Page 1

Page 2

OPERATORS MANUAL LYNX 2006

5900

6900

ST 550 F/600

Forest Fox

Yeti V-1300

Yeti V-800

Yeti 600 SDI

Ranger 550 F/600

Safari 400 F

ENGLISH

1

Page 3

CONTENT

SAFETY MEASURES ................................................................. 5

WARRANTY ................................................................................ 6

HOW TO IDENTIFY YOUR SNOWMOBILE ............................... 9

Serial Numbers ...................................................................................................... 9

CONTROLS / INSTRUMENTS ................................................. 10

1. Throttle lever .................................................................................................. 13

2. Brake lever ..................................................................................................... 13

3. Parking brake lever ........................................................................................ 13

4. Brake / parking brake / low oil level pilot lamp (Red) ................................... 14

5. Gear shift lever or RER button ...................................................................... 14

6. Reverse indicator lamp .................................................................................. 16

7. Handle bar ..................................................................................................... 16

8. Holding strap ................................................................................................. 16

9. Ignition switch/START/RER button ............................................................... 16

10.Tether cut-out switch ...................................................................................... 18

11. DESS pilot lamp ............................................................................................ 19

12. Emergency cut-out switch ............................................................................ 19

13. Headlamp dimmer switch ............................................................................. 20

14. High beam pilot lamp (Blue) ......................................................................... 20

15. Rewind starter handle ................................................................................... 21

16. Choke lever .................................................................................................... 21

17. Primer ............................................................................................................ 22

18. Speedometer ................................................................................................. 22

19. Odometer ....................................................................................................... 22

20. Trip meter ...................................................................................................... 22

21. Trip meter reset button/mode button ............................................................ 22

22. Fuel tank cap/gauge ..................................................................................... 24

23. Engine overheating warning lamp (Red) ....................................................... 25

24. Heated grip and throttle lever switch ............................................................ 25

25. Heated throttle lever switch ........................................................................... 25

26. Hood latches ................................................................................................. 25

ENGLISH

27. Electric power outlet ..................................................................................... 26

28. Fuse .............................................................................................................. 26

29. Front bumper ................................................................................................. 27

30. Storage compartment.................................................................................... 28

31. Rear rack ....................................................................................................... 28

32. Tool kit ........................................................................................................... 28

33. Spark plug holder .......................................................................................... 28

34. Seat strap ...................................................................................................... 29

35. Hitch .............................................................................................................. 29

36. Adjustable suspension .................................................................................. 29

Guidelines to adjust suspension ......................................................................... 30

2

Page 4

Suspension troubleshooting36

In deep snow ........................................................................................................ 36

FUEL AND OIL ......................................................................... 36

Recommended fuel .............................................................................................. 36

Recommended oil ................................................................................................ 37

COLD WEATHER CARBURETION MODIFICATIONS ............ 37

BREAK-IN PERIOD .................................................................. 38

Engine .................................................................................................................. 38

Drive belt .............................................................................................................. 38

10 hour inspection ...................................................................................................

PRE-OPEARATION CHECK .................................................... 38

CHECK LIST ............................................................................ 38

OPERATION INSTRUCTIONS ................................................. 39

Operations ........................................................................................................... 39

Starting the engine ............................................................................................... 39

Manual starting .................................................................................................... 41

Shutting off the engine ......................................................................................... 44

VEHICLE WARM UP ................................................................ 44

POST-OPERATION CARE ....................................................... 44

SPECIAL OPERATIONS .......................................................... 45

Engine overheating .............................................................................................. 45

Fuel flooded engine ............................................................................................. 45

Rear suspension slider shoe sticking ................................................................. 45

FLUID LEVELS

Brake system ...................................................................................................... 46

Chain case oil level/Gearbox oil level .................................................................. 47

Oil injection system............................................................................................. 49

Cooling system .................................................................................................... 50

Battery ................................................................................................................. 52

MAINTENANCE ........................................................................ 52

Vehicle cleaning and protection .......................................................................... 52

Belt guard removal and installation ..................................................................... 53

Drive belt removal and installation ....................................................................... 53

Drive chain tension .............................................................................................. 57

TRA drive pulley adjustment ................................................................................ 58

Drive belt condition .............................................................................................. 59

Brake condition .................................................................................................... 59

ENGLISH

3

Page 5

Brake adjustment ................................................................................................ 60

Rear suspension condition .................................................................................. 60

Suspension stopper strap condition ................................................................... 60

Track condition .................................................................................................... 60

Track tension and alignment ............................................................................... 60

Steering and front suspension mechanism......................................................... 61

Wear and condition of skis and runners ............................................................. 62

Exhaust system .................................................................................................. 62

Air filter cleaning .................................................................................................. 62

Headlight .............................................................................................................. 64

STORAGE AND PRE-SEASON PREPARATION ..................... 66

Storage................................................................................................................. 66

Pre-season preparation ....................................................................................... 66

TROUBLESHOOTING ............................................................. 67

TECH DATA .............................................................................. 70

SERVICE SCEDULE ............................................................... 72

ENGLISH

4

Page 6

Safety measures

* For vehicle with a parking brake always engage brake when snowmobile is

not in use.

* Throttle mechanism should be checked for free movement before starting

engine.

* The snowmobile can be stopped by activating the emergency cut-out switch,

pulling the tether cord or turning off the ignition key (if equipped).

* Engine should be running only when belt guard is secured in place. Never

run the engine without drive belt installed. Running an unloaded engine can

prove to be dangerous.

* Never run the engine when the track is raised off the ground or with the

hood opened or removed.

* Do not stud the track. At speed it may cause the track to tear and separate

from vehicle posing a risk of severe injury or death.

* Never start the engine in closed area or indoors.

* Maintain your snowmobile in top mechanical condition at all times.

* Snowmobile is not designed to be operated on public streets, roads or

highways. In most countries it is considered an illegal operation.

* Never charge or boost battery while installed on snowmobile.

* Do not lubricate throttle and/or brake cables and housings.

ENGLISH

5

Page 7

BRP FINLAND OY INTERNATIONAL LIMITED WARRANTY:

®

2006 LYNX

SNOWMOBILES

1. SCOPE OF THE LIMITED WARRANTY

BRP Finland Oy (BRP) warrants its 2006 LYNX snowmobiles from defects in

material or workmanship for the period and under the conditions described below.

All genuine LYNX parts and accessories, installed by an authorized BRP distributor/dealer (as hereinafter defined) at the time of delivery of the 2006 LYNX

snowmobile, carry the same warranty as that of the snowmobile.

Use of the product for racing or any other competitive activity, at any point, even

by a previous owner, will render this warranty null and void.

2. WARRANTY COVERAGE PERIOD

This warranty will be in effect from the date of delivery to the first retail consumer or

the date the product is first put into use, whichever occurs first and for a period of:

A) TWELVE (12) CONSECUTIVE MONTHS, for private use owners

B) TWELVE (12) CONSECUTIVE MONTHS, for commercial use owners

C) TWENTY FOUR (24) CONSECUTIVE MONTHS, for private use owners when

product was sold in a member state of the European Union.

The repair or replacement of parts or the performance of service under this warranty does not extend the life of this warranty beyond its original expiration date.

3. CONDITIONS TO HAVE WARRANTY COVERAGE

This warranty coverage is available only on 2006 LYNX snowmobile purchased as

new and unused by its first owner from a BRP distributor/dealer authorized to

distribute LYNX products in the country in which the sale occurred (BRP distri-

butor/dealer), and then only after the BRP specified pre-delivery inspection process is completed and documented. Warranty coverage only becomes available

upon proper registration of the product by an authorized BRP distributor/dealer.

Moreover, this warranty coverage is only available if the LYNX snowmobile is

purchased in the country or union of countries in which the purchaser resides.

BRP will not honor this limited warranty to any private use owner or commercial

use owner if the preceding conditions have not been met. Such limitations are

necessary in order to allow BRP to preserve both the safety of its products, and

ENGLISH

also that of its consumers and the general public.

Routine maintenance outlined in the Operators Guide must be timely performed

in order to maintain warranty coverage. BRP reserves the right to make warranty

coverage contingent upon proof of proper maintenance.

4. WHAT TO DO TO OBTAIN WARRANTY COVERAGE

The customer must notify a servicing BRP distributor/dealer within two (2) months

of the appearance of a defect, and provide it with reasonable access to the product and reasonable opportunity to repair it. The customer must also present to

the authorized BRP distributor/dealer, proof of purchase of the product and must

6

Page 8

sign the repair/work order prior to starting the repair in order to validate the warranty repair. All parts replaced under this limited warranty become the property of

BRP.

5. WHAT BRP WILL DO

BRPs obligations under this warranty are limited to, at its sole discretion, repairing parts found defective under normal use, maintenance and service, or replacing such parts with new genuine LYNX parts without charge for parts and labor,

at any authorized BRP distributor/dealer during the warranty coverage period.

BRP reserves the right to improve or modify products from time to time without

assuming any obligation to modify products previously manufactured.

6. EXCLUSIONS

The following are not warranted under any circumstances:

Normal wear and tear;

Routine maintenance items, tune ups, adjustments;

Damage caused by failure to provide proper maintenance and/or storage, as

described in the Operators Guide;

Damage resulting from removal of parts, improper repairs, service, maintenan-

ce, modifications or use of parts not manufactured or approved by BRP or

resulting from repairs done by a person that is not an authorized servicing

BRP distributor/dealer;

Damage caused by abuse, abnormal use, neglect, use of the product on sur-

faces other than snow, or operation of the product in a manner inconsistent

with the recommended operation described in the Operators Guide;

Damage resulting from accident, submersion, fire, theft, vandalism or any act

of God;

Operation with fuels, oils or lubricants which are not suitable for use with the

product (see the Operators Guide);

Snow or water ingestion;

Incidental or consequential damages, or damages of any kind including wit-

hout limitation towing, storage, telephone, rental, taxi, inconvenience, insurance

coverage, loan payments, loss of time, loss of income; and

Damage resulting from studs installed on tracks if the installation does not

conform to BRPs instructions.

7. LIMITATIONS OF LIABILITY

ENGLISH

THIS WARRANTY IS EXPRESSLY GIVEN AND ACCEPTED IN LIEU OF ANY

AND ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIMITATION ANY WARRANTY OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. TO THE EXTENT THAT THEY CANNOT BE

DISCLAIMED, THE IMPLIED WARRANTIES ARE LIMITED IN DURATION TO

THE LIFE OF THE EXPRESS WARRANTY. INCIDENTAL AND CONSEQUEN-

7

Page 9

TIAL DAMAGES ARE EXCLUDED FROM COVERAGE UNDER THIS WARRANTY. SOME STATES/ PROVINCES DO NOT ALLOW FOR THE DISCLAIMERS,

LIMITATIONS AND EXCLUSIONS IDENTIFIED ABOVE, AS A RESULT, THEY

MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU SPECIFIC RIGHTS,

AND YOU MAY ALSO HAVE OTHER LEGAL RIGHTS WHICH MAY VARY FROM

STATE TO STATE, OR PROVINCE TO PROVINCE.

Neither the distributor, any BRP distributor/dealer nor any other person has been

authorized to make any affirmation, representation or warranty regarding the product, other than those contained in this limited warranty, and if made, shall not be

enforceable against BRP.

BRP reserves the right to modify this warranty at any time, being understood that

such modification will not alter the warranty conditions applicable to the products

sold while this warranty is in effect.

8. TRANSFER

If the ownership of a product is transferred during the warranty coverage period,

this warranty shall also be transferred and be valid for the remaining coverage

period provided BRP or an authorised BRP distributor / dealer receives a proof

that the former owner agreed to the transfer of ownership, in addition to the coordinates of the new owner.

9. CONSUMER ASSISTANCE

(a)In the event of a controversy or a dispute in connection with this limited warran-

ty, BRP suggests that you try to resolve the issue at the dealership level. We

recommend discussing the issue with the authorized distributor/dealers service manager or owner.

(b)If further assistance is required, the distributors service department should be

contacted in order to resolve the matter.

(a)If the matter still remains unresolved then contact BRP by writing to us at the

address listed below.

BRP FINLAND OY

SERVICE DEPARTMENT

P.O. BOX 8040

ENGLISH

FIN-96101 ROVANIEMI

FINLAND

© 2005 Bombardier Recreational Products Inc. All rights reserved.

® Registered trademark of Bombardier Recreational Products Inc.

8

Page 10

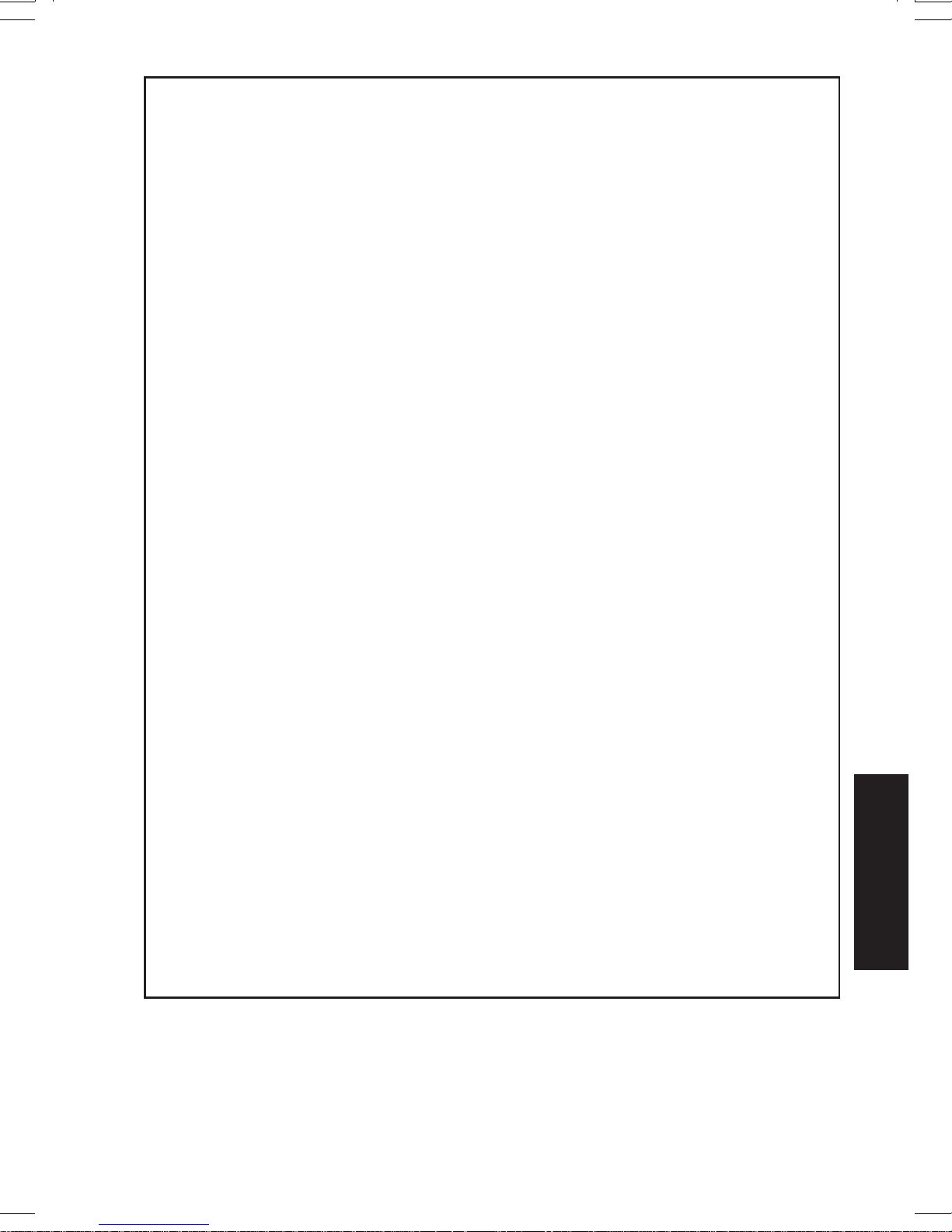

How to identify your snowmobile

Serial numbers

The main components of your snowmobile (engine and frame) are identified by

different serial numbers. It may sometimes become necessary to locate these

numbers for warranty purposes or to trace your snowmobile in the event of loss.

These numbers are required by the Lynx dealers to complete warranty claims

properly. No warranty will be allowed by BRP if the engine serial number or VIN is

removed or mutilated in any way. We strongly recommend that you take all the

serial numbers on your snowmobile and supply them to your insurance company.

1. Engine serial number

1. Engine serial number

ENGLISH

4-tec models

1. Engine serial number

9

Page 11

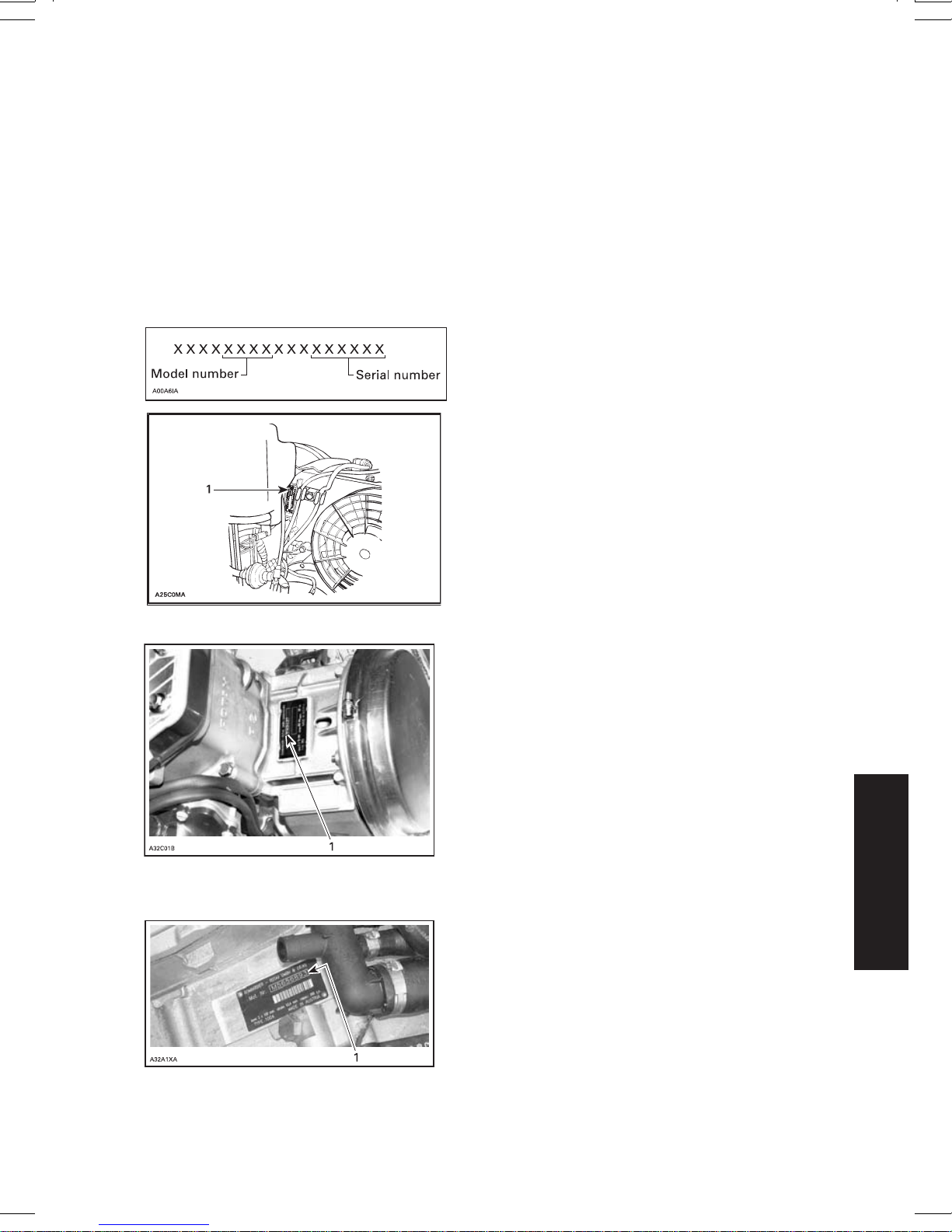

Controls / Instruments

Safari 400, Ranger 550 F, ST 600, ST 550 F, 5900 FCE/6900 FCE, Forest Fox S

Yeti V-1300, Yeti V-800, Yeti 600 SDI, Ranger 600

ENGLISH

1. Engine Management System (EMS) pilot lamp

2. Oil pressure pilot lamp

3. Cooling liquid pilot lamp

4. High beam pilot lamp

5. Battery charge pilot lamp

6. Brake pilot lamp

10

Page 12

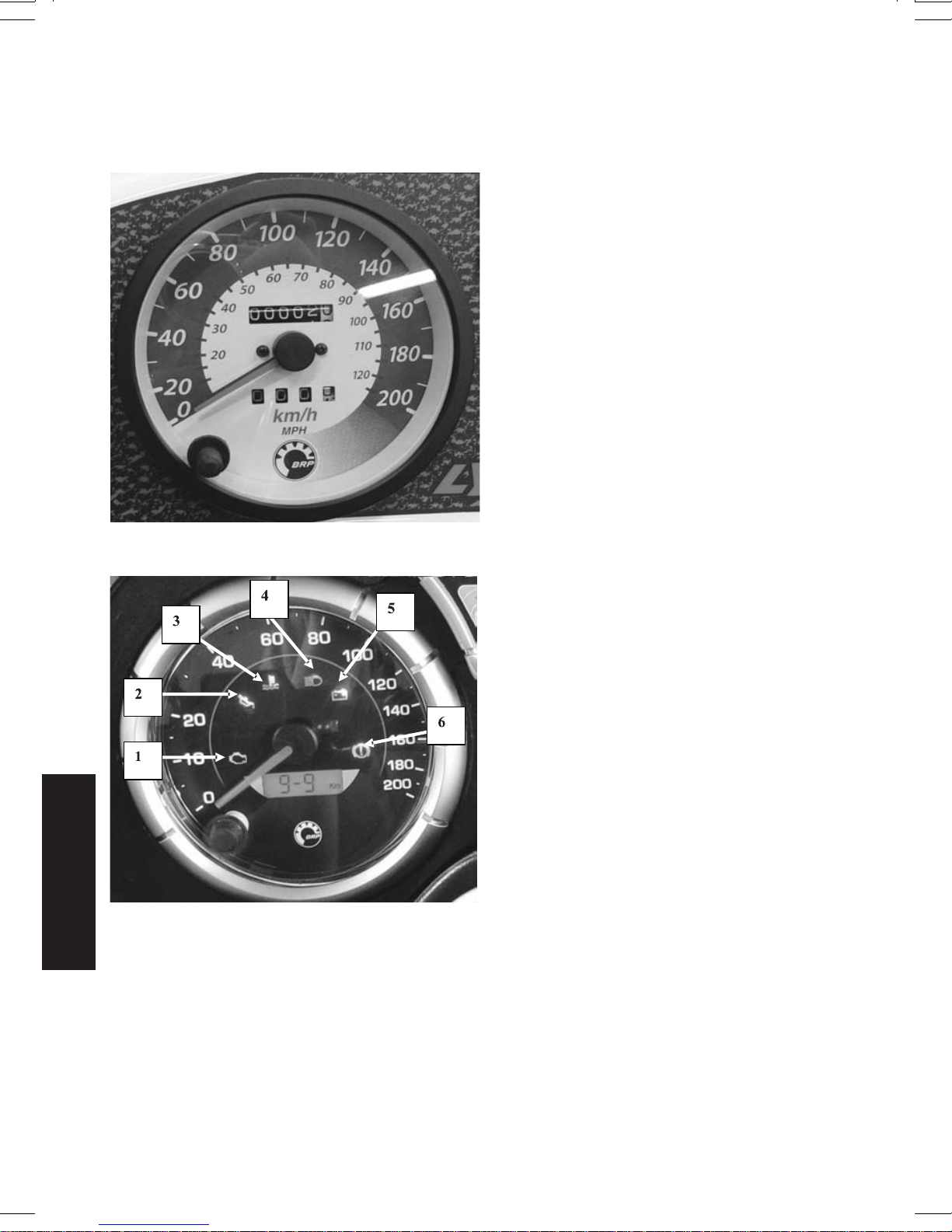

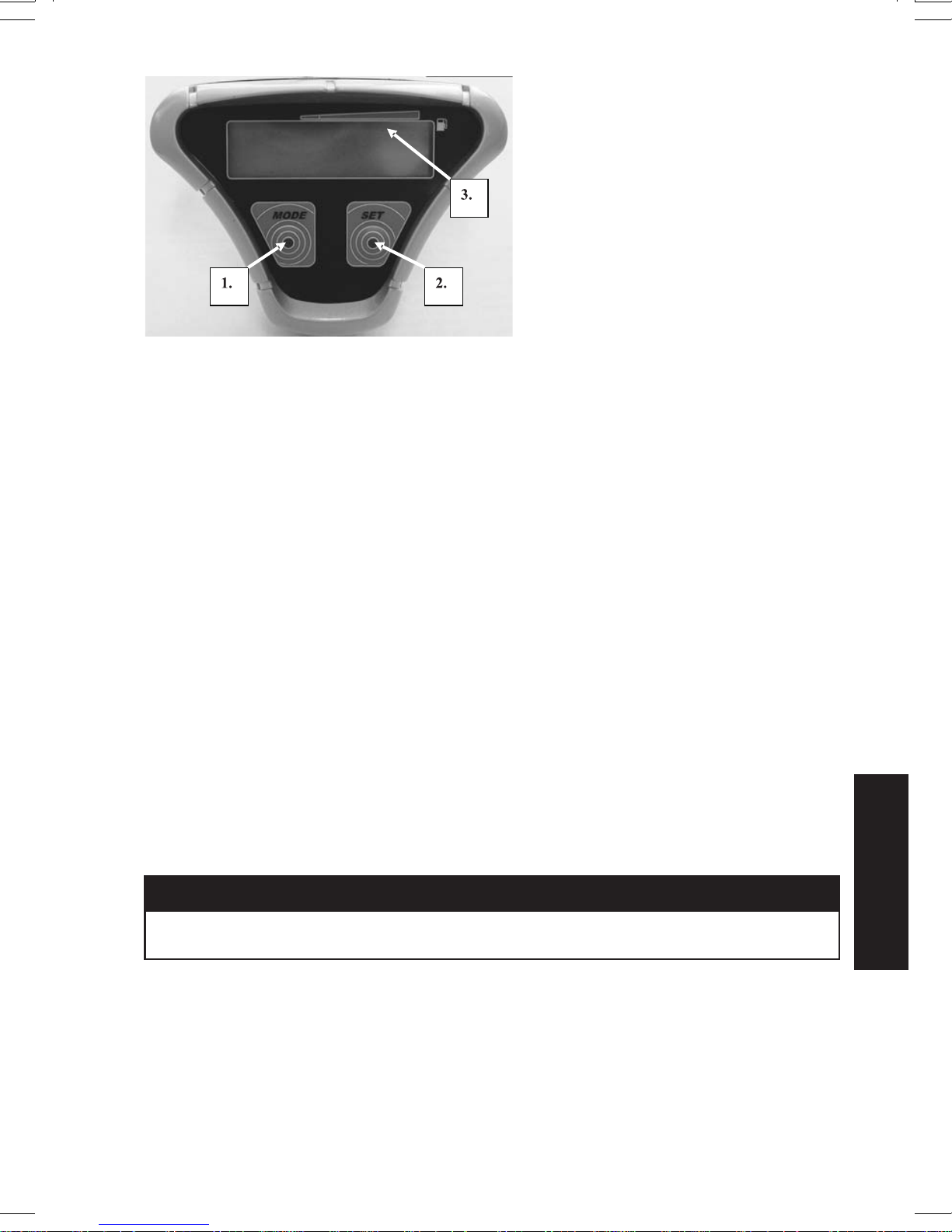

Multi-display

Note! Multi-display instrument is found in following models as standard: Yeti V-1300 and

Yeti 600 SDI.

Operation

When the vehicle is powered up will the multi-display run a short start up test of two

second by illuminating all segments of the display. At the end of the test the vertical lines

(3.) in the upper part of the display will indicate the fuel level while the clock will show up on

the main display.

At this moment it is possible to select the various functions of the instrument with the

MODE and SET keys.

By pressing the MODE key, in each pressing you can select following functions: Timer,

Calendar, Using hours, Temperature °C or °F.

Clock and calendar operation

NOTE! Before the clock and the calendar is set must the vehicle be power up.

YEAR

Power up the vehicle, press and keep the SET key pressed until the indication YE

shows up on the display which stands for YEAR (please note that you can enter the

programming phase only when the display shows date and clock). It is possible to

release the SET key at this moment and then go back pressing it again several times

to change the year, which has been set up in a cyclical way: 02, 03, 04

and so on; by keeping the key pressed down it changes faster.

,..., 98, 99, 00, 01,

MONTH

Press the MODE key until the indication MO shows up on the display which stands

MONTH. It is possible to release the MODE key at this moment and then go back

for

pressing the SET key several times to change the month, which has been set up in a

cyclical way: 12, 11, 02

faster.

DAY

Press the MODE key until the indication dY shows up on the display which stands

for DAY. It is possible to release the MODE key at this moment and then go back

pressing the SET key

in a cyclical way: 25, 26, 27,..., 31, 01, 02

down it changes faster.

HOUR

Press the MODE key until the indication Ho shows up on the display which stands

for HOUR. It is possible to release the MODE key at this moment and then go back

pressing the SET key several times to change the hours, which have been set up in

cyclical way : 23,00, 01

changes faster.

MINUTE

Press the MODE key until the indication Mn shows up on the display which stands

for MINUTE. It is possible to release the MODE key at this moment and then go back

pressing the SET key several times to change the minutes , which have set up in a

cyclical way: 59, 00, 01

changes faster.

,...,11 and so on; by keeping the key pressed down it changes

several times to change the day, which has been set up

and so on; by keeping the key pressed

,..., 21, 22, 23 and so on ; by keeping the key pressed down it

,..., 57, 58, 59 and so on; by keeping the key pressed down it

ENGLISH

After this press the MODE key again and the multi-display is released from the programming, the clock starts from 00 and memorizes the new data.

11

Page 13

Timer operation

NOTE! Before the timer is set must the vehicle be power up

After having selected the timer by pressing the MODE key (power on of the

TIMER writing on the on the left side of the display) it is possible to start timing

the hours, minutes and seconds by pressing the SET key; if 23 hours 59 minutes and 59 seconds are reached the timer automatically starts counting again

from 00.00.00. the timing can be blocked by pressing the SET key while the

MODE key has a triple function:

1) If it is pressed while the timer has been activated, it allows you to visualize the

following setting (calendar).

2) If it is pressed while the timer has been blocked (with the SET key) with a

value different from

3) If it is pressed while the timer is stopped at 00:00:00 it allows you to visualize

the following setting.

Using hours operation

NOTE! Before the using hours operation is set must the vehicle be power up

It is possible to visualize the using hours of the snow mobile with the Multidisplay; this setting is adjusted by the following conditions:

1) The increase of the hours is directly connected to the powering of the Multidisplay.

00:00:00 the timer can be reset.

2) The using hours can be voided only if the default procedures are strictly followed (see Default procedure section).

3) The using hours are visualized in complete hours (without minutes or seconds)

Thermometer operations

The Multi-display normally indicates the temperature in °C with a resolution of

1°C, however, it is also possible to select the visualization in °F by simply connecting pin no.1 and 5 of the 6-way DEUTSCH connector (NOTE! This operation

has to be carried out while the Multi-display is off). No calibration of the thermometer is provided.

Fuel indicator

The fuel level is represented on the upper part of the display by means of 11

vertical lines.

In Yeti V-1300 and Yeti 600 models are one vertical line is approximate 4 liter

gasoline.

ENGLISH

Default procedure

Default procedures aim to reset the using hours of the snow mobile;

a) Power the Multi-display by pressing the MODE and SET keys (no indica-

tions will show up on the display).

b) Keep pressing the keys (for about 20 seconds) until the indication dEF show

up on the display which stands for DEFAULT.

c) Release the keys: The Multi-display will go back to its normal working.

12

Page 14

1. Mode

2. Set

3. Vertical line

1. Throttle lever

Located on the right side of handlebar. When compressed, it controls the engine

speed and the engagement of the transmission. When released, engine speed

returns automatically to idle.

2. Brake lever

Located on the left side of handlebar. When compressed, the brake is applied.

When released, it automatically returns to its original position. Braking effect is

proportional to the pressure applied on the lever and to the type of terrain and its

snow coverage.

3. Parking brake button or lever

Located on left side of handlebar. Parking brake should be used whenever snowmobile is parked.

Whenever parking brake is applied and engine is running, injection oil level/parking brake pilot lamp lights up to remind you that it is engaged. Never leave your

snowmobile on downhill only with parking brake engaged.

Make sure parking brake is fully disengaged before operating the snowmobile.

Mechanical brake

To engage mechanism, squeeze brake lever and maintain while pulling button

with the other hand. There are 2 retaining notches on button lever; pull button its

locks on a notch then release brake lever.

To release mechanism, squeeze brake lever then fully push parking brake button.

Always release parking brake before riding.

ENGLISH

WARNING!

13

Page 15

Step 1: Squeeze and hold

Step 2: Fully pull

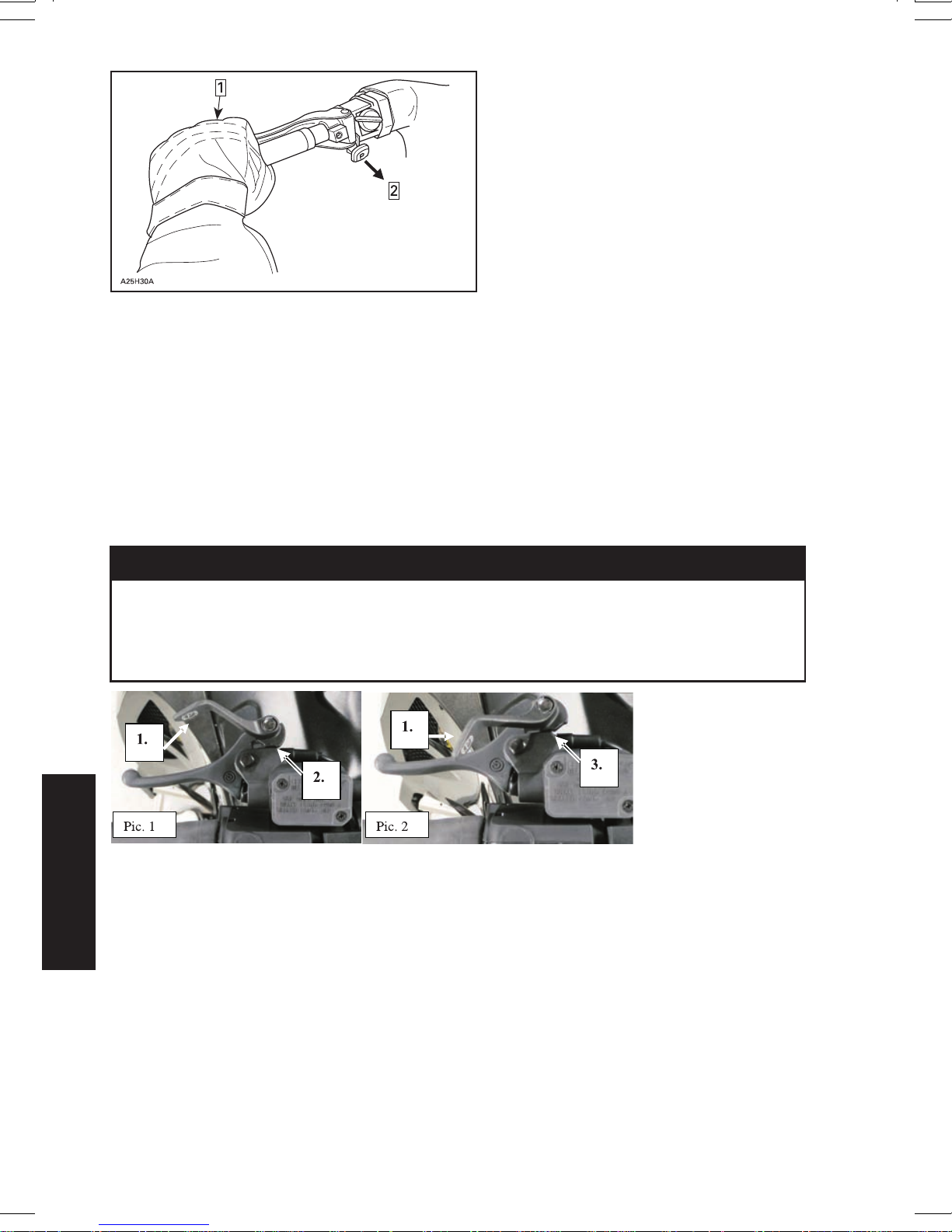

Hydraulic brake

To engage mechanism, squeeze brake lever and maintain while pulling locking

lever with a finger. Brake lever in picture 1 is compressed 25% of applying brakes

and in picture 2 is compressed 50% of applying brakes.

To release mechanism, squeeze brake lever. Locking lever will automatically return to its original position. Brake lever now returns to rest position. Always re-

lease parking brake before riding.

WARNING!

Locking keeps brake lever engaged and keeps pressure against brake disc.

Anyhow, this pressure may decrease so low, that it will not keep vehicle in

place. Never leave the snowmobile on hill only with parking brake applied.

1. Locking lever

2. Position 1

3. Position 2

ENGLISH

4. Brake/Parking brake/Low oil level pilot lamp (Red)

Lights when brake or parking brake is applied (with engine running).

This pilot lamp also lights up when injection oil level is low (with engine running).

Check oil level and replenish as soon as possible.

5. Gear shift lever or RER button

Gear box models: These models are equipped with 4-position gear shift lever; 2

gears forward, reverse gear and free position between 1. and 2. gear.

14

Page 16

Shifting procedure

NOTE! Shift the gear only when engine is running at idle and the speed is below 20 km/h.

Come to complete stop before selecting reverse gear.

Do not force lever. If unable to shift, apply throttle to move snowmobile. Stop

vehicle, then try again.

NOTE: These models: Whenever shifting the gear the snowmobile has to be

completely stopped, otherwise the gear system may get broken.

Electric reverse

Some models: These models are equipped with an electronic reverse (RER),

which is controlled by a RER button.

Reverse shift can be used when the snowmobile is stopped and engine is running

at idle.

Engine is running automatically forward when the snowmobile is started after

stalling or stopping.

Shifting in reverse

With the snowmobile completely stopped and engine running at idle, press and

release the RER button.

1. RER button

The reverse pilot lamp blink and a reverse alarm will sound once every second

with a half a second duration when the snowmobile is engaged in reverse.

Apply throttle slowly and evenly. Allow drive pulley to engage then accelerate

carefully.

ENGLISH

15

Page 17

Shifting in forward

With the snowmobile completely stopped and engine running at idle, press and

release the RER button.

Reverse pilot lamp and reverse alarm will stop.

Apply throttle slowly and evenly. Allow drive pulley to engage then accelerate

carefully

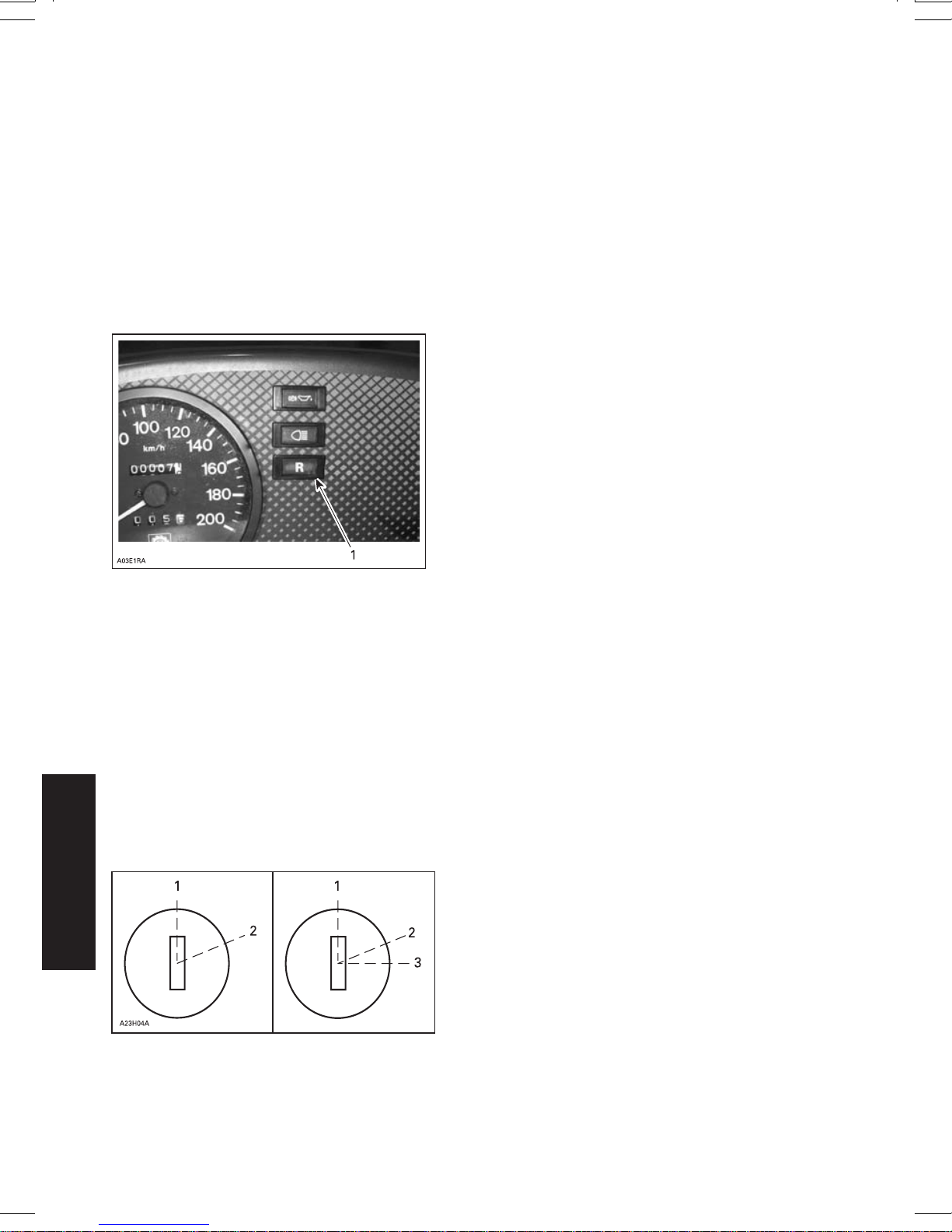

6. Reverse pilot lamp

This pilot lamp will light up when reverse is selected.

1. Reverse pilot lamp

7. Handlebar

The handlebar controls the steering of the snowmobile. As the handlebar is rotated to right or left, the skis are turned right or left to steer the snowmobile. Handlebar

height is adjustable. See an authorized Lynx dealer.

8. Holding strap

Holding strap provides a grip for driver when side-hilling.

9. Ignition switch / START/RER button

ENGLISH

Manual start Electric start models

1. OFF 1. OFF

2. ON 2. ON

3. START

16

Page 18

Manual Starting

To start the engine, turn the key to ON position, then pull rewind starter grip, To

stop the engine, turn the key to OFF position.

Electric Starting

To start engine, turn key to START position and hold until engine has started. See

illustration above.

NOTE: Do not use electric starter for more than 15 seconds. If start/rer button

is pressed when engine has started it could damage electric starter mechanism.

Release key as soon as the engine starts. Key returns to ON position as soon as

it is released.

If engine does not start on first try, turn key back to OFF position and wait a few

seconds before restarting. To stop engine, turn key to OFF position.

NOTE: Engine may be manually started with rewind starter if necessary.

If starter does not operate, check starting system fuse condition. Refer to FUSES.

START/RER button

START/RER button has two functions.

When the engine is not running, depressing the START/RER button and hold until

engine has started.

When the engine is running, depressing the START/RER button will command

the engine to reverse crankshaft rotation as driving the snowmobile is in reverse is

achieved by changing the direction of rotation of the engine, not by shifting the

chain case in reverse gear.

When depressing the START/RER button, the MPEM will practically slow down

the engine RPM to a stop and advance the ignition timing to cause crankshaft

rotation reversing.

Engine will automatically shift into forward when starting after stopping or stalling.

Shifting procedure will take place only when the engine is running.

If engine is running at a speed above 3800 RPM, the reverse function of the

START/RER button is cancelled.

It is recommended to warm up the engine to its normal operating temperature

before shifting.

ENGLISH

Start Mode

To start engine, push START/RER button and hold until engine has started.

NOTE! Do not hold START/RER button more than 10 seconds. A rest period

should be observed between the cranking cycles to let starter cool down. Holding

START/RER button when engine has started could damage starter mechanism.

17

Page 19

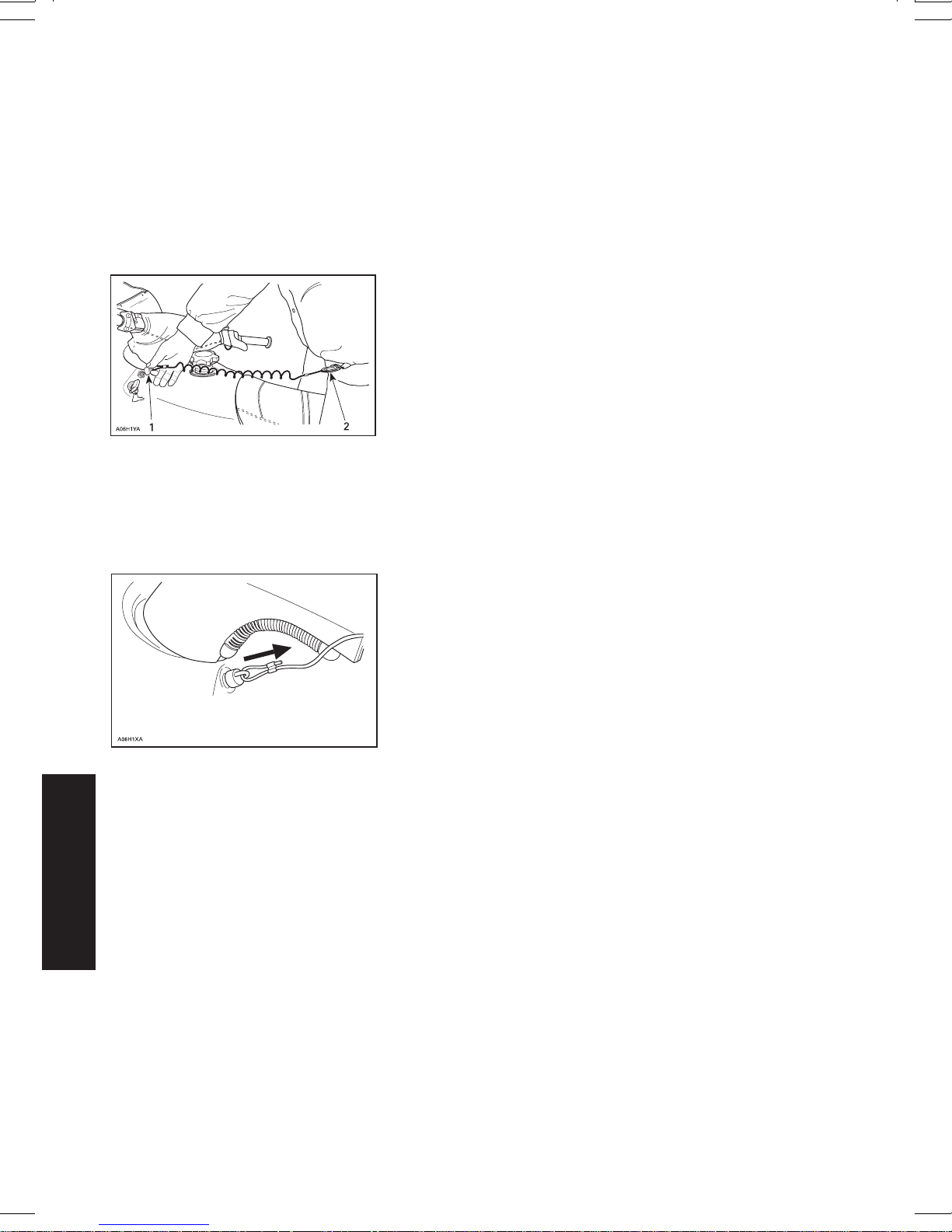

10. Tether cut-out switch

It shuts off engine preventing snowmobile to runaway if the operator falls off the

vehicle accidently.

Operation

Attach to clothing eyelet than snap tether cord cap over post before starting

engine.

1. Snap over post

2. Attach to eyelet

If emergency engine shut off is required, completely pull tether cord cap from

post.

Typical

Some Liquid-Cooled Models

On these models tether cut-out switch is part of tether cut-out system. This

system serves 3 functions. It shuts off engine preventing snowmobile to runaway

if the operator falls off the vehicle accidently.

Through the D.E.S.S.

ENGLISH

TM

(Digitally Encoded Security System), it acts as a lock by

preventing unauthorized use of your snowmobile thus deterring theft.

Finally, it prevents unintentional electric starter operation in vehicles so equipped

by disabling the electric starter and ignition circuits in the MPEM or ECU.

DESS (Digitally Encoded Security System) Description

This system is digitally encoded to provide you and your snowmobile with the

equivalent security as a conventional lock key.

The tether cord cap provided with your snowmobile contains an electronic chip in

which a unique digital code is permanently memorized. You authorized Lynx

18

Page 20

dealer programs this key code in the MPEM or ECU of your snowmobile to allow

engine operation above 3000 RPM if and only if this unique code has been read

after engine starting.

If a tether cord cap with different code is installed, the engine will start but cannot

reach drive pulley engagement speed to move vehicle.

Additional Tether Cord Caps

The MPEM/ECU of your snowmobile can be programmed by your authorized

Lynx dealer to accept 8 different key codes (tether cord caps).

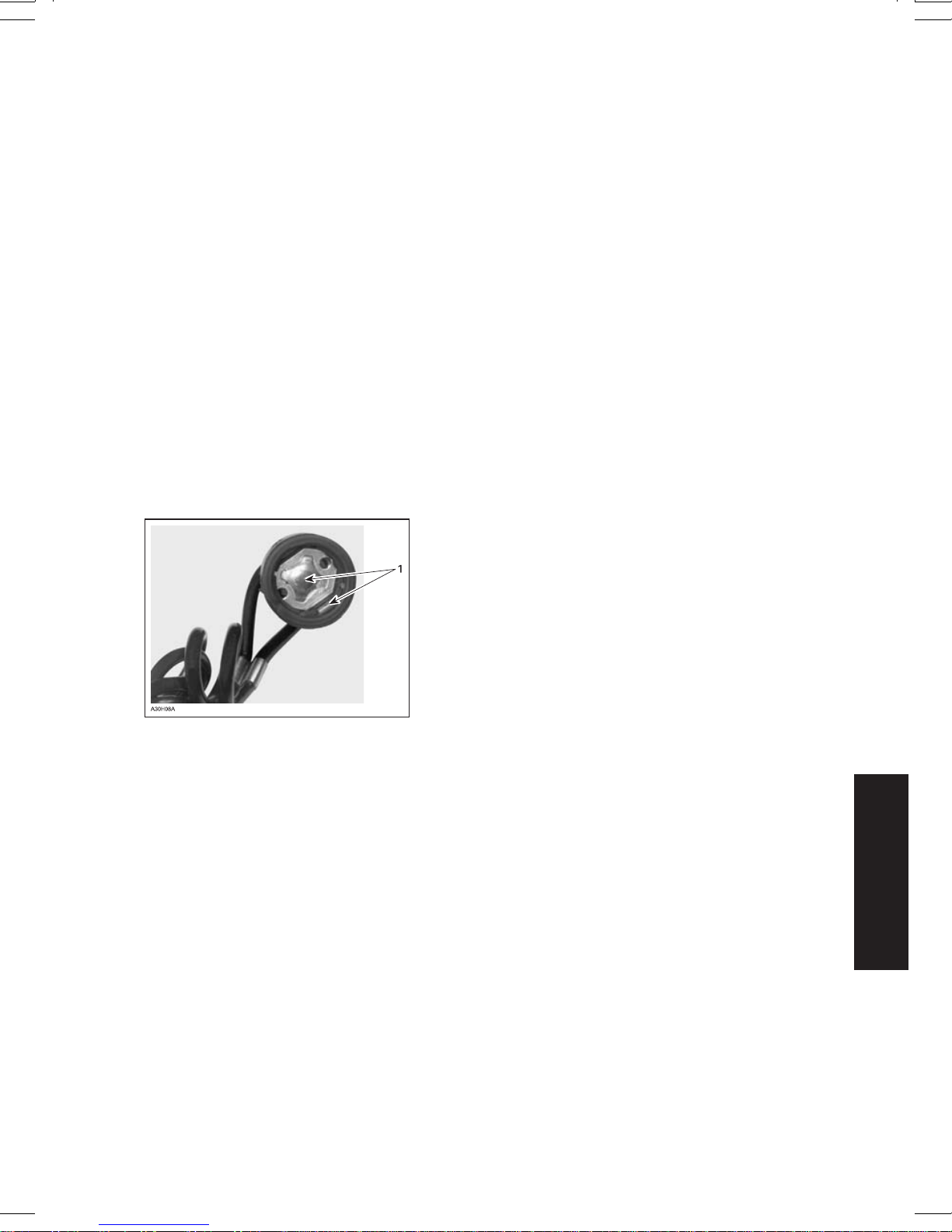

DESS Pilot Lamp Codes

DESS pilot lamp blinking slowly (one time per 1,5 second) means that a bad

connection has been detected. Vehicle can not be driven.

To check for bad connection, remove tether cord cap. Make sure the tether cord

cap is free of dirt or snow. Reinstall cap and restart engine. If a blink still occurs,

contact an authorized dealer.

1. Free of dirt and snow

A DESS pilot lamp blinking 3 times per second means that you have installed a

cap with a code that MPEM of this snowmobile was not programmed to recognize (wrong key). Vehicle can not be driven.

11. DESS pilot lamp

This lamp will light up to confirm DESS status. Refer to previous paragraphs for

description.

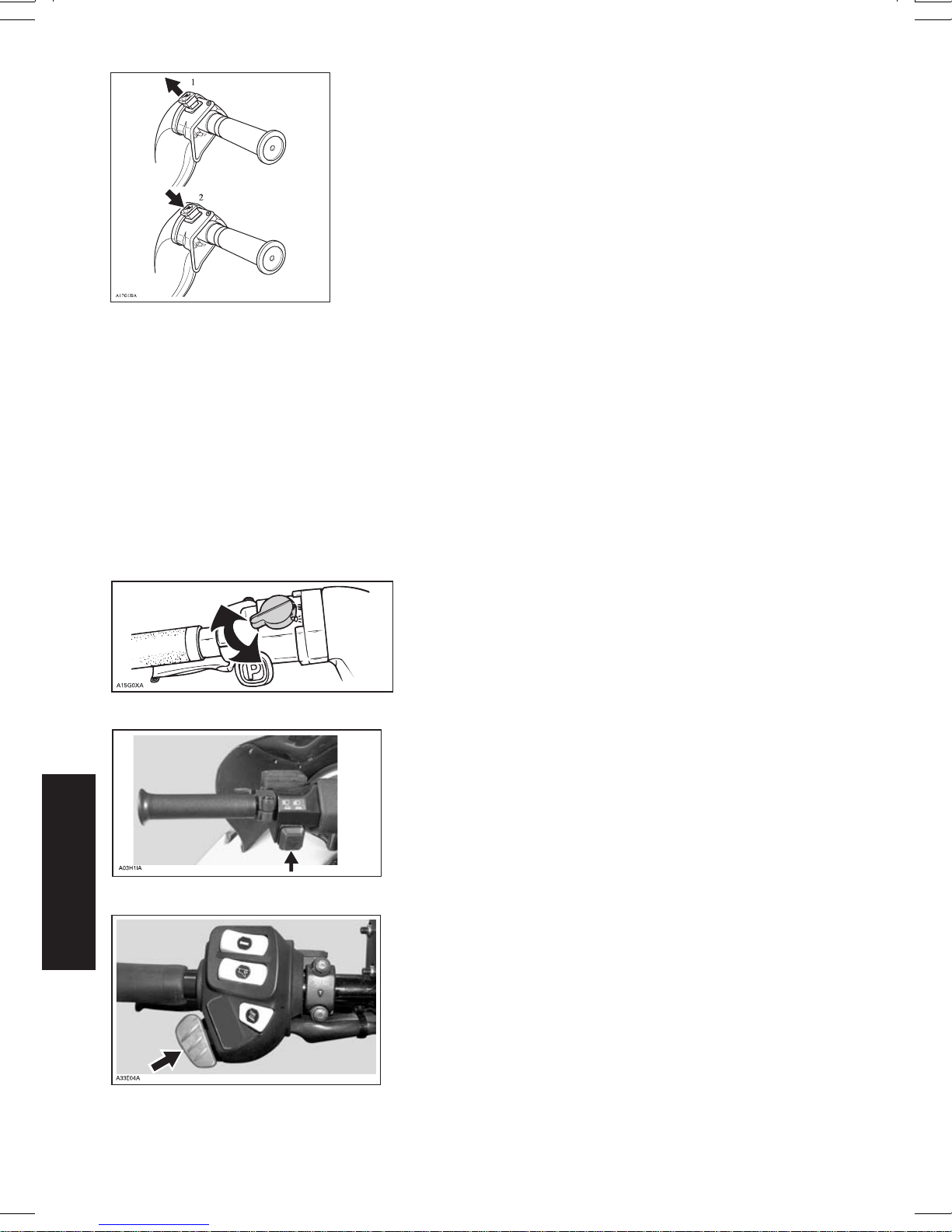

12. Engine cut-out switch

This push-pull type or toggle type switch is located on the right side of the handlebar. To stop the engine in an emergency, select OFF position and simultaneously apply the brake. To restart, button must be at the ON position.

19

ENGLISH

Page 21

1. ON

2. OFF

All operators of the snowmobile should familiarize themselves with the function of

this device by using it several times on first outing and whenever stopping the

engine there-after. This engine cut-out procedure will become a reflex and will

prepare operators for emergency situations requiring its use

13. Headlamp dimmer switch

Located on left hand side of handlebar, allows selection of headlamp beam. Note

that lights are automatically ON whenever the engine is running.

Some models

ENGLISH

14. High beam pilot lamp (Blue)

Lights when headlamp is on HIGH beam.

20

Page 22

Oil pilot lamp

2-tec models: This pilot lamp will glow up when injection oil level is low. Stop

vehicle in a safe place then, replenish injection oil reservoir.

4-tec models: This pilot lamp will glow up when engine oil pressure is too low.

Stop vehicle in a safe place then, check oil level and replenish as described in

FLUID LEVEL.

Restart engine, oil pilot lamp must turn off after few seconds. If oil pilot lamp still

glows up, stop engine and have lubrication system inspected by an authorized

Lynx dealer.

Low battery voltage pilot lamp

This lamp will light up to indicate a low battery voltage condition. See an authorized Lynx dealer as soon as possible.

Engine Management System (EMS) pilot lamp

This lamp will light up to indicate a trouble. Refer to TROUBLESHOOTING for

trouble code meaning and remedy.

15. Rewind starter handle

Auto-rewind type located on right hand side of snowmobile. Pull handle slowly

until a resistance is felt then pull vigorously. Slowly release handle.

16. Choke lever

0. OFF

1. Position 1

2. Position 2

Initial Cold Starting

NOTE:Do not operate the throttle lever with the choke lever on.

ENGLISH

Move the choke lever to position 2 and start the engine. As soon as the engine

starts move the lever to position 1. After a few seconds (10 seconds maximum)

move the choke lever to position OFF.

NOTE:In severe cold weather, colder than -20°C you may need to flip choke

lever from OFF position to position 1 a couple of times once engine is started.

21

Page 23

Warm engine starting

Start the engine without any choke. If the engine will not start after two pulls of the

rope or two 5 second attempts with the electric starter move choke lever to position 1. Start the engine without activating the throttle lever. As soon as the engine

starts move the choke lever to OFF.

17. Primer button

Pull and push button. It is not necessary when engine is warm.

To prime, activate button until a pumping resistance is felt. From this point, pump

2 or 3 times to inject fuel in intake manifold. After priming, ensure that primer

button is pushed back.

NOTE:In very cold temperature, it is recommended to rotate primer button 3 - 4

turns prior to pull it. This will eliminate the possibility of sticking.

18. Speedometer

Fan models and some liquid-cooled models: Direct reading screen shows

speed in km/h.

19. Odometer

Odometer records the total distance travelled in kilometers. It can be reset when

needed.

20. Trip meter

Records the distance travelled. It can be reset when needed.

21. Trip meter reset button

To reset the meter, push the button until all the numbers are zero (0).

ENGLISH

Mechanical speedometer

1. Odometer

2. Trip meter

3. Reset button

22

Page 24

Electronic speedometer

1. Mode button

Some liquid-cooled models: These models are equipped with electronic speedometer. It shows the speed either in kilometres or miles per hour.

Electronic speedo- and tachometer

Records total distance travelled until it is reset.

Mode button

Depress the mode button to change display. Each time engine is started, display

shows odometer. From that point depressing mode button again to return the

odometer.

ENGLISH

Depressing mode button again will change display for the resetable hourmeter.

Push mode button again to return to odometer.

Push and hold mode button for 2 seconds to reset the tripmeter or the resetable

hourmeter depending on the one displayed.

Electronic display

Odometer

Odometer records the total distance travelled and display it in kilometres.

Trip Meter

Records distance travelled since it has been reset. Distance travelled is displayed

in kilometres.

23

Page 25

Resetable hourmeter

Records engine running time in hours and minutes since it has been reset.

All models: Push and hold mode button for 2 seconds to reset the resetable

hourmeter.

Electronic display code

If your speedometer shows SCALE in the display, it means that the display

selector button is stuck in the down position or depressed when the electrical

system was activated.

Some models: At vehicle speed of 90 km/h and more the mode LCD screen will

show speed only instead of the selected mode.

NOTE! At the electronic speedometer display appears 9-9 when you power up

the vehicle. This means that the speedometer is calibrated to 9 teethed drive

sprocket.

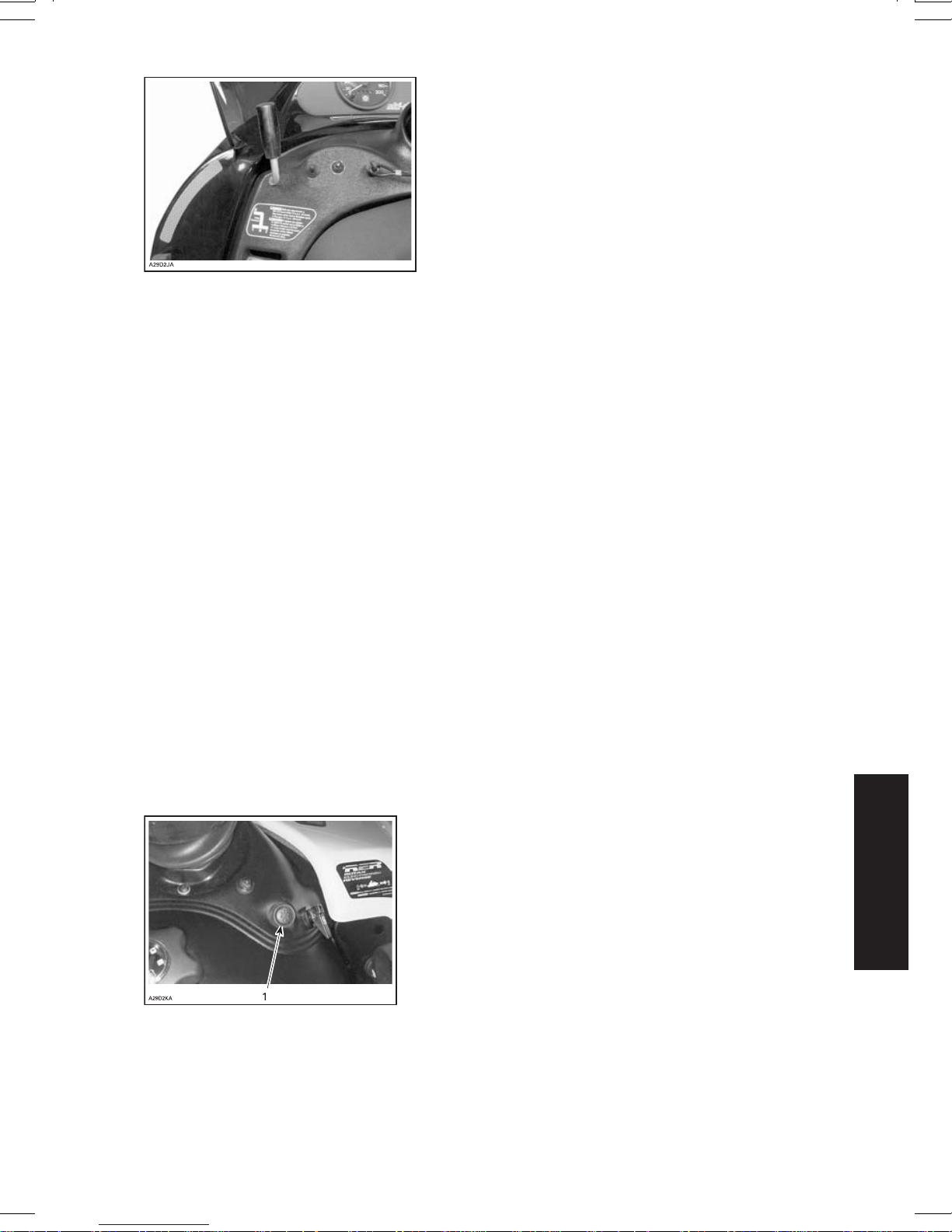

22. Fuel tank cap/gauge

Unscrew to fill up tank then fully tighten. Fuel tank cap features a mechanical

gauge.

Only Yeti 4-tec models

Located at rear of fuel tank cap the gauge facilitates fuel level reading.

ENGLISH

1. Full

2. Empty

Stop the engine before refueling. Fuel is inflammable and explosive under certain conditions. Open cap slowly. Do not smoke or allow open flames or sparks

in the vicinity. Do not overfill or top off the fuel tank before placing the vehicle in

a warm area. As temperature increases, fuel expands and might overflow.

Wipe off any fuel spillage from the vehicle.

WARNING!

24

Page 26

23. Engine overheat warning light (Red)

If this lamp glows; reduce snowmobile speed and run snowmobile in loose snow

or stop engine immediately.

24. Heating grip switch

It is a three position switch. Select the desired position to keep your hands at a

comfortable temperature.

1.HOT 2. OFF 3. WARM

Some models

1. Heated grip switch

2. Heated throttle lever switch

3. Hot

4. Warm

5. OFF

25. Heated throttle lever switch

Three-position switch. Select the desired position to keep your right thumb at a

comfortable temperature. See illustration.

Rear passengers heating grip switches

Three-position switch. Select the desired position to keep rear passengers hands

at comfortable temperature.

26. Hood latches

Stretch and unhook the latches to unlock the hood from its anchors. Lift hood

gently until stopped by retaining device. Close hood slowly then hook up latches.

25

ENGLISH

Page 27

27. Power outlet

A 12-volt electric appliance may be connected to that jack connector. Electric

current is supplied when ever engine is running. See FUSES for electric power

outlet fuse location.

28. Fuse

To remove fuse from holder, pull fuse out. Check if filament is melted.

1. Fuse

2. Check if melted

Fuse for starting system and electric power outlet

Starting system and electric power outlet is protected (if equipped) with 20 ampere fuse. If the starter and electric power outlet is out of function, check the fuse

condition and replace if needed.

NOTE:Do not use a higher rated fuse as this can cause severe damage to electric components and/or fire.

4-tec models and SDI: To open fuse box push on cover tab and tilt cover.

ENGLISH

1. Push tab

26

Page 28

1. Fuse description decal

2. Fuse remover/installer

3. Spare fuses

1. Fuse remover/installer

29. Front grab handle/ front bumper

To be used whenever front of snowmobile requires manual lifting.

1. Front grab handles

NOTE:Do not use skis to pull or lift snowmobile.

ENGLISH

27

Page 29

30. Storage compartment

Depending on model, storage compartment situates either under the seat or

inside of the seat.

31. Rear rack

Some models:Always readjust suspension according to the load. The capacity

of this rack is limited. Ride at very low speed when loaded. Avoid speed over

bumps.

1. Open latch

32. Tool kit

A tool kit containing tools for basic maintenance is supplied with the engine. Tool

bag is located under the seat or hood.

33. Spark plug holder

Some models: To keep spare spark plugs dry and prevent shocks that might

ENGLISH

affect the adjustment or break them, a holder is provided in engine compartment.

Firmly tighten them into the holder with spark plug socket (in tool kit) to ensure

that they will not be loosened by vibrations.

Spare spark plugs are not supplied with a new snowmobile.

Adjust spare spark plug gap according the TECHNICAL DATA before installation.

CAUTION: Do not attempt to adjust gap on spark plug BR9ECS; it is not adjustable.

28

Page 30

34. Seat strap

Seat strap provides a grip for the passenger.

35. Hitch

The hitch can be used to pull most equipment. Use a rigid tow bar.

NOTE! Remember to lock the hitch locking latch with a lock pin.

Following picture shows how much load is allowed and to transport and to pull.

This decal is found at end of rear racket on your own vehicle.

36. Adjustable suspension

Snowmobile handling and comfort depend upon suspension adjustments.

Choice of suspension adjustments vary with carrying load, drivers weight, personal preference, riding speed and field condition.

NOTE:Some adjustments may not apply to your snowmobile. Use special keys

in tool kit.

1. Rear springs - comfort and ride height

2. Suspended extension reverse performance, load and snow conditions

3. Shackle movement reverse performance, load and snow conditions

4. Center spring - handling

5. Stopper strap snowmobile weight transfer

6. Front shock - handling

ENGLISH

29

Page 31

Guidelines to adjust suspension

The best way to set up suspension, is to start from factory settings then customize each adjustment one at a time. Adjustments 2 through 6 are interrelated. It

may be necessary to to readjust center spring after adjusting front springs for

instance. Test run the snowmobile under the same conditions; trail, speed, snow,

driver riding position, etc. Change one adjustment and retest. Proceed methodically until you are satisfied.

NOTE:Whenever adjusting rear suspension, check track tension and adjust as

necessary.

Slight suspension bottoming occuring under the worst riding conditions indicates

a good choice of spring preload.

1. Rear Springs Comfort

IMPORTANT:Make sure that all objects to be transported are in place in rear

rack and under the seat.

When driver and passenger (if applicable) take place, rear of snowmobile should

collapse by 50 to 75 mm.

Proper adjustment

A. 50 to 75 mm

Too soft of adjustment

ENGLISH

1. Increase spring preload

30

Page 32

Too hard of adjustment

1. From the highest position, turn adjuster to select lowest position then, turn

adjuster to the desired position

2. Suspended Extension Adjustment

Suspended extension can be adjusted according to the load and snow conditions.

For better deep snow performance or to increase reverse performance in deep

snow; first loosen lock nut then tighten nut 3/4 turn after contacting washers.

Retighten lock nut. Adjust the same on both sides.

For trail riding with a load or for pulling a load, first loosen lock nut. Turn to a

maximum preload of 3 turns after lock nut touching washers. Retighten lock nut.

Adjust the same on both sides.

3. Shackle Movement Limiter

Forest Fox : Install rubber bumper if you are mainly pulling a load. Rubber bumper

improves the handling when pulling a load.

For deep snow riding, do not install horse shoe washers.

For trail riding with passenger and/or weight; install 1 horse shoe washer under

each rubber stoppers.

For trail ride with heavy load and/or pulling a load ; install 2 horse shoe washers

under each rubber stoppers.

CAUTION:Always install same amount of washers on both sides.

31

ENGLISH

Page 33

1. Horse shoe washer(s)

2. Nut

3. Lock nut

4. Center Spring Steering Behavior

Ride at moderate speed on a trail. If handlebar is felt too hard to turn, adjust

centre spring accordingly.

Good adjustment at moderate speed

1. Handlebar easy to turn neutral steering attitude

Too soft of adjustment

1. Handlebar harder to turn oversteering attitude

ENGLISH

1. Use adjuster wrench provided in tool kit to increase preload

32

Page 34

Too hard of adjustment - too much preload

1. Handlebar is very easy to turn understeering attitude

1. Use adjuster wrench provided in tool kit to decrease preload

5. Stopper Strap Weight Transfer

Ride at low speed then fully accelerate. Note steering behavior. Adjust stopper

strap length accordingly.

NOTE:Whenever stopper strap length is changed, track tension must be readjusted.

Good adjustment at full acceleration

1. Comfortable steering

2. Good weight transfer to the track

3. Light pressure of skis on the ground

Too long strap

1. Skis lift off the ground - too short strap

ENGLISH

33

Page 35

Too short strap

1. Heavy steering

1. Screw or unscrew knob to vary strap length

1. Bolt stopper strap to a different hole

6. Front Springs Handle

Ride at moderate speed and check for proper handling. Adjust front springs accordingly.

ENGLISH

Proper adjustment

1. Good handling and comfortable steering

34

Page 36

Too soft of adjustment

1. Bad handling

1. Increase spring preload

Too hard of adjustment

1. Steering hard to turn

1. Decrease spring preload

ENGLISH

35

Page 37

SUSPENSION TROUBLESHOOT

In deep snow

When operating the snowmobile in deep snow, it may be necessary to vary extension adjustment, stopper strap and/or riding position, to change the angle at

which the track rides on the snow. Operators familiarity with the various adjust-

ments as well as snow conditions will dictate the most efficient combination.

Fuel and oil

Recommended fuel

Refer to TECHNICAL DATA in the end of this manual.

NOTE:Never experiment with other fuels or fuel rations. The use of unrecommended fuel can result in snowmobile performance deterioration and damage to critical parts in the fuel system and engine components.

WARNING!

Do not overfill or top off the fuel tank before placing the vehicle in a warm area.

As temperature increases, fuel expands and might overflow. Fuel is inflam-

ENGLISH

mable and explosive under certain conditions. Wipe off any fuel spillage from

the vehicle.

Fuel System Antifreeze

When using oxygenated fuel, additional gas line antifreeze or water absorbing

additives are not required and should not be used.

36

Page 38

Recommended oil

2-tec models (not SDI):

Use BRP Synthetic Blend 2-stroke injection oil (P/N 293 600 071) or BRP Synthetic 2-stroke injection oil (P/N 293 600 045) or BRP Mineral 2-stroke injection oil

(P/N 1472325).

SDI models: In SDI models use BRP Fully Synthetic 2-stroke injection oil (P/N

293 600 045) or BRP Synthetic Blend 2-stroke injection oil (P/N 293 600 071).

CAUTION: Do not mismatch oil reservoir cap with fuel tank cap. On some models there is fuel gauge together with fuel tank cap. Oil reservoir cap is identified

OIL. Use only oil, which flows at -40º.

Oil is in injection oil reservoir.

Use only 2-stroke engine oil.

CAUTION: Never use four-stroke mineral or synthetic oil. Do not mix these with

outboard motor oil. Do no use NMMA TC-W, TC-W2 or TC-W3 outboard oil. Avoid

mixing different brands of API TC oil as resulting chemical reactions may cause

severe engine damage.

Always maintain a sufficient amount of recommended oil in the injection oil reservoir.

CAUTION: Check level and refill every time you refuel. Do not mismatch oil reservoir cap with fuel tank cap. Install cap that is identified with OIL

4-tec models: These models are equipped with 4-stroke engine. Use Bombardier 4-stroke synthetic oil 0W 40 (P/N: 293 600 054) 12x1l or fully synthetic

equivalent oil.

Gear box oil

Recommendation 75W140 (P/N 413803300, 12x355 ml).

Cold weather carburetion modifications

All vehicles has been calibrated for -20°C. They can be operated at warmer

winter temperatures without problems.

CAUTION:For colder temperatures than -20°C, carburetor(s) must be recalibrated to avoid engine damage. Refer to an authorized Lynx dealer.

ENGLISH

37

Page 39

Break-in period

Engine

IMPORTANT

A break-in period of 10-15 hours (about 500 km) is required for Rotax engines

before running the snowmobile at full throttle.

During break-in period, maximum throttle should not exceed ¾. However, brief full

acceleration and speed variations contribute to a good break-in.

All models except 4-tec and 2-tec SDI models: To assure additional protection during the initial engine break-in, 500 ml of recommended injection oil should

be added to fuel for the first full filling of fuel tank.

(P/N 1471599, 20x1l). Have spark plugs cleaned after engine break-in.

Drive Belt

A new drive belt requires a break-in period of 50 km. Avoid strong acceleration/

deceleration, pulling a load or high speed cruising.

10 Hour Inspection

We suggest that after the first 10 hours of operation 500 km or 30 days after

the purchase, whichever comes first, your snowmobile be checked by an authorized Lynx dealer.

NOTE! The 10 hour inspection is at expense of the snowmobile owner.

Pre oparation check

* Remove snow and ice from body including seat, footrests, lights, controls and

instruments.

* Verify that track and idler wheels are not frozen and free to turn.

* Activate the brake control and make sure the brake fully applies before the

ENGLISH

brake control lever touches the handlebar grip. It must fully return when released.

* Check the parking device. Apply parking brake and check if it operates easily

and smoothly.

* Activate the throttle control lever several times to check that it operates easily

and smoothly.

* Check operation of ignition switch, headlamp switch, taillight, brake light, pilot

lamps and tether/cut-out switches.

* Verify that skis and steering operate freely. Check corresponding action of

skis versus handlebar.

38

Page 40

* Check fuel and injection oil for levels and leaks. Replenish as necessary and

see an authorized Lynx dealer in case of any leaks.

* Verify that air filter(s) is free of snow, if so equipped.

* Make certain your snowmobile is pointed away from people or objects before

you start it.

* Be warmly dressed with clothing designed for snowmobiling.

Operating instruction

Propulsion

Depressing throttle lever increases engine RPM causing the drive pulley to engage. Depending on models engine RPM must be between 2500 and 4200 before

drive pulley engagement will occur.

Outer sheave of drive pulley moves toward inner sheave, forcing drive belt to move

upward on the drive pulley and simultaneously forcing the sheaves apart on the

driven pulley.

The driven pulley senses the load on the track and limits the belt movement. The

result is an optimized speed ratio between engine RPM and the speed of the

vehicle at any time.

Power is transferred to the track through the chaincase or gearbox and drive axle.

Turning

Handlebar controls the steering of the vehicle. As the handlebar is rotated to right

or left, the skis are turned right or left to steer the snowmobile.

Stopping

Before riding your snowmobile, you should understand how to stop it. This is

done by releasing the throttle and gradually depressing the brake lever on the left

side of the handlebar.

In an emergency, you may stop your vehicle by pressing the engine cut-out

switch located near the throttle control and applying the brake.

Remember, a snowmobile cannot stop on a dime. Braking characteristics vary

with deep snow, packed snow or ice. If the track is locked during hard braking,

skidding may result.

Starting the engine

Check throttle lever operation.

ENGLISH

Ensure that the engine cut-out switch is in the ON position.

Ensure that the tether cord cap is in position and that the cord is attached to your

clothing eyelet.

39

Page 41

Primer equipped vehicles

Starting the engine: To prime, activate button until a pumping resistance is felt.

From this point, pump 2 or 3 times to inject fuel in intake manifold.

After priming, ensure that primer button is pushed back.

NOTE:In very cold temperature, it is recommended to rotate primer button 3-4

turns prior to pull it. This will eliminate the possibility of sticking.

NOTE:Priming is not necessary when engine is warm.

Choke equipped vehicles

Initial cold starting:Do not operate the throttle lever with the choke lever on.

When temperature is below -10°C

Move the choke lever to position 2 and start the engine. As soon as the engine

starts move the lever to position 1. After a few seconds (max.10 seconds) move

the choke lever to OFF position.

NOTE:In severe cold weather, colder than -20°C you may need to flip choke

lever from OFF to position 1 a couple of times once engine is started.

0. OFF

1. Position 1

ENGLISH

2. Position 2

When temperature is above -10°C

Move the choke lever to position 1.

Grab the handle firmly and start the engine or electric starter if it is equipped.

As soon as the engine starts move the choke lever to OFF.

40

Page 42

4-tec models

Initial cold starting and warm engine starting

Use the electric starter.

CAUTION: 4-tec model: If the battery is empty, engine cannot be started. Charge

the battery or replace it if necessary.

Warm engine starting

Start the engine without any choke. If the engine will not start after two pulls of the

rope or two 5 second attempts with the electric starter move choke lever to position 1. Start the engine without activating the throttle lever. As soon as the engine

starts move the choke lever to OFF.

SDI engine starting procedure

General

IMPORTANT: On SDI engine with electrical starter, if the low battery voltage

pilot lamp is on, battery would not have enough power to start the engine. In

this case, use the manual rewind starter.

IMPORTANT: On SDI engine with electrical starter, if the battery is dead,

engine cannot be started. Have the battery recharged or replaced.

Procedure

- Recheck throttle control lever operation.

- Ensure that the tether cord cap is in position and that the cord is attached to

your clothing eyelet.

- Ensure that the engine cut-out switch is in the ON position.

Manual starting

- Grab manual starter handle, pull handle slowly until a resistance is felt , then

hold handle firmly and pull vigorously to start engine.

WARNING!

Do not apply throttle while starting.

Electrical starting (if so equipped)

ENGLISH

- Depressing the START/RER button will engage the electric starter and start

the engine.

- Release button immediately when engine has started.

41

Page 43

WARNING!

Do not apply throttle while starting.

WARNING!

Do not use electric starter for more than 10 seconds. A rest period should be

observed between the cranking cycles to let electric starter cool down. Using

electric starter when engine has started could damage electric starter

mechanism.

NOTE!

If for any reason, the engine cannot be cranked electrically, start engine manually using the rewind starter.

Rewind starter

All the fan cooled models: Set the key to ignition switch and turn to ON position.

Grab the handle firmly and crank the engine.

WARNING!

Do not activate the throttle lever during starting.

NOTE: There is no rewind starter handle in 4-tec model.

All models except 4-tec models

Emergency starting

The engine can be started with the emergency starter rope supplied with the tool kit.

Remove belt guard.

Do not wind the starting grope around your hand. Hold rope by the handle only.

Do not start the snowmobile by the drive pulley unless it is a true emergency

situation. Have the snowmobile repaired as soon as possible.

ENGLISH

Attach one end of emergency rope to rewind handle.

NOTE:The spark plug socket can be used as an emergency handle.

42

Page 44

Attach the other end of emergency rope to the starter clip supplied in the tool kit.

Hook up clip on drive pulley.

Wind the rope tightly around drive pulley. When pulled, pulley must rotate counterclockwise.

1. Knot on this side

1. Hook up starter clip

1. Clip

ENGLISH

43

Page 45

Pull the rope using a sharp, crisp pull so the rope comes free of the drive pulley.

Start the engine as per usual manual starting.

When starting the snowmobile in an emergency situation, using drive pulley, do

not reinstall the belt guard and return slowly to have snowmobile repaired.

Shutting down the engine

Release throttle lever and wait until engine has returned to idle speed.

Shut down the engine using either ignition switch, engine cut-out switch or tether

cut-out switch.

NOTE! In 4-tec models the shut down the engine must be done only by engine

cut-out switch. This gives the fan to operate longer if the engine has gone under

heavy pulling conditions this is to prevent overheating. Do not remove the tether

cut-out switch until the fan has stopped.

WARNING!

Always remove tether cord cap and key when vehicle is not in operation in

order to prevent accidental engine starting or to avoid unauthorized use by

others or theft.

Vehicle warm-up

Before every ride, vehicle has to be warmed up as follows:

Snowmobile must be securely supported by the rear bumper using a wide-base

snowmobile mechanical stand. Track must be 100 mm off the ground.

Start engine and allow it to warm up two or three minutes at idle speed.

Release barking brake.

WARNING!

Make sure wide-base snowmobile mechanical stand is stable. Stay clear of

the front of vehicle and the track. Do not use too much throttle during warm-up

or when track is free-hanging.

Apply throttle until drive pulley engages. Let track rotate at low speed for several

turns. The lower the vehicle temperature is the longer vehicle warm-up should be.

Shut-off the engine and remove the wide base snowmobile mechanical stand.

ENGLISH

Skis may be frozen on the ground. Grab both skis one at a time by their loops

and lift their front end slightly off the ground.

After restarting engine, the vehicle can be driven at low speed for the first 2 or 3

minutes of riding. After that, it may be driven up to the legal speed limit as per

normal safety practices.

Post operation care

Shut down the engine. Install rear of vehicle on a wide-base snowmobile mechanical stand.

Remove snow and ice from rear suspension, track, front suspension, mechanism and skis.

Protect vehicle with a snowmobile cover.

44

Page 46

Engine overheating

NOTE! (4-tec only) If the buzzer activates during high temperatures, turn off the

engine by engine cut-off switch, if this is not applied and the temperature continues to increase the engine will shut down by EMS system (Engine Management System) automatically. The vehicle will not shut down if it is being driven

and it will require that it is stopped without touching the throttle for 30 seconds

before doing so. If the buzzer activates shortly after driving again, check the

coolant level and fill it if necessary. If the buzzer still activates after shortly please

contact nearest authorized LYNX dealer for further investigation.

Fan cooled models: Shut down the engine.

Check for clogged air duct passages. Remove any foreign materials.

Check for proper fan belt condition and tension.

Liquid cooled models: Engine overheating pilot lamp will light up if engine is

too hot.

Reduce snowmobile speed and run snowmobile in loose snow or stop engine

immediately.

Check for adequate coolant level. See an authorized Lynx dealer.

Low Battery (only 4-tec models): When overheating pilot lamp light up does

the fan starts to rotate, this usually takes down the voltage level under its working

level from this point will EMS (Engine Management System) increase the idle

speed to 1500 RPM. This gives naturally more current to the battery and starts to

charge it up. If the battery pilot lamp stops lighting (in V-800 it flashes) this

means that the battery loading up. But still the idle speed does not come down at

this time, the engine must be stopped before it starts to operate in normal idle

speed which is for V-800, 1200 RPM and V-1300, 1300RPM.

Fuel flooded engine

Install new spark plugs and restart engine.

Rear suspension slider shoe sticking

Slider shoes are cooled and lubricated by snow. When riding at moderate or high

speed on a thin-snow-covered surface, slider shoes may stick on metallic track

guides.

Run snowmobile on a surface covered by snow or drive snowmobile at very low

speed.

Have slider shoes inspected by an authorized Lynx dealer.

NOTE! This situation comes up the more high profile track is. Avoid driving on

hard packed snow, ice surface or other surface, that has not enough snow to

ensure the lubrication.

It is noticeable that tracks with 35 mm or more high profile are not meant for the

trail ride (hard surface) but only for the deep snow ride. If the vehicle which is

equipped with this kind of track, is driven on hard packed snow, slider shoes may

stick on track metallic parts or the track can get damaged.

45

ENGLISH

Page 47

Fluid levels

WARNING!

It is recommended that the assistance of an authorized Lynx dealer be periodically obtained on other components/systems not covered in this guide. Unless otherwise specified, engine must be cold and not running. The tether cord

cap must be removed for all maintenance procedures.

CAUTION: Vehicle must be on a level surface before checking any fluid levels.

Brake system

Check brake fluid in reservoir for proper level. Add fluid as required.

CAUTION: Use only DOT 4 brake fluid from a sealed container.

Brake fluid reservoir

1. Minimum

Chain case models: Check the oil level by removing dipstick. Oil level must be

between lower and upper marks.

NOTE:It is normal to find metallic particles stuck to dipstick magnet. If bigger

pieces of metal are found, see an authorized Lynx dealer.

Remove metal particles from magnet.

Refill up to upper mark using recommended oil.

ENGLISH

NOTE:Do not use unrecommended other types of oil when servicing. Do not mix

synthetic oil with other types of oil.

46

Page 48

1. Dipstick

2. Oil level

3. Level between marks

Gear box models: To check, pull dipstick. Oil should reach level mark.

NOTE:Before initial start-up, the oil level may be higher than the full mark. After

first outing, oil level will decrease as the upper oil cavity fills with oil.

NOTE:Do not use unrecommended other types of oil when servicing. Do not mix

this synthetic oil with other types of oil.

Gear box models

ENGLISH

1. Full level mark

2. Lower level mark

47

Page 49

Engine oil level

Yeti V-1300: Make sure engine is at operating temperature. Snowmobile must be

on a level surface. Leave engine running at idle for 30 seconds. Stop engine and

wipe off the oil from the dipstick. Dipstick must be completely screwed in before

checking oil level. Oil level must be between minimum and maximum marks on

dipstick. The amount of oil between lower and full marks are 0,5 liter.

1. Lower level mark

3. Full level mark

V-810 engine type: Before checking the oil level the engine must be shut down

for 5 minutes. Snowmobile must be on a level surface. Pull out the dipstick and

wipe off the oil from the dipstick with a suitable rag or paper. Put the dipstick back

and pull out it again, check the oil level and fill if it is necessary. There are

capacity of 0,5 liter oil between lower and full mark.

ENGLISH

1. Full level mark

2. Lower level mark

Add Bombardier synthetic oil OW4O through dipstick hole as required.

48

Page 50

Injection oil system

Always maintain a sufficient amount of recommended injection oil in the injection

oil reservoir.

NOTE:Never allow oil reservoir to be almost empty.

WARNING!

Check level and refill every time you are refuelling vehicle. Wipe off any spillage. Oil is highly flammable when heated.

1. Injection oil reservoir

2. Max level: 13 mm from top

3. Level marks (¼, ½, ¾ )

ENGLISH

1. Injection oil reservoir

2. Max level: 13 mm from top

49

Page 51

Cooling system

Check coolant level at room temperature. Liquid should be at COLD LEVEL line

(engine cold) of coolant tank.

NOTE:When checking level at low temperature it may be slightly lower than

mark.

If additional coolant is necessary or if entire system has to be refilled, refer to an

authorized Lynx dealer.

1. COLD LEVEL line

ENGLISH

1. Coolant tank

2. COLD LEVEL line

50

Page 52

1. Coolant tank

2. COLD LEVEL line

4-TEC MODELS

Yeti V-800-Expansion tank near the muffler

1. Max level

2. Min level

3. Coolant expansion tank

4. Coolant filling tank

ENGLISH

Yeti V-1300- Expansion tank near the muffler

1. Max level

2. Min level

51

Page 53

Battery

Removal

WARNING!

Battery BLACK negative cable must always be disconnected first and connected last.

WARNING!

Never charge or boost battery while installed. Battery electrolyte contains

sulfuric acid which is corrosive and poisonous. In case of contact with skin,

flush with water and call a physician immediately.

WARNING!

Should the battery casing be damaged, wear a suitable pair of non-absorbent

gloves when removing the battery by hand.

WARNING!

Battery caps have do not have vent holes. Make sure that vent tube is not

obstructed.

Dry battery

These batteries are not wet type batteries. Electrolyte level can not be checked.

NOTE: During the summer storage the battery (specially dry battery) has to be

charged at least once a month. Otherwise the battery can not function in the

beginning of season.

Maintenance

Vehicle cleaning and protection

Remove any dirt or rust.

To clean the entire vehicle, use only flannel cloths or equivalent.

CAUTION:It is necessary to use flannel cloths or equivalent on windshield and

ENGLISH

hood to avoid damaging further surfaces to clean.

To clean the entire vehicle, including bottom pan and metallic parts use Bombardier Cleaner (P/N 293 110 001) spray can 400 g and (P/N 293 110 002 (4 L)).

CAUTION:Do not use Bombardier Cleaner on decals or vinyl.

For vinyl and plastic parts use Vinyl & Plastic Cleaner (P/N 413 711 200 (6 x 1 L)).

To remove scratches on windshield or hood use BOMBARDIER Scratch Remover

Kit (P/N 861 774 800).

CAUTION:Never clean plastic parts or hood with strong detergent, degreasing

agent, paint thinner, acetone, products containing chlorine, etc.

52

Page 54

Clean sheaves of both pulleys using BOMBARDIER Pulley flange cleaner (P/N

413 711 809).

Inspect the hood and repair any damage.

Touch up all metal spots where paint has been scratched off. Spray all metal parts

including shock chromed rods with BOMBARDIER LUBE (P/N 293 600 016).

Wax the hood and the painted portion of the frame fro better protection.

Apply wax on glossy finish only. Protect the vehicle with a cover to prevent dust

accumulation during storage.

The snowmobile has to be stored in a cold and dry place and covered with an

opaque tarpaulin. This will prevent sun rays from affecting vehicle finish.

Lift rear of vehicle until track is off the ground. Install on a mechanical stand.

Do not release track tension.

Drive belt removal and installation

1. Remove tether cord cap. Open engine compartment.

4-tec models only

1. Collar screw

2. Vent hose

3. Latch

1 Loosen collar screw on air silencer grommet.

2 Disconnect engine vent hose from air silencer.

1. Collar screw

2. Engine vent hose

3. Remove latch from air silencer.

53

ENGLISH

Page 55

1. Tighten to open pulley

1. Guard

2. Retaining pins

Stop engine using tether cord.

Open hood. Pull out clip then, open pin retainer. Remove belt guard.

1. Pin retaining

Screw tool in the threaded hole and tighten to open the pulley. Remove belt.

ENGLISH

1. Tighten to open pulley

Slip the belt over the top edge of the sliding half, as shown.

When reinstalling belt guard, position its cut-away toward front of snowmobile.

Refer to decal in belt guard.

54

Page 56

NOTE:Belt guard is purposely made slightly oversize to maintain tension on its

pins and retainers preventing undue noise and vibration. It is important that this

tension be maintained when reinstalling.

Typical

Drive belt installer/remover

1. Push tab down and pull panel out of bottom pan

ENGLISH

Pull panel out of bottom pan

55

Page 57

1. Tighten to open pulley

Turn sliding half clockwise then, pull on drive belt to open driven pulley. Follow

instruction on decals for belt removal and installation.

1. Turn sliding half clockwise

2. Pull belt to open driven pulley

Slip the belt over the top edge of the sliding half, as shown.

Installation

The maximum drive belt life span is obtained when the belt has the proper rotation

direction. Install it so the arrow printed on belt is pointing at front of vehicle.

ENGLISH

1. Arrow pointing at front of vehicle

56

Page 58

CAUTION:Do not force or use tools to pry the belt into place, as this could cut or

break the cords in the belt.

Clean sheaves of both pulleys using BOMBARDIER Parts Cleaner (P/N 413 711

809).

To install the drive belt, first place belt between drive pulley sheaves. Then, between driven pulley sheaves, finishing with bottom.

Follow instructions on belt guard.

Reinstall belt guard.

Drive chain tension

Chain case models: Remove hair pin.

Fully tighten tensioner adjustment screw by hand, then back off only far enough

for hair pin to engage in locking hole.

1. Hair pin

2. Adjustment screw

1. Hair pin

2. Adjustment screw

ENGLISH

57

Page 59

TRA Drive pulley adjustment

The drive pulley is factory calibrated to transmit maximum engine power at a

predefined RPM. refer to TECHNICAL DATA at the end of this guide. Factors such

as ambient temperature, altitude or surface condition may vary this critical engine RPM thus affecting snowmobile efficiency.

Calibration screws should be adjusted so that actual maximum engine RPM in

vehicle matches with the maximum horsepower RPM.

Use precision digital tachometer for engine RPM adjustment.

The adjustment has an effect on high RPM only.

To adjust, turn calibration screws.

CAUTION! Exceeding the engine RPM results to engine damage. Follow the

adjustment sets according technical data.