Page 1

Page 2

PROFESSJOJ'-JAL GRILLS

A MESSAGE TO OUR CUSTOMERS...

ou've just joined the world of Lynx

cooks ... a discriminating collection of

amateur and professional chefs that take

outdoor cooking to a new level.

Your grill has been designed and built

with meticulous attention to detail and it

offers some unique and powerful

features. You can achieve maximum

performance and enjoyment of these

features only by carefully reading the Use

& Care manual ... before your first cook-out.

iiiix

It includes important safety tips, great hints for better

griJl!ng and some delectable recipes for you to try.

You JJwant to keep it handy for easy reference.

Also, we enjoy hearing from our customers. We like to

hear about your successes but also about any

difficulties you are having. Please feel free to contact

us with any questions or problems, or just to share ........

a new redp.e You never know, your redpe could

end up in our next printing of this manual! Please

include the model number of your grill in your

correspondence.

With the proper use and care this product wiJJ

provide years of trouble-free service.

Should your Lynx grill change ownership, please

make sure that the new owner receives this manual.

Thanks again for your purchase. Enjoy!

Page 3

PROFESSIONAL GRILLS PROFESSIONAL GRILLS

READ THIS MANUAL CAREFULLY and completely before using your grill to reduce the risk of:

1) Fire

2) Burn hazard, personal injury or property damage

3) Ruined steaks or other unpleasant cooking experiences

4) Unapproved installation or servicing.

THIS PRODUCT IS DESIGNED FOR OUTDOOR USE ONLY. Improper installation, adjustment,

alteration, service or maintenance can cause property damage, injury or death.

Read this manual thoroughly before installation, use, or servicing of this product.

OOOO_.>OOOOOOOOOO<>OOOOOOOOO/OOOOOOOOOOOC>

DANGER

IF YOU SMELL GAS:

1) Shut off all gas supply lines to the grill.

2) Extinguish any open flames.

3) Carefully open lid. Remember, it may be

extremely hot!

4) If odor continues, keep everyone away

from the grill and immediately call your

gas supplier or your fire department.

WARNING

1) DONOTstoreorusegasolineorother

flammablevaporsandliquidsinthe

vicinityofthisoranyotherappliance.

2) AnLPcylindernotconnectedforuse

shallnotbestoredinthevicinityofthis

oranyotherappliance.

c_o_.>OooOOOOO_ooOOoo_oOOOo<>OooOOOOO_ooOo_

DANGER

S'IL Y A UNE ODEUR DE GAZ:

1) Coupez I'admission de gaz de I'appariel.

2) Eteindre toute flamme hue.

3) Ouvrir le couvercle.

4) Si I'odeur persiste, _loignez-vous de

I'appareil et appelez imm_diatement

le fournisseur de gaz ou le service

d'incendie.

WARNING

1) Ne pas entreposer ni utiliser de I'essence

nid autres vap,eurs ou liquides inflam-

mables clans le voisinage de I'appareil,

ni de tout autre appaAn LP cylinder not

connected for use shall not be stored in

the vicnity of this or any other appliance.

2) Une bouteille de propane qui n est pas

raccord@e en vue de son utiJisation, ne

dolt pas _tre entrepos@e dans le voisin-

age de cet appareiJ ou de tout autre

appareil.

O_C_OOOOO_OOOOOOO_ ..... OOOOOOO_

WARNING! CALIFORNIA PROPOSITION 65

1) The burning of gas cooking fuel generates some bymproducts which are on the list of sub-

stances which are known by the State of California to cause cancer or reproductive harm.

2) California law requires businesses to warn customers of potential exposure to such substanc-

es. To minimize exposure to the substances, always operate this unit accordin 9 to the use

and care instructions found in this manual. Be certain to provide adequate ventilation when

cooking.

3) California Proposition 65 lists "Silica, crystalline" which is used in one of the components of

the IR burner, as an agent known to the state of California to cause cancer.

3

Page 4

PROFESSIONAL GRILLS

WARNING

1) Never use dented, rusty or damaged propane cylinders. NEVER store additional or empty

propane cylinders in the grill cabinet or in the vicinity of this or any other appliance. Do not

store propane cylinders indoors or on their sides.

2) Children should NEVER BE LEFT ALONE or unattended in an area where a grill is located.

Place your grill well away from areas where children play. Do not store items that may interest

children in or around the grill, in the cart, or in the masonry enclosure.

3) NEVER move the grill when hot. When in use, portions of the grill are hot enough to cause

severe burns.

4) Always maintain the required clearances from combustibles as detailed. The grill is designed

for outdoor use only. NEVER use in a garage, building, shed, breezeway, or other enclosed

area. Do not use this grill under any overhead combustible construction.

5) Gas grills are not designed or certified for and are not to be installed in or on recreational

vehicles, portable trailers, boats or any other moving installation.

6) ALWAYS have an ABC Fire Extinguisher accessible -- never attempt to extinguish a grease

fire with water or other liquids.

7} STORING YOUR GRILL:Store your grill in a well-ventilated area. If stored indoors, detach

and leave LP. cylinder outdoors in a well-ventilated area away from heat and away from

where children may tamper with it

8) Keep any electrica/supply cord and the fuel supply hose away from any heated surfaces.

Electrical cords should be placed away from walkways to avoid tripping hazard.

9) Do not repair or replace any part of the grill unless specifically recommended in this manual.

Other service should be performed by a qualified technician.

10) If the grill is installed by a professional installer or technician, be sure that he/she shows you

where your gas supply shut-off is located. All gas lines must have a shut-off that is readily and

easily accessible. If you smell gas, check for gas leaks immediately. Check only with a soap

and water solution. (See iNDEX: Leak Testing for further details.) Never check for gas leaks with an

open flame.

11) Inspect the LP gas supply hose prior to each use of the grill. If there is evidence of excessive

abrasion or wear, or the hose is cut, it must be replaced before using the grill

12) Never remove the grounding prong from the plug or use this product with an ungrounded,

2-prong adapter.

13) This manual must remain with the product owner for future reference.

This product complies with ANSI standard Z21.58-2007/CSA 1.6-2007 and has been tested and

approved by Intertek.

To obtain replacement parts or service contact:

Lynx Professional Grills

5895 Rickenbacker

Commerce, CA 90040

888-879-2322

4

Page 5

PROFESSIONAL GRILLS

TABLE OF CONTENTS

A Message to our Customers; ...,.;. .................................................................................... 2

USE &

" ..... .:............................................................................................ 12

U,s_r_g"7 he f roSear BUrr_er........................................................................................... 13

O_irzg The Rotisserie Burrzer ........................................................................................... 14

&Sir_gThe Smoker Box ................................................................................................... 15

Cleaning Your I,ynx Grill ................................................................................................. 16

_oubleshooting Your I,ynx Grill ................................................................................... 19

Poter_ti(d Problems ......................................................................................................... 19

How 7b Obtair_ Service From Lyr_x .................................................................................. 22

The Lyr_x Story ............................................................................................................. 22

Warranty .......................................................................................................................... 23

INSTALLATION GUIDELINES ...................................................... 25

Bef'ore You Start ............................................................................................................... 27

[/shipmer_t arrives (t(_maged .......................................................................................... 27

Unpacking and Assembly ................................................................................................ 30

Electrical Connections ..................................................................................................... 31

Gas Connections ................................................................................................ _:...... , ,°,:32

Wiring Schematics ................................................................. :'-"u'; .........

L27 Non-Rotisserie Grill

L27 & L30 rotisserie Grill ..................................................

L36 & L42 rotisserie Grill ..................................................

L54 rotisserie Grill ............................................................

2010 Lynx Professional Grills Exploded Parts View ...............

2010 Lynx Professional Grills Parts list ..................................

5

Page 6

PROFESSIONAL GRILLS

This use & care manual covers the Lynx gd[[ models listed below.

Some features and options wi[[ vary based upon the mode[ that you purchased.

LY__L MOE_ELS

BUILT-IN

L27-2

L27 R-2

L27 PS R-2

L3OR-I

L3OPSR-1

L36R-1

L36PSR-1

L42R-1

L42PSR-1

L54PSR-1

FREESTANDING

L27 F-2

L27 FR-2

L27PSFR-2

L3OFR-I

L3OPSFR-I

L36PSFR-1

L42PSFR-1

L54PSFR-1

6

Page 7

PROFESSHONAL GRHLLS

IMPORTANT SAFETY PRECAUTIONS

PLEASE REVIEW THESE iMPORTANT SAFETY PRECAUTIONS

BEFORE YOU USE YOUR GRmLL

1) NEVER LEAVE THE GRmLL UNATTENDED WHmLE COOKING.

2) Ensure all tie-down wires have been removed from the burners.

3) Always use caution when operating the grill in a windy area. (See UNDEX: "Grilling in Windy Condi-

tions" for further details.)

4) Avoid wearing loose-fitting garments or long sleeves while grilling. They could ignite.

5) Never touch the grill racks, hood or immediate surrounding metal surfaces with your bare hands

while grilling.

6) Use an insulated glove or mitt when opening and operating the grill. Always open the grill lid

slowly to allow heat and smoke to escape before fully opening.

7) The grill hood must be fully opened while lighting the grill. Releasing fuel into a closed grill

before lighting wiJJnot make it light sooner or more efficiently. It will only risk explosion and

personal injury or death. Never Jean over hot grill surface or look directly into the grill when at-

tempting to light.

8) Do not heat unopened food containers as pressure build-up will cause the container to ex-

plode.

9) Do not use aluminum foil to line grill racks or drip pans. This wiJl alter the airflow or trap exces-

sive heat in the control area and can melt knobs and ignition modules. Such damage is specifi-

cally excluded from your warranty.

10) Never use charcoal or any other solid fuel in the grill.

11) Cooking excessively fatty meats and oils wiJJcause flare ups. Internal fires or damage caused by

them or by the grill being left unattended while cooking are not covered under the terms and

conditions of our warranty.

12) Never grill without the drip pan in place. Always ensure the drip pan is pushed all the way to

the back of the grill. Hot grease can leak downward and produce a fire or explosion.

13) Grease is extremely flammable. Let hot grease cool down before attempting to handle or dis-

pose of it. The drip tray should be cleaned of grease on a regular basis.

14) Do not use the grill unless a leak check has been performed on aJJgas connections. (SeeUNDEX:

"Leak Test Procedure" for further details.)

15) Never operate the grill while under the influence of alcohol or drugs.

16) Do not Jean on side shelves and never place a load weighing more than 25 pounds on a side

shelf.

17) If any burner does not light or goes out during operation, turn off aJJgas control knobs, open

the hood and wait five (5) minutes before attempting to redight.

Page 8

PROFESSIONAL GRILLS

18) Portable LP cylinders: Always shut off the main valve on the LP cylinder after each use.

19) Spiders and insects like to nest in the burners, venturis, valves and orifices of a grill, disrupting

the gas flow. This very dangerous condition can cause a fire behind the control panel, damag-

ing the grill and risking personal injury. If your grill has been unused for a long time, !,nspect

and dean the burners, venturis, valves and orifices. (See UNDEX: Cleaning the Brass Burner for further

details.)

o RI I[N GIN NDY COND IT][ O N S

\v ,° ...........

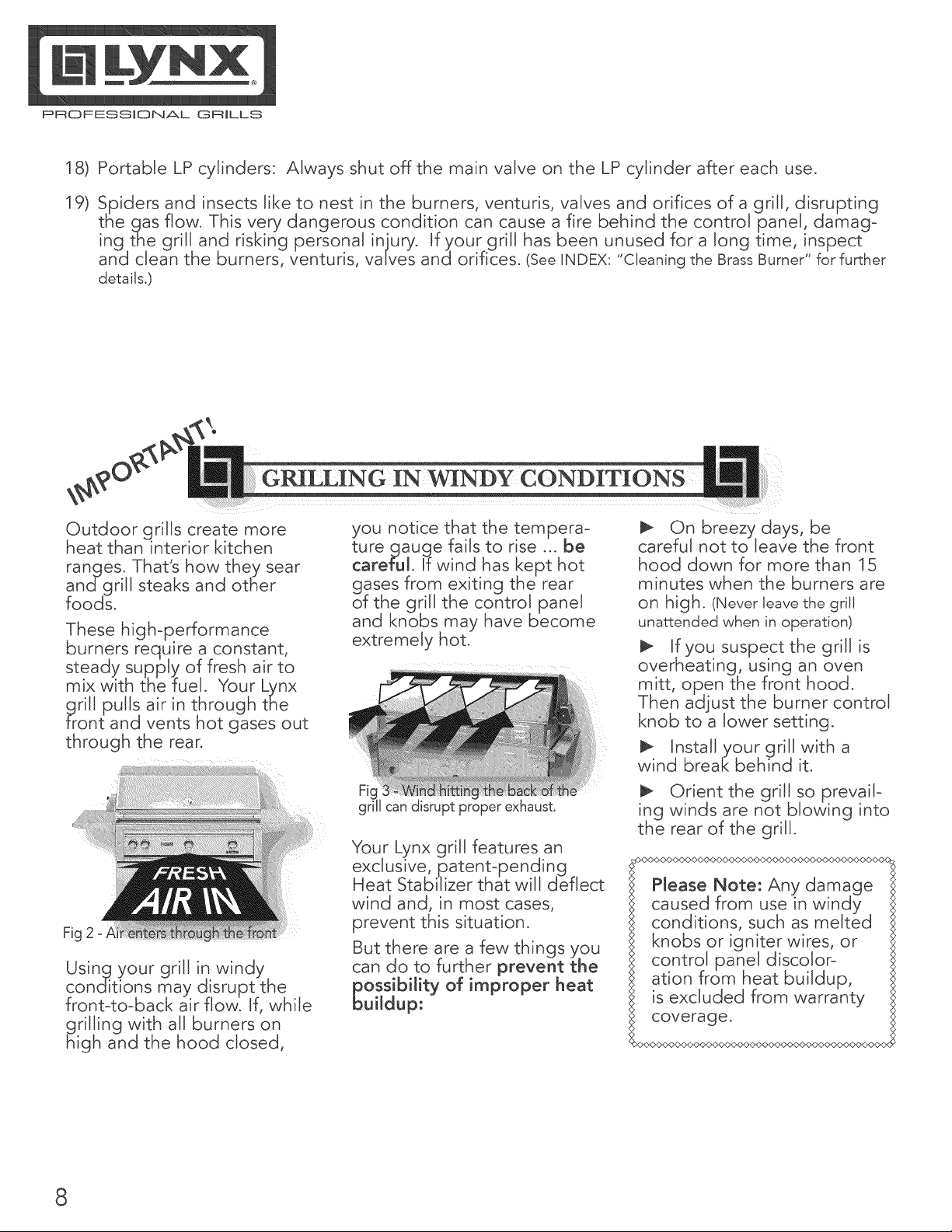

Outdoor grills create more

heat than interior kitchen

ranges. That's how they sear

andgrill steaks and other

foods.

These high-performance

burners require a constant,

steady supply of fresh air to

mix with the fuel. Your Lynx

9rill pulls air in through the

tront and vents hot gases out

through the rear.

Using. your grill in windy

conditions may disrupt the

front-to-back air flow. If, while

rilling with all burners on

igh and the hood closed,

you notice that the tempera-

ture gauge fails to rise ... be

careful. If wind has kept hot

gases from exiting the rear

of the grill the control panel

and knobs may have become

extremely hot.

Fi

can disrupt proper exhaust.

g

Your Lynx grill features an

exclusive, patent-pending

Heat Stabilizer that will deflect

wind and, in most cases,

prevent this situation.

But there are a few things you

can do to further prevent the

possibility of improper heat

buildup:

I_ On breezy days, be

careful not to leave the front

hood clown for more than 15

minutes when the burners are

on high. (Never leave the grill

unattended when in operation)

I_ If you suspect the grill is

overheating, using an oven

mitt, open the front hood.

Then adjust the burner control

knob to a lower setting.

Install your grill with a

wind break behind it.

1_ Orient the grill so prevail-

ing winds are not blowing into

the rear of the grill.

Please Note: Any damage

caused from use in windy

conditions, such as melted

knobs or igniter wires, or

control panel discolor-

ation from heat buildup,

is excluded from warranty

coverage.

<_>OO_JOOO<)OO<>OOO_O<>OOO_O<>OOO_X)OOOOO<'X>OO

8

Page 9

USING YOUR GRILL

PROFESSIONAL GRILLS

rilling requires high heat

for searing and low, con-

trolled heat for slow cooking.

Thinner cuts of food are often

cooked at a "HI" heat setting

with the lid open.

On the other hand, large,

thick pieces of meat or

poultry are often first seared

at the k/gk setting and then

grilled at a/owersett/'ng ...

Depending on the model you chose, your Lynx grill may be equipped with up to three different

burner types. The operation of each type varies, so it is important to understand all three.

Main Brass Burner

B urn e r

This heavy-duty, infrared burner

durable brass burner

is the standard main }ity infrared

burner found under

the briquette trays, foods and sealing

sometimes with the lid closed

... achieving the best results

in the middle of the food

without burning the outside.

Some foods are cooked using

direct heat and some using

indirect heat.

Your Lynx grill features a

variety of professional-level

burners and tools for meeting

the wide variety of cooking

ProSear TM

This advanced

)rovides high-

searing

in flavor.

challenges. We wiJJ reveal

how these features work for

you. So please read and

enjoy!

Rotisserie Burner

This adjustable infrared burner spans the

back of the cooking area and provides

consistent heat for slow rotisserie cooking,

BEFORE YOUR FIRST

USE

There are a few must-check

safety precautions to consider

before you use your grill.

Please be sure that:

[] All packing materials and

tie-down wires have been

removed from the burners.

]mg removed?

PRE,GR I CHECKL'IST

[] You have fuel connected.

(See INDEX: "Gas Requirements"

for further details.)

[] You have electric

connected. (See iNDEX: "Electric

Requirements" for further details.)

[] Aqualified plumber has

performed a leak test on all

the fittings that supply fuel to

your grill.

IF YOUR GRILL DOES

NOT LIGHT IN 4 TO 5

SECONDS you may need

to purge the line. (See

iNDEX: "Purging the Gas Line"

for further details.)

AT EACH NEW SEASON

t the start of each new

grilling season you should

remove the grilling racks and

briquette trays and check the

burners, venturis, orifices and

valves for obstructions.

Spiders and insects often nest

in these areas of the grill and

can disrupt air flow, causing

damage to the grill and

personal injury.

Also, check all hoses and

fittings for damage, abrasion,

wear and tear.

9

Page 10

PROFESSIONAL GRILLS

BEFORE EA 04

USE

Before any use, always make

sure that:

[] ... you do not smell gas

before you light the grill. If

you do smell gas, shut every-

thing off and have a qualified

plumber check for leaks.

[] ...YOU NEVER LEAVE THE

GRILL UNATTENDED WHILE

COOKING.

[] ... the cooking area is free

and clear of any combustibles,

besides your food, that might

ignite.

[] ... the control knobs turn

freely.

[] ... if you are using a

portable propane cylinder, it is

securely connected and leak

tested. (See INDEX: "Cylinder

Retention Instructions" for details.)

[] ... you know where the

main gas supply shut-off is

located

[] ... the burners are seated

properly in the grill with

mounting legs in the slots.

firmly on the frame with their mount:

in9 !egs inserte d into the frame slots.

[]

strongly or blowing on the

back of grill.

WARNING

1) Never attempt to light a burner if you smell gas.

2) Always keep the lid open (side-burner lids must be com-

pletely removed) when lighting your grill.

3) Releasing fuel into a closed grill before lighting will in-

crease the risk of explosion, property damage, personal

injury or death.

4) Keep your face and body as far from the grill as possible

when lighting. Any time a burner ctoesn t light within 5

seconds, turn off the control, wait 5 minutes for gas to dis-

sipate, and repeat the lighting procedure.

ELECTRIC IGNITION

efore proceeding, make

sureyou have completed

the Before Each Use"

checklist.

Follow these steps to light any

of the burners on your grill:

First, make

sure all burner

control knobs

are set to OFR

Push and hold

in for 2 seconds,

allowing the igniter to heat

up. Then rotate the knob to

"LITE". After ignition, set

the knob to the desired heat

setting.

FOR THE ROTISSERIE

BURNER:

a thermocouple sensor with a

safety valve that automatically

shuts off the flow of gas if the

burner goes out. (See INDEX:

"Windy Conditions" for tips on how

to prevent burner blow out)

To light the rotisserie burner,

push and hold the control

knob in for 2 seconds and

then turn the knob to the

"LITE" position.

After ignition CONTINUE

HOLDING THE CONTROL

KNOB IN for 30 to 60

seconds. During this time the

thermocouple will heat up and

the safety valve will remain

open.

If you release the control knob

before the thermocouple has

heated up, the safety valve

will shut off the flow of gas to

the rotisserie burner and you

will have to re-light the burner.

:ures

10

Page 11

PROFESSIONAL GRILLS

WARNING: PROPANE

Extremely cold temperatures

may cause your ProSear TM

burner to light/hs/b/e the

burner instead of out-

s/de. Once lit, if you hear a

'whooshing' sound, imme-

diately turn the burner knob

off to extinguish the flame

and then immediately re-

light the burner.

MANUAL LIGHTING

f a burner doesn't light after

several attempts, it can be

match lit using the lighting rod

stored in the drip tray.

Match-lighting your grill is

done in one of three ways,

depending upon which

burners are being lit.

First, make sure you've

returned all of the control

knobs to the OFF position

and have allowed 5 minutes

for any accumulated gas to

dissipate before attempting to

match light a burner.

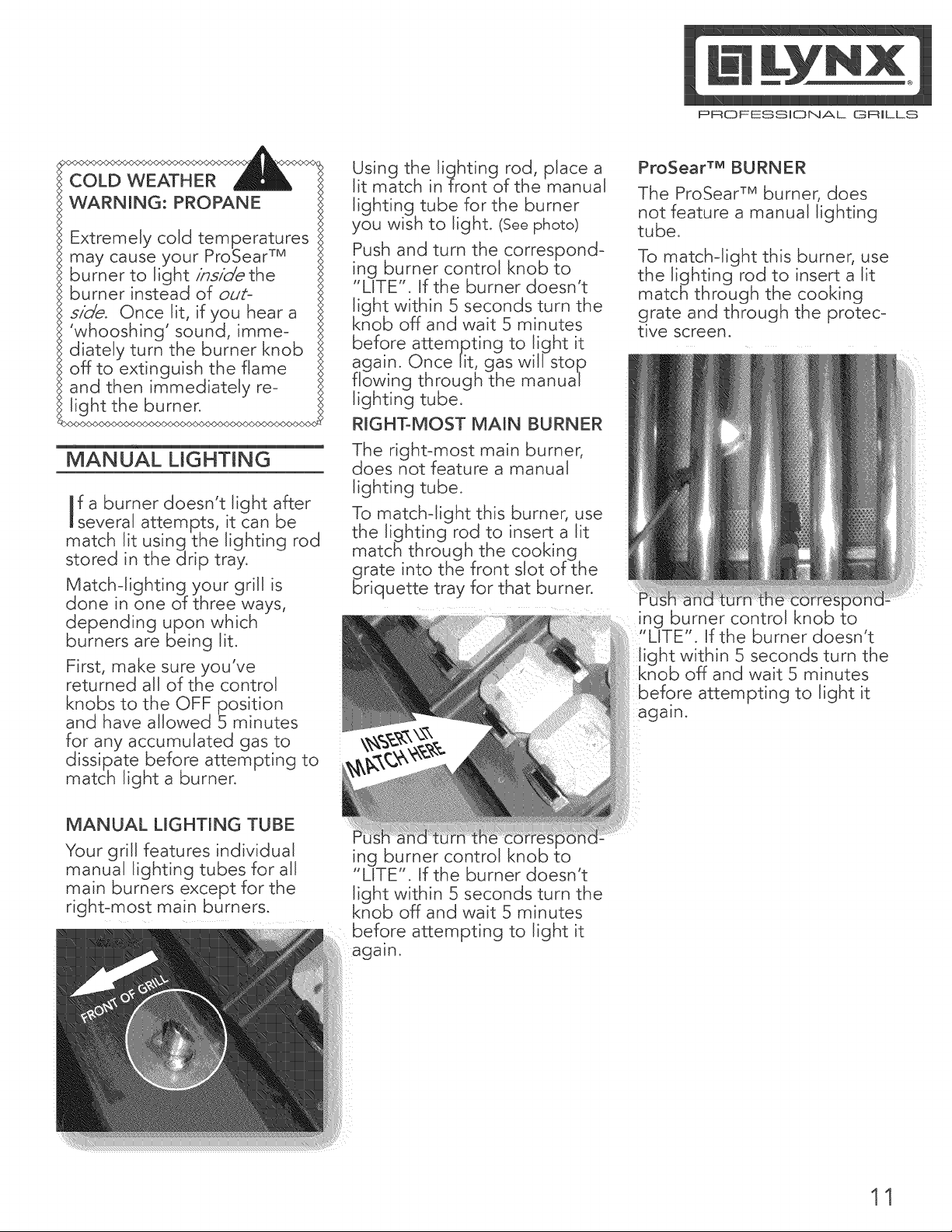

Using the lighting rod, place a

lit match infront of the manual

lighting tube for the burner

you wish to light. (See photo)

Push and turn the correspond-

ing burner control knob to

"LITE". If the burner doesn't

light within 5 seconds turn the

knob off and wait 5 minutes

before attempting to light it

again. Once [it, gas will stop

flowing through the manual

lighting tube.

RIGHT-MOST MAIN BURNER

The right-most main burner,

does not feature a manual

lighting tube.

To match-light this burner, use

the lighting rod to insert a lit

match through the cooking

grate into the front slot of the

briquette tray for that burner.

ProSear TM BURNER

The ProSear TM burner, does

not feature a manual lighting

tube.

To match-light this burner, use

the lighting rod to insert a lit

match through the cooking

grate and through the protec-

tive screen.

ing burner control knob to

"LITE". If the burner doesn't

ht within 5 seconds turn the

off and wait 5 minutes

before attempting to light it

again.

MANUAL LIGHTING TUBE

Your grill features individual

manual lighting tubes for all

main burners except for the

right-most main burners.

ing burner control knob to

"LITE". If the burner doesn't

light within 5 seconds turn the

knob off and wait 5 minutes

before attempting to light it

11

Page 12

PROFESSIONAL GRILLS

re-heating your grill every

time you use it is extremely

important. Pre-heating allows

the briquettes to properly

heat up, providing more even

and more consistent cooking

resu Its.

Pre-heat your grill by igniting

all main burners, including the

ProSear TM burner, and setting

them to "HI".

Then close the hood and

allow the grill to heat for 10

to 15 minutes. Once you've

reached your desired pre-

heat temperature, turn off

the burners that you won t be

using to cook your food.

WARNING!

DO NOT LEAVE THE

GRILL UNATTENDED

DURING THE PREHEAT

CYCLE OR AT ANY

TIME WHILE THE GRILL

IS IN USE.

PREHEATING FOR

MORE THAN 15 MIN-

UTES MAY OVERHEAT

THE GRILL, CAUSING

DAMAGE TO THE

GRILL.

>O_O#

TYPES OF COOKING

he main brass burners and

the ProSear TM burner in

your Lynx grill are capable

of creating a range of heat

intensities. By varying the

heat output, the number of

burners used and the position

of the hood, you can create

either direct or indirect heat

or a combination of both and

develop a wide variety of

succulent recipes. There are

two basic types of grilling in

an outdoor grill... D_?ectHeat

and/nc//?ect Heat

DIRECT HEAT

Direct heat cooking occurs

when foods are placed

directly over the heat source.

This form of heat is known as

"radiant" heat because the

heat radiates directly from the

source to the food.

Direct heat is a must when

you want to sear the outside

of your food to seal in flavor.

Lynx main brass burners

provide the heat necessary to

sear foods and seal in flavor.

INDIRECT HEAT

Indirect heat cooking occurs

when the food is not close to

the heat source. Heat reaches

the food via air movement

within the cooking area. This

form of heat is known as "con-

vection" heat.

Indirect, or "convection"

cooking is achieved byplacing

the food on one side of the

grill and igniting burners on

the other side. You leave the

burner below the food "OFF".

You should keep the hood

closed as much as possible

during this type of cooking to

maintain even heat around the

food. You regulate the heat

by adjusting the burner, using

the hood thermometer to

monitor the temperature.

12

Page 13

7 USING PROSEAR BURNER

PROFESSIONAL GRILLS

_rofessional

resta urant

:hefs have

,s relied

of heat

red

heat ... to create a higher

searing temperature than

what standard burners can

achieve. So Lynx provides the

ProSear TM infrared burner.

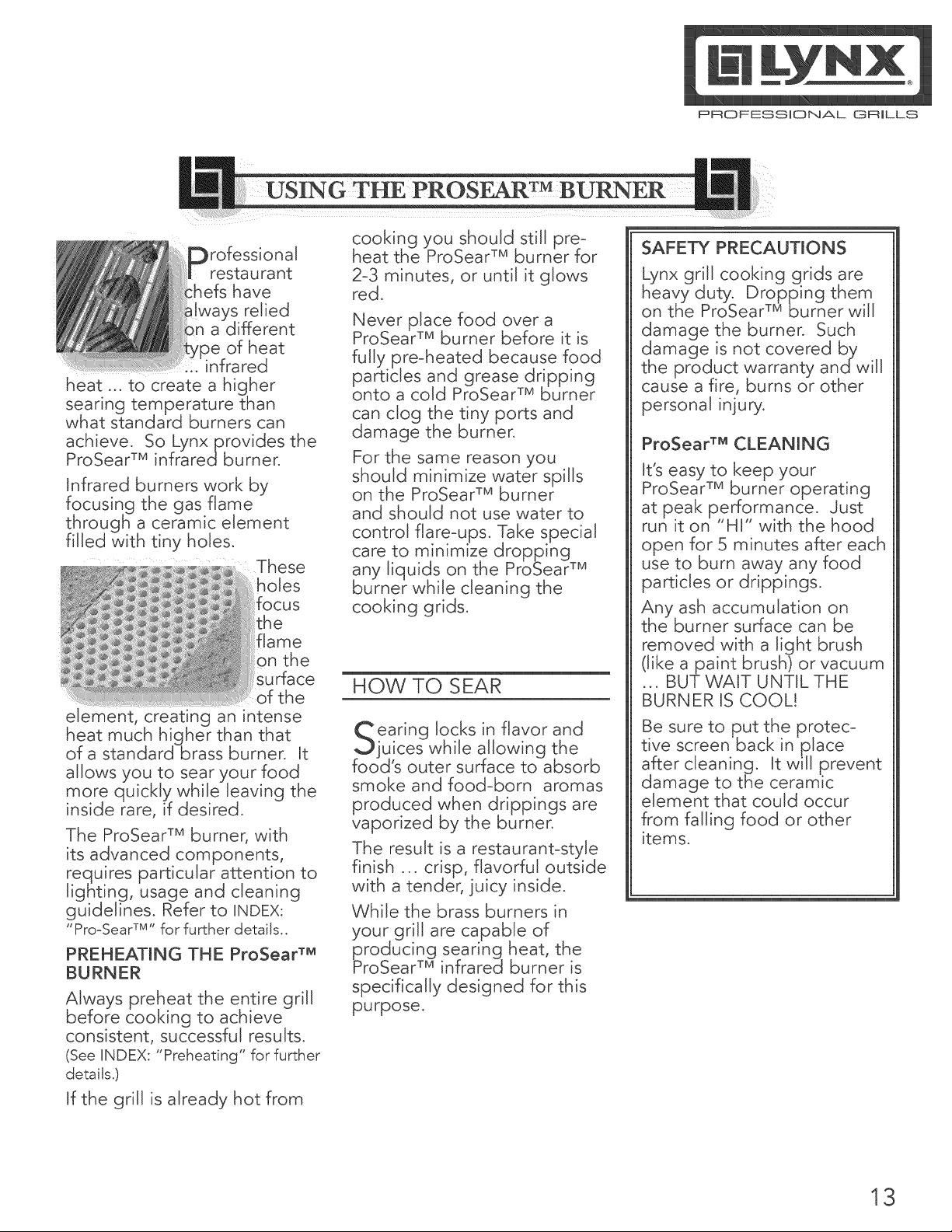

Infrared burners work by

focusing the gas flame

through a ceramic element

filled with tiny holes.

These

holes

focus

the

flame

on the

surface

of the

element, creating an intense

heat much higher than that

of a standard brass burner. It

allows you to sear your food

more quickly while leaving the

inside rare, if desired.

The ProSear TM burner, with

its advanced components,

requires particular attention to

lighting, usage and cleaning

guidelines. Refer to UNDEX:

"Pro-Sear TM''for further details..

PREHEATING THE ProSear TM

BURNER

Always preheat the entire grill

before cooking to achieve

consistent, successful results.

(See UNDEX: "Preheating" for further

details.)

If the grill is already hot from

cooking you should still pre-

heat the ProSear TM burner for

2-3 minutes, or until it glows

red.

Never place food over a

ProSear TM burner before it is

fully pre-heated because food

particles and grease dripping

onto a cold ProSear TM burner

can clog the tiny ports and

damage the burner.

For the same reason you

should minimize watereSpills

on the ProSear TM burn

and should not use water to

control flare-ups. Take special

care to minimize dropping

any liquids on the ProSear TM

burner while cleaning the

cooking grids.

HOW TO SEAR

earing locks in flavor and

ju!ces while allowing the

food s outer surface to absorb

smoke and food-born aromas

produced when drippings are

vaporized by the burner.

The result is a restaurant-style

finish ... crisp, flavorful outside

with a tender, juicy inside.

While the brass burners in

your grill are capable of

producing searing heat, the

ProSear TM infrared burner is

specifically designed for this

purpose.

SAFETY PRECAUTIONS

nx grill cooking grids are

eavy duty'. Dropping them

on the ProSear TM burner will

damage the burner. Such

damage is not covered by

the product warranty and will

cause a fire, burns or other

personal injury.

ProSear TM CLEANING

It's easy to keep your

ProSear TM burner operating

at peak performance. Just

run it on "HI" with the hood

open for 5 minutes after each

use to burn away any food

particles or drippings.

Any ash accumulation on

the burner surface can be

removed with a light brush

(like a paint brush) or vacuum

... BUT WAIT UNTIL THE

BURNER IS COOL!

Be sure to put the protec i

tive screen back in place

after cleaning. It will prevent

damage to the ceramic

element that could occur

from falling food or other

items.

13

Page 14

PROFESSIONAL GRILLS

J_ i!i!ii!i!i!i_i'_!i'__

otisserie cooking provides

an even delivery of heat to

your foods. It has no equal.

The constant rotation not only

cooks

USING THE ROTISSEPdE _RNER

foods

evenly, it al._

bastes. As juices rise to the

surface of the food, they

naturally flow around it as it

rotates. And, by moving the

burner out from beneath the

food, you avoid scorching

flare-ups.

Vo u r

will

l: more

juicier vv slow-

roasted on a Lynx's rotisserie.

The Lynx rotisserie system

consists of four main parts, the

motor, the skewer, the forks

and the infrared burner.

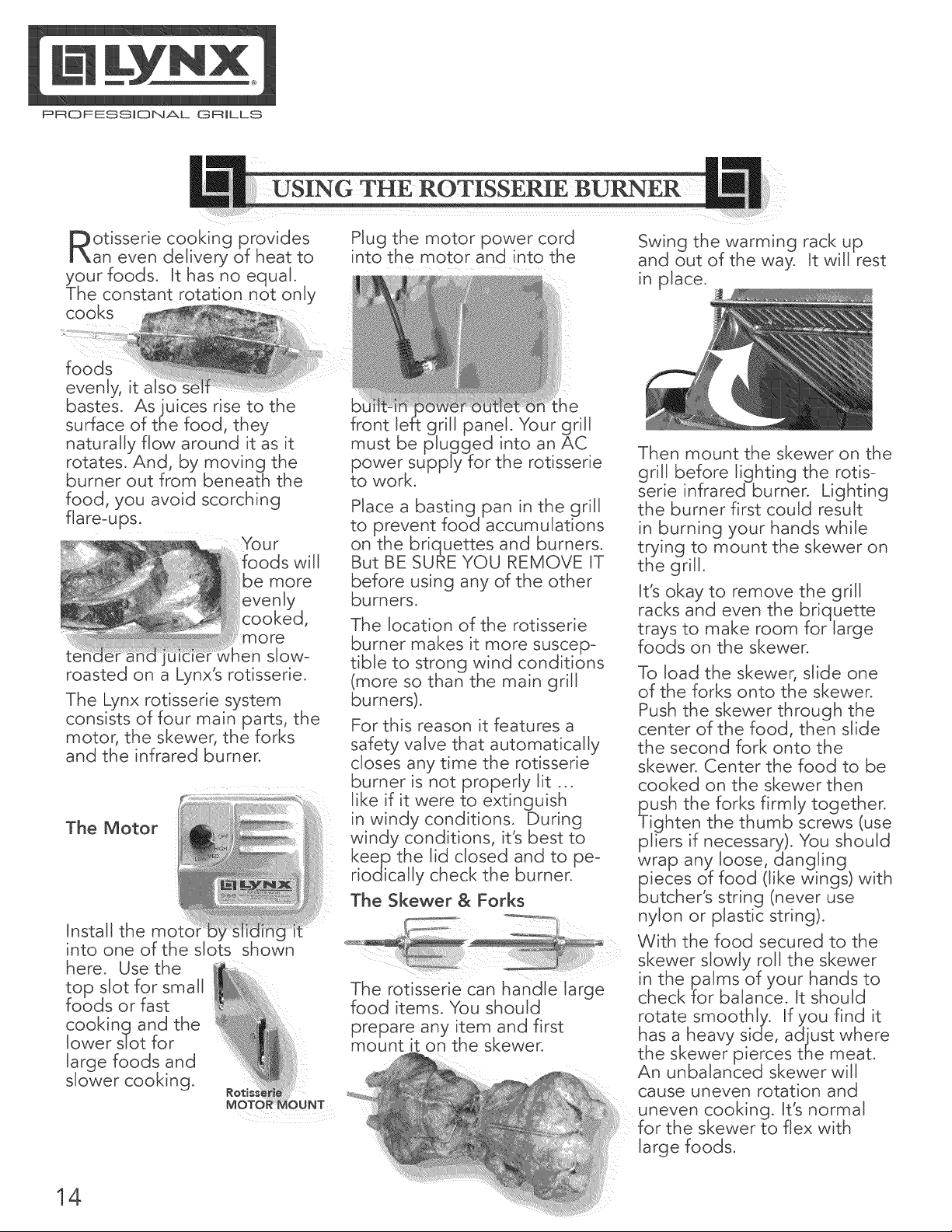

The Motor

Install the moto

into one of the slo]

here. Use the

top slot for small

foods or fast

cooking and the

lower slot for

large foods and

slower cooking.

it

]OWn

Plug the motor power cord

into the motor and into the

front lel Your grill

must be ed into an AC

power supp rotisserie

to work.

Place a basting pan in the grill

to prevent food accumulations

on the briquettes and burners.

But BE SURE YOU REMOVE IT

before using any of the other

burners.

The location of the rotisserie

burner makes it more suscep-

tible to strong wind conditions

(more so than the main grill

burners).

For this reason it features a

safety valve that automatically

closes any time the rotisserie

burner is not properly lit ...

like if it were to extinguish

in windy conditions; During

windy conditions, its best to

keep the lid closed and to pe-

riodically check the burner.

The Skewer & Forks

The rotisserie can handle large

food items. You should

prepare any item and first

mount it on the skewer.

Swing the warming rack up

and out of the way. It will rest

in place.

Then mount the skewer on the

grill before lighting the rotis-

serie infrared burner. Lighting

the burner first could result

in burning your hands while

trying to mount the skewer on

the grill.

It's okay to remove the grill

racks and even the briquette

trays to make room for large

foods on the skewer.

To load the skewer, slide one

of the forks onto the skewer.

Push the skewer through the

center of the food, then slide

the second fork onto the

skewer. Center the food to be

cooked on the skewer then

push the forks firmly together.

Tighten the thumb screws (use

pliers if You should

wrap any loose, gling

pieces of food (like wings) with

butchers string (never use

nylon or plastic string).

With the food secured to the

skewer slowly roll the skewer

in the palms of your hands to

check for balance. It should

rotate smoothly. If you find it

has a heavy side, adiust where

the skewer pierces the meat.

An unbalanced skewer will

cause uneven rotation and

uneven cooking. It's normal

for the skewer to flex with

large foods.

14

Page 15

Slide the pointed end of the

skewer into the motor and rest

the other end on the rollers on

the other side of the grill.

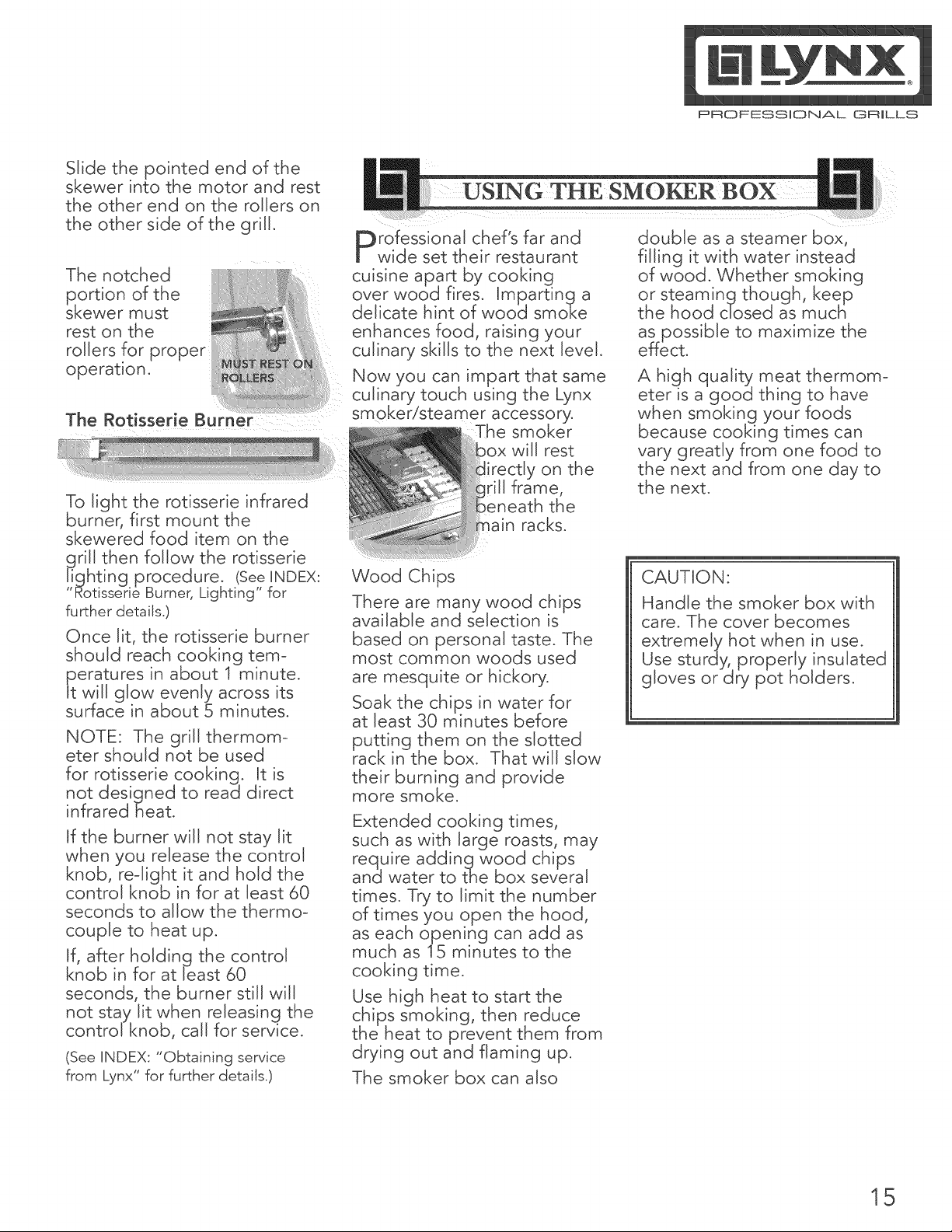

The notched

portion of the

skewer must

rest on the

rollers for proper

operation.

The Rotisserie Burner

To light the rotisserie infrared

burner, first mount the

skewered food item on the

jgrill then follow the rotisserie

!ghting procedure. (See UNDEX:

Rotisserie Burner, Lighting for

further details.)

Once lit, the rotisserie burner

should reach cooking tem-

peratures in about 1 minute.

it will glow evenly across its

surface in about 5 minutes.

NOTE: The grill thermom-

eter should not be used

for rotisserie cooking. It is

not designed to read direct

infrared heat.

if the burner wiJJ not stay lit

when you release the control

knob, re-light it and hold the

control knob in for at least 60

seconds to allow the thermo-

couple to heat up.

If, after holding the control

knob in for at least 60

seconds, the burner still will

not stay lit when releasing the

control knob, caJJ for service.

(See UNDEX: "Obtaining service

from Lynx" for further details.)

rofessional chef's far and

wide set their restaurant

cuisine apart by cooking

over wood fires, imparting a

delicate hint of wood smoke

enhances food, raising your

culinary skills to the next level.

Now you can impart that same

culinary touch using the Lynx

smoker/steamer accessory.

The smoker

will rest

:Jy on the

teneath the

in racks,

Wood Chips

There are many wood chips

available and selection is

based on personal taste. The

most common woods used

are mesquite or hickory,

Soak the chips in water for

at least 30 minutes before

putting them on the slotted

rack in the box, That wiJJ slow

their burning and provide

more smoke,

Extended cooking times,

such as with large roasts, may

require adding wood chips

and water to the box several

times. Try to limit the number

of times you open the hood,

as each opening can add as

much as 15 minutes to the

cooking time.

Use high heat to start the

chips smoking, then reduce

the heat to prevent them from

drying out and flaming up.

The smoker box can also

PROFESSmONAL GRmLLS

double as a steamer box,

filling it with water instead

of wood. Whether smoking

or steaming though, keep

the hood closed as much

as possible to maximize the

effect.

A high quality meat thermom-

eter is a good thing to have

when smoking your foods

because cooking times can

vary greatly from one food to

the next and from one day to

the next.

CAUTION:

Handle the smoker box with

care. The cover becomes

extremely hot when in use.

Use sturdy, properly" insulated

gloves or dry pot holders.

15

Page 16

PROFESSIONAL GRILLS

CLEANING YOUR GRILL

STAINLESS STEEL

nx products are known for

their attractive appearance.

We achieve this by selecting

only the finest grades of

stainless steel and applying

exacting workmanship.

In order to maintain this at-

tractive appearance over the

life of the grill it is important

to take the following steps:

After each use wiAe clown

the exterior of the grill to

remove grease and splatters.

Be sure to follow the

cleaning instructions for

keeping the grates and

burners clean and ready for

use.

Use a commercially

available Stainless Steel

cleaner to dean and polish

the exterior surfaces.

Doing these things on a

regular basis minimizes the

amount of effort required.

Part of the appeal ofyour Lynx

Grill is the fine grain finish.

When removing stubborn

stains:

Do not use metallic

abrasives and always rub in

the direction of the grain.

Some household cleaning

products are not suitable for

stainless steel; be sure to read

the label before using on your

Lynx Grill.

Always use the miJdest

cleaning solution first,

scrubbing in the direction of

the grain. Specks of grease

may gather in the grain of the

stainless steel andbake on to

the surface, giving the appear-

ance of rust.

To remove these baked-on

foods use a fine to medium

grit non-metallic abrasive pad

(Scotch Brite is good) in con-

junction with a stainless steel

cleaner.

Solutions used for

cleaning concrete and

masonry can be

corrosive and will

stainless steeJo Ensure your

Lynx products are well

protected before you allow

the use of such chemicals

near your griJh

SPECIAL NOTE FOR

LOCATIONS NEAR POOLS

AND COASTAL AREAS

The 304 stainless steel

material used in the con-

struction of a Lynx Grill is

highly rust resistant, however,

chlorine in the air from

swimming pools or the salt

from sea air may cause surface

rust to appear and even

create some pitting if left on

the product.

Here are a few tips to avoid

this:

Regularly wipe down the

exterior surfaces with a damp

cloth. (Micro fiber cloths such

as Ecioth perform very well).

Allow the surfaces to dry

before installing the cover.

-do not cover a damp grill.

In extreme environments

apply a rust inhibitor which

leaves a microscopic protec-

tive layer on the grill. Products

that provide a layer of vapor

corrosion inhibitors (VpCI TM)

protect the surface very well.

For seasonal storage use

the product referred to above,

ensure the grill is dry and then

cover and secure the cover to

minimize the amount of damp

air getting to the surfaces.

THE Lynx LIMITED LIFE TIME

WARRANTY PROVIDES PRO-

TECTION AGAINST RUST-

THROUGH OF PARTS THAT

RENDER THE PRODUCT

INOPERATIVE. IT DOES

NOT COVER OCCASIONAL

SURFACE RUST OR STAINING

DUE TO ENVIRONMENTAL

CONDITIONS.

After your first use certain

areas of the grill may discolor

from the intense heat given off

by the burners - this is normal

and cannot be cleaned off.

For light and heavy food

stains there are many different

stainless steel cleaners

available.

DRIP TRAY

he drip tray should be

cleaned after each use.

After the grill is completely

cool, remove the drip tray by

pulling it out until it stops,

then lifting the front edge

until the drip tray comes free.

16

Page 17

PROFESSIONAL GRILLS

Clean it with hot soapy water

or an oven-style cleaning

product and re-install.

Also, check the tray after rain.

If you ve left the grill

uncovered, you may need to

remove the drip tray drain

plug to drain the water from

the tray'. The drain plugcan

be removed with a flat-head

screwdriver.

WARNIN6 _

DO NOT ALLOW EXCESS

GREASE OR LIQUIDS TO

ACCUMULATE IN THE DRIP

TRAY AS THIS MAY CREATE

A FIRE HAZARD.

NEVER USE GRILL WITHOUT

DRIP TRAY PROPERLY IN-

STALLED

Remove the racks and then

the briquette trays by lifting

the front edge and pulling

them towardyou.

Flip the trays

.... and put

them back in

over the

Light

:he burners

_nd set them

"HI" for 5

: 10 minutes

to burn the briquettes clean.

Any remaining food items can

be brushed off using a soft

brush.

Be sure the trays have com-

pletely cooled before reinstall-

ing them.

Replacement briquette trays

can be ordered from Lynx or

from your dealer.

MAIN BRASS BURNERS

the front.

4) Angle the burner sideways

and lift it out.

Be careful not to change the

air shutter position.

To Clean the Brass Burner:

To maximize grill perfor-

mance, clean the exterior of

the burner with a wire brush.

Remove stubborn scale with a

metal scraper.

Clear any clogged ports with a

straightened paper clip. Never

use a wooden toothpick as

it may break off and clog the

port.

Shake out any debris through

the air shutter.

Use a flashlight to inspect the

burner inlet to ensure it is not

blocked. If obstructions can

be seen, clean it with a paper

clip or a pipe cleaner.

GRILLING RACKS

he easiest way to clean

the grill racks is to do so

immediately after turning off

the burners, while they are

still hot. Wearing a long BBQ

mitt to protect your hand

from steam, dip a brass bristle

brush in hot water and scrub

the grill rack. Dip the brush

frequently because the steam

helps remove baked-on foods.

CERAMIC BRIQUETTES

he ceramic briquettes

normally burn off any accu-

mulated food drippings. But

you may occasionally experi-

ence larger spills that don t

burn off under normal use.

When this happens, let the

grill cool completely.

ake sure the grill is com-

cool before pro-

Ensure that the gas supply is

off and all control knobs are in

the "OFF" position.

To Remove Brass Burners:

1) Remove the grill racks and

briquette trays.

2) Lift the burner up until the

legs exit the frame.

3) Then pull to the rear of

the grill so the burner head

comes off the brass orifice at

PROPER PLACEMENT OF

EACH BURNER IS CRITICAL.

AFTER CLEANING THEY

MUST BE CENTERED ON

THE BRASS ORIFICE, REST-

ING LEVEL WITHOUT ANY

ROCKING.

FAILURE TO MEET THESE

CONDITIONS MAY CAUSE

A VERY DANGEROUS CON-

DITION THAT CAN CAUSE

PERSONAL INJURY AND

PROPERTY DAMAGE.

v .....

17

Page 18

PnOFESS ONAL GRiLlS

PROSEARTM BURNER

t's easy to keep your

ProSear TM burner operating

at peak performance. Just run

it on "HI" with the hood open

for 5 minutes after each use to

burn away any food particles

or drippings.

Any ash accumulation on

the burner surface can be

removed with a light brush or

vacuum ... BUT WAIT UNTIL

THE BURNER IS COOL!

Every 3 to 6 months, remove

the burner (its held in place

by a set-screw) and inspect

the venturi (inlet) and orifice

to ensure that they're free of

obstructions.

Food debris on the inside

of the burner can be gently

shaken out. Do not touch the

ceramic surface.

Clean any obstructions with

a straight piece of metal coat

hanger, pipe cleaner or paper

clip.

When re-installing the

ProSear TM burner, be sure to

correctly position the burner

and the protective screen.

18

Page 19

PROFESSmONAL GRmLLS

TROUBLESHOOTING YOUR_GRILL

BEFORE YOU CA LL:

Please check a few things before you call for service:

Is there fuel supplied to the grill?

Is the main shut-off valve open?

Are you using correct type of fuel? (LP or Natural Gas) (See INDEX: "Gas Requirements" for further

details.)

Is your propane cylinder empty? Have you recently refilled the propane cylinder? If so, is the

connection tight?

Have you opened the valve on the propane cylinder?

Is the grill plugged in to a live electric circuit?

If you've checked the above items, review the trouble-shooting list below before calling for Lynx for

service.

GRILL WON'T LIGHT

Your Lynx grill uses an electric

ignition system that does not

spark. The igniters should

glow constantly when a

control knob is pushed in.

First, confirm that the grill is

getting electricity by turning

on the lights.

CHECK THE IGNITERS

[] Ensure that all burner

controls are set to OFR

[] Remove the racks and

briquette trays.

[] Watch an igniter as you

push in and hold the

corresponding control

knob. You will need either

a small mirror or shiny

metal object to see the

igniter under its cover.

(Be sure you push in the

correct control knob and

keep the knob in the

"OFF" position)

[] Check the remaining ,

igniters. If igniters don t

glow, proceed with trou-

bleshooting or match-

light the burner.

CHECK THE BURNERS

If the igniters are working

check to see if gas is

reaching the burners by" at-

tempting to match light a

burner.

BE CAREFUL! IF THE

BURNER FALLS TO IGNITE,

WAIT 5 MINUTES BEFORE

ATTEMPTING TO IGNITE

OTHER BURNERS! (See

INDEX: "Match Lighting" for

further details.)

If match lighting doesn't

work, re-check fuel connec i

tions for leaks and ensure

the supply is of the correct

type and is of adequate

pressure. (See INDEX: "Leak Test"

for further details.)

If the burner will light with a

match, then the igniter may

not be functioning correctly.

Call for service.

If the burner will not match

light, and you know you are

getting gas, wait for any

gas to dissipate and remove

the burner and check it for

blockages. (See INDEX: "Clean

the Brass Burner" for further details.)

YELLOW FLAME OR GAS

SMELL WHILE COOKING

IF YOU SMELL GAS WHILE

THE GRILL IS OPERATING,

IMMEDIATELY TURN OFF ALL

BURNERS AND SHUT OFF

THE MAIN FUEL SUPPLY.

PERFORM A LEAK TEST

(See INDEX: "Leak Test" for

further details.)

CHECK FOR BLOCKAGES

(See INDEX: "Clean the Brass

Burner" for further details.)

19

Page 20

PROFESSIONAL GRILLS

A yellow flame on the main

burners indicates a lack of air.

But, if the air around the grill

is dusty or if heavy grease is

present, some orange tips on

the burner flame are normal.

ADJUST THE AIR SHUTTER

To adjust for insufficient air,

adiust the air shutter. (See ,

iNDEX: Air Shutter Adjustment for

further details.)

LOW OR INSUFFICIENT

NO PART OF THE GRILL

SHOULD EVER BE LINED

WITH ALUMINUM FOIL.

Doing so will interfere with

airflow and can cause a low

heat condition.

Ensure that you've preheated

the main burners for at

least 10 to 15 minutes with

the hood closed and the

ProSear TM burner for 3

minutes.

Proper levelin 9 during instal-

lation is critical. A grill that is

out of level will cause erratic

burner combustion and inef-

ficient, uneven heating. A

carpenters spirit level should

be used to level the grill both

front-to-back and side-to-side.

If the low heat problem

persists:

CHECK THE GAS SUPPLY

LINE SIZING REQUIRE-

MENTS.)

CHECK THE GAS SUPPLY

LINE FOR KINKS OR

DAMAGE.

REPLACE any damaged

supply lines.

CHECK THE REGULATOR

Make sure that the regulator

& hose assembly is the one

designed for and supplied

with your Lynx 9rill and that

20

it is correctly set up for the

type of fuel you are using.

(See iNDEX: "Regulator Conver-

sion" for further details.)

The hose and regulator

provided by Lynx must be

used if your grill is set-up for

an LP Gas Cylinder.

Check that there is no

physical pressure being

applied to the regulator

attached to the back of the

grill. The regulator contains

a flexible diaphragm and

should not be allowed to

touch the grill body or its

surroundings.

CHECK FOR OBSTRUC i

TIONS

Ensure that the burners and

drip tray are clean and free

from obstructions.

LP (Propane) units:

IS THE CYLINDER

ALMOST EMPTY?

Almost-emAty cylinders may

not have sufficient pressure

to run the burners at high

heat.

HAVE THE LINE

PRESSURE CHECKED BY

A QUALIFIED TECHNll

ClAN (See iNDEX: "Gas

Requirements" for further

details.)

FLOW LIMITING DEVICE

Improper lighting proce-

dures may have activated

the LP cylinders flow control

device, reducing the heat

output.

To reset the flow control:

[] Shut off all burner

controls and close the LP

cylinder valve.

[] Wait 30 seconds and,

very slowly, reopen the

cylinder valve.

[] Wait a few seconds and

reJite a burner,

Bulk LP Cylinder Users

Bulk LP cylinder lines must

be properly regulated,

Ensure that you are using

a 4/11 appliance regulator

supplied by Lynx and

converted to LPgas. Also

ensure that you do not have

more than one regulator in

line.

Natural Gas units:

SUPPLY LINE

Ensure thatthe supply" line is

at least 3/4 inside diameter

or 1" outside diameter.

CHECK LINE PRESSURE

Natural gas pressure should

be at least 7" W.C. and 4"

W.C. pressure under full load

(with all burners on.)

CHECK BURNERS FOR

BLOCKAGES

CHECK FLAME CHAR-

ACTERISTICS. (See iNDEX:

"Flame, Correct Size" )

CLEAN OR ADJUST AIR

SHUTTER (See iNDEX: "Air

Shutter Adjustment."

WIND HITTING GRILL

Wind hitting the grill while in

use, especially winds blowing

into or across the hood gap

from behind, can cause poor

performance and in some

cases can cause the control

panel to get dangerously hot.

Steady or

g. sty

winos can

prevent

the normal

exhaust of

hot gases.

Locate ,our

grill ng

winds grilling in

windy conditions.

Page 21

PROFESSIONAL GRILLS

BURNER EXTINGUISHES

LOCATION

First determine if the problem

is being caused by location.

If the grill is subject to high

winds, reposition it to provide

some protection.

CHECK THE FLAME

Check the gas supply and

flame characteristics. (See

INDEX: "Flame, Correct Size")

BURNERS SEATED

Check to ensure that the

burners are correctly posi-

tioned in the gri!l. (See iNDEX:

"Burner Placement for further

details.)

Correctly-installed burners

should be seated firmly and

level with no side-to-side

movement.

BURNER EXTINGUISHES

ONLY WHEN SET TO

"LOW"

The valves on the grill feature

an adjustable low setting.

Fluctuations in gas pressure,

gas conversion and even in

the quality of the gas itself

may affect burner perform

mance at the LOW setting.

It could be either too high or

tOO lOW. (See iNDEX: "Burner

Adjustment" for further details.)

ROTISSERIE WON'T

LIGHT

Follow the same procedure as

described for the grill burners

to diagnose problems with the

rotisserie burner.

BE CAREFUL! The rotisserie

burner flame may be hard to

see in bright sunny conditions.

ROTISSERIE LIGHTS

BUT GOES OUT AS

SOON AS CONTROL IS

RELEASED

CHECK

THERMOCOUPLE

The control knob must be

held in for 30 to 60 seconds

after ignition for the rotis-

serie burner to stay lit. (See

iNDEX: "Lighting the rotisserie"

for further details.)

If the burner will not stay" lit

when you release the control

knob, re-light it and hold the

control knob in for at least

60 seconds to allow the ther-

mocouple to heat up.

If, after holding the control

knob in for at least 60

seconds, the burner still will

not stay lit when releasing

the control knob, call for

service.

(See INDEX: "Obtaining service

from Lynx" for further details.)

LIGHTS WON'T LIGHT

CHECK POWER

Ensure that the grill is

connected to a live AC

power source and check for

rotisserie motor operation.

RESET TRANSFORMER

Disconnect power from the

grill and wait 5 minutes for

the transformer to cool clown

and reset. Then reconnect

power. If, after resetting the

transformer and replacing

bulbs, you still do not have

power, call for service.

REPLACE THE BULB

Replacement bulbs are

halogen, 12 volt, 10W

max, T3 type with a

G4 bi-pin base.

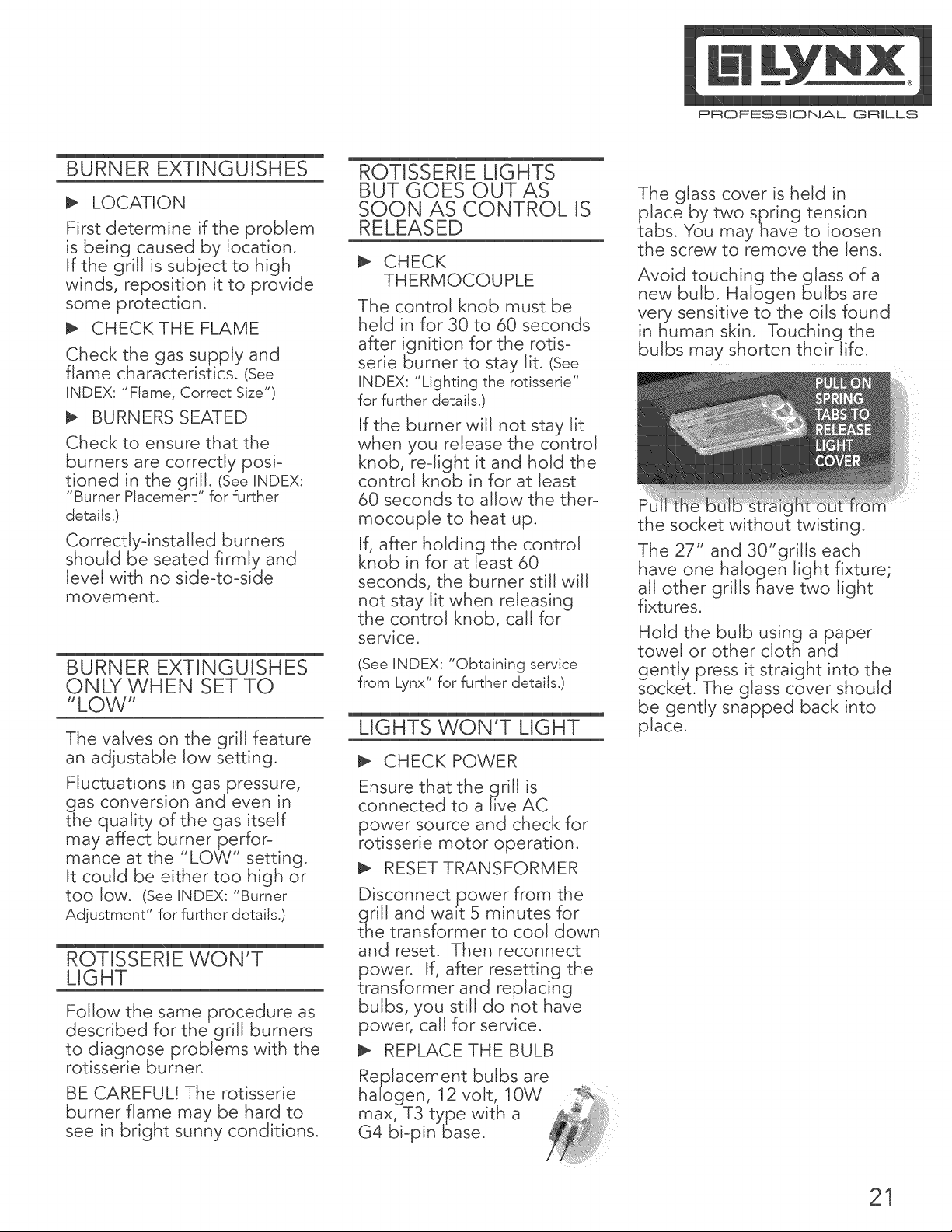

The glass cover is held in

place by two spring tension

tabs. You may have to loosen

the screw to remove the lens.

Avoid touching the glass of a

new bulb. Halogen bulbs are

very sensitive to the oils found

in human skin. Touching the

bulbs may shorten their life.

the socket without twisting.

The 27" and 30"grills each

have one halogen light fixture;

all other grills have two light

fixtu res.

Hold the bulb using a paper

towel or other cloth and

gently press it straight into the

socket. The glass cover should

be gently snapped back into

place.

21

Page 22

PROFESSIONAL GRILLS

Before calling for service,

lease make sure you have

tPhe following information:

[] Model number

[] Date of purchase

[] Proof of purchase by the

original owner

[] Serial number.

The serial number can be

located on the rating plate

which is located either on the

underside of the drip tray, on

the heat shield behind the

front panel, or on the inside

left cabinet wall (for most free-

standing grills).

L-YNx PnOFE:SSIONAL

For warranty service, contact

the Lynx Customer Service

Department for an authorized

service agent near you at:

(888) Buy-Lynx

(888-289-5969).

www.LynxG rills.corn

iiii

Your satisfaction is of the

utmost importance to us. If a

problem cannot be resolved

to your satisfaction, please

write, fax or emaiJ us:

Lynx Professional Grills

5895 Rickenbacker

Commerce, CA 90040

Service: (888) Buy-Lynx (888-

289-5969)

Tel: (323) 838-1770

Fax: (323) 838-1778

www.lynxgrills.com

Contact Lynx for replacement

parts. Parts are shipped RO.B.

Commerce, CA.

LYNX BEGAN WITH A VISION.

smaJJ group of manufactur-

ing engineers with over a

century of collective experi-

ence had a dream.

They dared to take

their extensive com-

mercial manufac-

turing know-how

and create a line of

outdoor cooking

products that otter

commercial elegance

and performance ....,_

to the consumer ,_

market.

Lynx has taken the

ua lity, workman-

ip, service and

innovation of the

commercial market

THE LYNX STORY

and incorporated it into the

Lynx Professional Grills line

of consumer and commercial

products. The combination

of creative design, superior

materials and

.qevates Lynx

roducts to a

of their

)wn.

original

are

ised every day

restaurants,

_otels and

parks

the USA:

LYNX SATISFIED CUS-

TOMERS

TGI Fridays • Applebee's

e Houston s ® Red Lobster ®

Hard Rock Car6 ®WoJfgang

Puck's ® Cheesecake Factory

P

e Red Robin ® Planet

Hollywood ® Hilton ® Hyatt

® Four Seasons Marriott Le

Meridian • Sheraton ® Conrad

International BeJJagio ® New

York New York • MGM Grand

® Treasure Island e Mirage ®

Paris ® Venetian ® Excalibur

® Mandalay Bay ® Riviera ®

Desert Inn ® Hard Rock Hotel

® Disney World

Page 23

PROFESSIONAL GRILLS

J° Limited Lifetime Warranty.

The stainless steel body housings, the solid brass grill burners and the ProSear TM burners are warranted to be free from

defects in material and workmanship when subjected to normal domestic use and service for the lifetime of the original

purchaser. This warranty excludes surface corrosion, scratches, and discoloration which may occur during regular use.

This warranty is limited to the replacement of the defective parts, with the owner paying all other cost including labor.

*Does not include the rotisserie infra-red burner.

II. Limited Five-Year Warranty,

The structural integrity of the interior grill parts, exterior, and drip pans are warranted to be free from defects in

material and workmanship, when subjected to normal domestic use and service, for a period of five years from the date

of purchase. This warranty is limited to the replacement of the defective parts, with the owner paying all other cost

including labor.

JJJ. Limited One-Year Warranty.

All other grill components are warranted to be free from defects in material and workmanship for a period of one year

from the original date of purchase. Lynx will replace or repair parts found to be defective at no cost to the original

purchaser.

IV. Limitations & Exclusions

1) Warranty applies only to the original purchaser and may not be transferred.

2) Warranty is in lieu of all other warranties, expressed or implied and all other obligations or liabilities related to the

sale or use of its grill products.

3) Warranty shall not apply and Lynx is not responsible for damage resulting from misuse, abuse, alteration of or

tampering with the appliance, accident, hostile environment, flare-up fires, improper installation, or installation not in

accordance with the instructions contained in this manual, or the local codes.

4) Lynx shall not be liable for incidental, consequential, specW or contingent damages resulting from its breach of this

written warranty or any implied warranty.

5) Some states do not allow limitations on how long an implied warranty lasts, or the exclusions of or limitations on

consequential damages. This warranty gives you specific legal rights and you may have other rights which vary from

state to state.

6) No one has the authority to add to or vary Lynx's warranty, or to create for Lynx any other obligation or liability in

connection with the sale or use of its products.

7) Limited to the replacement of defective parts with the owner paying all other costs including labor.

V. What is not covered.

Lynx shall not be responsible for and shall not pay for the following:

1) UnstaHation or start-up, damages or problems caused by improper installation or use;

2) Service by an unauthorized service provider;

3) Damage or repair due to service by an unauthorized service provider or use of unauthorized parts;

4) Units installed in common areas or non-residential applications such as day<are centers, bed and breakfast centers,

churches, nursing homes, restaurants, hotels, schools, etc.;

5) To correct normal adjustments or settings, due to improper installation, commissioning or local gas supply proper-

ties;

6) Shipping and handling costs, export duties, installation, removal, or rednstaHation cost;

7) Display medals are generally sold "as is." Ufyou have purchased a display modal, please be advised that it is sold

"as is" and that it is subject to the following warranty exclusions: any exterior or cosmetic damage is non warrant-

able; any missing components will be replaced at consumers expense; major handling damage to manifold, valve and

ignition system will be serviced at consumer's expense; all other warranty's (standard warranty) will remain in effect.

8) The cost of a service call to diagnose trouble. (See UNDEX: "Obtaining Service from Lynx" for further details.)

23

Page 24

PROFESSmONAL GRmLLS

24

Page 25

PROFESSIO[NAL GRILLS

INSTALLATION GUIDELINES ...................................................... 25

Be[ore You Start ............................................................................................................... 27

g shiprr_er_t ar'riv,_,s dg_rr_g_g_d.......................................................................................... 27

Unpacking and Assembly ................................................................................................ 30

Electrical Connections ..................................................................................................... 31

Gas Connections .............................................................................................................. 32

Final Checks .................................................................................................................... 34

Side Burner/I,PSGE Hookup ......................................................................................... 36

Wiring Schematics ........................................................................................................... 37

L27 Non-Rotisserie Grill ............................................................................................. 37

L27 & L30 rotisserie Grill ............................................................................................ 38

L36 & L42 rotisserie Grill ............................................................................................ 39

L54 rotisserie Grill ...................................................................................................... 40

2010 Lynx Professional Grills Exploded Parts View ......................................................... 41

2010 Lynx Professional Grills Parts list ............................................................................ 42

25

Page 26

PROFESSIONAL GRILLS

WARNING

1) Always maintain the required clearances from combustible construction as detailed. The

grill is designed for outdoor use only. NEVER use in a garage, building, shed, breezeway or

other enclosed area. This grill shall not be used under any overhead combustible construc-

tion.

2) Gas grills are not design certified for and are not to be installed in or on recreational ve-

hicles, portable trailers, boats or armyother movinginstallation

3) Keep any electrical supply cord and the fuel supply hose away from any heated surfaces.

Electrical cords should be placed away from walkways to avoid tripping hazard.

4) Do not repair or replace any part of the grill unless specifically recommended in this manual.

Other service should be performed by a qualified technician.

5) All gas lines must have a shut-off that is readily and easily accessible. Be sure the owner

knows where the shut-off is located. If you smell gas, check for gas leaks immediately. Check

only with a soap and water solution. Never check for gas leaks with an open flame. (See UN-

DEX: "Leak Testing" for further details.)

1) The outdoor cooking gas appliance and its individual shutoff valve must be disconnected

I_ rom the gas supply piping system during any pressure testing of that system at test pres-

sures in excess of 0.5 psi (3.5 kPa).

2) The outdoor cooking gas appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing of the gas supply pip-

ing system at test pressures equal to or less than 1/2 psi (3.5 kPa).

STATE OF MASSACHUSETTS

1) Massachusetts requires all gas be installed using a plumber or gas fitter carrying the appro-

priate Massachusetts license

2) All permanently-installed natural gas or propane installations require a "T" handle type

manual gas valve be installed in the gas supply line to this appliance.

3) This does not apply to portable propane installations using a 20 pound cylinder.

26

Page 27

PROFESSIONAL GRILLS

BEFORE YOU START

l_! IF SHIPMENT ARRIVES DAMAGED !_1

VISIBLE LOSS OR DAMAGE:

Be certain any visible damage to the carton is noted on freight bill or express receipt and signed

by the person making delivery.

FILE CLAIM FOR DAMAGES IMMEDIATELY, regardless of extent of damage.

CONCEALED LOSS OR DAMAGE:

If damage is unnoticed until the grill is unpacked, notify the transportation company or carrier im-

mediately and file a "concealed damage" claim with them. This should be done within (15) days

of the date delivery is made to you. Be sure to hold on to the container for inspection. We cannot

assume responsibility for damage or Joss incurred in transit. (See UNDEX: Obtaining Service from Lynx for

further details.)

WARNING

Never install this product into a combustible enclosure without an insulated jacket. Doing so

could result in fire, property damage and personal injury.

Never locate the grill under a roof or overhang, in a building, garage, shed or other such

enclosed area.

Never locate the grill under combustible construction.

Installation must conform with local codes or, in the absence of local codes, with either the

National Fuel Gas Code, ANSI Z223.1/NFPA 54, Natural Gas and propane Installation Code,

CSA B149.1, or Propane Storage and Handling Code, B149.2,

Cx>O<YJOOO/, _<_>OOO<X

IMPORTANT NOTES:

Where's the Wind?

When selecting a suitable

location, consider important

factors such as exposure

to the wind and foot-traffic

patterns.

If you have a freestanding

grill, position it so the prevail-

ing wind blows into the front

control panel (at your back

when grilling), supporting the

proper front-to-rear airflow.

Built-in grills located in areas

with prevailingwinds should

be protectedby a wind

barrier.

Winds hitting the backof the

grill directly may cause

problems, as well as wind

blowing along the hOOC!ga9.

Be po

How long is your run?

Keep all gas supply lines as

short as possible because

gas lines lose pressure over

distance and with each elbow

and tee that is added. This

drop in pressure affects grill

perTormance. (See INDEX:

"Gas Supply Line Runs" for further

details.)

Are you "on-the-level"?

Proper leveling during instal-

lation is critical. A grill that is

out of level will cause erratic

burner combustion and inef-

ficient, uneven heating. A

carpenters spirit level should

be used to level the grill both

front-to-back and side-to-side.

If the floor is uneven or has

a decided slope, re-leveling

may be required each time

you move a freestanding unit.

BUILTItN INSTALLATIONS:

The Lynx Built-In Grill is

designed for easy installation

into masonry enclosures.

27

Page 28

PROFESSIONAL GRILLS

NOTE:

Lynx buiitdn grills are intended

either for installation in a

buiJtdn enclosure constructed

of non-combustible materials

or for an installation in a built

in enclosure constructed of

combustible material when

installed with a Lynx insulating

jacket (LIJ).

For non-combustible applica-

tions, the grill drops into the

opening shown in the cutout

detail drawing (See UNDEX: Gas

Requirements") and hangs from

its counter-top trim. A deck is

not required to support it from

the bottom.

When using the insulated

jacket in a combustible

enclosure, the jacket must be

supported from the bottom by

a ledge on each side or a fuji

deckbeneath the jacket.

(See UNDEX: "Gas Requirements")

Pay spedaJ attention to the

rovisions shown for gas line

ook-up.

The enclosure should have

ventilation holes to prevent

gas build-up in the event of

a leak. The deck ledges and

counter should be fiat and

level. (refer to ANSI Z21.58

Enclosures For Self Contained

LP-Gas Supply Systems or

local codes for additional

information)

CLEARANCE TO COM-

BUSTIBLE MATERIALS:

Minimum clearance from the

sides and back of the grill to

adjacent combustible con-

struction below the top of

unit are 12 from the sides

and back.

D6gagement minimal entre

Jes _arois Jat@aJes et J'ard@re

de I'appariel et la construc-

tion combustible au-dessous

du panneau sup6rieur de

J'appareiJ (30 cm _ partir des

patois Jat@raJes et 30 cm

partir de J'arri_re).

Minimum clearance from

sides and back of unit to

adjacent combustible con-

struction extending above the

unit is 18 from the sides and

back.

D@gagement horizontal

minimal entre Jes patois

Jat@raJes et J'ard@re de

J'apparieJ et Ja construction

verticaJe combustible au-

dessus de J'appareil (45.7 cm

partir des patois Jat@rales et

45.7 cm _ partir de J'arri@re).

Do not use this appliance

under overhead combustible

surfaces,

Ne pas utiJiser cet appareil

sous une surface combus-

tible.

A minimum of 6" of clearance

is needed on the left side of

the grill above the counter

top tot the motor and skewer,

If the grill is to be iolaced into

a combustible enclosure, an

approved insulated jacket

is necessary and is available

only from your Lynx dealer,

Lynx insulated jackets have

been designed and tested

specifically for your Grill.

REAR HOOD CLEARANCE:

A 3 inch clearance is required behind the grill to allow the front

hood to open.

The grill exhausts combustion products and cooking greases to

the back. Never locate the grill where this exhaust will be difficult

to dean.

(3" min)

This grill requires that a 120

volt, 60 hertz, 15 amp GFI

certified outlet be installed by

a qualified electrician.

28

O O

Page 29

PROFESSIONAL GRILLS

CUT-OUT DIMENSIONS FOR BUILT-IN GRILLS

2" round or square holes

for manifold connection

(rearor bottom access)

_CocktailPro should have an

open bottom for plumbing

and drain access.

29"

Grill

1 1/8"-

mm.

CocktailPro*

Doors

Access

36 3/8"

min.

Warming Drawer/

Convenience Center

Note: Insulated jacket required for all grills installed

into a combustible enclosure. See detail below.

1/8" min. for model LUDE

3 1/2" min. for model LUDXL

2 1/2" min. for model LDR

Counter top Notch Detail

5

19"

\3 1/4" min.

Specifications are subject to change without notice.

Model A B C D E F 6 14

L27 26 22 10 7/8

L30 29 24 1/2 107/8

L36 35 22 101/8

L42 41 24 1/2 107/8

L54 53 24 1/2 107/8

I _ countertop I

_- [o overhang[___

9/16" for Grills

1/2" for Complementary Products

Model

LU27

LU30

LIJ36

LU42

LIJ54

a b ¢ d e f

33 S 24 4 I/2 3 11 5/8

36 5 261/2 41/2 3 115/8

42 5 24 4 I/2 3 11 5/8

48 S 261/2 41/2 3 115/8

60 5 261/2 41/2 3 115/8

b

Model A B C D E F G H

A . DQO

LDR21-1 19 1/4

LDR27-1 25 1/4

LDR30-1 28 1/4

LDR36-2 34 1/4

LDR42-1 40 1/4

LSB1 12 1/8 24 1/2 105/8

LSB2 12 1/8 24 1/2 105/8

LSB2PC 24 1/4 24 1/2 105/8

LPSGE 12 1/8 24 1/2 105/8

LPB 19 22 10 5/8

LUDE 24 12 1/8 19 1/4

LUDXL 24 1/4 17 1/4 18 9/16

L30WD 20 1/2 28 1/2 10

L42CC 24 1/2 40 I/4 19 3/8

• _ j •

CS3O 22 3/4 10 5/8

29

Page 30

PROFESSIONAL GRILLS

UNPACKING AND ASSEMBLY

he grill arrives nearly ready

to use and requires only

minor assembly.

By carefully following the

uncrating and unpacking

steps, you will improve the

customer's first Lynx experi-

ence.

Shipping weight on smaller

units is app. 300 pounds and

larger units may weigh over

500 pounds.

EXCESSIVE WEIGHT HAZARD!

Use two or more people to

move or install thls unit. Fail-

ure to follow this instruction

can result in back or other

injuries.

CRATE & CARTON:

IM PO RTA NT!

Do not remove staples

around the top of the

carton. These staples

hold a wooden pallet in

place inside the carton

that protects the unit from

damage. Removing these

staples may cause the

pallet to fall on the top of

grill.

How to Remove the

Carton

Cut the main strap holding

the grill to the pallet.

Remove the staples at the

bottom of the carton.

Lift off the carton.

With assistance, remove

grill from pallet and place

into desired location.

The wheels sit down in the

gaps of the shipping crate so

that the grill can sit safely and

solidly on the crate during

shipping. The grill cannot be

sliddirectly off of the pallet.

high enough to place a ramp_

under the wheel and then lift

the other end while rolling the

grill off of the pallet.

INTERIOR PACKING

Lynx uses sturdy tie-down

cables and straps to ensure

your grill arrives at your home

in the same condition that

it left our factory. BE SURE

YOU HAVE REMOVED ALL

TIE DOWNS BEFORE USING

YOUR GRILL.

Remove the white

accessory box and wood

packing, the grill racks, and

remove any loose items

from the firebox.

Carefully cut the

cable ties g

the

warming

rack and

rotisserie

spit (if

equipped).

Cut the strapping that

secures the briquette trays

and carefully lift them out,

front first.

Make sure you

remember

to remove

_he wire tie-

downs on the

bu rne rs.

It_ On ProSear TM models, cut

and remove ties from the

burner partition on the left

side of the ProSear TM

burner.

(Be sure to remove t

pack ng from u:_d'erthe cover,)

Ensure that all burners are

roperly seated on the

urner valve orifice and

sitting level with the legs

in the frame slots and no

side-to-side movement.

30

Page 31

PROFESSIONAL GRILLS

ELECTRICAL CONNECTIONS

WARNING - ELECTRICAL GROUNDING

Product installation must meet local electric codes or, in the absence of local codes, the latest

edition of the National Electrical Code ANSl/NFPA No. 70 or the Canadian Electrical Code

CGA 1.6b2005.

Use only a Ground Fault Interrupter (GFI) protected circuit with this outdoor cookin 9 gas ap-

pliance.

IMPORTANT: When connecting your rotisserie motor, first connect the motor to the grill and

then plug the grill into the outlet.

This grill is equipped with a three prong (grounding) electric plug for your protection against

shock hazard andmust be plugged directly into a properly grounded three prong outlet.

NEVER cut or remove the grounding prong from this plug.

Use only extension cords with a 3 prong grounding plug, rated for the power of the equip-

ment, and approved for outdoor use with a W-A" marking.

To protect against electric shock, do not immerse any part of the power cord, an extension

cord or any plugs in water or other liquid.