Instruction manual for rescue equipment

Hydraulic power unit P 600 OE

(Translation of the original instruction manual

175825085 EN

Edition 11.2014

replaces 01.2014

2

Contents Page

1. Danger classes 4

2. Product safety 5

3. Proper use 8

4. Functional description 9

4.1 Description 9

4.2 Structure of P600OE 11

5. Connecting the hoses / devices 12

6. Set-up and start-up 14

6.1 Installation 14

6.2 Commissioning 14

7. Operation 17

7.1 Operating the P600OE 17

7.2 Safety instructions 18

8. Dismantling the equipment / deactivation following operation 19

9. Tests 20

9.1 General information 20

9.2 Testing the devices 20

10. Maintenance and repair 22

10.1 General information 22

10.2 Preventive maintenance 22

10.3 Changing the hydraulic fl uid 23

10.4 Checking the fi lters 25

10.5 Changing the signs 25

11. Troubleshooting 26

12. Technical data 32

12.1 P600OE 33

12.1 P600OE 34

12.2 Noise emissions (based on the EN ISO 3744 standard) 35

12.3 Hydraulic fl uid recommendation 35

12.4 Operating and storage temperature ranges 35

12.5 Oscillation / vibration 35

13. EC Declarations of conformity 36

14. Accessories 37

14.1 Batteries 37

14.2 Battery charger 37

14.3 Power supply 38

15. Instructions regarding disposal 39

16. Notes 40

3

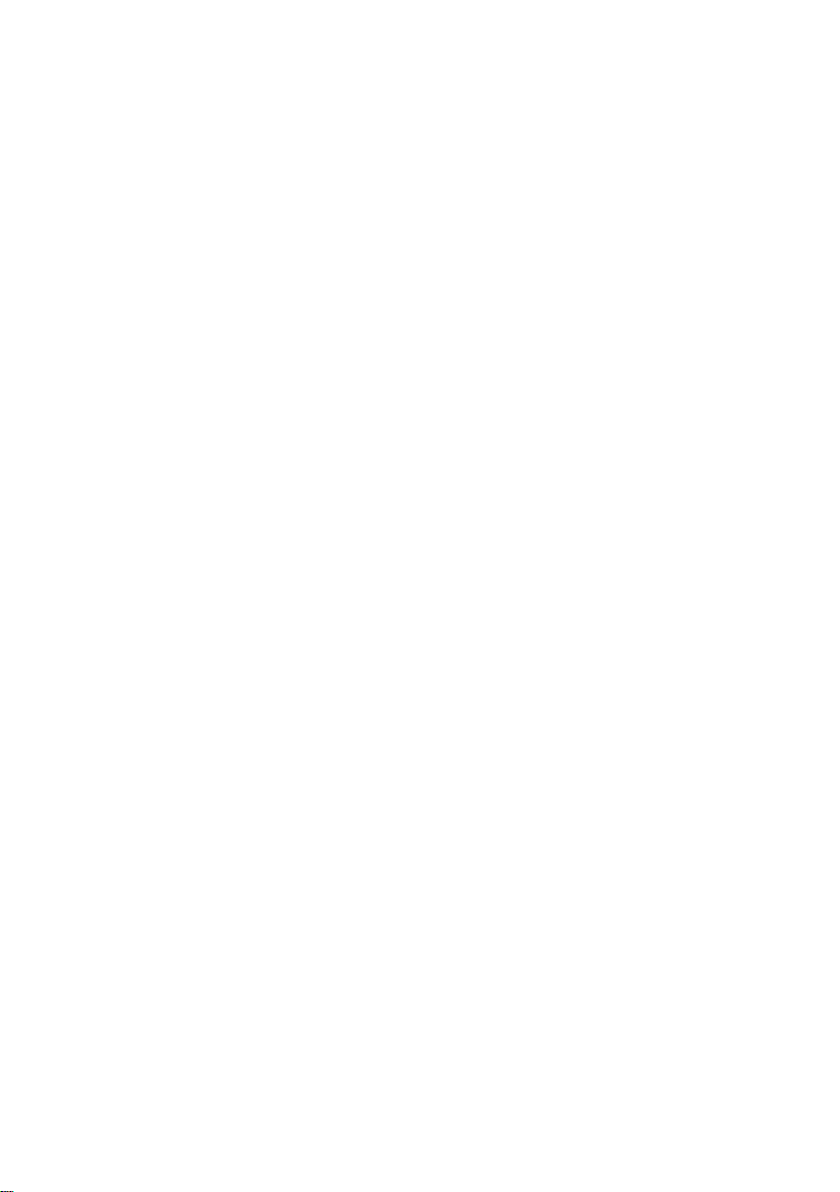

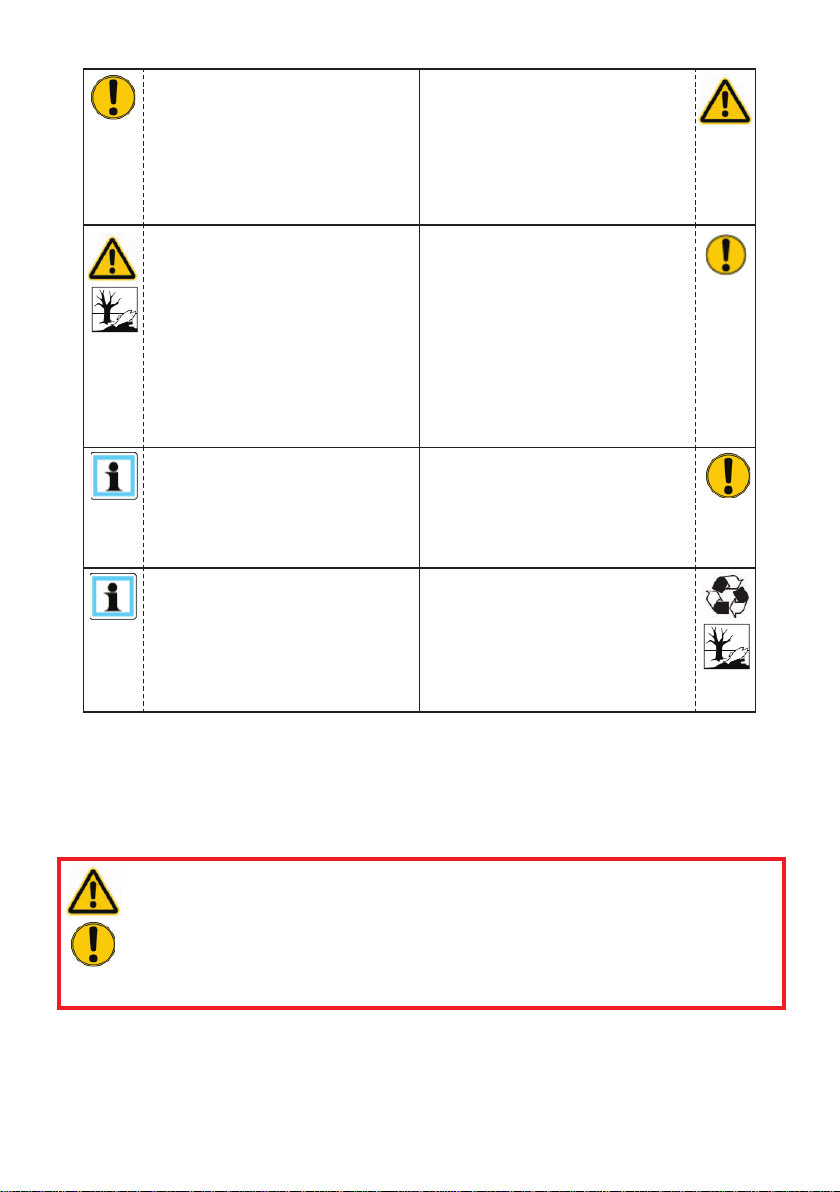

1. Danger classes

We distinguish between various categories of safety instructions. The table below provides

an overview of the symbols (pictograms) and signal words assigned to the specifi c danger

and also the possible consequences.

Pictogram

Damage /

injury to

Key word Defi nition Consequences

DANGER! Immediate danger

Death or severe

injury

WARNING!

Persons

CAUTION!

ATTENTION!

Property

- NOTE

Wear a helmet with a face guard

Wear protective gloves

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to property/

environment

Handling tips and

other important/

useful information

and advice

Potential death or

serious injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surroundings

No injury/damage

to persons/

environment/

device

Wear safety shoes

Proper recycling

Observe principles of environmental protection

Read and observe operating instructions

4

2. Product safety

LUKAS products are developed and manufactured to guarantee the best performance and

quality when used properly.

Operator safety is the most important aspect of the product design. Moreover, the operating

instructions are intended to aid the safe use of LUKAS products.

The generally applicable legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be complied with in addition to

the operating instructions.

The device may only be operated by persons with appropriate training in the safety aspects

of such equipment – otherwise, there is a danger of injury occurring.

We would like to point out to all users that they should read the operating instructions

carefully before using the equipment and fully comply with the instructions therein.

We further recommend having a qualifi ed trainer showing you how to use the product.

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

hydraulic equipment must also be observed!

Even if you have already received instruction, you should read the following safety instructions

again.

WARNING / CAUTION!

Ensure that the accessories used and the connected equipment are suitable

for the maximum operating pressure!

Make sure that no body parts

or clothing get between the

openly visible moving parts of

the device.

Wear protective clothing,

protective helm with visor,

safety shoes and protective

gloves.

Working under loads is

prohibited if they are raised

exclusively with hydraulic

devices. If this work is

unavoidable, suitable

mechanical supports are also

required.

The department responsible

must be informed immediately

of any apparent changes

(including the operating

behaviour). If necessary, the

equipment is to be deactivated

immediately and secured!

Inspect the device before and

after use for visible defects or

damage.

Inspect all cables, hoses

and screwed connections

for leaks and externally

visible damage! If necessary,

repair immediately! Squirting

hydraulic fl uid can result in

injuries and fi res.

5

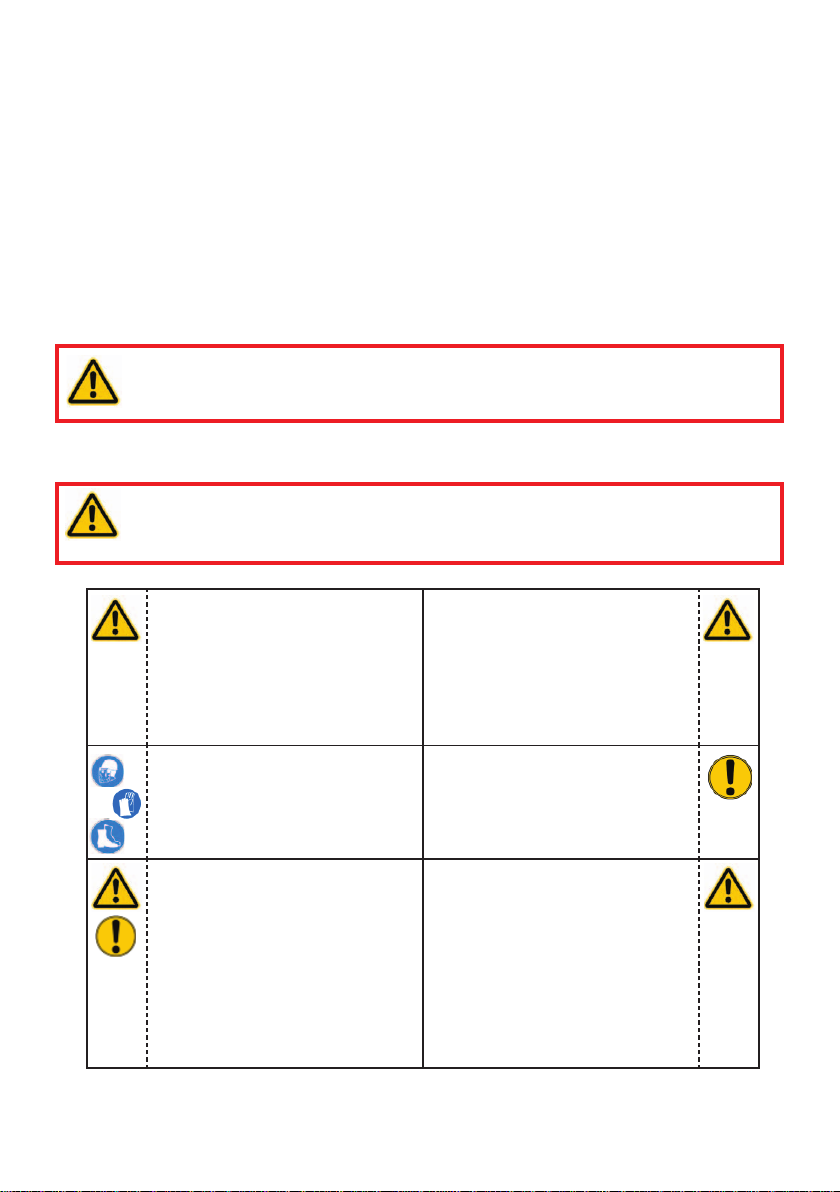

In the event of malfunctions,

shut down the device

immediately and make it safe.

Repair the fault immediately.

Observe all safety and danger

information on the device and

in the operating instructions.

Do not carry out any changes

(additions or conversions)

to the equipment without

obtaining the approval of

LUKAS beforehand.

All safety and danger

information on the device must

always be complete and in a

legible condition.

Make sure that all safety

covers are present on the

device and in proper working

condition.

Safety equipment must never

be disabled!

Make sure before switching

on/starting up the device and

during its operation, that this

will put no one in danger.

When working in the vicinity of

live components and cables,

appropriate measures must

be taken to avoid a transfer of

current or high-voltage arcing

to the device.

Any mode of operation which

compromises the safety and/

or stability of the device is

forbidden!

The maximum permissible

operating pressure must not

be changed.

Observe all intervals for

recurring tests and/or

inspections that are prescribed

or stated in the operating

instructions.

Use only original LUKAS

accessories and replacement

parts when carrying out

repairs.

When working with this

equipment or when

transporting it, ensure that you

do not get caught up in the

hose or cable loops and trip.

The build-up of static charge

and therefore possible

sparking must be avoided

when handling the device.

All damaged electrical

components e.g. scorched

cables, etc. are to be replaced

immediately!

6

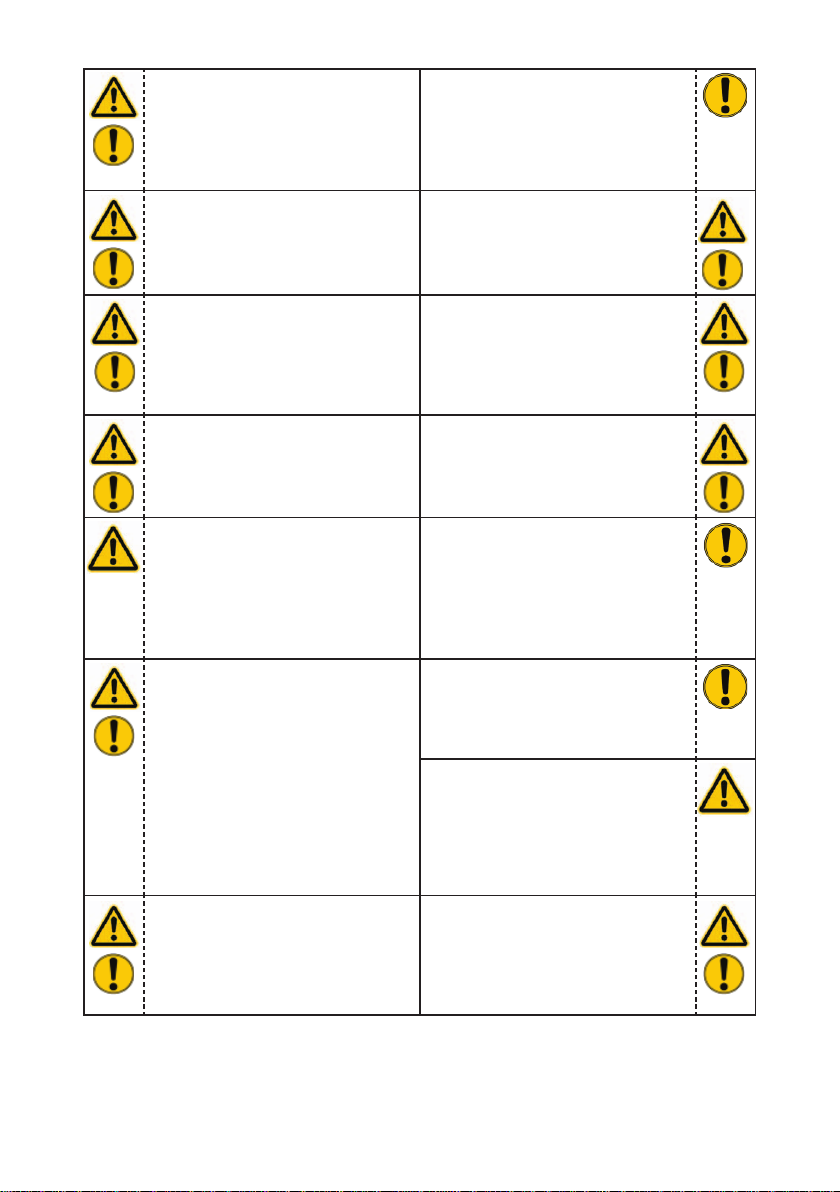

When setting up the units, it

must be ensured that they are

not impaired by the infl uences

of extreme temperatures.

The device is fi lled with

hydraulic fl uid. These hydraulic

fl uids can be harmful to your

health if swallowed or if their

vapours are inhaled. Direct

contact with the skin must be

avoided for the same reason.

Please also note that hydraulic

fl uids can also adversely affect

biological systems.

Ensure adequate lighting

when you are working.

Always keep these operating

instructions easily accessible

at the place of operation.

Damage to electrical

components may only be

repaired by a qualifi ed

electrician in compliance with

all applicable national and

international safety guidelines

and regulations.

When working with or storing

the device, ensure that the

function and the safety is not

adversely affected by external

extremes of temperature and

that the equipment is not

damaged. Please note that the

device can also heat up over a

long period of use.

Before transporting the device,

always check to see that the

accessories are positioned

securely to prevent the

possibility of an accident.

Make sure you properly

dispose of all removed parts,

leftover hydraulic fl uid, leftover

oil and packing materials.

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and are to

be implemented in addition to the operating instructions.

WARNING / CAUTION / ATTENTION!

If you still injure yourself on the hydraulic unit, clean the wound immediately and

consult a doctor to have it attended to!

If you get hydraulic fl uid in your eye, rinse it immediately several times with clear ,

clean water and consult a doctor!

Also, if you swallow hydraulic fl uid you should consult a doctor!

7

WARNING / CAUTION / ATTENTION!

The device is intended exclusively for the purpose stated in the operating instructions

(see chapter "Proper Use"). Any other use is not in accordance with its designated use.

The manufacturer/supplier cannot be held liable for any damage resulting from such use.

The risk of such misuse lies entirely with the user.

Proper use includes observance of the operating instructions and compliance with the

inspection and maintenance conditions.

Never work when you are overtired or intoxicated!

3. Proper use

The P600OE hydraulic unit is designed specially to supply hydraulic fl uid to a double-acting

LUKAS rescue unit.

The special feature of the P600OE is its compact lightweight construction. This means that

it is possible to work with hose-bound rescue equipment even in diffi cult to reach locations.

When working with this hydraulic unit, you must also observe all the regulations and directives

for safe and proper deployment of the connected rescue equipment.

The P600OE is NOT suitable for underwater deployment.

WARNING / CAUTION / ATTENTION!

The P600OE hydraulic unit is not explosion protected!

When using the equipment in explosion risk areas you must make sure that

operation of the unit does not trigger an explosion!

The responsibility for explosion prevention or for ruling out work with the P600OE

rests with the operator of the device or with the person responsible at the place

of use.

When working in areas at risk of explosion, all applicable legal,

national and international regulations, standards and safety rules

for preventing explosions must be observed without exception!

The equipment should not come into contact with acids or alkalis. If this is

unavoidable, clean the equipment immediately afterwards with a suitable

cleaning agent.

8

Y ou can order replacement parts and accessories for LUKAS equipment from your authorised

LUKAS dealer!

4. Functional description

4.1 Description

The P600OE is a compact lightweight electrically driven hydraulic pump. It is designed for

supplying hydraulic power to a double-acting LUKAS rescue unit.

Their use for supplying pressure / fl uid to rescue equipment of other manufacturers is possible,

yet requires the technical inspection and approval by LUKAS in each individual case.

CAUTION!

When selecting the units to connect to the unit, bear in mind that the maximum

possible useable volume of hydraulic fl uid is limited.

The max. required operating volume (hydraulic fl uid) of the connected unit must

not exceed the maximum possible useable volume of the hydraulic pump!

The volume of the tank on the P600OE is designed so that all LUKAS cutters, spreaders,

combi tools and the R410 and R412 rescue cylinders that are fi tted with Streamline can

be operated. The energy source for the P600OE can be either a mains power unit or an

accumulator battery. The mains power units and accumulator batteries that fi r into this

hydraulic unit can also be used for the LUKAS eDRAULIC units. When working with the

P600OE you can choose which energy source to use. Both the accumulator battery and the

mains power unit can be inserted in the opening provided in the body of the tool. Both will

lock in place automatically.

NOTE:

When connecting to the mains, if a very long connecting cable is used, the power

supply to the motor may be reduced as a result of the resistance in the cable.

This will reduce the power of the motor.

The hydraulic unit operates in two modes, the WORKING mode and the ECO mode.

It switches to mode required automatically.

In the WORKING mode, the P600OE provides the rescue unit with maximum volume

fl ow of the hydraulic fl uid at maximum pressure. In the ECO mode, we employ a special

speed drop facility. This mode facilitates a very long pump running time with the battery

charge. The speed drop facility reduces the volume fl ow of hydraulic fl uid to a minimum.

The P600OE automatically switches to the ECO mode after 2-3 seconds if the control valve

on the connected rescue unit is not being operated, in other words, when it is in neutral setting.

As soon as the control valve on the rescue unit is actuated, the pump switches automatically

to the WORKING mode. You now have the maximum power of the P600OE available.

The response time of the switchover from ECo to WORKING mode is less than 0.5 s and is

therefore hardly noticeable. The noise of the motor tells you which mode the hydraulic unit

is using.

At reduced temperatures (from approx. 5 °C) it switches to the ECO mode. The P600OE then

runs permanently in working mode. As soon as the oil has heated up, the normal function is

available again.

9

In addition, the P600OE is fi tted with LED lighting as standard in order to make working

under reduced visibility conditions easier.

The light-emitting diodes attached on the connection side light up the coupling area. The

main switch has also been provided with a light, so that you can see at a glance whether

the device is switched on.

The hydraulic tank is also lit. This allows you to see the fi ll level at any time if the lighting

conditions are poor.

The P600OE is fi tted with a single fl ow pump with two pressure stages, a low pressure stage

and a high pressure stage.

Low pressure stage (ND) = up to 14 MPa*

High pressure stage (HD) = up to 70 MPa*

The changeover from low pressure to high pressure is carried out automatically in the pump.

The maximum pressure is limited by a pressure limiting valve.

Connection with the rescue equipment is via extension hose pairs or a hose reel. They are

supplied in various lengths and kink-protection colours. The individual hoses in a pair of

hoses can be distinguished by their different colours.

(For specifi c details, please consult the LUKAS range of accessories or contact your

LUKAS dealer.

Lukas recommends that you do not use more than 10 m of total hose

length between the hydraulic pump and the rescue unit.

NOTE:

Always register your hydraulic unit on the LUKAS Hydraulik GmbH internet site.

Only then are you entitled to the extended guarantee.

Before you use couplings from a different company , you must contact LUKAS or

an authorised dealer.

You can order replacement parts and accessories for the P600OE from your authorised

LUKAS dealer!

*) 1 MPa = 10 bar)

10

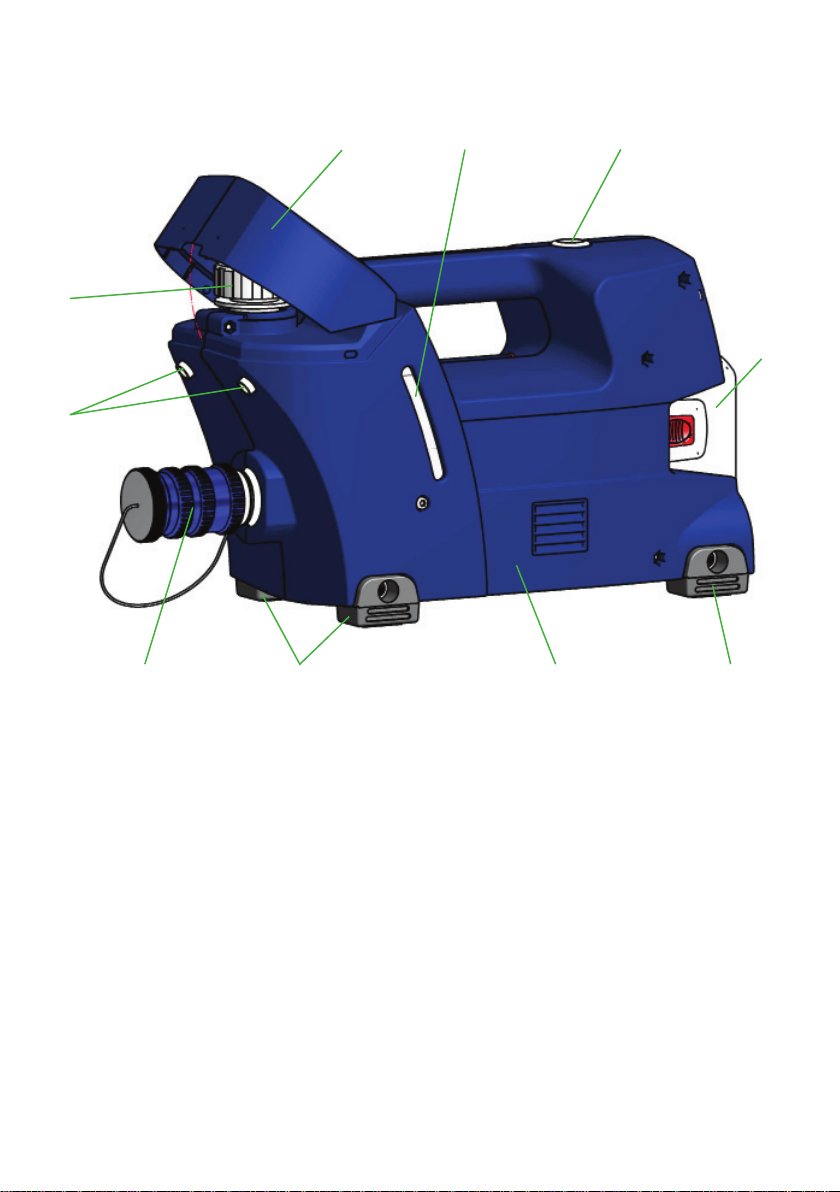

4.2 Structure of P600OE

2 9

3

6

4

881

5

7

1 Casing

2 Filler cover

3 Filler cap

4 Mono-coupling sleeve

with dust cap

5 ON / OFF switch

6 LED lighting

7 Battery or mains power

unit

8 Rubber buffer

9 Fill level display

(illuminated)

11

5. Connecting the hoses / devices

CAUTION!

When connecting the hose assemblies / units, always ensure that the connection

components are not soiled. If necessary, clean immediately!

WARNING / CAUTION / ATTENTION!

Before connecting equipment, make sure that all the components

used are suitable for the maximum operating pressure of the

hydraulic unit! In cases of doubt, you must consult LUKAS

directly before connecting the equipment!

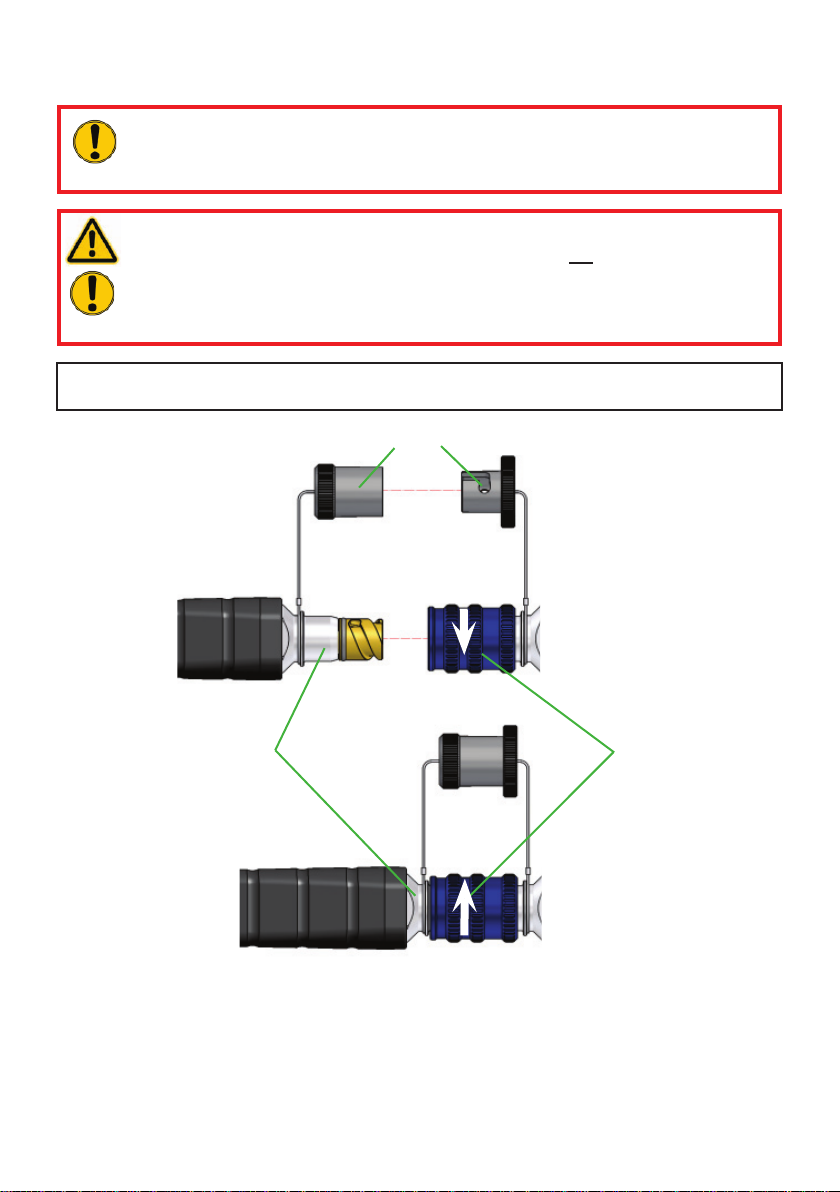

The hose lines / units are connected via quick-disconnect coupling halves (female and male)

to the hydraulic pump in such a way that they cannot be reversed.

Dust protection caps

0

Male coupling

1

0

Remove the dust caps before coupling together. Then push the male and female parts

together and turn the locking sleeve on the female coupling in the direction "1" until the

locking sleeve clicks in place. The connection has now been made and locked. Uncoupling

is accomplished by turning the locking sleeve in direction "0".

12

Female coupling

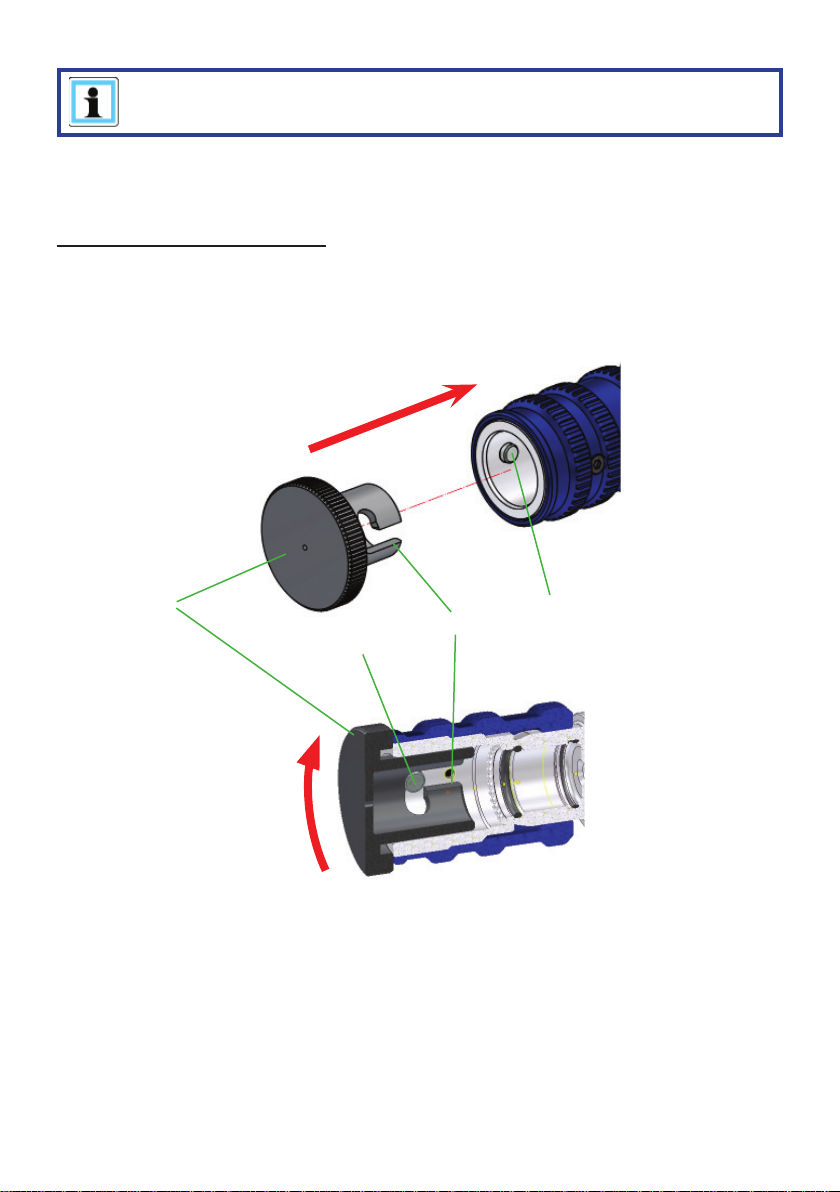

NOTE:

Couple together only when in ECO mode, or when the P600OE is switched off!

For dust protection, the supplied dust protection caps must be refi tted.

Fitting the dust protection caps:

The dust protection caps "A" have two external grooves "B". The dust protection caps must

be inserted in the female coupling in such a way that the grooves can be guided over the pins

"C". Screw in the dust protection caps to the limit stop to fi x in the female couplings.

A

B

C

13

C

6. Set-up and start-up

6.1 Installation

WARNING / CAUTION / ATTENTION!

The LUKAS Mini electric pump is not explosion protected!

When using the equipment in explosion risk areas you must make sure that

operation of the unit does not trigger an explosion!

The unit is to be set up in a suitable location (safe location / fl at surface / suffi cient distance

from vehicles, loads, sources of ignition, etc.).

LUKAS units work perfectly at an angle of up to 20°. However, in order to guarantee maximum

safety and fl uid withdrawal, they should be operated in as horizontal a position as possible.

The P600OE is designed in such a way that, when deactivated and with correctly fi tted fi ller

cap, no hydraulic fl uid can leak out, even if the pump were to tip over.

6.2 Commissioning

NOTE:

When delivered the hydraulic fl uid in the P600OE has a special High-Tech

running in additive mixed in. This can be seen with the different colour of the

hydraulic fl uid when the pump is delivered.

The additive optimises the running-in behaviour and the hydraulic function of the

pump. When topping up or fi lling with hydraulic fl uid, you should always observe

Item 12.3 in this manual.

Before starting up for the fi rst time, the battery (if fi tted) must be fully charged in an external

charger.

Commissioning procedure:

1. First check the condition of the pump.

- The casing should not be damaged.

- Hydraulic fl uid should not be coming out in an uncontrolled manner.

- The coupling should not be damaged

- The battery connection slot should not exhibit any function-inhibiting damage.

2. Then check the level of hydraulic fl uid in the in the pump.

The fl uid levels can be read off on the fi ll level indicator on the side of the unit. There are

3 marks on the fi ll level indicator. For precise reading off of the fl uid levels and for fi lling,

the hydraulic unit should be as level as possible.

14

Maximum fi ll level

Minimum fi ll level

The hydraulic fl uid level should never fall below this level,

even when the unit is running, since otherwise the pump will

be damaged!

3. If necessary, fi ll with hydraulic fl uid up to the maximum level.

Filling with hydraulic fl uid is carried out as possible:

a) Open the fi ller cover completely. Slight resistance must be overcome to open it.

This is designed to prevent inadvertent opening of the cover.

15

The fi ller cover can also be removed completely to make fi lling easier. To do this

open the fi ller cover by approx. 35° and pull the cover off towards the coupling.

Do not use force since this could damage the cover.

1. 2.

NOTE:

Do not fi ll up to the maximum mark because otherwise hydraulic fl uid

could come out of the fi ller cap when running.

b) Open the fi ller cap on the fl uid tank.

c) Fill with hydraulic fl uid up to the maximum mark.

You should use a funnel for fi lling to prevent spilling the hydraulic fl uid.

d) Close the tank again with the fi ller cap and remove any spilled hydraulic fl uid with

a suitable cloth.

e) Replace the fi ller cover (if removed) and close completely. It clicks into place when

closed.

16

4. Now insert the battery or the mains adapter into the unit (if not already fi tted). The mains

adapter must then be connected to the power supply.

5. The hydraulic unit must now be bled. This takes place fully automatically on the P600OE.

T o carry out bleeding you just have to switch the hydraulic pump on at the main switch and

let it run for two to three minutes without having a unit connected to it.

The fi ller cap is also fi tted with a vent which automatically bleeds the tank when the pump

is running.

6. After bleeding, check the level of fl uid in the tank again. Top up if necessary.

7. Finally, you can now connect the extension hoses or hose reels and/or connect the rescue

equipment directly.

7. Operation

7.1 Operating the P600OE

The P600OE has been designed to provide the user with the simplest method of operation.

For this reason, the pump only needs to be switched on and off and the rescue unit be connected to it. All the other functions are carried out fully automatically.

However, always connect the rescue unit before switching the hydraulic unit on. After switching on, the initiation sequence on the unit is run. This takes approx. 3 seconds. During this

period the LED in the main switch fl ashes and the motor runs for approx. 1.5 secs. in ECO

mode and approx. 1.5 secs. in working mode. As soon as the LED lights up permanently in

the main switch you can start working with the connected rescue equipment. If the connected

unit is not actuated, the unit switches back to the ECO mode after a few seconds.

CAUTION!

If a rescue unit is actuated during the initiation sequence, the pump could

inadvertently switch to the ECO mode during operation. T o restore full functionality

switch the pump off, switch it on again and allow the initiation sequence to run

as described above.

17

7.2 Safety instructions

World-wide, safety guidelines pertaining to the specifi c country must be observed and

complied with. In the Federal Republic of Germany, regular safety inspections according

to the legal accident insurance regulations (GUV - Gesetzliche Unfallversicherung) are

mandatory .

Wear the following when working with the unit:

- protective clothing,

- safety helmet with visor or protective goggles,

- protective gloves

- and, if necessary, ear protection

Always make sure that, before actuating the unit, no participating and/or non-participating

persons will be exposed to danger by the work with the unit or by working with the connected

rescue equipment!

WARNING / CAUTION!

When working, hydraulic fl uid can be emitted by damage to the unit or the hoses.

Since the units operate at a very high hydraulic pressure, hydraulic fl uid being

emitted can cause severe to the severest injury to persons. Those not involved

in the rescue operation should therefore keep at a distance appropriate to the

situation. Any trapped or enclosed persons must be protected.

In order to prevent such dangers, all measures must be taken to prevent damage

to the units and hoses!

18

8. Dismantling the equipment / deactivation

following operation

Procedure:

1. When the work is completed, the connected units must be returned to the starting

position.

This should mean that the hydraulic tank on the P600OE has the starting volume of

hydraulic fl uid.

2. Then switch off the device at the main switch.

3. Separate the connected unit from the hydraulic unit.

4. After each use, the pump must be cleaned externally and wiped down with a damp cloth.

CAUTION!

The electric contacts in the connection slot, on the battery and on the

mains power unit must not be cleaned with damp cloths! There are suitable

agents to provide corrosion protection for the electrical contacts.

5. Unplug the power supply (if used) by pulling the mains plug.

6. Fully press down the two unlocking buttons and carefully pull the battery or power

supply out of the device.

Do not use force!

Connection slot

NOTE:

You should not store the hydraulic unit for several weeks with the battery

in place.

Bear in mind that, if the unit is stored for an extended period, the hydraulic

fl uid in the tank will age and needs to be replaced at regular intervals .

Do not store the pump, the battery and the mains power unit in a damp or

dusty environment!

19

9. Tests

9.1 General points

The P600OE is subject to very high levels of mechanical loading as a result of the high

operating pressure. A visual inspection must therefore be carried out after every use and at

least one visual inspection must be carried out every six months. These inspections enable

the early detection of wear and tear, which means that punctual replacement of these

wearing parts prevents damage.

CAUTION!

Clean off any dirt before checking the device!

When cleaning the equipment, take care not to use any cleaning agent with a pH

value outside the range 5 - 8!

WARNING / CAUTION / ATTENTION!

In order to carry out maintenance and repair work, tools appropriate for the job

and personal protection equipment must be used.

The maintenance and repair staff must have adequate technical and specialised

knowledge. LUKAS offers appropriate training courses for this.

9.2 Testing the devices

An annual inspection of the tool is due once per year. This inspection must be performed by

a person with the necessary expertise. This means that the person must possess adequate

specialist knowledge and experience in the fi elds of electrical engineering and hydraulics, so

that they can objectively assess the condition of the tool.

At least every 3 years or when there might be doubts regarding the safety or reliability of

the unit, an additional function check is to be carried out (in this connection, comply with the

applicable national and international regulations with regard to the maintenance intervals of

rescue equipment). In the Federal Republic of Germany , regular safety inspections according

to the legal accident insurance regulations (GUV - Gesetzliche Unfallversicherung) are

mandatory .

We recommend carrying out a function check at the following intervals:

Operating time per day Functional check

up to 1 hour 1 x annually

up to 8 hours 1 x per quarter

up to 24 hours 1 x per month

In addition to these test intervals you need to carry out a function test if:

- the unit makes suspicious noises,

- there is a justifi ed suspicion of internal damage to the unit.

20

If the noises and suspicions referred to above arise several times in a month, or if maximum

pressure cannot be achieved during the function test, you need to contact LUKAS customer

service immediately. The contact details are given in the Chapter "Fault analysis".

Inspections to be carried out:

Visual inspection

• No visible damage to the housing,

• General tightness (leaks),

• ON/OFF switch in proper working order, undamaged

• Couplings must be easy to couple,

• Dust protection caps must be present

• Labels completely existent and legibly,

• Illumination of main switch, work area and tank illumination fully functional.

Battery and power supply

• Casing undamaged,

• Electrical contact surfaces clean and undamaged

• Cable undamaged

• Battery(-ies) fully charged (when used)

• Charging state display of lithium/ion battery(-ies) fully functional

Functional check

• no suspicious noises,

• tests at maximum load. When the maximum pressure is achieved, the pump switches

to the ECO mode after a short time. As soon as the pressure drops slightly, the pump

automatically switches back to the working mode.

(Recommendation: use the LUKAS test kit, including testing instructions, for the function test).

21

10. Maintenance and repair

10.1 General points

NOTE:

Always register your tool on the LUKAS Hydraulik GmbH internet site. Only then

are you entitled to the extended guarantee.

Because of the complex construction and the high hydraulic pressure, repair work must

only be carried out by the unit manufacturer or by personnel specially trained by the unit

manufacturer and by authorised LUKAS dealers.

For these reasons, only simple maintenance work is listed in this manual.

Components of the unit must only ever be replaced by genuine LUKAS spare parts.

The components that can be replaced are shown in the spare parts list. Also, any necessary

special tools, installation instructions, safety aspects, tests that always need to be observed

can be found in the spare parts list.

During assembly, make especially sure that all components are clean, since dirt can

damage the rescue tool!

WARNING / CAUTION / ATTENTION!

Protective clothes must be worn when repairs are being carried out, since the

devices may also be pressurised when not in operation.

10.2 Preventive maintenance

10.2.1 Care instructions

The unit should be cleaned externally with a damp cloth from time to time (not the electrical

contacts in the connection slot, on the battery and on the mains unit)

There are special agents for treating the electrical contacts, that are suitable for cleaning and

providing corrosion protection for the electrical contacts. Use must only use these agents on

the contacts.

(In case of doubt, contact your authorised LUKAS dealer or LUKAS directly!)

10.2.2 Functional and stress test

If there is any doubt regarding the safety or reliability of the equipment, a function and stress

test must also be performed.

LUKAS offers appropriate testing equipment for this.

22

10.3 Changing the hydraulic fl uid

After approx. 200 deployments, but after three years at the latest, replace the hydraulic fl uid.

The fl uid should be replaced when it is warmed up. When replacing the hydraulic fl uid, the

pump must be deactivated and the battery or the mains unit must be removed from the

connection slot.

The old hydraulic fl uid must be disposed of properly.

Procedure:

1. Open the fi ller cover. Removal of the fi ller cover will make the subsequent tasks easier.

1. 2.

2. Remove the fi ller cap on the fl uid tank.

23

3. Pour the hydraulic fl uid into a suitable collection vessel.

4. Place the P600OE on level, fl at ground and fi ll up to the maximum mark.

5. Then close the tank again with the fi ller cap and insert the battery into the connection

slot or connect the pump to the power supply.

6. Switch the pump on and let it run for approx. 2-3 minutes. This bleeds the pump.

7. Check the level in the tank again and top up if necessary.

8. Then fi t the fi ller cover back in place and close off the tank access on the unit.

24

10.4 Checking the fi lters

The air inlet fi lter should be checked at least once a year. The fi lter can be checked from the

outside if the mains unit (or battery) is removed (see illustrations below).

If the fi lter is severely contaminated, it will need to be replaced. At the same time, the fi lters

in the air exhaust must be replaced. To do this, the housing must be opened up by trained

personnel and the fi lter replaced (see also spare parts list).

Procedure:

1. Tilt the P600OE as shown in the illustrations.

2. Check the status of the fi lter.

10.5 Changing the labels

All damaged and/or illegible labels (safety instructions, type plate, etc.) must be renewed.

Procedure:

1. Remove damaged and/or illegible labels.

2. Clean surfaces with industrial alcohol.

3. Affi x new labels.

Take care to affi x the labels in the correct positions. If you are no longer sure about this, then

please contact your authorised LUKAS dealer or LUKAS itself.

25

11. Troubleshooting

Fault Check Cause Solution

The PO600OE

switches

inadvertently to the

Eco mode when

working with a

rescue unit

The initiation sequence

period of 3 seconds

is not allowed to be

carried out

Switch the pump off

and on again. Use the

rescue unit only after

the initiation sequence

has been fully carried

out. Flashing light

in the on/off switch

goes to permanent

light (see also

Paragraph 7.1)

Electric motor does

not start following

activation of the

main switch

Battery or mains

unit positioned

correctly in the

connection slot

and locked in

position

Check connection

of mains unit

Correct battery

fi tted?

Battery or mains unit

not inserted properly

Mains unit cable not

connected

Incorrect battery Use stipulated battery

Battery fl at Charge battery

Battery or mains unit

defective

Fault in power supply to

the mains unit

Remove the battery

or mains unit from the

pump and re-insert.

Connect mains unit

cable to the power

supply

Use a different battery

or mains unit.

Troubleshooting the

power supply

Use a different power

supply

P600OE defective Shut down immediately

and have repaired by

authorised service

facility, authorised

dealer or directly by

LUKAS

26

Fault Check Cause Solution

P600OE stops

during operation

Battery or mains

unit positioned

correctly in the

connection slot

and locked in

position

Battery or mains unit

not inserted properly

Remove the battery

or mains unit from the

pump and re-insert.

Electric motor not

providing full power

Check connection

of mains unit

Check battery

charge status

Mains unit temperature

too high as a result

of continuous use

and high ambient

temperature

Mains unit not correctly

connected

Cable losses in

extension cable or

cable drums too great

(electrical resistance)

Mains unit fault Use a battery or

Battery almost fl at Charge battery

Battery defective Replace battery

Fault in power supply to

the mains unit

Allow mains unit to cool

down (see operating

instructions of mains

unit)

Re-insert the mains unit

Use a different suitable

extension cable or cable

reel or connect directly

to power supply

different mains unit.

Troubleshooting the

power supply

Use a different power

supply

P600OE defective Shut down immediately

and have repaired by

authorised service

facility, authorised

dealer or directly by

LUKAS

27

Fault Check Cause Solution

Pump does not

switch to WORKING

mode after actuating

the connected

rescue unit

Initiation sequence

not allowed to run

completely

Control valve of

connected rescue unit

actuated too slowly or

too tentatively.

Switch unit off, then

switch it on again and

wait for initiation

Actuate the control

valve again.

Pump does not

switch back to ECO

mode

The motor / engine

is running, but the

connected rescue

equipment is not

moving / moving

very slowly upon

activation of the

valve.

Rescue unit not

connected correctly

(locking sleeve on

the coupling not fully

rotated to "1")

Too low ambient

temperature

Check hose Hose assembly not

connected properly or is

damaged

Connect a

different unit and

check whether

it works when

actuated

The previously

connected unit is

defective.

Mono-coupling (female)

defective

P600OE defective Shut down immediately

Turn the locking sleeve

on the coupling fully to

the end position "1".

No repair or fault

rectifi cation required

Check connection of

hose and reconnect if

necessary.

Rectifi cation see

operating instructions of

the connected unit

Replace mono-coupling

(female)

and have repaired by

authorised service

facility, authorised

dealer or directly by

LUKAS

28

Fault Check Cause Solution

The connected

rescue equipment

does not move on

activation of the

valve, or moves

only very slowly or

unevenly.

Connect a

different unit and

check whether

it works when

actuated

The previously

connected unit is

defective.

Air in the hydraulic

supply

Rectifi cation see

operating instructions of

the connected unit

Vent the hydraulic

system.

Leaks from pump

body itself

Connected rescue

device does not

reach its fi nal

position

Check hydraulic

fl uid volume in

hydraulic reservoir

Mono-coupling on

connection hose is

defective

Mono-coupling (female)

defective

P600OE defective Shut down immediately

P600OE defective Shut down immediately

Insuffi cient fl uid in the

hydraulic reservoir

Replace connection

hose

Replace mono-coupling

(female)

and have repaired by

authorised dealer, motor

/ engine manufacturer

or directly by LUKAS

and have repaired by

authorised service

facility, authorised

dealer or directly by

LUKAS

Top up hydraulic fl uid

to the maximum fi lling

level

Important! Before

topping up the rescue

equipment, return to

the base position!

Usable hydraulic fl uid

volume of the unit is

insuffi cient

29

Use a different rescue

device with a demand

quantity below the

maximum usable

quantity of the unit

Fault Check Cause Solution

Connected rescue

device does not

reach its specifi c

performance data

Maximum permitted

operating pressure of

the pump is not reached

Have repaired by

authorised service

facility, authorised

dealer or directly by

LUKAS

During function test:

A pressure gauge

installed between the

rescue equipment

and the hydraulic

power pack does

not indicate the

maximum operating

pressure of the

equipment.

Maximum pressure

not achieved

Check the details

of the rescue

device

Connected unit

defective

The operating pressure

of the connected

rescue device is locked

internally

Connected rescue

device is defective

Hydraulic unit defective Have repaired by

Mono-coupling on

connection hose is

defective

Hydraulic unit defective Have repaired by

Rectifi cation see

operating instructions of

the connected unit

No repair or fault

rectifi cation required

Rectifi cation see

operating instructions of

the connected unit

authorised service

facility, authorised

dealer or directly by

LUKAS

Replace connection

hose

authorised service

facility, authorised

dealer or directly by

LUKAS

30

Fault Check Cause Solution

Fluid coming out

from hydraulic fl uid

tank

Connected unit

not in base

position yet and

fl uid coming out of

fi ller cap?

Return of the hydraulic

fl uid from the rescue

device exceeds the

reservoir’s maximum

quantity when fi lled.

Reduce fl uid level in

the hydraulic tank to

"Minimum" mark, move

the unit to the base

position and then fi ll

back up with hydraulic

fl uid to the "Maximum"

level

Fluid leaks from a

different location?

Hydraulic fl uid milky

and cloudy

Hose lines cannot be

coupled

It is frequently not

possible to couple

hose assemblies

Leak in the couplings Is the coupling

damaged?

Leak from tank, lines or

seals

Water or condensation

water in the system

Coupling defective. Coupling must be

Coupling defective. Coupling must be

Coupling defective. Coupling must be

Replace defective

components or repair

by authorised dealer or

Lukas directly

Replace hydraulic fl uid

immediately

replaced immediately.

replaced immediately.

replaced immediately.

The useful operating

time between the

individual charging

cycles is less

than 15 minutes,

despite charging the

batteries according

to the instructions.

Battery defective Replace battery

31

If you cannot rectify the malfunctions, inform an authorised LUKAS dealer or the LUKAS

customer service department immediately!

The address of the LUKAS Customer Service Department is:

LUKAS

Weinstraße 39, Erlangen, 91058 Germany

Phone: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

12. Technical data

Since all values are subject to tolerances, minor differences may occur between the data on

your equipment and the data in the following tables.

The values may also differ because of reading inaccuracies and/or tolerances in the

measuring equipment used.

NOTE:

The following tables contain only the technical data necessary for operation and

storage.

Further information about your device is available directly from LUKAS.

32

12.1 P600OE

Type P 600 OE

Item number

Dimensions (excluding battery)

L x W x H

Motor power rating

Max. operating pressure

1)

(HD)

Volume fl ow

1)

(HD)

Max. operating pressure

2)

(ND)

Volume fl ow

2)

(ND)

Max. fi ll volume

Hydraulic fl uid

81-53-10

(175825000)

[mm] 460 x 182 x 257

[in.] 18.11 x 7.17 x 10.12

[kW] 1.0

[HP] 1.34

3)

[MPa]

70

[psi.] 10000

[l/min] 0.45

[gal.-US/min] 0.12

3)

[MPa]

14

[psi.] 2

[l/min] 2.4

[gal.-US/min] 0.64

[l] 1.5

[gal.-US] 0.40

Max. usable volume

Hydraulic fl uid

Weight (without battery with

hydraulic fl uid)

Weight (with battery and hydraulic fl uid)

Weight (with mains unit and

hydraulic fl uid)

Nominal electrical voltage

(with power supply)

Nominal electrical voltage

(with lithium/ion battery)

1)

HD = High-pressure

2)

ND = Low pressure

[l] 1.2

[gal.-US] 0.32

[kg] 8.3

[lbs.] 18.3

[kg] 9.2

[lbs.] 20.3

[kg] 10.0

[lbs.] 22.05

[V] 25

[V] 25.2

3)

1MPa = 10 bar

33

12.1 P600OE

Power consumption at full load [A] 40

Max. power consumption 230VAC

(with eDraulic Power Supply 230 VAC)

Starting current 230VAC (with eDraulic

Power Supply 230 VAC)

Max. power consumption 110VAC

(with eDraulic Power Supply 110 VAC)

Starting current 110VAC (with eDraulic

Power Supply 110 VAC)

[A] 7

[A] 16

[A] 10

[A] 22

Protection category IP54

Max. permissible hose length

[m] 10

[ft.] 32.81

1)

HD = High-pressure 2)ND = Low pressure

3)

1MPa = 10 bar

34

12.2 Noise emissions (based on the EN ISO 3744 standard)

Used power source Lithium-ion battery Power supply

Idling (measured at

a distance of 1 m)

Full load

(measured at a

distance of 1 m)

Idling (measured at

a distance of 4 m)

Full load

(measured at a

distance of 4 m)

[dB(A)] 54 54

[dB(A)] 71 71

[dB(A)] 53 53

[dB(A)] 67 67

12.3 Hydraulic fl uid recommendation

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil code Viscosity rating Remarks

A -20 .... +55°C HM 10 VG 10

Oil temperature range Oil code Viscosity rating Remarks

A

recommended viscosity range: 10...200 mm²/s (10…200 cSt.)

Supplied with HM 10 DIN ISO 6743-4.

-4.0 .... +131°F HM 10 VG 10

CAUTION!

Before you use hydraulic fl uids from a different manufacturer, you must contact

LUKAS or an authorised dealer.

12.4 Operating and storage temperature ranges

Operating temperature [°C] / [°F] -20 … +55 -4 … +131

Ambient temperature

(device in operation)

Storage temperature

(device not in operation)

[°C] /

[°F] -25 … +45 -13 … +113

[°C] /

[°F] -30 … +60 -22 … +140

12.5 Oscillation / vibration

The total oscillation value / vibration value to which the upper limbs are exposed, is below

2.5 m/s².

35

13. EC Declarations of conformity

36

14. Accessories

14.1 Batteries

Only LUKAS lithium-ion rechargeable batteries may be used to operate the P600OE.

These guarantee optimum performance and maximise the operating time of the units.

Charging

state

indicator

Query

button

NOTE:

Pay strict attention to the separate operating instructions for the battery.

14.2 Battery charger

Only the "eDRAULIC Power Pack Charger" may be used for the lithium/ion batteries.

NOTE:

Pay strict attention to the separate operating instructions for the battery charger.

37

14.3 Power supply

The P600OE has a unique power supply with integrated electronics, allowing the devices to

be operated for an almost unlimited time by connecting them to an external power source.

The power supply converts the voltage of the external power source in such a way that it may

be used instead of a battery.

Cable

Filter

Adapter

Cable

Mains plug

Structure:

There is an adapter on one side of the power supply which can be simply inserted into

the connection slot of the devices and locked. The other side has a mains plug. Both are

connected by a cable. The mains plug is a Schuko plug with Protection Classifi cation IP68.

The integrated fi lter is appropriate for the conversion of AC voltage to DC voltage.

NOTE:

Pay strict attention to the separate operating instructions for the power supply.

38

15. Instructions regarding disposal

Please properly dispose of all packing

materials and removed parts.

Electrical equipment, accessories and packaging should always be disposed of in an

environmentally compatible way.

Only for EU countries:

Do not dispose of electrical equipment with your household waste!

According to the European Directive 2002/96/EC governing electrical and electronic waste

and their application in national legislation, old electrical equipment must be separately

collected and recycled in an environmentally compatible manner.

Please also take into account the notes in the separate operating instructions for the batteries.

39

16. Notes

40

414243

LUKAS

A unit of the IDEX Corporation

Weinstraße 39, Erlangen, 91058 Germany

Phone: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

www.lukas.com

Hydraulik GmbH

Made in GERMANY

© CopyTRUE 2012 LUKAS Hydraulik GmbHP600OE_manual_175825085_en.indd

Loading...

Loading...