Page 1

MAKE THE MOST OF YOUR

LM15ICER

OUTDOOR CLEAR ICE MACHINE

CARE & USE/INSTALLATION

Page 2

CONTENTS

Contents:

Warranty registration ..........................................................2

Safety information ...............................................................3

Unpacking your appliance ..................................................3

Installing your appliance ......................................................4

Leveling the appliance ....................................................4

Cabinet clearances .........................................................5

Electrical connection ......................................................5

Installing the drain plumbing ...............................................6

Gravity drain ...................................................................6

Drain pump .....................................................................7

Installing the water supply ...................................................8

Drain System Test .................................................................9

Ice maker operation ..........................................................10

Product dimensions ..........................................................12

Using your Electronic control ............................................14

Starting your appliance ..................................................14

Turning your appliance "ON" or "OFF" ..........................15

Control lock ...................................................................15

Door ajar alarm.............................................................15

Delay start / Vacation mode .........................................15

Error codes ...................................................................16

Options menu ...............................................................16

Normal and eco mode .............................................16

Cleaning your ice machine ..............................................17

Clean reminder ............................................................17

Clean mode ...............................................................17

Care and cleaning .............................................................19

Energy saving tips ............................................................19

Obtaining service .............................................................19

Troubleshooting the ice machine .....................................20

Preparing the ice machine for storage ...........................22

Drain pump removal .........................................................25

The Lynx Story ...................................................27

Warranty Registration:

It is important you send in your warranty registration card

immediately after taking delivery of your appliance or you

can register online at:

www.lynxgrills.com/support/registration

The following information will be required when registering

your appliance.

Model Number

Serial Number

Date of Purchase

Dealer’s name and address

The service/model number and serial number can be found

on the serial plate which is located inside the cabinet on the

left side near the top. (See Figure 1).

XXXXXXXXXXXXXX

XXXXXXXXXXXXXX

XXXXXXXXXXXX

Figure 1

CARE AND USE/INSTALLATION

2

Page 3

SAFETY INFORMATION AND UNPACKING YOUR APPLIANCE

Important Safety Instructions

Warnings and safety instructions appearing in this guide are not meant to cover all possible conditions and situations that

may occur. Common sense, caution, and care must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

!

WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!

CAUTION

CAUTION-Hazards or unsafe practices which could

result in personal injury or property / product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding

internal components in place. The owners manual is

shipped inside the product in a plastic bag along with the

warranty registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance

has been thoroughly inspected and found to be in good

condition. If there is damage, the packaging will be needed

as proof of damage in transit. Afterwards please dispose of

all items responsibly.

!

WARNING

WARNING - Dispose of the plastic bags which can

be a suffocation hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

CARE AND USE/INSTALLATION

3

Page 4

INSTALLING YOUR APPLIANCE

!

CAUTION

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the

appliance to sit upright for a period of at least 24 hours

before plugging in. This will assure oil returns to the

compressor. Plugging the appliance in immediately may

cause damage to internal parts.

!

WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous - even if they sit out for "just a few hours".

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent

accidents.

Before you throw away your old refrigerator or

freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

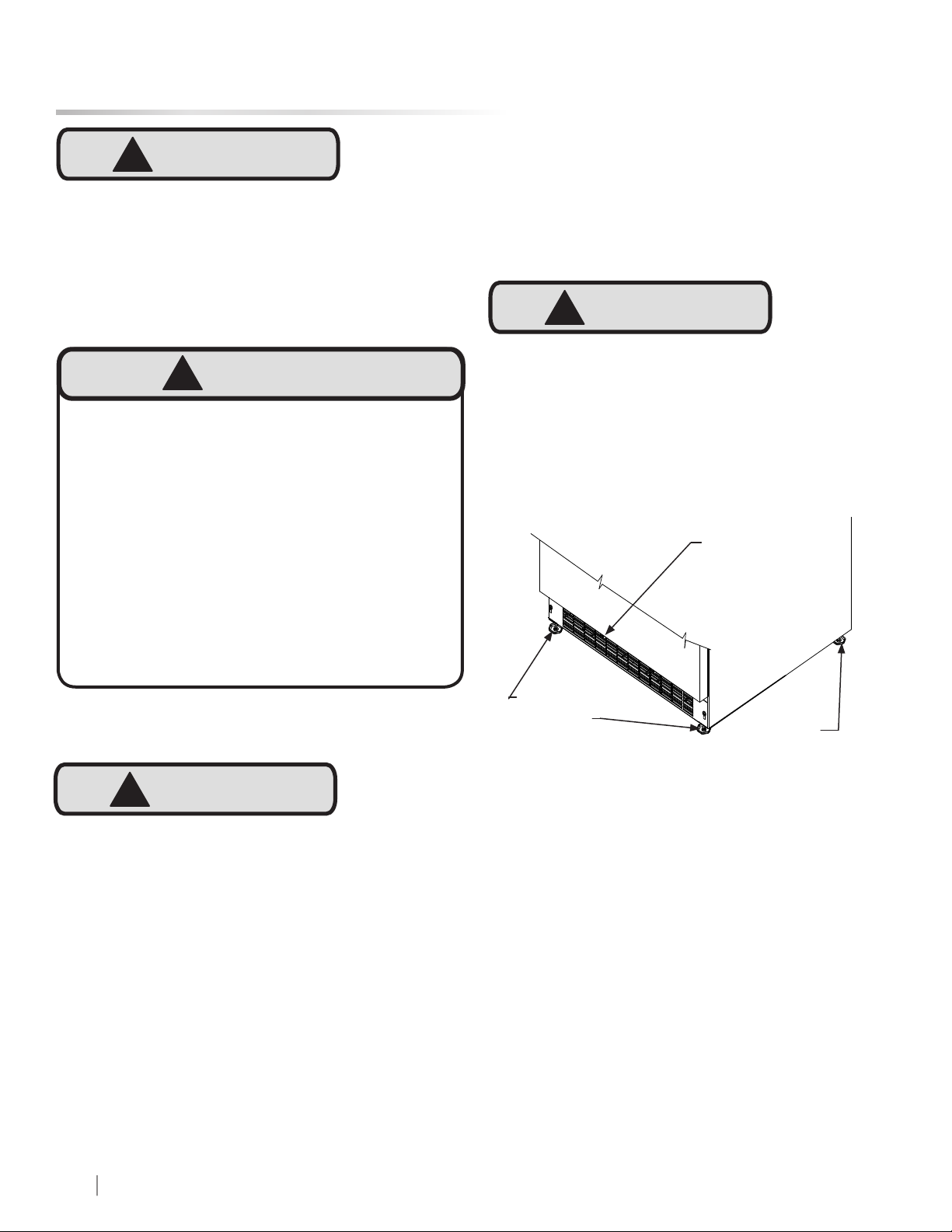

Cabinet Clearance

Ventilation is required from the bottom front of the appliance.

Keep this area open and clear of any obstructions. Adjacent

cabinets and counter top can be installed around the

appliance as long as the front grille remains unobstructed.

Overlay door models with articulated hinges are intended

for built-in applications only.

!

CAUTION

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat

exchanger. Restrictions to this air ow will result in

increased energy usage, loss of cooling capacity and low

ice production. For this reason it is important this area not

be obstructed and the grille openings kept clean. Lynx Grills

does not recommend the use of a custom made grille as air

ow may be restricted. (See Figure 2).

Front Grille,

keep this area

open.

!

CAUTION

Outdoor Installation

Do not install in a location where the ice machine will

be exposed to direct sun exposure as this may result in

unsatisfactory performance.

Select Location

The proper location will ensure peak performance of

your appliance. We recommend a location where the ice

machine will be out of direct sunlight and away from heat

sources. To ensure your product performs to specications,

the recommended installation location temperature range

is from 55 to 90°F (13 to 32°C) for built in ice machines and

55 to 100°F (13 to 38°C) for freestanding ice machines.

Ice machines will not perform correctly in ambient

temperatures less than 55°F (13°C).

CARE AND USE/INSTALLATION

4

Front Leveling

Legs

Figure 2

Leveling Legs

Adjustable legs at the front and rear corners of the

appliance should be set so the unit is rmly positioned on

the oor and level from side to side and front to back. The

overall height of your Lynx appliance may be adjusted

higher (by turning the leveling leg out) and lower (by turning

the leveling leg in). Cabinet height adjustment dimensions

are shown in Table "A".

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the

appliance forward using caution. On a level surface check

the appliance for levelness and adjust accordingly.

The front grille screws may be loosened to raise and

lower the grille to the desired height. When adjustment is

complete tighten the two front grille screws. (See Figure 5).

Rear

Leveling

Legs

Page 5

INSTALLING YOUR APPLIANCE

Model

LM15ICER

Minimum

(85.7 cm)

Table A

Figure 3

Height

33 3⁄4"

Maximum

Height

34 3⁄4"

(88.3 cm)

Do not remove

ground prong

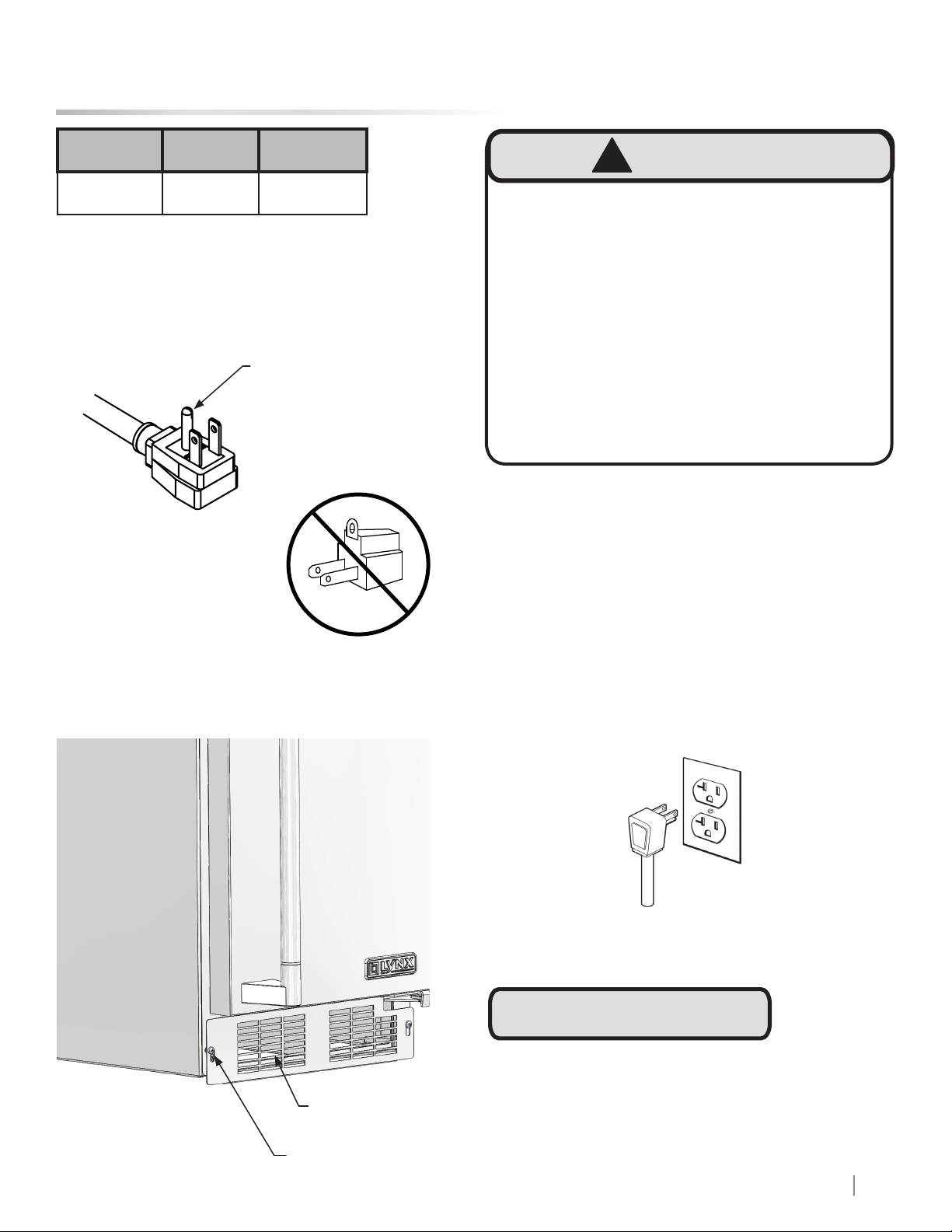

Figure 4

!

WARNING

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any circumstances,

be installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the power

cord. (See Figure 3).

• Do not use an adapter. (See Figure 4).

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

This product is factory equipped with a power supply cord

that has a three-pronged, grounded plug. It must be plugged

into a mating grounding type receptacle in accordance with

the National Electrical Code and applicable local codes

and ordinances (see Figure 6). If the circuit does not have

a grounding type receptacle, it is the responsibility and

obligation of the customer to provide the proper power

supply. The third ground prong should not, under any

circumstances, be cut or removed.

Figure 5

Front grille

Front grille screw

Figure 6

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to

nuisance tripping which will cause the appliance to shut

down. GFCI’s are generally not used on circuits with power

equipment that must run unattended for long periods of

time, unless required to meet local building codes and

ordinances.

CARE AND USE/INSTALLATION

5

Page 6

INSTALLING THE DRAIN PLUMBING

!

CAUTION

!

CAUTION

Failure to use an adequate drainage system, will result in

surrounding water damage and/or poor ice production.

!

WARNING

Electrical Shock Hazard

Reasonable care and safe methods should be practiced. Do NOT work with energized electrical equipment in a wet area. Read and follow the installation

instructions listed in this manual.

Drain Plumbing

Your ice machine requires drain plumbing. There are 2

variations of ice machines in regards to the installation of

the drain plumbing, without a drain pump (gravity drain),

and with a drain pump.

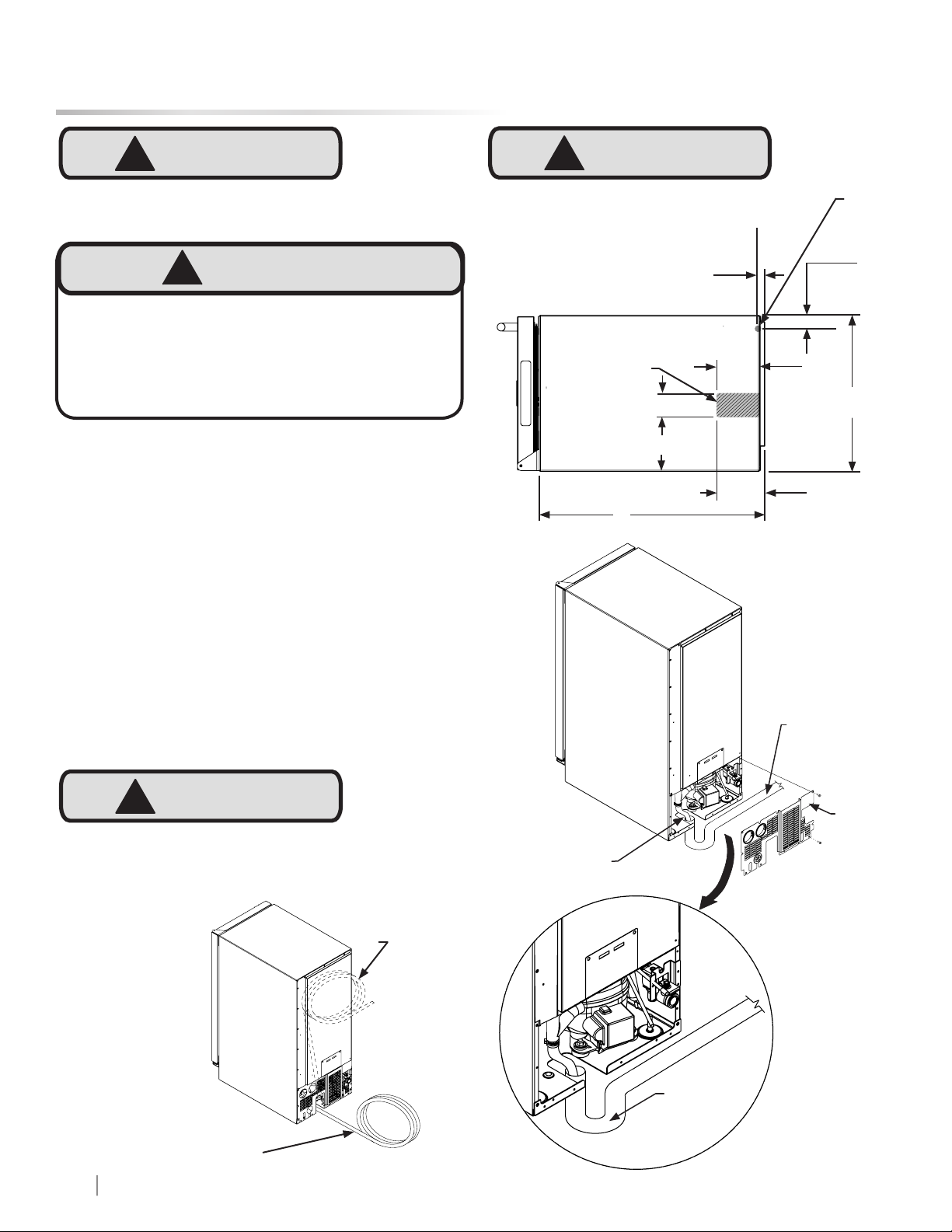

Gravity Drain (no drain pump):

The ice machine is shipped with the drain line installed,

coiled and secured to the back of the cabinet as shown

in Figure 7. It can be uncoiled, routed to an appropriate

drain and cut to length as required. Additionally there is the

provision of drain routing through the cut-out in the bottom

of the unit, (see the gray area in Figure 8). A drain can be

installed in this gray area with the drain line cut to a short

length and positioned into the drain as shown in Figure 9,

or if the ice machine is to be built-in, the drain tube could be

routed through a hole in the oor in this gray area to a drain

below.

Observe and follow all local building codes

when installing this ice machine and drain

lines.

Figure 8

Drain access in

bottom of unit

51⁄8" (13 cm)

211⁄2"

(54.6 cm)

(17mm)

21⁄4"(5.7 cm)

C

L

11

⁄16"

(10.4 cm)

(11.5 cm)

Water

supply

inlet

11⁄4"

(3.2 cm)

C

L

43⁄32"

147⁄8"

(37.8 cm)

417⁄32"

Drain pipe, (not

provided)

!

CAUTION

The gravity drain line must be routed no higher than 6"

(15.2 cm) off the oor to assure proper drainage.

Drain line coiled

and secured to

the back of the

unit

Figure 7

Uncoil the drain line, route

to an appropriate drain and

cut to the required length

CARE AND USE/INSTALLATION

6

Drain tubing, cut

to length and in-

stall in the drain

Access

panel

Figure 9

Sanitary

trap

Page 7

INSTALLING THE DRAIN PLUMBING

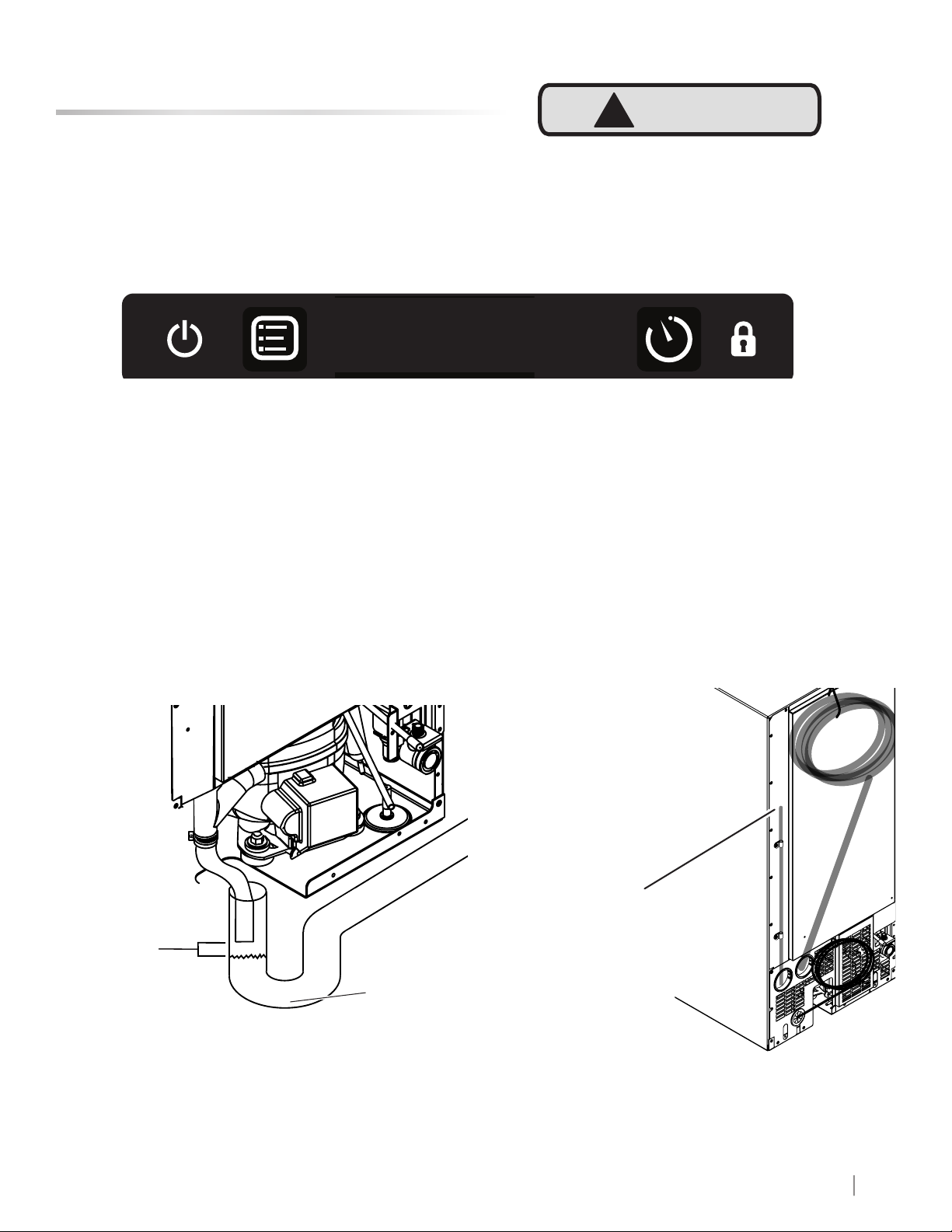

Optional Drain Pump.

An optional drain pump is available if you have purchased

an ice machine without one and do not have access to a

gravity drain. Installation instructions are provided with the

optional drain pump. Contact Lynx Grills Customer Service

at 888.289.5969 or your dealer for ordering.

!

CAUTION

This drain pump is designed to be installed in Lynx ice

machines only and approved for use with water only.

!

WARNING

Electrical Shock Hazard

Risk of electrical shock or personal injury could occur

due to moving components, if the machine compartment

access cover is removed before unplugging the ice

machine power cord.

Drain line coiled and

secured to the back of the

cabinet. Uncoil, route to

an appropriate drain and

cut to length.

Drain pump

vent tube.

Keep this

open to

assure air

ows freely

as water

enters

the pump

reservoir.

Figure 10

CARE AND USE/INSTALLATION

7

Page 8

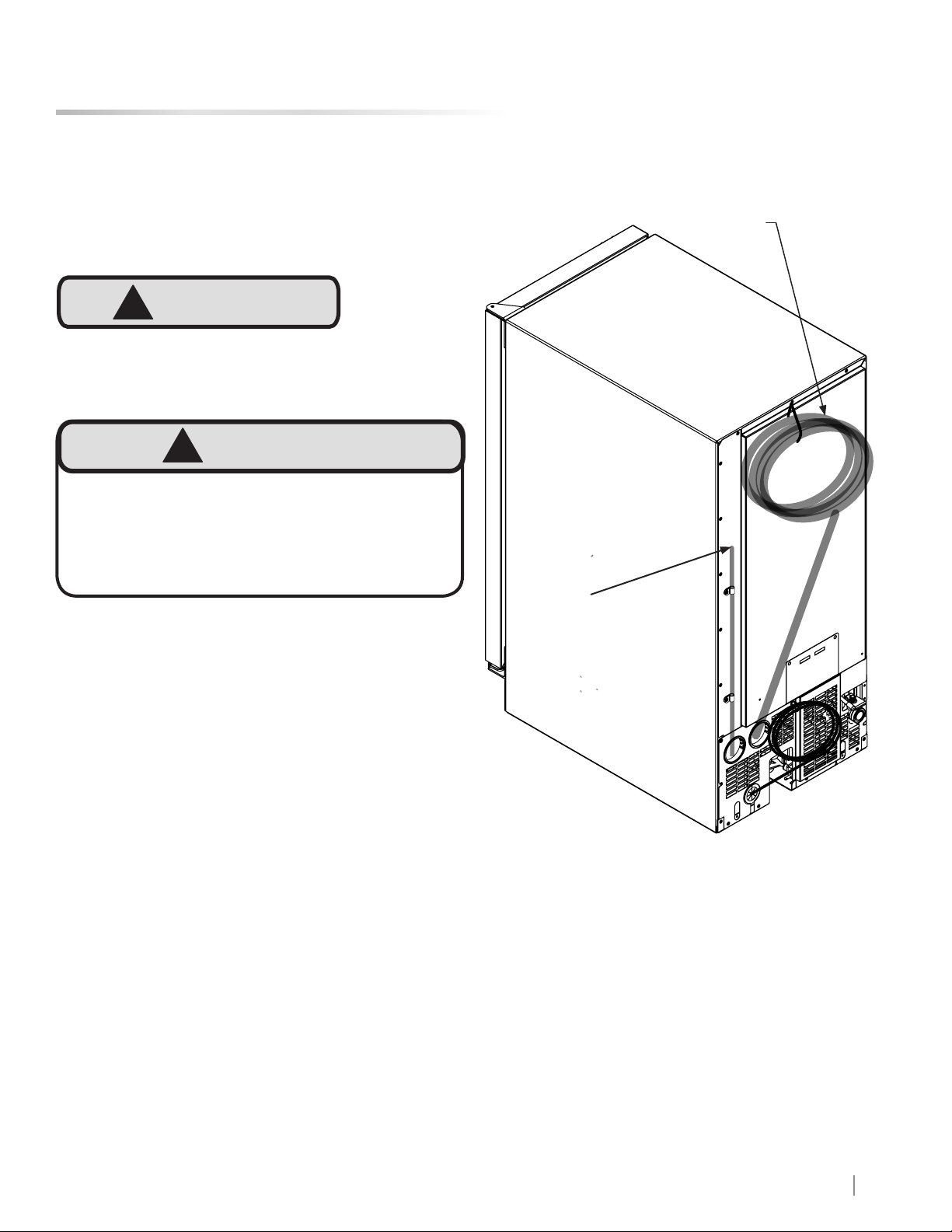

INSTALLING THE WATER SUPPLY

Water Supply

!

CAUTION

Observe and follow all local building codes when installing

this appliance.

This ice machine must be connected to a potable cold

water supply line. delivering water pressure between a

minimum of 20 psi and a maximum of 120 psi.

Use 1⁄4" copper tubing for your water supply which is available

at any local hardware or plumbing supply store. Route the

1

⁄4" copper tubing to suit your installation being sure not

to kink the tubing. Purchase enough copper tubing length

to allow a coil to be formed behind the unit for a "service

loop" which will allow the appliance to be pulled out from

the installation for servicing or cleaning. (See Figure 11).

Connect the copper tubing to the "top side" of a cold water

pipe to prevent the ice-maker from plugging with sediment.

A shutoff valve is recommended on the water supply line to

ease servicing the appliance. NOTE: A SELF-PIERCING

TYPE VALVE IS NOT RECOMMENDED as they are prone

to clogging with sediment which will create pressure drop

reducing the water supply to the unit.

Connect the copper tubing water supply to the water valve

inlet with a 1/4" compression nut tting.

IMPORTANT: Secure the water supply line to the back of

the cabinet with the screw and strain relief clamp provided

in the corner of the back panel. (See Figure 11).

Water supply

service loop

to shut off

valve

Figure 11

Back view of

ice machine

Water

Supply

Line

Clamp and

Screw

Water

supply

line

Make certain all connections are watertight after

installation. Form the tubing so that it will not vibrate

against the cabinet body or kink when your appliance is

moved in and out of position.

This ice machine is designed to make clear ice from the

majority of water sources on a daily basis. If your results

are unsatisfactory, your water may need to be ltered or

treated. A water specialist can recommend proper water

treatment.

!

CAUTION

To prevent water leaks:

• The water line tting is to be used with copper tubing

only. Do not use with plastic tubing.

• Do not use any thread sealers on this water line tting.

CARE AND USE/INSTALLATION

8

Compression

tting

Water valve

inlet

NOTE

Reverse osmosis, (RO), water, softened water, and deionized water are not recommended as they can adversely

affect the quality and quantity of the ice.

Page 9

DRAIN SYSTEM TEST

ICE

DOOR

!

CAUTION

Procedure for Testing Drain System

(both gravity and drain pump models)

Drain pump models have a safety feature that will interrupt power to the unit if a high-limit condition occurs to prevent

ooding. This safety feature can be initiated by a restriction in the drain system and will continue until high-limit condition

is corrected, at which time power will be restored to the unit. Power interruption can be detected when no icons are

visible in the display area of the user interface (Figure 12). Once power is returned, a startup chime will sound followed

by a self-test, and "OFF" should be visible in the display area.

On/off Menu Delay timer Lock

ECO

hours

1 4 6 8

days

OFF CLEAN

Figure 12: User interface display during power interruption.

Once the drain line is plumbed, perform the following:

1. Plug the ice machine into 115v power supply.

2. Place unit in the nal installation location.

3. Turn the unit off via the user interface (display will indicate “OFF”). The drain pump will still be operational during off

mode if the unit has one.

4. Slowly pour 3-qts of water into the ice storage bin. All water should drain completely.

5. If water drains fully and without power interruption, the drain system has been successfully tested and further

installation of the ice machine can be continued.

6. If the water does not drain or a power interrupt occurs, check the following:

a. There are no kinks or restrictions in the drain line. (Note: Drain line needs to be cut to the required length and any

excess tubing should be removed to prevent possible restrictions).

b. Your drain line is plumbed into an open drain (Figure 13).

c. The vent tube on the back of the unit is open (Figure 14).

Air gap

between

end of

drain line

and top of

water level

Sanitary trap

Figure 13: Example of an open drain.

7. After checking the above requirements, repeat step 4 and verify the water drains completely without power

interruption. If problems persist call a qualied service technician and/or plumber.

Drain pump vent

tube. Keep this

open to assure

air ows freely as

water enters the

pump reservoir.

Figure 14: Location of vent tube.

CARE AND USE/INSTALLATION

9

Page 10

OPERATION OF THE ICE MACHINE

The Ice Making Process

Your ice machine is unique in how it forms ice with fractional freezing to form a slab of ice that is clear and has less

dissolved solids than the water it is produced from. This is

accomplished by running water over the cold evaporator

plate (see Figure 16) which gradually freezes the water to

produce the ice slab. Pure water freezes rst, leaving the

dissolved solids in the residual reservoir water to provide

clear ice.

Figure 16

When the ice slab reaches the correct thickness, the ice

sheet is released and slides onto the grid cutter (see Figure

16). Here, the ice slab is cut into squares by the grid cutter’s heated wires (see Figure 19). The water containing

the dissolved minerals is drained after each freezing cycle.

Fresh water enters the machine for the next ice making

cycle.

Figure 18

Water distributor

Front

panel

Figure 17

Grid Cutter

Ice

Deector

Bin Level

Sensor

Evaporator

Circulation

Pump

Water

reservoir

Reservoir

drain plug

CARE AND USE/INSTALLATION

10

Page 11

OPERATION OF ICE MACHINE

The ice machine will keep producing ice until the ice

machine’s bin is full and will restart automatically when

ice needs to be replenished in the bin. The ice bin is

not refrigerated, and some melting will occur by design

to preserve the ice quality and clarity. Allow your ice

machine to run for 24-48 hours to accumulate ice in the ice

machine’s bin.

Figure 19

Ice Production

In normal mode the ice machine will produce up to 39

pounds (17.7 kg) of clear ice in a 24-hour period when

installed in a 72°F ambient with a 55°F water supply. In

"ECO" mode (see page 16) the ice machine will produce up

to 29 pounds (13.2 kg) of clear ice in the 24 hour period.

NOTE

“Initial” ice production and ice accumulated in the storage

bin will vary signicantly. This is normal. During the rst

24-hours of operation the unit will produce up to 39 lbs of

ice at the above ambient and water temperature conditions,

but when starting with an empty ice storage bin, the storage

bin may only accumulate up to 18 lbs of ice. By design,

the ice storage bin is maintained at a temperature slightly

above freezing to allow the stored ice to slowly melt, to

preserve the ice quality and clarity and assure a constant

supply of fresh ice. As ice is accumulated in the bin, the ice

production rate will overcome the ice melt and the storage

bin will ll to capacity.

The bin level sensor is located in the ice bin, it senses

when the ice supply is low or full and starts or stops the ice

making process accordingly.

NOTE

If the water supply is turned off to the ice machine be sure

to set the electronic control to the “OFF” position or remove

power to the unit.

New Sounds

The ice machine will make sounds that are different than

your household refrigerator. Because these sounds are

new to you they may be of a concern but are most likely

normal. The ice production process will make noises that

are not typical in a refrigeration product, ice falling onto

hard surfaces, water cascading across the evaporator, and

valves opening and closing. Following are some of the

sounds that you may hear:

A buzzing sound will be heard when the water valve

opens to ll the water reservoir.

A rattling noise which could be water owing through the

water line.

A splashing sound when water is owing over the

evaporator plate and into the water reservoir.

A "thud" when the ice slab is released from the

evaporator plate and slides onto the grid cutter.

"Clicks" when the cubes fall into the ice storage bin.

A gurgling sound which is refrigerant owing in the ice

machine.

An air noise from the condenser fan.

CARE AND USE/INSTALLATION

11

Page 12

PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "J"

LM15ICER

15"

(38.1 cm)

**34" to 35"

(86.4 to 88.9 cm)

"B"

24"

(61 cm)

147⁄8"

(37.8 cm)

"A"

333⁄4" to 343⁄4"

(85.7 to 88.3 cm)

235⁄8"

(60 cm)

259⁄16"

(64.9 cm)

3713⁄32"

(95 cm)

1611⁄16"

(42.4 cm)

Figure 20a

Figure 21

"E"

Figure 20

"C"

"D"

If necessary to gain clearance inside the rough-in

opening a hole can be cut through the adjacent cabinet and the power cord routed through this hole to a

power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this application as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application, (see Figure 21).

CARE AND USE/INSTALLATION

12

Page 13

PRODUCT DIMENSIONS

PRODUCT DATA

MODEL

LM15ICER 115V/60Hz/15A

ELECTRICAL

REQUIREMENTS #

"J"

PRODUCT

WEIGHT

105 lbs

(47.7 kg)

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

# A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and

appliance.

"H"

"D"

"E"

Figure 22

(S) solid

door shown

"G"

(54.6cm)

211⁄2"

"F"

CL

Water

inlet

11⁄4"

(3.2 cm)

47⁄8"

(12.4 cm)

615⁄16"

(17.6 cm)

CL Gravity

drain

CARE AND USE/INSTALLATION

13

Page 14

USING YOUR ELECTRONIC CONTROL

ICE

DOOR

On/off Menu Display area Delay timer Lock

ECO

hours

1 4 6 8

days

OFF CLEAN

Figure 23

User interface display

Display icons:

"ON/OFF" icon : used for turning the appliance on and off.

"MENU" icon : used to access optional functions in the user interface.

"Clock" icon : used to enter the Delay start/

vacation mode.

"LOCK" icon : used to lock out functions in

the user interface.

Display area text:

ICE

ECO

OFF

DOOR

CLEAN

Signies the appliance is on and producing

ice.

Signies the appliance is in economical ice

production mode.

Signies the appliance is off

Signies a door ajar alarm condition.

Cleaning is recommended or the appliance

is in the clean mode.

Delay start/Vacation mode:

hours

days

When lit, this signies the delay start/vacation mode

is operational.

1

4

6

Hours or days timer is set for

Hours or days will be lit

8

NOTE

The control display is covered with a clear plastic protective

lm. This lm may be removed by carefully lifting at a

corner.

Starting your clear ice machine:

Plug the ice machine into a 115 volt wall outlet,

(see page 5 for electrical information). Your

appliance is shipped from the factory in the "ICE" mode

and will begin start-up of ice production after the start-up

routine.

Upon applying power to the unit, or after a power

interruption, the Ice machine will perform a self-test,

followed by a harvest cycle to clear any in-process ice

production. This start-up routine, (“after power is applied

to the unit”), takes approximately 13 minutes to complete

before an ice production cycle starts.

If the appliance does not start, conrm the wall outlet has

power, and the control is in the "ICE" mode, (see Options

section below). Do not start the ice machine in "ECO"

mode. "ECO" mode should only be used after there is a full

bin of ice.

ICE

CARE AND USE/INSTALLATION

14

Page 15

USING YOUR ELECTRONIC CONTROL

Turning your ice machine On and Off:

If your appliance is on, "ICE" will be displayed.

To turn the appliance off, push and hold the "ON/

OFF" icon for 3-seconds. The display will show

"OFF" .

NOTE

When turned off, the ice machine will complete its

current ice production cycle then shut off.

The drain pump (if equipped) and the interior light

will still be functioning during the OFF mode. To

turn the appliance back on, press and hold the "ON/OFF"

icon for 3-seconds, the display will show "ICE".

!

WARNING

Turning the ice machine "OFF" will only terminate the

ice production, it does not remove power from the appliance. Always unplug the power cord from the wall

outlet before servicing the unit.

Control Lock:

The user interface can be locked to avoid unintentional changes from things like cleaning. To lock

the appliance, push and hold the "LOCK" icon for

5-seconds. The "LOCK" icon will ash 3 times, then change

to steady back-lit. To unlock the user interface, press and

hold the "LOCK" icon for 5-seconds, and the back-light will

turn off.

ICE

OFF

ICE

NOTE

Door ajar alarm:

If the door is open, or not closed properly for 5

minutes the "DOOR" indicator will illuminate and

ash and an audible tone will sound. The audible

alarm can be muted by pressing the "Lock" keypad.

This alarm condition can be reset by closing the

door or momentarily pressing the "ON/OFF" icon,

(i.e.-if you are cleaning the storage compartment, etc.). The

alarm will recur in 5 minutes if the alarm condition persists.

Delay start/Vacation mode:

Your ice machine is equipped with a delay start function.

This feature can be used to temporarily shut the appliance

off for 1, 4, 6, or 8 hours or days. Upon completion of the

selected delay period, the appliance will resume operation.

This is ideal for temporarily stopping ice machine noises or

to save water and electricity if you are away from home but

want fresh ice upon your return.

To enter the delay start mode, press the "CLOCK"

icon while the appliance is in "ICE" mode. This will

delay the next harvest by the time displayed. Each

additional press of the "CLOCK" icon will add time,

from 1, 4, 6, or 8 hours, to 1, 4, 6, or 8 days. The next

press after 8 days will leave delay set

mode. After the desired time has been

selected, press the "ON/OFF" icon for 2 seconds

to accept, your unit will shut off and a clock icon

and your selected time will be displayed. When the

selected time has elapsed, normal ice production will

resume.

To cancel the delayed start, press and

hold the "ON/OFF" icon until the appliance enters OFF, then press and hold

the "ON/OFF" icon again until the appliance enters "ICE" mode.

1 4 6 8

DOOR

hours

days

OFF

ICE

The "LOCK" icon is the only active key in this mode. If other

icons are pressed while in the lock mode the "LOCK" icon

will ash 3 times, and an audible tone will sound, to remind

the user the appliance is in the lock mode.

CARE AND USE/INSTALLATION

15

Page 16

USING YOUR ELECTRONIC CONTROL

Error codes:

The ice machine is monitored continuously. Any OPEN or

SHORTED circuit condition with a temperature sensor or

miscommunications between the control and user interface

will initiate an ERROR CODE as listed below:

Error Codes

Error Displayed Code Error Description Action to Take

Bin Sensor error

System Sensor error

Communication error

Options menu:

"OFF" will ash continuously in 1

second intervals in the display. No

audible alarm will sound.

"ICE" will ash continuously in

the display. No audible alarm will

sound.

Continual ashing of all indicators

on the display.

Failed temperature sensor. Machine operation will imme-

diately enter an OFF state.

Failed condenser temperature sensor. Machine opera-

tion will continue but ice production cycle will not adapt to

varying ambient conditions, so ice quality may vary.

Loss of communication between the main board and the

user interface.

Call service to have the

temperature sensor replaced.

Call service to have the

temperature sensor replaced.

Call service to have a

diagnostic check.

Normal and ECO mode:

Your ice machine comes with an optional "ECO" mode.

This new feature allows you to tailor ice production to a

conservative rate, saving approximately 25% energy and

30% water from routine operation. While in this mode

ice production will slow and the appliance will use less

water and electricity. "ECO" mode should only be initiated

after there is a full bin of ice. To enter "ECO" mode do the

following:

• Press the "MENU" icon twice and the green

"ECO" will ash.

ECO

• Press and hold the "ON/OFF" icon until the

green "ECO" stops ashing and remains

illuminated.

• To return to the standard operating rate press the

"MENU" icon twice, the ECO will turn off and the

"ICE" will be ashing. Press and hold the "ON/

OFF" icon until the "ICE" stops ashing and

remains illuminated.

ICE

CARE AND USE/INSTALLATION

16

Page 17

CLEANING YOUR ICE MACHINE

Clean reminder:

A "CLEAN" reminder will occur every 6 months

to remind you that it may be time to clean your

appliance. Over time mineral build up on the cold

evaporator plate can occur which can adversely

affect the quality of your ice. This build-up is

dependent on your water source and usage. Normal

ice production will continue while the "CLEAN" reminder

is displayed. You may clear the "CLEAN" reminder at any

time by momentarily pressing the "ON/OFF" icon. When

reset, the "CLEAN" reminder will reset and not occur for

another 6 months. If you choose to clean the appliance at

this time, see the options menu section below.

Clean mode:

To ensure maximum performance and ice quality, it is

recommended to clean your ice machine once every six

months. This simple cleaning routine will also ensure water

and energy use continues at optimum efciency.

CLEAN

NOTE

Once you have your cleaner:

Turn the ice machine off by pressing and holding

the "ON/OFF" icon for 3 seconds. "OFF" will be

displayed on the control.

Remove all ice from the ice bin (see Figure 27).

Drain the water from the water reservoir by removing the

black plug from the bottom of the fresh water reservoir (see

Figure 28). After the water is drained, replace the plug in

the bottom of the reservoir.

Allow all of the ice to fall from the evaporator plate

and remove any ice from the grid cutter. If there is ice

embedded in the grid cutter wires, wait for it to melt and

fall out. Do not try to remove ice that is embedded in

the grid cutter wires as that may break the wires. (See

Figures 21 and 22).

!

CAUTION

Forcing ice through the grid cutter will break the grid cutter

wires.

OFF

Homes with poor water quality or high clear ice usage

might require more frequent cleaning.

!

CAUTION

To clean your ice machine you will need to purchase a

"nickel safe" ice maker cleaner. Cleaner can be obtained by

contacting Lynx Grills Customer Service at 888.289.5969.

Remove all ice

from the evaporator

plate and grid cutter

area that is not

embedded in wires

Figure 24

Figure 25

CARE AND USE/INSTALLATION

17

Page 18

CLEANING YOUR ICE MACHINE

Refer to your cleaning solution instructions to determine

the proper amount of cleaning solution to add based on

2 quarts (1.9 liters) of water. Lift fascia door up to access

evaporator plate (See Figure 29). Pour the cleaning

solution slowly on the evaporator plate so it ows down into

the fresh water reservoir. (See Figure 30).

Figure 26

Remove all of

the ice from

the ice bin

Lift fascia door up to

access evaporator plate

Splash shield

brackets

Figure 29

Replace the splash shield if removed.

Turn the ice machine back on by pressing and

holding the "ON/OFF" icon for 3 seconds. The

display will indicate "ICE" mode. Press and hold the

"MENU" icon until a ashing "CLEAN" is displayed. Press the "ON/OFF" icon until "CLEAN"

stops ashing. Your ice machine will now enter

the clean cycle.

The clean and rinse cycle will take about 49 minutes.

Splash shield

ICE

CLEAN

Figure 28

CARE AND USE/INSTALLATION

18

Figure 27

Remove the

black reservoir

drain plug from

the bottom of

the reservoir.

Figure 28b

After the clean cycle is complete the ice machine

will return to the "OFF" position.

After the cleaning cycle is completed, verify that all build-up

has been removed. If not repeat the clean cycle procedure.

Evaporator

plate

Grid cutter

Pour cleaning solution slowly

onto the front edge of evaporator

plate behind the grid cutter.

Figure 30

OFF

Page 19

CARE AND CLEANING AND ENERGY SAVING TIPS

OBTAINING SERVICE

Front Grille

Be sure that nothing obstructs the required air ow openings

in front of the cabinet. At least once or twice a year, brush or

vacuum lint and dirt from the front grille area (see page 4).

!

CAUTION

SHOCK HAZARD: Disconnect electrical power from the

appliance before cleaning with soap and water.

Cabinet

The painted cabinet can be washed with either a mild soap

and water and thoroughly rinsed with clear water. NEVER

use abrasive scouring cleaners.

Cleaning

Routine cleaning of the stainless steel surfaces will serve

to greatly extend the life of your product by removing

contaminants. This is especially important in coastal areas

which can expose the stainless to sever contaminants such

as halide salts (sodium chloride).

It is strongly recommended to periodically inspect and

thoroughly clean crevices, weld points, under gaskets,

rivets, bolt heads, and any locations where small amounts

of liquid could collect, become stagnant, and concentrate

contaminants. Additionally, any mounting hardware that is

showing signs of corrosion should be replaced.

Interior

Wash interior compartment with mild soap and water. Do

NOT use an abrasive cleaner, solvent, polish cleaner, undiluted detergent or chlorine based cleaners.

Care of Appliance

1. Avoid leaning on the door, you may bend the door

hinges or tip the appliance.

2. Exercise caution when sweeping, vacuuming or

mopping near the front of the appliance. Damage to the

grille can occur.

3. Periodically clean the interior of the appliance as

needed.

4. Periodically check and/or clean the front grille as

needed.

In the Event of a Power Failure

If a power failure occurs, try to correct it as soon as

possible. Minimize the number of door openings while the

power is off so as not to adversely affect the appliance's

temperature.

Light assembly replacement

All models use LED lamps to illuminate the interior of the

appliance. This component is very reliable, but should

one fail, contact the Lynx Grills Customer Service at

888.289.5969 for replacement of the LED.

Energy Saving Tips

The following suggestions will minimize the cost of

operating your ice machine appliance.

1. Do not install your appliance next to a hot appliance,

(stove, dishwasher, etc.). heating air duct, or other heat

sources.

2. Install product out of direct sunlight.

3. Assure the front grille vents at front of the ice machine

beneath the door are not obstructed and kept clean to

allow ventilation for the refrigeration system to expel

heat.

4. Plug your appliance into a dedicated power circuit. (Not

shared with other appliances).

5. Minimize door openings and duration of door openings.

6. Set the control to the “off” position if accessing the

interior to spot clean or remove large quantities of ice

requires the door to be open for an extended period of

time.

7. Use ECO mode if maximum ice production quantities

are not required.

8. Use the delay start function if the ice machine will not

be used for long periods of time.

If Service is Required:

• If the product is within the rst year warranty period

please contact your dealer or call Lynx Grills Customer

Service at 888.289.5969 for directions on how to obtain

warranty coverage in your area.

• If the product is outside the rst year warranty period,

Lynx Grills Customer Service can provide recommendations of service centers in your area.

• In all correspondence regarding service, be sure to

give the service number, serial number, and proof of

purchase.

• Try to have information or description of nature of the

problem, how long the appliance has been running, the

room temperature, and any additional information that

may be helpful in quickly solving the problem.

• Table "C" is provided for recording pertinent information

regarding your product for future reference.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State

Dealer’s Zip Code

Appliance Serial Number

Appliance Service Number

Date Warranty Card Sent (Must be

within 10 days of purchase).

Table C

CARE AND USE/INSTALLATION

19

Page 20

TROUBLESHOOTING THE ICE MACHINE

Before You Call for Service

If the appliance appears to be malfunctioning, read through

this manual rst. If the problem persists, check the troubleshooting guide below. Locate the problem in the guide and

refer to the cause and its remedy before calling for service.

The problem may be something very simple that can be

solved without a service call. However, it may be required

to contact your dealer or a qualied service technician.

Troubleshooting guide:

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the unit's wiring.

• Replace all parts and panels before operating.

!

WARNING

Electrocution Hazard

Ice Machine Operation

Ice machine does not operate

Is the ice machine’s power cord plugged in? Plug the

power cord into a grounded 3 prong outlet.

Is the electronic control showing the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is a fuse blown or a circuit breaker been tripped? Replace a blown fuse or reset a tripped circuit breaker.

Is the temperature of the room cooler than it normally

is? The minimum room temperature is 55°F (13°C). The

bin thermistor may be sensing the room temperature and

shut off before the bin is full of ice. If the room temperature

remains low the ice machine may not restart.

Is there a drain pump in the ice machine? The drain

pump is designed to temporarily shut the unit off when

large quantities of water create a high-limit condition. Wait

a few minutes as the drain pump will continue to operate

to dispose of the excess water. If there is still water in the

ice bin check the drain pump vent line and drain line for

obstructions or kinking.

The ice machine is noisy

Many sounds of an ice machine are different than your

household refrigerator. This subject is discussed on page

11, but check the following:

Do you hear water being circulated in the ice machine? This is a normal sound as water is added once

every ice making cycle.

Ice Production

Little or no ice production from the ice machine

Is the electronic control set to the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is water getting to the ice machine? Make sure nothing

is restricting the water supply such as a closed water valve

or a blown fuse or tripped circuit breaker, or a kinked supply line, or low water pressure.

Has the ice machine just been started? A typical ice

production cycle can take up to 11⁄2 hours. Initial start up

cycles can take longer. Check the ice machine after 24

hours for ice accumulation in the bin.

Is the reservoir drain plug in place? Check that the

reservoir drain plug is properly seated.

Is the water distributor tube restricted? Run a cleaning

cycle to clean the ice machine. Also check any lters to

make sure they are not restricted.

Is the condenser fan air ow restricted? Make sure the

grille in the front of the ice machine is open for proper air

circulation.

Is the room and/or water temperature to warm? Move

the ice machine to an area where the ambient temperature

is below 90°F (32°C) for built-in ice machines or below

100°F (38°C) for freestanding ice machines. The ice machine should not be placed next to a heat source such as

an oven. Check the cold water connection.

Is there a “whoosing” sound? Make sure water is getting to the ice machine. Also check to make sure the drain

plug is fully seated in the water reservoir.

Is there an ice slab caught between the evaporator

plate and the grid cutter? First check to see if the ice

machine is level. If the ice machine is level run a cleaning

cycle.

CARE AND USE/INSTALLATION

20

Is there scale build up in the ice machine? If there is

scale build up on the evaporator, the ice machine needs to

be cleaned. See “Cleaning the Ice machine”.

Page 21

TROUBLESHOOTING THE ICE MACHINE

Ice Quality

Odor, grey color, or off taste in the ice

Is there mineral scale build up on the evaporator

plate? The ice machine needs cleaning. See “Cleaning

the Ice Machine”.

Is there a high mineral content in the water? The water

may need to be ltered.

Are food items being stored in the ice bin? Remove

food from the ice bin.

Unpleasant Odors may require the use of a charcoal lter

on the water supply line.

Clumps of ice

Are there clumps of ice in the bin? If the ice isn’t used

on a regular basis it will melt and form into clumps. Break

up the ice clumps with the ice scoop.

Ice cubes are too big or too small

Is there low ice consumption? Ice is slowly melting in

the ice bin which will affect the size of the cubes. This is

normal. When the ice bin needs to be replenished, cubes

will return to the regular size.

Is the ice slab releasing? Clean the evaporator. See

“Cleaning the Ice Machine”.

Is the distributor tube restricted? Check the water line

to the ice machine to make sure there are no restrictions

or kinks in the line. Check all lters to make sure they

are not restricted. Check that the water ows evenly out

of the distributor tube, if not, clean the ice machine. See

“Cleaning the Ice Machine”.

Troubleshooting the Drain Pump

NOTE

If the drain pump reservoir (not the ice machine bin)

reaches overll condition, the power to the ice machine will

be shut off.

If the ice machine is not working, check the following:

• Make sure there is power at the receptacle.

• Make sure the ice machine is turned on.

• Make sure the ice bin is not full.

Then check the drain pump:

The pump does not run:

• Make sure the pump is plugged in and there is power

to the receptacle.

• Check the inlet to the drain pump for debris and clean

as needed. Remove clamps and inlet tube from drain

pump to check for and remove debris.

• Make certain the vent line is free of kinks/sharp bends

or restrictions.

• Make certain there is enough water to activate the

drain pump. It will take at least one (1) quart (.95 liters)

of water to activate the drain pump.

The pump runs, but no water is pumped out:

• Check that the vent is clear and free of restrictions.

• Check the discharge line to make certain there are no

restrictions.

• Make sure that the discharge tubing has not exceeded

the maximum lift of eight (8) feet (2.44 meters) and the

horizontal run is not greater than twenty (20) feet (6.1

meters).

Plumbing Problems

Is the drain hose aligned over the drain? Move the ice

machine to align the drain.

Is the ice machine draining properly? Check that there

are no kinks or restrictions in the drain lines; this can

cause water to back up in the ice bin. Check that foreign

material is not blocking the ice bin drain located at the

right rear corner of the ice bin. Check the drain pump

discharge and vent line or any restrictions or kinks. Check

that the drain pump is level.

NOTE

If there are plumbing issues outside of the ice machine,

they cannot be repaired by the service technician. A

qualied plumber will have to be called.

The pump runs and then quickly turns off repeatedly:

• Check to make certain the drain pump is level.

• Check that the vent is clear and free of restrictions.

The ice machine is running but not producing ice:

• Check to make sure water is not backing up in the ice

bin.

CARE AND USE/INSTALLATION

21

Page 22

PREPARING THE ICE MACHINE FOR STORAGE

If the ice machine is moved, not used for an extended

period of time, or will be in an area that will be near freezing

temperatures, it is necessary to remove any remaining

water in the ice-making system.

!

CAUTION

This ice machine must have all water drained and removed

to prevent ice machine damage as well as possible water

damage to the surrounding area in freezing conditions.

These damages are not covered under warranty.

!

CAUTION

Do not use any type of anti-freeze or other solution as a

substitution for properly draining the ice machine.

Clean the Ice Machine

Cleaning the ice machine will help prevent mold and mildew

growth as well as sanitize the ice machine for storage

or when it is put back into service. See page 18 for

instructions for cleaning the ice machine.

!

WARNING

Electrocution Hazard

Risk of electrical shock or personal injury could occur

due to moving components, if machine compartment

access cover is removed before unplugging the ice

machine.

Draining and Removing Water from the Ice-Making

System with a Gravity Drain.

1. Turn off the water supply to the ice machine.

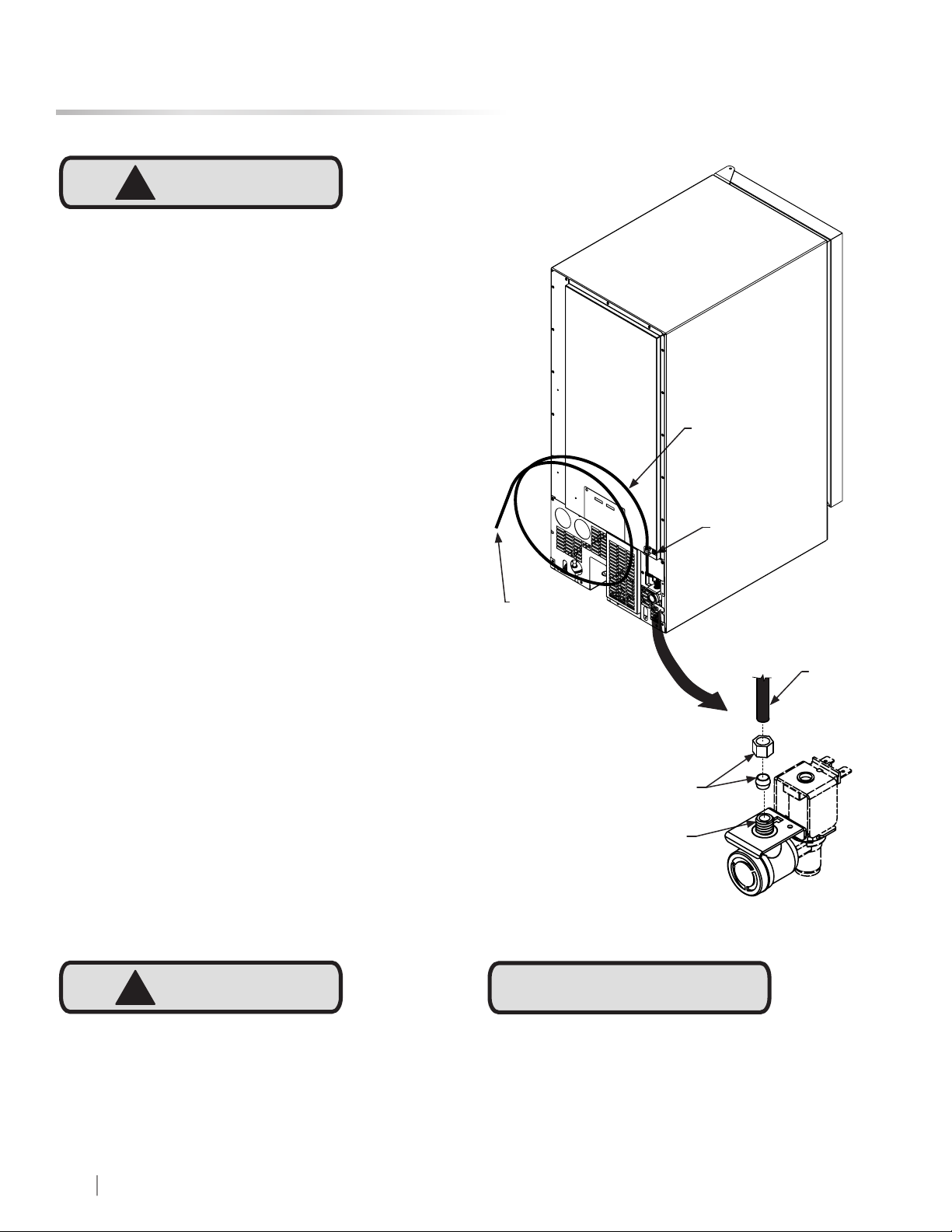

2. Disconnect the water supply tting at the inlet of the

water valve. (See Figure 31a).

3. Change the electronic control to the "CLEAN" position

for approximately one (1) minute. This will energize and

open the water valve and remove most of the water

from the water valve and the water valve’s outlet water

line to the reservoir.

4. Change the electronic control to the "OFF" position.

This will energize and open the drain valve to drain the

reservoir and the ice machine drain system.

5. Unplug the ice machine from the electrical outlet.

6. Remove the access cover from the rear of the ice

machine. (See Figure 32).

Figure 31

Back view of

ice machine

Water

supply

line

Water supply

tting

Water valve

inlet

Figure 31a

Access

cover

CARE AND USE/INSTALLATION

22

Screw

Figure 32

Page 23

PREPARING THE ICE MACHINE FOR STORAGE

7. Disconnect the water valve’s outlet water line to the

reservoir and drain the remaining water left in the water

line trap area. (See Figure 33 and 33a).

8. Reconnect the water valve outlet water line.

(See Figure 33 and 33a).

9. Reinstall the ice machine’s access cover.

10. Clean and dry the ice machine’s storage bin.

11. Prop the door open for air circulation to prevent mold

and mildew.

12. Leave the water supply line disconnected or reconnect

the supply line and leave it shut off. Do NOT turn the

water on and allow water to enter back into the water

valve.

Draining Water for Factory Installed Drain Pump

Applications

Follow steps 1 through 12 for the gravity drain then do the

following:

13. Install the winterization plug in the water drain hole

inside the ice bin. (See Figure 34).

Figure 33

To disconnect the water outlet

line: Push up on the white collar

and pull the plastic water line

from the bottom of the water

valve.

To reconnect the water outlet

line: Simply insert the plastic

tubing into the white collar and

push until it stops (about 1⁄2", 12

mm, of water line will enter the

valve).

Figure 33a

White

collar

Plastic outlet

water line

Winterization

plug

Figure 34

CARE AND USE/INSTALLATION

23

Page 24

PREPARING THE ICE MACHINE FOR STORAGE

14. Remove the top clamp from the vent tube, for easier

access for the air hose.

15. Apply air pressure (approximately 10 psi) to the end of

the vent tube which will purge the remainder of the

water from the drain pump and the drain line. (See

Figure 35).

16. Reinstall the vent tube and clamp to the back of the ice

machine and remove the winterization plug from the ice

bin and save it for future use.

Vent

tube

Remove

clamp

screw

To Restart the Ice Machine

1. Reconnect or turn on the water supply line.

2. Reconnect drain tubing if removed.

3. Plug in the power cord to a wall outlet and turn the ice

machine on, (refer to page 16 for turning the ice machine on and off).

4. Check the water inlet, drain lines, and ttings for any

water leaks.

5. Check drain pump (if equipped) operation by pouring

approximately two (2) quarts of water into the ice storage bin. The drain pump should activate and discharge

water (refer to Drain Pump on page 6). Check for

water leaks at all hose connections.

Drain Pump Removal Instructions:

1. Unplug the ice machine from the electrical supply and

remove the rear access cover from the ice machine.

(See page 26 for instructions).

2. Remove the front panel and the toe grille from the front

of the ice machine. See Figures 37 and 37a.

3. Remove the front and rear drain pump brackets. See

Figures 38, 38a and 39.

4. Unscrew the 3 hose clamps and remove the 3 hoses

from the front of the drain pump. (See Figure 36).

5. Unscrew the leveling leg in the back corner until the

end of the threaded portion is ush with the threaded

nut insert in the base. (see Figure 36).

Figure 35

CARE AND USE/INSTALLATION

24

Drain

line

Remove

these 3 hose

clamps, then

remove the

3 tubes from

the drain

pump

Unscrew the

leveling leg so

the end of the

threads is ush

with the top of

the nut insert.

Figure 36

Drain pump ground

wire connection

Page 25

DRAIN PUMP REMOVAL INSTRUCTIONS

Front

panel

Figure 37

Toe grille

Front of ice machine

Figure 37a

Front

panel

#10-24 hex nut

Front drain

pump bracket

Figure 38

Toe grille

Remove the

hex nut on

front drain

pump bracket

with the 3⁄8"

socket then

remove the

bracket.

Rear of ice machine

Figure 39

carriage bolt

Figure 38a

Rear drain

pump bracket

#10-24 hex nut

carriage bolt

Remove the hex nut on

rear drain pump bracket

with the 3⁄8" socket then

remove the bracket.

CARE AND USE/INSTALLATION

25

Page 26

DRAIN PUMP REMOVAL INSTRUCTIONS

6. Rotate the drain pump and remove from the ice

machine, (See Figure 40). It may be necessary to

disconnect the ground wire connection in the back

ange of the cabinet. (See Figure 36).

7. Disconnect the ice machine power cord from the drain

pump (See Figure 41).

8. Drain the water in the drain pump’s reservoir by turning

the pump upside down and allowing water to drain

through the pump’s inlet and vent tube ttings.

9. Installation of drain pump is reverse of this procedure.

Additional issues to be inspected by the installer

upon service replacement:

1. The drain pump must be level.

2. No pinched water lines.

3. No interference with electrical cords or wiring.

4. The drain pump should not set on any obstacles,

wiring, etc.

5. Secure all hose clamps leading to and from the

drain pump.

6. Insure that the vent tube height is adequate - 18

inches minimum.

7. Insure that drain height is adequate - maximum

of 8 feet.

8. Insure that drain length is adequate - maximum

of 20 feet.

9. Checked for water leaks after installation of the

drain pump.

10. Check for vibrations caused by improper

installation.

11. Insure that there is no interference with back

access cover.

12. Insure that the hole grommets are in place at

each location so that any vent or drain tubes do

not rub on any sharp surfaces.

Figure 40

Rotate drain pump and

remove from back of

ice machine.

Figure 41

Ice machine

power cord

CARE AND USE/INSTALLATION

26

Page 27

THE LYNX STORY

• TGI Fridays

• Applebee’s

• Houston’s

• Red Lobster

• Hard Rock Café

• Wolfgang Puck’s

• Cheesecake Factory

• Red Robin

• Planet Hollywood

• Hilton

• Hyatt

• Four Seasons Marriott

Le Meridian

• Sheraton

• Conrad International

• Bellagio

• New York New York

• MGM Grand

• Treasure Island

• Mirage

• Paris

• Venetian

• Excalibur

• Mandalay Bay

• Riviera

• Desert Inn

• Hard Rock Hotel

• Disney World

Lynx began with a vision.

A small group of manufacturing engineers with over a century of collective experience had a dream. They dared to

take their extensive commercial manufacturing know-how

and create a line of outdoor cooking products that offer commercial elegance and performance to the consumer market.

Lynx has taken the quality, workmanship, service and innovation of

the commercial market and incorporated it into the Lynx Professional

Grills line of consumer and commercial products. The combination

of creative design, superior materials and exceptional craftsmanship

elevates Lynx products to a class of

their own.

Lynx original commercial products are used every day in

restaurants, hotels and theme parks across the USA:

Lynx Satised Customers

CARE AND USE/INSTALLATION

27

Page 28

LYNX LIMITED WARRANTY

*

I. Limited One-Year Warranty

Lynx warrants that it will supply all necessary parts and labor

to repair or replace any component which proves to be

defective in material and workmanship, subject to condition

and exclusions stated below, for a period of one year from the

date of purchase by the end user.

II. Limited Five-Year Warranty

During years 2-5, Lynx will supply replacement parts for the

hermetically sealed refrigeration system which consists of

the compressor, condenser, drier, accumulator, bypass valve,

connecting tubing and the evaporator that are proven to be

defective due to workmanship or materials subject to the

conditions and exclusions below.This warranty is limited to

the replacement of the defective parts, with the owner paying

a processing fee and all other costs including labor.

V. Limitations & Exclusions

1) This Warranty shall apply to products purchased and

located in the United States and Canada. Products must

be purchased in the country where service is requested.

2) Warranty applies only to the original purchaser and may

not be transferred.

3) Warranty is in lieu of all other warranties expressed or

implied and all other obligations or liabilities related to the

sale or use of Lynx products.

4) Warranty shall not apply and Lynx is not responsible

for damage resulting from misuse, abuse, failure to

provide reasonable and necessary required maintenance,

natural disaster, animals, alteration of or tampering with

the appliance, accident, hostile environment, improper

installation or operation, or an installation not in

accordance with the instructions contained in this manual,

or the local codes.

4) Warranty does not apply to products installed in any

commercial or non-residential application. Examples of

excluded applications include, but are not limited to day

care centers, schools, bed and breakfast centers, churches,

private clubs, fire stations, club houses, common areas in

multi-family dwellings, restaurants, hotels, nursing homes,

food service locations and institutional food service

locations. *Contact Lynx for Common Area Warranty.

5) To correct normal adjustments or settings, due to improper

installation.

6) Shipping and handling costs, export duties, installation,

removal, or re-installation cost (RMA excluded).

7) Display models are sold “as is”. If you have purchased

a display model, please be advised that it is sold “as is”

and that it is subject to the following warranty exclusions:

any exterior or cosmetic damage is nonwarrantable;

any missing components will be replaced at consumers

expense; major handling damage to manifold, valve and

ignition system will be serviced at consumer’s expense; all

other warranties will remain in effect.

8) The cost of a service call to diagnose complaint.

9) Modification to Lynx product will void related warranties.

10) The original bill of sale, deliver date or serial number

cannot be verified.

11) Defective parts ar not returned for inspection if so

requested by Lynx.

12) The refrigeration equipment is not in the possession of

the original end use purchaser.

13) Any content loss due to product failure.

5) Lynx shall not be liable for incidental, consequential,

special or contingent damages resulting from its breach of

this written warranty or any implied warranty.

6) Some states do not allow limitations on how long an

implied warranty lasts, or the exclusions of or limitations on

consequential damages. This warranty gives you specific

legal rights and you may have other rights which vary from

state to state.

7) No one has the authority to add to or vary Lynx’s warranty,

or to create for Lynx any other obligation or liability in

connection with the sale or use of its products.

8) Limited to the replacement of defective parts with the

owner paying all other costs including labor.

VI. What is not covered: Lynx shall not be responsible for

and shall not pay for the following

1) Installation or start-up, damages or problems caused by

improper installation or use;

2) Service by an unauthorized service provider;

3) Damage or repair due to service by an unauthorized

service provider or use of unauthorized parts;

Page 29

The best outdoor kitchen products come from:

Lynx Grills, Inc. 7300 Flores Street Downey, CA 90242

Service: (888)-289-5969 Fax: (562) 299-6789

www.lynxgrills.com

41014991-EN Rev A

3/7/18

All specications and product designs subject to change without notice. Such revisions do not entitle

the buyer to corresponding changes, improvements, additions, replacements or compensation for

previously purchased products.

Loading...

Loading...