Page 1

Page 2

/ L

A Message to Our Customers...

Thank You for choosing LYNX as your new gas grill. With proper use and care, we're confi-

dent that our product will provide years of trouble-free service. Careful attention has been put

into every detail of this grill and, by reading this entire manual before your first use, you will be

assured of maximum performance and enjoyment.

This manual also contains important safety tips and some hints for better grilling. Please keep it

in a convenient location so it will be available to answer any future questions. Should your LYNX

grill change ownership, please make sure that the new owner receives this manual.

We love to hear from our customers. Please feel free to contact us with any questions or prob-

lems, or to share a new recipe. Please include the model number of your grill inyour correspon-

dence. Thanks again for your purchase. Enjoy!

Page 3

This manuel covers the following 2008 Lynx products:

Installation, Care and Use

of Your Lynx Professional

Cooking Product

GRILL MODELS

L27 & L27F

L27R & L27FR

L30R & L3OFR

L36R & L36FR

L42R & L42FR LPSGE

PROSEAR MODELS

L3OPSR & L3OPSFR

L36PSR & L36PSFR

L42PSR & L42PSFR

L54PSR & L54PSFR

SIDE BURNER MODELS

LSB2PC

LSB1

LSB2

FOR OUTDOOR USE ONLY

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ THIS MANUAL

THOROUGHLY BEFORE INSTALLATION, USE OR SERVICING OF THIS EQUIPMENT

CALIFORNIA PROPOSITION 65 WARNING

The burning of gas cooking fuel generates some by-products, which are on the list of substances, which are

known by the State of California to cause cancer or reproductive harm. California law requires businesses to

warn customers of potential exposure to such substances.To minimize exposure to the substances, always

operate this unit according to the use and care instructions found in this manual. Be certain to provide

adequate ventilation when cooking. California Proposition 65 lists "Silica, crystalline"which is used in one of

the components of the IR burner, asan agent known to the state of California to cause cancer.

NOTE TO INSTALLER

This manual must remain with grill. Check your local building codes for proper method of installation. In

the absence of local codes, this unit should be installed in accordance with National Fuel Gas Code No. ANSI

Z21.58D-2002 USA or CAN/CGA-B149.1/.2 Natural Gas/Propane Code.(Canada) latest edition or the National

Electrical Code ANSI/NFPA No. 70 or the Canadian Electrical Code CGA 1.662005 or latest edition.

In Massachusetts: All gas products must be installed using a" Massachusetts" licensed

plumber or gas fitter. A'T" handle type manual gas valve must be installed in the gas supply

line to this appliance.This applies to permanently installed natural gas and propane instal-

lations. This does not apply to propane portable installations using a 20 pound tank (not

included) plus regulator and hose assembly, which is supplied with propane gas grills.

Rev. 12-07

Page 4

Important Safety Considerations

WARNING!Read this manual carefully and completely before using your grill to reduce the risk of fire, burn

hazard or other injury, and to ensure proper installation and servicing.

FOR YOUR SAFETY

If you smell gas:

1. Shut off gas to the appliance.

2. Extinguish any open flames.

2. Open lid.

4. If odor continues, keep away from the

appliance and immediately call your gas

supplier or fire department.

FOR YOUR SAFETY

1. Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of

this or any other appliance.

2. An LP cylinder not connected for use shall

not be stored in the vicinity of this or any

other appliance.

AVERTISSEMENT

S'ily a une odeur de gaz:

1.Coupez I'admission de gaz de I'appariel.

2. leteindre toute flamme nue.

3.Ouvrir le couvercle.

4. Si I'odeur continue, evite I'appareil et appelle

tout de suite votre fournisseur de gaz ou les

pompiers.

AVERTISSEMENT

1. Ne pas entreposer ni utiliser de I'essence ni

d'autres vapeurs ou liquides inflammables

dans le voisinage de I'appareil, ni de tout

autre appareil.

2. Une bouteille de propane qui n'est pas

raccordee en vue de son utilisation, ne doit

pas _tre entreposee dans le voisinage de cet

appareil ou de tout autre appareil.

FOR OUTDOOR USE ONLY: If stored

indoors, detach and leave L.P. cylinder

outdoors.

BEFORE LIGHTING

1. Read instructions before lighting.

2. Open lid during lighting.

3. If ignition does not occur in 5 seconds, turn

the burner control(s) off, wait 5 minutes, and

repeat the lighting procedure.

B_LyNX

POUR UTILISATION A L'EXTCRIEUR

SEULEMENT: Si I'appareil est entrepos_

I'interieur, enlever les bouteilles et les

laisser _ I'ext_rieur.

AVANT D'ALLUMER

L'APPAREIL

1. Lisez les instructions avant d'allumer I'appareil.

2.Ouvrez le couvercle avant d'allumer I'appareil.

3. Si I'appareil ne s'allume pas en 5 secondes,

fermez le robinet du brOleur, attendez 5 min-

utes, et procedez de nouveau a I'allumage.

Page 5

Table of Contents

Precautions for Installation and Storage ............................................................. 2

Locating Your Grill ................................................................................. 4

Cutout Dimensions for 2008 Built-ins ............................................................... 5

Unpacking and Assembly .......................................................................... 6

Electrical Requirements & Hook-up ................................................................. 7

Gas Requirements & Hook-up ...................................................................... 8

Precautions for Using Your Grill ................................................................... I 0

LeakTesting ..................................................................................... 11

Model Identification ............................................................................. 12

Using the Grill ................................................................................... 13

Lighting the Brass Burners ........................................................................ 14

Using the ProSear Burner ......................................................................... I 5

Using the Rotisserie .............................................................................. 16

Using the Smoker Box ............................................................................ 17

Cleaning the Grill ................................................................................ 18

Burner Cleaning & Adjustment ................................................................... 19

Troubleshooting ................................................................................. 20

Light Bulb Replacement .......................................................................... 21

Replacing the Briquettes ......................................................................... 21

Side Burner/LPSGE Gas Hookup .................................................................. 22

Lighting the Side Burner or LPSGE................................................................ 23

Warranty ........................................................................................ 24

How to Obtain Service ........................................................................... 25

Wiring Diagrams .............................................................................. 26-27

Gas Plumbing Requirements ..................................................................... 28

Parts Diagram .................................................................................... 29

Parts List ......................................................................................... 30

IF SHIPMENT ARRIVES DAMAGED:

1) VISIBLE LOSSOR DAMAGE: Be certain this is noted on freight bill or express receipt and signed by

person making delivery.

2) FILE CLAIM FOR DAMAGES IMMEDIATELY, regardless of extent of damage.

3) CONCEALED LOSSOR DAMAGE: If damage is unnoticed until merchandise is unpacked, notify

transportation company or carrier immediately and file "concealed damage"claim with them.This

should be done within (15) days of date delivery is made to you. Be sure to retain container for

inspection. We cannot assume responsibility for damage or loss incurred in transit.

See page 25 for information on obtaining service or contacting Lynx.

B _lyNX

Page 6

Precautions for Installation and Storage

I) DO NOT store or use gasoline

or other flammable vapors and

liquids in the vicinity of this or

any other appliance.

2) Never store additional or

empty propane cylinders in the

grill cabinet or around the grill.

Do not store propane cylinders

indoors or on their sides. Never

use dented, rusty or damaged

propane cylinders.

3) Children should not be left

alone or unattended in an area

where a grill is located. Placeyour

grill well away from areas where

children play. Do not store items

that may interest children in or

around the grill, in the cart or in

the masonry enclosure. When in

use, portions of the grill are hot

enough to cause severe burns.

4) Never move the grill when hot.

S) Always adhere to the required

clearances from combustibles as

detailed. The grill is designed for

outdoor use only. Never use in a

garage, building, shed, breeze-

way or other enclosed area.

6) Gas grills are not design cer-

tified for and are not to be

installed in or on recreational

vehicles, portable trailers, boats

or any other moving installation.

7) Have an ABC Fire Extinguisher

accessible -- never attempt to

extinguish a grease fire with

water or other liquids.

8) Store your grill in a well-ven-

tilated area. Remove the L.P.cyl-

inder, if so equipped, and store

it outdoors in a well-ventilated

area away from heat and away

from where children may tam-

per with it.

9) Keep any electrical supply

cord and the fuel supply hose

away from any heated surfaces.

Electrical cords should be placed

away from walkways to avoid

tripping hazard.

10) Do not repair or replace

any part of the grill unless spe-

cifically recommended in this

manual. Other service should be

performed by a qualified tech.

11) If the grill is installed by a

professional installer or techni-

cian, be sure that he shows you

where your gas supply shut-off is

located. All gas lines must have

a shut-off that is readily and eas-

ily accessible. If you smell gas,

check for gas leaks immediately.

Check only with a soap and

water solution. Never check for

gas leaks with an open flame.

SPECIAL NOTE ON USING YOUR GRILL IN WINDY CONDITIONS

As a high-performance gas ap-

pliance, your Lynx grill requires

significant amounts of air to sup-

port the combustion process.

Your grill has been engineered

to take air in through the con-

trol panel area, and exhaust the

combustion byproducts out

through the gap between the

front and rear hoods (see figure

3-2 at right).

Using your grill in windy condi-

tions can disrupt the proper flow

of air through your grill, lead-

ing to reduced performance, or

in certain severe cases, causing

heat buildup in the control panel

area. This can lead to problems

such as having the control knobs

melt, or burn hazards when the

control panel surfaces become

too hot to touch.

During windy conditions, it is

best if you don't use your grill.

If you have a freestanding grill,

it is best to position the unit so

the prevailing wind blows into

the front control panel (or at

your back), thus supporting the

proper airflow. Winds hitting

the back of the grill directly are

the most likely to cause prob-

lems, although wind blowing

along the hood gap can also be

problematic.

Please note that damage to

your grill resulting from use

in windy conditions, such

as melted knobs or igniter

wires, or control panel dis-

coloration from heat build-

up, are excluded from war-

ranty coverage.

2 B_lyNX

Page 7

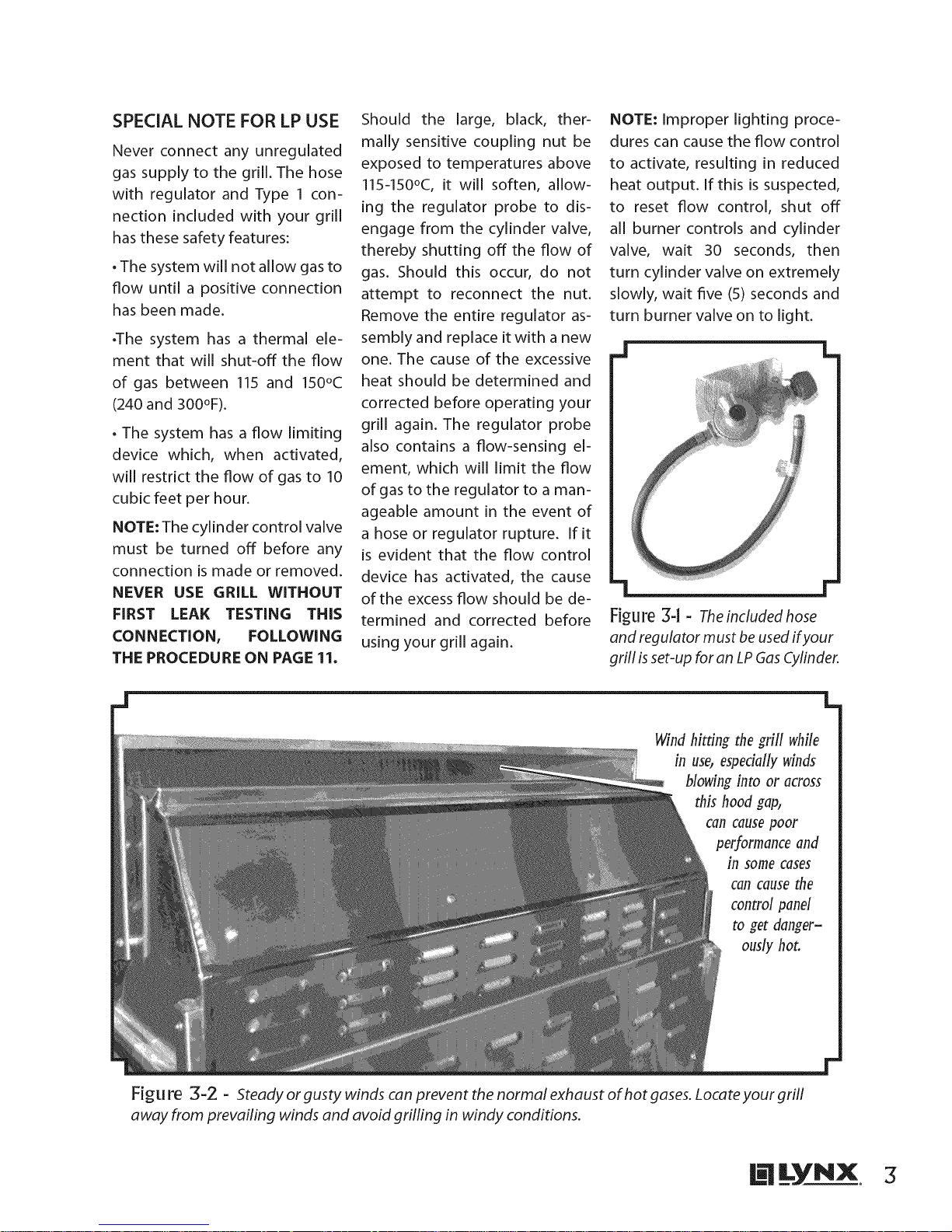

SPECIAL NOTE FOR LP USE

Never connect any unregulated

gas supply to the grill. The hose

with regulator and Type 1 con-

nection included with your grill

has these safety features:

. The system will not allow gas to

flow until a positive connection

has been made.

.The system has a thermal ele-

ment that will shut-off the flow

of gas between 115 and 150°C

(240 and 300°F).

. The system has a flow limiting

device which, when activated,

will restrict the flow of gas to 10

cubic feet per hour.

NOTE: The cylinder control valve

must be turned off before any

connection is made or removed.

NEVER USE GRILL WITHOUT

FIRST LEAK TESTING THIS

CONNECTION, FOLLOWING

THE PROCEDURE ON PAGE 11.

Should the large, black, ther-

mally sensitive coupling nut be

exposed to temperatures above

115q50°C, it will soften, allow-

ing the regulator probe to dis-

engage from the cylinder valve,

thereby shutting off the flow of

gas. Should this occur, do not

attempt to reconnect the nut.

Remove the entire regulator as-

sembly and replace it with a new

one. The cause of the excessive

heat should be determined and

corrected before operating your

grill again. The regulator probe

also contains a flow-sensing el-

ement, which will limit the flow

of gas to the regulator to a man-

ageable amount in the event of

a hose or regulator rupture. If it

is evident that the flow control

device has activated, the cause

of the excess flow should be de-

termined and corrected before

using your grill again.

NOTE: Improper lighting proce-

dures can cause the flow control

to activate, resulting in reduced

heat output. If this is suspected,

to reset flow control, shut off

all burner controls and cylinder

valve, wait 30 seconds, then

turn cylinder valve on extremely

slowly, wait five (5) seconds and

turn burner valve on to light.

J L

l-

Figure 3-1 - Theincludedhose

and regulator must be used ifyour

grill isset-up for an LP GasCylinder.

Wind hitting the grill while

in use, especially winds

blowing into or across

this hood gap,

Call cause poor

performance and

in some cases

can cause the

control panel

ous/y hot.

Figu re 3-2 - Steady or gusty winds can prevent the normal exhaust of hot gases. Locate your grill

away from prevailing winds and avoid grilfing in windy conditions.

@LYNX 3

Page 8

Locadng Your GH

When selecting a suitable loca-

tion, take into account concerns

such as exposure to wind and

traffic paths. Try to keep all gas

supply lines as short as possible.

Never locate the grill under a

roof or overhang, in a build-

ing, garage, shed or other such

enclosed area. A carpenter's

"spirit level" should be used to

assure that the unit is level both

front-to-back and side-to-side.

If it is not level, burner combus-

tion may be erratic or the unit

may not function efficiently. If

the floor is uneven or has a de-

cided slope, re-leveling may be

required after each moving of a

freestanding unit.

BUILT-IN INSTALLATIONS:

The LYNX Built-In Grill is designed

for easy installation into mason-

ry enclosures. For non-combus-

tible applications, the grill drops

into the opening shown in the

cutout detail drawing and hangs

from its counter-top trim. A deck

isnot required to support it from

the bottom. When using the in-

sulated jacket in a combustible

enclosure, the jacket must be

supported from the bottom by a

ledge on each side or a full deck

beneath the jacket. Review the

detailed drawing and pay spe-

cial attention to the provisions

shown for gas line hook-up. It is

recommended that the enclo-

sure have ventilation holes to

prevent gas build-up inthe event

of a leak. The deck ledges and

counter should be flat and level.

If your grill isequipped with a to-

tisserie, electrical service should

be provided (on the Left Side of

most models).

REARHOOD CLEARANCE:

Clearance is required behind the

grill to allow the front hood to

open (see figure 4q). 27" and 36"

models require a minimum of 2"

clearance, while 30", 42" and 54"

models require a minimum of

4" clearance. The grill exhausts

combustion products and cook-

ing greases to the back. Never lo-

cate the grill where this exhaust

will be difficult to clean.

2" rain. for 27" grills

4" rain. for all other sizes

Figu re 4-1 - Requireddearance

to allow opening of front hood.

CLEARANCE TO COMBUSTIBLE

CONSTRUCTION:

Minimum clearance from sides

and back of unit to adjacent

combustible construction below

top of unit are 12" from sides and

12"from back.

D_gagement minimal entre les

parois lat_rales et I'arri¢re de

I'appafiel et la construction com-

bustible au-dessous du panneau

sup_fieur de I'appareil (30 cm

partir des parois lat_rales et 30 cm

partir de I'arri¢re).

Minimum horizontal clearance

from sides and back of unit to

adjacent vertical combustible

construction extending above

top of unit is 12" from sides and

12"from back.

D_gagement horizontal minimal

entre les parois lat_rales et I'arri¢re

de I'appafiel et la construction

verticale combustible au-dessus

de I'appareil (30 cm _ partir des

parois lat_rales et 30 cm _ partir

de I'arfi¢re).

Do not use this appliance under

overhead combustible surfaces.

Ne pas u_'liser cet appareil sous

une surface combustible.

A minimum of 6" of clearance is

needed on each side of the grill

for the motor and skewer.

If the grill is to be placed into

a combustible enclosure, an

approved insulated jacket is

necessary and isavailable from

your LYNX dealer. Use only a

LYNX insulated jacket as it

has been designed and tested

specifically for your Grill. Refer

to next page for cutout dimen-

sions.

WARNING

Installing this product

into a combustible en-

closure without an insu-

lated jacket could result

in fire, property damage

and personal injury.

4 lil YNX

Page 9

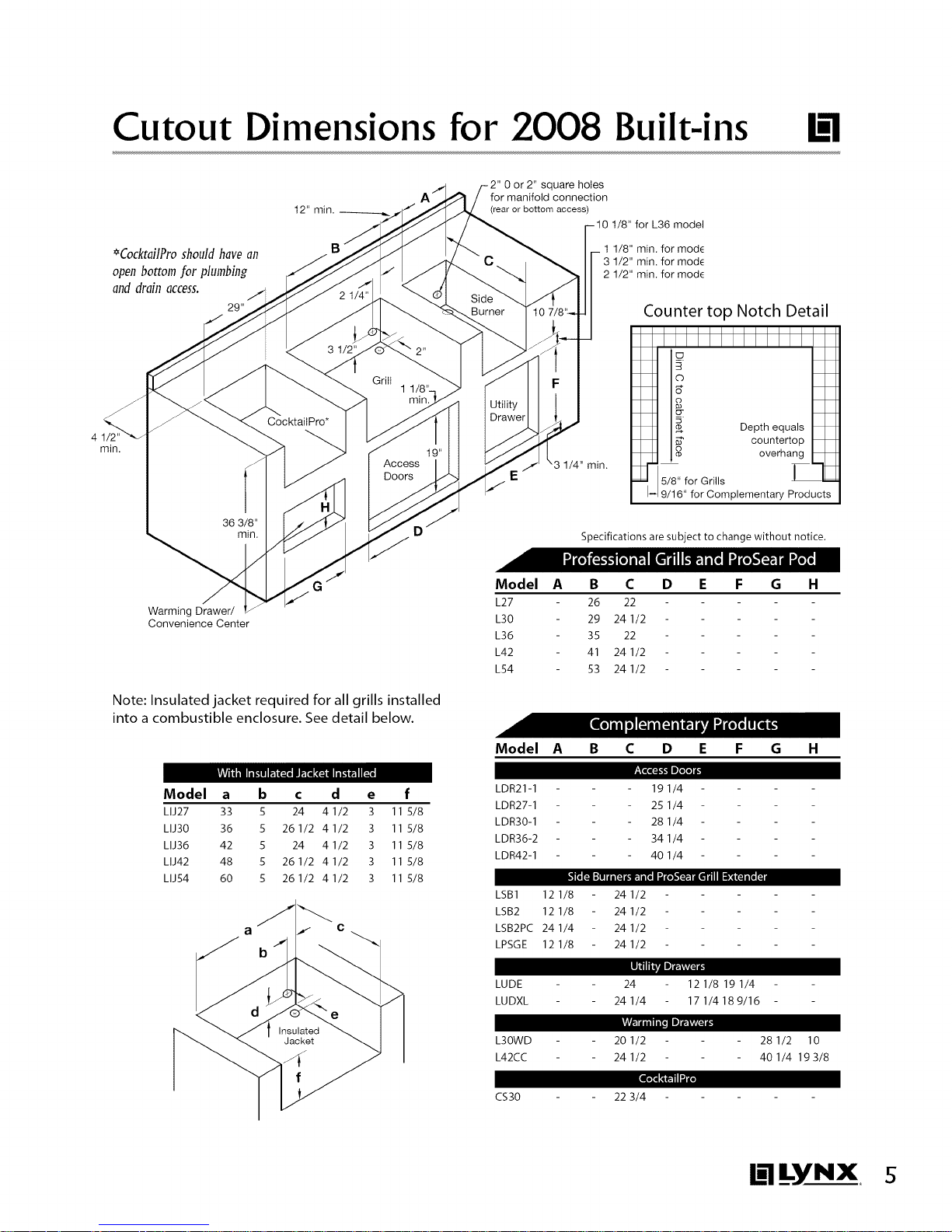

Cutout Dimensions for 2008 Built-ins

0 or 2" square holes

for manifold connection

(rear or bottom access)

*CocktailPro should have an

open bottom for plumbbg

and drain access.

2g"

1/8" for L36 model

1 1/8" min. for mod_

3 1/2" min. for mod_

2 1/2" min. for mod_

Counter top Notch Detail

IIIIIIIIIIII1

41/2"

min.

Warming Drawer/

Convenience Center

Note: Insulated jacket required for all grills installed

into a combustible enclosure. See detail below.

Model a b c d e f

LIJ27 33 5 24 4 1/2 3 11 5/8

LIJ30 36 5 261/2 41/2 3 11 5/8

LIJ36 42 5 24 4 1/2 3 11 5/8

LIJ42 48 5 26 I/2 4 I/2 3 11 5/8

LIJ54 60 5 26 1/2 4 1/2 3 11 5/8

b

O DecPthur_q _taol; I_

] o overhang I_t

_r 5/8. for Grills _-_ TM

--I 9/16" for Complementary Products

Specifications are subject to change without notice.

Model A B C D E F G H

L27 26 22

L30 29 24 1/2

L36 35 22

L42 41 24 1/2

L54 53 24 1/2

Model A B C D E F G H

LDR21-1

LDR27-1

LDR30-1

LDR36-2

LDR42-1

_Jl__l [_lll_fl

LSB1 12 1/8

LSB2 12 1/8

LSB2PC 24 1/4

LPSGE 12 1/8

191/4

251/4

281/4

341/4

401/4

24 1/2

24 1/2

24 1/2

24 1/2

_I_ID_

LUDE

LUDXL

24

24 I/4

12 I/8 19 I/4

17 I/4189/16

L30WD

L42CC

CS30

20 I/2

24 I/2

22 3/4

28 I/2 10

40 1/4 19 3/8

B_lyNX s

Page 10

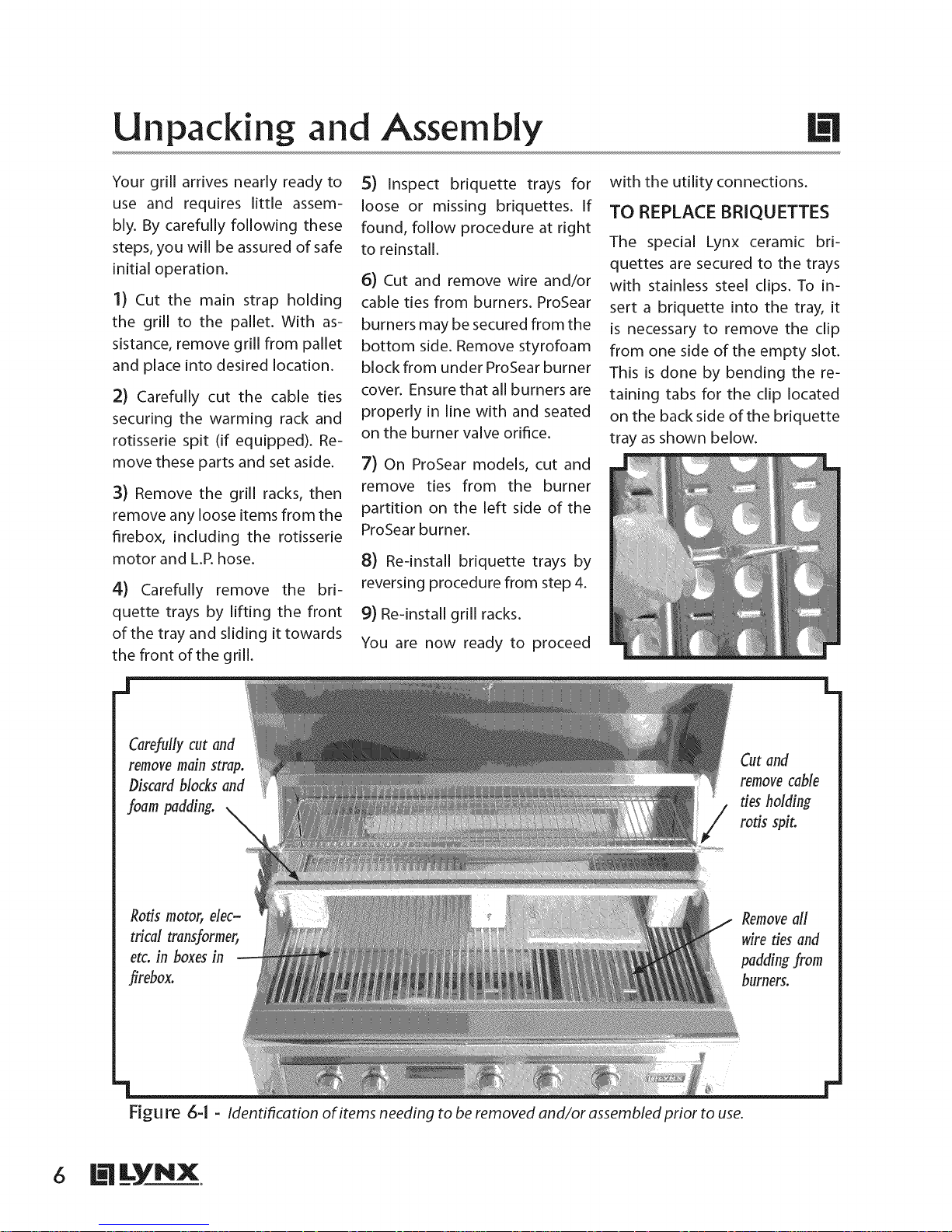

Unpacking and Assembly

Your grill arrives nearly ready to

use and requires little assem-

bly. By carefully following these

steps, you will be assured of safe

initial operation.

1) Cut the main strap holding

the grill to the pallet. With as-

sistance, remove grill from pallet

and place into desired location.

2) Carefully cut the cable ties

securing the warming rack and

rotisserie spit (if equipped). Re-

move these parts and set aside.

3) Remove the grill racks, then

remove any loose items from the

firebox, including the rotisserie

motor and L.R hose.

4) Carefully remove the bri-

quette trays by lifting the front

of the tray and sliding it towards

the front of the grill.

S) Inspect briquette trays for

loose or missing briquettes. If

found, follow procedure at right

to reinstall.

6) Cut and remove wire and/or

cable ties from burners. ProSear

burners may be secured from the

bottom side. Remove styrofoam

block from under ProSear burner

cover. Ensure that all burners are

properly in line with and seated

on the burner valve orifice.

7) On ProSear models, cut and

remove ties from the burner

partition on the left side of the

ProSear burner.

8) Re-install briquette trays by

reversing procedure from step 4.

9) Re-install grill racks.

You are now ready to proceed

with the utility connections.

TO REPLACE BRIQUETTES

The special Lynx ceramic bri-

quettes are secured to the trays

with stainless steel clips. To in-

sert a briquette into the tray, it

is necessary to remove the clip

from one side of the empty slot.

This is done by bending the re-

taining tabs for the clip located

on the back side of the briquette

tray as shown below.

F[gu re 6-1 - Identification of items needing to be removed and/or assembled prior to use.

6 @LYNX

Cut and

remove cable

ties holding

rotis spit.

Removeall

wireties and

burners,

Page 11

Electrical Requirements Hook-up

WARNING

Electrical Grounding

Instructions:

This outdoor gas cooking appli-

ance is equipped with a three-

prong (grounding) plug for your

protection against shock hazard

and should be plugged directly

into a properly grounded three-

prong outlet. Do not cut or remove

the third prong from this plug.

AVERTISSEMENT

Instruction pour la mise _ la

terre electrique:

Cet appareil est muni d'une fiche

trois broches (mise _ la terre) afin

de vous prot_ger des chocs et dolt

_tre branch_ directement dans une

prisede courant _ trois broches ad_-

quatement mise _ la terre, line faut

pas couper ou enlever la broche de

mise _ la terre de cette fiche.

CONNECTION TO AC

Installation should include an

outdoor 120VAC 15A GFI electri-

cal outlet located adjacent to the

grill. A qualified electrician can

install a GFI outlet either inside

the island enclosure for built-in

units, or near the normal location

of use for freestanding units. The

GFI plug has an internal breaker

which reduces shock hazard.

For freestanding grills, simply

plug the electrical cord into a GFI

plug. For built-in units, the sup-

plied 12Vtransformer is connect-

ed to the grill during installation

(see Fig. 7-1).

Figure 74 - Transformer con-

nectionpoint on left rear grill

frame.

Once connected to the grill, the

power cord may be plugged into

a GFI outlet. If the electrical sys-

tem fails to operate, a connection

may have come loose in shipping.

See the Troubleshooting section

for more details.

BATTERY REPLACEMENT

(Recommended Batteries include:

Rayovac Maximum Plus Alkaline -

#813,D size/Duracell Coppertop Al-

kaline - #MN1300, D size/ Energizer

Alkaline - #E95,D size)

Your grill includes two D Cell

batteries that provides backup

power for the electronic ignition

system. To replace the batteries,

follow this procedure:

1) Locate the battery compart-

ment. On free standing models

this is located inside the grill cart

on back left. (For 42" free stand-

ing models you will need to re-

move both storage drawers). For

built-in models it is located under

the unit where the installer has

mounted the battery and trans-

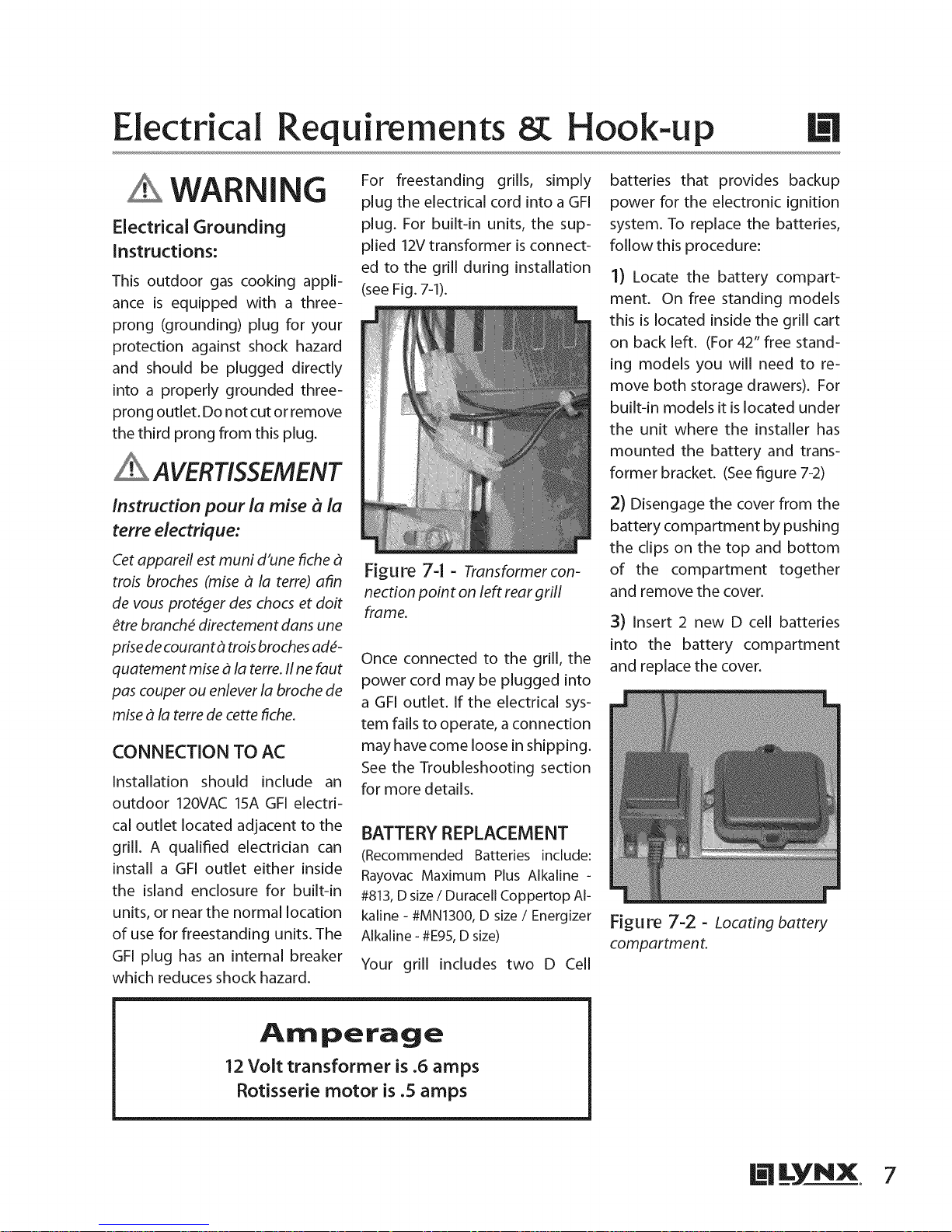

former bracket. (See figure 7-2)

2) Disengage the cover from the

battery compartment by pushing

the clips on the top and bottom

of the compartment together

and remove the cover.

3) Insert 2 new D cell batteries

into the battery compartment

and replace the cover.

Figure 7-2 - Locating battery

compartmen t.

Amperage

12 Volt transformer is .6 amps

Rotisserie motor is .5 amps

Page 12

Gas Requirements Hook-up

Your grill is setup to use either

propane (LP)or natural gas (NAT).

It is very important that the

grill rating plate matches

with your gas supply.

The rating plate is located in one

or more of the following places:

• under the drip tray

• on the heat shield behind the

front panel

• on the inside left cabinet wall

(most freestanding grills)

Do not attempt to operate the

grill on any gas other than what

the grill is orificed for and what

the regulator is set for. Should

you need to convert your grill

for use with a different gas type,

a conversion kit, available from

your dealer, is required.

Never connect an unregu-

lated gas line to the grill.

so as to calculate what size diam-

eter pipe is needed, for the total

length of pipe from the gas main

(at house) to grill hook-up. If the

gas line is too small, the grill will

not function properly. In no case

should pipe less than 3/4" in-

side diameter or 1" outside

diameter be used to connect

this product.

An installer-supplied gas

shut-off valve must be in-

stalled in an easily acces-

sible location. All install-

er-supplied parts must

conform to local codes

with the National Electrical

Code, ANSI/NFPA 70-1990

and the National Fuel Gas

Code, ANSI Z21.58D-2002.

The appliance and its individual

shut off valve must be discon-

nected from the gas supply

piping system during any pres-

sure testing of that system at

test pressures above 1/2" PSIG

(3.5KPA). The appliance must

be isolated from the gas supply

piping system by closing its in-

dividual manual shut off during

any pressure testing. Do not ap-

ply threading compound to the

first two pipe threads as to avoid

clogging of the burner valves

and orifice. Do not put sealant

on any male end of flare fittings.

For built-in installations, it is rec-

ommended that anyflexible pipe

used be kept as short as possi-

ble. For freestanding units using

natural gas, it is strongly recom-

mended that a quick disconnect

kit from Lynx be installed. This

kit, part #LQD, is available from

,our dealer.

IMPORTANT- See Gas

Plumbing Requirements

on page 28 for additional

information

NATURAL GAS

The installation of the grill must

conform with local codes or, in

the absence of local codes, to

the National Fuel Gas Code ANSI

Z21.58D-2002 or latest edition. If

installed in Canada, installation

must be in accordance with Gas

Code CAN / CGA-B149.1/.2 and

local codes.

The gas supply line must be

sized to accommodate all the

gas-fired equipment that may

be connected to that supply,

i.e. total BTU output to be con-

sumed, needs to be determined

8 B_lyNX

Fittingsshown below are for a

typicd installation and are not

supplied with the grill. As each

installation may require differ-

ent plumbing, Lynx recomlnends

that this step be performed by

a qualified technician.

Male to 3/4" Female elbow

Incoming natural

as supply pipe

Shut-off valve

Convertible Regulator --

supplied with gril!

(Gas type conversion

requires conversion kit -

contact dealer for details)

3/4" Min. Dia.

flexible connector

NPT

J

Figu re 8-1 - Typical attachment for using natural gas.

L

Page 13

L.P. GAS

Grills orificed for use with L.P.gas

come equipped with an LP hose/

regulator assembly for connec-

tion to a standard 20 lb. L.P.cyl-

inder (Type 1).All fttings neces-

sary to attach the hose/regulator

to the grill are included. The L.P.

tank is not included. Operating

pressure: 11.0" W.C.

L.P.Tank Requirements

A dented or rusty L.P.tank may

be hazardous and should be

checked by your L.R supplier.

Never use a cylinder with a dam-

aged valve. Always check for

leaks after every L.Rtank change

(see page 11).

The L.R gas cylinder must be

constructed and marked in ac-

cordance with the specifications

for L.R gas cylinders of the U.S.

Department of Transportation

(DOT) and designed for use with

a Type 1 system only. Do not

change the regulator/hose as-

sembly from that supplied with

the unit or attempt to use a

5LP-A equipped regulator/hose

assembly with a standard 510

POL tank/valve assembly. The

cylinder must be provided with

a shut off valve terminating in

an L.R gas supply cylinder valve

outlet specified, as applicable,

for connection Type 1.

Turn off LP-gas supply at cylinder

when appliance is not in use.

Fermez I'alimentation en GPL

la bouteille si I'appareil ne fonc-

tionne pas.

The LP-gas supply cylinder must

be disconnected when this ap-

pliance is not in use.

La bouteille de GPL doit _tre d_-

connect_e si cet appareil ne fonc-

tionne pas.

Your local L.P. filling station

should be equipped with the

proper equipment to fill your

tank. If trading your tank in,

always ensure to obtain only

Type 1 201b cylinders with an

overfill protection device.

L.P.Connections

Connect the 3/8"flare end of the

L.R hose to the brass adapter on

the manifold (as shown in fig-

ure 9-1). Connect the Regulator

to the tank (with the tank valve

fully closed). Although the flow

of gas is stopped when the Type

1 system is disconnected, you

should always turn the L.R tank

main valve off after each use

and during transport of the tank

or unit. Insert the regulator inlet

into the tank valve and turn the

black coupler clockwise until the

coupler is tight. Do not over-

tighten the coupler.

To disconnect the coupler, first

make sure the main tank valve

is turned off. Grasp the coupler

and turn counter clockwise. The

inlet will then disengage.

For hard plumbed LP connec-

tions to a large source (tank), a

4/11 regulator must be utilized.

Never connect an unregulated

gas line to the grill.

Gas Line Purging

To purge the L.P.gas line, make

sure all controls are in the OFF

position. Turn the main tank

valve on SLOWLY and turn one

burner control valve on the unit

to the "light" position (DO NOT

LITE GRILL). Leave control ON for

about 20 seconds to allow the

air in the system to purge. Wait

5 minutes before attempting to

light the burners.

Do not attempt lighting the grill

within 5 minutes after purging!

Use regulator here for L

hard-plumbed L.P.hookup

(LYNX P/N 30781)

L.Rhose/regulator

Cylinders must be stored

outdoors in a well-ventilat-

ed area out of the reach of

children. If the appliance

is stored indoors, the L.R

cylinder must be removed

from the appliance, and

stored outside.

3/8"flare fitting (hose ships

pre-installed on grill)

1

20 Ib.Type 1 L.P.tan

Figure 9-1 - Typical attachment to L.Rtank.

B_lyNX 9

Page 14

Precautions for Using Your Grill

READ THIS MANUAL CARE-

FULLY AND COMPLETELY

BEFORE USINGYOURGRILL

TO REDUCE THE RISK OF

FIRE, BURN HAZARD OR

OTHER INJURY.

Safety Precautions

1)NEVER LEAVE THE GRILL UN-

ATTENDED WHILE COOKING.

2) Prior to using grill ensure that

all tie down wires have been re-

moved from burners.

3) Never operate the grill in a

windy area. See page 2 for de-

tails.

4) Avoid wearing loose-fitting

garments or long sleeves while

using the grill. Never touch the

grill racks, hood or immediate

surrounding metal surfaces with

your bare hands as these areas

become extremely hot during

use and could cause burns.

S) Use an insulated glove or mitt

when opening and operating

the grill. Open grill lid slowly to

allow heat and smoke to escape

before fully opening.

6) Never lean over hot grill sur-

face or look directly into the grill

when attempting to light. The

grill hood must be fully opened

when lighting.

7) Do not heat unopened food

containers as pressure build-up

may cause container to burst.

8) Do not use aluminum foil to

line grill racks or drip pans. This

will alter combustion airflow or

trap excessive heat in the control

area. This can result in melted

knobs and ignition modules.

Never cover or block grilling area

with anytype of pots and/or pans.

These damages are specifically

excluded from your warranty.

9) Never use charcoal in the grill.

10) Be aware that cooking exces-

sively fatty meats and other such

products will cause flare ups.

Internal fires or damage caused

by flare-ups or the grill being left

unattended while cooking, are

not the responsibility of LYNX

and any resulting damage is not

covered under the terms and

conditions of our warranty.

11) Never grill without the drip

pan in place. The drip pan must

be pushed all the way to the back

of the grill. Without the drip pan

in place, hot grease could leak

downward and produce a fire or

explosion hazard.

12) Grease is extremely flam-

mable. Let hot grease cool down

before attempting to handle

or dispose of it. The drip tray

should be cleaned of grease on

a regular basis.

13) Do not use the grill until a

leak check has been performed

(see page 11).

14) Do not operate grill under

the influence of alcohol or drugs.

15) If equipped, never place

more than 30 pounds on a side

shelf. Do not lean on shelves.

16) If any burner does not light

or goes out during operation,

turn off all gas control knobs

with hood open and wait five (5)

minutes before attempting to

re-light.

WARNING

Spiders and insects can

nest in the burners of

this or any other grill,

and cause gas to flow

from the front of the

burner. This is a very

dangerous condition

which can cause a fire to

occur behind the valve

panel, thereby damag-

ing the grill and making

it unsafe to operate.

If your grill has been

stored or unused for a

prolonged period, it is

recommended that the

burners be removed, in-

spected, and cleaned if

needed according to the

instructions on page 19.

Jo LYNX

Page 15

Leak Testing

To Perform Leak Test

1) Create a soapy solution of

equal parts mild dish washing

detergent and water.

2) Confirm that all control knobs

are in the off position.

3) Turn on fuel supply. For natu-

ral gas, turn valve handle 1/4turn

to align with gas flow. For L.R,

turn cylinder valve knob counter

clockwise one full rotation.

4) Apply soap solution gener-

ously by paint brush or squirt

bottle on all connections and

fittings, as indicated in figures 1

and 2.

S) If "growing" bubbles appear

on any of the connection points,

then you have detected a gas

leak. IMMEDIATELY turn off the

gas supply by reversing step 3.

CAUTION DANGER

To prevent fire or explosion hazard, DO NOT use or

permit sources of ignition in the area while perform-

ing a leak test. Perform leak test outdoors only. Never

perform a leak test with fire or flame. DO NOT SMOKE

WHILE PERFORMING THE LEAK TEST!

J L

Fixing a Gas Leak

1) After shutting off gas sup-

ply, push in and turn on control

knobs to release pressure, then

turn the knobs back to off.

2) Wash off soapy solution with

cold water and towel dry.

3) Stop a leak by tightening

the loose joint, or by replacing

the faulty part with a replace-

ment part recommended by the

manufacturer. DO NOT attempt

to repair the L.P.cylinder valve if

it should become damaged; the

cylinder MUST BE REPLACED.

4) Perform a new leak test to en-

sure that no leaks are present.

.l

r

Figu re 11-1= Leak testing points when using natural gas.

J L

Figu re 11-2- Leak testing points when using L.P.gas.

blL_YNX .

Page 16

Model Identification

54" Professional

Light Rotis Grill Grill

Switch

42" Professional 30" Professional

Light Rotis Grill Grill

Switch

36" Professional

Grill

(opt. ProSear)

Grill ProSear Rotis

Light Rotis Grill Grill

Switch (opt. ProSear)

27" Professional

@@ @

[

Light Rotis Grill Grill Grill

Switch (opt. ProSear)

Light Rotis Grill Grill

Switch (opt.)

BURNER TYPE IDENTIFICATION

Depending on the model, your Lynx grill may be equipped with up to three different burner types. The

operation of each burner type varies, so it is important to familiarize yourself with all three.

Brass - This is the standard

main gril! burner found under

the briquette trays

J2 @LYNX

ProSear - Thisisa high

intensity infrared burner that

is optional on most models.

Rotis- This is an infrared

burner found in the rear of

the grill above the grill racks.

Page 17

Using the Grill

Grilling requires high heat for

searing and proper browning.

Most foods are cooked at the

"HI" heat setting for the entire

cooking time (with the lid open).

However, when grilling large

pieces of meat or poultry, it may

be necessary to turn the heat to

a lower setting after the initial

browning. This cooks the food

through without burning the

outside. Foods cooked for a long

time or foods basted with a sug-

ary marinade may need a lower

heat setting near the end of the

cooking time.

HOW TO SEAR

Searing locks in flavor and juices

while allowing the outer surface

to absorb smoke and food aro-

ma that is produced as grease

and drippings are vaporized by

the burner. The result is a crisp,

flavorful outside with a tender,

juicy inside. While the brass

burners in your grill are capable

of producing searing heat, the

ProSear infrared burner is specif-

ically designed for this purpose.

1) Properly pre-heat the grill by

following the lighting instruc-

tions on pages 14-15.

2) Leaving the burners setto "HI",

place food on grill grids for 2-3

minutes per side, or until food is

easily turned without sticking.

3) Adjust the burners to a lower

setting and continue cooking un-

til desired doneness is reached,

turning the food as needed.

INDIRECT COOKING

Indirect cooking is achieved by

placing the food only on one side

of the grill. Leave the burner be-

low the food "OFF" and an adja-

cent grill burner on "HI". Keep the

hood closed as much as possible

and regulate the heat with the

burner control, monitoring inter-

nal temperature with the hood

thermometer (if equipped).

1) Properly pre-heat the grill by

following the lighting instruc-

tions on pages 14-15.

2) Once grill has been preheated,

turn off any burners not required

for cooking. The lid should be

closed as much as possible while

using the indirect method.

3) Place the food on the grill and

cook to the desired doneness.

Adjust heat setting as required

to maintain desired temperature.

WARNING

Never place food over

a ProSear burner that

is not lit and pre=heat-

ed. Food particles and

grease dripping onto a

cold ProSear burner can

clog ports and damage

the ceramic burner. This

damage is not covered

by your warranty.

PRE-GRILLING CHECKLIST

Before lighting the grill, perform the following checks to ensure safe operation:

[] Specified clearances maintained to combustibles?

[] All internal packaging removed?

[] Knobsturn freely?

[] Pressure regulator connected to proper gas type?

[] Unit is leak tested and free of leaks?

[] User informed of gas supply shut off valve location?

[] Burners are sitting properly on orifices?

[] Wind is not blowing too strongly and/or hitting back of grill?

Once these checks are complete, you are ready to begin using your grill.

blLYNX B

Page 18

Lighting the Brass Burners

WARNING

Never attempt to lig ht grill

if odor of gas is present.

Hood must be open when

lighting. Keep face and

body parts asfar from grill

as possible when lighting.

Always wait at least 5 min-

utes before attempting to

relight a hot burner.

Before proceeding, make sure

you have completed the check-

list on the previous page. These

checks should be performed be-

fore each use of the grill.

Follow these steps to light the

main brass grill burners:

1) Open hood. Do not attempt to

light grill with the hood closed.

2) Check to ensure that all burner

control knobs are set to OFF.

3) Turn on main gas supply.

Purge if needed (see page 9).

4) Push in and turn burner con-

trol knob to LITE. Hold knob in

for 5 seconds.

S) If burner does not light, turn

knob to OFF,wait 5 minutes to al-

low gas to dissipate, and repeat

step 4 above.

After preheating,turn offall burn-

ers not required, carefully open

the hood, and adjust remaining

burners to desired temperature.

DO NOT LEAVE THE GRILL UNAT-

TENDED DURING THE PREHEAT

CYCLE OR AT ANY TIME WHILE

THE GRILL IS IN USE. DO NOT

ALLOW GRILL TO PREHEAT FOR

PROLONGED PERIODS OF TIME.

OVERHEATING THE GRILL CAN

CAUSE DAMAGE TO THE GRILL

AND PERSONAL PROPERTY.

MATCH LIGHTING

If burners will not light after sev-

eral attempts, the burners can be

match lit. If you've just attempt-

ed to light the burner with the

igniter, allow 5 minutes for any

accumulated gas to dissipate.

Make sure all knobs are in the

OFF position. Keep your face as

far away from the grill as pos-

sible. With the hood open, pass

the alternate lighting rod (Fig-

ure 14-1) with a lit paper match

clipped to the end past the ports

of the burner. Push and turn the

corresponding control knob of

the burner to LITE. If the burner

does not light in 4 seconds, turn

the knob off and wait 5 minutes

before attempting again.

LOW HEAT ADJUSTMENT

The valves on the grill feature

an adjustable low setting. Due

to fluctuations in gas pressure,

heating value or gas conversion,

you may feel it necessary to ad-

just gas flow in the low position.

Do not adjust the infra-red rotis

or ProSear burners.

1) Light the burner.

2) Turn the control knob to the

lowest setting (all the way coun-

ter-clockwise).

3) Remove the knob.

4) While holding the valve shaft

with pliers, insert a thin fiat

tipped screwdriver into the shaft

and while viewing the burner,

adjust to a minimum stable flame

(see figure 14-2).

valve

stem

-i

Figure 14-2- Adjusting

brass burner low heat setting.

PREHEATING THE GRILL

Before cooking, always preheat

the grill for best results. To pre-

heat the grill, light all main burn-

ers and set to HIGH, including

the ProSear burner. Close the grill

hood and allowto preheat for 10-

15 minutes, or until the tempera-

ture reaches 450°F.

14 gYNX.

Figure |4-| - Alternate

lighting rod.

Page 19

Using the ProSear Burner

The ProSear burner has some

special components and warn-

ings specific to its design. Be sure

to read this section completely

before using your ProSear.

SAFETY PRECAUTIONS

1) Do not light the grill until you

have carefully read and under-

stand the lighting instructions.

2) Ensure that burner ties and

packing materials are removed

before lighting the burners.

3) Special care should be ex-

ercised to avoid dropping any

liquids on the hot burners when

cleaning the cooking grids.

4) The cooking grids are heavy.

Extra caution must be used

when removing or replacing

the cooking_grids. The tiles

within the IR burner(s) will be

permanently damaged ifa cook-

ing grid or other object comes

into contact with them. Such

damage is not covered by the

product warranty and may cause

a fire, burns or other injury.

WARNING

Do not allow water to

spill on the IR burners.

Never allow water to

contact the hot burn-

ers. Never use water to

control flare=ups. Water

contact will damage the

burners and is not cov-

ered by the warranty.

LIGHTING THE PROSEAR

1) Open hood completely. Do

not attempt to light grill with the

hood closed.

2) Checkto ensure that all burn-

er control knobs are set to OFF.

3) Turn on main gas supply.

Purge if needed (see page 9).

4) Push in and turn burner con-

trol knob to LITE. Hold knob in

for 5 seconds.

S) If burner does not light, turn

knob to OFF, wait 5 minutes to

allow gas to dissipate, and re-

peat step 4 above.

The ProSear burner is ready to

use when it glows red, usually 2-

3 minutes after lighting.

PROSEAR IR SIDE BURNER

ONLY

For installation and hook up,

refer to page 22 and 23.

Allow unit to cool completely

before grasping handle to lower

lid. Handle may be hot.

In windy conditions, remove the

lid from the unit by releasing

latch at rear and sliding out of

remaining hinge pin.

Keep lid closed when not in use.

BURNER CLEANING

After each use, it is impor-

tant to operate the ProSear

burners on "HI" with the

hood open to burn away

any food particles or drip-

pings. Operate the burners

on "HI" for 5 minutes.

Some ash may accumulate on

the burner surface over time.

Occasionally, you should brush,

blow or vacuum this debris from

the surface of the burner. Only

perform this operation when the

burners are completely cool.

Every 3 to 6 months, inspect the

burner venturi (inlet) to ensure

there are no obstructions. If any

obstructions can be seen, then

follow the burner cleaning pro-

cedure on page 19.

COLD WEATH EIR

WARNING

FOR L.P. UNITS

If lighting the main IR

burners in extremely

cold conditions, there

may be a possibility of

'burn back'. Once lit,

if you hear a 'whoosh-

ing' sound, immediately

turn the burner knob off

to extinguish the flame.

Wait several minutes

before attempting to re=

light the burner.

b'iLYNX Js

Page 20

Using the Rotisserie

The rotisserie system consists of

three main parts - the motor, the

skewer which holds the food,

and the infrared rotis burner. The

rotisserie evenly cooks large cuts

of meat by turning them contin-

uously in front of a high-intensi-

ty burner. The rotis is capable of

turning up to a 25 lb. cut of meat.

THE MOTOR

The rotisserie motor runs on 12

volt DC power that is supplied

by the grill. To power the motor,

plug the "L" shaped jack of the

power cord into the motor, and

plug the other end into the jack

provided on the left side of the

grill (see figure 16-1). This hook-

up allows for simple installation

and removal of the motor for

storage when not in use.

Figure 16-1 - Rotis motor

powerjack located on grill

NOTE: The grill must be con-

nected to 115 volt AC power as

described on page 7 for the rotis

motor to function.

Install the motor onto the grill by

sliding it onto the bracket locat-

ed on the left side of the grill.

THE SKEWER

To load the skewer, slide one of

the meat holders onto the skew-

er. Push the skewer through the

center of the food, then slide the

second meat holder onto the

skewer. Center the food to be

cooked on the skewer then push

the meat holders firmly together.

Tighten the thumb screws (use

pliers if necessary). It may also be

necessary to wrap the food with

butchers string (never use nylon

or plastic string) to secure any

loose portions.

Remove the warming rack and,

if needed, remove the grill racks

and briquette trays to gain bet-

ter clearance. It is normal for the

skewer to flex when cooking

large foods. Place a basting pan

beneath the food for basting

and to ease cleaning.

Never operate a qrill burner

with a bastincj pan in place.

The skewer for the rotis is assem-

bled into the motor assembly

by placing the pointed end into

the motor, and resting the short,

round end (threaded end on 27"

models) onto the support at the

opposite side of the grill. With

the skewer pushed into the mo-

tor, it should rest on the bracket.

The Lynx rotisserie features dual

positions to accommodate larg-

er cuts of meat or to allow slow-

er cooking (see figure 16-2). Any

food to be cooked should be a

minimum of 2" from the surface

of the infrared burner.

position - for small

such as game hens

Figu re l&-2 - Dualposition

ro tisserie systern.

THE INFRARED BURNER

The location of the rotis burner

makes it more susceptible to

strong wind conditions (more

so than the main grill burners).

For this reason you should avoid

operating the rotis during windy

conditions. As an added safety

feature, the burner is equipped

with an automatic safety valve

which will not allow gas to flow

to the rotis burner if it is not

properly lit. To light the rotis

burner, follow this procedure:

1) Open hood completely. Do

not attempt to light grill with the

hood closed.

2) Load food onto skewer, and

install motor and skewer onto

grill in desired cooking position.

3) Check to ensure that all burn-

er control knobs are set to OFF.

4) Turn on main gas supply.

Purge if needed (see page 9).

S) Push in and turn burner con-

trol knob to LITE. Hold knob in

for 30 to 60 seconds.

6) If burner does not light, turn

knob to OFF, wait 5 minutes to

continued...

J6 B_lyNX

Page 21

allow gas to dissipate, and re-

peat step 5 above.

Figu re 17-I - Properrotis

thermocouple position.

Once lit, the rotis burner should

reach cooking temperatures in

about 1 minute. The glow will

even out in about 5 minutes.

If the burner will only stay lit with

the control knob depressed, the

thermocouple position may

need to be adjusted (see figure

17-1)to ensure proper function.

To adjust, ensure that only the

last 1/4 to 1/2" of thermocouple

extends over ceramic and that it

is located close to the surface.

NEVER ATTEMPT TO ADJUST

WHEN THE BURNER IS HOT.

MATCH LIGHTING

If the ignition system fails to light

the burner, it can be match lit ac-

Using the Smoker Box

cording to the procedure found

on page 14.

Always use basting pan

under the rotisserie to

keep drippings off the

burners and briquettes.

Never operate main grill

burners with basting

pan in place. Allow to

cool completely before

removing from grill.

By adding wood smoke to the

grilling process, meats and vege-

tables will have a more tradition-

al BBQ flavor. In order to use the

smoker box, remove the first set

of grill racks and set the smoker

box in the opening so that the

front and rear tabs rest on the

grill frame, and replace grill rack.

WARNING

Never use smoker box

over a ProSear burner.

Wood Chips

There are many wood chips

available and selection is based

on personal taste.The most com-

mon chips used are mesquite or

hickory. Always soak the chips in

water prior to putting them into

the box. Use the High position to

start the chips smoking, then

Figure 17-2 - Smoker box

installed in to grill for use.

reduce the heat to a lower level

to prevent them from drying out

and flaming. If the wood chips

do flame up, add a small amount

of water through the recessed

hole in the lid to extinguish the

flame. Use caution when adding

water to a hot box to avoid steam

burns. This tray may also be filled

with water to produce steam.

Whether smoking or steaming,

the grill should remain closed as

much as possible to maximize

the effect. During extended

roasting periods, it is normal to

add fresh wood chips and water

to the box several times. Limit

the amount of times the hood

is opened, as each opening can

add as much as 15 minutes to

the cooking time.

CAUTION: Handle the smoker

box with care. The cover be-

comes extremely hot when in

use. Use sturdy, properly insulat-

ed gloves or dry pot holders.

It is recommended that a high

quality meat thermometer be

used when smoking, as cooking

times can vary greatly by cut of

meat or environmental factors.

Figure 17-:3 - Wood Chip

Tray

I_LYNX, 17

Page 22

Cleaning the Gri

The best way to keep your grill

looking great is to use a cover,

manufactured by Lynx, when the

grill is not in use. While stainless

steel is very durable, some care is

required to ensure the long life

of your grill.

STAINLESS STEEL

Your grill has a directional pol-

ished grain - any cleaning should

be carried out along this grain

and not across it.

The grill is made from non-rust-

ing and non-magnetic stainless

steel. After initial usage, areas

of the grill may discolor from

the intense heat given off by

the burners = this is normal

There are many different stain-

less steel cleaners available.

Always use the mildest cleaning

procedure first, scrubbing in the

direction of the grain. Specks of

grease can gather on the sur-

faces of the stainless steel and

bake on to the surface and give

the appearance of rust. To aid

removal, use a fine to medium

grit non-metallic abrasive pad

(Scotch Brite is good) in conjunc-

tion with a stainless steel cleaner.

Always rub in the direction of the

grain.

The best maintenance for stain-

less steel is to wipe it down with

a damp cloth. This is especially

true if a swimming pool is locat-

ed near the grill, as prolonged

contact with chlorinated water

can pit the stainless steel. This

damage is not covered by your

warranty. Never use steel "Brillo"

pads or similar products as these

will leave traces of material

behind which will quickly rust

and is not a defect in the Grill.

GRILL RACKS

The easiest way to clean the grill

racks is to do so immediately

after cooking and turning off

the burners. Wearing a long BBQ

mitt to protect your hand from

steam, dip a brass bristle brush

in hot water and scrub the grill

rack. Dip the brush frequently

as the steam aids the cleaning

process. If grill is allowed to cool

before cleaning, cleaning will be

more difficult.

NEVERUSEWATERTO CLEANTHE

GRILL RACK ABOVE A PROSEAR

BURNER. LIQUID FALLING ONTO

AN UNLIT PROSEARBURNERCAN

CAUSE PERMANENT DAMAGE.

THE GRILL RACK ABOVE THE

PROSEARWILL NORMALLY BURN

CLEAN DURING THE 5 MINUTE

CLEANING BURN AFTER USE. IF

GRILL RACK REQUIRESFURTHER

CLEANING, ALLOW TO COOL

AND REMOVE FROM GRILL.

DRIP TRAY

The drip tray should be cleaned

after every use of the grill.

DO NOT ALLOW EXCESSGREASE

OR LIQUIDS TO ACCUMULATE

IN THE DRIP TRAY AS THIS MAY

CREATEA FIRE HAZARD.

Allow the grill to cool complete-

ly, then remove the drip tray by

pulling it out from the grill until

it stops, then lifting the front

edge until the drip tray comes

free. Clean with hot soapy water

or commercial cleaning product,

rinse, dry and reinstall in grill.

NEVERUSEGRILL WITHOUT DRIP

TRAY PROPERLYINSTALLED.

BRIQU ETTE TRAYS

Although they normally burn

clean with use, it is necessary

to clean the briquette trays on

occasion. After allowing the grill

to cool completely, remove the

grill racks, then remove the bri-

quette trays by lifting the front

edge and pulling toward you.

Set the trays upside-down onto

their mounting points, and oper-

ate the grill burners on high

for 20-30 minutes to burn the

briquettes clean. If it becomes

necessary to replace any or all

the briquettes, replacements

are available from your dealer.

Replace briquettes following the

instructions on page 6.

WARNING

Always keep the area

surrounding the grill

free from all combus-

tible materials, liquids,

vapors, debris and ob-

structions. Maintain at

least 3"clearance around

grill for proper airflow.

J8 lil YNx.

Page 23

Burner Cleaning Adjustment

Before removing burners

ensure the gas supply is off

and the knobs are in the

"off" position. Make sure

the grill has completely

cooled before proceeding.

To Remove Brass Burners:

Remove the grill racks and bri-

quette trays. Grasp the burner,

pull it up and slightly to the rear

of the unit so the burner head

comes off the brass orifice at

the front. Angle the burner side-

ways, and remove. Be careful not

to upset the air shutter position.

Brass Burner Cleaning:

To maximize grill performance,

clean the exterior of the burner

with a wire brush. Clear stub-

born scale with a metal scraper.

Clear any clogged ports with a

straightened paper clip. Never

use a wooden toothpick as it

may break off and clog the port.

Shake out any debris through

the air shutter. Use a flashlight

to inspect the burner inlet to en-

sure it is not blocked. If obstruc-

tions can be seen, use a metal

wire coat hanger that has been

straightened out to clean.

Brass Burner Air Adjustment

Each grill burner is tested and

adjusted at the factory prior to

shipment; however, variations

in the local gas supply or a con-

version from one gas to another

may make it necessary to adjust

the burners. The flames of the

Grill burners should be visu-

ally checked and compared to

fig. 19-1. Flames should be blue

and stable with no yellow tips,

excessive noise or lifting. If any

of these conditions exist, check

if the air shutter or burner ports

are blocked by dirt, debris, or

spider webs. If needed, proceed

with air shutter adjustment.

1½"_qame

height

Figure |9-1 - Showing

proper flame characteristics.

The amount of air which enters

a burner is governed by a sheet

metal disk at the inlet called an

air shutter. It is locked in place by

a set screw which must be loos-

ened prior to lighting the burner

for adjustment (see fig. 19-2).

To Adjust:

1) Be extremely careful as the

burner may be very hot.

2) If the flame is yellow, indicat-

ing insufficient air, turn the air

shutter counterclockwise to al-

low more air to the burner.

3) If the flame is noisy and tends

to lift away from the burner, indi-

cating too much air, turn the air

shutter clockwise.

4) Once adjusted, turn the burn-

er off and allow to cool. Remove

burner, tighten set screw and

reinstall the briquette trays and

grill racks.

Figure 19-2- Air shutter set

screw location on burner

PROSEAR BURNER

For day-to-day cleaning, see in-

structions on page 15. If burner

inlet is obstructed, use a metal

wire coat hanger that has been

straightened out to clean.

WARNING

IT IS CRITICAL TO CEN-

TER EVERY BURNER ON

ITS ORIFICE AND FOR

THE BURNERS TO REST

LEVEL AND NOT ROCK. IF

THE BURNERS ARE NOT

CENTERED CORRECTLY,

A VERY DANGEROUS

CONDITION EXISTS THAT

CAN CAUSE PERSONAL

INJURY AND DAMAGE

TO THE UNIT.

bl_LYNX J9

Page 24

Troubleshooting

If the Grill does not function

properly, use th is checklist before

contacting Lynx for service.

GRILL WON'T LIGHT

Check to ensure that all burner

control knobs are set to OFF.

Push control knob in and ensure

that the ignition is glowing. If

ignition is not glowing, pro-

ceed with troubleshooting or

match-light the burner. If the

igniters are working correctly,

next determine if gas is reaching

the burners. Ensure the gas sup-

ply is turned on, and that there

are no leaks, according to the

procedure on page 11. Attempt

to match-light a burner accord-

ing to the procedure on page

14. If the burner will light with

a match, then the igniter may

not be functioning correctly, or

may not be adjusted correctly.

See above or call for service. If

the burner will not match light,

and the gas supply has been

confirmed, check the burner for

blockages according to the pro-

cedure on page 19.

YELLOW FLAME/GAS SMELL

IF YOU SMELL GAS WHILE

THE GRILL IS OPERATING,

IMMEDIATELY TURN OFF ALL

BURNERS. Perform a leak test,

check for blockages and check

the air shutter adjustment

according to page 19.

NOTE: If the grill is operating in

a dusty area or if heavy grease

is present, some orange tips on

the burner flame are normal.

LOW/INSUFFICIENT HEAT

Ensure that adequate preheat

time has elapsed. Brass burners

should preheat for at least 15

minutes with the hood closed;

ProSear burners should preheat

for at least 3 minutes.

If adequate preheat time was

allowed, check the gas supply

for a damaged and/or kinked

supply line. Replace if necessary.

On LP units, a mostly empty tank

may not have sufficient pres-

sure to run the grill at high heat.

Replace with a full tank. Make

sure that the regulator/hose

assembly being used is the unit

supplied with the grill. On natu-

ral gas units, ensure that the

supply line is at least 3/4" inside

diameter or 1" outside diameter.

Check the Natural Gas supply

pressure to ensure at least 7"

W.C. and 4"W.C. pressure under

full load (all burners on.) For LP,

11" W.C. supply (not to exceed

14") with 11"under full load.

If gas supply is adequate, check

burners for blockages and check

flame characteristics according

to the procedure on page 19

and clean or adjust air shutter if

needed. Check also that there is

no pressure being applied to the

regulator attached to the back

of the grill. This regulator con-

tains a flexible diaphragm and

should not be allowed to touch

the grill body or surroundings.

Check to make sure that the

burners and the drip tray are

clean and free from obstruc-

tions. Clean if necessary. NOTE:

No part of the grill should ever

be lined with aluminum foil as

it will interfere with airflow and

can cause a low heat condition.

BURNER BLOWS OUT

First determine if the problem

is being caused by location.

If location is subject to high

winds, reposition grill to provide

some protection. Check the gas

supply and flame characteris-

tic according to the procedure

under Low/Insufficient Heat.

Check to ensure that the burners

are correctly positioned in the

grill according to the procedure

on page 19. Correctly installed

burners should be seated firmly

with no side-to-side movement.

ROTISSERIE WON'T LIGHT

Follow the same procedure as

described above for the grill

burners to diagnose problems

with the Rotisserie IR burner.The

IR burner flame may be hard to

see in bright sunny conditions.

LIGHTS WON'T OPERATE

Ensure that the grill has AC

power by removing the D cell

battery according to the instruc-

tions on page 7, and then press-

ing a burner control knob to test

the spark igniter. If the ignit-

ers don't function, no AC power

is connected. If the igniters do

function, replace the bulb.

20 B_LyNX

Page 25

Light Bulb Replacement

TO CHANGE LIGHT BULBS

Remove the glass light cover by

grasping the edge of the glass

and gently prying it off. It may

be necessary to remove one

screw. Pull the old bulb straight

out from socket - do not twist.

Replacement bulbs are halogen,

12 volt, T3 type with a G4 bipin

base. The 27" and 30" grill uses

one lOW bulb, all others use two

lOW bulbs.

AVOID TOUCHING THE

GLASS OF NEW BULBS.

B

Install new bulb by gently press-

ing it into the socket. Replace

glass cover by gently snapping

back into place.

Figtl re 21-1 - Remove glass cover to access work light bulb.

Replacing the Briquettes 1,1

TO REPLACE BRIQUETTES

The special Lynx ceramic bri-

quettes are secured to the trays

with stainless steel clips. To in-

sert a briquette into the tray, it

is necessary to remove the clip

from one side of the empty slot.

This is done by bending the re-

taining tabs for the clip located

on the back side of the briquette

tray as shown below.

WARNING

The edges of the clips

may be sharp. Pliers

MUST be used to remove

clips - never attempt to

remove them by hand as

injury may result.

B_lyNX 2J

Page 26

Side Burner/LPSGE Gas Hookup

B

BUILT-IN INSTALLATION J

1) Shut off gas supply at main

valve.

2)

Disconnect all plumbing (if al-

ready attached) from grill and

gas supply valve.

3)

Remove all fittings from grill

manifold.

Install side burner into cutout

4)

in counter top.

S)

Connect gas supply to grill

and side burner as shown in

the figure at right for your

proper gas type.

6)

Turn gas supply on and leak

test all connections.

CART INSTALLATION

Natural Gas

Valve 1/2"Min

(_ N.G.Outlet Shuf-Off

Inter Connecting

Pipe Work

_ Regula_,r_+_ / ...... _.

=7 Flex _'7P_7_%_ )

L

L.EARV,EW/

N ........ 1/2"Close Nipple

1/2"Tee

BBQ Manifold

__ _ _ //---l/2"MIPFitting

/-- -- _ 1/2" OD Stainless

/ li _ Steel FJexible H°se.......

7Side B..... tt_ ..... 1/2" F[P Fitting

j Side Burner or

1

................................................................................................................................................................................................Grill Extender

_J

1/2") Union (Coupler)

:112" Male-Female

./ Street Elbow

31e

1) Shut off gas supply at main

valve.

2)

Disconnect all plumbing (if al-

ready attached) from grill and

gas supply valve.

3)

Remove all fittings from grill

manifold.

Install side burner onto cart

4)

according to the directions

supplied with the cart mount-

ing kit.

S)

Connect gas supply to grill

and side burner as shown in

the figure at right for your

proper gas type.

6)

Turn gas supply on and leak

test all connections.

/

LP Gas

,-I

O

m

__ High pressure flexible

hose & regulator existing

on grill

1/2"FIP x 3/8"MIP Flare

Elbow or 1/2"FIP or 1/2"

FIP x 3/8"MIP Flare

Fitting

Use regulator here for

hard-plumbed L.R hook-up

L

=E

1/2"Close Nipple

1/2"Tee

pple

Union (Coupler)

1/2" Male-Female

Street Elbow

I

1/2" O.D.Stainless

_Steel Flexible Hose

i-- 1/2" FIP Fitting

__1/2" Male-Female

Street Elbow

i

Side Burner or

1

Grill Extender

g

F

22 B_lyNX

Page 27

Lighting the Side Burner or LPSGE

B

WARNING

Never attempt to light

burner if odor of gas

is present. Lid must be

open/off when lighting.

Keep face and body as

far from unit as possible

when lighting. Always

wait at least 5 minutes

before attempting to re-

light a hot burner.

Before proceeding, make sure

you have completed a leak test.

This check should be performed

before each use of the side burn-

er or grill extender.

Follow these steps to light the

burners:

1) Open or remove lid complete-

ly. Do not attempt to light burn-

ers with the lid closed.

2) Check to ensure that all burn-

er control knobs are set to OFF.

Push control knob in and ensure

that the ignition is glowing. If

ignition is not glowing, proceed

with troubleshooting or match-

light the burner.

3) Turn on main gas supply.

Purge if needed (see page 9).

4) Push in and turn burner con-

trol knob to LITE. Hold knob in

for 5 seconds.

S) If burner does not light, turn

knob to OFF, wait 5 minutes to

allow gas to dissipate, and re-

peat step 4 above.

PREHEATING THE LPSGE

Before cooking, always preheat

the ProSear burner for best re-

sults. To preheat, light the burn-

er, set to HIGH and allow to pre-

heat until the burner glows red,

usually about 2-3 minutes.

DO NOT LEAVE THE UNIT

UNATTENDED DURING

THE PREHEAT CYCLE OR AT

ANY TIME WHILE IN USE.

DO NOT ALLOW UNIT TO

PREHEAT FOR PROLONGED

PERIODS OF TIME. OVER-

HEATING THE UNIT CAN

CAUSE DAMAGE TO THE

UNIT AND TO PERSONAL

PROPERTY.

MATCH LIGHTING

If burners will not light after sev-

eral attempts, the burners can be

match lit. If you've just attempt-

ed to light the burner with the

igniter, allow 5 minutes for any

accumulated gas to dissipate.

Make sure all knobs are in the

OFF position. Keep your face as

far away from the unit as pos-

sible. With the lid removed, pass

the alternate lighting rod with a

lit paper match installed to the

ports of the burner. Push and

turn the corresponding control

knob of the burner to LITE. If the

burner does not light in 4 sec-

onds, turn the knob off and wait

5 minutes before attempting

again.

LOW HEAT ADJUSTMENT

NOTE: ADJUSTMENT IS

FOR SIDE BURNERS ONLY.

PROSEAR BURNERS ARE

PRESET AT THE FACTORY

AND SHOULD NOT BE AD-

JUSTED.

The valves on the side burner

feature an adjustable low set-

ting. Due to fluctuations in gas

pressure, heating value or gas

conversion, you may feel it nec-

essary to adjust gas flow in the

low position.

1) Light the burner.

2) Turn the control knob to the

lowest setting (all the way coun-

ter-clockwise).

3) Remove the knob.

4) While holding the valve shaft

with pliers, insert a thin flat

tipped screwdriver into the shaft

and while viewing the burner,

adjust to a minimum stable

flame (see figure 23-1 ).

knob

Figure 23-1 - Adjusting

side burner low heat setting.

B_lyNX 23

Page 28

Warranty

I. Limited Lifetime Warranty. The stainless steel body housings, the solid brass grill burners and the ProSear burn-

ers_-are warranted to be free from defects in material and workmanship when subjected to normal domestic use

and service for the lifetime of the original purchaser. This warranty excludes surface corrosion, scratches, and discol-

oration which may occur during regular use.This warranty is limited to the replacement of the defective parts, with

the owner paying all other cost including labor. _Doesnot include the rotisserie infra-red burner.

II. Limited Five-Year Warranty. The structural integrity of the interior grill parts, exterior, and drip pans are warrant-

ed to be free from defects in material and workmanship, when subjected to normal domestic use and service, for

a period of five years from the date of purchase. This warranty is limited to the replacement of the defective parts,