Page 1

Installation, Care and Use of

Your Lynx Beverage Tower

Kits

Lynx Beverage Kits

Model L24TWS Single Tower and L24TWD Double Tower

Introduction:

Your Lynx Beverage Kits comes with all of the components necessary to install a

keg tap and tray to an outdoor island or to the Lynx model L24BF outdoor

refrigerator. An optional Tower Base (L24TWB) and caster kit (L24CST) is

available to set this kit up as a mobile beverage station as shown, when used

with the L24BF.

The Lynx model L24BF outdoor refrigerator has been designed specifically to

work with the Beverage Kits. The volume is designed to accommodate two 1/6

kegs, or all single standard keg sizes except a ½ keg or larger (not provided), the

CO2 tank and required connections.

WARNINGS:

CO2 cylinders contain high pressure gas which can be hazardous if not handled

properly. Make sure you READ and UNDERSTAND the procedures included with

the CO2 cylinders BEFORE installation.

Beverage Tower Kit Components

A) Single or Double Keg Tower

B) Low Profile Keg Coupler (D System for North American Beers)

C) Regulator, Dual Gauge CO2 (Kit contains all hoses and fittings, Sleeve

D) CO2 Gas Cylinder connectors, bushing and insulator sleeves)

E) Spill Tray L24TWD L24TWS

A

B

E

Lynx Professional Grills, Inc.

7300 Flores St., Downey, CA 90242

Phone: (562)299‐6900 Fax: (562)299‐6978 | www.lynxgrills.com P/N 33913 Rev. C 1/14

C

D

Page 2

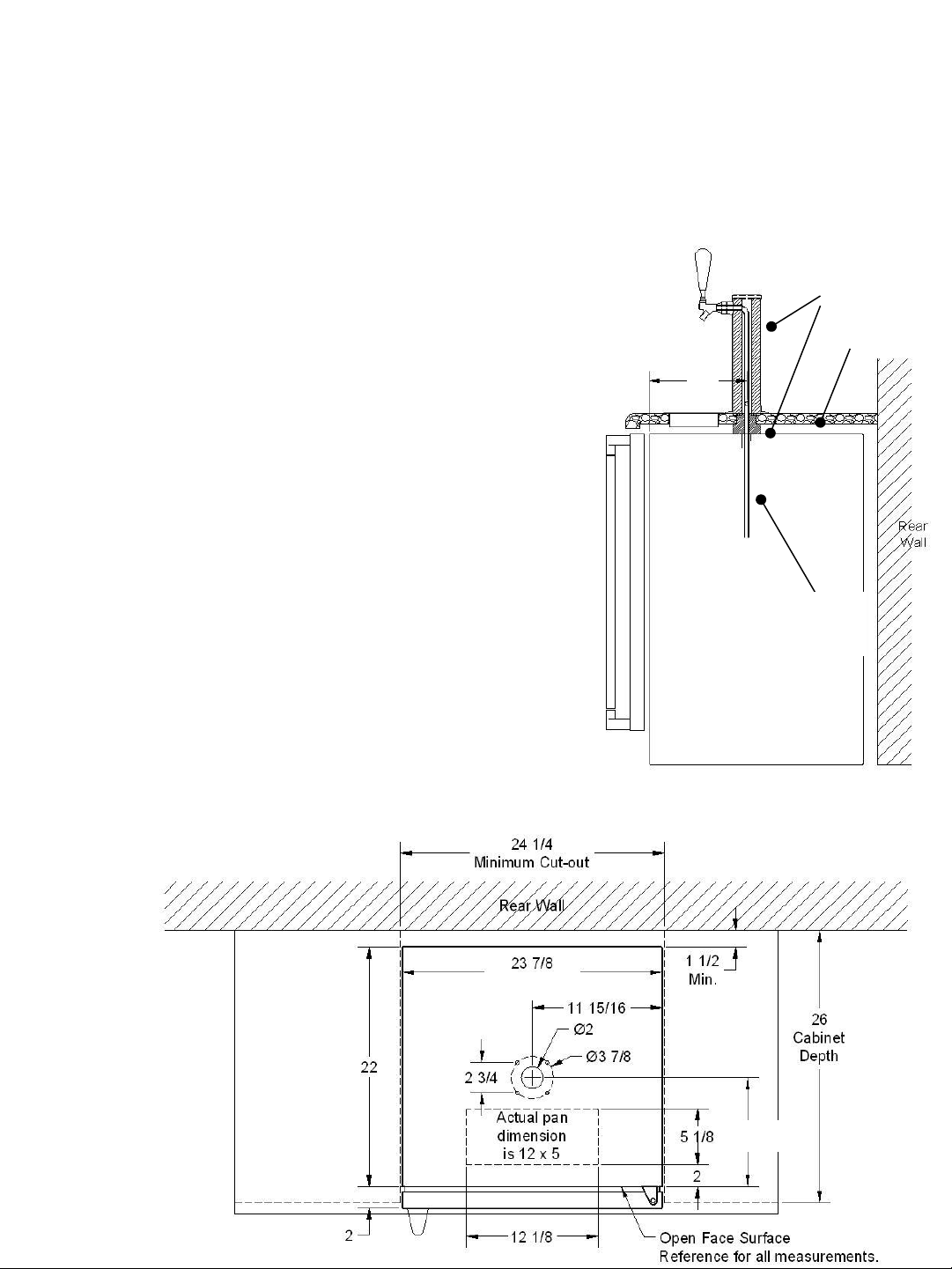

L24TWR Tower Kit - Mounting your kit directly to an island.

1) Determine the location of the refrigerator in the island installation. It should be positioned nearly flush to the face

surface of the island for easy access and alignment with the tower. The refrigerator cavity should be 35” high x 241/2” wide x 26” deep.

2) Position the refrigerator in the island opening at the exact position. Open the door and make a reference mark on the

underside of the countertop at the face of the open refrigerator. This surface represents the best guide for locating the

hole in the countertop. Each refrigerator door is custom set at the factory for the best seal. The face of the closed door

varies slightly from unit to unit. DO NOT use the closed door surface as a reference.

3) Remove the refrigerator from the cabinet while drilling the holes for mounting. Using the diagram at the bottom of this

page as a guide, mark the center of a 2” diameter hole and drill through the countertop for the beverage line.

4) Locate and drill the 4 mounting holes to secure the keg tower.* Four

#12 screws have been provided. A ¼” diameter hole is sufficient for

these bolts. If another securement method (i.e. lead anchors) are used,

follow the manufacturers recommendations.

5) A flush mount drip tray is provided as an option. Refer to the diagram

below and cut the opening required if this option is to be installed.

6) Prepare the tower assembly for installation. A 14 inch length of

insulating foam has been provided to install inside the tower base. The

installation of this foam is critical to the proper operation of the

beverage tower kit. Failure to properly insulate the tower base could

cause excessive foam and incorrect temperature control. Insert the

foam around the beverage line and insert it into the beverage tower

with about 2” protruding from the base.

7) Place the large flat rubber gasket over the hole in the countertop.

8) Feed the beverage tube into the hole in the countertop

9) Align the gasket and secure the tower to the countertop with the 4

screws provided. From the underside insert the washers and nuts.

Tighten the screws completely.

10) Remove the black plastic plug from the top center of the refrigerator.

Keep in a safe place for future use.

11) Bring the beverage tube out to the front of the opening designed for

the refrigerator. Begin to slide the L24BF refrigerator into the opening.

Before the refrigerator is halfway into position, feed the beverage tube

through the hole in the top. Alternately slide the refrigerator back and

draw the tube into the refrigerator to remove any kinks in the hose.

When finished, the hose should align like the illustration on the right.

12) Add the tap and handle with the wrench provided.

13) Insert the spill tray into the countertop.

13 11/16

Beverage

Tube

insulation

counter

* Before drilling

mounting holes,

position the tower on

the counter top to

ensure proper tap

alignment. Holes may

be drilled out to ½” to

provide additional

adjustment.

L24BF Width

13 11/16

Page 3

Connecting the Keg to the Beverage Tower.

1) Attach the clear hose from the beverage tower to the

barbed fitting with the hose clamp provided. Insert the

rubber washer provided into the fitting.

2) An elbow is included to provide additional space above the

keg coupler. Secure the elbow to the top outlet of the keg

coupler with a washer between. Attach the clear hose

fitting, with washer, to the elbow. Use a wrench to tighten

the connections.

3) The colored hose line is installed onto the side barbed

fitting of the keg coupler and the barbed fitting below the

CO2 regulator. Press the tube onto the fittings and secure

with the two hose clamps.

Refer to the instructions provided with the CO2 tank before

attaching the tank to the regulator.

4) With the regulator and tank in the OFF position, attach the

regulator securely to the CO2 tank with a wrench.

The Kit is Ready to Attach a Keg.

The Beverage Tower Kit is provided with a standard D Style coupler.

This style is appropriate for most domestic beers. Additional styles

are available from restaurant supply or beverage companies.

1. Align lug locks on

coupler with lug housing in

top of keg; insert coupler.

2. Turn coupler 1/4 turn

clockwise; the coupler is

now secured to keg.

Operating the Beverage Tap:

1) Insert the CO2 canister in the rear left shelf inside the refrigerator.

2) Place the beer keg inside the refrigerator and arrange all hoses such

that none are pinched.

3) Slowly open the main valve on the CO2 canister. Check for leaks.

4) Slowly open the regulator ball valve to pressurize the keg.

5) Toggle the tap handle on the tower to dispense a small amount of

liquid. This will “charge the system”.

6) Adjust the T-handle on the regulator to between 8 and 14 PSI. The

pressure setting will vary for beer type and keg style. Refer to the

troubleshooting guide and experimentation to set the pressure

accordingly.

7) Allow the system to rest for several hours before use. Temperature

and pressure are critical to satisfactory results.

3. Push down on the

coupler and give another ¼

turn, to open beer and CO2

ports in keg. The keg is now

tapped.

CO2 Tank level

Main Valve

8-14 PSI

T-Handle

Ball Valve

Page 4

When not in use:

Part No.

Qty

Part No.

Qty

1

32413

33845

Single Tap, or

9

32404

2 80411

Beverage Center Deck Assembly

10

33029

33847

3

32414

11

32403

Keg Coupler, Domestic (Style D)

4

32399

12

33030

5

L24TWB

13

33027

6

33010

14

33028

7

33011

15

33022

8

33031

16

33023

We recommend that the CO2 canister be shutoff and the ball valve closed if the Beverage kit will not be used for an

extended period of time. Keep the CO2 tank inside the refrigerator and all connections intact.

The CO2 tank should be replaced or refilled when the CO2 Tank level indicator falls into the red indicator zone (below 300

PSI). Check with your beverage provider for local sources of CO2.

Storage:

For seasonal storage of the Beverage Kit we recommend that the CO2 tank be stored upright in a cool place. The Tower

Base may be disconnected from the keg coupler and removed from the island installation. To help prevent heat loss

replace the black plastic cap into the top of the refrigerator (see page 2 step 1) . The cap may be installed into the top or

from the inside if more convenient. Seal all hoses and connectors in an air tight plastic bag to avoid dirt and insects during

storage. We recommend that you obtain a cleaning kit and purge the fluid lines seasonally. These may be obtained from

your beverage supplier or on line.

Wild Beer Description

Beer, when drawn, is all foam, or too much foam and

not enough liquid beer.

Causes

Beer drawn improperly

Creeping regulator

Applied pressure is set too high

Hot spots in line

Use of non-insulated beer line

Beer runs are too long for proper cooling

Tapped into a warm keg (Should be 34°- 38°

Cooler malfunctioning

Kinks, dents, twists or other

obstructions in line

Faucets in bad, dirty or worn condition

Flat Beer Description

Foamy head disappears quickly;

beer lacks usual zestful brewery fresh flavor

Causes

Dirty glasses (not beer clean)

Sluggish regulator

Applied pressure is set too low

CO2 is turned off at night

Contaminated air source

(associated with compressed air)

Moisture in air system

Beer too cold

Loose tap or vent connections

Cloudy Beer Description

When beer in glass appears hazy, not clear

Causes

Frozen or nearly frozen beer

Old beer

Beer that has been unrefrigerated for

long periods of time

Dirty glass

Dirty faucet

Unrefrigerated foods placed on top of cold keg

Contaminated air source

False Head Description

Large soap-like bubbles, head dissolves very quickly

Causes

Applied pressure required does not correspond to

beer temperature

Small beer line into a large faucet shank

Beer lines warmer than beer in keg

Dry glasses

Improper pour

Unpalatable Beer Description

Off-Taste

Causes

Dirty or old beer lines

Dirty faucet

Contaminated air source, or unfiltered

Unsanitary bar conditions

Description

Tower Assembly

Tower Assembly Double Tap 1

Tubing, 7/8 OD, x 12 1

Insulation, Tower Armaflex 1

Tower Base w/Leveling Feet 4

Base, Spill Tray Insert 1

Grate, Spill Tray Insert 1

Faucet Wrench 1

Description

C02 Cylinder, 5 Pounds, Alum 1

Regulator, Single Tap, CO2, or

1

Regulator Double Tap, CO2 1

Rubber Washer (Coupler) 2

Hose, CO2 to Coupler 1

Hose Clamps, CO

Hose, Coupler to Tower 1

Hose Clamps, Tower 1

2

1

2

Loading...

Loading...