LynTec PDS-10 User Manual

L y n T e c PDS-10 series Power Delay Sequencer

Relay based power sequencer for sound systems — Turns on front-end gear first, power amplifiers last Protects expensive loudspeaker systems from damaging power-on or power-off click & pop transients

Tested, complete package — low labor — mount next to any circuit breaker panel to sequence AC power "hot" lines

Time proven, reliable, G-E RR7P3 latching relays snap in and have low voltage plug-in connectors

Low power consumption — no continuous relay coil current

— runs cool for long life

Diagnostic LEDs and internal ON - OFF test switches speed installation for testing and troubleshooting

Cabinet and all components connected to high voltage are UL listed — low voltage electronics are isolated.

4, 8 or 10 20/30 A circuits — 120 or 240 volt models available

Up to 6 One Touch remote control locations possible

Kill function uses external contact for instantaneous shutdown.

HurryOff function shuts down immediately if you hold down any OFF button for 2 seconds.

Great for Ohh.... no........ situations.

Daisy-chains for unlimited circuit count. Interfaces with LynTec MSLC, MSP, SLC, SP or multiple PDS sequencing systems.

New Features

Multiple delay options.

Variable step rate

Completion contact option on last step can be used for additional indicators or to trigger more equipment.

ONE TOUCH

REMOTE POWER CONTROL

SHOWN ACTUAL SIZE

Green LED illuminated |

Red |

SS-2 Sequencer Switch Set

One SS-2 switch set is supplied with each panel.

How they work

Applies AC to low level, frontend electronics... waits for them to stabilize... (clicks and pops are ignored by un-powered power amplifi ers)...

AC is then sequenced to power amplifi ers spreading high inrush currents over time.

Protects valuable loudspeaker systems by delaying turn-on until all low level equipment has stabilized.

139-0512-00.1 |

Page 1 of 4 |

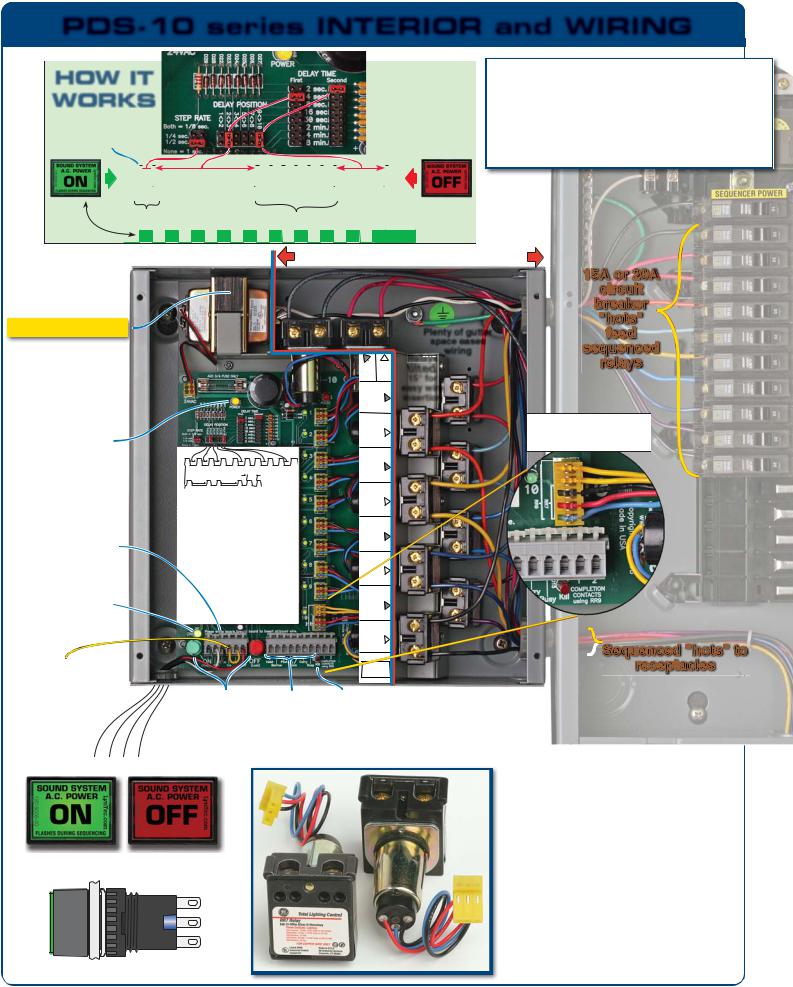

PDS-10 series INTERIOR and WIRING

HOW IT

WORKS |

|

|

|

|

|

|

|

|

|

Easily selectable |

||||||

|

|

|

|

|

|

|

|

|

Circuit jumpers |

|||||||

Sequencer pulses on |

|

|

|

|

|

|

|

|

|

set field adjustable |

||||||

|

|

|

|

|

|

|

|

|

|

programming |

||||||

and off coils of latching |

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

power relays. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 second delay |

|

|

|

|

|

|

|

|

2 second |

|

|

|

|

|

|

|

allows front end stabilization |

|

|

|

|

|

|

|

|

COMPLETION |

|

timing.eps |

||

AC circuit #1 2 |

3 4 5 6 7 8 9 |

|

Optional |

|||||||||||||

CONTACT |

10 |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

delay |

|

|

|

|

|

Front End Electronics |

|

|

Power Amplifiers |

|

RR9 auxiliary |

-00.2c |

|||||||||

|

|

|

|

COMPLETION |

||||||||||||

Shaded area indicates ON LED illumination |

|

|

|

|

|

|

|

|

|

CONTACTS |

0512 |

|||||

|

|

|

|

|

|

|

|

|

close. |

- |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

139 |

ON

This circuit breaker panel is shown for illustration purposes and is not sold by LynTec.

To avoid nuisance circuit breaker tripping on high inrush current devices, specify High Magnetic circuit breakers.

High Magnetic type breakers typically have the HM suffix such as Square D QO120HM, Cutler Hammer CH120HM or G-E THQL1120HM.

LOW VOLTAGE SECTION

LOW VOLTAGE SECTION

DIVIDING

24 V — 40 VA Power transformer. WALL Connect to 10A circuit breaker.

Mark

SEQUENCER POWER

with supplied label.

HIGH VOLTAGE SECTION

Plenty of gutter space eases wiring

|

|

|

|

Relays |

Relay |

Relay |

tilted |

||

STEP |

A |

STEP |

B |

|

|

|

15° for |

||

STEP |

Relay |

easy wire |

||

___ = C |

|

insertion |

||

15A or 20A circuit breaker "hots" feed sequenced relays

POWER led

Lever actuated cage-clamp terminal strips.

Press white levers toward board to insert stripped wire.

ON led Flashes during sequencing, stays lit at end of on sequence.

V+ to V- jumper must be in LAST sequencer in system to guarantee ON led stays on at the end of the on sequence.

146-0328-00e

|

|

|

|

|

|

|

|

|

|

|

STEP |

Relay |

|

|

|

|

|

|

|

|

|

|

|

___ = D |

|

1 |

2 |

3 |

|

4 |

5 |

6 |

7 |

8 |

9 |

10 |

STEP |

Relay |

|

___ = E |

|||||||||||

|

|

TIMING DIAGRAM |

STEP |

|

|

|

|

|||||

|

First |

|

Second |

RATE |

|

|

|

|

|

|

||

1 |

Delay |

3 |

|

Delay |

5 |

6 |

|

|

|

|

|

|

|

2 |

|

4 |

|

|

|

|

|

||||

START |

|

DELAY TIME and STEP RATE are |

|

|

|

|

STEP |

Relay |

||||

Press |

|

1 second if no jumpers are installed. |

|

|

|

|

||||||

ON |

|

|

|

|

|

|

|

|

|

|

|

= F |

switch |

|

|

PDS-10 |

|

|

___ |

||||||

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

||||||

|

www.LynTec.com |

800-724-4047 |

|

|

|

|||||||

How it works |

|

|

|

|

|

|

|

STEP |

Relay |

|||

When an ON button is activated, the on |

LED starts |

|

||||||||||

|

|

= G |

||||||||||

flashing. Steps 1 to 10 are activated with delays as |

|

___ |

||||||||||

determined by selected jumpers. The process is reversed |

||||||||||||

when the OFF button is pressed. |

|

|

|

|

|

|

|

|||||

ZipOff |

|

|

|

|

|

|

|

|

|

|

|

|

2 seconds after power fails, all relays will zip-off, shedding |

STEP |

Relay |

||||||||||

the load. System will automatically re-sequence when |

|

___ = H |

||||||||||

power resumes. |

|

|

|

|

|

|

|

|

||||

KILL |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

Connecting the KILL terminal to common will light the |

|

|

|

|||||||||

KILL LED and trigger ZipOff, turning off all relays.When |

|

|

|

|||||||||

the KILL contact is opened the KILL LED will extinguish |

|

STEP |

Relay |

|||||||||

and the on sequence will resume. |

|

|

|

|

___ = I |

|||||||

HurryOff |

|

|

|

|

|

|

|

|

||||

Holding down the OFF button for 2 seconds will invoke |

|

|

|

|||||||||

ZipOff without an automatic restart. Press ON to restart. |

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

STEP |

Relay |

|

|

|

|

|

|

|

|

|

|

|

___ = J |

|

|

|

|

|

|

|

|

|

|

|

|

as-built |

|

|

|

|

|

|

|

|

|

|

|

|

RELAY |

|

|

|

|

|

|

|

|

|

|

|

|

STEP order |

|

|

|

|

|

|

|

|

|

|

|

|

146-0149-02 PDS-810 Relay Cap |

|

|

Test switches |

|

|

Expansion |

Connect Kill line to Common with external switch |

|||||||

|

provide local |

|

|

terminals for |

|

for immediate shutdown. |

||||||

|

|

control for |

|

|

daisy-chaining |

Kill led lights to indicate external switch closure. |

||||||

|

troubleshooting |

|

to other LynTec |

Sequence resumes operation when switch opens. |

||||||||

|

remote switch |

|

|

sequencers |

|

|

||||||

wiring.

GE RR7P3 Latching Relay

-CC option

RR9 Replaces RR7 to add Completion Contacts.

Sequenced "hots" to receptacles

Sequenced "hots" to receptacles

Supplied SS-2 remote Switch Set — Actual Size

Wiring: Typically "half" of a Cat 5 cable. 4 conductors - 22-26 ga. - 5,000 ft. max.

idec

Switches mount in 5/8" dia. round holes on 1" centers in material up to 1/4" thick. Solder wire connections.

139-0512-00.2

GE RR7 and RR9 Relay ratings

Power Contacts: Latching

20A Tungsten, 125Vac 1/2HP motor at 110-125Vac

30A Ballast, 277Vac 1 1/2 HP motor at 277Vac

30A Resistive, 277Vac

20A Ballast, 347Vac 1 1/2 HP motor at 220-277VAC 20A Resistive, 347Vac

FOR COPPER WIRE ONLY

This product is NEC 110 Compliant when used in accordance with the following: Suitable For Use On A Circuit Capable Of Delivering Not More Than 10 kA Sym. Amps., 277 Volts Maximum.

UL Listed 508G Industrial Control Equipment — CSA certified

Low voltage characteristics — RR7P3 and RR9P5

P3 and P5 suffi xes denote a 3 pin and 5 pin, .156" AMP or Molex connector respectively.

RR9 pilot contact rating: (COMPLETION CONTACTS)

Normally open, 1A, 24 VAC isolated, close at end of on sequence.

Actuating coils: 21-30 Vac (class 2) Momentary. OFF (1-black),

ON (2-red), Common (3-Blue) 55-60 Ohms DCR, each coil.

Page 2 of 4

Loading...

Loading...