Page 1

Instruction manual for rescue equipment

Rescue Rams

alternative coupling system:

10

12

11

8

14

4

1 Star grip

2 Control valve

3 Hydraulic cylinder

2

1

7

3

2

4 Piston rod (R41x)

5 Piston rod 1 (R42x; R43x)

6 Piston rod 2 (R42x; R43x)

7 Handhold

1

8 Claw, piston side

9 Claw, cylinder side

7

10 Hose, pressure

11 Hose, return

12 Mono-coupling male

11

13 Quick-disconnect coupling

(male)

10

14 Quick-disconnect coupling

(female)

13

6

5

3

9

174010085 EN

9

(Translation of the original instruction manual)

12

Edition 10.2014

replaces 01.2014

Page 2

Content Page

1. Hazard classes 4

2. Product safety 5

3. Safety regulations for hydraulic hoses 8

3.1 Advices for hoses 9

3.2 Safeguarding the environment in the event of failure of the

hoses 9

3.3 Storage of hoses 9

3.4 Labelling the hoses 10

3.5 Dates for inspections and replacement of hoses 10

3.6 Examples of possible defects of hoses 10

4. Proper use 11

5. Description of the functions 12

5.1 Description 12

5.2 Circuit diagram 12

5.3 Control of the operating movements 12

5.4 Type R 41x 13

5.5 Type R 43x / R 42x 13

5.6 Hydraulic supply 13

5.7 Hoses 13

6. Connecting the equipment 14

6.1 General information 14

6.2 Coupling the mono-couplings 14

6.3 Coupling the quick-disconnect couplings (alternative system) 15

7. Operation 16

7.1 Preparatory measures 16

7.2 Danger notes 18

7.3 Operating the star grip

7.4 Use of extensions 19

8. Dismantling the equipment / deactivation following operation 19

8.1 Rescue ram 19

8.2 Hydraulic unit 20

8.3 Hoses 20

9. Maintenance and service 20

(cover: item 1) 19

2

Page 3

10. Repairs 21

10.1 General information 21

10.2 Preventative service 22

10.3 Repairs 23

11. Troubleshooting 26

12. Technical Data 29

12.1 Recommended hydraulic fl uid 33

12.2 Hoses 33

12.3 Operating and storage temperature ranges 33

13. EC Declarations of conformity 34

14. Notes 35

3

Page 4

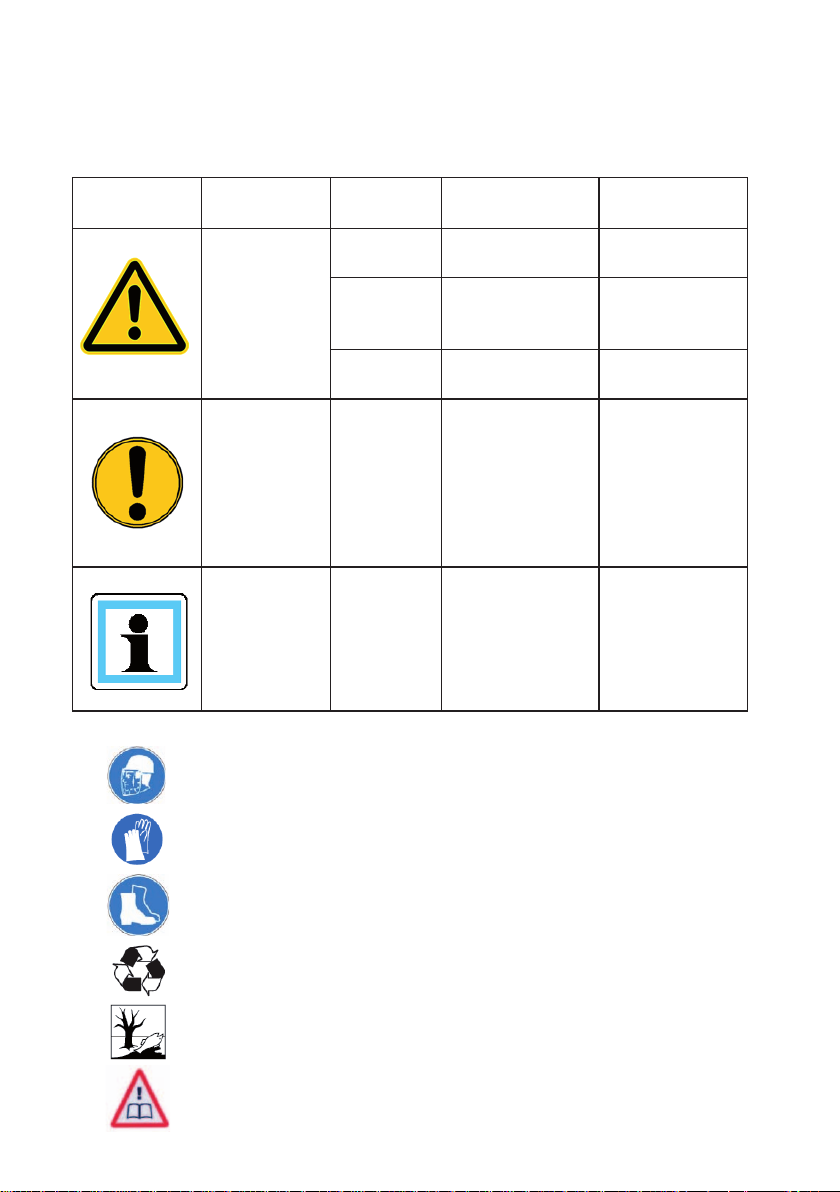

1. Hazard classes

We distinguish between various categories of safety notes. The table below gives you an

overview of the assignment of symbols (pictograms) and key words to the specifi c hazard

and possible consequences.

Pictogram

Wear helmet with face protection

Damage /

injury to

human

device

- REMARK

Key word Defi nition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

CAUTION!

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to device /

environment

Advice for

application and

other important /

useful information

and advice

Death or major

injury

Potential death or

major injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surrounding

materials

No injury /

damage to

persons /

environment /

equipment

Wear safety gloves

Wear safety shoes

Proper recycling

Observe principles of environmental protection

Read and observe operating instructions

4

Page 5

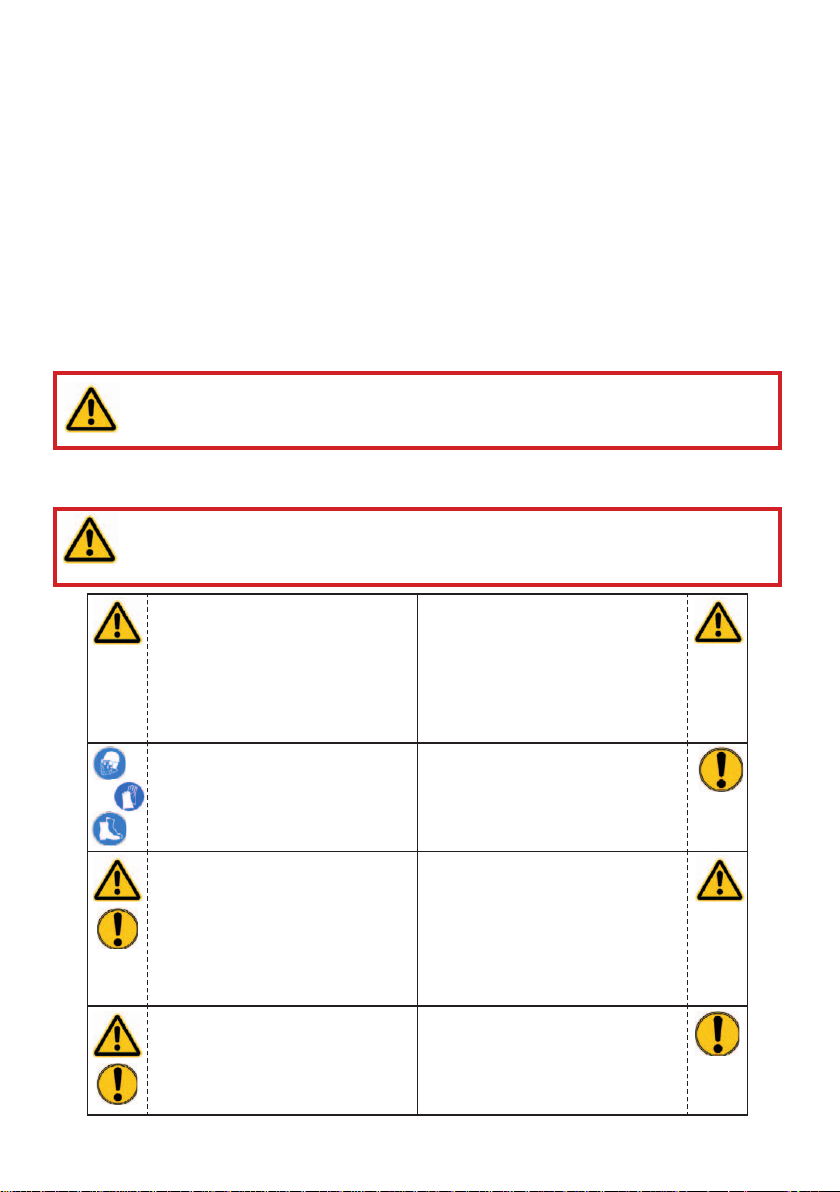

2. Product safety

LUKAS products are developed and manufactured in order to guarantee the best performance

and quality when used properly.

Operator safety is the most important aspect of the product design.

Moreover, the operating instructions are intended to help the safe use of LUKAS products.

The generally applicable, legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be implemented in addition to

the operating instructions.

The equipment may only be operated by persons with appropriate training in the safety

aspects of such equipment – otherwise, there is a danger of injury occurring.

We would like to point out to all users that they should read carefully the operating instructions

and the instructions contained therein before they use the equipment, and that they should

carefully follow such.

We further recommend that a qualifi ed trainer train you in the use of the product.

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

hydraulic equipment must also be observed!

Even if you have already received instructions on how to use the equipment, you should still

read the following safety notes through again.

WARNING / CAUTION!

Ensure that the accessories and connected equipment used are suitable for

the max. operating pressure!

Please ensure that no body

parts or clothing get stuck

between the visibly moving

parts (e.g. piston claw and

cylinder).

Wear protective clothing, safety

helmet with visor, protective

gloves

The responsible department

is to be informed immediately

of any changes (including to

the operating behaviour)! If

necessary, the equipment is

to be deactivated immediately

and secured!

In the event of malfunctions,

immediately deactivate the

equipment and secure it. The

malfunction is to be repaired

immediately .

It is prohibited to work under

load if this load is lifted

exclusively by hydraulic

equipment. If this work

is absolutely imperative,

additional mechanical supports

must be used.

Inspect the equipment before

and after use for visible defects

or damage

Inspect all cables, hoses

and screwed connections for

leaks and externally visible

damage! If necessary, repair

immediately! Squirting oil can

result in injuries and fi res.

Do not carry out any changes

(additions or conversions)

to the equipment without

obtaining the prior approval of

LUKAS.

5

Page 6

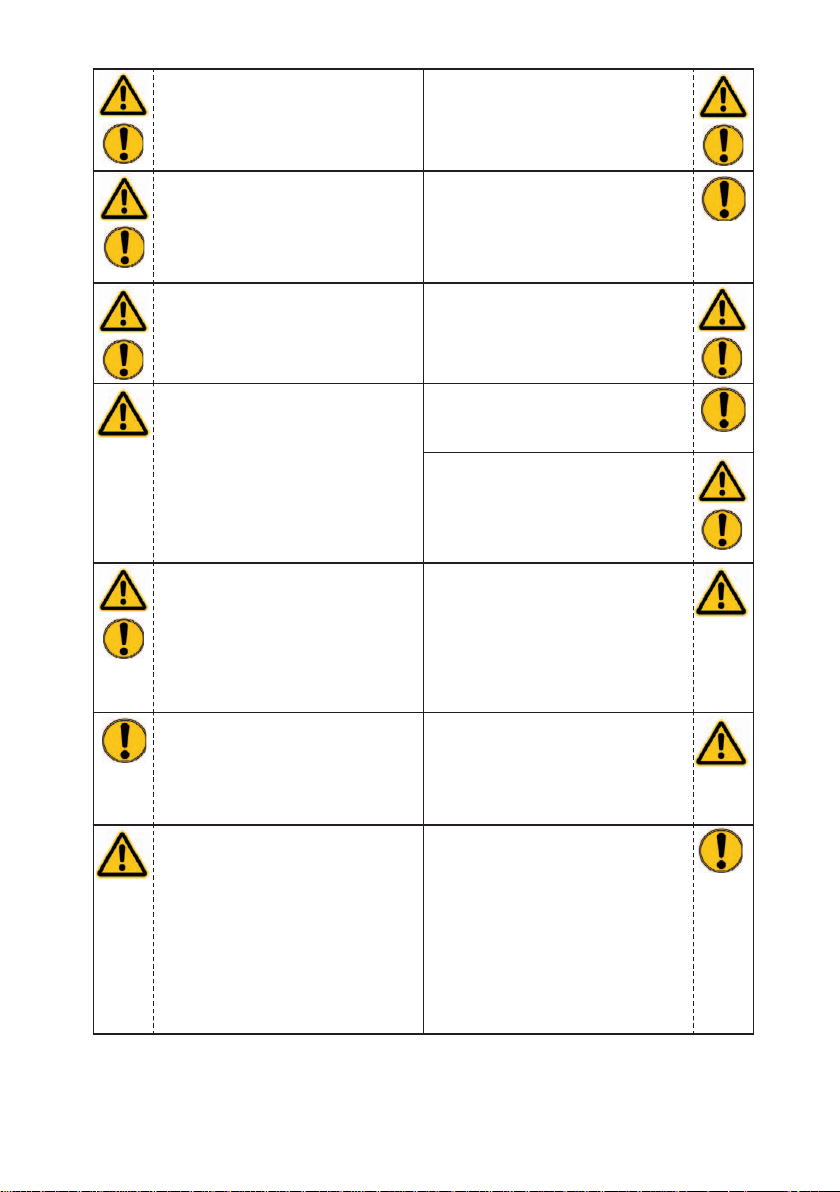

Observe all safety and danger

notes on the equipment and in

the operating instructions.

All safety and danger notes on

the equipment are to be kept

complete in a legible condition.

Any mode of operation which

impairs safety and/or stability

of the equipment is forbidden!

Safety devices may never be

deactivated!

Before the equipment is

switched on/started up, and

during its operation, it must

be ensured that nobody is

endangered by the operation of

the equipment.

When working close to live

components and cables,

suitable measures must be

taken to avoid current transfers

or high-voltage transfers to the

equipment.

The build-up of static charge

with the potential consequence

of spark formation is to be

avoided when handling the

equipment.

The equipment is fi lled with a

hydraulic fl uid. These hydraulic

fl uids can be dangerous to

health if swallowed or their

vapours inhaled. Direct contact

with the skin is to be avoided

for the same reason. Please

also note that hydraulic liquids

can also have a negative effect

on biological systems.

Comply with all specifi ed

dates or dates specifi ed in

the operating instructions

pertaining to regular controls /

inspections on the equipment.

The maximum permitted

operating pressure noted on

the equipment must not be

exceeded.

Only original LUKAS

accessories and spare parts

may be used for repairs.

Please ensure that, when

working with this equipment

or during transportation of

such, you don’t get stuck in the

looped hoses and trip.

Please note that, when

applying pressure, tearing or

breaking can cause falling

material, or sudden removal of

such can cause it to suddenly

catapult off: necessary

precautions need to be taken.

Only touch any broken-off parts

wearing protective gloves,

since the torn edges can be

very sharp.

When working with or storing

the equipment, ensure that

the function and the safety

of the equipment are not

impaired by the effects of stark

external temperatures or that

the equipment is damaged in

any way. Please note that the

equipment can also heat up

over a long period of use.

6

Page 7

Ensure adequate lighting when

you are working.

Always keep these operating

instructions within reach where

the equipment is used.

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and are to

be implemented in addition to the operating instructions.

Before transporting the

equipment, always ensure that

the accessories are positioned

such that they cannot cause an

accident.

Ensure the proper disposal

of all removed parts, left-over

hydraulic fl uid, left-over oil and

packaging materials!

WARNING / CAUTION!

The equipment is to be used exclusively for the purpose stated in the operating

instructions (see chapter “Proper Use”). Any other or further use is not considered

proper use. The manufacturer / supplier is not liable for any damages resulting from improper

use. The user bears sole responsibility for such.

Observance of the operating instructions and compliance with the inspection and maintenance

conditions are part of the proper use.

Never work when you are overtired or intoxicated!

7

Page 8

3. Safety regulations for hydraulic hoses

WARNING / CAUTION / ATTENTION!

- Never bring the hoses into contact with brake fl uid.

- The hoses are to be cleaned immediately should they come into contact with the

following fl uids:

• acids, lyes, solvents

• alcohol, fuel and ATF (Automatic Transmission Fluid)

• battery acid

• phosphate ester

It is also imperative that the hoses be inspected for damage following cleaning! If necessary ,

the hose assemblies are to be replaced!

1

2

3

4

5

8

6

Fig. 2

Page 9

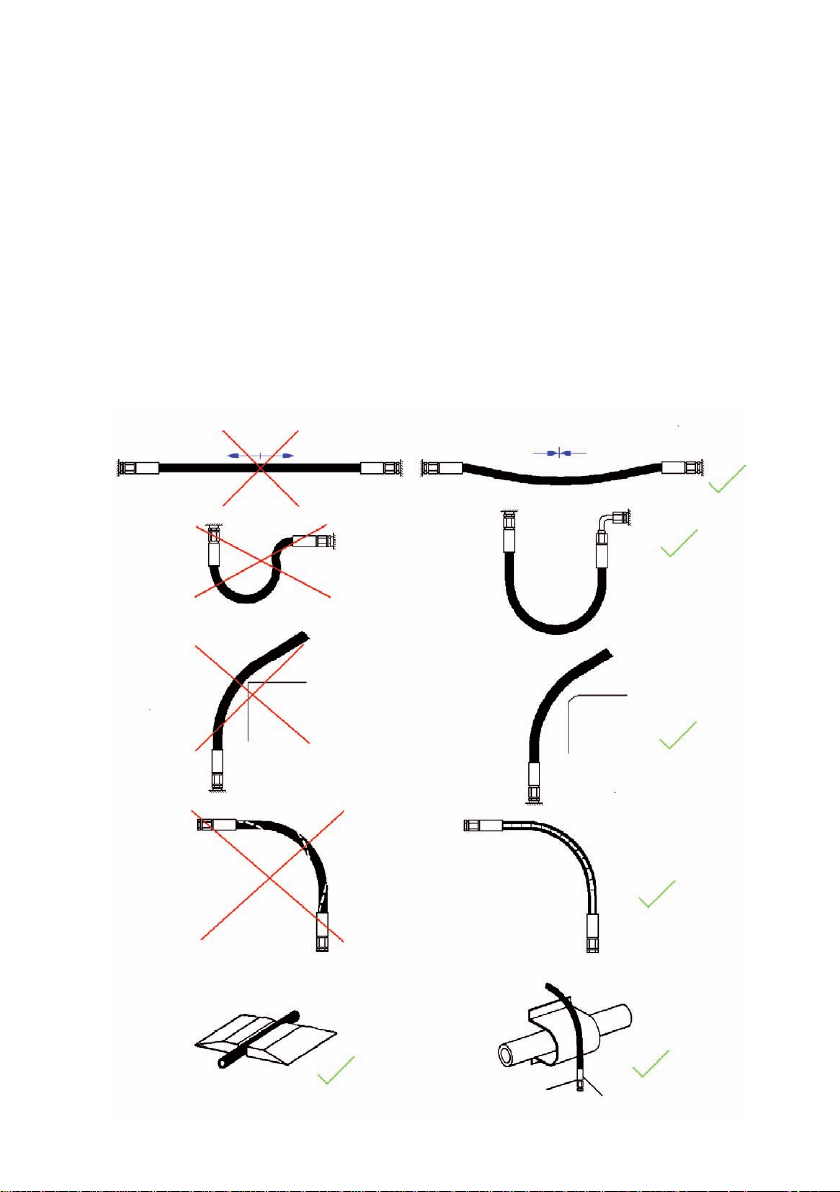

3.1 Advices for hoses

- The determined operating pressure may not be exceeded.

- Tensile load and torsion to the hoses must be avoided (see fi gure 2, item 1). 1).

- Do not kink the hoses (see fi gure 2, item 2). 2).

- Do not drag or lay hoses across sharp edges (see fi gure 2, item 3). 3).

- Do not connect twisted hoses (see fi gure 2, item 4). 4).

- Never drive over the hoses with a motorised vehicle. Hoses laid loosely across roads or

paths are to be protected from damage e.g. by hose protection ramps (see fi gure 2, item 5).

- In the event of high external temperatures, the hoses are to be installed either at an

adequate distance from the heat-radiating components or are to be protected by suitable

measures (see fi gure 2, item 6).

- Do not hang any weights on the hoses.

3.2 Safeguarding the environment in the event of failure of the hoses

Hoses must be laid or secured such that, in the event of a failure of the hose, danger is

avoided as far as possible.

Danger can be caused by:

- The hose thrashing about following a tear caused by external infl uences, for example.

- The pressure media leaking under pressure,

- The lighting of leaking pressure media within the vicinity of an ignition source.

The danger can be avoided by means of protective coverings or screening, for example.

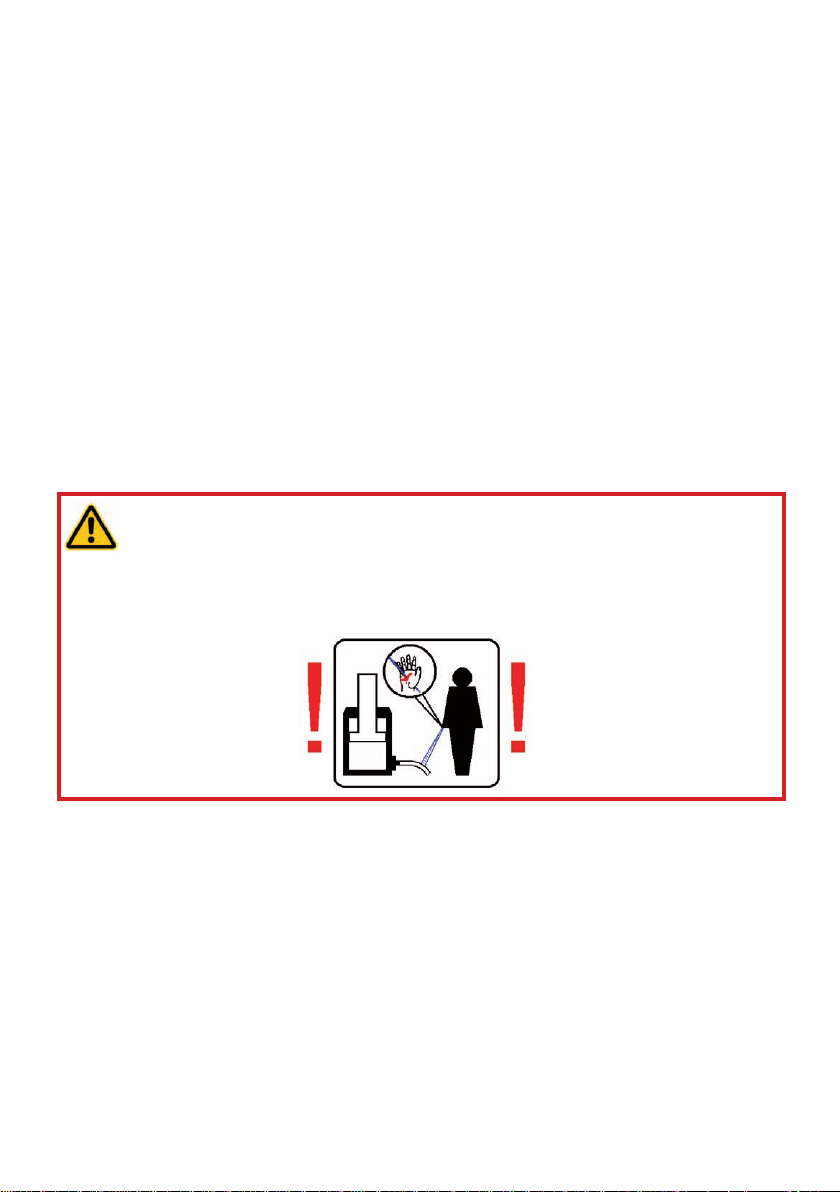

WARNING / CAUTION

- Leaking hydraulic fl uid under high-pressure can cause serious injuries to the

skin.

- In the event of injuries, immediately consult a doctor!

Hydraulic fl uid must immediately be removed from wounds!

- Do not use your fi ngers to detect leaks!

- Relieve the hydraulic system before you loosen connections!

for hairline cracks!

3.3 Storage of hoses

- Even when stored correctly and used properly, hoses are subject to a natural ageing

process. This means that their period of storage and period of use are restricted.

The following is to be observed when storing the hoses:

- Store in a cool, dry and low-dust condition (possibly wrap in plastic fi lm). Avoid direct

sunlight and UV rays. Screen from heat sources in the vicinity.

- Do not use any ozone-forming lighting fi xtures such as fl uorescent light sources,

mercury vapour lamps) or electrical equipment close to the equipment.

- Store hoses such that they are stress-free in a fl at position. If storing in rings, the

smallest bending radius stated by the manufacturer may not be exceeded.

9

Page 10

3.4 Labelling the hoses

- The hose is to bear the name of the manufacturer and the authorised operating

pressure.

- The press sleeve is to bear the maximum authorised operating pressure and the

manufacturers identifi cation and month / year of manufacture.

manufacturers identifi cation

month / year operating pressure

3.5 Dates for inspections and replacement of hoses

- After each use, inspect the hoses for external damage, tears, kinks and swollen

points!

- The operator is responsible for ensuring that the hoses are replaced at regular intervals,

even if there are no visible safety defects on the hoses.

- The hoses must be replaced 10 years after its manufacture (see labelling) at the

latest!

- Hoses are to be inspected by an expert to ensure that they are safe before they are

used for the fi rst time and then at least once per year. Please see the following for

possible defects.

An expert is somebody who, due to his professional education and experience, has suffi cient

knowledge in the fi eld of hydraulic hoses and who is familiar with the relevant national health

and safety regulations at work, guidelines and generally acknowledged technical regulations

(e.g. EN standards) such that he can assess the safe condition of the hydraulic hoses..

3.6 Examples of possible defects of hoses

- Damage to the external layer through to the inside (e.g. abrasive spots, cuts or tears).

- Embrittlement of the external layer (formation of cracks on the hose material).

- Distortions not in line with the natural form of the hoses, in pressure-free or in pressurised

condition or bend, e.g. separation of the layers, blistering, squashed parts, kinks.

- Leaks.

- Installation requirements have not been complied with.

- Shifting of the hose from its fi tting.

- Damage or deformations to the fi tting which impair the function and stability of the fi tting

or the connection between the hose and the fi tting.

- Corrosion to the fi tting or metal insert which impairs the function and stability.

- Periods of storage and use have been exceeded.

10

Page 11

4. Proper use

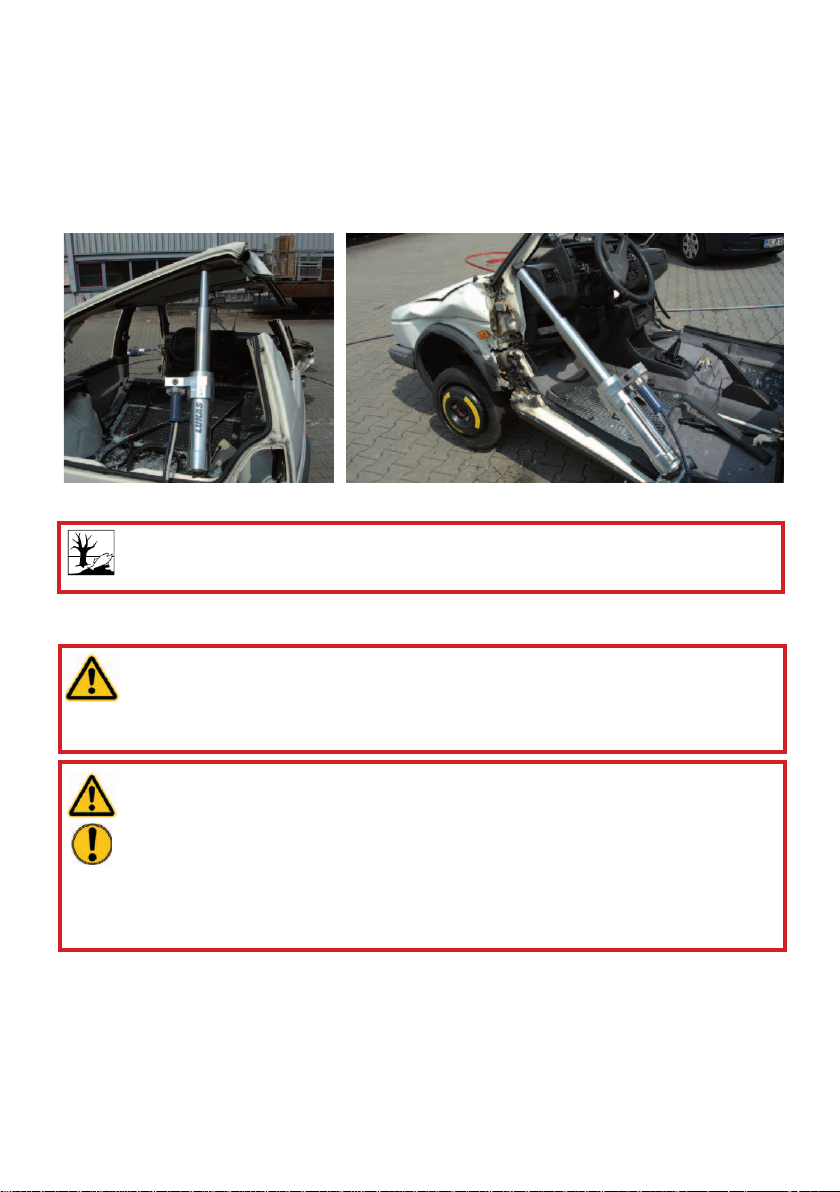

The LUKAS rescue equipment is designed specifi cally for the emergency services. Their

objective is to free people trapped in traffi c accidents when the clearance distance of a

spreader is insuffi cient e.g. by spreading or lifting car parts (see fi gure below). Their objective

in other disasters is to rescue buried or trapped persons (e.g. to remove pieces of concrete

from collapsed houses).

The equipment can also be used under water at a depth of up to 40m (131 ft).

CAUTION!

In this case, you must strictly observe any leaks in order to avoid threats to the

environment.

Basically, objects can be pushed away or their position can be altered.

WARNING / CAUTION!

All objects which have to be moved are to be secured using stable supports or

substructures. Furthermore, it must be ensured that the rescue ram cannot slip.

We recommend that you use support bearings. These are available in the LUKAS

accessories programme.

WARNING / CAUTION!

The following may not be squeezed:

- live cables

- hardened parts such as steering columns and rollers

- explosive bodies such as airbag cartouches

NEVER operate the rescue equipment at a higher operating pressure than that

stated in the chapter “Technical data”. A higher setting can result in material

damage and/or injuries.

Spare parts and accessories for the rescue tool can be ordered from your authorisied

LUKAS-dealer!

11

Page 12

5. Description of the functions

5.1 Description

The rescue rams are double-acting hydraulic cylinders. Extension / retraction are carried out

hydraulically. The direction of travel is controlled via a valve with star grip.

All rescue rams ensure full load-holding function when disconnected from the hydraulic

supply (e. g. when being unintentional decoupled; defective hose, and so on).

(For reasons of safety, rams R414 are internally safeguarded from 63 MPa = 630bar. When

the safeguarding valve responds a screeching noise can occur. Even if the screeching

noise occurs in unloaded condition, deactivate the equipment immediately and contact your

authorized dealer or LUKAS directly!)

5.2 Circuit diagram

T o enable comprehension of the function, a simplifi ed circuit

diagram (hydraulic cylinder of the rescue equipment (A) +

hand valve (B) ) are depicted here.

Extend

piston

A

B

Retract

piston

5.3 Control of the operating movements

The piston movement is controlled via the star grip of the mounted valve.

(see cover, item 1 and, below, fi gure 3).

fi g. 3

star grip

12

Page 13

5.4 Type R 41x

Type R 41x rescue rams are one-stage cylinders for applying pressure with a constant

pressure force along the entire stroke.

5.5 Type R 43x / R 42x

Type R 43x / R 42x rescue rams are multi-stage cylinders for applying pressure. Depending

on the piston stage, they have varying pressure forces. However, the pressure force remains

constant within one piston stage. An advantage offered by this range is the large stroke at a

relatively low construction height.

5.6 Hydraulic supply

A LUKAS motor pump or hand pump only may be used to drive the equipment.

If the pump unit is a different make, you must make sure that it complies with LUKAS

specifi cations, otherwise potential dangers may occur which are not the responsibility of

LUKAS. Ensure in particular that the authorised operating pressure is not exceeded.

REMARK:

Before you use pumps from a different manufacturer, you must contact LUKAS

or an authorised dealer.

5.7 Hoses

The pump unit and the rescue ram are connected by hoses.

13

Page 14

6. Connecting the equipment

6.1 General information

There are two short hoses on the side of the equipment: they are connected to the pump unit

via two hoses. All hose assemblies are marked with a colour and have couplings to enable

unmistakable connection.

REMARK:

The devices can be equipped with different coupling systems.

They differ only by the article number and not by the designation.

Of course the coupling systems can also be reequipped at a later time.

WARNING / CAUTION!

Before connecting the equipment you have to pay attention that all

used components are suitable to the max operation pressure of

the pump unit! In the case of doubt you have to inquire LUKAS

directly!

6.2 Coupling the mono-couplings

The equipment is connected to the hydraulic pump via mono-coupling halves (male and

female).

dust protection caps

mono-coupling

halve (male)

Before coupling, remove dust protection caps, then connect male and female, and turn

the locking sleeve of the female to direction „1“ until the locking sleeve locks into place.

The connection is now in place and secure. Decoupling is by turning the locking sleeve to

direction „0“.

The equipment can also be coupled under pressure provided the connected equipment is

not activated.

14

mono-coupling

halve (female)

Page 15

REMARK:

We recommend coupling the coupling halves in a pressureless state, when

working in areas with low ambient temperature and the usage of extension hose

assemblies / hose reels, otherwise decoupling could need very high expenditure

of force.

To protect them from dust, the accompanying dust protection caps must be put back on.

WARNING/CAUTION!

The mono-couplings may not be screwed off the hose assemblies and / or the

hose assemblies be confused!

6.3 Coupling the quick-disconnect couplings (alternative system)

The equipment is connected to the hydraulic pump via quick-disconnect-coupling halves

(male and female).

X

Y

Before coupling unlock the connect socket by turning the sleeve into position X. Retract

sleeve and connect plug and socket. Release sleeve and turn it into position Y.

Now the connection has been made and locked. Uncoupling is done in the reverse order.

CAUTION!

Always connect the return line fi rst and afterwards the supply line!

REMARK:

Coupling of the devices is only possible, when the hoses are depressurized.

To protect them from dust, the accompanying dust protection caps must be put back on.

WARNING/CAUTION!

The quick-disconnect-couplings partly have special functions. Therefore it is not

allowed to screw them off from the hoses or to exchange them!

15

Page 16

7. Operation

7.1 Preparatory measures

7.1.1 Commissioning

Before commissioning and following repairs, the equipment must be deaerated.

- Connect the equipment to the hydraulic pump (see chapter “Connecting the

equipment”).

- Extend / retract the equipment without any load at least twice (see chapter “Operation

of the star grip”).

REMARK:

We recommend that during the deaeration, the attached aggregate for the

hydraulic supply should stand on a higher level than the body of the rescue

tool.

Recommended procedure for the deaeration of the rescue tool:

1.) open and close fully with the piston rod facing upwards.

2.) open and close fully with the piston rod facing downwards.

3.) open and close fully with the piston rod facing upwards.

4.) open and close fully with the piston rod facing downwards.

7.1.2 Inspection of the pump unit

See separate operating instructions for the relevant pump unit (or for the hand

pump).

REMARK:

Before each start-up of the hydraulic unit you have to make sure that the actuating

valves are set to depressurized circulation.

REMARK:

Before coupling the quick-disconnect couplings, the actuating valves of the

hydraulic unit are set to depressurized circulation.

If you use mono-couplings, you can also couple when the hoses are pressurized!

16

Page 17

7.1.2 Support

Before you can work using the rescue ram, you must ensure adequate support: this includes

a necessary substructure. The rescue rams come equipped with a claw on the cylinder side

and on the piston side so that they can become hooked (see fi gure 4). If this support is

inadequate, such as in the case of a pushed-away front of car (see fi gure 5) or when lifting

a vehicle (see fi gure 6), additional support bearings, cylinder attachments and, if necessary,

protection using a belt, for example, are also necessary. Appropriate support bearings and

practical cylinder attachments are available from the LUKAS accessories programme.

fi g. 4:

fi g. 5:

fi g. 6:

17

Page 18

WARNING / CAUTION!

Never use a rescue ram without claw or adequate accessories! The cylinder could

slip away while moving and this could result ininjuries of the user. Furthermore

the piston rod or the adapter of the claw could be damage thereby.

WARNING / CAUTION!

When positioning the rescue ram (without LUKAS support bearings), it is

imperative that all four ends of both the piston claw and the cylinder claw are

fl ush.

When positioning the rescue ram (to a LUKAS support bearing), it is imperative

that the area between the four ends of the claw are fl ush with the round bar of

the bearing.

This avoids a one-sided application of force into the cylinder. Lifted objects must

then be secured by means of stable supports or substructures!

7.2 Danger notes

Before activating the rescue ram, always ensure that there is no danger to persons either

involved / uninvolved in the action by the movement of the piston rod or by fl ying fragments.

Further avoid unnecessary damage to property belonging to others, objects not involved by

the cylinder pistons / fl ying fragments.

Holding the piston rod during operation of the equipment is

strictly forbidden!

18

Page 19

7.3 Operating the star grip (cover: item 1)

Extend piston ( ):

Turn the star grip in a clockwise direction (in the direction of the

relevant symbol) and keep in this position.

Retract piston ( ):

Turn the star grip in an counterclockwise direction (in the direction of

the relevant symbol) and keep in this position.

“Dead-man” function:

Following release, the star grip automatically returns to the central

position, guaranteeing the full load-holding.

7.4 Use of extensions

The R410 rescue ram may only be operated with the

LUKAS extension (length = 250mm). No other rescue

ram may be operated with an extension: furthermore,

operation is only permitted using the original LUKAS

extension. The extension is assembled from the righthand side as depicted.

WARNING / CAUTION!

Rescue rams with extensions are to be carefully monitored during their use. If

there are signs of a serious change to its behaviour, work is to be interrupted

immediately and, if necessary, even stopped altogether. After every use /

interruption to use, carefully control the cylinder and the extension for damage!

Extension

Rescue Ram

8. Dismantling the equipment / deactivation following

operation

8.1 Rescue ram

Once work has been completed, the rescue rams are to be retracted so that just a few mm

protrude. This relieves the hydraulic and mechanical strain on the equipment.

REMARK:

Due to fl uctuations to the ambient temperature, the storage of rescue rams can

cause small lifting motions in the equipment. This effect is a physical reaction to

the expansion of the hydraulic fl uid enclosed in the piston and rod side. For this

reason, the storage room for rescue rams is to be designed such that there is up

to 30mm (1.18 in.) space to allow for a potential extension to the length.

*) 1 mm = 0.04 in.

19

*)

Page 20

8.2 Hydraulic unit

Upon completion of work, the unit must be deactivated.

8.3 Hoses

First of all, decouple the pressure hose then the return hose as described in chapter

“Connecting the equipment”.

Ensure that you put the dust protection caps back on to the couplings.

9. Maintenance and service

The equipment is subject to very high mechanical stresses. A visual inspection is to be

carried out after every use: however, at least one visual inspection is to be carried out

annually. These inspections enable the early detection of wear and tear, which means that

punctual replacement of this wearing parts prevents breakages from occurring. A function

test is also to be carried out every three years or should there be any doubt regarding the

safety or reliability of the equipment.

(Please also observe the relevant valid national and international regulations pertaining to

service intervals of rescue equipment). In the Federal Republic of Germany, regular safety

inspections according to the regulations of the Gesetzlichen Unfallversicherung (GUV;

connoted ‘Legal accident insurance’) are mandatory.

CAUTION!

Clean off any dirt before controlling the equipment!

WARNING / CAUTION!

In order to carry out maintenance and repair works, tools appropriate for the job

and personal protecting equipment are essential.

Inspections to be carried out:

Visual inspection

Rescue ram

• Cylinder and piston rod are to be free of damage and deformation,

• Correct, fi rm fi t of the claws,

• Condition of the claws (chipped spots),

• General tightness (leaks),

• Operability of the star grip,

• Existence and stability of handhold,

• Labels completely existent and legibly,

• Couplings must be easy to couple,

• Dust protection caps must be available.

Hoses

• Visual control for visible damage,

• Control for leaks.

Function test

• That the piston stroke can be extracted / retracted to its full length (see chapter “T echnical

data”)

• Flawless extension / retraction upon activation of the star grip.

• no further movement of the piston upon interruption of the valve activation during the

process (“dead-man’s” function)

20

Page 21

10. Repairs

10.1 General information

Servicing may only be carried out by the manufacturer or personnel trained by the

manufacturer and by authorised LUKAS dealers.

Only LUKAS spare parts may be used to replace all components (see spare parts list) since

special tools, assembly advice, safety aspects, inspections might have to complied with (see

also chapter “Maintenance and Service”).

During assembly, ensure the complete cleanliness of all components, since dirt can

damage the rescue equipment!

WARNING / CAUTION!

Protective clothes must be worn when repairs are being carried out, since parts

of the units can also be pressurised in an idle state.

REMARK:

Always register your tool on the LUKAS Hydraulik GmbH internet site. This is the

only way to guarantee extended warranty cover.

REMARK:

Before you use couplings from a different company , you must contact LUKAS or

an authorised dealer.

REMARK when using the quick-disconnect-coupling system:

Overpressure protection of the rescue equipment

(model with yellow coupling nipple on the return hose)

If the equipment’s short hoses are not connected to a hydraulic unit, temperature

increases can inadvertently cause pressure to build up in the equipment. Hence,

the return hose of the equipment is equipped with a safety coupling (quickdisconnect coupling male, yellow). Unwanted overpressure (approx. 1.5 Mpa) is

automatically released via this nipple: hydraulic fl uid leaks.

Should an hydraulic fl uid leak on the coupling male be more frequent, please

contact your dealer or LUKAS itself.

If couplings from a different company are used which do not have this function,

the overpressure protection can react in the valve of the rescue equipment.

Hydraulic fl uid leaks in the area of the star grip. Following the reduction in

pressure, the valve is once again tight.

Should the valve leak permanently, please immediately contact your dealer or

LUKAS itself.

CAUTION!

Because LUKAS rescue equipments are appropriate for highest achievements,

only components may be exchanged, which are specifi ed in the spare parts list

of the appropriate equipment.ipment may only be exchanged, when:

- you have participated on a appropriate LUKAS service training.

- you have the explicit permission of the LUKAS Service department (After inquiry,

examination for the distribution of permission. Examination in each individual

case necessary!)

21

Page 22

10.2 Preventative service

10.2.1 Care regulations

The exterior of the equipment is to be cleaned from time to time in order to protect it from

external corrosion. Oil is to be applied to the metallic surfaces.

10.2.2 Function and load test

If there is any doubt regarding the safety or reliability of the equipment, a function and load

test must also be performed.

LUKAS offers appropriate test equipment to this end.

10.2.3 Changing the hydraulic fl uid

- The hydraulic fl uid must be changed after the equipment has been used approx. 200

times / after three years at the latest.

- It must always be changed whenever the hydraulic fl uid for the accompanying pump

(motor / hand pump) is changed. This is to prevent the fresh hydraulic fl uid from becoming

contaminated by the used fl uid from the rescue equipment.

Procedure:

1. Completely retract rescue ram.

2. Change the hydraulic fl uid of the pump. Please observe the separate operating instructions

for the pump being used!

3. Screw off the return hose on the pump:

- when the hose connection is directly into the pump:

completely unscrew the connection nut of the connection piece of the blue return

hose.

- when the hose connection is via mono-coupling to the pump:

remove the cover from the mono-coupling (male).

completely unscrew the connection nut of the blue returnhose on the mono-coupling

(male).

- when the hose connection is via quick-connect-coupling to the pump:

completely unscrew the connection nut on the quick-disconnect-coupling of the blue

return hose.

4. Put the return hose into a separate collecting basin for the hydraulic fl uid still in the

equipment.

5. Slowly extend the rescue ram (the pump must be working during this time). The old

hydraulic fl uid from the ring space side runs via the return hose into the separate collecting

basin, and is to be disposed of in the same manner as the old hydraulic fl uid of the

pump.

6. Switch the pump off (motor pump) / no longer activate it (e.g. hand pump).

7. Reconnect the return hose to the pump:

- when the hose connection is directly into the pump:

screw the connection nut of the connection piece of the blue return hose back on.

(Please observe the necessary torque of M

- when the hose connection is via mono-coupling to the pump:

screw the connection nut of the blue return hose back onto the mono-coupling (male).

(Please observe the necessary torque of M

Pull back the cover on the couplings as far as the limit stop.

- when the hose connection is via quick-connect-coupling to the pump:

screw the connection nut back onto the quick-disconnect-coupling of the blue return

hose.

(Please observe the necessary torque of M

8. Deaerate the rescue ram as described in the chapter “Preparatory measures”.

= 40 Nm!)

A

= 40 Nm!)

A

= 35 Nm!)

A

22

Page 23

10.3 Repairs

10.3.1 Changing or tightening hoses

Hoses of the pressure and/or return pipe leaks or hoses are defective. Tighten the hoses on

the safety valve.

(Please note! Observe torque of M

REMARK when using mono-couplings:

If you want to change the hoses, you have to dismantle the mono-couplings.

CAUTION (by usage of mono-coupling-system)!

Take care that the port ‘T’ of the rescue cylinder is always connected to the port

‘T’ of the mono-coupling.

CAUTION (by usage of quick-disconnect-coupling-system)!

The return hose, which is screwed onto the port “T” of the rescue cylinder, must

be equipped with a quick-disconnect-coupling (male) always.

However the supplying hose line must be equipped with a quick-disconnectcoupling (female).

= 40 Nm!)

A

Procedure:

BC

1. Loosen the 2 “B” screws in the handle sleeve

with quick-disconnect protective sleeves “C”

(hexagon socket)

A

2. Remove handle sleeve A and tighten screwed

connection. If necessary, renew seals.

D

EF

3. Dismantle hose D and sealing ring E. (There

is no need to carry out this point if the hoses

are just being tightened).

4. Screw the hose with sealing ring back on.

Please ensure that the insulating washer F is

on and correctly assembled.

5. Tighten the hose connection on the safety valve. (Please note! Observe the necessary

torque of M

= 40 Nm!)

A

dismantle

assemble

6. Then replace handle sleeve, protective sleeves and screws, tighten (Torque: 5Nm) and

secure it with threadlocking fl uid (e. g. LOCTITE 243).

23

Page 24

10.3.2 Mono-couplings

The mono-couplings on the connection hoses of the equipment must be replaced in the

event of:

- external visible damage,

- the locking device not working,

- hydraulic fl uid continually leaking in a coupled/uncoupled state.

WARNING / CAUTION!

Never repair couplings: they are to be replaced by original LUKAS parts!

During assembly , tighten the connection nut of the hose assembly with a torque of M

= 40 Nm.

A

Procedure:

1. Remove the cover from the couplings.

2. Loosen the connection nuts of the hose assembly and remove the coupling.

3. Position the new coupling and tighten the connection nuts of the hose assemblies

with a torque of M

= 40 Nm and push the cover of the couplings back on.

A

CAUTION!

Take care that the port ‘T’ of the rescue ram is always connected to the port ‘T’

of the mono-coupling.

24

Page 25

10.3.3 Quick-disconnect-couplings

The quick-disconnect-couplings on the connection hoses on the equipment must be replaced

in the event of:

- external visible damage,

- the locking device not working,

- hydraulic fl uid continually leaking in a coupled/uncoupled state.

WARNING / CAUTION!

Never repair couplings: they are to be replaced by original LUKAS parts!

During assembly , tighten the connection nut of the hose assembly with a torque of M

= 35 Nm.

A

Procedure:

1. Loosen the connection nut of the hose assembly and remove the coupling.

2. Position the new coupling and tighten the connection nut of the hose assemblies

with a torque of M

= 35 Nm.

A

CAUTION!

The return hose, which is screwed onto the port “T” of the rescue ram, must be

equipped with a quick-disconnect-coupling (male) always.

However the supplying hose line must be equipped with a quick-disconnectcoupling (female).

10.3.4 Labels

All damaged and/or illegible labels (safety notices, type plate, etc.) must be renewed.

Procedure:

1. Remove damaged and/or illegible labels.

2. Clean the surfaces using acetone or industrial alcohol.

3. Attach new labels.

Ensure that you attach the labels in the right position. If you are no longer sure about this,

then please contact your authorised LUKAS dealer or LUKAS itself.

25

Page 26

11. Troubleshooting

Trouble Control Cause Solution

Cylinder piston

moves slowly or

jerkily when activated

Equipment doesn’t

come up with the full

power.

Following release,

the star grip doesn’t

return to the central

position

with mono-couplingsystem: Hoses

cannot be coupled

with monocoupling-system:

It is frequently not

possible to couple

hose assemblies

with quickdisconnect-couplingsystem: Hoses

cannot be coupled

Hydraulic fl uid leak

on the hoses or the

fi xing-ins

Damages on the

surface of the

hydraulic hoses

Are the hoses

connected

properly?

Does the pump

unit work?

Have you checked

the hydraulic fl uid

level in the supply

pump?

Is it hard to move

the star grip?

Control the

degree of viscosity

and application

temperature of

the used hydraulic

fl uid

Is the pump

working?

Are the hoses

defective?

Air in the hydraulic

system

Insuffi cient

hydraulic fl uid in

the pump

Damage to the

torsion spring for

reset

Soiled valve or

star grip

Defective valve

Other mechanical

damage (e. g. star

grip)

Pressure too high

(e.g. caused by

too-high ambient

temperature)

Coupling defective Coupling needs to be

Hydraulic fl uid

not adapted to

the application

situation

Coupling defective Coupling needs to be

Pressurized Relieve pump

Coupling defective Coupling needs to be

Leak, possible

damage

Mechanical

damages or

contact with

aggressive agents

Deaerate pump

system

Top up hydraulic fl uid,

deaerate

Repair by an

authorised dealer, by

personnel specially

trained by LUKAS, or

by LUKAS itself

Set hydraulic pump

to pressureless

circulation

replaced immediately

Hydraulic fl uid

must be replaced

(see chapter

“Recommended

Hydraulic fl uids”)

replaced immediately

replaced immediately

Replace hoses

Replace hoses

26

Page 27

Trouble Control Cause Solution

Hydraulic fl uid leak

on the piston rod

Leak on the handhold Increase load? Load increase

Is the set pressure

on the pump

adapted to comply

with the maximum

permissible

pressure for

the rescue

equipment?

Hoses in handhold

loose?

Check the

connections of the

mono-coupling

(female)

Especially by usage

of quick-disconnectcouplings: Leak on

the handhold

Especially by usage

of mono-couplings:

Leak on the handhold

Is the return

hose connected

correctly?

check the

connections of the

hoses

Defective rod seal Repair by an

Damage to the

piston

(e.g. something

has fallen onto the

part to be lifted,

thereby suddenly

increasing the

load)

Pressure release

in the Rescue tool.

Hoses in handhold

not tightened

Supply and return

connection of the

mono-coupling

(female) inverted

Return hose is not

coupled correctly

or not connected.

hose connection

to the couplings

interchanged

Returnline

disabled

authorised dealer, by

personnel specially

trained by LUKAS, or

by LUKAS itself

Secure the loads and

move them by using

other tools

Position ram on a

different place, where

the load to be moved

is lower

Use supporting

equipment to move

the load.

Following the

reduction in pressure,

no further leak is

present.

Should, however,

there be a further

leak on the handhold,

immediately

deactivate the rescue

equipment, and

contact an authorised

dealer or LUKAS

itself.

Tighten hoses.

Reconnect the

hoses of the monocooupling (female) in

the right way

Re-connect the return

hose and secure it.

reconnect the hoses

to the coupling in the

right way

disconnect the

returnline from the

coupling, clean it and

reconnect it.

27

Page 28

Trouble Control Cause Solution

with mono-couplingsystem: Leak in the

couplings

with quickdisconnect-couplingsystem: Leak in the

couplings

If it isn’t possible to rectify the malfunctions, inform an authorised LUKAS dealer or the

LUKAS customer service department immediately!

The address for the LUKAS customer service department is:

Is the coupling

damaged?

Is the coupling

damaged?

Is the leak only

on the coupling

male (in uncoupled

status)?

coupling damaged Coupling must be

coupling damaged Coupling must be

Safety valve

reacted

replaced immediately

replaced immediately

After pressure

release there is no

more leakage.

LUKAS

Weinstraße 39, D-91058 Erlangen

Postfach 2560, D-91013 Erlangen

Tel.: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

28

Page 29

12. Technical Data

Since all values are subject to tolerances, minor differences may occur between the data on

your equipment and the data in the following schedules!

Type R 420 R 422 R 424 R 430

Ref. No.

Pressure force

(piston 1)

Pressure force

(piston 2)

Pressure force

(piston 3)

max. stroke

(piston 1)

max. stroke

(piston 2)

max. stroke

(piston 3)

Piston stroke

overall

Length (retracted)

Length (extended)

Dimensions

w x h

Weight including

hydraulic fl uid

fi lling

max. operating

pressure

min. needed

volume of

hydraulic fl uid

coupling system mono-coupling

classifi cation acc. to

DIN EN 13204

* 1 MPa = 10 bar

** Necessary volume of hydraulic fl uid in the hydraulic unit to operate the unit

(differential volume on piston / rod side)

[kN] 269 269

[lbf.] 60474 60474

[kN] 134 134

[lbf.] 30124 30124

[kN] - 39

[lbf.] - 8800

[mm] 295 365 445 295

[in.] 11.6 14.4 17.5 11.6

[mm] 280 340 430 280

[in.] 11.0 13.4 16.9 11.0

[mm] - 245

[in.] - 9.65

[mm] 575 705 875 820

[in.] 22.6 27.8 34.5 32.3

[mm] 480 550 625 475

[in.] 18.9 21.7 24.6 18.7

[mm] 1055 1255 1500 1295

[in.] 41.5 49.4 59.1 51.0

[mm] 112 x 221

[in.] 4.41 x 8.70

[kg] 16,8 18,8 21,1 17,7

[lbs.] 37.0 41.4 46.5 39.0

[MPa]* 70

[psi.] 10000

[l]** 1,5 1,8 2,2 1,6

[gal.US]

81-40-30

(174040000)

0.40 0.48 0.58 0.42

TR 266/295-

133/280-17

81-40-32

(174050000)

TR 266/365-

133/340-19

29

81-40-34

(174060000)

TR 266/445-

133/430-21

81-40-40

(174070000)

Page 30

Type R 410 R 412 R 414

Ref. No.

Pressure force (in

all operating

ranges)

Piston stroke

Length (retracted)

Length (extended)

Dimensions

w x h

Weight including

hydraulic fl uid

fi lling

max. operating

pressure

min. needed

volume of

hydraulic fl uid

coupling system mono-coupling

classifi cation acc. to

DIN EN 13204

[kN] 137 124

[lbf.] 30799 27876

[mm] 300 500 700

[in.] 11.8 19.7 27.6

[mm] 450 680 900

[in.] 17.7 26.8 35.4

[mm] 750 1180 1600

[in.] 29.5 46.5 63.0

[mm] 95 x 174

[in.] 3.74 x 6.85

[kg] 13,1 17,8 24,3

[lbs.] 28.9 39.2 53.6

[Mpa] * 70

[psi.] 10000

[l] ** 0,5 0,8 1,2

[gal.US]

81-40-20

(174110000)

0.13 0.21 0.32

R 135/300-13R 135/500-18R 122/700-

81-40-22

(174120000)

81-40-24

(174130000)

24

* 1 MPa = 10 bar

** Necessary volume of hydraulic fl uid in the hydraulic unit to operate the unit

(differential volume on piston / rod side)

30

Page 31

Type R 420 R 422 R 424 R 430

Ref. No. 114070000 114040000 114060000 114050000

Pressure force

(piston 1)

Pressure force

(piston 2)

Pressure force

(piston 3)

max. stroke

(piston 1)

max. stroke

(piston 2)

max. stroke

(piston 3)

Piston stroke

overall

Length (retracted)

Length (extended)

Dimensions

w x h

Weight including

hydraulic fl uid

fi lling

max. operating

pressure

min. needed

volume of

hydraulic fl uid

coupling system quick-disconnect-coupling

classifi cation acc. to

DIN EN 13204

[kN] 269 269

[lbf.] 60474 60474

[kN] 134 134

[lbf.] 30124 30124

[kN] - 39

[lbf.] - 8800

[mm] 295 365 445 295

[in.] 11.6 14.4 17.5 11.6

[mm] 280 340 430 280

[in.] 11.0 13.4 16.9 11.0

[mm] - 245

[in.] - 9.65

[mm] 575 705 875 820

[in.] 22.6 27.8 34.5 32.3

[mm] 480 550 625 475

[in.] 18.9 21.7 24.6 18.7

[mm] 1055 1255 1500 1295

[in.] 41.5 49.4 59.1 51.0

[mm] 112 x 221

[in.] 4.41 x 8.70

[kg] 16,8 18,8 21,1 17,7

[lbs.] 37.0 41.4 46.5 39.0

[MPa]* 70

[psi.] 10000

[l]** 1,5 1,8 2,2 1,6

[gal.-US] 0.40 0.48 0.58 0.42

TR 266/295-

133/280-17

TR 266/365-

133/340-19

TR 266/445-

133/430-21

* 1 MPa = 10 bar

** Necessary volume of hydraulic fl uid in the hydraulic unit to operate the unit

(differential volume on piston / rod side)

31

Page 32

Type R 410 R 412 R 414

Ref. No. 114110000 114120000 114130000

Pressure force (in

all operating ranges)

Piston stroke

Length (retracted)

Length (extended)

Dimensions

w x h

Weight including

hydraulic fl uid fi lling

max. operating

pressure

min. needed volume

of hydraulic fl uid

coupling system quick-disconnect-coupling

classifi cation acc. to

DIN EN 13204

* 1 MPa = 10 bar

** Necessary volume of hydraulic fl uid in the hydraulic unit to operate the unit

(differential volume on piston / rod side)

[kN] 137 124

[lbf.] 30799 27876

[mm] 300 500 700

[in.] 11.8 19.7 27.6

[mm] 450 680 900

[in.] 17.7 26.8 35.4

[mm] 750 1180 1600

[in.] 29.5 46.5 63.0

[mm] 95 x 174

[in.] 3.74 x 6.85

[kg] 13,1 17,8 24,3

[lbs.] 28.9 39.2 53.6

[Mpa] * 70

[psi.] 10000

[l] ** 0,5 0,8 1,2

[gal.-US] 0.13 0.21 0.32

R 135/300-13R 135/500-18R 122/700-

24

32

Page 33

12.1 Recommended hydraulic fl uid

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil code Viscosity rating Remarks

A -20 .... +55°C HM 10 VG 10

Oil temperature range Oil code Viscosity rating Remarks

A

-4.0 .... +131°F HM 10 VG 10

recommended viscosity range: 10...200 mm²/s

Supplied with HM 10 DIN ISO 6743-4.

CAUTION!

Before using hydraulic fl uids, which do not correspond to the above-mentioned

specifi cations and/or are not purchased from LUKAS, you have to contact

LUKAS itself!

(10…200 cSt.)

12.2 Hoses

Bending radius Rmin = 38 mm (Rmin = 1.5 in.)

Pressure resistance

Temperature resistance - 40°C ... + 100°C

Operating fl uid Mineral oil according to DIN EN ISO 6743-4

Safety factor: Burst pressure / max. Operating pressure,

min. 4 : 1

(- 40°F … + 212°F)

12.3 Operating and storage temperature ranges

Operating temperature [°C] -20 … +55

Storage temperature (device not in operation) [°C] -30 … +60

Operating temperature [°F] -4 … +131

Storage temperature (device not in operation) [°F] -22 … +140

33

Page 34

13. EC Declarations of conformity

34

Page 35

14. Notes

35

Page 36

Please dispose all packaging materials and

dismantled parts properly

LUKAS

A Unit of IDEX Corporation

Hydraulik GmbH

Weinstraße 39, D-91058 Erlangen

Tel.: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

www.lukas.com

Made in GERMANY

© Copyright 2014 LUKAS Hydraulik GmbHrescue_rams_manual_174010085_en.indd

subject to revision

Loading...

Loading...