Page 1

®

IVD MAGPIX

Hardware

Installation and User

Manual

Page 2

Luminex IVD MAGPIX Hardware Installation and User Manual

WMDE

Bergerweg 18

6085 AT Horn

The Netherlands

© Luminex Corporation, 2010. All rights reserved. No part of this publication may be

reproduced, transmitted, transcribed, or translated into any language or computer

language, in any form or by any means without prior express, written consent of:

LUMINEX CORPORATION

12212 Technology Boulevard

Austin, Texas 78727-6115

Voice: (512) 219-8020

Fax: (512) 219-5195

U.S.A.

Luminex® IVD MAGPIX® Hardware Installation and User Manual

PN 89-00002-00-272 Rev. A

October 2010

Luminex Corporation (Luminex) reserves the right to modify its products and services at

any time. This guide is subject to change without notice. Although prepared to ensure

accuracy, Luminex assumes no liability for errors or omissions, or for any damages

resulting from the application or use of this information.

2

The following are trademarks or registered trademarks of Luminex: Lumine x, xMAP,

MagPlex,

All other trademarks, including Windows, Sporicidin, Cole-Parmer

are trademarks of their respective companies.

xPONENT, and MAGPIX.

, Parafilm, and ProClin

Page 3

Standard Terms and Conditions For Use of Instrument Product

By opening the packaging containing this product ("Product") or by using such Product in any manner, you are

consenting and agreeing to be bound by the following terms and conditions. You are also agreeing that the following

terms and conditions constitute a legally valid and binding contract that is enforceable against you. If you do not

agree to all of the terms and conditions set forth below, you must promptly return the Product for a full refund prior to

using them in any manner.

1. Acceptance - ALL SALES ARE SUBJECT TO AND EXPRESSLY CONDITIONED UPON THE TERMS AND

CONDITIONS CONTAINED HEREIN, AND UPON BUYER'S ASSENT THERETO. NO VARIATION OF THESE

TERMS AND CONDITIONS SHALL BE BINDING UPON LUMINEX CORPORATION ("LUMINEX") UNLESS

AGREED TO IN WRITING AND SIGNED BY AN AUTHORIZED REPRESENTATIVE OF LUMINEX. For purposes of

this agreement, "Seller" shall mean either Luminex, if the Product is purchased directly from Luminex, or a Luminex

authorized reseller. Buyer, by accepting the Product shall be deemed to have assented to the terms and conditions

set forth herein, notwithstanding any terms contained in any prior or later communications from Buyer and whether or

not Seller shall specifically or expressly object to any such terms.

2. Warranties - THIS WARRANTY IS APPLICABLE FOR PARTS AND SERVICE FOR LUMINEX INSTRUMENTS

PURCHASED DIRECTLLY FROM LUMINEX TO BUYER AND ONLY TO THE EXTENT SUCH INSTRUMENTS ARE

LOCATED IN NORTH AMERICA AND THE COUNTRIES THAT COMPRISE THE EUROPEAN UNION. LUMINEX

MAKES NO WARRANTY, EITHER EXPRESS OR IMPLIED, WITH RESPECT TO PRODUCTS SOLD,

DISTRIBUTED, LOCATED OR USED OUTSIDE OF NORTH AMERICA OR THE COUNTRIES COMPRISING THE

EUROPEAN UNION. PRODUCTS SOLD OUTSIDE OF NORTH AMERICA OR THE COUNTRIES COMPRISING

THE EUROPEAN UNION ARE SOLD ONLY ON AN "AS IS, WHERE IS" BASIS. NOTWITHSTANDING THE

FOREGOING, LUMINEX SHALL PROVIDE BUYER A WARRANTY ON FIELD SERVICE PARTS PROCURED

FROM LUMINEX FOR MAINTENANCE OF LUMINEX INSTRUMENTS IN ALL COUNTRIES IN THE WORLD AND

PER THE TERMS AND CONDITIONS HEREIN. TO THE EXTENT THAT THE FOREGOING DISCLAIMERS ARE

INVALID OR UNENFORCEABLE UNDER THE LAWS OF ANY JURISDICTION, THE WARRANTY, DISCLAIMER,

LIMIT ATION OF LIABILITY AND OTHER PROV ISIO NS SET FORTH BELOW SHALL THEREUPON BE EFFECTIVE

TO THE FULLEST EXTENT PERMITTED BY APPLICABLE LAW.

Notwithstanding Buyer's acceptance thereof, if Product is purchased directly from Luminex, Luminex warrants that for

a period of twelve (12) months from date of delivery that the Product sha ll conform in all material respects with the

Product Specifications provided by Luminex with the Product. The warranty provided herein specifically excludes any

software or hardware not provided by Luminex. If Product is purchased from a Luminex authorized reseller, any

warranty obligations shall be provided in writing directly by such Luminex authorized reseller to Buyer. THIS

WARRANTY IS EXCLUSIVE AND LUMINEX MAKES ANY OTHER WARRANTY, EXPRESS OR IMPLIED,

INCLUDING WITHOUT LIMITATION ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. Seller's warranties made in connection with this sale shall not be effective if Seller has

determined, in its sole discretion, that Buyer has misused the Product in any manner, has failed to use the Product in

accordance with industry standards or practices or has failed to use the Product in accordance with instructions, if

any, furnished by Seller.

BUYER'S EXCLUSIVE REMEDY WITH RESPECT TO PRODUCT PROVED TO SELLER'S SATISFACTION TO BE

DEFECTIVE OR NONCONFORMING SHALL BE REPAIR OR REPLACEMENT OF SUCH PRODUCTS WITHOUT

CHARGE OR REFUND OF THE PURCHASE PRICE, IN SELLER'S SOLE DISCRETION, UPON THE RETURN OF

SUCH PRODUCTS IN ACCORDANCE WITH SELLER'S INSTRUCTIONS BELOW. NEITHER SELLER NOR

LUMINEX SHALL IN ANY EVENT BE LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES OF

ANY KIND RESULTING FROM ANY USE OR FAILURE OF THE PRODUCT, EVEN IF SELLER OR LUMINEX HAS

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGE INCLUDING, WITHOUT LIMITATION, LIABILITY FOR

LOSS OF WORK IN PROGRESS, DOWN TIME, LOSS OF REVENUE OR PROFITS, FAILURE TO REALIZE

SAVINGS, LOSS OF PRODUCTS OF BUYER OR OTHER USE OR ANY LIABILITY OF BUYER TO A THIRD

PARTY ON ACCOUNT OF SUCH LOSS, OR FOR ANY LABOR OR ANY OTHER EXPENSE, DAMAGE OR LOSS

OCCASIONED BY SUCH PRODUCT INCLUDING PERSONAL INJURY OR PROPERTY DAMAGE UNLESS SUCH

PERSONAL INJURY OR PROPERTY DAMAGE IS CAUSED BY SELLER'S GROSS NEGLIGENCE.

In the event that Product is located outside of North America or the European Unio n and fails to conform to the

warranty set forth herein, during the warranty period: (i) Buyer shall notify Luminex in a timely manner in writing that

Page 4

Luminex IVD MAGPIX Hardware Installation and User Manual

such Product failed to conform and shall furnish a detailed explanation of any alleged

nonconformity; (ii) Buyer at it's expense will contract either Luminex or a Luminex trained service

engineer to assess the issue and identify the defective FS-PART; and (ii) at Luminex's option and

election, Buyer shall either return such nonconforming Product to Luminex's manufactu ring facility

or destroy such Product and provide Luminex with written certification of destruction. In the event

that a FS-PART is returned to Luminex's manufacturing facility, Luminex may analyze such FSPART for defects. In the event that Luminex determines that su ch FS-PART is not defective, the

FS-PART shall be shipped to Buyer then Buyer shall be responsible for the payment for such FSPART and related shipping charges. Furthermore, in the event that Luminex determine s that such

FS-PART is defective then Luminex shall be responsible for the payment for such FS-PART and

related shipping charges. Except as expressly provided herein, Buyer shall not have the right to

return a Product to Luminex without Luminex's prior written consent.

3. Buyer's Use of Product - Buyer shall not use this Product for any commercial purpose, including

without limitation performance of testing services, unless expressly agreed to in writing by Luminex

or as specifically authorized by Luminex through a Luminex distributor. Buyer agrees that no rights

or licenses under Luminex's patents shall be implied from the sale of the Product, except as

expressly provided herein or as specifically agreed to in writing by Luminex, and Buyer does not

receive any right under Luminex's patent rights hereunder. Buyer acknowledges and agrees that

the Product are sold and licensed only for use with Luminex's laser based fluorescent analytical test

instrumentation. Buyer further acknowledges that, unless otherwise indicated on the Product label,

the Product has not received approval from the United States Food and Drug Administration or

other federal, state or local regulatory agencies and have not been tested by Seller or Luminex for

safety or efficacy in food, drug, medical device, cosmetic, commercial or any other use, unless

otherwise stated in Seller's technical specifications or material data sheets furnished to Buyer.

Buyer expressly represents and warrants to Seller that Buyer will use the Product in accordance

with the Product label, if applicable, and will properly test and use any Product in accordance with

the practices of a reasonable person who is an expert in the field and in strict compliance with the

United States Food and Drug Administration and all applicable domestic and international laws and

regulations, now and hereinafter enacted.

BUYER HEREBY GRANTS TO LUMINEX A NONEXCLUSIVE, WORLDWIDE, UNRESTRICTED,

ROYALTY-FREE, FULLY PAID-UP LICENSE, WITH THE RIGHT T O GRANT AND AUTHORIZE

SUBLICENSES, UNDER ANY AND ALL PATENT RIGHTS IN INVENTIONS COMPRISING

MODIFICATIONS, EXTENSIONS, OR ENHANCEMENTS MADE BY BUYER TO THE PRODUCT

OR TO THE MANUFACTURE OR USE OF THE PRODUCT ("IMPROVEMENT PATENTS"), TO

MAKE, HAVE MADE, USE, IMPORT, OFFER FOR SALE OR SELL ANY AND ALL PRODUCT;

EXPLOIT ANY AND ALL METHODS OR PROCESSES; AND OTHERWISE EXPLOIT

IMPROVEMENT PATENTS FOR ALL PURPOSES. NOTWITHSTANDING THE FOREGOING,

"IMPROVEMENT PATENTS" SPECIFICALLY EXCLUDES PATENT CLAIMS CONCEIVED AND

REDUCED TO PRACTICE BY BUYER CONSISTING OF METHODS OF SAMPLE

PREPARATION, METHODS OF CONJUGATING PRODUCT TO ANAL YTES, THE COMPOSITION

OF MATTER OF THE SPE CIFIC CHEMISTRIE S OF THE ASSAYS DEVELOPED BY BUYER AND

METHODS OF PERFORMING THE ASSAYS (I.E ., THE PROTOCOL FOR THE ASSAY).

Buyer has the responsibility and hereby expressly assumes the risk to verify the hazards and to

conduct any further research necessary to learn the hazards involved in using the Product. Buyer

also has the duty to warn Buyer's customers, employees, agents, assigns, officers, successors and

any auxiliary or third party personnel (such as freight handlers, etc.) of any and all risks involved in

using or handling the Product. Buyer agrees to comply with instructions, if any, furnished by Seller

or Luminex relating to the use of the Product and not misuse the Product in any manner. Buyer

shall not reverse engineer, decompile, disassemble or modify the Product. Buyer acknowledges

that Luminex retains ownership of all patents, trademarks, trade secrets and other proprietary rights

relating to or residing in the Product and Buyer receives no rights to such intellectual property rights

by virtue of its purchase of Product other than as expressly set forth herein. Buyer shall have no

right to use any trademarks owned or licensed to Luminex without the express written permission of

Luminex.

4. Buyer's Representations, Release and Indemnity - Buyer represents and warrants that it shall

use the Product in accordance with Paragraph 2, "Buyer's Use of Product," and that any such use

4

Page 5

of Product will not violate any law, regulation, judicial order or injunction. Buyer agrees to release, discharge, disclaim

and renounce any and all claims, demands, actions, causes of action and/or suits in law or equity, now existing or

hereafter arising, whether known or unknown, against Seller and Luminex, and their respective officers, directors,

employees, agents, successors and assigns (collectively the "Released Parties"), with respect to the use of the

Product. Buyer agrees to indemnify and hold harmless the Re leased Parties from and against any suits, losses,

claims, demands, liabilities, costs and expenses (including attorney, accounting, expert witness, and consulting fees)

that any of the Released Parties may sustain or incur as a result of any claim against such Released Party based

upon negligence, breach of warranty, strict liability in tort, contract or any other theory of law or equity arising out of,

directly or indirectly, the use of the Product or by reason of Buyer's failure to perform its obligations contained herein.

Buyer shall fully cooperate with the Released Parties in the investigation and determination of the cause of any

accident involving the Product which results in personal injury or property damage and shall make available to the

Released Parties all statements, reports, recordings and tests made by Buyer or made available to Buyer by others.

5. Patent Disclaimer - Neither Seller nor Luminex warrants that the use or sale of the Product will not infringe the

claims of any United States or other patents covering the product itself or the use thereof in combination with other

products or in the operation of any process.

End-User License Agreement (EULA) for Luminex® Software

This Luminex End-User License Agreement (“EULA”) is a legal agreement between you (either an individual or a

single entity, also referred herein as “you”) the end-user and Luminex Corporation (“Luminex”) regarding the use of the

xPONENT software product provided to yo u ab o v e , whi ch includes computer SOFTWARE and online or electronic

documentation and may include associated media and printed materials (if any) (“SOFTWARE”). The terms also apply

to any updates, supplements, web content or internet-based services, such as remote access.

BY USING THE SOFTWARE, YOU ACCEPT THESE TERMS. IF YOU DO NOT ACCEPT THEM, DO NOT USE THE

SOFTWARE. INSTEAD, RETURN IT TO LUMINEX OR THE LUMINEX AUTHORIZED THIRD PARTY FROM WHICH

YOU PURCHASED THE SOFTWARE FOR A REFUND OR CREDIT. IF YOU COMPLY WITH THESE LICENSE

TERMS, YOU HAVE THE RIGHTS TO USE THE SOFTWARE AS SPECIFICALLY SET FORTH BELOW.

1. OVERVIEW. The SOFTWARE is protected by copyright laws and international copyright treaties, as well as other

intellectual property laws and treaties. The SOFTWARE is licensed, not sold.

2. ADDITIONAL LICENSING REQUIREMENTS AND/OR USE RIGHTS.

a) Trial and Conversion. Some or all of the SOFTWARE may be licensed on a trial basis. Your rights to use trial

SOFTWARE are limited to the trial period. The trial SOFTWARE and length of the trial period are set forth

during the activation process. The SOFTWARE may be used for evaluation purposes only during the trial

period and not for any commercial use, including without limitation to any diagnostic use. You may have the

option to convert your trial rights to perpetual rights. Conversion options will be presented to you at the

expiration of your trial period.

b) Activation. You can activate the SOFTWARE by obtaining a license key provided by Luminex Techn ical

Support at

c) Branding. You may only add additional branding or other graphics to SOFTWARE with Luminex’s express

written consent.

d) Upgrades. You may only obtain updates or upgrades for the SOFTWARE from Luminex Technical Support at

orders@luminexcorp.com or authorized resellers. For more information on obtaining updates from authorized

resellers, see http://www.luminexcorp.com.

3. GRANT OF LICENSE. Subject to the terms and conditions of this EULA, Luminex hereby grants to you a

nonexclusive, nontransferable, nonassignable license (without right to sublicense) under Luminex’s copyrights

and trade secrets to use the SOFTWARE on a single computer running with a single unit of a specific model of

Luminex instrument, as such model is identified on the packaging included with the SOFTWARE. You may make

one (1) copy of the SOFTWARE for backup or archival purposes only. You may also install the SOFTWARE on up

support@luminexcorp.com or 1-877-785-2323 or 1-512-381-4397.

Page 6

Luminex IVD MAGPIX Hardware Installation and User Manual

to three (3) additional computers for purposes of performing ancillary tasks (i.e. preparing

templates/protocols, performing further analysis or re-running previous data), provided such

computers are at a single location and are NOT connected with a Luminex instrument. In

addition, You may purchase the right to use the SOFTWARE on additional computers, as

agreed to in writing with Luminex or its authorized reseller, for purposes of performing ancillary

tasks (i.e. preparing templates/protocols, performing further analysis or re-running previous

data), provided such computers are at a single location and are NOT connected with a Luminex

instrument. Although no rights or licenses under any of Luminex's patents are granted by or

shall be implied from the license of the SOFTWARE or the sale of Luminex instrumentation to

you, the purchaser, you may obtain a license under Luminex’s patents, if any, to use this unit of

Luminex instrumentation with fluorescently labeled microsphere beads authorized by Luminex

by purchasing such beads from Luminex or an authorized Luminex reseller.

4. RESTRICTIONS

• SOFTWARE must only be installed and operated on a single computer running with a

Luminex instrument, as set forth above.

• You may not use this SOFTWARE for any commercial purpose, including in the

performance of testing services, unless expressly agreed to in writing by Luminex or as

authorized in writing by Luminex through an authorized reseller of the SOFTWARE.

• You may only use the SOFTWARE with microspheres manufactured by Luminex or with kits

developed, manufactured and distributed by licensees authorized in writing by Luminex.

• You must maintain all proprietary notices on all copies of the SOFTWARE.

• You may not distribute copies of the SOFTWARE to third parties.

• You may not reverse-engineer, decompile, disassemble, or otherwise attempt to derive

source code from the SOFTWARE.

• You may not copy (other than one backup or archival copy), distribute, sublicense, rent,

lease, transfer or grant any rights in or to all or any portion of the SOFTWARE.

• You must comply with all applicable laws regarding the use of the SOFTWARE.

• You may not modify or prepare derivative works of the SOFTWARE, including modifying any

branding or graphics.

• You may not use the SOFTWARE in a computer-based service business or publicly display

visual output of the SOFTWARE.

• You may not transmit the SOFTWARE over a network, by telephone, or electronically by any

means.

5. TERM AND TERMINATION. Your rights under this EULA are effective until termination. You

may terminate this EULA at any time by destroying the SOFTWARE, including all computer

programs and documentation, and erasing any copies residing on your computer equipment.

Luminex may terminate this EULA upon thirty (30) days written notice to you. Your rights under

this EULA automatically terminate without further action on the part of Luminex if you do not

comply with any of the terms or conditions of this EULA. Upon any termination of this EULA, you

agree to destroy the SOFTWARE and erase any copies residing on your computer equipment.

6. RIGHTS IN SOFTWARE. All rights and title in and to the SOFTWARE and any copies thereof

are owned by Luminex or its suppliers. This EULA is not a sale and does not transfer to you any

title or ownership interest in or to the SOFTWARE or any patent, copyright, trade secret, trade

name, trademark or other intellectual property right therein. You shall not remove, alter, or

obscure any proprietary notices contained on or within the SOFTWARE and shall reprodu ce

such notices on any back-up copy of the SOFTWARE. All title and intellectual property rights in

and to the content which may be accessed through use of the SOFTWARE is the property of

the respective content owner and may be protected by applicable copyright or other intellectual

property laws and treaties. This EULA grants you no rights to use such content.

7. EXPORT RESTRICTIONS. You agree that you will not export or re-export the SOFTWARE to

any country, person, entity, or end-user subject to U.S.A. export restrictions. You hereby

warrant no state or federal agency has suspended, revoked, or denied your export privileges.

6

Page 7

8. NO WARRANTY. THE SOFTWARE IS LICENSED “AS IS.” ANY USE OF THE SOFTWARE IS AT YOUR OWN

RISK. THE SOFTWARE IS PROVIDED FOR USE ONLY WITH LUMINEX PRODUCTS. TO THE MAXIMUM

EXTENT PERMITTED BY APPLICABLE LAW, LUMINEX AND ITS SUPPLIERS DISCLAIM ALL WARRANTIES,

EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, AND NONINFRINGEMENT.

9. LIMITATION OF LIABILITY. IN NO EVENT SHALL LUMINEX OR ITS SUPPLIERS BE LIABLE FOR ANY

SPECIAL, INCIDENTAL, INDIRECT, OR CONSEQUENTIAL DAMAGES WHATSOEVER (INCLUDING,

WITHOUT LIMITATION, DAMAGES FOR LOSS OF BUSINESS PROFITS, BUSINESS INTERRUPTION, LOSS

OF BUSINESS INFORMATION, OR ANY OTHER PECUNIARY LOSS) ARISING OUT OF THE USE OF OR

INABILITY TO USE THE SOFTWARE, EVEN IF LUMINEX HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES.

10. MISCELLANEOUS. This EULA is governed by the laws of the State of Texas, U.S.A., without reference to

conflicts of laws principles. You shall not assign or sublicense or otherwise transfer the rights or license granted

hereunder, by agreement or by operation of law, without the prior written consent of Luminex, and all assignments

in violation of this prohibition shall be null and void. This EULA is the complete and exclusive agreement of

Luminex and you and supersedes all other communications, oral or written, relating to the subject matter hereof.

No change to this EULA shall be valid unless in writing and signed by the party against whom enforcement is

sought. The waiver or failure of Luminex or you to exercise in any respect any right or rights provide d for herein

shall not be deemed a waiver of any further right hereunder. If any provision of this EULA is held unenforceable,

the remainder of this EULA will continue in full force and effect.

Page 8

Luminex IVD MAGPIX Hardware Installation and User Manual

8

Page 9

Table of Contents

Chapter 1: About This Manual............................................................................................. 1

Overview......................................................................................................................... 1

Warnings and Notes........................................................................................................ 1

Symbols .......................................................................................................................... 2

Chapter 2: Safety and Regulatory Considerations............................................................... 3

Intended Use .................................................................................................................. 3

Regulatory Labels and Warnings.................................................................................... 4

Testing and Certifications................................................................................................ 6

Safety Practices.............................................................................................................. 7

General...................................................................................................................... 7

Mechanical ................................................................................................................ 7

Electrical.................................................................................................................... 7

Electromagnetic Compatibility ................................................................................... 7

Bar Code Reader Laser............................................................................................. 8

Heat........................................................................................................................... 8

Fluids......................................................................................................................... 8

Biohazard .................................................................................................................. 8

Indicator Light............................................................................................................ 9

Decontamination Procedure............................................................................................ 9

Disposal of Instrument .................................................................................................... 9

Chapter 3: Installation Procedure ...................................................................................... 11

Unpacking and Assembling the PC............................................................................... 12

Unpacking and Assembling MAGPIX............................................................................ 13

Connecting the Components......................................................................................... 15

Preparing MAGPIX........................................................................................................ 17

Removing the Shipping Plug................................................................................... 17

Installing the Sample Probe..................................................................................... 20

Installing the Drive Fluid.......................................................................................... 22

Powering Up MAGPIX................................................................................................... 25

Performing an Initial Startup.......................................................................................... 27

Installation Diagrams..................................................................................................... 28

Shipping Checklist......................................................................................................... 29

Chapter 4: Technical Overview.......................................................................................... 31

How MAGPIX Operates................................................................................................ 31

System Components. .................................................................................................... 34

Software .................................................................................................................. 34

Hardware................................................................................................................. 34

Reagents................................................................................................................. 35

Subsystems .................................................................................................................. 36

Electronic Subsystem.............................................................................................. 36

Fluidics Subsystem.................................................................................................. 37

i

Page 10

Luminex IVD MAGPIX Hardware Installation and User Manual

Mechanical Subsystem............................................................................................. 42

Optical Subsystem.................................................................................................... 44

Recommended Additional Equipment............................................................................ 44

Uninterruptible Power Supply (UPS) or Surge Protector.......................................... 44

Printer....................................................................................................................... 45

Barcode Labels......................................................................................................... 45

Vortex....................................................................................................................... 45

Bath Sonicator.......................................................................................................... 45

System Specifications.................................................................................................... 45

General Specifications.............................................................................................. 45

Environmental Conditions......................................................................................... 45

Electronics................................................................................................................ 46

Optics ....................................................................................................................... 46

Fluidics ..................................................................................................................... 46

Microtiter Plates ........................................................................................................ 46

Microspheres............................................................................................................ 46

Chapter 5: Operational and Maintenance Procedures........................................................ 47

General Maintenance Precautions................................................................................. 47

Accessing the Side Compartment.................................................................................. 48

Daily Procedures ........................................................................................................... 48

Initializing MAGPIX ................................................................................................... 48

Verifying MAGPIX..................................................................................................... 48

Maintaining Fluids..................................................................................................... 49

Shutting Down MAGPIX........................................................................................... 49

Weekly Procedures ....................................................................................................... 50

Cleaning MAGPIX .................................................................................................... 50

Cleaning the Sample Probe...................................................................................... 50

Performing a Visual Inspection................................................................................. 51

Calibrating and Verifying MAGPIX ........................................................................... 51

Removing Clogs....................................................................................................... 51

Monthly Procedures....................................................................................................... 52

Semi-Annual Procedures............................................................................................... 52

Maintaining Air Filters............................................................................................... 52

Replacing the Syringe Seal...................................................................................... 54

Annual Procedures ........................................................................................................ 55

Replacing the Sample Probe Tube .......................................................................... 55

Replacing the Drive Fluid Filter ................................................................................ 56

As Needed Maintenance................................................................................................ 57

Replacing Fuses....................................................................................................... 57

Maintenance Logs.......................................................................................................... 58

Short Term Maintenance - One Week...................................................................... 58

Long Term Maintenance - One Year........................................................................ 59

Chapter 6: Troubleshooting Procedures............................................................................. 61

Overview........................................................................................................................ 61

Power Supply Problems................................................................................................. 62

Communication Problems.............................................................................................. 62

Clogs.............................................................................................................................. 63

ii

Page 11

Contents

Fluid Leaks.................................................................................................................... 63

Sample Probe Problems ............................................................................................... 64

Calibration Slowness and Failure. ..... ............................................................................ 65

Verification Slowness and Failure................................................................................. 66

Acquisition Slowness and Failure ................................................................................. 67

Carryover Problems ...................................................................................................... 68

Bead Detail Irregularities............................................................................................... 68

Appendix A: Storage........................................................................................................ 71

Storing MAGPIX............................................................................................................ 71

Preparing MAGPIX for Use After Storage..................................................................... 71

Appendix B: Shipping....................................................................................................... 73

Preparing MAGPIX for Shipping ................................................................................... 73

Shipment Checklist ....................................................................................................... 74

Appendix C: Part Numbers .............................................................................................. 75

Hardware....................................................................................................................... 75

Reagents....................................................................................................................... 75

iii

Page 12

Luminex IVD MAGPIX Hardware Installation and User Manual

iv

Page 13

CHAPTER 1 About This Manual

Overview

Read this manual carefully before using the MAGPIX system. It provides vital information

about the following aspects of MAGPIX:

• Safety issues

• Regulatory considerations and labeling

• Installation

• Operation

• Maintenance

• Troubleshooting

• Storage

• Shipping

• Part Numbers

Warnings and Notes

The following informational notes and warnings appear as necessary in this manual.

NOTE: This message is used to provide general helpful information. No

safety or performance issues are involved.

CAUTION: This message is used in cases where the hazard is minor or only

a potential hazard is present. Failure to comply with the caution

may result in hazardous conditions.

WARNING: This message is used in cases where danger to the opera tor or to

the performance of the instrument is present. Failure to comply

with the warning may result in incorrect performance, instrument

failure, invalid results, or hazard to the operator.

DANGER: This message is used in cases where significant risk of serious

injury or death is present.

1

Page 14

Luminex IVD MAGPIX Hardware Installation and User Manual

Symbols

You may encounter these symbols throughout this manual. They represent war nings,

conditions, identifications, instructions, and regulatory agencies.

TABLE 1. Symbols

Symbol Meaning Symbol Meaning Symbol Meaning

Puncture/

Pinch Point

Warning

Hand Crush/

Cut/Force

From Above

Caution,

Risk of

Electric

Shock

Protective

ground

In vitro

Diagnostic

Medical

Device

General

Warning,

Caution, Risk

of Danger

Heat/Hot

Surface

Warning

Laser

Warning

~ Alternating

current (ac)

Serial

Number

Warning,

Biological

Hazard

Burn Hazard/

Hot Surface

Consult

Instructions

for Use

Catalog

Number

Batch

Code

Use By

Expiration

Date

Date of

Manufacture

Power Off

Power On

2

Temperature

Limitation

Manufacturer

MET Mark Fuse

Waste

Electrical and

Electronic

Equipment

(WEEE)

European

Union

Conformity

Page 15

CHAPTER 2 Safety and Regulatory

Considerations

Become familiar with the safety information in this chapter before using MAGPIX. This

system contains electrical and mechanical components that, if handled improperly, are

potentially harmful. In addition, biological hazards may be present during system

operation. Therefore, Luminex recommends that all system users become familiar with the

specific safety advisories below in addition to adhering to standard laboratory safety

practices. Do not perform procedures on MAGPIX that are not specifically described in

this manual, unless you are directed to do so by Luminex Technical Support.

Intended Use

The MAGPIX system is a clinical multiplex test system intended to measure and sort

multiple signals generated in an in vitro diagnostic assay from a clinical sample. This

instrument system is used with a specific assay to measure multiple analytes that aid in

diagnosis. The device includes a signal reader unit, raw data storage mechanisms, data

acquisition software and software to process detected signals.

3

Page 16

Luminex IVD MAGPIX Hardware Installation and User Manual

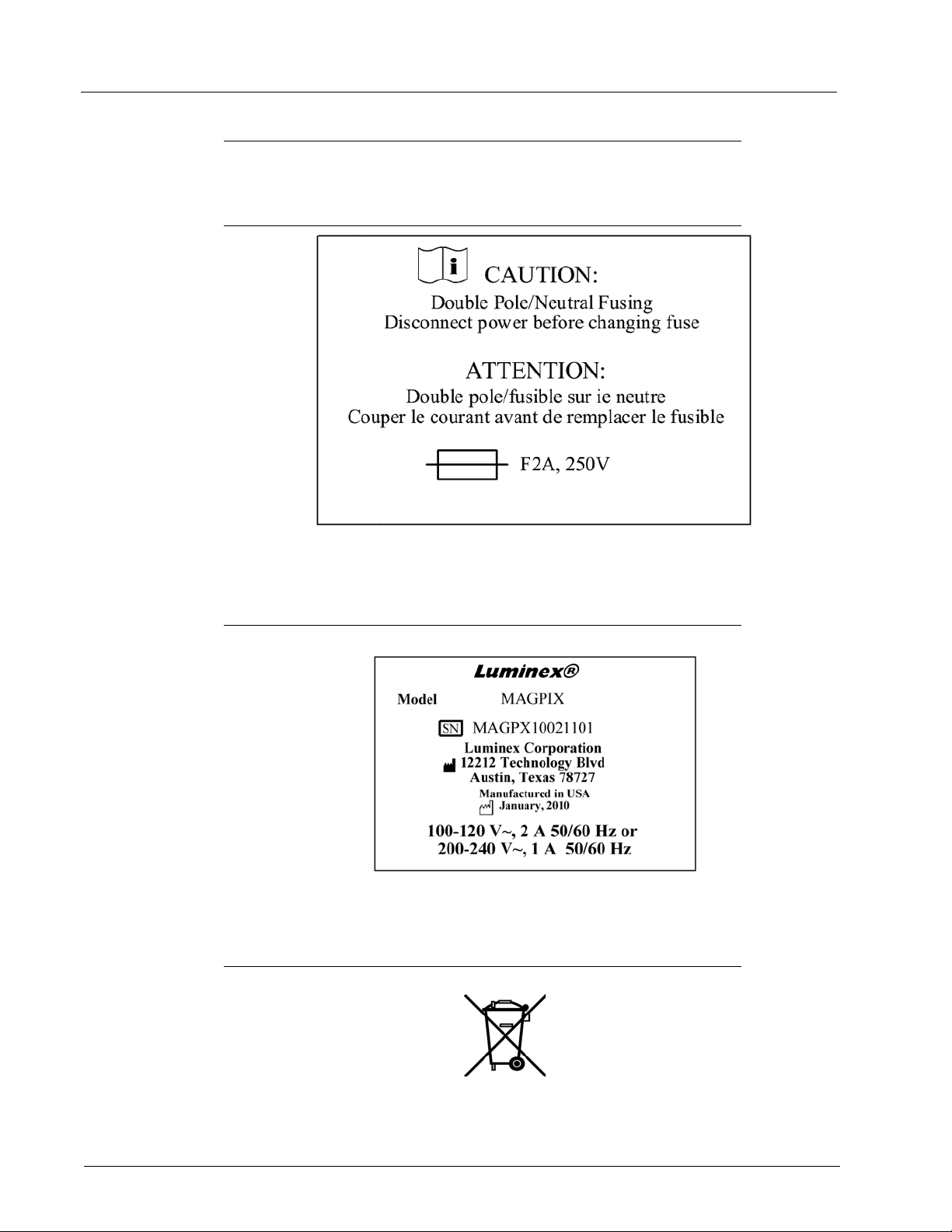

Regulatory Labels and Warnings

The following fuse caution label appears on MAGPIX.

FIGURE 1. Fuse Caution Label

A voltage label appears on the back of MAGPIX. It displays the MAGPIX serial number,

model number, power requirements, and manufacturer’s information.

FIGURE 2. Serial Number and Voltage Label

The WEEE (Waste Electrical and Electronic Equipment) label appears.

FIGURE 3. WEEE Symbol

4

Page 17

Safety and Regulatory Considerations

A label with legal information appears on MAGPIX.

FIGURE 4. Legal Information

Because MAGPIX complies with European Union safety requirements, it displays an EC

representative label.

FIGURE 5. EC Representative

Patient information appears on MAGPIX.

FIGURE 6. Patent

5

Page 18

Luminex IVD MAGPIX Hardware Installation and User Manual

E112918

Testing and Certifications

MAGPIX has been tested by MET and complies with safety requirements for the United

States and Canada.

FIGURE 7.

In addition, MAGPIX complies with European Union (EU) safety requirements and

therefore may be marketed in the Europe Single Market. The following European Union

compliance label appears on the back of the MAGPIX instrument.

FIGURE 8. European Union Compliance Label

MET Mark

6

Page 19

Safety and Regulatory Considerations

Safety Practices

In any situation in which you encounter this symbol, consult this manual or other Luminex

documentation to determine the nature of th e potentia l ha za rd and an y necessar y actio ns

you must take.

CAUTION: The protection provided by the equipment can be impaired or the

warranty voided if the Luminex MAGPIX system is used in a

manner not specified by the instructions or by Luminex

Corporation.

General

Keep the side access door closed and latched during normal operations.

DANGER: Do not, under any circumstances, remove the housing of the

instrument. Use of controls or adjustments or performance of

procedures other than those specified in Luminex MAGPIX

documentation can result in exposure to hazards.

Always observe standard laboratory

safety practices.

Mechanical

MAGPIX has parts that move during operation. Risk of personal injury is present. The

moving parts present puncture and pinching hazards. Keep your hands and fingers away

from the plate carrier slot, syringe pump, and sample probe during operation. The plate

carrier ejects without warning, especially during multiplate batches. Observe all warnings

and cautions. Keep the access door closed and latched during normal operations.

Electrical

Do not perform any maintenance or cleaning of the electrical components in the system,

with the exception of replacing fuses.

Observe the fuse caution stated on the fus e ca ut ion labe l. See “Fuse Caution Label” on

page 4. Be aware of the voltage of the instrument. See “Serial Number and Voltage Label”

on page 4.

Electromagnetic Compatibility

MAGPIX complies with the emission and immunity requirements described in IEC 613261 and IEC 61326-2-6. The electromagnetic environment should be evaluated prior to

operation.

WARNING: Do not use this instrument in close proximity to sources of strong

electromagnetic radiation, for example, unshielded intentio nal RF

sources, as these may interfere with the proper operation.

WARNING: Always handle MAGPIX according to Luminex instructions to

avoid any possible interference from its electromagnetic fields.

7

Page 20

Luminex IVD MAGPIX Hardware Installation and User Manual

Bar Code Reader Laser

The accessory bar code reader is classified under FDA 21 CFR 1040 .10 and 1040.11 as a

Class II laser product. In accordance with IEC 60825-1, the accessory bar code reader is

classified as Class 2.

The bar code reader laser presents a potential hazard to eyesight.

WARNING: Do not stare into the barcode reader beam or shine it into other

people’s eyes.

Heat

The heater plate, used to warm the plate carrier of the Y platfor m, can be heated between

35°C and 60°C.

CAUTION: Do not use the heater plate as an incubator. Its purpose is to

maintain the temperature of the microtiter pl ate while the plate is

in the MAGPIX instrument. Monitor the heater plate temperature

while it is in use. If it overheats, discontinue use and contact

Luminex Technical Support.

WARNING: The heater plate of the MAGPIX plate car rier may be ho t and can

cause personal injury if touched. Do not touch the heater plate.

Fluids

This instrument contains fluids. In the event of a fluid leak, turn off all power to the system

and disconnect all power cords. The on/off switch is not a method of disconnection; the

power cord must be removed from the outlet. Contact Luminex Technical Support for

further information.

DANGER: Do not operate the instrument in the presence of leaking fluid.

Monitor waste fluid levels periodically as a pre

container to overflow. Empty the waste fluid container each time you replace the Drive

Fluid container.

caution. Do not allow the waste fluid

Biohazard

Human and animal samples may contain biohazardous infectious agents. To avoid

pressurization problems, the waste fluid container is vented, so beware of biohazardous

aerosol material.

WARNING: Where exposure to potentially biohazardous material, including

aerosol, exists, follow appropriat e biosafety procedures and use

personal protective equipment (PPE). PPE includes gloves,

gowns, laboratory coats, face shields or mask and eye protection ,

respirators, and ventilation devices. Observe all local, state,

federal and country-specific biohazard handling regulations when

disposing of biohazardous waste material.

8

Page 21

Safety and Regulatory Considerations

Indicator Light

The lights inside the front panel of MAGPIX indicate the status of the system and are

harmless. The blue light-emitting diodes (LEDs) do not emit light in the UV spectrum.

Decontamination Procedure

Occasions may arise when it becomes necessary to decontaminate the entire MAGPIX

instrument. If you must decontaminate the instrument, sanitize the accessible surfaces

and the internal fluidics system. This is particularly import ant when bioh azardous samples

have been run.

WARNING: Wear appropriate personal protective equipment when handling

parts that come into contact with potentially biohazardous

samples.

To decontaminate MAGPIX:

1. Remov

household bleach solution diluted to 10% to 20% in water in the off-plate rea gent block

of the system.

2. Use

bleach solution followed by two wash commands with distilled water.

3. Emp

to 20% bleach solution followed by a distilled water rinse.

4. T

5. Clea

diluted to 10% to 20%.

6. Op

7. Clea

(10% to 20%).

e all specimens and all Luminex MAGPIX reagents. Leave distilled water and

the software to run a sanitize command with the diluted (10% to 20%) household

ty the off-plate reagent block and the waste container and clean each with a 10%

urn off MAGPIX and unplug the power cord.

n all exterior surfaces with mild detergent followed by a ho usehold ble ach solution

en the side access door of the instrument.

n all accessible surfaces with detergent followed by the household bleach solution

Disposal of Instrument

Within the European Union, the W aste Electrical and Electronic Equipm ent Directive 2002/

96/EC requires that you properly dispose of electrical and electronic equipment when it

reaches its end of life.

If you are disposing of a Luminex MAGPIX instr ume nt, decontaminate the system. See

“Decontamination Procedure” on page 9. Next, contact Luminex Technical Support for a

Return Material Authorization (RMA) num be r at +1-5 1 2-38 1- 4 39 7 (o ut sid e of th e U.S. ).

n the equipment to the following Luminex location:

Retur

Luminex Corporation

12201 Technology Blvd., Suite 130

Austin, Texas 78727, USA

For information about disposal of MAGPIX outside of the European Union, contact

uminex Technical Support at 1-877-785-2323 within the US and at +1-512-381-4397

L

outside of the US. For information about disposal of th e barcod e scann er , PC, or mon ito r,

refer to the manufacturer documentation.

9

Page 22

Luminex IVD MAGPIX Hardware Installation and User Manual

10

Page 23

CHAPTER 3 Installation Procedure

Before handling or unpacking MAGPIX, make certain th at the selected site is approp riate.

See “Installation Diagrams” on page 28 for handling and site installation requirements and

detailed dimensions of MAGPIX.

Check for these requirements:

• Indoors

• Operating temperature of 15-35°C (59-95°F)

• Operating relative humidity of 20-80%, noncondensing

• Operating altitude up to 2400m (7874 ft) above mean sea level

• Available electrical power outlet with protective earthing and easy accessibility

• Available area of approximately 3‘ X 3’ (91.44cm), including a 2” (5.08cm) clearance

between the back of MAGPIX and any wall or vertical surface.

• Stable, level surface

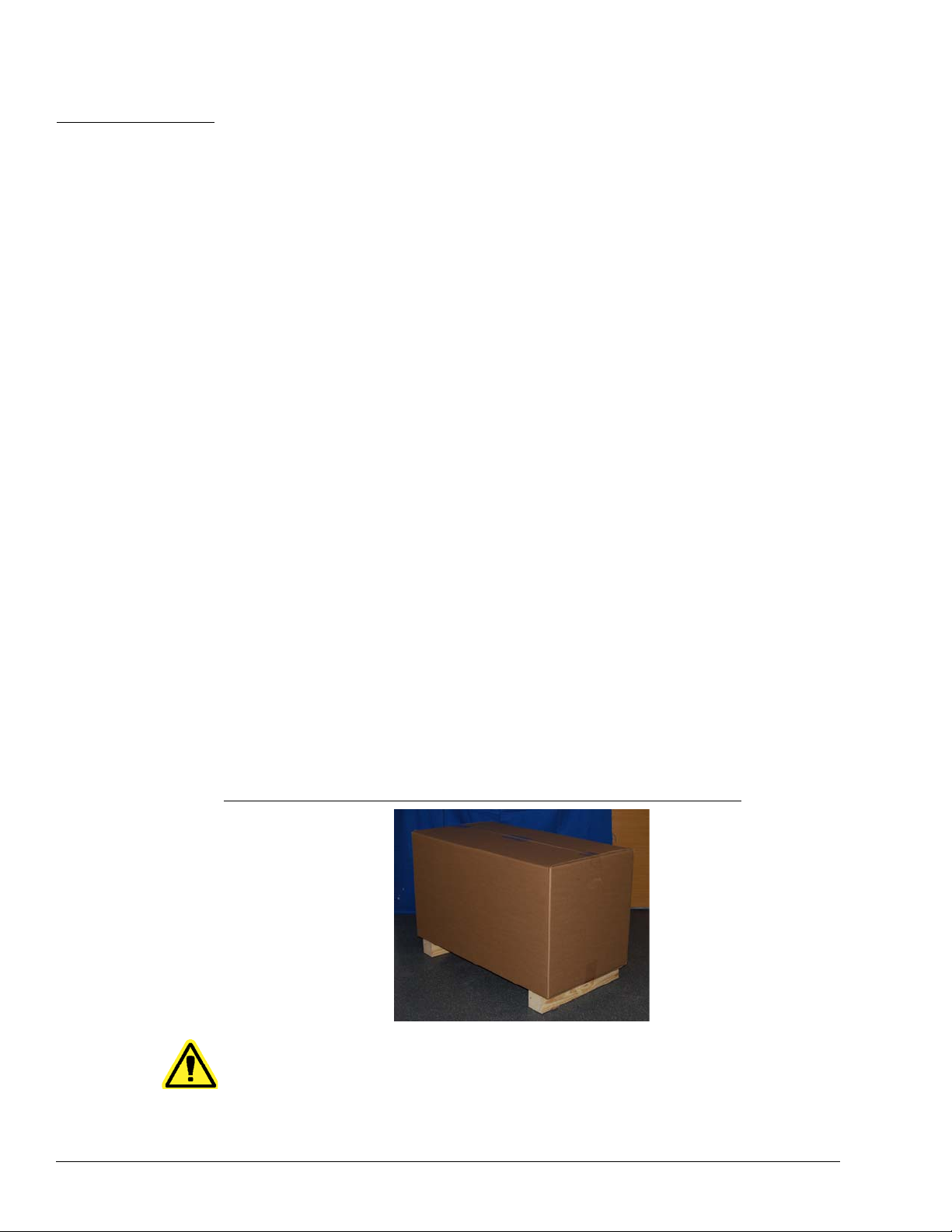

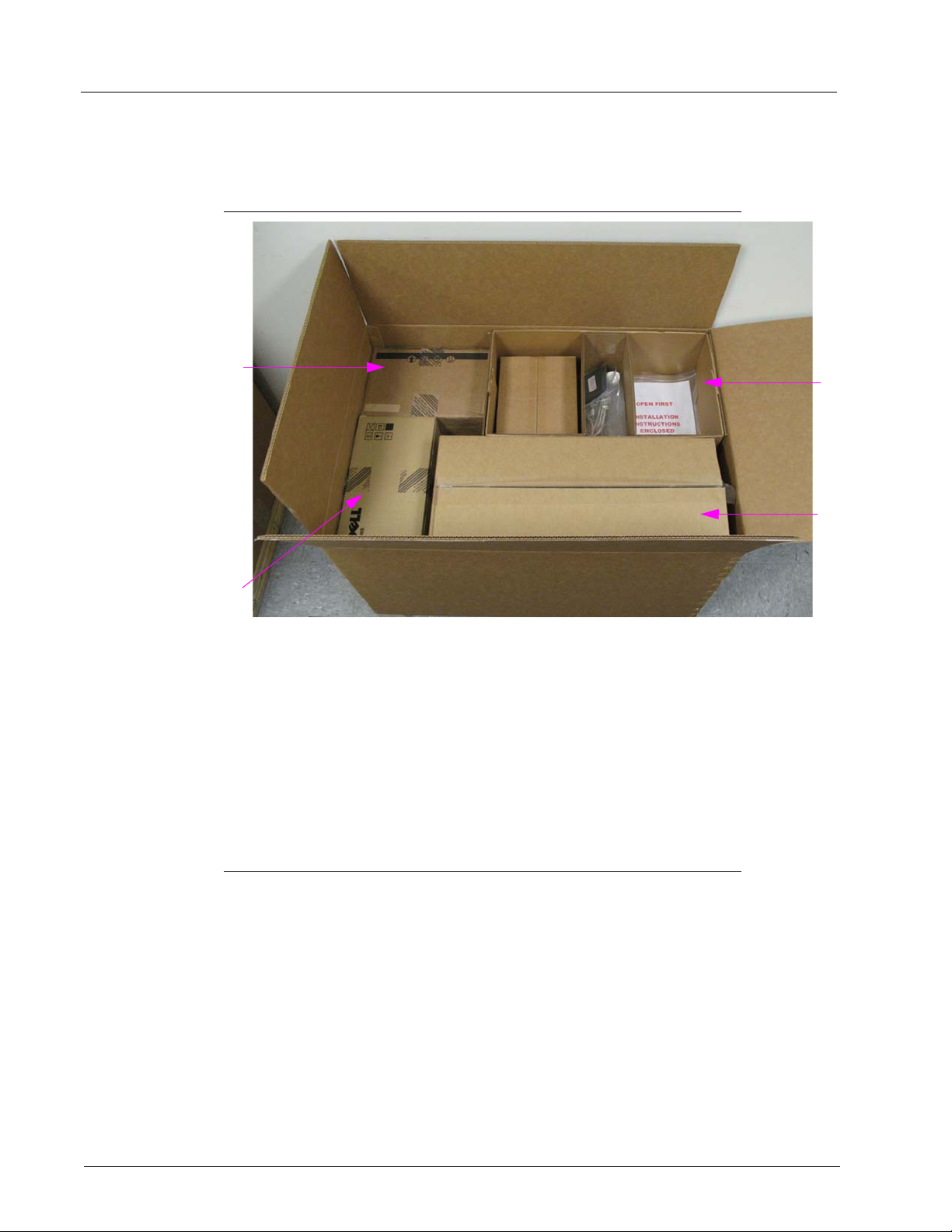

MAGPIX arrives in a large, corrug

FIGURE 9. The MAGPIX Overpack

ated cardboard overpack on skids.

CAUTION: This overpack is too heavy to be lifted by one person

(approximately 119lbs (53.97kg), a three-person lift) and should

be moved mechanically. Be careful the overpack is not punctur ed

during any necessary moving.

11

Page 24

Luminex IVD MAGPIX Hardware Installation and User Manual

1

2

3

4

Within the overpack are separate cartons for the PC, the monitor, the 2-pack of Drive

Fluid, and the MAGPIX instrument. In addition, a divided tray contains the cables, CDs,

and printed material.

FIGURE 10. Inside the Overpack

1PC carton

2 Monitor carton

3 Accessory tray (monitor stand and Drive Fluid cartons are

underneath)

4 MAGPIX carton

Each individual carton can be handled by one person. The MAGPIX carton and the PC

carton each weigh less than 40 pounds (18.14 kg).

Unpacking and Assembling the PC

Begin the installation process with the PC. The computer and monitor are in the boxes at

the end of the overpack (See Figure 10.); the monitor stand is in a box underneath the

accessory tray.

The computer and monitor boxes include all the necessary cords and peripheral devices

well as complete installation instructions. Follow those instructions to set up the PC.

as

To set up the PC:

1. Remo

2. Asse

ve the three boxes containing PC components from the overpack.

mble the components using PC Installation Instructions or the instructions

provided by the PC vendor. Both are in the PC boxes.

12

Page 25

FIGURE 11. The Assembled PC

Installation Procedure

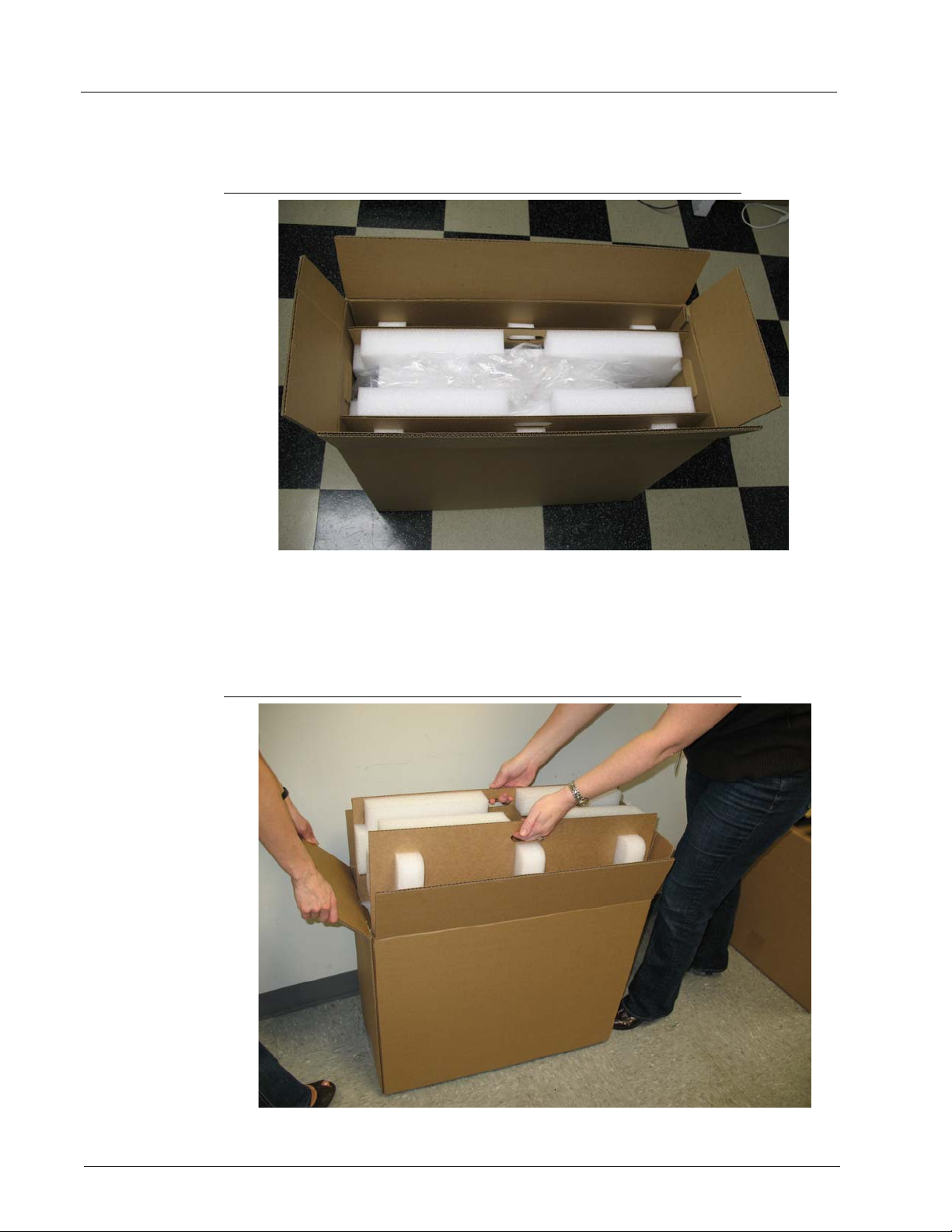

Unpacking and Assembling MAGPIX

To install the MAGPIX instrument:

1. Remo

ve the MAGPIX carton from the overpack.

FIGURE 12. Removing the MAGPIX Carton

13

Page 26

Luminex IVD MAGPIX Hardware Installation and User Manual

The MAGPIX instrument is inside a plastic bag and surrounded by foam inserts attached

to a corrugated cardboard insert.

FIGURE 13. The MAGPIX Carton, Opened

2. Remove MAGPIX from its carton by pulling on the handles that extend from the

cardboard insert.

NOTE: It

is helpful to have another person hold down the carton wh ile you

pull out MAGPIX.

FIGURE 14. Pulling MAGPIX from its Carton

14

3. Put the instrument on a stable, flat surface. This may require two people.

Page 27

4. Fold down the cardboard panels from each side of the instrument.

FIGURE 15. Removing the Packing Materials

Installation Procedure

5. Pull the plastic bag down from the top.

6. Place MAGPIX on

people.

Before proceeding with the installation, che

checklist on page 29 and make certain you can locate all listed items. Check contents to

make certain no damage h as occurred du ring shipp

contact Luminex Technical Support (in the U.S. and Canada, 1-877-785-BEAD

(-2323); outside of the U.S. and Canada, +1 512-381-4397; in Europe, +31 162 408 333).

to a lab bench or other flat, stable surface. This may require two

ck the contents of the overpack with the

ing. If anything is missing or damaged,

Connecting the Components

To connect the components:

ocate the cords in the accessory tray of the overpack.

1. L

FIGURE 16. Power Cord and USB Cable

15

Page 28

Luminex IVD MAGPIX Hardware Installation and User Manual

2. Plug the power cord into the back of the instrument.

3. Connect

the USB cable to the PC and to the connector labeled P1 on the back of

MAGPIX. Use the top right USB port on the PC.

FIGURE 17. Power Cord and USB Cable Connected

4. Connect the barcode scanner (if ordered) to the computer.

FIGURE 18. All Components Connected

16

Page 29

Installation Procedure

Preparing MAGPIX

Preparing MAGPIX includes removing the shipping plug, installing the Drive Fluid, and

installing the sample probe.

Removing the Shipping Plug

Inside the side access door of MAGPIX, a shipping plug holds the sample probe assembly

in place. Use the door access tool included in the accessory tray to open the side access

door and remove the plug.

CAUTION: MAGPIX should not be plugged into a power source when you

open this compartment.

To open the side access door and remove the shipping plug:

cate the door access tool in a small plastic bag in the accessory tray of the overp ack.

1. Lo

FIGURE 19. Door Access Tool

2. Insert the tool in the side access door latch and turn it one quarter turn clockwise.

FIGURE 20. Door Access Toll Inserted and Turned

3. Slide the door to the right.

17

Page 30

Luminex IVD MAGPIX Hardware Installation and User Manual

FIGURE 21. Sliding Open the Door

4. Raise the probe assembly and locate the shipping plug.

FIGURE 22. The Shipping Plug in Position

18

5. Pull the probe holder up, then, holding MAGPIX on the top with one hand to stabilize it,

firmly push the probe assembly away from you with your other hand. Be prepared to

use some strength.

Page 31

FIGURE 23. Pushing the Probe Assembly

6. With the probe assembly out of the way, lift out the shipping plug.

FIGURE 24. Lifting Out the Shipping Plug

Installation Procedure

19

Page 32

Luminex IVD MAGPIX Hardware Installation and User Manual

Installing the Sample Probe

MAGPIX comes with two sample probes, but the probe is not pre-installed.

To install the sample probe:

cate the sample probe, which is shipped in a tube in the accessory tray.

1. Lo

FIGURE 25. The Sample Probe and Its Container

2. Pull the probe assembly toward you and push it down.

3. Comp

letely unscrew the probe fitting on top of the probe holder by turning it

counterclockwise.

FIGURE 26. Unscrewing the Probe Fitting

20

4. Put the probe into the opening left by the probe fitting. It should slip down and catch at

the bottom of the opening.

Page 33

FIGURE 27. Inserting the Sample Probe

Installation Procedure

5. Reinstall the probe fitting, tightening it until it clicks into place.

FIGURE 28. The Sample Probe in Position

6. Close and latch the side access door.

21

Page 34

Luminex IVD MAGPIX Hardware Installation and User Manual

Installing the Drive Fluid

The overpack includes a carton contain ing two containers of Drive Fluid. Open the carton

and remove one container to install in the instr ument.

To install the Drive Fluid container:

cate the carton of Drive Fluid containers.

1. Lo

FIGURE 29. Drive Fluid Carton and Container

22

2. Open the carton and remove a container of Drive Fluid.

Page 35

3. Open the door of the fluid compartment on the front of MAGPIX.

FIGURE 30. The Fluid Compartment

Installation Procedure

4. Pull the Drive Fluid tube and plug in the left side of the fluid compartment forward until

it extends outside the compartment. Pu ll it to the left to allow room to insert the Drive

Fluid container.

FIGURE 31. Pulling out the Drive Fluid Tube and Plug

23

Page 36

Luminex IVD MAGPIX Hardware Installation and User Manual

5. Insert the Drive Fluid container part of the way into the fluid compartment opening and

remove the seal.

FIGURE 32. Removing the Seal

6. Connect the Drive Fluid tube and plug to the opening on the top of the Drive Fluid

container.

FIGURE 33. Connecting the Tube and Plug to the Container Opening

24

Page 37

Installation Procedure

7. Slide the container into the tray o n the lef t sid e of the fluid compartment. The container

tray is constructed to hold the container in place.

FIGURE 34. Sliding in the Drive Fluid Container

8. After the container is fully inserted, check the valve on the front of the waste fluid

container to make certain it is securely attached and close the door of the fluid

compartment.

Powering Up MAGPIX

MAGPIX has two on/off switches: a hard power switch and a soft power switch.

To power on MAGPIX:

1. Plug

2. T

the power cord from the back of the instrument into a power outlet.

NOTE: Lu

urn on the hard power switch. This is th e to ggle switch at the lower right corner of the

back of MAGPIX.

NOTE: T

minex recommends the use of a surge protector or UPS device

with MAGPIX. For more information, see “Uninterruptible Power

Supply (UPS) or Surge Protector” on page 44.

he hard power switch controls flow of power to the instrument.

25

Page 38

Luminex IVD MAGPIX Hardware Installation and User Manual

FIGURE 35. The Hard Power Switch

3. When you are ready to begin testing, turn on the soft power switch on the front of

MAGPIX. The blue LED in the hexagonal window lights up as confirmation that the

power is on. MAGPIX requires approximately 45 seconds to start up.

NOTE: The

soft power switch activates and deactivates the unit.

FIGURE 36. The Soft Power Switch

26

4. After MAGPIX is powered on, use the software to eject the tray carrier to put the off

plate reagent block in place.

Page 39

Installation Procedure

Performing an Initial Startup

Before using MAGPIX to analyze samples, perform an initial startup routine. All the

necessary procedures are described in the Luminex IVD xPONENT for MAGPI X Sof tware

User Manual and the Luminex xPONENT for MAGPIX Software Quick Guide.

To perform an initial startup:

1. From the Home page, select Probe and Heater, then perform a probe height

adjustment using a standard 96-well microtiter plate. If you use a plate with conical

wells, use one calibration sphere in the selected well. If you use a magwash or filter

plate, use two 5.08 mm discs stacked together in the selected well. Locate the sphere

and discs in the Probe Height Calibration Kit provided with the instrument.

2. After the probe has been calibrated, select the Cmds & Routines tab, then select

Revive After Storage from the routine drop down menu. Run Revive After Storage.

3. After the Revive Afte r S tor age routine is complete, select the Au to Maint tab and run

the Calibration/Verification procedure.

NOTE: Before running the calibration and verification procedure, be sure

to load the lot information on the CDs that are part of the

separately shipped Calibration and Verification Kits.

27

Page 40

Luminex IVD MAGPIX Hardware Installation and User Manual

Installation Diagrams

28

Page 41

Shipping Checklist

The MAGPIX overpack contains the following items:

Item Qty Part Number

MAGPIX Instrument 1 55-00022-00-002

PC 1 64-00087-00-001

Monitor 1 64-10049-00-001

All-in-One Monitor Stand 1 64-10050-00-001

Drive Fluid 2-pack 1 40-50014

Waste Bottle 1 CN-0261-01

Sample Probe 2 CN-0221-01

Power Cord 1 CN-P0XX-01

Installation Procedure

USB Cable 1 CN-0271-01

Side Access Door Tool 1 CN-0264-01

Sample Probe Height Adjustment Kit 1 CN-0263-01

Off-plate Reagent Block 1 CN-0260-01

xPONENT 4.1 Software for MAGPIX (DVD) 1 CN-SW20-01

Installing MAGPIX

xPONENT for MAGPIX IVD Quick Guide

IVD MAGPIX Installation and Hardware User Manual (CD) 1 CN-M082-01

IVD xPONENT for MAGPIX Software User Manual (CD) 1 CN-M084-01

PC Installation Instructions

96-wellplate Heater Block (optional) 1 CN-0224-01

Barcode reader (optional) 1 CN-PC03-01

1 89-30000-00-236

1 CN-M083-01

1 89-30000-00-263

NOTE: A MAGPIX Calibration Kit and a MAGPIX Performance

Verification Kit are shipped separately.

29

Page 42

Luminex IVD MAGPIX Hardware Installation and User Manual

30

Page 43

CHAPTER 4 Technical Overview

This chapter describes the operation, components, subsystems, and technical

specifications of MAGPIX.

How MAGPIX Operates

MAGPIX combines a fluidics system, a mechanical system, an electronic system and an

optical system with magnetic microspheres and complex computer analysis to perform

multiplex assays.

The mechanical system begins the process. An operator places a 96-well microtiter plate

on the plate carrier, which transports the plate into the instrument. The carrier moves

along the y axis, to allow the sample probe access to each column of the microtiter plate.

The sample probe assembly moves along the x and z axes, allowing it to access each row

of the microtiter plate. Between the y-axis movement of the carrier and the x-axis

movement of the sample probe, all wells of the microtiter plate are accessible.

The fluidics system handles the acquisition and transportation of the sample. The sample

probe descends into each well, drawing a sample for testing and drawing Drive Fluid from

the Drive Fluid container. The sample moves through the fluid tubing to the optics module,

transported by the Drive Fluid.

In the optics module, a magnet holds the magnetic microspheres in place while first a red

(classification) LED and then a green (reporter) LED illuminate them. They are imaged

during each illumination. After the images are recorded , the magnet withdraws, releasing

the microspheres for transport to the waste fluid container an d to clear the way for the next

sample.

xPONENT software analyzes the images, the red-illuminated images to classify the

microspheres and the green-illuminated images to determine what elements of the sample

have bonded to their surfaces. It reports the results to the operator.

31

Page 44

Luminex IVD MAGPIX Hardware Installation and User Manual

1

3

5

4

2

6

FIGURE 37.

MAGPIX Front & Right Side

1 Status indicator light

32

2 Soft on/off switch

3 Access door for plate carrier.

4 Access door for fluid compartment. For a more detailed illustration, see

Figure 46 on page 41.

5 Side access door

6 Side access door latch

Page 45

Technical Overview

1

2

3

FIGURE 38.

MAGPIX Back & Left Side

1 Communications port (P1)

2 Power input module

3 Rear air filter

33

Page 46

Luminex IVD MAGPIX Hardware Installation and User Manual

System Components

The following topics describe details of the three components of the Luminex MAGPIX

system: software, reagents, and hardware.

Software

Luminex xPONENT for MAGPIX software provides complete control of the MAGPIX

instrument and performs the analysis. The softwar e requires a dedicate d PC. For updated

information about the PC or operating system, see Luminex IVD xPONENT for MAGPIX

Software User Manual or access http://www.luminexcorp.com. Click the Support link to

open the FAQ list.

Under most circumstances, the PC that comes with the MAGPIX system is preloaded with

xPONENT for MAGPIX software. Luminex provides a software DVD to use if you need to

reinstall the software or need to inst all it on anothe r computer. If you install the software on

another PC, be sure that the PC meets the minimum specifications, including 4.0 GB of

RAM and a 2.66 GHz processor. The number of installations you can perform is limited by

your license.

The software DVD automatically installs the basic software only. To install the various

upgrades, contact Luminex Technical Support (1-877-785-2323 within the US and +1-512381-4397 outside of the US). A Technical Support representative can supply you with the

correct license number to install upgrades.

CAUTION: If you need to uninstall the software, follow carefully the procedure

provided by Luminex Technical Support.

The software is documented in two ways: in online help, which can be accessed from

within the application itself, and in PDF form, which is available on the Luminex website

and on a CD included with the shipped system.

CAUTION: Luminex recommends that you do not install additional software

on the PC that runs xPONENT for MAGPIX, with the exception of

Adobe Acrobat. Acrobat is required to view the PDFs and is

included on the installation CD. The operation of xPONENT for

MAGPIX has been validated only when it is the only program

running on the dedicated PC.

Hardware

The Luminex MAGPIX system includes the following hardware:

• The MAGPIX instrument

• Personal computer (PC) and necessary peripherals, including a monitor , keyboard and

mouse

• Power cable to connect MAGPIX to power outlet

• USB communication cable to connect MAGPIX to PC

• Two sample probes

• Sample probe height adjustment kit

• Off-plate reagent block

• Additional empty waste fluid container

34

Page 47

Technical Overview

• Side door access tool

• Barcode reader (optional)

• Heater block (optional)

The hardware is shipped with a quick insta llation guide , a quick so f tware user guide , a CD

co

ntaining both the software user manual and the hardware installation and user manual,

and a DVD containing the software.

Reagents

xMAP technology requires two kinds of reagents: common laboratory reagents and

reagents created especially for Luminex instruments.

CAUTION: Adhere to standard laboratory safety practices when handling

hazardous, toxic, or flammable reagents and chemicals. Contact

Luminex Technical Support when in doubt about compatibility of

cleaning and decontamination agents or materials.

Required Laboratory Reagents

• 10 - 20% household bleach solution

• 70% isopropanol or 70% ethanol solution

• 0.1N NaOH

• Sporicidin® Disinfectant

• Mild detergent

• Distilled water

WARNING: Isopropanol and ethanol are flammable liquids. Keep them away

from heat, open flames, and sparks in a well-ventilated area.

Remove them from the instrument when they are not in use.

xMAP Technology Reagents

• Drive Fluid (unit volume sufficient to run eight 96-well plates)

• MAGPIX Calibration Kit (to normalize the CL1 and CL2 classification channels and the

RP1 reporter channel parameters)

• MAGPIX Performance Verification Kit (to verify system integrity associated with the

CL1 and CL2 classification channels, the RP1 reporter channel, and the system

fluidics)

CAUTION: Protect MAGPIX calibration and verification reagents from light at

all times to avoid photobleaching of the microspheres.

WARNING: Luminex Drive Fluid contains ProClin

cause allergic reactions in some people. Additional information is

available in the Drive Fluid MSDS.

MAGPIX is shipped with a 2-pack of Drive Fluid. A MAGPIX Calibration Kit and a MAGPIX

Performance V erification Kit are shipped separately.

®

as a preservative. This can

35

Page 48

Luminex IVD MAGPIX Hardware Installation and User Manual

1

2

Subsystems

MAGPIX includes four subsystems: electronic, fluidic, mechanical and optical.

Electronic Subsystem

The electronics subsystem provides the power for operation and control of the MAGPIX

system and communication between its parts.

Power Input Module

The power input module contains the input power plug, hard power toggle switch, and

fuses. This is the protective earthing point for the MAGPIX system. The mating power cord

connector type is IEC-320-C13. The mating power cord provides electrical power to the

instrument when it is connected to an electrical outlet and is the means of disconnection.

The power input auto-senses the voltage range.

FIGURE 39. Power Input Module

1 Hard power toggle switch 2 Input power plug

WARNING: Do not obstruct this means of disconnection. Connect only to

outlets that contain protective earthing. Before changing a fuse,

turn off the instrument and unplug the power cord to avoid any

danger of electrical shock.

36

Page 49

Technical Overview

Communications Port

The communications port connects MAGPIX to the computer. It is a USB port, labeled P1.

FIGURE 40. Communications Port

Printed Circuit Board Assemblies

MAGPIX requires a series of printed circuit board assemblies (PCBAs), including four

major boards: optics control, XY controller, imaging, and processor. These PCBAs are all

contained within the same area as the optical system, are not accessible to the user, and

require no user maintenance.

Fluidics Subsystem

The fluidics subsystem handles the flow of liquid through MAGPIX. MAGPIX has two

doors that access its fluidics system: a side access door and a front door to the fluid

compartment.

Side Compartment and its Components

The side access door, at the upper front of the right side, provides access to the side

compartment, which contains the sample probe assembly, the sample valve, the tube

between the probe and the sample valve, the filter for the Drive Fluid, and the syringe

pump.

The side access door is secured with a latch th

CAUTION: Keep the side access door closed and latched during normal

operation. Unlatch it only to perform maintenance on the usermaintainable parts of the fluidics system.

at requires a door access tool to open.

37

Page 50

Luminex IVD MAGPIX Hardware Installation and User Manual

FIGURE 41. Side Access Door

FIGURE 42. Interior of Side Access Door

38

Page 51

Technical Overview

1

2

3

4

5

6

7

8

Syringe Pump and Drive Fluid Filter

The syringe pump draws fluid from the Drive Fluid cont ainer, in the bottom compartment of

the instrument. The fluid first passes through the Drive Fluid filter , which removes particles

greater than 35 microns in diameter.

The pumping action results from the up-and-down movement of the plunger guide in its

unting bracket, which moves the plunger up and down in the glass cylinder, drawing

mo

Drive Fluid in through the filter and into the valve and forcing it out into the sample loop.

FIGURE 43.

Syringe Pump and Drive Fluid Filter

1 Drive Fluid filter 5 Mounting bracket

2 Plunger 6 Plunger guide

3 Tube from Drive Fluid container 7 Syringe pump valve

4 Glass cylinder 8 Sample loop

WARNING: Avoid contact with moving parts.

39

Page 52

Luminex IVD MAGPIX Hardware Installation and User Manual

1

2

3

5

6

4

7

8

9

Sample Probe Assembly

The stainless steel sample probe fits inside a holder. A probe fitting screws into the top of

the holder, keeping the pro be in pla ce. Fro m the probe, thr ough the fitting, exten ds a tube

that passes through a strain relief and a ttaches to th e sample valve. The samp le loop from

the syringe pump also enters the sa mple value, an d a tu be extend s fr om it into the op tical

chamber, carrying the sample mixed with Drive Fluid.

A wheel pulley, covered by a protective shield, moves the probe assembly along the x

is.

ax

FIGURE 44. Sample Probe

Assembly

1 Sample loop 4 Valve-to-optical chamber

tube (coded red)

2 Strain relief 5 Sample probe 8 Probe holder

3 Probe-to-valve tube

(coded black)

6 Sample valve 9 Probe fitting

WARNING: Avoid contact with moving parts.

WARNING: Wear appropriate personal protective equipment when handling

7 Protective cover on

wheel pulley

parts that come into contact with potentially biohazardous

samples.

40

Page 53

Technical Overview

1

2

3

The Fluid Compartment

At the bottom of the front panel of MAGPIX, a door folds down to provide access to the

fluid compartment. Within that compartment, two trays hold the Drive Fluid and waste fluid

containers. Internal sensors monitor the fullness of the waste fluid container and the

emptiness of the Drive Fluid container. When either container reaches an unacceptable

level, MAGPIX stops. Luminex IVD xPONENT for MAGPIX Software User Manual

provides instructions for setting up an alert to warn you about unacceptable fluid levels.

FIGURE 45. Door to Fluid Compartment

The Drive Fluid container comes pre-filled and is disposable. The reusable waste fluid

container receives waste from the system . The waste and Drive F luid tubes connect to the

waste fluid and Drive Fluid containers using clear tubing.

WARNING: Wear appropriate personal protective equipment when handling

parts that come into contact with potentially biohazardous

samples. Make certain the waste fluid container is properly

vented.

FIGURE 46. Fluid Compartment, Interior

41

Page 54

Luminex IVD MAGPIX Hardware Installation and User Manual

1

2

1 Drive Fluid container in place

2

3 Valve attaching waste tubing to waste fluid container

Waste fluid container in place

Mechanical Subsystem

x-Axis and y-Axis Movement

The MAGPIX mechanical subsystem includes the plate carrier and the assembly that

moves the sample probe. The carrier moves along the y axis, to allow the sample probe

access to each row of the microtiter plate. The sample probe assembly mo ves along the x

and z axes, allowing it to access each column of the microtiter plate. Between the y-axis

movement of the carrier and the x-axis and z-axis movement of the sample probe, all wells

of the microtiter plate are accessible.

FIGURE 47. MAGPIX Plate Carrier Assembly

42

1 Microtiter plate area

2 Off plate reagent block area

Page 55

FIGURE 48. MAGPIX Sample Probe Assembly

1

2

Technical Overview

1 Pulley wheel that moves sample probe assembly along x-axis (cover removed)

2 Sample probe

Air Filters

MAGPIX has two air filters, one on the bottom of the instrument and one on the back of

the instrument. These filters require periodic cleaning to perform optimally.

The filter on the bottom of MAGPIX

instrument. This requires lifting up or tilting the instrument. The filter on the back of

MAGPIX can be slid up out of its holder.

CAUTION: Before lifting the instrument, remove all liquid from the off plate

reagent block and remove the fluid containers.

FIGURE 49. Bottom of MAGPIX showing filter in place in holder

can be slid out of its holder toward the front of the

43

Page 56

Luminex IVD MAGPIX Hardware Installation and User Manual

FIGURE 50. Back of MAGPIX showing filter in place in holder

Optical Subsystem

The MAGPIX optical subsystem consists of red and green LED illumination, a CCD-based

imager, an ima ging chamber, and a magnet to hold the magnetic microspheres in place

during the imaging process. The optical subsystem is contained in the same area as the

PCBAs. It is not accessible by the user and requires no user maintenance.

Recommended Additional Equipment

Successful operation of the Luminex MAGPIX system may require additional equipment.

Uninterruptible Power Supply (UPS) or Surge Protector

Luminex recommends using either an uninterruptible power supply (UPS) or a surge

protector to protect your system from power outages. Use a UPS that provides 585 Watts/

960 VA for at least 60 minutes. Select a surge protector that fits your requirements with

regard to electrical environment, endurance, suppressed voltage rating, and method of

protection. The surge protector requires three outlets and a minimum rating of 585 Watts.

Either piece of equipment should bear an appropriate safety certification mark for your

region, for example, Underwriters Laboratory (UL), Canadian Standards Association

(CSA), or Conformité Europeénne (CE).

44

Page 57

Technical Overview

Printer