Page 1

LYNXTechnik AG

Broadcast Television Equipment

© 2012 LYNX Technik AG all rights reserved

®

Reference Manual

D VD 5830

Triple 3GBit/s Dual SDI/ASI Distribution Amplifier

Revision 1.0

April 2012

This Manual Supports Device Revisions:

D VD 5830 Firmware Revision 494

Control System GUI Release 6.0.0

Information in this document is subject to change without notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or mechanical for any purpose, without express written permission of

LYNX Technik AG.

LYNX Technik AG may have patents, patent applications, trademarks, copyrights or other intellectual property rights

covering the subject matter in this document. Except as expressly written by LYNX Technik AG, the furnishing of this

document does not give you any license to patents, trademarks, copyrights or other intellectual property of LYNX Technik

AG or any of its affiliates.

LYNX Technik AG

Brunnenweg 3

D 64331 Weiterstadt

Germany

www.lynx-technik.com

Page 2

D VD 5830 Reference Manual. Rev 1.0

Page 2 of 17

Contents

CONTENTS .......................................... ..................... ..................... ...................... .............. 2

WARRANTY ......... ............... .............. ................ ............... ............... ............... ................ .... 3

REGULATORY INFORMATION ........................................................................................ 4

E

UROPE ..................................... .................. ................ ................... ................ ................. 4

USA ................................................................................................................................ . 4

GETTING STARTED ...... ................................... ................................... .............................. 5

P

ACKAGING ........................................ ........................................ ..................................... . 5

ESD

WARNING ................................................................................................................. 5

Preventing ESD Damage ................................ .............................. .......................... .... 5

PRODUCT DESCRIPTION ............... ........ ......... ........ ......... ........ ......... ........ ........ ........ ...... 6

F

UNCTIONAL DIAGRAM ...................................................................................................... 6

M

ODULE LAYOUT .............................................................................................................. 7

CONNECTIONS ................................................ ............. .............. ................ ............. ......... 8

INSTALLATION .................................................................................................................. 8

SETTINGS AND CONTROL .............................................................................................. 9

S

WITCH SETTINGS .......................................................................................................... 10

Switch Function Detail .......................... .................................................................. .. 10

Factory Preset Condition ........ .................................................................................. 11

Auto Store ..................................................................................................... ............ 11

ALARM/LED STATUS INDICATORS ................... .......................................................... 12

Channel Condition Indicators LED 1, 2 and 3 .............. ............................. ............... 12

Alarm Indicator ................................ ................................................................... ....... 12

Local/remote LED ......... .. ...... .. ... ..... ... ..... ... ... ..... ... ..... ... .. ...... .. ...... .. ... ..... ... ..... ... ... .... 12

Power Indication ....................................................................................................... 12

CONTROL SYSTEM GUI .......................... ..... ... ... ..... ... .. ...... .. ...... .. ... ..... ... ... ..... ... ..... ... .. .. 13

Main Tab ......... ... ... ..... ... ..... ... .. ...... .. ...... .. ...... .. ... ..... ... ..... ... ..... ... ... ..... ... ..... ... .. ...... .. .. 14

Events Tab ................................. ............................................................................... 15

SPECIFICATIONS ............................................................................................................ 16

SERVICE .............................................. ................ .................. ................ ................... ....... 17

Parts List ....................................... .................................................................. .......... 17

Technical Support ..................................................................................................... 17

Contact Information................................................................................................... 17

Page 3

D VD 5830 Reference Manual. Rev 1.0

Page 3 of 17

Warranty

LYNX Technik AG warrants that the product will be free from defects in materials

and workmanship for a period of three (3) years from the date of shipment. If this

product proves defective during the warranty period, LYNX Technik AG at its

option will either repair the defective product without charge for parts and labor,

or will provide a replacement in exchange for the defective product.

In order to obtain service under this warranty, customer must notify LYNX

Technik of the defect before expiration of the warranty period and make suitable

arrangements for the performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service center designated by

LYNX Technik, with shipping charges prepaid. LYNX Technik shall pay for the

return of the product to the customer if the shipment is within the country which

the LYNX Technik service center is located. Customer shall be responsible for

payment of all shipping charges, duties, taxes and any other charges for

products returned to any other locations.

This warranty shall not apply to any defect, failure, or damage caused by

improper use or improper or inadequate maintenance and care. LYNX Technik

shall not be obligated to furnish service under this warranty a) to repair damage

resulting from attempts by personnel other than LYNX Technik representatives to

install, repair or service the product; b) to repair damage resulting from improper

use or connection to incompatible equipment; c) to repair any damage or

malfunction caused by the use of non LYNX Technik supplies; or d) to service a

product which has been modified or integrated with other products when the

effect of such modification or integration increases the time or difficulty servicing

the product.

THIS WARRANTY IS GIVEN BY LYN X TE CHNIK WITH RESPECT TO THIS

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED.

LYNX TECHNIK AND ITS VENDORS DISCLAIM ANY IMPLIED WARRANTIES

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. LYNX

TECHNIK`S RESPONISIBILITY TO REPAIR AND REPLACE DEFECTIVE

PRODUCTS IS THE SOLE AND EXCLUSIVE REMEDY PROVIDED TO THE

CUSTOMER FOR BREACH OF THIS WARRANTY. LYNX TECHNIK AND ITS

VENDORS WILL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

INCIDENTIAL, OR CONSEQUENTIAL DAMAGES IRRESPECTIVE OF

WHETHER LYNX TECHNIK OR THE VENDOR HAS ADVANCE NOTICE OF

THE POSSIBILITY OF SUCH DAMAGES.

Page 4

D VD 5830 Reference Manual. Rev 1.0

Page 4 of 17

Regulatory information

Europe

Declaration of Conformity

USA

FCC 47 Part 15

This device complies with part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

Note: This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to the part 15 of the FCC Rules. T hese limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense

We LYNX Technik AG

Brunnenweg 3

D-64331 Weiterstadt

Germany

Declare under our sole responsibility that the product

TYPE: D VD 5830

To which this declaration relates is in conformity with the following

standards (environments E1-E 3 ):

EN 55103-1 /1996

EN 55103-2 /1996

EN 60950 /2001

Following the provisions of 89 /336/EEC and 73/23/EEC directives.

Winfried Deckelmann

Weiterstadt, April 2012

Place and date of issue Legal Signature

Page 5

D VD 5830 Reference Manual. Rev 1.0

Page 5 of 17

Getting Started

Most CardModules are installed into the rack frames and system tested in the factory. If

this is an upgrade part, or service exchange item then the module is supplied in a padded

cardboard carton which includes the CardModule, rear connection plate and mounting

screws.

Packaging

The shipping carton and packaging materials provide protection for the module during

transit. Please retain the shipping cartons in case subsequent shipping o f the product

becomes necessary. Do not remove the module from its protective static bag unless

observing adequate ESD precautions. Please see below.

ESD Warning

This product is static sensitive. Please use caution and use preventative measures to

prevent static discharge or damage could result to module.

Preventing ESD Damage

Electrostatic discharge (ESD) damage occurs when electronic assemblies or the

components are improperly handled and can result in complete or intermittent failure.

Do not handle the module unless using an ESD-preventative wrist strap and ensure that

it makes good skin contact. Connect the strap to any solid grounding source such as any

exposed metal on the rack chassis or any other unpainted metal surface.

Caution

Periodically check the resistance value of the antistatic strap. The measurement should

be between 1 and 10 Megohms.

Page 6

D VD 5830 Reference Manual. Rev 1.0

Page 6 of 17

Product Description

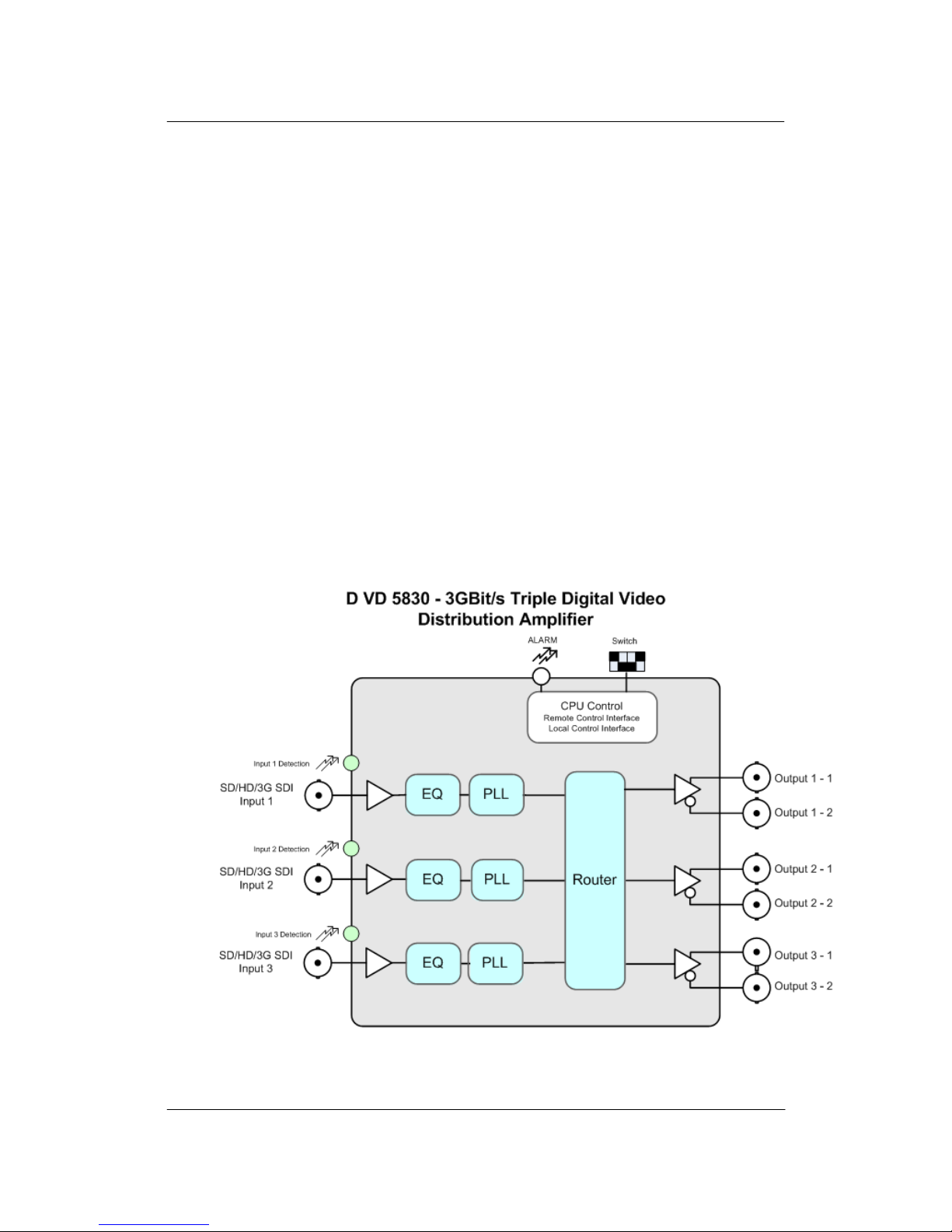

The D VD 5830 is a high quality triple channel 3GBit/s / HD / SD SDI/ASI distribution

amplifier designed primarily for broadcast and professional applications.

Flexible configurations allow the D VD 5830 to be used in dual 1 to 4 applications or 1 to

8 applications. Inputs can be reclocked, or non-reclocked. Auto detection of multirate

digital video bit rates in reclocked mode (143Mbit/s, 177Mbit/s, 270Mbit/s, 360Mbit/s,

1.485 GBit/s, 2.985GBit/s) and will transparently pass data from 15 Mbits/s to 2.985 GBit

Mbits/s in non-reclocked mode.

All outputs are ASI compatible.

Note: To ensure high signal quality the SDI receivers are located on the connection plate.

The D VD 5830 is part of the 5000 series of CardModules, which offer high quality,

modularity and flexibility in a small form factor ideal for applications where space is at a

premium.

Functional Diagram

Page 7

D VD 5830 Reference Manual. Rev 1.0

Page 7 of 17

Module Layout

Module Front Termination Panel

CardModule

Page 8

D VD 5830 Reference Manual. Rev 1.0

Page 8 of 17

Connections

Video

The D VD 5830 uses standard 75 Ohm BNC connectors. We recommend the use of high

quality video cable for digital video connections to reduce the risk of errors due to

excessive cable attenuation. Max cable lengths the modu le will support are shown below.

SDTV = 250m Belden 8281 (270Mbits/s)

HDTV = 140m Belden 1694A (1.485Gbits/s)

3GBit/s = 80m Belden 1694A (2.97Gbits/s)

Note. Due to the compact design of the connection plate it will be necessary to

use a connection tool to secure the BNC video connectors.

Installation

If this module was supplied as part of a system it is already installed in the rack

enclosure. If the module was supplied as a field upgrade please follow the installation

procedure below.

NOTE Observe static precautions when handling card. Please see ESD

warnings on Page 5.

Each Card Module is supplied with a rear connection panel and two mounting screws.

Please follow the following procedure for installation of the card module into the Series

5000 Card Frame.

1. Select a slot in the card frame where the CardModule will be located.

2. Remove the blank connection panel from the rear of the rack (if fitted)

3. Install the rear connection panel using the screws supplied. Do not tighten the

screws fully

4. Slide the card module into the card frame and carefully check the CardModule

connects to the rear connection plate. The card should fit easily and should not

require excessive force to insert, if you feel any resistance, there could be

something wrong with the rear connection panel location. Do not try and force the

connection this may damage the connectors. Remove the rear connection panel

and check alignment with the CardModule.

5. Insert and remove the CardModule a few times to ensure correct alignment and

then tighten the two screws to secure the rear connection plate.

Unused BNC inputs and BNC outputs should be terminated with

75Ohm to avoid any RF interference in between the channels

Page 9

D VD 5830 Reference Manual. Rev 1.0

Page 9 of 17

Settings and Control

The D VD 5830 has an integrated micro-controller, which enables the module to be

configured and controlled locally via the dip-switch or from remote when using one of the

optional controllers and control software.

Once set, all settings are automatically saved in non-volatile internal memory. (Flash

ram) The module will always recall the settings used prior to power down.

Page 10

D VD 5830 Reference Manual. Rev 1.0

Page 10 of 17

Switch Settings

Below the switch settings for the 8-position dip-switch are defined.

Switch Function Detail

Dip Switch 1

This switch is used to enable or disable local adjustments. Set to ON enables the setting

of the other dip switches to configure the module. Set to OFF will prevent any switch

settings taking effect.

Note. The module has a microcontroller and flash ram. When this switch 1 is set to ON

any configuration settings made on the module with the dip switches will automatically be

written into flash ram and stored. (see Auto Store) The module will function normally with

the switch left in the ON position but it is recommended to set it to OFF to prevent

accidental changes to the stored module configuration if the switches are moved.

Dip Switch 2,3 and 4

This switch configures channels be reclocked or non reclocked. ON sets reclocked, OFF

sets non-reclocked

Dip Switch 5, 6 and 7

Not used

Dip Switch 8

This switch configures the slew rate for the outputs if in non-reclocked mode. Set to

SLOW (OFF) for SD signals, set to FAST (ON) for HD or 3GBIt/s signals

Swit

ch

Setting Function

1

ON Enable Local Adjustment

OFF Disable Local Adjustment

2

ON Output 1 reclocked

OFF Output 1 non-reclocked

3

ON Output 2 reclocked

OFF Output 2 non-reclocked

4

ON Output 3 reclocked

OFF Output 3 non-reclocked

5

ON

OFF

6

ON

OFF

7

ON

OFF

6

ON Outputs: Fast Slew Rate in non-reclocked mode

OFF Outputs: Slow Slew Rate in non-reclocked mode

Page 11

D VD 5830 Reference Manual. Rev 1.0

Page 11 of 17

Factory Preset Condition

The D VD 5830 is delivered programmed and preset for the following mode of operation:

Switch 1 ON Local Adjustment Enabled

Switch 2 -4 ON reclocked

Switch 8 ON FAST

If this is the mode of operation required, then no adjustments are necessary.

Auto Store

If no parameters are changed for 10 seconds then the current settings will be written into

flash memory automatically, this can be seen by the channel status LEDS flashing yellow

four times.

Page 12

D VD 5830 Reference Manual. Rev 1.0

Page 12 of 17

Alarm/LED Status Indicators

The D VD 5830 module has integral LED indicators, which serve as alarm and status

indication for the module. Function is described below.

Channel Condition Indicators LED 1, 2 and 3

3 status LEDs are provided to indicate the status of the SDI inputs,

Alarm Indicator

There is also a single alarm LED on the lower edge of the module.

This is visible through the card frame front cover and provides a general indication

of the module status.

LED OFF indicates power is lost, or there is a power supply fault.

Local/remote LED

Power Indication

There are two LEDs on the lower edge of the module indicating the presence of the two

power supply voltages (main power supply and redundant power supply).

LED Color Indication

Green

Input Present

Red

Input missing

LED Color Indication

Green

All Signals Present (locked)

Yellow

one or two signals missing

Red

All Input signals missing

LED Color Indication

Gree

Local control via DIP switches active, all

settings according to local DIP switches

off

Current settings may be overwritten

through remote control

LED 1 Indication

Green

Power from Main PSU ok

off

No power from Main Power Supply

LED 2 Indication

Green

Power from Redundant PSU ok

off

No power from Redundant PSU

Page 13

D VD 5830 Reference Manual. Rev 1.0

Page 13 of 17

Control System GUI

When using the module in a system with the optional LYNX control system all module

settings are available on an intuitive Windows GUI interface.

Any settings made using the control system will override any settings made locally. All

settings are stored automatically in the module flash R AM .

The above screenshot shows the complete module GUI. The Device info area contains

information about the module including name and firmware revision. If used as part of a

larger system (using the LYNX central control system) the modules position and physical

location is displayed above the “locate” button.

Note. The Locate function is a tool used to quickly identify a module in larger

systems. Selecting “locate” will flash the module alarm LED yellow. (This does

not effect module operation)

The first screen displayed when the module is selected is the Main Tab this is a graphical

representation of the modules overall function and signal flow (left to right).

The area at the bottom of the screen is the error log. Any fault condition (or event) will be

time stamped and entered into the log.

There are a number of “Tabs” along the top of the screen which splits up the module

settings into a number of logical displays. The various GUI screens and primary functions

are described below.

Page 14

D VD 5830 Reference Manual. Rev 1.0

Page 14 of 17

Main Tab

This screen is the main interface and is presented first when the module is displayed in

the GUI.

The input detection indicates the bit rate of a connected signal. If no signal is

detected the color of the input detection will turn red.

The three check boxes enable or disable the input re-clocking of the respective

input.

The three sets of two outputs can be mapped on either of the three inputs by

using the 3 x 3 selection matrix. Just click on the radio buttons to set a cross

point.

Unused BNC inputs and BNC outputs should be terminated with

75Ohm to avoid any RF interference in between the channels

Page 15

D VD 5830 Reference Manual. Rev 1.0

Page 15 of 17

Events Tab

The Events Tab is where the module alarming and error notifications are configured for

the module.

The GUI has an integrated error log, which is a simple text log file stored in the controller

PC. This will record an event and timestamp it. The log can be seen at the bottom of the

GUI screen and can be scrolled through using the scrolling bar.

Log in GUI Function

Events are selectable, you can chose if you want to record a particular event in the log

(or not) or configure it to only record one side of the event. (For example you might want

to log when a SDI input was removed but do not want to log when it came back). The

ON/OFF trigger can be configured for each of the available events shown in the list and is

setup using the checkboxes provided.

Event Enabled

By default all alarm conditions are activated (checked), by de-selecting a specific alarm

condition in this column you are telling the module to ignore this condition completely. It

will not color the Alarm LED, log and event in the GUI or send a SNMP trap. This is

useful if for example you never have anything connecte d to input 2 and want the card to

ignore this input condition completely you would simply de-select “SDI Input 2 No Input”

and it will be ignored.

SNMP Support

If the system is using a RCT 5031 Master Controller and the SNMP option is installed

then the “SNMP Trap” columns become available.

Here you can configure what events you would like to transmit a “SNMP trap” for over the

network. (This has no impact or influence over the internally error log maintained by the

LYNX control system)

(Internal LYNX error logging and external SNMP traps can be configured independently).

Note. The simulated event is part of the GUI simulator and allows us to force a

particular error condition for testing and demonstration purposes.

Page 16

D VD 5830 Reference Manual. Rev 1.0

Page 16 of 17

Specifications

V

ideo Inputs

Signal Type Serial digital video SMPTE 292M, 259M-C, 424M

No. of inputs 3 (one for each channel)

Connector BNC

Impedance 75 Ohm

Cable

Equalization

Up to 250m Belden 8281 (270MBit/s)

Up to 140m Belden 1694A (1.485GBit/S)

Up to 80m Belden 1694A (2.97GBit/s)

Return Loss > 15 dB (270MBit/s)

> 10dB (1.485GBit/s)

Digital Video Outputs

Signal Type Serial digital video SMPTE 259M-C, 292M, 424M

No. of outputs 3 (3 outputs in pairs of 2)

Connector BNC

Impedance 75 Ohms

Jitter < 0.2 UI (270MHz)

< 0.2 UI (Alignment Jitter); < 1.0 UI (Timing Jitter); (1.485GHz)

< 0.3 UI (Alignment Jitter); < 3.0 UI (Timing Jitter); (2.97GHz)

Return Loss > 15 dB (1.5GBit/s)

Control

Local Controls Dip Switch

Remote Control Comprehensive remote control and status monitoring supported when used with a LYNX Controller

option

Electrical Specifications

Voltage 12 VDC

Power <5 W

Safety IEC 60950/ EN 60950/ VDE 0805

Mechanical

Size 283mm x 78mm

Weight CardModule 150g, connector plate 70g

Ambient

Temperature 5°C to 40°C Maintaining specifications

Humidity 90% Max non condensing

Page 17

D VD 5830 Reference Manual. Rev 1.0

Page 17 of 17

Service

Parts List

Due to the very dense design and high level of integration there the module is not user

serviceable. Please contact LYNX for repairs or to request an exchange unit.

Technical Support

If you are experiencing problems, or have questions please contact your local distributor

for further assistance.

Technical support is also available from our website.

Please do not return products to LYNX without an RMA. Please contact your authorized

dealer or reseller for more details.

More detailed product information and product updates may be available on our web site:

www.lynx-technik.com

Contact Information

Please contact your local distributor; this is your local and fastest method for obtaining

support and sales information.

LYNX Technik can be contacted directly using the information below.

Address LYNX Technik AG

Brunnenweg 3

D-64331 Weiterstadt

Germany

Website www.lynx-technik.com

E-Mail info@lynx-technik.com

LYNX Technik manufactures a complete range of high quality modular products for

broadcast and Professional markets, please contact your local representative or visit our

web site for more product information.

LYNXTechnik AG

Broadcast Television Equipment

®

Loading...

Loading...