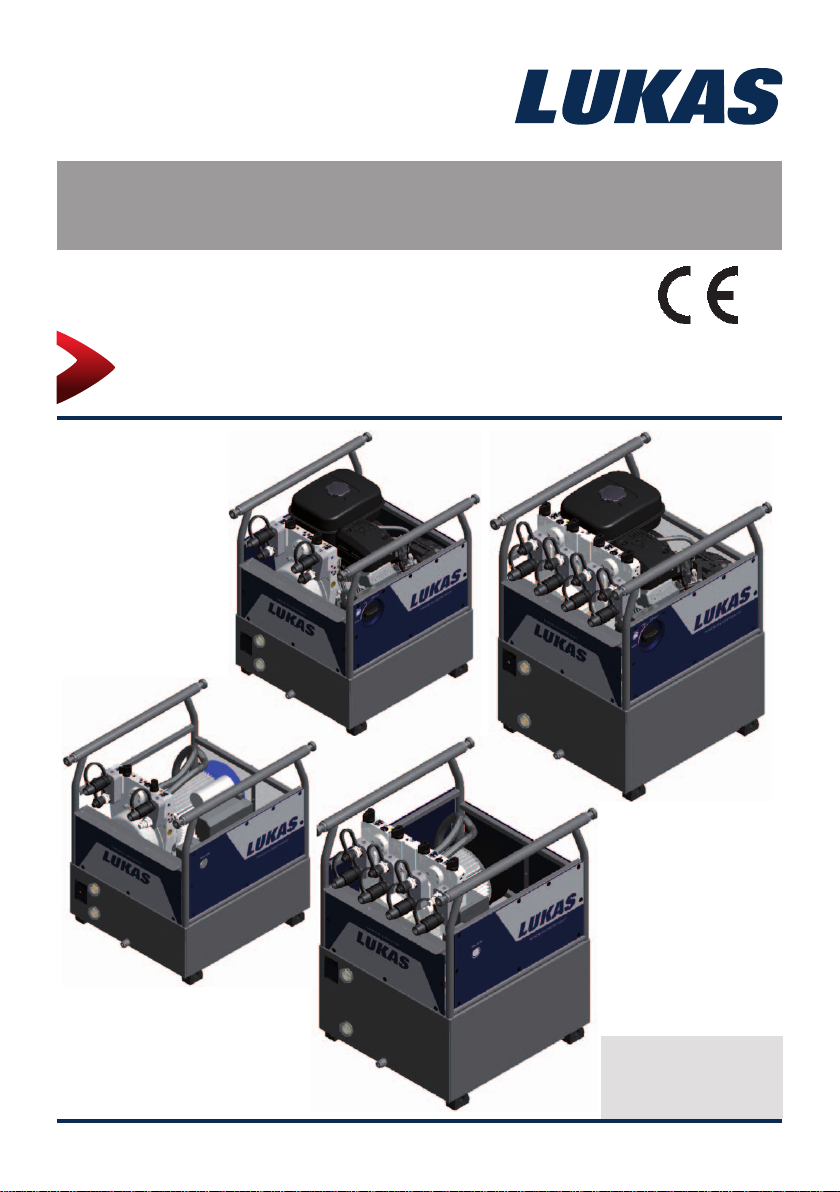

Page 1

Instruction manual

Rerailing equipment

Hydraulic power units GC/PC 650

GC 650

PC 650

1450000085 EN

Edition 08.2014

(Translation of the original instruction manual)

Page 2

Content Page

1. Danger classifi cations 5

2. Product safety 6

3. Proper use 10

4. Assembly marking 1 1

5. Functional description 11

5.1 General information 11

5.2 Layout of the units 12

5.3 Motor variants 13

5.4 Valve variants 14

5.5 Pumps 15

5.6 Frame with side sections 15

5.7 Connection to the control table 15

6. Connecting the hoses / devices 16

7. Erection and start-up 17

7.1 Set-up 17

7.2 Start-up 17

8.1 Starting the engines 18

8. Operation 18

8.2 Stopping the engine 19

8.3 Topping up with fuel (only on combustion engines) 20

8.4 Controlling the valves 20

9. Dismantling the equipment / deactivation following operation 22

10. Tests 23

10.1 Recommended test intervals 23

10.2 Hydraulic units with combustion engine 24

10.3 Hydraulic units with electric motor 25

10.4 Hoses (optional pairs of hose extensions) 25

11.1 General information 26

11. Maintenance and repair 26

11.2 Service work on the hydraulic unit 27

11.3 Additional service work on unit with combustion engine 29

11.4 Couplings 33

2

Page 3

Content Page

12. Troubleshooting 34

13. Technical data 40

13.1

13.2 GC 650-4POWER 42

13.3 GC 650E-2POWER 43

13.4 GC 650E-4POWER 44

13.5 PC 650-2POWER 45

13.6 PC 650-4POWER 46

13.7 Noise emissions of the power units 47

13.8 Sparking plug 47

13.9 Sparking plug spanner 47

13.10 Fuel 47

13.11 Engine oil 48

13.12 Hydraulic fl uid recommendation 48

13.13 Operating and storage temperature range 48

14. EC Declarations of conformity 49

15. Notes 50

GC 650-2POWER 41

3

Page 4

4

Page 5

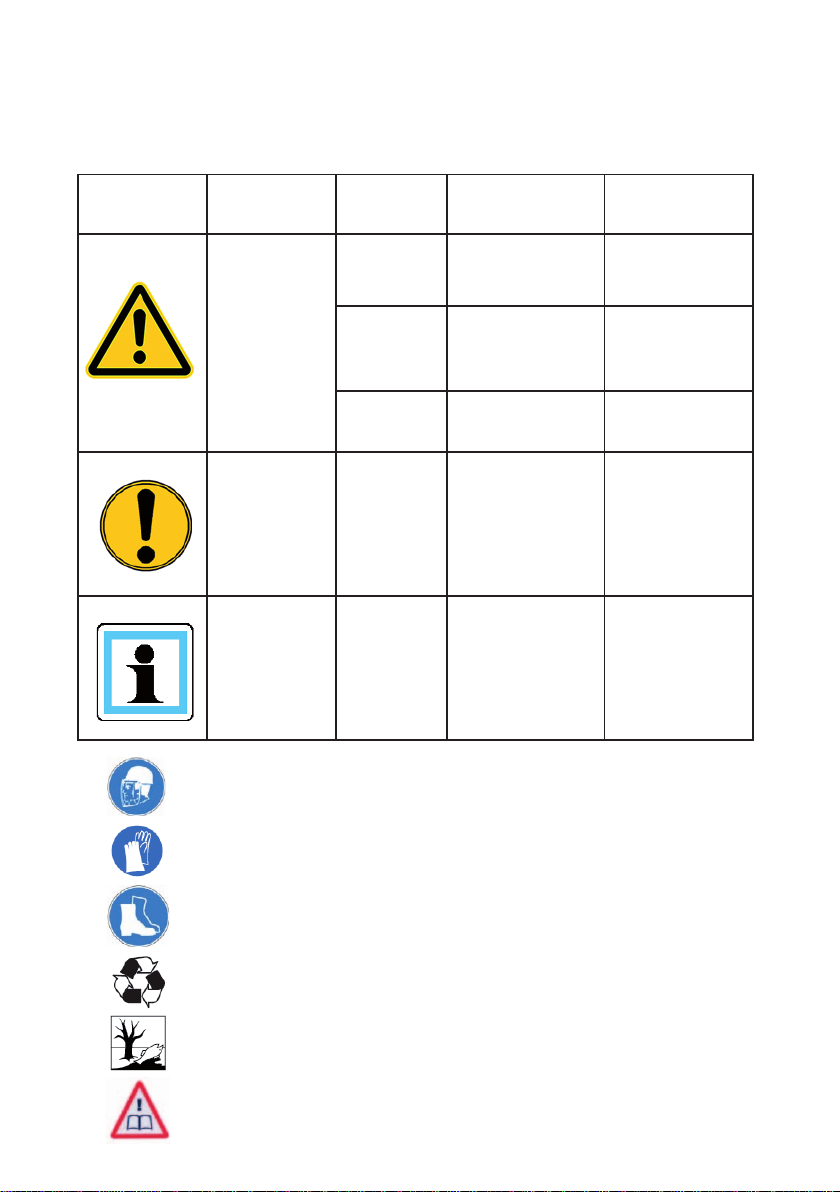

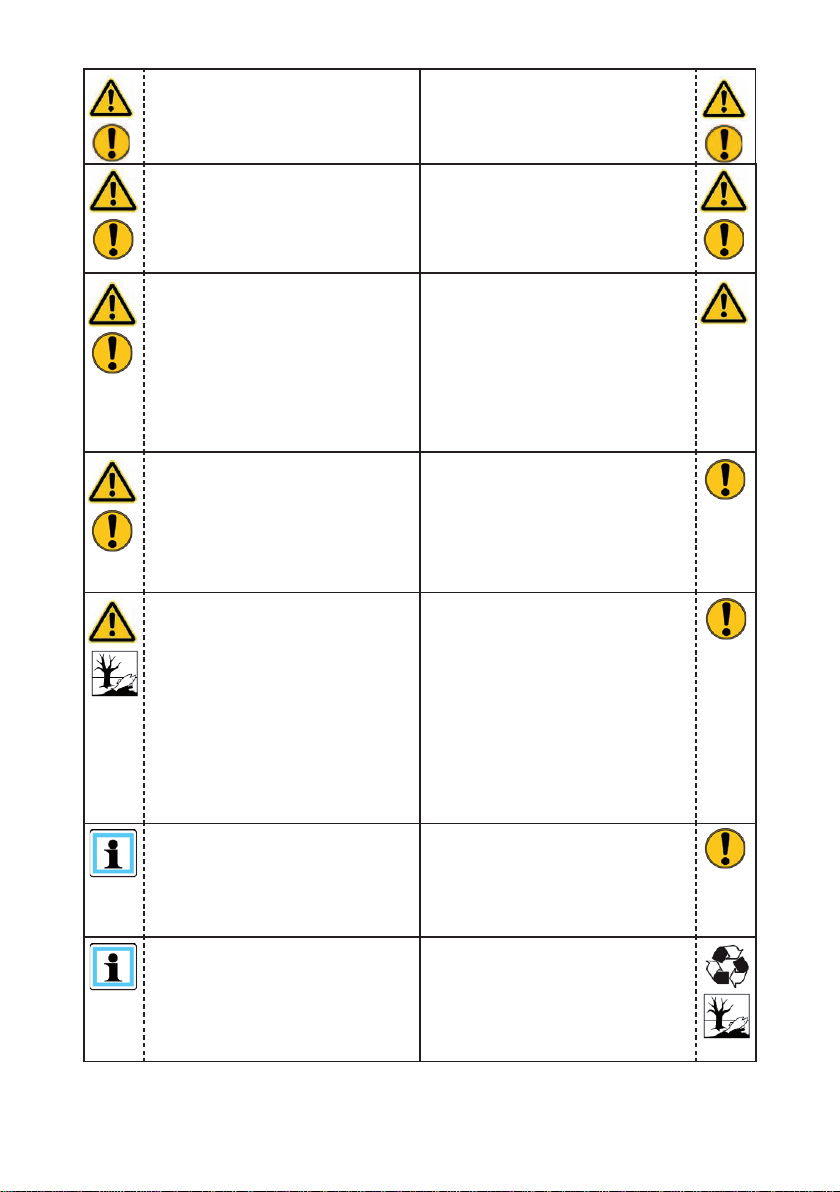

1. Danger classifi cations

We differentiate between various different categories of safety instructions. The table shown

below provides an overview of the assignment of symbols (pictograms) and signal words to

the specifi c danger and the possible consequences.

Pictogram

Damage /

injury to

Persons

Property

- NOTE

Key word Defi nition Consequences

DANGER! Immediate danger

Potentially

WARNING!

CAUTION!

ATTENTION!

dangerous

situation

Less dangerous

situation

Danger of damage

to property/

environment

Handling tips and

other important/

useful information

and advice

Death or severe

injury

Potential death or

serious injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surroundings

No injury/damage

to persons/

environment/

device

Wear a helmet with a face guard

Wear protective gloves

Wear safety shoes

Proper recycling

Protect the environment

Read and follow the operating instructions

5

Page 6

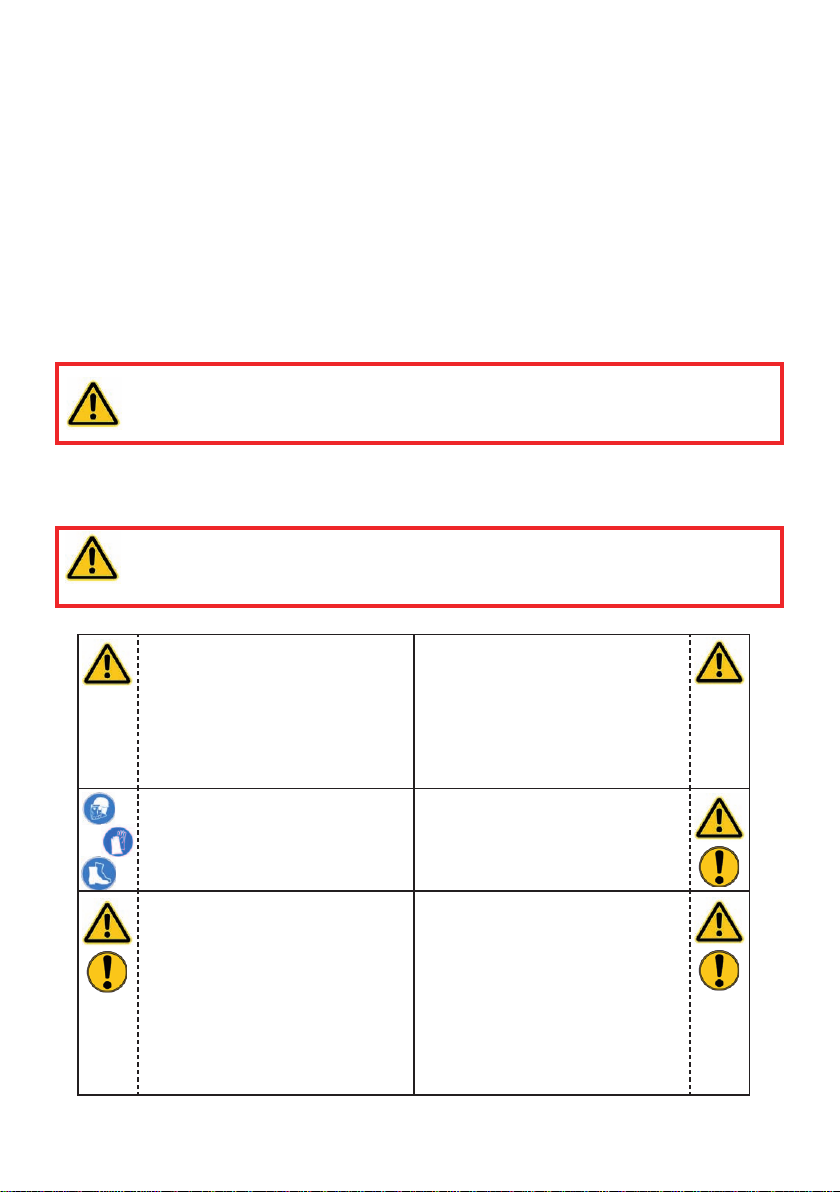

2. Product safety

LUKAS products are developed and manufactured to ensure the best performance and

quality when used as intended.

The safety of the operator is the most important consideration in product design. Furthermore,

the operating instructions are intended to help in using LUKAS products safely.

The generally applicable legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be complied with in addition to

the operating instructions.

The equipment must only be operated by persons with appropriate training in the safety

aspects of such equipment – otherwise, there is a danger of injury.

We would like to point out to all users that they should read carefully the operating instructions

and the instructions contained therein before they use the equipment, and that they should

carefully follow such.

We further recommend you have a qualifi ed trainer show you how to use the product.

CAUTION!

The operating instructions for the hoses, the accessories and the connected

devices must also be heeded!

Even if you have already received instruction on how to use the equipment, you should still

read through the following safety instructions again.

CAUTION!

Ensure that the accessories and connected equipment are suitable for the

maximum operating pressure!

Please ensure that no body

parts or clothing get stuck

between the visibly moving

parts.

Wear protective clothing, safety

helmet with visor, safety shoes

and protective gloves.

Working under suspended

loads is not permitted where

such loads are being lifted only

by means of hydraulic devices.

If working under suspended

loads is unavoidable, suitable

mechanical props are also

required.

Immediately report any changes

that occur (including changes

in operating behaviour) to

the appropriate persons/

departments! If necessary, the

equipment is to be shut down

immediately and secured!

Check the equipment for visible

fl aws or damage before and

after use.

Check all lines, hoses and

screwed connections for leaks

and externally visible damage,

and repair immediately!

Escaping hydraulic fl uid can

cause injuries and fi res.

6

Page 7

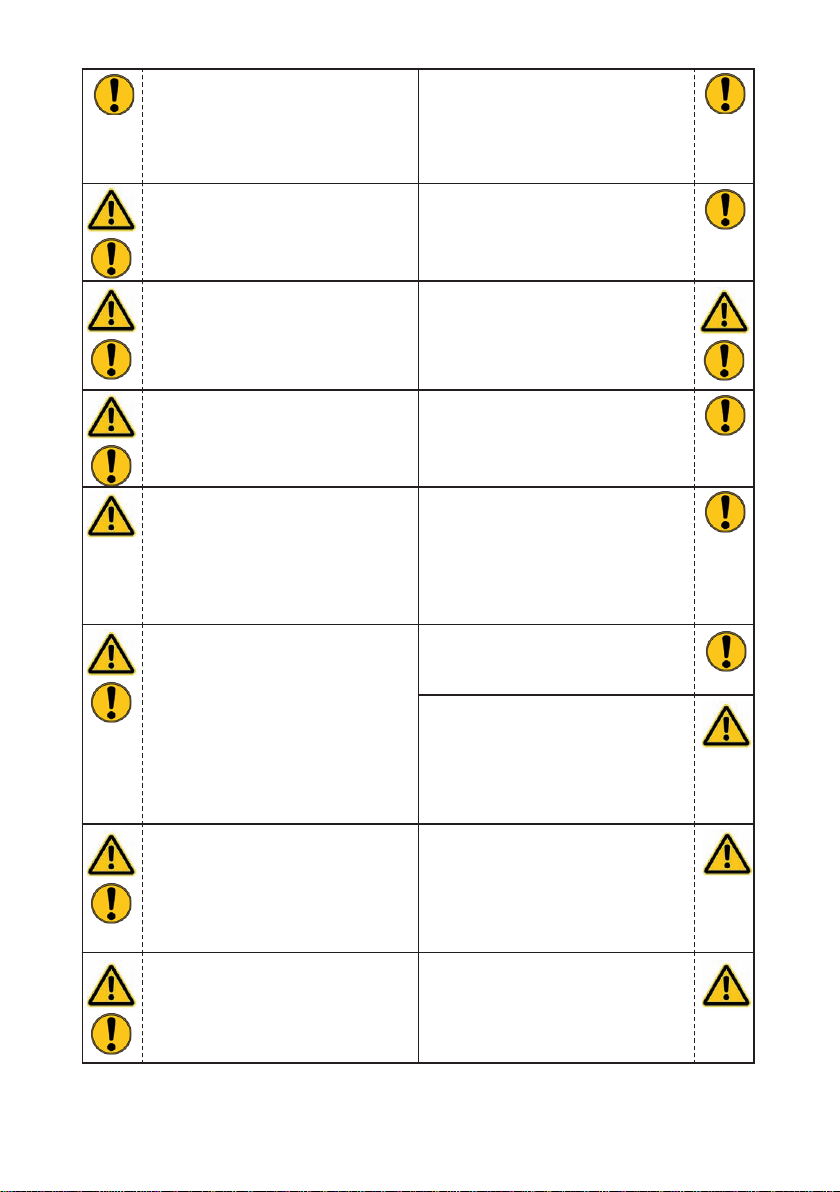

In the event of malfunctions,

immediately deactivate the

device and secure it. Repair the

fault immediately.

Do not carry out any changes

(additions or conversions) to the

equipment without obtaining the

approval of LUKAS beforehand.

Observe all safety and danger

information on the device and in

the operating instructions.

Please ensure that all safety

covers are present on the

equipment and that they are in

proper and adequate condition.

Safety devices must never be

disabled!

Make sure before switching

on/starting up the device and

during its operation, that this will

put no one in danger.

When working close to live

components and cables,

suitable measures must be

taken to avoid current transfers

or high-voltage transfers to the

equipment.

All safety and danger

information on the device must

always be complete and in a

legible condition.

Any mode of operation which

compromises the safety and/

or stability of the device is

forbidden!

The maximum operating

pressure set on the equipment

must not be changed!

Observe all intervals for

recurring tests and/or

inspections that are prescribed

or stated in the operating

instructions.

Only genuine LUKAS

accessories and spare parts are

to be used for repairs.

When working with this

equipment or when transporting

it, ensure that you do not get

caught up in the hose or cable

loops and trip.

The build-up of static charge

and therefore possible sparking

must be avoided when handling

the device.

Motorised pumps must not be

operated in areas at risk of

explosion!

Do not touch the engine and

exhaust system when running

with combustion engine pumps

because of the danger of

burning.

Combustion engines must not

be operated in enclosed spaces

because of the danger of

poisoning and / or smothering.

7

Page 8

If you spill any fuel when using

combustion engines, you must

remove the spilled fuel completely before starting the engine.

Keep combustion engines and

their fuels away from sources

of ignition since otherwise there

will be a danger of explosion.

Refuelling whilst the engine is

running is strictly prohibited!

All damaged electrical

components e.g. scorched

cables, etc. must be replaced

immediately!

In order to prevent the danger

of fi re, you should ensure

adequate ventilation when

operating combustion engines

and you must keep a safety

distance of at least 1m (39.4

in.) to walls and other screens.

Make sure that the combustion

engines are always standing on

as fl at and horizontal a surface

as possible to prevent fuel from

leaking out.

The equipment is fi lled with

hydraulic fl uid. This hydraulic

fl uid can be detrimental to

health if it is swallowed or its

vapour is inhaled. Direct contact

with the skin must be avoided

for the same reason. Also,

when handling hydraulic fl uid,

note that it can negatively affect

biological systems.

Make sure there is adequate

lighting while working.

Always keep these operating

instructions easily accessible at

the place of operation.

Damage to electrical

components must only

be repaired by a qualifi ed

electrician in compliance with

all applicable national and

international safety guidelines

and regulations.

When setting up the units, you

must make sure that they are

not impaired by the infl uences

of extreme temperatures.

When working with or storing

the equipment, ensure that the

function and the safety of the

equipment are not impaired

by the effects of severe

external temperatures or that

the equipment is damaged in

any way. Please note that the

equipment can also heat up

over a long period of use.

Before transporting the

equipment, always ensure that

the accessories are positioned

in such a way that they cannot

cause an accident.

Ensure the proper disposal of

all removed parts, leftover oil,

hydraulic fl uid and packaging

materials.

8

Page 9

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and are to

be implemented in addition to the operating instructions.

WARNING/CAUTION!

The device is intended exclusively for the purpose stated in the operating instructions

(see chapter "Proper Use"). Any other use is not considered to be as intended. The

manufacturer/supplier is not liable for any damage resulting from use not as intended. The

user bears sole responsibility for such use.

Proper use includes observance of the operating instructions and compliance with the

inspection and maintenance conditions.

Never work in a fatigued or intoxicated state!

WARNING / CAUTION / ATTENTION!

However, if you still injure yourself on the hydraulic unit, clean the wound

immediately and consult a doctor to have it attended to!

If you get hydraulic fl uid in your eye, rinse it immediately several times with clear,

clean water and consult a doctor!

Also, if you swallow hydraulic fl uid you should consult a doctor!

9

Page 10

3. Proper use

LUKAS hydraulic power units are specially designed to supply LUKAS rerailing equipment

with hydraulic fl uid and pressure. LUKAS rerailing equipment, such as a traversing unit or

one or more hydraulic cylinders is used for erecting and rerailing of rail-bound vehicles.

Their use for supplying pressure / fl uid to rescue equipment of other manufacturers is

possible, yet requires the technical inspection and approval by LUKAS in each individual

case.

The equipment is not designed to operate without hoses or equipment (operating time

without hoses or equipment < 15 minutes).

The equipment type groups GC and PC 650 have been developed for rerailing technology

and for use in combination with the control table.

When working with the units described here, make sure that participating and non-participating

persons in the vicinity of the work and during the lifting procedure are not endangered by the

connected hoses and equipment.

WARNING / CAUTION / ATTENTION!

The safety instructions in this operating instruction manual concerning the site of

erection and type of erection must always be observed!

LUKAS units type GC and PC 650 are not explosion protected!

You can obtain accessories and replacement parts for the hydraulic power unit from your

authorised LUKAS dealer!

ATTENTION!

When selecting the units to connect to the unit, bear in mind that the maximum

possible useable volume of hydraulic fl uid is limited.

The sum of the max. required operating volume of oil (hydraulic fl uid) of all

connected equipment must not exceed the maximum possible usable volume

of the power unit!

NOTE:

Always register your hydraulic unit on the LUKAS Hydraulik GmbH internet site.

This is the only way to guarantee your extended warranty cover.

Before you use couplings from a different company , you must contact LUKAS or

an authorised dealer.

10

Page 11

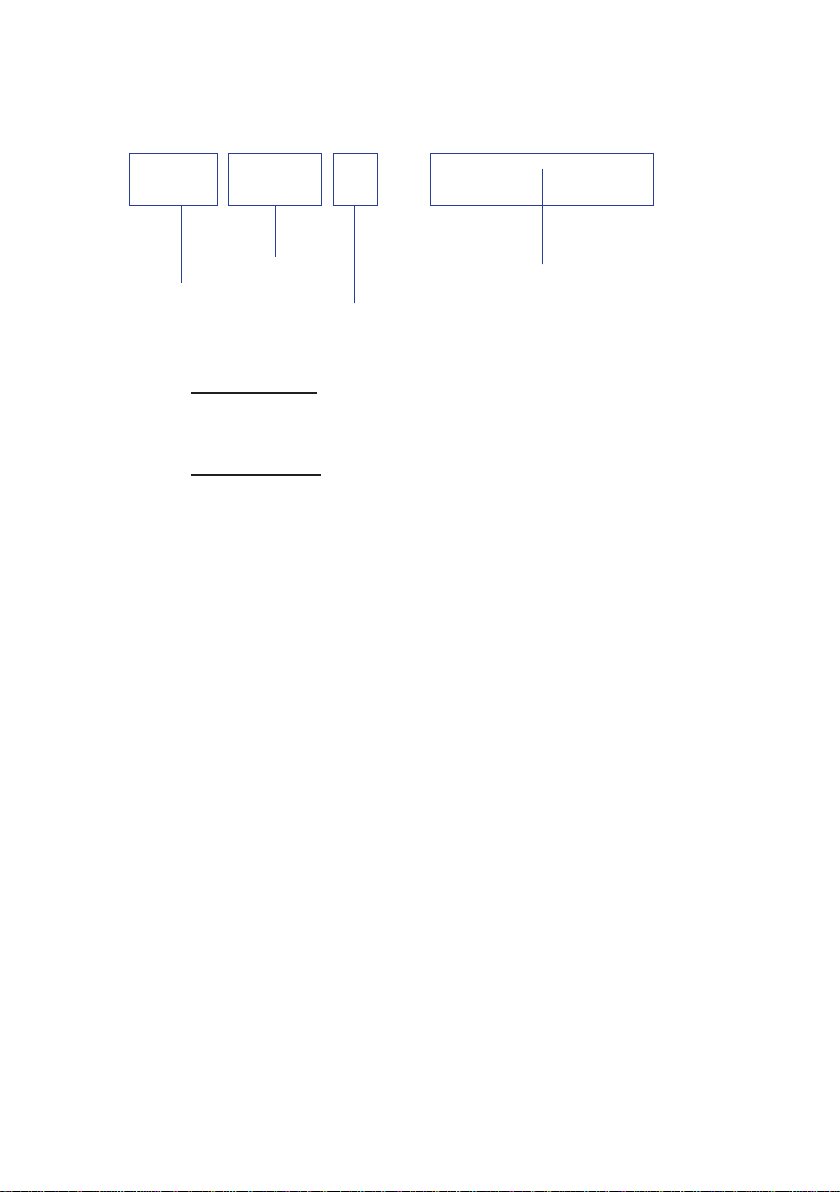

4. Assembly marking

GC

Motor variants and

coding for hydraulic

power units

Valve variants:

2POWER = Simultaneous operation

4POWER = Four circuit operation

Motor variants:

PC = Electric motor (operation via mains supply)

GC = Petrol engine

650 E

Type group

with electric starter

-

2POWER

Valve variants

5. Functional description

5.1 General information

On all LUKAS hydraulic power units, a hydraulic pump is always driven by a motor

(combustion engine or electric motor).

The pump conveys hydraulic fl uid from the tank to the connected equipment and generates

the hydraulic pressure.

The fl uid distribution is then controlled by valves.

11

Page 12

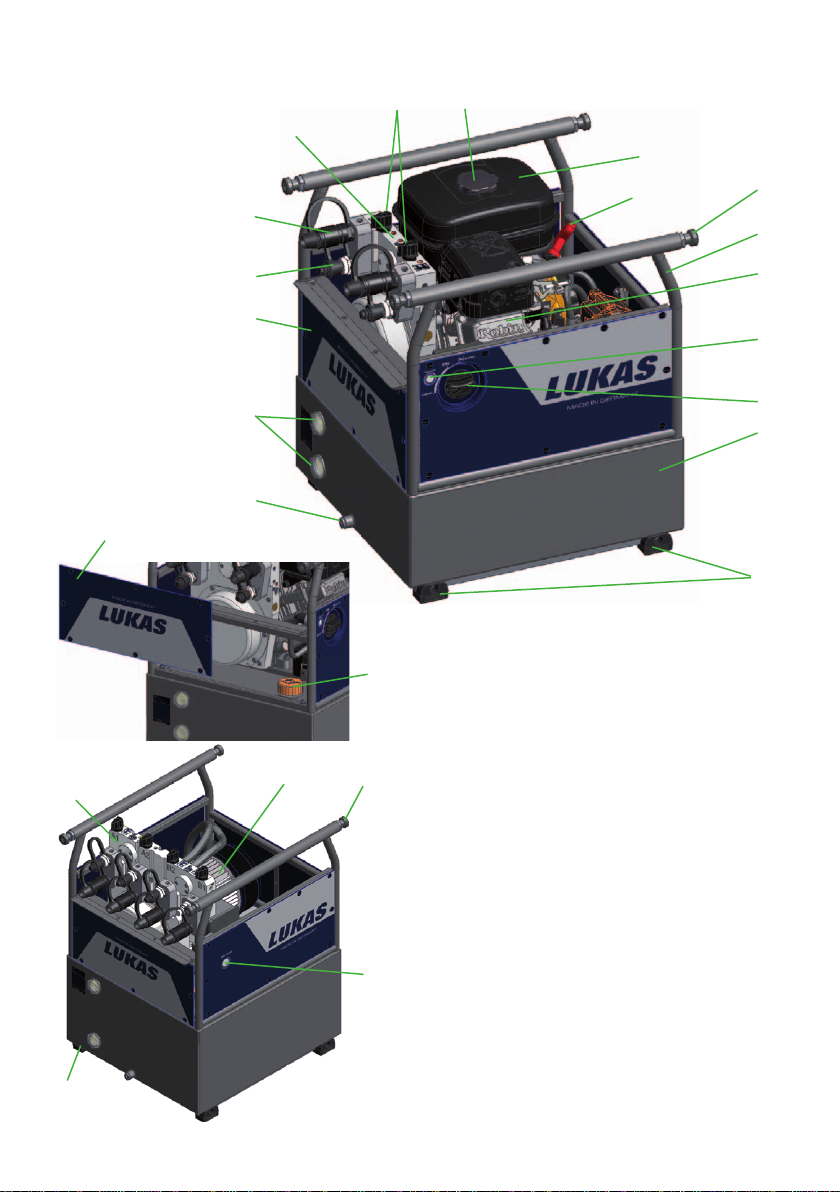

5.2 Layout of the units

4

9

8

12

2

7

17

13

15

10

14

20

18

14

1 Hydraulic fl uid tank

11

19

4

17

16

2 Petrol tank

3 Petrol engine with hydraulic pump

4 Connection block with control valves

(2 or 4 valves)

5 Engine switch

6 Electric starter button

7 Cable-pull starter

8 Valve control lever

9 Quick-disconnect coupling (female)

10 Quick-disconnect nipple (male)

11 Filler cover hydraulic fl uid

12 Filler cover petrol

13 Frame

14 Side cladding (clip fi xing)

15 Rubber buffer

16 ON - OFF -switch for electric motor

17 Telescopic carrying handle (can be

pulled out)

18 Drain screw for hydraulic fl uid

19 Electric motor with hydraulic pump

20 Sight window for hydraulic fl uid

3

6

5

1

15

12

Page 13

5.3 Motor variants

WARNING / CAUTION / ATTENTION!

For all motor variants, also comply with the separate operating instructions of

each motor manufacturer.

5.3.1 Electric motor

These hydraulic units are equipped with an electric motor. The electric motor is fed with power

from the mains or with power produced by generators. When operating with generators you

must make sure that voltage fl uctuations are not produced because these will have a direct

effect on the feed rate and durability of the hydraulic power unit.

The possible operating voltage and current frequency required can be taken from the

Chapter "Technical Data".

NOTE:

When connecting to the mains, if a very long connecting cable is used, the

power supply to the motor may be reduced as a result of the resistance in the

cable. This will reduce the power of the motor.

5.3.2 Petrol engine

These hydraulic units are equipped with a combustion engine driven by the fuel "petrol".

The units can be fi tted with an electric starter in addition to the cable-pull starter (optional).

NOTE:

The engine installed in the LUKAS power units does not match every detail of

the engine described in the manufacturer's separate operating instructions. On

account of the specifi c application in rerailing technology, and in order to ensure

the safety of the entire hydraulic power unit, components have been modifi ed

or adapted to suit.

Nevertheless, it is important that you follow all safety rules and operating,

maintenance and storage instructions in the separate engine instructions as

absolute since they are not affected by adjustments made by LUKAS.

The starter battery is automatically charged up by the integrated generator when the engine

is running. If the battery has become fl at after an extended storage period you should start

the unit with the cable-pull starter. This causes the battery to be charged up automatically.

If the battery is still not charged after running for about half an hour it could have the following

causes:

- the contacts (connection plug) have come loose and need to be reconnected.

- battery is defective and needs to be replaced.

- there is damage to the generator or the engine. In these cases you should contact

LUKAS customer service.

13

Page 14

5.4 Valve variants

The valves are always rigidly mounted in a connection block. This block is directly integrated

in the hydraulic power unit. The hoses (pressure and return) are always connected to the

connection block. The units are equipped with either a 2POWER or a 4POWER connection

block.

The hoses and equipment are connected with the connecting block via plug couplings.

5.4.1 Control valve "Two fl ow mode" (2POWER)

This valve enables the connection of two double-acting hydraulic units. With this valve you

can operate two units at the same time and independently of each other.

You have two switching possibilities. The two switching levers can be used to pressurise or

depressurise the individual connections.

5.5.2 Control valve "Four fl ow mode" (4POWER)

This valve enables the connection of four double-acting hydraulic units. With this valve you

can operate four units at the same time and independently of each other.

You have four switching possibilities. The four switching levers can be used to pressurise or

depressurise the individual connections.

ATTENTION!

When operating several rerailing units with one unit, ensure that the usable

volume of hydraulic fl uid in the reservoir is greater than the maximum possible oil

volume of all connected rerailing units. In the hydraulic fl uid tank, we differentiate

between the fi lling volume and the usable volume.

14

Page 15

5.5 Pumps

LUKAS hydraulic power units are fi tted with a two circuit or a four circuit pump, depending

on the type. The pumps are rigidly connected to the connecting block.

Double-fl ow pump for operating with 2POWER valve

For-fl ow pump for operating with 4POWER valve

The pumps used always have two pressure stages per pump feed fl ow, one low pressure

and one high pressure.

Low-pressure level (LP) = up to 14 MPa*

High-pressure level (HP) = up to 53 MPa*

The changeover from low pressure to high pressure is carried out automatically by the pump.

The maximum pressure is limited by a pressure limiting valve.

WARNING / CAUTION / ATTENTION!

For safety reasons, the pressure set on this valve must not be adjusted (without

the approval of LUKAS directly)!

*) 1 MPa = 10 bar

5.6 Frame with side sections

All the hydraulic power units described here are enclosed in a frame.

The frame and the side parts serve to protect the unit from external infl uences (e.g. dirt,

damage etc.) and also for transporting using the frame itself or the carrying handles.

The starter system on units having combustion motors are also mounted on the frame or the

side parts.

5.7 Connection to the control table

Connection to the rerailing equipment is exclusively via the control table. Either via the

connecting hoses rigidly fi xed to the control table or via additional pairs of hose extensions if

the power unit is not installed directly under the control table. The hose extension pairs are

supplied in various lengths.

The individual hoses can, if required, also be marked with coloured snap rings to make it

easier to allocate the hoses.

(For specifi c details, please consult the LUKAS range of accessories or contact your

LUKAS dealer.)

15

Page 16

6. Connecting the hoses / devices

ATTENTION!

When connecting the hose lines, always ensure that the connection components

are not dirty. If necessary, clean before connecting!

NOTE:

Before connecting or disconnecting the hoses on the hydraulic power unit, make

sure that the power unit is switched off or, with a unit with an electric motor (PC

650) that it is isolated from the mains (pull the plug out)! This represents an

increased safety measure in order completely to prevent any movement of the

equipment.

WARNING / CAUTION / ATTENTION!

Before connecting the equipment, make sure that allthe

components used are suitable for the maximum operating

pressure of the hydraulic unit! In cases of doubt, you must

consult LUKAS directly before connecting the equipment!

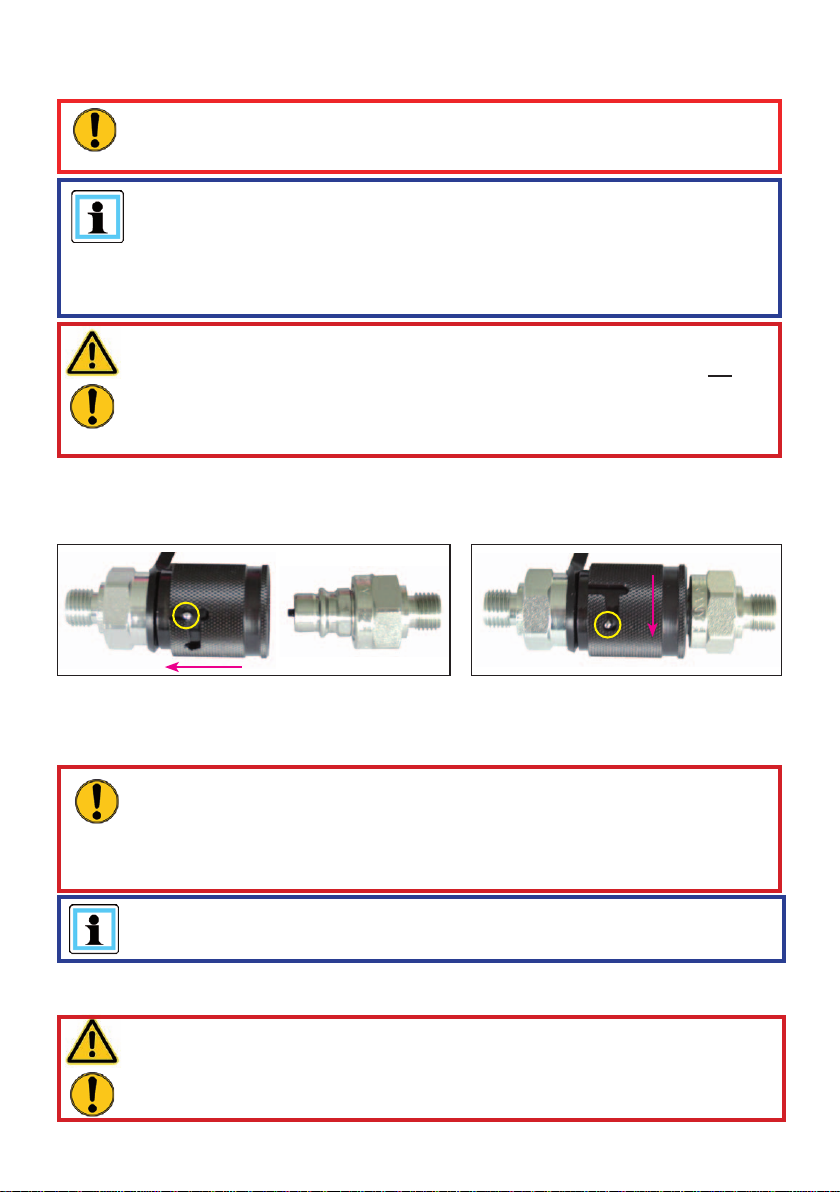

Coupling the Quick-disconnect couplings

The equipment is connected to the hydraulic pump via quick-disconnect coupling halves

(male and female).

X

Y

Before coupling, remove dust caps and then pull back and hold the locking sleeve of the

female coupling half (position X). Connect the male and female couplings and release the

locking sleeve. Then turn the locking sleeve to position Y. The connection has been made

and locked. Uncoupling is done in the reverse order.

ATTENTION!

Always couple the return line (tank line - marked T on the pump block) fi rst

and then the supply line (pressure line - marked P on the pump block)!

On disconnecting, you should always disconnect the supply line rst (pressure

line) and only then the return line!

NOTE:

Coupling is only possible if the hoses are depressurised.

For dirt protection, the supplied dust protection caps must be refi tted.

WARNING / CAUTION / ATTENTION!

Some quick-disconnect couplings have special functions.Therefore, you must

not unscrew them from the hoses or swap them over!

16

Page 17

7. Erection and start-up

7.1 Set-up

WARNING / CAUTION / ATTENTION!

Because of possible spark formation, combustion engine units and electrical

equipment must not be used in an explosion-risk area. Units with combustion

engines must not be used in enclosed spaces, as there is a danger of poisoning

and asphyxiation!

The unit is to be set up in a suitable location (secure location / fl at surface / suffi cient distance

from vehicles, loads, sources of ignition, etc.).

LUKAS units work perfectly at an angle of up to 10°. However, in order to guarantee maximum

safety and function, they should be operated in as horizontal a position as possible.

7.2 Start-up

NOTE:

Before commissioning for the fi rst time, or after longer periods of storage, on

units having a combustion engine, you must fi rst connect the starter battery and

check the oil level in the engine! If necessary, top up the engine oil!

For safety reasons, the LUKAS power units are supplied without engine oil,

hydraulic fl uid and fuel!

Proceed as follows to commission:

1. You must fi rst check the level of fl uids in the power unit.

The hydraulic fl uid level can be seen from the outside on the circular sight window at the

top and at the bottom of the tank. You should be able to see hydraulic fl uid in the top sight

window of the hydraulic tank. Set up the power unit horizontally and on an even surface in

order to be able to read the fl uid levels accurately or to top up. The fuel tank can be fi lled

ATTENTION!

Never mix up the fuel and hydraulic fl uid tanks when fi lling the tank; this can

damage the power unit!

up to the top of the petrol fi lter insert. A maximum of three litres of petrol should be poured

in, however, (correspondingly less if the power unit is resting at an angle).

2. On hydraulic power units with an electric motor, you must now connect the mains plug to

the power supply.

3. The hydraulic power unit must then be bled. Set all levers of the control valves to the

neutral position (see Chapter "Operation"). The actual venting is carried out in the units in

a different manner, depending on the drive motor:

a) Petrol engine:

- remove the plug lead from the sparking plug (on the back of the unit).

- slowly turn the engine over with the starter cable-pull several times.

- then replace the plug lead.

17

Page 18

b) Electric motor (mains operation):

- switch the motor on and switch it off again after approx. 15 seconds. Repeat

this process several times. (Before switching back on, the motor must be at a

standstill!)

This procedure makes sure that the pump draws fl uid slowly and is well bled. The hydraulic

fl uid tank is equipped with automatic bleeding, so that additional bleeding measures are

not required.

4. Check the levels of fl uid in the tanks again. If necessary, you should top up with fl uid.

8. Operation

ATTENTION!

The control levels on the hydraulic power units should always be switched to

the neutral position prior to starting the motor in order to prevent unwanted

movements of connected hydraulic equipment for safety reasons.

8.1 Starting the engines

8.1.1 Petrol engines

Before starting the combustion engines, check that the fuel tank is full and that the engine

oil level is within the permitted tolerances (petrol engines). If necessary, top up the relevant

fl uid (see also the operating instructions of the engine manufacturer in the scope of supply).

Engine starting procedure:

3. Set the engine switch to the "CHOKE" position

( ) (if the engine is warmed up, or if the ambient

temperature is higher, start the engine with the

switch in the "ON" position.)

4. Starting with the electric starter:

Push the starter button

Starting with the cable-pull starter:

Pull the handle on the cable-pull starter slowly up

to over the compression point (resistance is felt).

Allow it to go back to the starting position and then

pull it sharply all the way.

NOTE:

If the engine does not start after several attempts to start it, repeat the

procedure described above with the engine switch in the "ON" position.

5. Guide the handle on the cable-pull starter back into the starting position with your hand.

6. After 20 to 30 seconds warming up, turn the engine switch to the "ON" position (if it was

previously set to "CHOKE").

18

Page 19

8.1.2 Electric motors

Before starting the motor, check that all electrical connections and cables are in a good

condition. Then connect the mains cable (for motors with mains power supply) to the supply

socket.

Starting is carried out by pushing the ON/OFF switch on the side part of the power unit. The

ring around the switch lights up when the power unit is switched on.

ATTENTION!

Electric motors pull a very high start-up current for a short period. For this reason,

when using a generator, make sure that it can deliver the appropriate current.

The power supply must be fused with at least a 25 A fuse.

8.2 Stopping the engine

8.2.1 Petrol engines

The engine on the power unit stops automatically when the fuel tank is empty . However, you

should avoid this and switch it off before running to empty to prevent the carburettor from

running dry.

The following procedure is required for stopping the engine manually:

Engine stop procedure:

1. Check that all the connected equipment is in the basic position (start position).

2. Set the levers of the control valves to the neutral position (depressurised).

3. Set the engine switch to the "OFF" position.

WARNING / CAUTION!

Never touch the hot engine parts: this could result in severe burns.

8.2.2 Electric motors

Set the levers of the control valves to the neutral position (depressurised).

The motor is switched off again by pushing the ON/OFF button on the side part again. The

illumination of the switch goes out.

When the motor is switched off, the supply capability of the connected hydraulic pump is

also stopped.

19

Page 20

8.3 Topping up with fuel (only on combustion engines)

The engine must be switched off for refuelling!

Procedure:

1. Open the fuel tank cap.

2. Top up the tank with fuel to the maximum level (top of petrol fi lter insert).

WARNING / CAUTION / ATTENTION!

Be sure not to spill fuel. In particular, hot engine parts must not come into

contact with fuel; danger of fi re otherwise!

If fuel is spilled, it must be cleaned up immediately with a suitable absorbent

cloth. In doing so, be careful not to burn yourself on one of the hot engine

parts! The used cloth must then be cleaned or disposed of according to the

relevant provisions and guidelines!

3. Close the fuel tank again properly with the fuel tank cap.

8.4 Controlling the valves

ATTENTION!

The control levels on the hydraulic power units should always be switched to

the neutral position (de-pressurised) prior to starting the engine in order to

prevent unwanted movements of connected hydraulic equipment.

8.4.1 Control valve "Two fl ow mode" (2POWER)

There are two levers mounted on the connection block of this valve.

Each of the two small levers is assigned to one pressure port. The pressure

application of the corresponding pressure hose is controlled (" ") or the

connection is depressurised (" ") by switching the relevant lever over.

NOTE:

All switching levers must always be completely switched on up to the end stop.

20

Page 21

8.4.2 Control valve "Four fl ow mode" (4POWER)

There are four levers mounted on the connection block of this valve.

Each of the four small levers is assigned to one pressure port. The pressure

application of the corresponding pressure hose is controlled (" ") or the

connection is depressurised (" ") by switching the relevant lever over.

NOTE:

All switching levers must always be completely switched on up to the end stop.

21

Page 22

9. Dismantling the equipment / deactivation following operation

After completing the work and before stopping the unit, place all connected units to the base

setting (storage setting). You can then stop, or switch off, the motor on the unit, and if you

are using an electric motor this should be disconnected from the mains.

WARNING for power units with combustion engines!

Check that the engine switch is set to the “OFF“ position and remains there to

prevent the unwanted starting of the power unit!

Couplings:

ATTENTION!

The operating pressure in the system must be dissipated before uncoupling

the hoses.

When the rerailing work is complete you must release the operating pressure

in the installation/system.

If the connected hose lines are to be dismantled during shut-down, decouple as described

in Chapter "Connecting the hose lines". Then replace the dust protection caps onto the plug

couplings.

Clean any coarse contamination from the hydraulic tank before putting into storage. If the

storage period is extended then the unit must be cleaned completely externally and the

mechanically moving parts must be oiled.

If storing a unit with combustion engine, you should also remove the fuel from the fuel tank

and disconnect and/or remove the starter battery.

Avoid storing the hydraulic power units in a damp environment.

Observe the additional regulations in the separate operating instructions for the hoses.

CAUTION!

Several people may be required to transport to the storage location, depending

on the weight of the hydraulic power unit.

22

Page 23

10. T ests

The hydraulic power units are subject to very high levels of stress. A visual inspection must

therefore be carried out after every use and at least one visual inspection must be carried out

every six months. This reveals signs of wear in good time and punctual replacement of these

wear parts prevents damage to the equipment. Also check regularly that all the securing

screws are tightened (if applicable, comply with prescribed tightening torques).

Every three years or if there is any doubt regarding the safety or reliability of the equipment, a

functional test must also be performed. (Please also observe the relevant valid national and

international regulations pertaining to service intervals of hydraulic equipment). Operating

time per day In the Federal Republic of Germany, regular safety inspections according to

the regulations of the Gesetzlichen Unfallversicherung (GUV; connoted ‘Legal accident

insurance’) are mandatory.

ATTENTION!

Clean off any dirt before checking the equipment!

WARNING / CAUTION / ATTENTION!

To perform inspection, maintenance and repairs, personal safety equipment

appropriate for the work is an absolute requirement (if necessary also use

screening).

10.1 Recommended test intervals

10.1.1 Visual inspection

A visual inspection must be carried out after every use, but at least once every six months.

10.1.2 Function check

Operating time per day Functional test

up to 1 hour 1 x annually

up to 8 hours 1 x per quarter

up to 24 hours 1 x per month

In addition to these test intervals you need to carry out a function test if:

- the unit makes unusual noises,

- there is a justifi ed suspicion of internal damage to the unit.

If the noises and suspicions referred to above arise several times in a month, or if the

maximum pressure cannot be achieved during the function test, you need to contact LUKAS

customer service immediately . The contact details are given in the Chapter "Fault analysis".

23

Page 24

10.2 Hydraulic units with combustion engine

Visual Inspection

Hydraulic power units

• check that all hydraulic connections are still tight

• general tightness, no leaks (sweated oils do not have any infl uence on the function),

• is there any detectable damage to the engine, connecting blocks, on the frame or the side

sections,

• Is there any sign of damage to the hydraulics and/or fuel tank,

• Side plates present and tightened,

• Presence and legibility of the identifi cation plate, all actuation signs, instruction signs,

markings and warnings,

• The presence and perfect condition of all covers (e.g. exhaust defl ector),

• The presence and perfect condition of thermal protection mats,

• Is there still a minimum distance of 10 mm between the tanks and the hot parts of the

engine,

• All fl uid levels are within the specifi ed tolerances,

• Are the starters in proper working order and undamaged?

• Are the electrical cables in proper working order and undamaged?

• Is the electric starter battery in proper working order and undamaged?

• Couplings must be easy to couple,

• Dust protection caps must be available,

• All required accessory parts (e.g. sparking plug, sparking plug spanner and fuel can) are

present.

• Are the extending handles undamaged and functional

Functional test

• No unusual noises

• Starter functioning?

• Engine switch fully functional,

• Tests for maximum load (connect to control table and apply pressure with the valve

switching lever (a unit must not be connected to the control table) until the maximum

operating pressure is reached. Read-off via pressure gauge on control table).

24

Page 25

10.3 Hydraulic units with electric motor

Visual Inspection

Hydraulic power units

• Check that all hydraulic connections are still tight

• General tightness, no leaks (sweated oils do not have any infl uence on the function),

• Is there any damage apparent to the motor, valve blocks or on the casing?

• Side plates present and tightened,

• Presence and legibility of the identifi cation plate, all actuation signs, instruction signs,

markings and warnings,

• The presence and perfect condition of all covers (e.g. exhaust defl ector),

• All fl uid levels are within the specifi ed tolerances,

• ON/OFF switch in proper condition and not damaged,

• Couplings must be easy to couple,

• Dust protection caps must be available,

• All attached electrical parts (e.g. cables and plugs) are present and undamaged.

• Are the extending handles undamaged and functional

Functional test

• No unusual noises

• Tests for maximum load (connect to control table and apply pressure with the valve

switching lever (a unit must not be connected to the control table) until the maximum

operating pressure is reached. Pressure read-off via pressure gauge on control table).

10.4 Hoses (optional pairs of hose extensions)

Visual Inspection

Extension hoses

• Visual check for damage , cracks and leaks,

• Age check of the hoses (replace after latest 10 years),

• Hose connecting fi ttings with couplings on extension hoses tightly connected and not

leaking,

• Couplings must be easy to couple,

• Dust protection caps available?

25

Page 26

11. Maintenance and repair

11.1 General information

LUKAS hydraulic power units type GC and PC 650 have a complex structure and therefore

require only a small amount of maintenance. For general service work, special training

is not necessary; however, knowledge about the function of the power units, the legal

safety instructions and dealing with the required tools are basic prerequisites.

For safety reasons, repair work to the hydraulic power unit must only be carried out

ATTENTION!

Never use unnecessary force during maintenance work that could damage the

components of the power unit or compromise operational safety.

by the equipment manufacturer or by personnel specially trained for the purpose by the

equipment manufacturer, and by authorised LUKAS dealers.

WARNING / CAUTION / ATTENTION!

Protective clothes must be worn when maintenance and repairs are being

carried out, since the devices may also be pressurised when not in operation.

During work, ensure that all components are particularly clean, since dirt can

damage the rescue equipment!

ATTENTION!

Since LUKAS hydraulic units are designed for top performance, only those

components in the replacement parts lists for the relevant unit can be replaced.

Any other components in the unit may only be replaced if:

- You have participated in an appropriate LUKAS service training course.

- You have the express permission of LUKAS Customer Service (after request,

verifi cation that permission may be granted. An examination in each individual

case is necessary!)

When cleaning the equipment, please note that no cleaning agents must be used

having a pH value outside the range 5 - 8!

ATTENTION!

Attention must be paid to ensuring that no operating fl uids escape from units

with combustion engines during repair work!

26

Page 27

11.2 Service work on the hydraulic unit

11.2.1 Care instructions

The exterior of the device must be cleaned from time to time (not the electrical contacts)

and the metallic surfaces (not the electrical contacts) must be treated with a suitable agent

to protect against corrosion.

(In case of doubt, contact your authorised LUKAS dealer or LUKAS directly!)

11.2.2 Function and load test

If there is any doubt regarding the safety or reliability of the equipment, a function and load

test must also be performed.

11.2.3 Replacing the hydraulic fl uid

- The engine must be switched off or the unit must be isolated from the mains!

- After approx. 200 deployments, but after three years at the latest, replace the hydraulic fl uid.

- The fl uid is best replaced after it has warmed up.

- The used hydraulic fl uid must be disposed of properly.

27

Page 28

Procedure for hydraulic fl uid replacement:

1. Switch the engine off or isolate the electric motor from the mains. Place the power unit

on a slightly elevated base so that the drain plug for the hydraulic fl uid can be easily

reached.

2. Place a suitable collection vessel under the drain screw "A" or the hydraulic oil drain

opening into which it is screwed.

3. Remove the side panel to gain access to the hydraulic tank closure. Open the fi ller cap

"B", remove the drain screw "A" and the sealing ring "C" and let the hydraulic fl uid fl ow

into the prepared collection vessel (see illustration).

A

C

B

4. Fit the components "A" and "C" back in place in reverse order.

5. Pour the new hydraulic fl uid through the fi ller neck into the tank and close the neck again

with fi ller cap "B".

6. The unit then has to be bled again as described in the Chapter "Commissioning".

28

Page 29

11.2.4 Changing decals

All damaged and/or illegible decals (safety notices, type plate etc.) must be replaced.

Procedure:

1. Remove damaged and/or illegible decals.

2. Clean surfaces with industrial alcohol.

3. Affi x new decals.

Take care to affi x the decals in the correct positions. If this is no longer known, you should

ask your authorised dealer or contact LUKAS directly.

11.3 Additional service work on unit with combustion engine

(also observe the separate instructions from the engine manufacturer)

You must conduct the following service measures every 50 operating hours:

• Wash the air fi lter element. Reduce the maintenance intervals if being used in dirty or

dusty environments.

• Check the sparking plug and clean if required

You must conduct the following service measures every 100 operating hours:

• Replace the engine oil. Reduce the maintenance intervals if being used in dirty or

dusty environments.

You must conduct the following service measures every 200 operating hours:

• Set the electrode gap on the sparking plug

• Clean the fuel fi lter

You must conduct the following service measures every 500 operating hours:

• Replace the sparking plug and the fi lter element

• Clean and adjust the carburettor, valve clearance, valve seat and cylinder head.

You must conduct the following service measures every 1000 operating hours or every

2 years:

• Check the starter

• Inspect the engine for damage

• Replace the fuel line.

NOTE:

The fi rst engine oil change must be carried out after 20 working hours. The

subsequent oil changes should be carried out after 100 hours.

For dismantling the sparking plug, use a commercially-available sparking plug

spanner with universal joint and spanner size of 21 mm.

A straight / rigid sparking plug spanner would damage or break off the sparking

plug!

Also observe the separate engine manufacturer's operating instructions supplied

with the equipment!

29

Page 30

11.3.1 Replacing and cleaning the air fi lter

Keeping the air fi lter in good condition is extremely important.

Penetrating dirt leads to damage and wear in the engine in case of incorrect installation,

incorrect servicing or unsuitable fi lter inserts. Always keep the air fi lter insert clean.

Procedure:

1. Remove the rear side panel on the hydraulic power unit by releasing the fi xing clips and

lifting the panel away.

2. Release the fi xing hook for the protection cover at the bottom and remove the fi lter insert.

3. For cleaning, tap carefully to release the dirt and blow out the dust. Never use oil!

Wash the insert in clean water. Remove the water from the polyurethane insert by

squeezing (not twisting) as far as possible, and dry the insert.

5. Then re-fi t the fi lter.

Protective cover

Air fi lter insert

Fixing hook for protective cover

30

Page 31

11.3.2 Replacing, cleaning and setting the sparking plug

Procedure:

1. Remove the right side panel on the hydraulic power unit by releasing the fi xing clips.

2. Remove the sparking plug lead. The plug is very tight, but is only a push-fi t. However ,

when releasing it make sure that you do not tilt the plug or apply a side load to the

sparking plug. In the worst case, this can destroy the sparking plug and it can cause

expensive repairs as a consequence.

4. Unscrew the sparking plug from the engine using a sparking plug spanner with a universal

joint and having a size of 21 mm.

Sparking plug

connector

3. If the sparking plug is sooted-up you need to clean it with a sparking plug cleaning agent

or a brush. If the sparking plug is irreparably damaged (e.g. by burning out the electrodes

or by deformation) it must be replaced by a new one.

4. Set the electrode gap to 0.6 to 0.7 mm.

5. Then re-fi t the sparking plug.

Sparking plug

0.6 - 0.7 mm

11.3.3 Replacing the engine oil and the engine oil fi lter

For the procedure for replacing the engine oil and engine oil fi lter, please refer to the separate

operating instructions of the engine manufacturer! You need to remove the hydraulic tank

31

Page 32

from the power unit before you can drain the engine oil. See the relevant LUKAS spare parts

list.

Engine oil dipstick

(Engine oil fi ller

opening)

Oil drain screw

11.3.4 External charging or replacing the starter battery

Procedure:

1. Remove the left side panel "A" on the hydraulic power unit by releasing the fi xing clips "B".

2. You can now see the starter battery "C". First remove the negative terminal ("-") from the

battery and then the positive terminal ("+").

B

A

C

32

Page 33

3. If you want to charge the battery using an

external charger you need to connect it now.

(Observe the operating instructions for the

charger being used)

If the battery is defective it needs to be

replaced. To do this, release the fi xing strap "D"

by pulling the tab downwards and unhooking

it to the side. Remove the battery. Take care

when inserting the battery to make sure you

are doing it correctly (see illustration, left).

Installation of the battery is carried out in

CD

reverse order.

11.4 Couplings

WARNING / CAUTION / ATTENTION!

Couplings must not be repaired! They need to be replaced by genuine

LUKAS parts!

The quick-disconnect couplings must be replaced if:

- there is external damage,

- the locking does not function,

- hydraulic fl uid continues to leak in the coupled/uncoupled state.

Procedure for coupling to valve block:

1. First empty the hydraulic tank as described in the chapter "Replacing the hydraulic fl uid".

2. Unscrew the coupling half (nipple and/or sleeve).

3. Remove coupling part(s).

4. Screw the new part(s) into the valve block.

5. Screw in the coupling part(s) and tighten to a torque of M

6. The hydraulic fl uid tank must be refi lled and the power unit vented.

33

= 35 Nm.

A

Page 34

12. T roubleshooting

In the case of defects which directly affect the motor / engine, please consult the separate

operating instructions of the motor / engine manufacturer.

Fault Check Cause Solution

Electric motor

does not run after

actuating the switch

or does not achieve

full power

Check electric

motor connection

cable

Extension cable

or cable drum

used?

Mains cable not

connected

Defect in connection

cable

Cable not completely

uncoiled

Cable losses in

extension cable or

cable drums too great

(electrical resistance)

Connect mains cable

correctly

Shut down immediately

and have it repaired by

an authorised dealer,

engine manufacturer

or directly by LUKAS

Uncoil the mains cable

completely

Use a different suitable

extension cable or

cable drum.

Electric motor

connected to a

suitable battery?

Electric safety

device in power

supply has

triggered

Are all valves set

to pressure-free

(rest setting)?

Battery fl at Charge battery

Electric motor not

suitable for battery

operation

Power supply not

suitable for electric

motor

Electric safety device

in power supply has

triggered although it is

suitable for operation

of the motor.

Electric motor

defective or

overloaded due to a

different defect in the

unit

34

Connect the motor

to a different suitable

power supply

Connect the motor

to a different suitable

power supply

Safety device too

small, use a different

fuse.

Shut down immediately

and have it repaired by

an authorised dealer,

engine manufacturer

or directly by LUKAS

Page 35

Fault Check Cause Solution

Combustion engine

will not start

Check fuel level

in tank

Electric starter

present?

Check fuel line Fault in the fuel line Shut down immediately

Check starter

button and motor

switch

Hydraulic power

unit or engine

not suitable

for the working

environment

Check air fi lter Air fi lter contaminated Clean or replace the

Are all valves set

to pressure-free

(rest setting)?

Fuel tank empty Top up with fuel

Electric starter battery

fl at

Starter button or

cable-pull starter not

actuated

Engine switch not set

to Choke

Ambient temperature

too low

Not enough oxygen in

the air because of the

altitude of application

location of the

hydraulic motor

Combustion motor defective or overloaded

due to different defect

in the unit

Charge electric starter

battery or use cablepull starter

and have it repaired by

an authorised dealer,

engine manufacturer

or directly by LUKAS

Actuate starter button

or cable-pull starter

Set engine switch to

Choke

For the solution,

consult the separate

operating instructions

of the engine

manufacturer.

Use a different

hydraulic fl uid or

operating fl uid that

is suitable for the

relevant ambient

temperature (see

Chapter "Technical

Data")

Use a different more

suitable hydraulic unit.

Have the engine set to

the altitude of application by an authorised

dealer, engine manufacturer or LUKAS

direct (only if the unit is

to be used frequently

at this altitude).

air fi lter.

Have repaired by

authorised dealer,

engine manufacturer

or directly by LUKAS

35

Page 36

Fault Check Cause Solution

The engine is

running, but

the connected

equipment does

not move upon

activation of the

valve.

The connected

rescue equipment

does not move on

activation of the

valve, or moves

only very slowly or

unevenly.

Check hose Hose assembly not

connected properly or

damaged

Check the switch

position of the

valve lever on the

pump block of the

hydraulic unit

Connect a

different unit and

check whether

it works when

actuated

Connect a

different unit and

check whether

it works when

actuated

Check the switch

position of the

valve lever on the

pump block of the

hydraulic unit

Valve not switched

to supply line

pressurisation.

Defective pump unit Have it repaired by

The previously

connected unit is

defective.

Plug-in coupling

(female) defective

The previously

connected unit is

defective.

Pressure relief on

the unit is still active

(circulation at static

pressure)

Defective pump unit Have it repaired by

Air in hydraulic system Vent the hydraulic

Female coupling

defective

Check connection of

hose and reconnect if

necessary.

Switch valve to

pressure load of the

supply line.

authorised dealer or

directly by LUKAS

Rectifi cation see

operating instructions

of the connected unit

Replace plug-in

coupling (female)

Rectifi cation see

operating instructions

of the connected unit

Check the switching

positions of the

valve lever(s) and, if

necessary, reset (as

far as the end position)

authorised dealer or

directly by LUKAS

system

Replace the coupling

sleeve

36

Page 37

Fault Check Cause Solution

Connected

equipment does

not reach its end

position

Check hydraulic

fl uid volume in

hydraulic tank

Insuffi cient fl uid in the

hydraulic tank

Top up hydraulic fl uid

to the maximum fi ll

level

Attention! Before

topping up, return the

connected equipment

to the base position!

Connected

equipment does

not reach its

performance data

(force)

During function test:

A pressure gauge

installed between

the equipment

and the hydraulic

power unit does

not indicate the

maximum operating

pressure of the

power unit.

Check the

stated data of

the connected

equipment

Usable hydraulic fl uid

volume of the unit is

insuffi cient

Maximum permitted

operating pressure

of the pump is not

reached

Pump block defective Have it repaired by

Connected unit

defective

The operating

pressure of the

connected equipment

is locked internally

Connected unit

defective

Hydraulic unit

defective

Use a different unit

with a demand quantity

below the maximum

usable quantity of the

power unit

Have the pressure

limiting valve reset or

repaired by authorised

dealer or directly by

LUKAS

authorised dealer or

directly by LUKAS

Rectifi cation see

operating instructions

of the connected unit

No repair or fault

rectifi cation required

Consult the separate

operating manual

for the connected

equipment

Have it repaired by

authorised dealer or

directly by LUKAS

37

Page 38

Fault Check Cause Solution

Fluid coming out of

hydraulic fl uid tank

Leaking fl uid

between engine and

fl ange bearing

Hydraulic fl uid milky

and cloudy

Connected

unit not in rest

position yet and

fl uid coming out

of fi ller cap?

Fluid leaks from a

different location?

Returning the

hydraulic fl uid from the

equipment exceeds

the tank’s maximum

capacity.

Leak from tank, lines

or seals

Radial shaft seal

on the drive shaft is

defective

Water / condensation

in the system

Reduce fl uid level in

the hydraulic tank to

“Minimum” (bottom

sight glass), move

the unit to the base

position and then fi ll

back up with hydraulic

fl uid to the “Maximum”

level (top sight glass)

Replace defective

components or repair

by authorised dealer or

Lukas directly

Have it repaired by

authorised dealer or

directly by LUKAS

Replace the hydraulic

fl uid immediately

Hoses cannot be

coupled

Carrying handles

cannot be pulled out

or pushed in.

Carrying handles

cannot be locked or

unlocked

Hose reel does not

turn

Equipment cannot

be fi xed on the

equipment shelf

Pressure too high (e.g.

caused by ambient

temperature too high)

Coupling defective Coupling must be

Carrying handles are

still locked

Carrying handles or

frame defective

Carrying handles or

frame defective

Holding brake still

active

Hose reel defective Have it repaired by

Equipment shelf set

incorrectly

Equipment shelf

defective

Switch valve block to

circulation at static

pressure

replaced immediately

Unlock the carrying

handles and then pull

them out.

Replace the carrying

handles or the frame.

Replace the carrying

handles or the frame.

Release the holding

brake

authorised dealer or

directly by LUKAS

Reset the equipment

shelf to suit the

equipment.

Replace equipment

shelf.

38

Page 39

Fault Check Cause Solution

It is frequently not

possible to couple

hose assemblies

Hydraulic fl uid not

adapted to the

application situation

Hydraulic fl uid must be

replaced (see chapter

“Recommended

Hydraulic fl uids”)

Coupling defective Coupling must be

Leak from the

couplings

Fluid leak on the

hoses or the fi ttings

Damages on the

surface of the hoses

Contact an authorised LUKAS dealer or the LUKAS Customer Service Department directly

if the malfunctions cannot be rectifi ed.

The address for the LUKAS Customer Service department is:

LUKAS

A unit of the IDEX Corporation

Weinstrasse 39, D-91058 Erlangen, Germany

Tel.: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

Coupling defective Coupling must be

Leak, possible damage Replace hoses

Mechanical damage

or contact with

aggressive agents

replaced immediately

replaced immediately

Replace hoses

39

Page 40

13. T echnical data

Since all values are subject to tolerances, minor differences may occur between the data on

your equipment and the data in the following tables.

The values may also differ because of reading inaccuracies and/or tolerances in the

measuring equipment used.

NOTE:

The following tables contain only the most important Technical Data.

Additional data concerning your unit can be obtained from LUKAS on request.

40

Page 41

13.1 GC 650-2POWER

Device type GC 650-2POWER Units Remarks

Item number 70-10-10

Dimensions l x w x h 537 x 451 x 600 mm

21.1 x 17.8 x 23.6 in.

Operating

pressure

Delivery quantity High-

Change-over

pressure

Delivery quantity Low

Motor Power 4.2 kW Petrol, 4-stroke

Idle speed 3300 rpm

Volume of

hydraulic fl uid

Ambient

temperature

Weight 74 kg including hydraulic

Specifi cation of

hydraulic fl uid

Volume of petrol 3 l 4-stroke petrol

max. 53 MPa

7700 psi

2 x 0.9 l/min simultaneously

pressure

2 x 0.24 gpm

14 MPa from low to high

pressure

2000 psi

2 x 3.1 l/min simultaneously

pressure

2 x 0.82 gpm

max. 27.5 / 23 l Fill/useful volume,

horizontal

7.3 / 6.1 gal.

-20 … +55 °C

-4 … 131 °F

fl uid

163 lbs.

HM 10 ISO 6743-4

engine

0.8 gal.

1)

HD = High pressure 2) ND = Low pressure

41

3)

1MPa = 10 bar

Page 42

13.2 GC 650-4POWER

Device type GC 650-4POWER Units Remarks

Item number 70-10-20

Dimensions l x w x h 537 x 451 x 677 mm

21.1 x 17.8 x 26.7 in.

Operating

pressure

max. 53 MPa

7700 psi

Delivery quantity High-

4 x 0.7 l/min simultaneously

pressure

4 x 0.18 gpm

Change-over

pressure

14 MPa from low to high

pressure

2000 psi

Delivery quantity Low

4 x 2.6 l/min simultaneously

pressure

4 x 0.69 gpm

Motor Power 5.1 kW Petrol, 4-stroke

Idle speed 3600 rpm

Volume of

hydraulic fl uid

max. 45 / 40 l Fill/useful volume,

horizontal

11.9 / 10.6 gal.

Ambient

-20 … +55 °C

temperature

-4 … 131 °F

Weight 97 kg including hydraulic

fl uid

214 lbs.

Specifi cation of

HM 10 ISO 6743-4

hydraulic fl uid

Volume of petrol 3 l 4-stroke petrol

engine

0.8 gal.

1)

HD = High pressure 2) ND = Low pressure

42

3)

1MPa = 10 bar

Page 43

13.3 GC 650E-2POWER

Device type GC 650E-2POWER Units Remarks

Item number 70-10-15

Dimensions l x w x h 537 x 451 x 600 mm

21.1 x 17.8 x 23.6 in.

Operating pressure max. 53 MPa

7700 psi

Delivery quantity High-

pressure

Change-over

pressure

Delivery quantity Low

pressure

Motor Power 4.2 kW Petrol, 4-stroke

Idle speed 3300 rpm

Volume of hydraulic

max. 27.5 / 23 l Fill/useful

fl uid

Ambient

temperature

Weight 80 kg including

Specifi cation of

hydraulic fl uid

Volume of petrol 3 l 4-stroke petrol

2 x 0.9 l/min simultaneously

2 x 0.24 gpm

14 MPa from low to high

pressure

2000 psi

2 x 3.1 l/min simultaneously

2 x 0.82 gpm

volume,

horizontal

7.3 / 6.1 gal.

-20 … +55 °C

-4 … 131 °F

hydraulic fl uid

176 lbs.

HM 10 ISO 6743-4

engine

0.8 gal.

1)

HD = High pressure 2) ND = Low pressure

43

3)

1MPa = 10 bar

Page 44

13.4 GC 650E-4POWER

Device type GC 650-4POWER Units Remarks

Item number 70-10-25

Dimensions l x w x h 537 x 451 x 677 mm

21.1 x 17.8 x 26.7 in.

Operating pressure max. 53 MPa

7700 psi

Delivery quantity High-

pressure

Change-over

pressure

Delivery quantity Low

pressure

Motor Power 5.1 kW Petrol, 4-stroke

Idle speed 3600 rpm

Volume of hydraulic

max. 45 / 40 l Fill/useful

fl uid

Ambient

temperature

Weight 103 kg including

Specifi cation of

hydraulic fl uid

Volume of petrol 3 l 4-stroke petrol

4 x 0.7 l/min simultaneously

4 x 0.18 gpm

14 MPa from low to high

pressure

2000 psi

4 x 2.6 l/min simultaneously

4 x 0.69 gpm

volume,

horizontal

11.9 / 10.6 gal.

-20 … +55 °C

-4 … 131 °F

hydraulic fl uid

227 lbs.

HM 10 ISO 6743-4

engine

0.8 gal.

1)

HD = High pressure 2) ND = Low pressure

44

3)

1MPa = 10 bar

Page 45

13.5 PC 650-2POWER

Device type PC 650-2POWER Units Remarks

Item number 70-10-30

Dimensions l x w x h 537 x 451 x 577 mm

21.1 x 17.8 x 22.7 in.

Operating pressure max. 53 MPa

7700 psi

Delivery quantity High-

pressure

Change-over

pressure

Delivery quantity Low

pressure

Motor Power 2.2 (230/50) kW

Idle speed 2940 rpm

Volume of hydraulic

max. 27.5 / 23 l Fill/useful

fl uid

Ambient temperature -20 … +55 °C

Weight 76 kg including

Specifi cation of

hydraulic fl uid

2 x 0.7 l/min simultaneously

2 x 0.18 gpm

14 MPa from low to high

pressure

2000 psi

2 x 2.6 l/min simultaneously

2 x 0.69 gpm

single phase,

(VAC/

electric motor

Hz)

volume,

horizontal

7.3 / 6.1 gal.

-4 … 131 °F

hydraulic fl uid

168 lbs.

HM 10 ISO 6743-4

1)

HD = High pressure 2) ND = Low pressure

45

3)

1MPa = 10 bar

Page 46

13.6 PC 650-4POWER

Device type PC 650-4POWER Units Remarks

Item number 70-10-40

Dimensions l x w x h 537 x 451 x 672 mm

21.1 x 17.8 x 26.5 in.

Operating pressure max. 53 MPa

7700 psi

Delivery quantity High-

pressure

Change-over

pressure

Delivery quantity Low

pressure

Motor Power 3.5 (400/50) kW (VAC/

Idle speed 2980 rpm

Volume of hydraulic

max. 45 / 40 l Fill/useful

fl uid

Ambient

temperature

Weight 99 kg including

Specifi cation of

hydraulic fl uid

4 x 0.6 l/min simultaneously

4 x 0.16 gpm

14 MPa from low to

high pressure

2000 psi

4 x 2.2 l/min simultaneously

4 x 0.58 gpm

three-phase,

Hz)

electric motor

volume,

horizontal

11.9 / 10.6 gal.

-20 … +55 °C

-4 … 131 °F

hydraulic fl uid

218 lbs.

HM 10 ISO 6743-4

1)

HD = High pressure 2) ND = Low pressure

46

3)

1MPa = 10 bar

Page 47

13.7 Noise emissions of the power units

Device type Noise level L(WA)

Idle Full load

GC 650E-2POWER

GC 650-2POWER

GC 650E-4POWER

GC 650-4POWER

PC 650-2POWER 91 96

PC 650-4POWER 90 97

97 101

101 103

13.8 Sparking plug

Sparking plug type: BR6HS (NGK)

13.9 Sparking plug spanner

Sparking plug spanner with universal joint having a size

of 21 mm

13.10 Fuel

Lead-free petrol

Fuel:

ROZ 91 to ROZ 98

max. permitted bioethanol proportion: 10%

47

Page 48

13.11 Engine oil

13.12 Hydraulic fl uid recommendation

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil designation Viscosity rating Remarks

A -20 .... +55°C HM 10 VG 10

Oil temperature range Oil designation Viscosity rating Remarks

A

recommended range of viscosity: 10...200 mm²/s (10…200 cSt.)

Supplied with HM 10 DIN ISO 6743-4.

-4.0 .... +131°F HM 10 VG 10

ATTENTION!

Before you use hydraulic fl uids from a different manufacturer, you must contact

LUKAS or an authorised dealer.

13.13 Operating and storage temperature range

Operating temperature [°C] / [°F] -20 … +55 -4 … +131

Environmental

temperature (device in

operation)

Storage temperature

(device not in operation)

[°C] / [°F] -25 … +45 -13 … +113

[°C] / [°F] -30 … +60 -22 … +140

48

Page 49

14. EC Declarations of conformity

49

Page 50

15. Notes

50

Page 51

51

Page 52

WARNING / CAUTION / ATTENTION!

Before connecting the equipment, make sure that

all the components used are suitable for the

maximum operating pressure of the hydraulic

unit! In cases of doubt, you must consult LUKAS

directly before connecting the equipment!

Please dispose of all packaging materials and

removed items properly.

LUKAS

A unit of the IDEX Corporation

Weinstrasse 39, D-91058 Erlangen, Germany

Tel.: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

www.lukas.com

Hydraulik GmbH

Made in GERMANY

© Copyright 2014 LUKAS Hydraulik GmbHGC_PC_650_power_units_manual_145000085_en.indd

Subject to changes

Loading...

Loading...