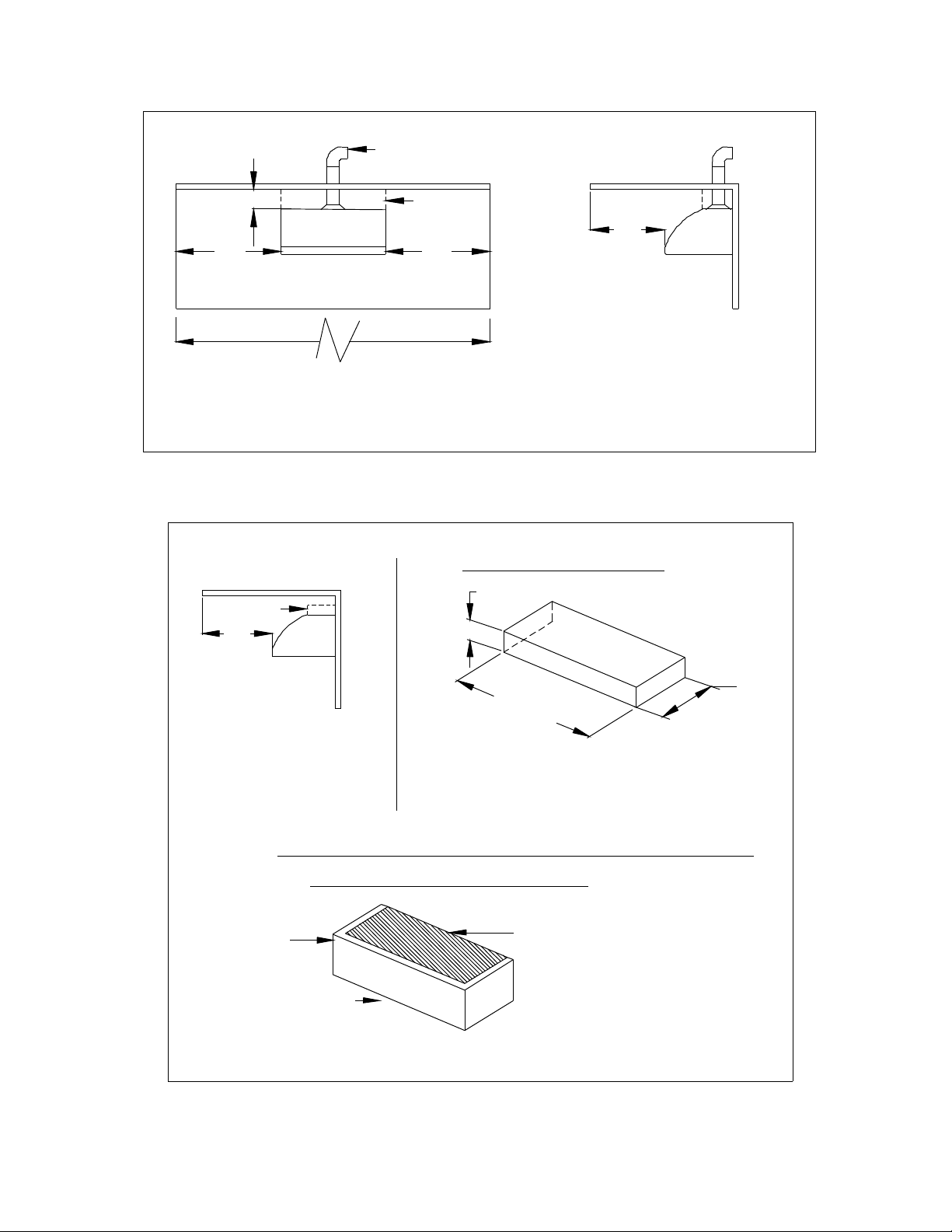

FIG-1

4"

HOOD MODELS LOHI

TOP EXHAUST

Bottom View Of Cabinet -

Internal Or Remote Blowers

C

5" "A"

L

7-1/8"

7-1/8"

10-1/4"

Hood Width

36"

48"

60"

12"

Dim "A"

10-3/8

14-3/8

20-3/8

FIG-2

Remove Knock Out # 1

Sheet Metal Screws. Tape All Joint & Seams

Air Flow

LOHI

Rotate

Into

Position

& Secure

With 2 Screws

Secure Transition To Hood Using #6 X 3/8"

FIG - 4

Remove Knock Out # 2

LOHI

Rotate

Into

Position

& Secure

With 2 Screws

FIG - 5

Use # 33895

Transition

To 10" Duct

Or Wall Cap

Route To Outside

W/Wall Cap - LOHC

Secure Transition To Hood Using #6 x 3/8"

Sheet Metal Screws. Tape All Joints And Seams.

Wiring Access

3/4"

Add Furring Strips To Provide An Even

Bottom Surface For The Hood Mounting

Use # 33895

Transition

To 10" Duct

12"

3"

All Hoods

The 10" Discharge With Transition

Will Be On The Center Line Of Hood Width

And On Center Line of 12" Dimension.

HOOD MODELS LOHI

REAR EXHAUST

FIG - 6

Bottom View Of Cabinet

Internal Or Remote Blowers

A

5"

B

FIG - 7

10-1/2"

A

Center Of Round Duct Using

Transition

4"

Wiring Access

Add Furring Strips To Provide An Even

Bottom Surface For The Hood Mounting

Rear Exhaust

1-3/4"

Width Of Hood

Back Wall

Vertical Discharge

10" Duct to

Discharge W/Roof Cap

Transition # 33895

30"

C

L Top Of Hood

"A"

3/4"

14-1/2"

7-1/4"

C

L Of Hood

18"

Hood Width

36"

48"

60"

12"

Back Wall

Top Of Hood

7-1/8"

A

18"

Cut Hole In Drywall

To Accept Transition # 33895

FIG - 3

Dim "A"

10-3/8

14-3/8

20-3/8

Page 3 of 8 P/N 11857.00 Rev A

Page 4

Outside Patio or Lanai Installation

Construction methods and installation shall comply with all local building codes. Internal

ducting shall be sealed using outdoor rated metal duct tape.

The LYNX hood with stainless steel canopy is approved for installation in an outside patio or lanai area if the area

is covered with a protective roof over the hood (wall style hoods are to be also mounted to a solid protective rear

wall) and installed with a GFCI protected branch circuit. Roof or Wall Caps are to be sealed to prevent moisture

migration to structure interior; use an outdoor rated sealant suitable for adhesion to the installation materials. See

Fig-8 for rear exhaust installation and Fig-9 for top exhaust installation.

Wall Cap

A A

B

Rear

Exhaust

A = 42" Minimum B = 30" Minimum

Front View

Fig - 8

See Fig – 10 for structure with elevated roof/ceiling.

The Roof shall cover the top of the hood and extend a minimum of 42” from each side of the hood and 30”

minimum from the outer most edges of the hood front.

Since, outdoor areas are subject to strong cross drafts it is recommended that the hood extend at least 3 – inches, and

preferably 6 – inches, over either side of the cooking area to maximize the cooking discharge capture area. Cross

drafts will affect the efficiency of the ventilation system and cooking discharge can escape capture by the

hood/ventilation system. Be sure to plan for adequate ventilator (blower) capacity to minimize cross drafts

influencing the removal of cooking discharges.

Side View

Page 4 of 8 P/N 11857.00 Rev A

Page 5

The installation instruction that accompanies the hood shall be followed to ensure all safety Instructions and

guidelines are adhered to. NOTE: Hood is recommended for use over domestic gas or electric appliances. Not

recommended for use over solid fuel fired appliances. See Fig-10 for soffit construction

12"

Roof Cap

Soffit

B

A

A

Top

Exhaust

B = 30" MinimumA = 42" Minimum

Front View

Side View

Fig - 9

See Fig – 10 for structure with elevated roof/ceiling.

For installations with elevated Roof/Ceiling use a Soffit, or optional stainless steel extension

Constructed Soffit

MIN

4"

Soffit

B

Top

Exhaust

12"

Hood Widths

B = 30" Minimum

Side View

Soffit Top, Sides

& Front Shall Be

Enclosed. Fasten

To Top Of Hood

Stainless Canopy Extension

Canopy

Extension

Fasten Wall Board

Panel To Underside

Of Top Flange

Fasten To Top

Of Hood

Fig - 10

Soffit shall be constructed of materials suitable for outdoor installation and be sealed to prevent moisture migration

to structure interior.

Page 5 of 8 P/N 11857.00 Rev A

Page 6

NOTE: 4-1/4” Tall Starting Transition is Included with the Hood.

Transition dimensions may very. Before assembling transitions to hood, fit them into

the prepared cabinet opening to be sure the openings are large enough to accommodate

4-1/4"

the transition. Enlarge the hole if required

Attach the transition (See DUCTING, pg 1), supplied with hood as described previously

in this instruction.

14-1/4"

Transition # 33895

INSTALLATION and USE & CARE INSTRUCTIONS

BAFFLE FILTER KIT

INSTALLER:

1. You are now ready to install the baffle filters. Remove all packaging and the protective plastic covering

from the filters.

2. Grasp the filter by the center baffle, see FIG-11, with the spring end facing you and the grease collector

channel facing down and toward the rear of the hood. Position the spring end of the filter into the upper

channel of the front escutcheon, compress the spring by pulling the filter toward you and rotate the rear of

the filter up and into the rear retaining recess formed by the rear escutcheon and retaining clip.

Release the filter, being sure it is positioned properly in the channels. You should be able to push up and pull

down on the filter without having it come out of position. You can bend the spring slightly outward if the

filter is not pressing securely against the rear escutcheon.

3. The filter has an integral grease collector and is dishwasher safe. To clean your filter simply grasp the filter

by its center baffle, pull toward the front of the hood and rotate the rear of the filter down and away from the

hood, see FIG-12.

4. For best dishwasher results, position the filters in the dishwasher rack with the baffles positioned

horizontally.

Please leave these Installation Instructions with unit for the owner.

10-3/8"

Spring

1

Position

In Upper

Channel

Wrong

Fig - 11

2

Pull

3

Rotate UP & Into

Retaining recess

Grease

Collector

Channel

Rotate Down

1

Fig - 12

Pull

2

3

Remove Filter

Page 6 of 8 P/N 11857.00 Rev A

Page 7

HOOD

2

(4) LIGHT

18 W # 5C

1

LIGHT

RIGHT

MODELS WITH

18 B # 8B

LOHI

18 B # 2

18 R # 4

MOTOR

BLOWER

INTERNAL

18 Red

18 Blue

18 Black

18 White

2

3

1

1

4

2

3

4

18 BL # 3

3-SPD

ROTARY

1

A

SWITCH

3

2

B

18 B # 8A

18 W # 5B

18 B # 24

18 W # 25

18 R #22

18 BL # 23

BOX

RECEPTACLE

18 B #12

18 G #11

L1

18 W #13

12 B # 1

18 B # 6

6

3

5

2

4

1

18 W # 5A

18 B # 7A

SWITCH

LIGHT

LEFT

LIGHT

1

18 W # 9A

Wiring Diagram - Internal Blower & Lighting

Included With LOHE Blower

See Wiring Diagram For External Blower

G

N

18 W # 15

POWER SUPPLY

18 W # 9B

18 B # 7B

2

(4) LIGHT

MODELS WITH

Page 7 of 8 P/N 11857.00 Rev A

Page 8

Lynx Professional Grills

6023 E. Bandini Blvd.

Commerce, CA 90040

Service: (888) Buy-Lynx

(888-289-5969)

www.lynxgrills.comwww.lynxgrills.com Fax: (323) 838-1778

Page 8 of 8 P/N 11857.00 Rev A

Page 9

Installation Instructions

Model: LOHE

Ventilator for External Installation

IMPORTANT SAFETY INSTRUCTIONS:

READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING. Installation must comply with all applicable

codes.

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

a) Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b) Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means to prevent

WARNING: TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE

WARNING - To Reduce The Risk Of Fire Or Electric Shock, Do Not Use This Fan With Any Solid-State Speed

CAUTION:

CAUTION – For General Ventilating Use Only. Do Not Use To Exhaust Hazardous Or Explosive Materials And

NOTE: THESE INSTRUCTIONS DESCRIBE THE INSTALLATION OF THE LOHE REMOTE

Page 1 of 4 P/N 11864.00 Rev A

READ AND SAVE THESE INSTRUCTIONS

IMPORTANT: Save for local electrical inspector's use.

INSTALLER: Please leave these instructions with this unit for the owner.

OWNER: Please retain these instructions for future use.

FOLLOWING:

power from being switched on accidentally. When the service disconnecting means cannot be locked, securely fasten a

prominent warning device, such as a tag, to the service panel.

THE FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable codes

and standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety standards

such as those published by the National Fire Protection Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d) Ducted fans must always be vented to the outdoors.

Control Device

To reduce the risk of fire and to properly exhaust air, be sure to exhaust air outside. Do not exhaust air

into spaces within walls or ceiling or into attics, crawl spaces or garages.

Vapors.

VENTILATOR WITH A LYNX HOOD. IF USED WITH ANOTHER MANUFACTURER’S HOOD,

REFER TO THEIR SPECIFICATIONS FOR POWER REQUIREMENT COMPATABILITY.

LOHE: 1-HP 3-SPEED MOTOR, 115V AC, 60Hz /20 Amp CIRCUIT REQUIRED

Page 10

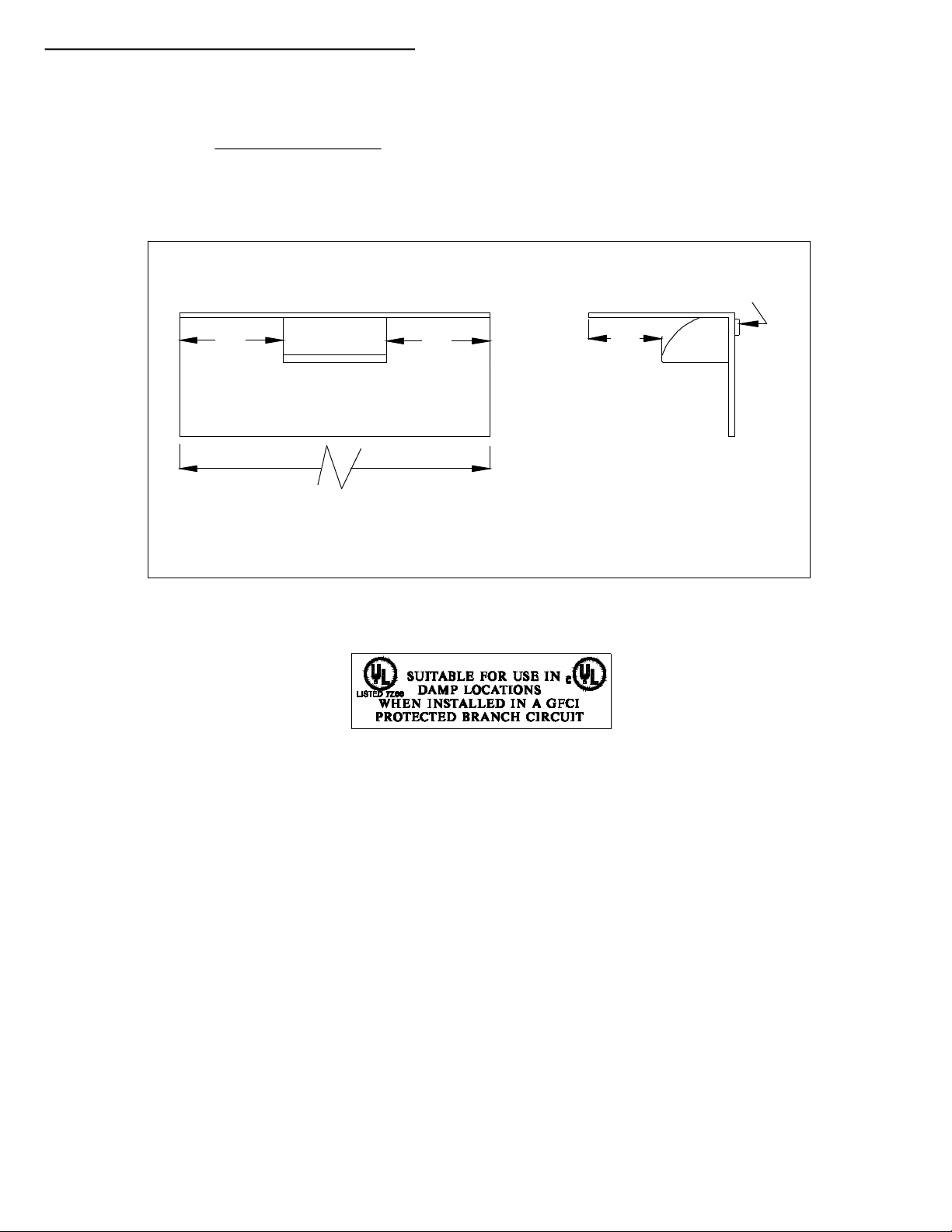

1. Provide square hole through the roof or wall as shown by dash lines for conduit as shown in Fig-2. For reference,

location of 10" duct connection and wiring connection is shown with solid lines.

2. Remove shipping bracket per separate instruction. SEE PAGE - 2

3. Install ventilator on roof or wall, with discharge (screened end) pointing down, according to STANDARD ROOFING

PROCEDURES. Note: Front discharge edge should be on top of shingles and rear and side edges under shingles. Note:

Unit must be sealed between roof or wall and underside of flange with roofing mastic to prevent leaks. For installation

on a flat roof, or roofs with pitch of less than 1-1/2" in 12", install ventilator on curb as shown in Fig-3. Position

curb on sloping roof with 2" dimension facing down slope. Position curb on flat roofs so that discharge (screened

end) points away from prevailing wind.

4. Connect the ventilator to exhaust system with a 10" diameter metal duct only. Use 10" adjustable elbow to adjust to roof

angle. Tape and screw all joints to prevent air leaks. See Fig-4.

5. Remove top cover of ventilator to access wiring connections. Retain mounting screws.

6. Run electrical conduit per local code to conduit outlet in bottom plate of ventilator (use liquid tight connection). Other

end of conduit will connect to electrical box in your LYNX hood. See hood installation instructions for hood wiring

location. See Fig – 6.

7. Run four (4) 16 ga wires in conduit (1-black, 1-white, 1-blue and 1-red) between the ventilator and hood. Check for

local code compliance. The ground wire should be 16 ga wire. See Fig-6 for wiring details. Check for local code

compliance.

8. Dimensions of ventilator are shown in Fig-5.

9. When connecting the hood to power supply, replace the black-#12 wire and white-#13 wire on hood with the wires

supplied with the remote blower.

Power supply for the LOHE plus hood requires a 120v, 20 amp, 60 Hz circuit, connected per local codes.

10. Rotate ventilator blower wheel to be sure it turns freely and does not rub on motor brackets. Check damper door to be

sure it moves freely and spring returns door to closed position.

11. Check screen guard to be sure it is in position and secure.

12. Replace cover removed in Step-4 and secure with screws provided. All screws must be in place on cover.

13.

See Fig-1 for typical hood installations.

Check for removal of shipping bracket.

ATTENTION INSTALLER

Remove

*************************

Remove

*************************

Remove

Attention Installer

Remove Shipping Bracket

And Wood Supports

Before Installing

Page 2 of 4 P/N 11864.00 Rev A

Page 11

FIG - 1

TYPICAL INSTALLATION

Roof Mount

10" Elbow

10" Duct

10" Transition

FIG - 2

14"

Air

Discharge

18"

Roof

Hood

Top View

Down Slope

of

Roof or Wall

10" Elbow

10" Transition

Hood

Outside Wall Mount

FIG - 3

2"

Air

Discharge

Outside Wall

1-1/2"

6"

10-1/2"

1-1/2"

Air

Discharge

4-1/2"

Conduit

7-3/4"

FIG - 4

10" Adjustible

Elbow

Screw and

Tape Joint

10" Diameter

Duct

2"

24"

5-5/8"

8"

24"

FIG - 5

10-1/4"

10" Duct

Connector

1-5/8"

7-1/2"

8"

30"

3"

4"

30"

7-1/8"

2-3/4"

Page 3 of 4 P/N 11864.00 Rev A

Page 12

Power Supply

N

G L1

18 G #11

18 W #13

18 B #12

Hood

Receptacle

Box

FIG - 6

18 W #25

18 B #24

18 BL #23

18 R #22

Receptacle

Plug

1

1

2

2

3

3

4 4

1. Remove Shaded Twist Ons

2. Remove Wires At Receptacle

Junction Box

Remote Blower

18 R #4

12 B #1

18 W # 15

Change #12 & #13 TO 12GA Wire (Supplied)

Model LOHE Only

Power Supply

N G L1

Hood

Receptacle

Box

18 B #2

18 BL #3

White

Capacitor

Green

Black

Yellow

Yellow

Blue

Red

Conduit

12 B #12

18 G #11

1 1

2

2

12 W #13

3 3

44

12 B #1

18 W # 15

18 R #4

18 B #2

18 BL #3

Motor

A. Access the hood junction box, remove the designated twist on connectors.

B. Access the remote blower wiring box by removing the top cover, set aside screws for later use.

C. Run four wires per local code, in conduit from remote blower to hood.

NOTE: maintain white, black, blue and red color code from blower wiring box to hood connections.

D. Connect 4-wire from blower to hood with twist-on connectors from step – A; remote white to #13 & 15, remote black to

#24 black, remote blue to #23 blue and remote red to #22 red.

NOTE: When connecting the hood to power supply, replace the black #12 wire and white #13 wire on hood with the 12

ga. wires supplied with the ventilator. See Fig – 6.

When remote blower is to be grounded to the Power Supply Main Ground use appropriate wire gage per local

codes. See Fig – 6.

If the blower is grounded through the Hood the 16 ga Green Pigtail wire at the hood Must Be Changed to 12

Ga, or Appropriate Wire Gage to Comply With Local Codes.

CAUTION: To prevent malfunction and/or harm to electrical components, connections are to be made per diagram and

instructions.

E. Check rotation of blower wheel to be sure it rotates freely and does not rub brackets.

F. Replace blower top cover and screws from step – B.

Lynx Professional Grills

6023 E. Bandini Blvd.

Commerce, CA 90040

Service: (888) Buy-Lynx

(888-289-5969)

www.lynxgrills.comwww.lynxgrills.com Fax: (323) 838-1778

Page 4 of 4 P/N 11864.00 Rev A

Page 13

Remove parts from carton. Remove all corrugated packaging shims between motor and

INSTALLATION INSTRUCTION

CAUTION: Before installing ventilator read the HOOD INSTALLATION

INSTRUCTIONS.

PARTS INCLUDED: 1 - Ventilator Assembly

4 - #8 x ½ Pan Head SMS

1 – Wire Harness (#33896)

1 – Wire Tie

A

LOHI

1) Install Hood & Transition per hood installation instruction.

2)

housing.

3) Rotate ventilator wheels to confirm they rotate freely.

4) Connect Wire Harness #33896 to Hood Receptacle Box.

5) Install ventilator per HOOD INSTALLATION INSTRUCTION using 2- screws.

6) Connect Ventilator to Hood Receptacle Plug on Front Panel using Wire Harness #33896, (if required

excessive wires shall be attached to blower body flange notch at point - A using wire tie, twist wire 3

to 4 times to secure excess wire – see picture).

7) Check operation of ventilator per HOOD INSTALLATION INSTRUCTIONS.

IC

GREY

BLACK

MOTOR

YELLOW

WHITE

GREEN

BODY

GREEN

MOTOR

GREY

WHITE

BLACK

IC

WIRING

LOHI

Lynx Professional Grills

6023 E. Bandini Blvd.

Commerce, CA 90040

Service: (888) Buy-Lynx

(888-289-5969)

www.lynxgrills.comwww.lynxgrills.com Fax: (323) 838-1778

Page 1 of 1 P/N 11863.00 Rev A

BLUE

RED

RED - MED

BLUE - HI

WHITE

BLUE

RED

YELLOW

BLUE

RED

YELLOW

YELLOW - LO

WHITE - COM

WHITE

BLACK

RED - LO

BLUE - MED

BLACK - HI

WHITE - COM

BLUE

RED

WHITE

WHITE

WHITE

WHITE

TO HOOD

RECEPTACLE

PLUG

WIRE HARNESS

P/N 33896

Page 14

INSTALLATION INSTRUCTIONS

GRAVITY DAMPER AND COLLAR WITH

BIRD SCREEN

INSTALLER:

Please leave these Installation Instructions with unit for the owner.

PART # LOHC

Do not force shutter into opening!, Do not open shutter by lifting individual blades!.

Do not install shutter leaning forward or backward!

1. Shutter frame should be mounted level and squarely on outside wall. Care should be taken not to

twist the shutter frame. Never cover shutter with siding or masonry work. Shutter should be

mounted so it can be removed any time in case of damage.

2. Shutter should operate as freely after installation as it did before.

3. CAUTION: Shutter flaps must open in the direction of airflow.

4. Caulking compound is recommended between shutter frame edges and the wall.

If Siding is present it should be made to overlap Damper Flashing on top & sides.

5. Clean and lubricate shutter at the same time that the fan is clean.

6. Tape the joint with a high-grade duct tape or metal (preferred) tape.

7. Check installation for proper fan operation – shutter flaps must Open with fan ON and Close with

fan OFF.

OUTSIDE

OF WALL

SHUTTER

MOUNTING

SCREWS

(NOT INCLUDED)

DO NOT TIGHTEN

MOUNTING SCREWS

TOO TIGHT

INSIDE OF

WALL

METAL DUCT 10" ROUND

FITS INSIDE BIRD SCREEN

DIRECTION OF

AIR FLOW

COLLAR

WITH BIRD

SCREEN

Lynx Professional Grills

6023 E. Bandini Blvd.

Commerce, CA 90040

Service: (888) Buy-Lynx

(888)-289-5969

www.lynxgrills.comwww.lynxgrills.com Fax: (323) 838-1778

P/N

Page 15

HOOD EXTENSION KITS

INSTALLATION INSTRUCTIONS

LHE636, LHE1236 / LHE648, LHE1248 / LHE660, LHE1260

CAUTION: Read this instruction and your hood installation instruction before starting installation. Plan the

complete installation before starting any work. This includes all aspects of the installation

including hood location, ducting, electrical requirements and adequacy of mounting

surfaces.

NOTE: The duct and electrical connection cutouts, when using a canopy extension, are to be per this

instruction and not those described in the hood installation instruction.

1. Prepare ceiling opening to accept duct and transition installation per Fig - 1.

Locate the 120 volt, 60 Hz power supply in the crosshatched area “A”. You can increase the total

opening by the area, “A” which will allow access to the hood junction box from the space above the

ceiling.

2. To prepare the wall for hood mounting, locate the four (4) mounting holes (7/32 Dia.) in the hood back

and layout the hole pattern on the wall.

Note: Use # 10 screws to fasten hood to wall framing or wall anchors and #10 screws if framing

is not present. Do not screw into wallboard.

HINT: You can mount the canopy extension to the hood, position hood against wall/ceiling, and mark

the mounting hole locations on the wall.

3. Lay hood in its back surface, position canopy extension on the hood top and secure with six (6) #8- SMS

provided, three (3) on each side. See Fig - 2.

4. Install transition to top of hood per instructions supplied with same.

5. Position hood, as prepared above, and secure with (4) #10 screws (see step-2).

6. Complete the electrical connections, duct connections and install ventilator per hood installation

instructions. Turn power on and check all operations.

Fig - 1

" A "

NOTE: Provide Cutout In Ceiling for

Transition/Ducting

Center Of Transition/Ducting

Ceiling

6"

C

Of Hood

L

Wall

Fig -2

Extension

Hood

Screw From

Inside Of Hood

Loading...

Loading...