Lumenis VersaPulse PowerSuite User manual

9HUVD3XOVH“ 3RZHU6XLWH•

6(59,&( 0$18$/

This service manual is to be used in conjunction with the operator manual for the product. The operator manual contains important information regarding instrument description, location of controls, specifications, and normal operating procedures.

! "

#$% ! "

&

'$" "( % ) )

9,6,%/( $1' ,19,6,%/( /$6(5 5$',$7,21 $92,' (<( 25 6.,1 (;32685( 72 ',5(&7 25 6&$77(5(' 5$',$7,21

* +',-!"( # . / 00

* +',-!"( 1

2400 Condensa Street

Santa Clara, CA 95051

(408) 764-7000

0636-499-00 REV. C

This manual is copyrighted with all rights reserved. Under the copyright laws, this manual cannot be copied in whole or part without express written permission of Lumenis, Inc. Permitted copies must carry the same proprietary and copyright and copyright notices as were affixed to the original.

Please note that while every effort has been made to ensure that the data given is accurate, the information, figures, illustrations, tables, specifications, and schematics are subject to change without notice.

Lumenis and the Lumenis Logo are registered trademarks of Lumenis, Inc.

Please direct all inquiries about this manual to:

Lumenis, Inc. Technical Support C-35 2400 Condensa Street Santa Clara, CA 95051 (408) 764-3638

Lumenis, Inc.

0636-499-00 REV. C

',6&/$,0(5

Lumenis service manuals are written specifically for use by Lumenis service engineers who have received formal training in the servicing of Lumenis Equipment, and by customers who have taken and passed a Lumenis certification service training course for the equipment being serviced. Information on certification service training courses offered to customers can be obtained by contacting the Technical Coordinator at (800) 367-7899.

Lumenis does not accept responsiblity for personal injury or property damage resulting from the servicing of Lumenis equipment by its customers or by third parties, except where such injury or property damage is a direct result of Lumenis’s negligence. Customers, by accepting the service manual, agree to indemnify Lumenis against any claims alleging personal injury or property damage resulting from the servicing of Lumenis equipment by the customer or by third parties, except where such injury or property damage is a direct result of Lumenis’s negligence. These limitations include situations where Lumenis personnel are advising customers on the repair of Lumenis equipment over the telephone, via fax or e-mail.

The servicing of Lumenis equipment by persons who have not passed a current Lumenis certification service training course for that equipment will void Lumenis’s product warranty.

VersaPulse PowerSuite• Service Manual Disclaimer 0636-499-00 REV. C

5(9,6,21 ,1)250$7,21

This is the REV. C release of the VersaPulse® PowerSuite™ Service Manual . Contact Lumenis Technical Support to determine if this is the most current release of this service manual.

Each page of this manual has a revision level at the bottom. This indicates the release level for the individual sections. Note that when the manual is updated, not all of the sections are necessarily updated, so some sections may have a revision level earlier than the release revision level for the manual (the revision level for the manual is the revision letter that appears on the cover and in the first sentence of this revision information page). The following list provides a complete list of the revision information, by section, for this release of the service manual.

Cover page, copyright page, disclaimer page, this page, table of contents page(s) are all revision C with the corresponding section(s) of the manual.

SECTION 1 |

0636-499-01 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 2 |

0636-499-02 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 3 |

0636-499-03 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 4 |

0636-499-04 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 5 |

0636-499-05 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 6 |

0636-499-06 |

REV. B |

ECO# 69741 |

DATE: July 2001 |

SECTION 7 |

0636-499-07 |

REV. C |

ECO# 69741 |

DATE: July 2001 |

NOTE:

Field Service Bulletins (FSBs) released for this service manual are listed in the VersaPulse PowerSuite FSB Index. Each time an FSB for this manual is released or updated, the Index is also updated and distributed with the FSB. The current index is placed behind the single sheet that makes up Section 7, and the FSB’s are placed in order behind the Index. Contact Lumenis Technical Support for the date of the most current FSB Index.

SECTION 8 |

0636-499-08 |

REV. C |

ECO# 69741 |

DATE: July 2001 |

VersaPulse PowerSuite• Service Manual Revision Information 0636-499-00 REV. C

7$%/( 2) &217(176

1.0GENERAL INFORMATION

1.1Use of This Manual

1.2Conventions Used in This Manual

1.3Serial Numbers

1.4Certification Compliance

1.5Service Information & FDA Compliance

2.0INSTALLATION

2.1 Introduction

2.2 Product Specifications

3.0CALIBRATION, ALIGNMENT & ADJUSTMENT

3.1Introduction

3.2Optical Alignment

3.3Electrical Adjustments

3.4Mechanical Adjustments

3.5Energy Calibration

3.6System Optimization Check

3.7Operational and Safety Check

3.8Periodic Maintenance

4.0THEORY OF OPERATION

4.1Introduction

4.2Power Switching, Conditioning and Distribution

4.3Cooling

4.4Control Electronics

4.5Flash Lamp Supply Circuits

4.6Optics

4.7Software

5.0TROUBLESHOOTING

5.1Overview

5.2Interior Access & Parts Location

5.3Service Mode

5.4Fault Isolation

5.5Test Points & LED Arrangment

VersaPulse PowerSuite• Service Manual Table of Contents 0636-499-00 REV. C

5.6Remove/Replace Procedure

5.7Troubleshooting

6.0SELECTED PART NUMBERS

7.0FIELD SERVICE BULLETINS

8.0SCHEMATICS & DRAWINGS

VersaPulse PowerSuite• Service Manual Table of Contents 0636-499-00 REV. C

7$%/( 2) &217(176

*(1(5$/ ,1)250$7,21

,167$//$7,21

&$/,%5$7,21$/,*10(17$'-8670(17

7+(25< 2) 23(5$7,21

7528%/(6+227,1*

6(/(&7(' 3$57 180%(56

),(/' 6(59,&( %8//(7,16

6&+(0$7,&6 '5$:,1*6

*(1(5$/ ,1)250$7,21

86( 2) 7+,6 0$18$/

&219(17,216 86(' ,1 7+,6 0$18$/

6(5,$/ 180%(56

&(57,),&$7,21 2) &203/,$1&(

6(59,&( ,1)250$7,21 )'$ &203/,$1&(

,167$//$7,21

,1752'8&7,21

|

6,7(,163(&7,21 |

|

813$&.,163(&7/$6(5 |

|

&21),*85( $& &21752/3&% |

|

$''&22/$17 |

|

785121 |

|

&86720(5'(021675$7,21 |

352'8&7 63(&,),&$7,21

&$/,%5$7,21 $'-8670(17 $/,*10(17

,1752'8&7,21

|

29(59,(: |

|

6$)(7<35(&$87,216 |

237,&$/ $/,*10(17

|

)2/',1*0,5525 $/,*10(17 |

|

<$* &+$11(/ $/,*10(17 |

|

0$.,1*7(67%8516 |

|

$'-867,1* 7+(<$* &+$11(/237,&6 |

|

5(621$725 $/,*10(17 |

|

6(5920,5525 $/,*10(17 |

|

),%(5 $/,*10(17 |

|

|

|

3<52'(7(&725 $/,*10(17 |

|

$,0,1*%($0 $/,*10(17 |

(/(&75,&$/ $'-8670(176

|

92/7$*(&21),*85$7,21 |

|

)$163((' $'-8670(17 |

|

63($.(592/80( $'-8670(17 |

0(&+$1,&$/ $'-8670(176

|

(;7(51$/),%(56(16(6:,7&+ $'-8670(17 |

|

%/$676+,(/'6(16(6:,7&+ $'-8670(17 |

(1(5*< 021,725 $1' $872 &$/,%5$7,21

6<67(0 237,0,=$7,21 &+(&.

|

),%(5 $/,*10(177(67 |

|

9(5,)<&$/,%5$7,21'(/,9(5('32:(5287 2) 7+(),%(5 |

|

)/$6+/$033(5)250$1&(&+(&. |

23(5$7,21$/ $1' 6$)(7< &+(&.287

3(5,2',& 0$,17(1$1&( 5(48,5(0(17

7+(25< 2) 23(5$7,21

,1752'8&7,21

|

23(5$7,21$/29(59,(: |

|

)81&7,21$/29(59,(: |

32:(5 6:,7&+,1* &21',7,21,1* ',675,%87,21

|

,138732:(5 |

|

32:(5',675,%87,21 |

|

785121 |

|

&,5&8,7%5($.(521.(<6:,7&+2)) |

|

7851216(48(1&( |

|

6+87'2:1 |

|

/2:92/7$*(32:(56833/,(6 |

&22/,1*

|

&20321(176 |

&21752/ (/(&7521,&6

|

29(59,(: |

|

0,&52352&(6625 |

|

',*,7$/, 2 &,5&8,76 |

|

'$ $' &219(56,21&,5&8,76 |

|

'& 32:(56833/<021,725&,5&8,76 |

|

$8',2 $03/,),(5&,5&8,7 |

|

6+877(5)2276:,7&+5(027(,17(5/2&.&,5&8,76 |

|

6(59202725&21752/&,5&8,7 |

|

+936 &21752/&,5&8,76 |

|

(1(5*<021,725&,5&8,76 |

|

86(5,17(5)$&( $1'5(027(&21752/&,5&8,76 |

|

$,0,1*',2'(/$6(5&,5&8,7 |

|

),%(5 $1'%/$676+,(/'326,7,216(16(&,5&8,76 |

|

|

|

6(59,&( $77(18$725&,5&8,7 |

|

/2:(1(5*< $77(18$725&,5&8,7 |

)/$6+/$03 32:(5 &,5&8,76

237,&6

62)7:$5(

7528%/(6+227,1*

29(59,(:

|

6(59,&(3+,/2623+< |

|

6$)(7<35(&$87,216 |

,17(5,25 $&&(66 3$576 /2&$7,21

6(59,&( 02'(

)$8/7 ,62/$7,21

|

785121 $1'6+87'2:1)$8/7,62/$7,21 |

|

³12)$8/7&2'(5(3257('´ )$8/7,62/$7,21 |

|

³)$8/7&2'(5(3257('´ )$8/7,62/$7,21 |

7(67 32,176/(' $55$1*(0(17

|

&21752//(53&% /('6 |

5(029( 5(3/$&( 352&('85(

|

)/$6+/$035(3/$&(0(17 |

|

&21752//(53&% 5(3/$&(0(17 |

|

:$7(5),/7(55(3/$&(0(17 |

7528%/(6+227,1*

6(/(&7(' 3$576

63(&,$/ 722/6 86(5 5(3/$&($%/( 68% $66(0%/,(6 &21752/ 6<67(0 35,17(' &,5&8,7 %2$5'6

+,*+ 92/7$*( 32:(5 6833/< &+$66,6 6.,16

&+$66,6 (/(&75,&$/ 0$-25 68% $66(0%/,(6 &$%/( 6(76 +$51(66(6 &22/,1* 6<67(0

237,&6 &20021

237,&6+2/0,80

237,&6 1(2'<0,80

),(/' 6(59,&( %8//(7,16

),(/' 6(59,&( %8//(7,16

9(56$38/6( 32:(568,7( ),(/' 6(59,&( %8//(7,1 ,1'(; -8/<

180%(5 '$7(7,7/(

&2',1* ,16758&7,2169(56$38/6(352'8&7 /,1(

-8/<

9(56$38/6( 32:(568,7( )6% 5(9 + +,*+ 92/7$*( 32:(5 6833/< &21752//(5 3&% 3 1 0$<

,1752'8&7,21

5(9,6,21 + &21752//(5 3&% ,1752'8&7,21 3$576 5(48,5('

5(752),7 ,16758&7,216

9(56$38/6( 32:(568,7( )6% 62)7:$5( &+$1*(6 1(;7 &$// 5(752),7

-8/<

6&+(0$7,&6 $1' '5$:,1*6

*(1(5$/ ,1)250$7,21

1.1 USE OF THIS MANUAL

This manual contains service instructions for the Lumenis VersaPulse® PowerSuite™ series of Holmium and Neodymium YAG surgical lasers. The content of this manual is intended solely for use by Lumenis Field Service Engineers and Lumenis trained and certified customer technicians. Lumenis, Inc. cannot be responsible for service or repairs attempted by uncertified persons, and the use of this manual by such persons is prohibited.

This manual is to be used in conjunction with the Lumenis Operator Manual for the VersaPulse PowerSuite laser. The operator manual contains important information regarding instrument description, location of controls, specifications and normal operating procedures.

As necessary, Lumenis Service Technical Support releases Field Service Bulletins (FSB) for the VersaPulse PowerSuite laser. These FSB’s supplement the information in this manual. As they are released, the FSB’s become a part of this manual (Section 7).

1.2 CONVENTIONS USED IN THIS MANUAL

Within the text, logic signals that are active low (“notted”) will appear inside of slash marks, as illustrated below.

/ATTENIN/

These signals are “active”, or true, when the logic level is low. When the logic signal /ATTENIN/ is low, the attenuator loop is “OK” (complete). When the logic signal /ATTENIN/ is high, the attenuator loop is not OK (open). In most of the schematic diagrams such signals are indicated by the usual solid line above the signal name, as illustrated below.

ATTENIN

The schematics in this manual do not include individual numbers for the logic elements or operational amplifiers within a single component. For example, U1 which is illustrated on the next page, contains two

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

*(1(5$/ ,1)250$7,21 |

5(9 % |

|

operational amplifiers. The top op amp would be referred to as U1-1 (its output is pin 1) and the other would be referred to as U1-7.

2 |

|

|

|

|

|

1 |

|

|

|

|

|

||

3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

||||

6 |

|

|

|

|

|

7 |

|

|

|

|

|||

|

|

|

|

|

||

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

||||

1.3 SERIAL NUMBERS

Serial numbers for the VersaPulse PowerSuite laser are in the following format:

MYPHWVXXX

where M is the month produced

(“A” is January, “B” is February, etc..) Y is the last digit of the year produced

(0 is 2000, etc..)

P is a number indicating maximum system power (9=100W, 6=60W, 4=45W, 3=30W)

( D=60W Ho/100W Nd, E=80W Ho/100W Nd) H is the number of laser heads installed (1, 2, 3 or 4)

W is a number indicating the mix of rods intalled (see below)

V is a number indicating power supply configuration (1= 220VAC single phase)

2XXX is the number of the laser built (2001, 2002, etc..)

W:3 = Holmium only

4 = Ho/Nd:YAG

*(1(5$/ ,1)250$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

1.4 CERTIFICATION OF COMPLIANCE

The VersaPulse PowerSuite laser is designed and tested in accordance with Lumenis’s procedures for self certification for a CE mark.

The CE mark is a certification label which allows Lumenis to sell the VersaPulse PowerSuite Lasers throughout the European community. This label certifies that the VersaPulse PowerSuite laser meets all regulations set forth by various countries in Europe. It is important to ensure that this label is on the laser chassis.

((&

1.5 SERVICE INFORMATION & FDA COMPLIANCE

In compliance to the FDA, brochures and specifications sheets must include a reproduction of a complete warning logotype or Class IIa warning statement as required on the product (1040.10(h)(2)(i)). Servicing information must contain the following (1040.10(h)(2)(ii)):

•Procedures for service with appropriate warnings to avoid exposure. (Refer to Section 3)

•A schedule of maintenance to maintain the product in compliance (Refer to Section 3)

•A list of controls that could increase the level of accessible radiation.

••The energy UP/DN buttons on the LCD touch screen display.

••The power UP/DN buttons on the LCD touch screen display.

••The energy UP/DN buttons on the remote control display.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

*(1(5$/ ,1)250$7,21 |

5(9 % |

|

••The power UP/DN buttons on the remote control display.

•Identification of removable portions of protective housings. (Refer to Section 5)

•Procedures to avoid exposure. (Refer to Section 3)

•Reproductions of required labels and warnings.

••Below are illustrations of required labels and warnings applicable to this Service Manual:

! "

#$% ! "

&

'$" "( % ) )

* +',-!"( # . / 00

* +',-!"( 1

Remote

Interlock

|

|

|

|

|

|

|

(REAR VIEW) |

||

|

|

|

|

|

*(1(5$/ ,1)250$7,21 |

|

|

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

|

|

|

5(9 % |

|

/DVHU DSHUWXUH DW GLVWDO HQG RI ILEHU

(FRONT VIEW)

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

*(1(5$/ ,1)250$7,21 |

5(9 % |

|

*(1(5$/ ,1)250$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

,167$//$7,21

2.1 INTRODUCTION

WARNING: Installation by untrained persons is a potential hazard to the persons doing the installations, others present, and to the equipment itself. In addition, improper installation is a potential hazard to the user, persons present during use, and patient.

These installation instructions are provided for use by Lumenis Service Engineers who have completed certification service training on the VersaPulse® PowerSuite™ laser. Installation by untrained persons is a potential hazard to the person or persons performing the installation, others present and to the equipment itself. In addition, improper installation is a potential hazard to the user, persons present during use and patient.

2.1.1 Site Inspection

1.Check for proper site set up. This includes proper AC service and adequate space for the console.

AC power configuration: The VersaPulse PowerSuite requires 220 VAC±10%, 50/60 Hz, 30 Amps (32 Amps for 100W Holmium) single phase electrical service. The power cord is a 26 ft. cable with two conductors and a ground. An AC Control PCB behind the right side cover allows for tapping of the isolation transformer to the setting closest to the incoming electrical service. The system can be hard wired to the electrical service or installed to the electrical service with a plug and receptacle. Customers are responsible for supplying electrical connections (i.e., electrical receptacle and mating plug).

Console dimensions and weight: The console measures 36” L x 18” W x 39” H. It weighs approximately 350 lbs. A minimum of 18” of air space is required around the unit to provide adequate cooling air circulation.

The system requires approximately 2.5 gallons of distilled water for its closed loop cooling system. The coolant must be added as described in this procedure.

Complete specifications for the VersaPulse PowerSuite laser are included later in this section and in the VersaPulse PowerSuite laser Operator Manual. Contact Technical Support in Santa Clara, CA. if there are any questions concerning site preparation.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

,167$//$7,21 |

5(9 % |

|

2.Verify the AC mains voltage at the site.

Frequency: |

50/60Hz |

Voltage: |

220 VAC ±10% |

Current: |

30A (32A for 100W Holmium) |

Phase: |

Single (I) |

2.1.2 Unpack & Inspect Laser

1.Check the crate/carton for any shipping damage.

The shipper is responsible for any damage to the system in shipment. If the crate/carton appears to be damaged, report the damage to the customer and shipper.

2.Remove the console and accessories from the crate (refer to Fig. 2.1).

a.Loosen the six butterfly clamps securing the side door and lower the side door (the side door is used as a ramp to remove the console from the crate). Remove the protective foam and accessories box. Install the ramps onto the base, then roll the unit down the ramps.

b.Return all packing material to the crate and save for future use.

,167$//$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

|

ACCESSORY |

|

BOX |

FOAM |

|

PADDING (6) |

DISTILLED |

INSIDE THE |

WATER |

CRATE |

|

BUTTERFLY CLAMPS |

|

(6) SECURE THE SIDE |

|

DOOR |

|

COVER RAMP

FIG. 2.1

SHIPPING

CRATE

3.Move the system to its installation location.

The VersaPulse PowerSuite laser rolls best when pushed from the front handles. The front wheels swivel, the rear wheels do not.

4.Open/remove covers and do a visual inspection of the interior.

Refer to Section 5 for information on removing the covers. Open the front cover, then remove the top and two side covers. Inspect the interior carefully for loose or broken electrical or optical connections, loose or broken plumbing connections, or any indication of shipping damage.

2.1.3 Configure AC Control PCB

Refer to Section 3.3.1 for additional details.

1. AC voltage configuration preparation.

a. Measure the mains voltage and record.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

,167$//$7,21 |

5(9 % |

|

b.Verify the VersaPulse PowerSuite is not connected to the AC mains.

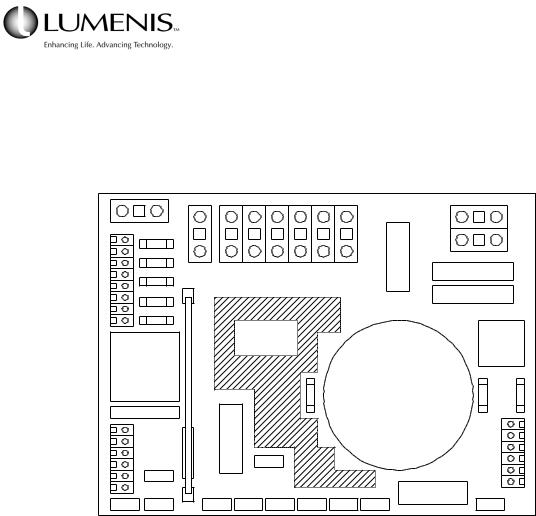

2.Locate the AC Control PCB (behind the right side panel) and identify TB5 & TB2 (top of the PCB). Refer to Fig. 2.2.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

# |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

! |

! |

|

! |

! |

! |

! |

! |

! " |

! |

|

FIG. 2.2 AC CONTROL PCB

3.Locate the large brown wire in TB5-1 and position the other end in TB2 as follows:

a.For mains voltage in 190 - 210 VAC range, connect TB5-1 to TB2-2.

b.For mains voltage in 211 - 230 VAC range, connect TB5-1 to TB2-3.

c.For mains voltage in 231 - 264 VAC range, connect TB5-1 to TB2-4.

4.Locate the two small blue jumper wires in TB7 (bottom right). Position the jumpers as follows:

a.For mains voltage in 190 - 210 VAC range, jumper TB7: 1-3, 4-6.

b.For mains voltage in 211 - 230 VAC range, jumper TB7: 1-3, 5-6.

,167$//$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

c.For mains voltage in 231-264 VAC range, jumper TB7: 2-3, 5-6.

5.Record the voltage range on the Certification Report.

6.Connect to AC service.

CAUTION: Once connected to the site electrical service, lethal voltages are present inside the unit. The AC power is present at the circuit breaker, main contactor and the AC Control PCB. Review and understand the safety subtopic in Section 5 before proceeding.

The system can be hard wired to electrical service, but is more typically connected by a plug to an electrical outlet.

If the system is to be hard wired, the customer must provide an electrician to wire the cord end into the electrical service outlet. A lockable electrical service disconnect switch must be installed if the system is hard wired.

If the system is to be plugged into an electrical receptacle, the appropriate receptacle should already be installed by the customer’s electrician. The installing engineer connects the plug to the end of the VersaPulse PowerSuite electrical cable.

2.1.4 Add Coolant

Add coolant (distilled water) to the fill reservoir. The coolant will drain out of the fill reservoir and into the main reservoir. The system uses approximately 2.5 gallons of coolant. Most coolant can be added at this time - until the fill reservoir level stays up. The system coolant level will be “topped off” after the system is turned on (in a later step).

NOTE: Use distilled water only! Do not use alcohol or glycol based additives.

2.1.5 Turn On

CAUTION:

•Once the circuit breaker is turned on and power is applied to the VersaPulse PowerSuite laser, wait a few minutes and observe for any indication of failure of the mains or turn-on components. Check for any coolant leaks.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

,167$//$7,21 |

5(9 % |

|

•The system will fire during the turn-on sequence regardless if SW3 (Autocal) on the CPU PCB is left or right and the BRH plug is installed. Only those persons required should be present during this portion of the installation - those present must wear appropriate laser safety eyewear and follow all laser safety precautions.

•The cooling fan blades are not covered. The fan is located on top of the heat exchanger. It operates whenever the system is turned on. Keep tools, system parts and body parts clear of the fan blades.

1.Turn and hold the keyswitch to the START position, then after approximately two seconds, release it to the ON position. The system will go through its start up sequence. Observe for normal start up, and for any indication of leaks in the cooling system.

2.Add additional coolant if necessary.

NOTE: Only add water if disconnected from AC mains.

Turn system off and disconnect from the AC mains. Top off the fill reservoir. Reconnect to AC mains and cycle the machine off and on several times, adding coolant as necessary until the fill reservoir level stays up to approximately half full as the system runs.

3.Perform Fiber Alignment Test, Verify Calibration procedure and the Operational & Safety checks in Section 3.

4.Replace all covers and prepare the system for demonstration to the customer.

2.1.6 Customer Demonstration

1.Demonstrate the system operation to the customer.

2.Fill out and mail the “self mailer” installation quality audit report (for U.S. Field Service).

3.Fill out the System Certification report.

,167$//$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

2.2 PRODUCT SPECIFICATION

Specifications are subject to change without notice.

VersaPulse Power Suite Dual Wavelength laser

Treatment beam wavelengths

Ho:YAG (2.1µm)

Nd:YAG (1.06µm)

7DEOH : 0RGHO

Wavelength |

Power |

Energy |

Exposure |

Pulse Rate |

Pulse Width |

|

Time |

||||||

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ho:YAG |

0 - 60W |

0.2 - 3.5 J* |

n/a |

5 - 40 pulses/ |

600µs Max |

|

(2.1µm) |

|

|

|

sec.* |

|

|

|

|

|

|

|

|

|

Nd:YAG |

0 - 100W** |

0.08 - 1.67J |

0.1 - 180 sec.* |

60 pulses/ |

2ms Max |

|

(1.06µm) |

|

|

or |

sec. |

|

|

|

|

|

continuous |

|

|

|

|

|

|

|

|

|

7DEOH : 0RGHO

Wavelength |

Power |

|

Energy |

Exposure |

Pulse Rate |

Pulse Width |

|

|

Time |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ho:YAG |

0 - 80W |

|

0.2 - 3.5 J* |

n/a |

5 - 40 pulses/ |

600µs Max |

|

(2.1µm) |

|

|

|

|

sec.* |

|

|

|

|

|

|

|

|

|

|

Nd:YAG |

0 - 100W** |

|

0.08 - 1.67J |

0.1 - 180 sec.* |

60 pulses/ |

2ms Max |

|

(1.06µm) |

|

|

|

or |

sec. |

|

|

|

|

|

|

continuous |

|

|

|

|

|

|

|

|

|

|

|

* adjustable in variable increments |

|

|

|

|

|

||

** adjustable in 5 Watt increments |

|

|

|

|

|

||

VersaPulse PowerSuite Holmium laser |

|

|

|

|

|||

Treatment beam wavelength |

|

|

|

|

|||

|

|

|

|

|

|

|

|

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

|

,167$//$7,21 |

||||

5(9 % |

|

|

|

|

|

||

7DEOH +R <$* —P

Model |

Power |

Energy |

Pulse Rate |

Pulse Width |

|

|

|

|

|

|

|

|

|

|

30 Watt |

30W |

0.2 - 3.5J |

5 - 25 pulses/ |

600µs Max |

Ho:YAG |

|

|

sec. |

|

|

|

|

|

|

45 Watt |

45W |

0.2 - 3.5j |

5 - 40 pulses/ |

600µs Max |

Ho:YAG |

|

|

sec. |

|

|

|

|

|

|

60 Watt |

60W |

0.2 - 3.5J |

5 - 40 pulses/ |

600µs Max |

Ho:YAG |

|

|

sec. |

|

|

|

|

|

|

100 Watt |

100W |

0.2 - 3.5J |

5 - 50 pulses/ |

600µs Max |

Ho:YAG |

|

|

sec. |

|

|

|

|

|

|

VersaPulse PowerSuite Dual Wavelength and Holmium lasers

Laser Classifications:

US FDA CDRH laser classification: Class IV

European EN 60825 laser classification: Class 4

Aiming Beam:

Type: Diode

Power: 1 mW maximum, Continuous Wave

US FDA CDRH laser classification: Class IIIa

European EN 60825 laser classification: Class 3A

Principal output: Red, 650nm (±10 nm)

Input Power

Frequency: 50/60 Hz

Voltage: 220 VAC ±10%

Phase: Single

Current: Holmium 100W systems, 32A

All other Holmium systems, 30A

Dual wavelength systems, 30A

Cooling

Internal water-to-air heat exchanger or optional secondary cooling system

,167$//$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

Cooling air requirements

Minimum 46 cm (18 in.) from walls

Physical characteristics

Width: 46 cm (18 in.)

Length: 91 cm (36 in.)

Height: 99 cm (39 in.)

Weight: 163kg (360 lbs.)

Power cord length

8.0 m (26 ft.)

Footswitch cable length

3.7 m (12 ft.)

Environmental requirements (operating)

Maximum altitude: 3,050 m (10,000 ft.)

Temperature range: 10• C to 30• C (50• F to 86• F) - must be above dew point

Maximum humidity: 90% at 27• C (81• F) non-condensing

Environmental requirements (non-operating)

Maximum altitude: 9,144 m (34,564 ft.)

Temperature range: 10• C to 50• C (50• F to 122• F) - must be above dew point

Maximum humidity: 90% at 55• C (131• F) non-condensing

Optional external cooling system

Cooling capacity: 4.5 kW

Flow rate: 0.25 lps (4gpm)

Temperature set point: 20• C (68• F)

Connections: Quick connect

Line size: 1/2 inch minimum

Compatible delivery systems: (The laser is intended for use only with Coherent-qualified delivery systems)

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

,167$//$7,21 |

5(9 % |

|

,167$//$7,21 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

&$/,%5$7,21 $'-8670(17

$/,*10(17

3.1 INTRODUCTION

3.1.1 Overview

This section contains procedures for the checks and adjustments required to maintain the Lumenis VersaPulse® PowerSuite™ Laser. The procedures assume the reader has successfully completed a Lumenis service training course on the VersaPulse PowerSuite laser. Service performed by untrained or unqualified persons can be a hazard to the person or persons doing the service and to others present during the servicing. An improperly serviced medical system can be a hazard to the equipment user, to others present during use, and to the patient upon whom the laser is used.

The procedures should be performed in the order presented, from beginning to end. If only a portion of the procedures are done, the servicing engineer must consider the possible effect of doing just that portion of the procedures (i.e., there may be adjustments done earlier or later in the procedures that impact or are impacted by the portion performed).

Optical Alignment, Topic 3.2, this is performed when the System Check out procedure indicates a problem, any of the various optical/electro-optical/servo components have been adjusted/replaced or the system cannot meet specifications during the various calibration procedures.

Electrical Adjustments, Topic 3.3, verifies the Fan Speed Controller PCB is properly adjusted for optimal cooling and the speaker volume is properly adjusted.

Mechanical Adjustments, Topic 3.4, verifies that various mechanical switches and latches are properly set.

Energy Calibration, Topic 3.5, calibrates the voltage output of the two energy monitor circuits to the Field Service Engineer’s calibrated power meter.

System Optimization Check, Topic 3.6, verifies that the system is operating optimally after the preceeding procedures (i.e., optical, electrical and etc.) have been completed and test the calibration at all operating points.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

&$/ $'-867 $/,*1 |

5(9 % |

|

Operational and Safety Check, Topic 3.7, is an operational check of the system. It confirms that the system turns on properly, responds properly to operator inputs, delivers the multiplexed YAG beam into the center of an attached fiber, and provides an adjustable aiming beam through the fiber. It also confirms that the proper fault messages are displayed when various connectors (i.e., footswitch and remote interlock plug) are disconnected and the system is prevented from firing.

Periodic Maintenance, Topic 3.8, provides information on periodic maintenance checks to ensure optimum performance of the system.

TOOLS & EQUIPMENT REQUIRED: |

|

Power Calibration Test Fibers |

10mm Aperture Alignment Tool 0622-919-51 |

for Ho/Nd 0623-973-01 |

Transimpedance Amplifier 0614-868-51 |

Field Master |

Calibrated Oscilloscope |

Cross-Hair Alignment Tool 0621-131-51 |

FSH Head |

Zap-It paper 3207-0091 |

Berol 8800 red Marker |

Ink/Burn Test Fiber 0621-675-01 |

Poly Bags |

DVM & Leads |

|

Two test fibers are shipped with the system. Check the fiber focus as described in Section 3, Topic 3.2.

3.1.2 Safety Precautions

Lethal voltages and laser emission are the primary dangers to the servicing engineer. In addition to the general safety precautions which always apply when working on electronics and lasers, the servicing engineer must be aware of the following specific precautions:

•Only Lumenis certified VersaPulse PowerSuite YAG service engineers should attempt any service on this system.

•Even with the keyswitch and the breaker in the “OFF” position there are lethal voltages present inside the console. Always disconnect the main electrical service before working on the console.

•Storage capacitors inside the system are capable of holding a lethal charge, even after power has been removed from the unit. A charge level indicator LED located on the Simmer/Start Control PCB flashes at a rate proportional to the level of charge on the main charging capacitor. The LED can be seen through a small access window on the High Voltage Power Supply cover next to the Controller PCB. Do not rely on this indicator to determine that the main charging capacitor has been discharged. Before contacting the main charging capacitor, disconnect the system from the primary power.

&$/ $'-867 $/,*1 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

•Do not touch the YAG Cavity Module when the system is on - IT IS A SHOCK HAZARD.

The YAG Cavity Module is electrically isolated from the chassis and can be at a voltage potential much higher than ground. A Neon lamp on the Starter Indicator PCB indicates lamp start high voltage is present when flashing. B+ is always on the pod’s terminal block.

•Both Holmium & Nd:YAG laser emissions are invisible to the human eye. Because the YAG laser energy can not be seen, there is no visible indication of the primary or reflected beam. Eye protection that attenuates the YAG wavelengths to a safe level must be worn by all persons in the area of the laser system, whenever the laser is being serviced.

•The YAG laser light and its reflections are potential burn hazards and can ignite flammable materials. Use extreme caution when operating the system with covers opened or removed. The covers contain the beam and reflections safely within the console. Only those persons required should be present during servicing and eye protection that safely attenuates the YAG wavelengths must be worn by all present.

•The YAG laser light and its reflections are potential hazards to the eye and skin. Use extreme caution when operating the system with the covers opened or removed. The covers contain the beam and reflections safely within console. Only those persons required should be present during servicing and eye protection that safely attenuates the YAG wavelengths should be worn by all those present.

3.2 OPTICAL ALIGNMENT

Perform the Optical Alignment procedures whenever any optical or electro-mechanical device have been replaced or adjusted in the optics bench or in the laser head. Note that the procedures should be performed in the order presented, from beginning to end. If only a portion of the procedures are done, the servicing engineer must consider the possible effect of doing just that portion of the procedures (i.e., there may be adjustments done earlier or later in the procedures that impact or are impacted by the portion performed).

3.2.1 Folding Mirror Alignment

This is not normally performed in the field. contact Lumenis Technical Support Department for additional tooling and instructions if required to perform this alignment.

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

&$/ $'-867 $/,*1 |

5(9 % |

|

3.2.2 YAG Channel Alignment

When properly adjusted the YAG channel will meet each of the following three criteria.

•The cavity HR will be positioned to direct the YAG output to the center of the first relay mirror, and the cavity OC will be positioned to provide maximum power for that HR position.

•The first relay mirror and second (plano) relay mirror will direct the YAG energy off the two folding mirrors so that it is centered through the wedge optic apertures and centered into the proximal end of the fiber.

The adjustment procedure for a single channel follows. The procedure is a complete check out and alignment for a single channel. The procedure is meant to be done in the order given, from beginning to end.

It may often be appropriate to do less than the complete adjustment, but in such a case the field service engineer must consider the possible effect of doing only a portion, i.e., the adjustment may have an effect on some other portion of the alignment. As an example, if a single channel is only slightly out of center at the fiber port, it can usually be corrected by simply adjusting the first relay mirror (using the fiber detector signal) and then confirming the adjustment using a test fiber burn.

When replacing a damaged optic, it should not be necessary to do the entire procedure. Try to bring the system back into alignment by adjusting the optic that was replaced.

3.2.2.1 Making Test Burns

(Refer to Fig 3.2 and 3.3) Checking out and aligning the YAG channels requires making burns on photopaper to check alignment. The Alignment Aperture and Cross Hair Aperture are two special purpose tools used when making burns.

In general, when making burns, lower pulse energies and fewer total pulses are better. As the total energy of the burn increases, the footprint becomes "blurred". In some cases it will be necessary to get a "multiplexed footprint", i.e., the paper is burned by more than one channel, allowing the YAG beam positions to be compared. In other cases a single channel burn will be required. The service engineer can select the channels to be fired, a lamp current and a pulse rate at the service screens. Setting a lower pulse rate allows the footswitch to be operated to obtain just a single pulse from a channel, or from each selected channel.

The alignment aperture is used to center the YAG beam(s) in front of the second wedge optic. It holds a piece of burn paper (covered on both sides with plastic to contain splatter). A good burn will fall inside the aperture (the aperture will not clip the beam). The tool is keyed with two small posts that fit into holes on the face of the second wedge optic housing block. To use the aperture, slide burn paper and plastic in through the side, then insert it on the second wedge optic housing.

&$/ $'-867 $/,*1 |

9HUVD3XOVHŠ 3RZHU6XLWHŒ 6HULHV 6HUYLFH 0DQXDO |

|

5(9 % |

Loading...

Loading...