Cutter Series LSI

84150/1362-85 GB

Issue 12.2005

Replaces 6.2004

Operating Instructions

Recycling System

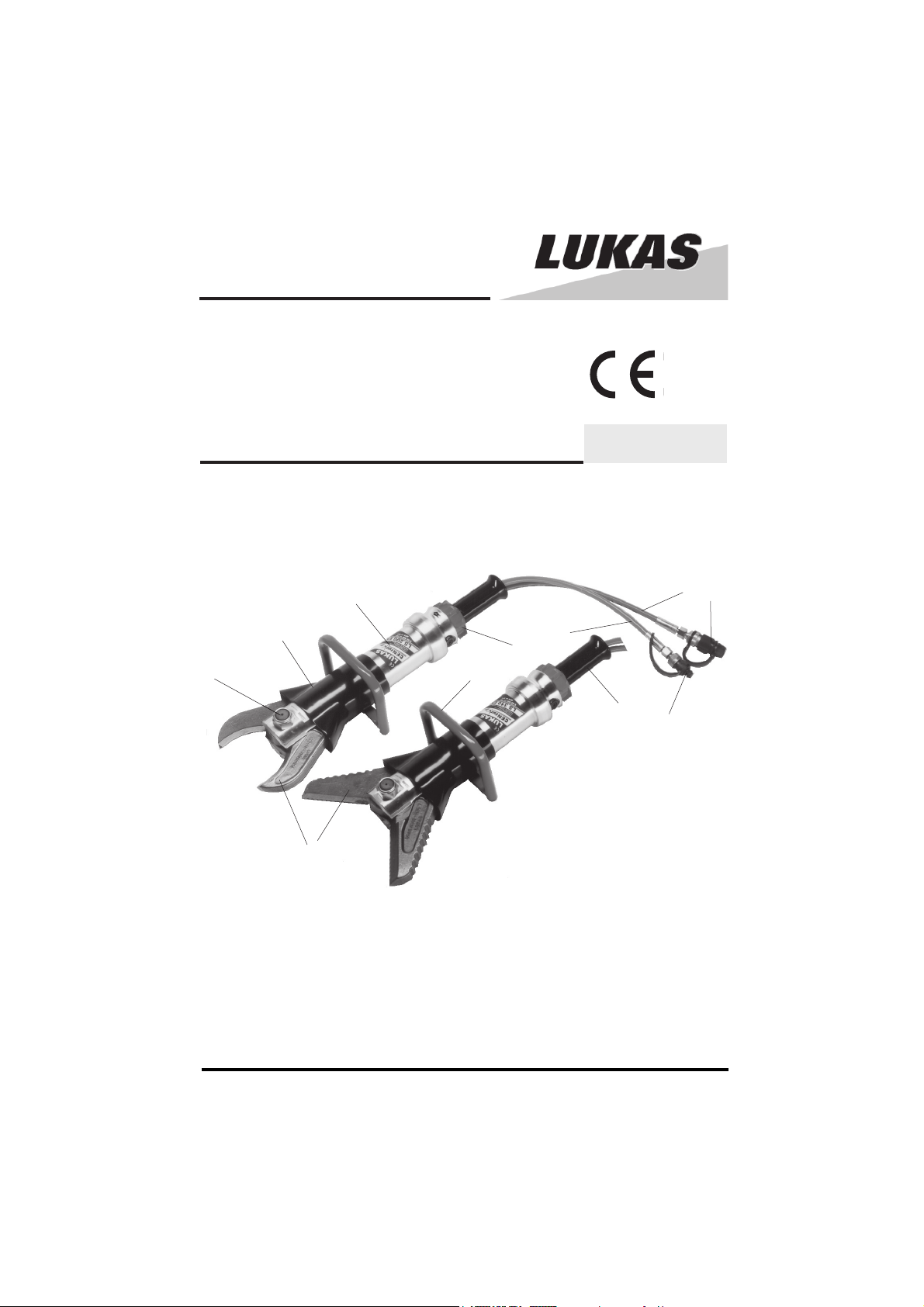

8 2

3

9

1

7

6

5

4

11

10

1 Control valve with star shape ring

2 Quick-connect socket StMu 61 - 0

3 Quick-connect plug StNi 61 - D

4 Cutter blades, resp. blade arm

5 Central bolt with selfl ocking nut

6 Protecting hose

7 Hydraulic cylinder

8 Hose, red: Pressure

9 Hose, blue: Return

10 Handle

11 Handle

2

Content page

1 Basic operation and designated use of the machine 3

2 Organizational measures 3

3 General safety instructions 4

4 Instructions for maintenance and service 5

5 Safety Instructions for Hydraulic Hoses 5

6 Intended use 8

7 Function and performance 8

8 Connection of the tool 9

9 Operation 10

10 Cutting 10

11 Dismantling of the device / Stop after operation 11

12 Maintenance 11

13 Repairs 12

14 Troubleshooting 16

15 Technical data 17

3

1 Basic operation and designated use of the machine

1.1 The machine has been built in accordance with state-of-the-art standards and

the recognized safety rules. Nevertheless, its use may constitute a risk to life and limb

of the user or of third parties, or cause damage to the machine and to other material

property.

1.2 The machine must only be used in technically perfect condition in accordance

with its designated use and the instructions set out in the operation manual, and only

by safety-conscious persons who are fully aware of the risks involved in operating the

machine. Any functional disorders, especially those affecting the safety of the machine/

plant, should therefore be rectifi ed immediately!

1.3 The machine is exclusively designed for the use described in the operating manual.

Using the machine for purposes other than those mentioned in the manual, such as

driving and controlling other pneumatic systems, is considered contrary to its designated

use. The manufacturer/supplier cannot be held liable for any damage resulting from

such use. The risk of such misuse lies entirely with the user.

Operating the machine within the limits of its designated use also involves observing

the instructions set out in the operating manual and complying with the inspection and

maintenance directives.

2 Organizational measures

2.1 The operating manual must always be at hand at the place of use of the

machine!

2.2 In addition to the operating instructions, observe and instruct the user in all other

generally applicable legal and other mandatory regulations relevant to accident prevention

and environmental protection.

This also applies for wearing protective clothing, helmet with visor or goggles and

protective gloves.

2.3 In order to avoid innjuries, the machine must only be operated by a specially

trained operator who has undergone a safety training.

2.4 Observe all safety instructions and warnings attached to the machine. Make sure

that safety instructions and warnings attached to the machine are always complete and

perfectly legible.

2.5 Never make any modifi cations, additions or conversions which might affect safety

without the supplier‘s approval. This also applies to the installation and adjustment of

safety devices and valves.

2.6 Spare parts must comply with the technical requirements specifi ed by the

manufacturer. Spare parts from original equipment manufacturers can be relied to do so.

It is only allowed to use original LUKAS spare parts of LUKAS system components.

2.7 Replace hydraulic hoses at the specifi ed or adequate intervals, even if no defects are

detected which might affect safety. This must be done after 10 years, at the latest!

2.8 Adhere to prescribed intervals or those specifi ed in the operating manual for routine

checks and inspections.

4

3 General safety instructions

3.1 In the event of malfunctions, stop the machine immediately and lock it. Have any

defects rectifi ed immediately.

3.2 Before starting up or setting the machine in motion and during operation of the

machine make sure that nobody is at risk.

3.3 It is strictly forbidden to get a part of the body between the blades of the device!

There is the danger of cutting!

3.4 Consider that no hair and protective clothing parts come into the proximity of the

mobile parts, it could be drawn in!

3.5 Grab the equipment only at the intended grasps, in order to avoid squeezings

3.6 Do not store the equipment in the proximity of heat sources! The equipment is

thermally well conductive and the consequence could be that the User can get light

burns!

3.7 Consider the maximally permissible pressure. This is noted directly on a label on

the equipment.

3.8 Before transporting the machine always check that the accessories have been

safely stowed away.

3.9 Make sure that there is enough lighting during work.

3.10 Avoid any operation that might be a risk to the user and/or the machine stability.

3.11 Check the machine at least after every operation for obvious damage and defects.

Report any changes (incl. changes in the machine’s working behaviour) to the competent

organization /person immediately. If necessary, stop the machine immediately and lock

it. All lines, hoses and screwed connections have to be checked for leaks and obvious

damage. Repair damage immediately. Splashed oil may cause injury and fi re.

3.12 All safety equipment has to be checked for completeness and fl awless condi-

tion:

- instruction markings and warning signs (safety instructions),

- check safety cover (e.g. motor-safety covers, heat protection etc.) if they are available and if they are in good condition.

3.13 Do not stress hoses mechanically (pulling, buckling etc.).

3.14 Touch the cut off parts only with protective gloves, because the cut edges are very

sharp.

3.15 The cutting tool may not be served in drunk, druggy or similar conditions. Otherwise

there is the danger that situations are misjudged.

3.16 Parts under mechanical stess may only be cutted, when you have secured them

5

4 Instructions for maintenance and service

4.1 For the execution of maintenance and service work, tools and workshop equip-

ment adapted to the task on hand are absolutely indispensable.

Work on the hydraulic system must be carried out only by personnel having special

knowledge and experience with hydraulic equipment.

4.2 Before putting into operation clean the machine, especially connections and threaded

unions, of any traces of oil, fuel or preservatives before carrying out maintenance/repair.

Never use aggressive detergents. Use lint-free cleaning rags and pay attention that the

components are meticulously clean during reassembling after repair.

4.3 During dismantling of machines it is necessary to collect the outrunning hydraulic

liquids completely, so that they cannot reach the ground. They have to be disposed

properly accord-ing to the instructions.

4.4 Always tighten any screwed and thread connections that have been loosened

during maintenance and repair. Observe the stipulated torques.

4.5 Work on the electrical system or equipment may only be carried out by a skilled

electrician himself or by specially instructed personnel under the control and supervision of such electri- cian and in accordance with the applicable electrical engineering

rules.

4.6 The electrical equipment of machines is to be inspected and checked at regular

intervals. Defects such as loose connections or scorched cables must be rectifi ed immediately.

4.7 Aggressive material (acid, lye, solvent, vapour) can damage the machine. It is

necessary to clean the whole machine if it must be exceptionally operated under such

conditions or gets into touch with these materials. Additionally, the machine must be

checked as described under 3.11.

5 Safety Instructions for Hydraulic Hoses

- By no means the hose must be exposed to brake fl uid as this fl uid will destroy

outer layer of hose

- do not expose the hose to any of the following aggressive fl uids:

• acid, lye or solvent

• alcohol and fuel

• battery and automatic transmission fl uid

• phosphate ester

A T T E N T I O N !

6

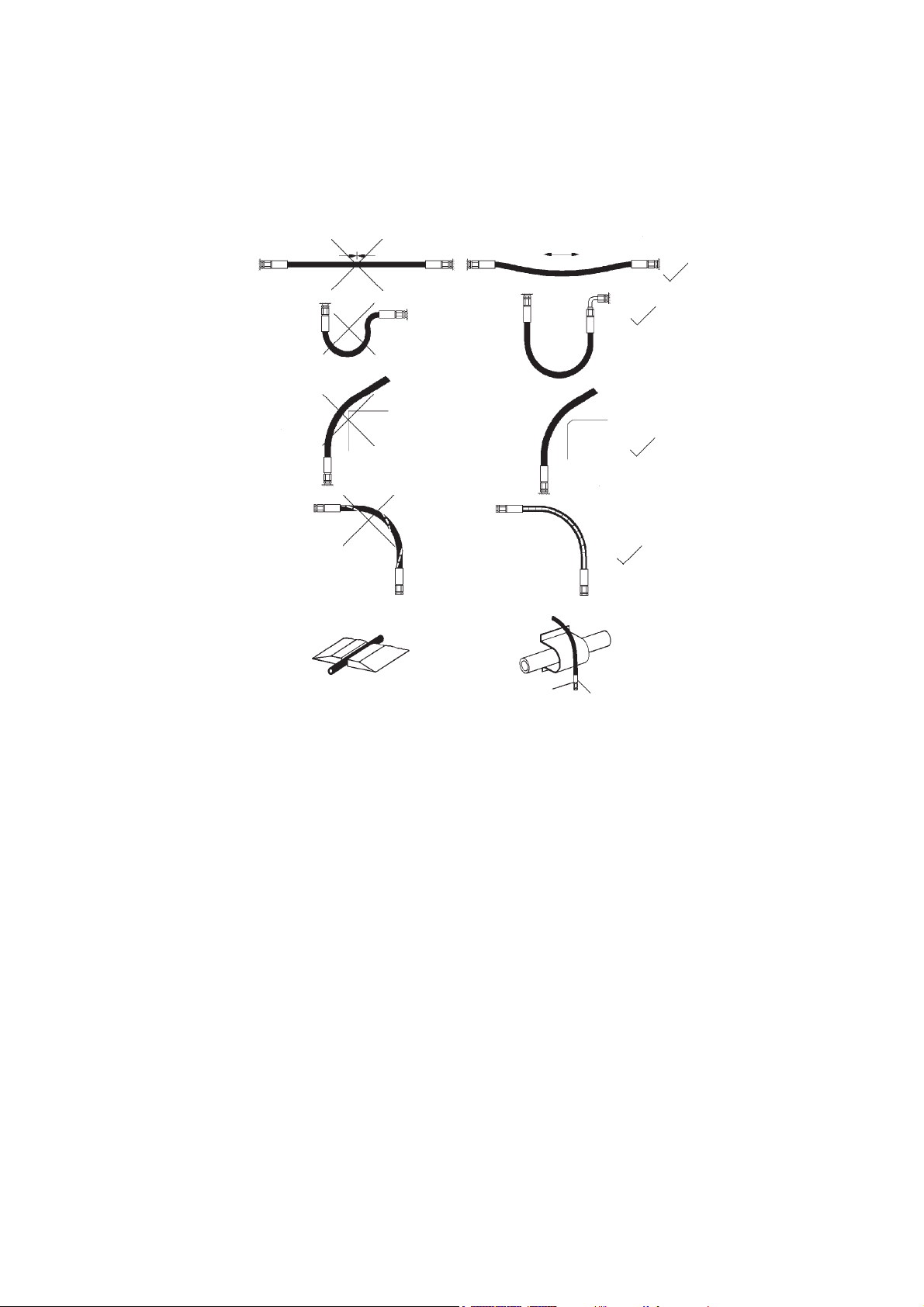

5.1 Handling of hoses

- never exceed the permissible working pressure as stated on hose and/or literature

- avoid any tension (see fi gure 1) and do not hang any load onto the hose

- never exceed the minimum bend radius as resulting kink will cause failure of hose

(see fi gure 2)

- do not allow hose to contact sharp edges or rough objects (see fi gure 3)

- avoid any twisting of hose (see fi gure 4)

- do not run over hose with any vehicle or equipment ! Hoses which are put on the

surface of sidewalk or street have to be suitably protected (see fi gure 5)

- do not allow hose to contact areas of high temperature such as muffl ers, exhaust

manifold, heaters or burners. Protect the hose as shown in fi gure 6 or install it in

suffi cient distance from the source of heat.

- never interline hose with that of a different manufacturer.

5.2 Protection of the working area in case of breakdown of hoses

Hoses have to be installed or protected in such a way that dangers are prevented, if

possible, in case of breakdown of the hoses.

Danger can be caused by:

- Uncontrolled hose movement after a hose rupture caused e.g. by external infl uence.

- Emerging of the pressure medium under pressure.

- Infl ammation of pressure medium near igniting sources.

7

5.2.1 Do not go near leaks!

- High pressure oil easily punctures skin causing

serious injury, gangrene or death!

- If injured, seek emergency medical help!

Immediate surgery is required to remove oil!

- Do not use fi nger or skin to check for leaks!

- Lower load or relieve hydraulic pressure before

loosening fi nttings!

5.3 Storage of hoses

- Hoses are subject to a natural aging even if they are stored correctly. Therefore,

their storage and service time is limited.

When storing the hoses please observe the following:

- Store them cool, dry and dustless (eventually wrapped with plastics sheeting);

prevent direct solar radiation and UV rays; shield heat sources which are near the

hoses.

- Do not use any ozone producing lamps (e.g. fl uorescent light sources, mercury vapor lamp) or electrical devices next to the hoses.

- Hoses have to be stored freely of tension and in a horizontal position. If they are

stored in rings the smallest bending radius determined by the manufacturer must

not fall below.

5.4 Marking of hoses

- The hose is marked with the manufacturer‘s name and quarter/year of production.

- The max. allowable pressure and month/year of production is indicated on the

hose end fi tting.

5.5 Inspection and replacement intervals of hoses

- After each operation the hoses have to be checked for external damages,

cracks, kinks and bubbles!

- The operator has to replace the hoses in appropriate period of times, even if there

are no visible security defects on the hoses.

- The hoses have to be replaced 10 years as from date of manufacture at the

latest (see marking on the hose)!

Hoses are subject to a natural aging even if they are stored correctly. Therefore,

their storage and service time is limited.

- Hoses have to be checked by a skilled person before the fi rst putting into

operation of the technical device and afterwards at least once a year for their

safe working condition.

A skilled person is somebody having suffi cient knowledge concerning hydraulic hoses

due to his special training and knowledge. He/she must be acquainted with the local

safety working conditions, accident prevention regulations, technical regulations and

approved standards (e.g. DIN-Standards), so that he/she is capable to estimate the

8

5.6 Examples for possible defects of hoses

- Damages of the surface and the interior (e.g. chafe marks, cuts or fi ssures).

- Embrittlement of the surface (fi ssuration of the hose material).

- Deformations, which are not in accordance with the natural shape of the hoses, in

pressureless condition or under pressure or in case of bendings, e.g. separation

of material layers, blister formation, squeezing or break spots.

- Leakage points.

- Instructions for installation were not observed.

- Emerging of the hose from the end fi ttings.

- Damages or deformations of the end fi ttings which deteriorate the function and

stability of the end fi ttings or the connection between hose and end fi tting.

- Corrosion of the end fi ttings or the metal inlets, which deteriorates the function and

stability.

- Storage and operation periods were exceeded.

6 Intended use

LUKAS LSI cutters are specially designed for cutting steel, suffi ciently hard ferrous

metals, sheet steel and cables. Depending on the material to be cut, cutter blades in

different shapes are available.

7 Function and performance

7.1 Description

The devices are designed in such a way that a hydraulically actuated piston via mechanical joints symmetrically closes two identical blade arms positioned opposite each

other to cut the object in question. The blade geometry is adapted to the application so

as to avoid as for as possible a sliding of the material to be cut.

7.2 Connection diagram

For your better understanding the hydraulic diagram

is showing in simplifi ed manner the tool‘s hydraulic

cylinder (A) with control valve (B).

7.3 Control of movements in operation

The arm movement is controlled by the fi rmly mounted star grip control valve (see

cover page item 1).

7.4 Hydraulic oil supply

Only LUKAS motor/engine pump or hand pump is used for operating the devices.

If the power pack comes from a manufacturer other than LUKAS, it must be ensured that

it fulfi ls the LUKAS specifi cations, as otherwise dangers may occur for which LUKAS

cannot be held liable. Especially it has to be made sure that the permissible working

pressure of 50 MPa (500 bar) is not exceeded without consultation with LUKAS.

7.5 Hoses

The connection between motor pump and cutter unit is normally effected with LUKAS

hoses. If pipes are to be used, please contact LUKAS.

9

8 Connection of the tool

8.1 Hydraulic

Two short hoses are fi tted to the tool; they are connected with the motor pump via a

hose pair (5 m / 10 m / 20 m, as is necessary). All hoses are colour marked and have

quick-connect couplings so that they can be connected without the risk of mix-up:

HP = High pressure ——> red R = refl ux ——> blue.

8.2 Connection of the plug-in coupling counterparts for HP and R

hoses

The device is connected to the hydraulic pump with the plug-in coupling counterparts

(plug and socket), there being no risk of mix-up.

Before coupling, remove the dust protection covers and unlock the connect socket with

adjusting ring by turning it. Withdraw the sleeve and connect plug and socket while

holding the sleeve in this position. Release the sleeve and set the showglass to „red“

with the adjusting ring. Now the parts are connected and locked. Decoupling is done

in the reverse order.

Note regarding the modifi ed release mechanism as of June 2003

When connecting the hoses, be aware of the following basic functions of the quick

couplers:

Set the sleeve to position X and pull it back • separate plug and socket • for connection

of a tool,

reverse this prodecure.

Connection of the hoses is possible only, when they are depressurized.

In order to prevent contamination of the tool lines protect the couplings with delivered

X

10

Attention!

Quick couplers partly have special functions. Therefore it is not allowed screwing

them off from the hoses or to exchange them.

9 Operation

9.1 Preparatory measures

9.1.1 Initial start-up

Check the machine before initial start-up for obvious damage and defects. All lines, hoses

and screwed connections have to be checked for leaks and obvious damage.

Before initial start-up and after repairs, the device must be vented:

- Connect the device to the hydraulic pump (see item 8).

- Fully open and close the device at least twice without load (see item 9.2).

9.1.2 Inspection of operating state of the pump power pack

——> See separate Operating Instructions of the power pack (or manual pump) in

question.

Note:

Before working on the motor pump or for coupling/decoupling the hoses, make sure that

the motor pump is switched off (electric connection) or disconnected from the mains

and that the lines are unpressurized.

9.2 Operating of the star grip 1

Opening of the blades:

Rotate star shape ring 1 to the right hand side and hold it in this position.

Closing of the blades:

Rotate star shape ring 1 to the left hand side and hold it in this position.

Load sustain function:

If released, the star shape ring 1 returns automatically to center position, maintaining

fully the load sustain function.

10 Cutting

10.1 Safety advise

In each country, the country-specifi c safety regulations must be regarded.

When working in an environment which involves a risk of explosions, do not use motor/

engine powered pumps. Instead, use hand pumps.

When operating cutter devices, wear

- protective clothing

- helmet with visor or goggles

- protective gloves.

Before any operation of the cutter unit make sure that the movement of the blades does

not constitue a risk to persons or that the blades or cut-off parts jerking away cannot

damage property.

Do not get your hands in between the blade arms.

Do not cut

- live wires,

- pressurized gas or fl uid lines,

- prestressed and hardened parts (such as springs, spring steels, steering columns,

11

10.2 Principles on cutting

The blades must be applied at a right

angle to the object to be cut. To enhance

cutting performance, cut as close as

possible to the blade fulcrum. On cutting,

the gap between the blade tips must not

be larger than 3 mm (Risk of blade fracture!).

10.2.1 Attention!

With cutters having curved blades the blade tips must by no means be loaded with full

cutting capacity. Cutting of profi les of up to 2 mm thickness is permissible.

11 Dismantling of the device / Stop after operation

11.1 Cutter unit

After operation, close the blades to a distance of a few mm. This relaxes the unit

hydraulically and mechanically.

11.2 Hydraulic power pack

Stop the hydraulic power pack after operation.

This is mandatory before taking one of the following steps:

11.3 Hoses

Uncouple the red hose fi rst and the blue hose second as described under 8.2. Put dust

caps over the couplings.

12 Maintenance

After each operation inspect the components for perfect function (when the device is

dirty, clean it before inspection):

Visual inspection

Cutter blades

• Cutting edges free from spalling and deformation.

• Distance of blades in transverse direction < 1mm.

• Cutting surfaces slide past each other without contact.

• Blades free from cracks.

• Corrugation of the tips clean and edged without fi ssures.

Cutter unit

• No leakages.

• Easy operation of the star grip.

• Handle existing and fast.

• Check of central bolt tightening torque (see also drawing to Section 13.3.1)

MA = Torque (see item 15.2).

Hoses

• Check according safety instructions for hoses (see item 5).

• Check for oil leakage.

Function testing

• Perfect opening and closing with the star grip valve.

12

13 Repairs

13.1 General

Servicing must be carried out only by the device manufacturer or by personnel trained

by the manufacturer or the authorised LUKAS dealers.

For replacement on all components, use only genuine LUKAS spare parts as specifi ed

in the spare parts list, as here possibly required special tools, mounting information,

safety aspects, testing must absolutely be taken into account. See section 4.

Protection of the device against hydraulic overload

Through uncorrect hose connection or temperature increase pressure can be built up

in the cylinder unintentionally. Therefore, the return hose (0,5 m / blue) of the tool is

equipped with a safety coupling (quick connect plug, colour yellow). Overpressure (approx. 1.5 MPa) is released through this plug: oil comes out. This oil is not a malfunction

of the plug!

Should the tool have been equipped with couplers of different brand which do not have this safety

function, overpressure would be released through another safety valve (adjusted to approx.

30 MPa) included with the control valve block. In this case oil spill would be observed

in the star grip area.

As soon as suffi cient pressure is released the valve becomes tight again. Should further

constant leakage ocur, please have the tool inspected by LUKAS personnel.

13.2 Preventive maintenance

13.2.1 Routine inspections

Regularly check the central bolt tightening torque. MA = Torque (see item 15.2).

Damaged blades can be repaired by regrinding of the cutting edge up to a total of 0.5

mm. Special care must be taken to have the inner cutting faces run parallel.

Attention !

When you are working with the cutter blades pointing upwards, it must be made sure

that no larger objects are falling into the rubber protection boot. Such objects might get

jammed into the lever system which can cause serious damage to the tool.

After each application in upright position the cutter head must be inspected on eventual

pollution, and it must be cleaned if necessary

picture 1

Remove handle and pull the protection boot back.

13

picture 2

Clean the mechanical parts (see picture 2) with compressed air from dirt and metal

chips.

If the upper sealing lips of the protection boot are damaged too seriously, the boot must

be changed against a new one.

13.2.2 General inspections

The mechanical transmission elements of the cutter unit are subjected to very high

mechanical stressing and must, therefore, be inspected at certain intervals. This helps

to detect wear early so that fractures of these wearing parts can be prevented by

replacing them in time.

Parts in perfect condition can be fi tted again after careful application of LUKAS special

grease for cutter units.

Parts with insignifi cant wear (fretting marks) can be repaired by polishing and fi tted

again after greasing.

More pronounced wear marks require replacement of the damaged parts (by pairs).

At these intervals, crack testing of the cutter blades is equally mandatory. For this

purpose, a special crack test kit is available.

To protect the device against external corrosion clean its surface from time to time and

slightly grease it with oil.

13.2.3 Function and load test

If there is any doubt as to the safety and reliability of the equpiment, carry out an

additional function and load test. For this purpose, LUKAS offers a test kit as appropriate

equipment.

13.2.4 Change of hydraulic oil

- After 200 uses, latest after 2 years, the hydraulic oil has to be changed.

- In any case if the oil of the pump (motor / hand pump) which belongs to the unit

is changed. By changing the used oil, it should be avoided that the new oil is pol-

14

Procedure:

The cutter tool is in closed (retracted) position • Change of oil has to be effected at the

pump.

Screw off the return hose at the pump:

- in case of hose connection: screw off the connecting piece of the blue return

hose.

- in case of quick connect couplings: screw off totally the coupling nut of the

quick connect coupling of the blue return hose.

Extend pump with tool slowly • Collect the used oil at the piston rod side in a separate

tank and dispose of the used oil (as the used oil of the pump) • Do not operate the

pump any longer.

Connect the return hose again to the pump:

- Tighten the coupling nut of the quick connect coupling according to 13.3.6,

- Screw the hose nipple into the valve bloc with MA = 45 Nm,

- Ventilate the tool according to 9.1.1.

13.3 Repairs

13.3.1 Cutter blades and levers

Cutter blades and levers have to be replaced in the case of visual heavy damge and cracks

or when the blades are becoming too weak due to frequent regrinding. (13.2.1).

- Unscrew the nut of the central bolt (size open-jawed

spanner see 15.2) and drive out the central bolt.

- Remove the retaining rings with a pair of Seeger ring

pliers.

- Replace the blade arms after thorough cleaning and

greasing of the sliding surfaces.

- Tighten the nut of the central bolt with the tightening

torque specifi ed in 15.2.

- Note:

The bolts are accessible with the blade arms closed.

Attention: prior to mounting all sliding surfaces have to be carefully cleaned and greased

with LUKAS special grease.

Remark: Faulty parts such as blades, bolts or sliding disks have to be changed pairwise.

The levers have to be replaced if e.g. during change of blades damages appear such

as wear on the surface, cracks or deformation of the bores. Lever exchange should be

made by a authorized LUKAS dealer or the LUKAS service department.

13.3.2 Oil spill out of the control valve handle (see cover page item 10)

Pressure or return hose are not tightened properly.

Procedure:

Loosen the 2 allen screws (SW5) inside the handle sleeve and remove them together

with the short plastic isolation sleeves. Pull handle sleeve backwards until the hose

connection points become visible and retighten the retaining nut. Change hose connection sealing rings if necessary. Place handle sleeve again and tighten it with the 2

allen screws. Make sure that the plastic isolation sleeves are placed properly on the

allen screws before mounting.

13.3.3 Change of protection boot

The rubber protection boot shall protect the operator against injuries caused by the

15

Procedure:

Remove the carrying handle (held by 2 screws) • Dismount cutter blades / blade arms

(see 13.3.1) • pull the faulty boot from the cylinder body and place the new one properly,

i.e. that the carrying handle fi xing screws go easily through the corresponding holes in

the boot. Mount and tighten carrying handle.

13.3.4 Carrying handle (see cover page item 11)

Damaged carrying handles have to be replaced immediately.

Procedure:

Remove the handle (held by 2 screws) and change it against a new one • Change

screws and disks if necessary.

13.3.5 Labels

All damaged or illegible indentifi cation stickers (Safety instructions, type label a.s.o)

have to be replaced.

Procedure:

Remove damaged stickers and clean surface with acetone • Put on new stickers.

13.3.6 Quick couplers

Quick couplers on the hoses have to be replaced when

- external damage can be observed • the locking sleeve doesn´work any more • oil

spill occurs even when the coupling is properly connected.

Remark: Faulty couplers have to be changed completely against genuine LUKAS

spares, i.e. it is not permissible to make any repair work.

The retaining nut on the hoses has to be tightened with a torque of MA = 45 Nm.

14 Troubleshooting

If the defects cannot be repaired, please contact an authorised LUKAS dealer or the

LUKAS service department under following address:

LUKAS Hydraulik GmbH,

Weinstraße 39, D-91058 Erlangen, PO Box 2560, D-91013 Erlangen,

Service phone 09131/698 348,

FAX 09131/698 353.

16

Trouble Check Cause Remedy

Hoses cannot be Pressurized Relieve pump

coupled pressure

On actuating blades Hoses correctly Air in the hydraulic Thoroughly vent

move slowly or by connected power system pump unit: see 9.1.1

jerks pack operating

No pressure build-up Not enough oil in hand Refi ll oil and vent

or motor pump. system (see opera

ting instruction

9.1.1)

Star grip doesn‘t return Return spring is Ask authorized

to middle position damaged or return dealer or LUKAS

when released mechanism is dirty themselves for

repair

Oil leakage out of Untightness, eventually Replace hoses

hoses or hose fi ttings damages

Surface of hydraulic Contact with Change hoses

hoses is dissolved agressive fl uids

Blades spread up at Torque of the center For retightening,

tips to a gap of more bolt nut is unsuffi sient see 13.2.1

than 3 mm even if not

fully loaded

Leakages on the Seal defective piston Replacement of

piston rod rod seals by authorized

dealer or LUKAS

themselves

17

15 Technical data

* 1MPa = 10 bar

**

Necessary oil quantity in the hydraulic power pack for operating the tool

(Difference in quantity piston / rode side)

15.1 Cutting performance / cutting forces

Type LSI 240 LKS 10

Dimensions lxwxh

without conection hoses 750x190x163 405x112x195

(mm)

Opening at tips (mm) 285 48

Weight incl. oil fi lling (kg) 15.2 5.3

Operating pressure (MPa) * max. 50 max. 63

Useable oil quantity (l) ** 0.20 0.03

Type LSI 200 LSI 220 LSI 230 LSI 235

Dimensions lxwxh

without conection hoses 670x190x163 725x190x163 737x190x163 760x190x163

(mm)

Opening at tips (mm) 125 150 225 265

Weight incl. oil fi lling (kg) 13 14.2 15 13.8

Operating pressure (MPa) * max. 50

Useable oil quantity (l) ** 0.20

Max. Dimensions of Material

LSI 200 LSI 200 LSI 220 LSI 220

Type of Form Strength max. cutting Continous max. cutting Continous

material of Rm performance cutting performance cutting

material performance performance

N/mm2 mm mm mm mm

750 dia. 23 dia. 18 dia. 23 dia. 18

500 dia. 25 dia. 20 dia. 25 dia. 20

500 40 x 4 30 x 4 40 x 4 30 x 4

Steel 500 dia. 65 x 3 dia. 60 x 3 dia. 72 x 3 dia. 50 x 3

500 50 x 50 x 5 50 x 50 x 4 50 x 50 x 5 50 x 50 x 4

500 60 x 8 60 x 6 80 x 8 80 x 6

500 60 x 30 x 6 40 x 40 x 4 60 x 30 x 6 40 x 40 x 4

Alu 400 dia. 28 dia. 24 dia. 28 dia. 24

Copper 200 dia. 35 dia. 28 dia. 35 dia. 28

18

Max. Dimensions of Material

LSI 230 LSI 230 LSI 235 LSI 235

Type of Form Strength max. cutting Continous max. cutting Continous

material of Rm performance cutting performance cutting

material performance performance

N/mm2 mm mm mm mm

750 dia. 23 dia. 18 dia. 23 dia. 18

500 dia. 25 dia. 20 dia. 25 dia. 20

500 55 x 4 40 x 4 55 x 4 40 x 4

Steel 500 dia. 72 x 3 dia. 60 x 3 dia. 72 x 3 dia. 60 x 3

500 45 x 45 x 6 50 x 50 x 5 45 x 45 x 6 50 x 50 x 5

100 x 10

500

60 x 15

80 x 8 80 x 10 80 x 8

500 65 x 40 x 6 60 x 30 x 6 65 x 40 x 6 60 x 30 x 6

Alu 400 dia. 28 dia. 24 dia. 28 dia. 24

Copper 200 dia. 35 dia. 28 dia. 35 dia. 28

Max. Dimensions of Material

LSI 240 LSI 240 LKS 10 LKS 10

Type of Form Strength max. cutting Continous max. cutting Continous

material of Rm performance cutting performance cutting

material performance performance

N/mm2 mm mm mm mm

750 dia. 23 dia. 18 dia. 15 dia. 12

500 dia. 25 dia. 20 dia. 16 dia. 13

500 55 x 4 40 x 4 20 x 3 20 x 2

Steel 500 dia. 72 x 3 dia. 60 x 3 dia. 25 x 3 dia. 20 x 3

500 45 x 45 x 6 50 x 50 x 5 20 x 15 x 3 15 x 15 x 3

100 x 10

500

60 x 15

80 x 8 16 x 10 20 x 6

500 65 x 40 x 6 60 x 30 x 6 -- - Alu 400 dia. 28 dia. 24 dia. 20 dia. 16

Copper 200 dia. 35 dia. 28 dia. 20 dia. 18

For daily use it is to be distinguished between max. cutting performance and cutting

performance under permanent duty.

In the interest of a long tool life and acceptable service intervals, we recommend not to

exceed permanently the fi gures given for permanent duty. Applications in the range of

the max. cutting performance require a perfect condition of the blades and shortened

service intervals.

19

15.2 Central bolt / Torque

15.3 Oil recommendations

For LUKAS hydraulic devices, use mineral oil in accordance with DIN 51 524 and

others.

Recommended viscosity range: 10 ... 200 mm²/s,

delivered with HLP 22 to DIN 51 524.

Type LSI 2.. LKS 10

Central bolt M 24 x 1.5 (SW 36) M 20 x 1.5 (SW 36)

Torque (Nm) 120 + 10 80 + 10

Range of oil temperature Viscosity rating Remarks

A - 24 ... + 30 °C HL 5

B - 18 ... + 50 °C HLP 10

C - 8 ... + 75 °C HLP 22

D + 5 ... + 80 °C HLP 32

E - 8 ... + 70 °C HF - E 15 biodegradable

LSI_84150_1362_Ausg1205_e.indd Subject to revision

© Copyright 2000 LUKAS Hydraulik GmbH

LUKAS Hydraulik GmbH

A Unit of IDEX Corporation

Weinstraße 39, 91058 Erlangen • Germany

Postfach 2560, 91013 Erlangen • Germany

Tel.: + 49 (0) 9131 / 698-0

Fax + 49 (0) 9131 / 69 83 94

Internet: http://www.lukas.de

e-mail: info@lukas.de

Loading...

Loading...