Operating Instructions

Recycling system

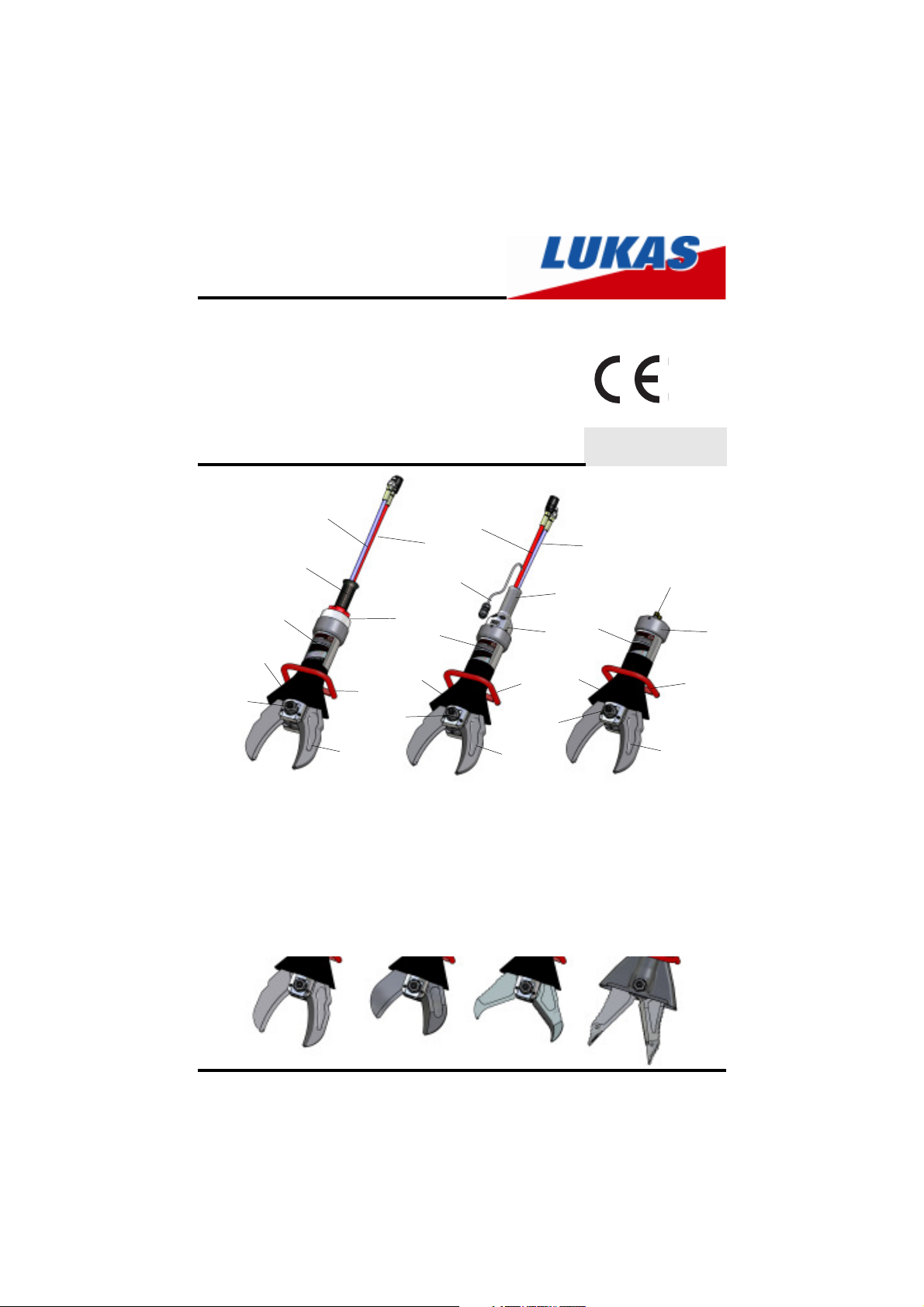

Cutter

LSI 501, LSI 511, LSI 530, LSI 55

9

11

6

7

5

4

with 4/3-way-valve

1 4/3-way-valve with star grip

2 Electric control unit

3 Cylinder bottom

4 Cutter blades

5 Central bolt with self-locking nut

and lubricating nipple

6 Hydraulic cylinder

7 Hand guard

1

12

7

5

with electric controls

8

8

13

6

12

4

8 Hose line red: pressure

with quick-connect socket

9 Hose line blue: return

with quick-connect plug

10 Connecting nipple

11 Handhold

12 Handgriff

13 Power connection

84150/1490-85 GB

Issue 07.2006

9

11

6

2

7

5

with cylinder bottom

10

3

12

4

LSI501

LSI511

LSI530

1

LSI55

Content Page

1 Correct use of the device 3

2 Organisational measures 3

3 General safety instructions 4

4 Maintenance and servicing instructions 5

5 Safety instructions for hose lines 6

6 Functions and performance 8

7 Connecting the device 9

8 Operation 11

9 Cutting 13

10 Dismantling of the device / switching off after use 14

11 Maintenance 14

12 Repairs 15

13 Troubleshooting 19

14 Technical data 20

2

1 Correct use of the device

1.1. The device has been constructed according to the latest technology and the

recognised safety regulations. However, danger to life or limb can arise for the operator

or third parties occur during use or the device and other items can be damaged.

1.2. Only use the device in perfect condition and according to the instructions, safely

and safety conscious! Immediately repair (or arrange repair of) malefunctions which

can affect safety!

1.3 The cutter is mainly used in recycling and demolition works. The cutting tool is

intended for long-term industrial use. It is designed for cutting steel, sufficiently hard

non-ferrous metals, steel sheets and cables. Depending on the type of use, devices

are available with different blade shapes.

Typical cutting performance is listed under „Technical Data“.

1.4 The following must not be cut:

- energised cables

- Pipes with pressurised gas or fluids

- Pre-tensioned and hardened parts such as springs, struts, steering columns

and millings

- Mixed materials, e.g. steel/concrete

1.5 The device (without electrical controls) is suitable for underwater use up to 40 m.

1.6 Devices with cylinder bottom are intended for externally controlled processes.

They are mainly used on robots, cranes or other manipulators.

1.7 The manufacturer / supplier is not liable for damage resulting from incorrect use.

The user alone bears the risk. Correct use also includes observing the operating

instructions and the inspection and maintenance conditions.

2 Organisational measures

2.1 Always store the operating instructions to hand at the location where the device

is used.

2.2 In addition to the operating instructions, generally applicable statutory and other

binding regulations regarding accident prevention and environmental protection must

be observed and applied.

This also includes the wearing of work or protective clothing, helmet with visor or

protective goggles, gloves and, if necessary, ear protectors.

2.3 The device must only be used by a properly trained person, familiar with safety

regulations, as otherwise there is a danger of injury.

2.4 Comply with all safety and risk notices on the device! Keep all safety and risk

notices legible.

2.5 Do not change the device, add or change anything on the device without the

manufacturer’s consent. This is also the case for fitting and adjusting safety equipment

and valves.

3

2.6 The operating pressure marked on the device must not be exceeded.

2.7 Only original LUKAS parts and original LUKAS accessories and system

components should be used for repairs.

2.8 Prescribed and named deadlines for tests/inspections as stated in the operating

instructions must be observed.

2.9 Properly dispose of all packaging materials and removed parts.

3 General safety instructions

3.1 In the event of a malfunction, immediately shut off and secure the device. Repair

(arrange repair) immediately.

3.2 Before start-up / running and during operation, ensure that nobody can be

endangered by the running device. This also means checking the device for loose

connections.

3.3 Do never grip between the blades and take care that body parts (e. g. hair, fingers)

or clothing are never insert between openly visible movable parts.

3.4 Only touch the cutting parts with protective gloves as cutting edges are very sharp.

3.5 Please note that cut material can fall or catapult away as a result of its sudden

removal and suitable protective measures should be taken.

3.6 When working, you must ensure there is sufficient illumination.

3.7 After each use of the device, check for external damage and deficiencies.

Immediately report changes detected (including changes to its operation) to the

appropriate office. If necessary, immediately shut off and secure the device. Check

all hydraulic and electrical lines, hoses and threaded connections for leakage and

check for external damage and immediately repair. Leaking oil can lead to injuries

and fires. Damaged electrical lines can lead to short circuits and electric shocks

which can result in death.

3.8 All types of work which affect the safety and stability of the device are prohibited.

Damage can also occur as a result of the device falling over and/or persons can be

injured by the falling device. Take care if you use a balancer that in case of a

malfunction there is also the possibility that the device could fall down.

3.9 You must check that all safety equipment is complete and in perfect condition:

- Labels and notices (safety notices)

- Safety covers (e.g. hand guard, etc.) are on and in perfect condition.

3.10 When working near energised components and lines, suitable measures

should be taken to avoid current transfers or high voltage transfers to the device.

3.11 The device is filled with hydraulic fluid. These hydraulic fluids can affect your

health if drunk or if their fumes are inhaled. Direct skin contact should be avoided for

this reason. When working with hydraulic fluids, please be aware that they can have

a negative impact on biological systems.

4

3.12 The generation of an electrostatic charge producing sparks as a possible

consequence should be avoided when working with the device.

3.13 When working with or storing the device, ensure that the function and safety of

the device are not affected by large external temperature effects and that it is not

damaged. Please note that the device can heat up as a result of prolonged use.

3.14 Safety equipment must never be disconnected.

3.15 Never work when overtired or inebriated.

3.16 Before transporting the device, always check that the accessories are secure.

3.17 Make sure that you do not caught by hose lines and cables and trip when using

or transporting the device.

4 Maintenance and servicing instructions

4.1 In order to carry out maintenance and service work, equipment suitable for the

work is required. Only staff with specific knowledge and experience in hydraulics may

work on the device!

4.2 Clean oil and all dirt from device and, in particular, connections and screw joints

before starting working. Do not use an aggressive detergents. Use a fibre-free cloth

and ensure thorough cleanliness, especially when rebuilding.

4.3 When dismantling the device, ensure that all escaping hydraulic fluid is collected,

that it does not enter the soil and that it is disposed of in accordance with existing

provisions.

4.4 Always tighten loosened screws and threaded connections when assembling

and observe the prescribed torque.

4.5 Work on electrical devices may only be undertaken by a specialist electrician or

by trained persons under the supervision of a specialist electrician corresponding to

the electrical technical regulations.

4.6 Aggressive media (acids, soaps, solvents, steam) can damage the device. If the

device has to be operated in such an environment in exceptional cases, or if it comes

into contact with such items, the entire device must be thoroughly cleaned. Moreover,

a check according to No. 3.7 above must be undertaken.

4.7 LSI tools must be inspected at regular intervals for dirt in the hand guard, notably

when working overhead. This dirt must immediately be removed (see also

„Maintenance).

4.8 The electrical equipment of the device must regularly be inspected/checked.

Deficiencies, such as loose connections and braised cables, must immediately be

remedied.

5

5 Safety instructions for hose lines

A T T E N T I O N !

- The hoses must never come into contact with brake fluid.

- After coming to contact with the following fluids, the hoses must immediately be

cleaned:

• acids, soaps, solutions / diluted

• alcohol and fuels

• battery acids and ATF

• phosphate esters

It is also essential that the hose lines are checked for damage after cleaning. The

hose lines must be replaced if necessary.

1

2

3

4

5

picture 2

6

6

5.1 Handling instructions for hose lines

- The defined operating pressure must not be exceeded.

- The hoses must not be subjected to tension and torsion (see picture 2, fig. 1).

- The hose line must not be bent (see picture 2, fig. 2).

- Do not pull or lay hoses across edges (see picture 2, fig. 3).

- Do not connect twisted hoses (see picture 2, fig. 4).

- Never drive a vehicle over the hoses. Loose hose lines laid on roads and paths

must be protected against damage, e.g. with hose bridges (see picture 2, fig. 5).

- In the event of high temperatures occurring externally, the hose lines must either

be fitted a sufficient distance from the heat-emitting components or protected by

suitable measures (shields) (see picture 2, fig. 6).

- Weights must not be suspended on the hose lines.

- Objects must not be allowed to fall onto the hose lines.

5.2 Securing the environment in the event of a hose failing

Hose lines must be laid or secured such that risk of the hose failing is avoided.

Danger can occur as a result of:

- the hose moving back and forth after tearing, e.g. through external influence,

- the pressure medium escaping under pressure,

- escaping pressure medium igniting close to a igniting source.

The danger can be avoided, for example, with protective coverings or shields.

5.2.1 Beware of hairline tears

- Escaping high-pressure oil can cause serious injuries

when impinge to the skin.

- In the event of an injury, immediately consult a doctor!

- Oil must immediately be cleaned from the wound.

- Do not search for leaks using a finger.

- Depressurise the hydraulic system before loosening

connections.

5.3 Storing hose lines

- Hose lines are subject to natural aging even when stores correctly and with

permissible loads. As a result, their storage time and period of use are limited.

When storing hose lines, the following should be observed:

- Store cool, dry and dust-free (ideally, wrapped in plastic); avoid direct sunlight or

UV radiation; shield from nearby sources of heat.

- Do not use ozone-forming lights (e.g. fluorescent lights, mercury vapour lamps)

or electrical devices in the immediate surroundings

- Hose lines must be stored de-energised and in a lying position. If storing in

rings, the smallest bend radius as recommended by the manufacturer, must not

be exceeded.

5.4 Labelling the hose lines

- The hose is labelled with manufacturer and operating pressure.

- The maximum permissible operating pressure and month./year of manufacture

are labelled at the pressurised neck.

7

5.5 Periods for checking and replacing hose lines

- Check the hose lines for external damage, tears, bends and inflating after

every use.

- The operator must ensure that hose lines are replaced at reasonable intervals,

even if no safety deficiencies can be detected on the hose.

- The hose line must be replaced 10 years after manufacture at the latest (see

label)!

- Hose lines must be checked before first start-up of the technical equipment

and then at least once a year to ensure a safe working condition by a properly

trained person. For examples of possible deficiencies, see 5.6 below.

5.6 Examples of possible deficiencies to hose lines

- Damage to the external layer to the insert (e.g. chafing, cuts or tears).

- External layer becoming brittle (tears to the hose material).

- Deformations not corresponding to the natural shape of the hose when under

pressure or depressurised, or when bent, e.g. separation of layers, bubbles,

squashed areas, bends.

- Leaks.

- Installation requirements not observed.

- Hose leaves the fittings.

- Damage or deformation to the fittings which alleviates the function and stability of

the fittings or the hose – fittings connection.

- Corroded fittings or metal inserts, which alleviates the stability.

- Storage times and period of use exceeded.

6 Functions and performance

6.1 Description

The device is designed such that a hydraulic piston is connected across two equal,

opposing, symmetrical blades via mechanical joints and so cuts materials. The

blades are designed for the application in terms of their geometry so that sliding of

the material being cut is avoided as much as possible.

6.2 Controlling the working movements

6.2.1 LSI cutter with 4/3-way valve

The movement of the blades is controlled by the star grip on the fitted valve (see first page

pos. 1).

The circuit diagram is simplified here to make

the function comprehensible

(hydraulic cylinder (A) + 4/3-way valve (B).

6.2.2 LSI cutter with electrical controls

The movement of the blades is controlled by the electric control unit on the fitted

valve (see first page pos. 2).

The circuit diagram is simplified here to make

the function comprehensible

(hydraulic cylinder (A) + 4/3-way valve (B).

8

cutting

open

cutting

open

6.2.3 LSI cutter with cylinder bottom

The cutter with cylinder bottom is controlled with pressure to the correspondingly

labelled connection nipple (see first page pos. 10). Control is not directly on the

tool, but through external controls.

The blades are opened with pressure to connector

nipple „B“.

The blades are closed with pressure to connector

nipple „A“.

cutting

open

6.3 Hydraulic power

Only LUKAS hydraulic aggregate should be used to operate the device. If the

pump aggregate is made by another manufacturer, please ensure that it is

designed in accordance with LUKAS specifications, as otherwise potential

dangers can occur, for which LUKAS cannot be responsible. If in doubt, contact

the authorised LUKAS dealer or LUKAS direct.

Ensure that the permissible operating pressure for LUKAS LSI devices of 50

MPa (= 500 bar) is not exceeded without consulting LUKAS.

6.4 Hose lines

The connection between pump aggregate and cutting tool is normally via LUKAS

hose lines.

When connecting a piping, contact LUKAS directly in advance.

7 Connecting the device

7.1 Hydraulical

7.1.1 LSI cutter with 4/3-way valve or with electrical controls

The device has two hose lines; these are connected with the pump aggregate via

a pair of hoses (5 m or 10 m as required). All hose lines are colour marked and

fitted with quick connectors so that they cannot be mistaken:

HP = High pressure ——>red R = Return ——>blue

7.1.2 LSI cutter with cylinder bottom

The device has two connectors for hose lines; these will be connected with the

pump aggregate via a pair of hoses (5 m or 10 m as required) (not included in the

delivery). The hose lines are directly screwed to the cylinder bottom and tightened

with a torque of 45Nm. Ensure that the high pressure hose are screwed into

connection „A“ and the return hose is screwed to connection „B“!

7.2 Connection of the plug-in coupling counterparts for HP and R hoses

The device is connected to the hydraulic pump with the plug in coupling conterparts

(plug and socket), there being no risk of mix-up.

When connecting the hoses, be aware of the following basic functions of the quick

couplers:

X

X

9

Y

Before connecting, withdraw and hold the locking socket (position X). Connect the nipple

and socket and release the locking socket. Then turn the locking cover to position Y.

The connection has now been made and secured. Decoupling is carried out in reverse.

It is only possible to connect the device if the hoses are depressurised.

The supplied dust covers are used to protect against dust.

Attention!

The quick couplings currently have a special function therefore must not be unscrewed

from the hose lines and/or replaced!

7.3 Electrical (only cutters with electric controls)

The device has an approx,. 0.5 m electrical cable with a plug. This plug is connected

with the coupling of the electrical power cable and in parallel with the hose line pair

from the pump engine.

7.4 Mechanical (only cutters with cylinder bottom)

When using the cutter in a manipulator, important principles must be observed in

order to exclude danger to life and limb and to the device:

- The device must be freely rotatable around its long axis (possible through axis

on the robot or corresponding rotor hub / LUKAS accessories) for vertical

positioning to the cut material.

- The addition of protective covers and/or measures for switch securing (e.g.

safety light barrier) must be ensured.

Important!

In any case, installation must be agreed technically and in terms of safety with LUKAS!

7.5 Mechanical fixing on a balancer from the LUKAS accessories

(only cutters with 4/3-way valve or electric controls)

First setup the weight of the cutter on the

green swivel (see arrow on the picture left)

on the reverse of the balancer, this

guarantees that the cutter will remain

hanging at any desired height.

Fix the balancer to the intended suspension

(e. g. arm hook) by using the attached hook

(see picture right, pos. 1). 1

10

Then fix the LSI cutter to the swivel hanger (see

picture left).

Note: The device cannot be clamped tighter in

2

The swivel hanger has 2 holes in order to equalise

differences in center of gravity (see picture left, pos.

2) by fixing the clevis into the second hole.

The LSI cutter should now be hanging

vertically aligned to the steel cable (see

picture right).

the hanger! This is because the cutter is

pivoted in the swivel hanger.

3

Catch:

extraction

locked

Catch:

extraction

unlocked

Unlock the balancer by pulling out the

spring bolt (see picture left, pos. 3) and

turning it counterclockwise to the second, slightly higher positioned catch

and release the spring bolt to snap in.

8 Operation

8.1 Initial operation

Before first starting up, check the device for external, apparent damages and deficiencies!

Check all lines, hoses and screwed connections for leakages and external damages.

Before connecting the LSI-cutter, check the pump intended for use (see the separate

operating instructions for the pump).

Before the first starting up and after repairs, the device must be ventilated:

- Connect device to the hydraulic pump (see „Connecting the device“)

- Fully open the device twice without load until the blades can no longer move, then

immediately switch to idle and immediately close to approx. 2 mm.

11

8.2 Operating the 4/3-way valve with the star grip

Open device (extend):

Turn the star grip clockwise and hold in this position until the blades reach the desired

opening width.

Do not hold the star grip in this position if the blades have already reached their

maximum position.

Close device (retract):

Turn the star grip counterclockwise and hold in this position until the blades reach the

desired opening width or until the blades are closed completely.

Do not hold the star grip in this position if the blades are already fully closed.

Load holding function:

After release, the star grip automatically returns to the middle position with the full

guarantee of the load holding function.

8.3 Operating the electric controls

Open device (extend):

Press the green marked button until the blades reach the desired opening width.

Do not hold the green button down if the blades have already reached their maximum

position.

Close device (retract):

Press the red marked button until the blades reach the desired opening width.

Do not hold the red button down if the blades have already reached their maximum

position.

Load holding function:

After releasing the button, the blades remain in the selected position with the full

guarantee of the load holding function.

Note: Nothing happens if both buttons are pressed simultaneously (blades do

not move).

8.4 Operating with the cylinder bottom

To operate an LSI cutter with cylinder bottom, the controls are not directly on the device,

but instead are external. Please be attend to the separate operating instructions for the

controls you intended to use

Open device (extend):

The blades open with pressure via connection „B“.

Close device (retract):

The blades close with pressure via connection „A“.

The following must be observed because of the external controls:

If persons are working close to the device while it is in operation, the necessary steps

for securing the operating area must be taken (e.g. protective equipment, automatic

safety off (e.g. „safety light barriers“) or manual „Emergency Stop“-switches).

12

9 Cutting

9.1 Safety instructions

- Woldwide all national safety guidelines must be observed and complied.

- If there is a explosion risk, do not use motor pumps because of sparks. In such

cases, manual pumps must be used.

When working with the cutter, you must wear:

- work or protective clothing,

- Helmet with visor or goggles,

- Gloves

Before using the cutter, ensure that the movement of the blades does not represent a

danger to persons or objects as a result of blade movement or catapulted cut materials.

It is strictly forbidden to grip between the blades!

The following must not be cut:

- energised cables

- Lines with pressurised gas or fluid

- Pre-stressed and hardened components (such as springs, spring steel,

steering columns, rollers)

- Composite materials (steel/concrete)

9.2 Cutting procedure

The blades must be applied at right angles

to the object to be cut. Higher cutting

performance is achieved if the cutting is

as close as possible to the blade fulcrum.

When cutting, the gap between the blade

tips must not exceed 3 mm (Risk of blade

fracture).

right false

9.2.1 Attention!

When cutting with curved blades, on the blade tips the full cutting performance must

not be utilized. Cutting in profiles up to 2 mm thickness is permitted.

9.3 Spreading procedure (only LSI 55)

Use front region of the tips only for enlaging a gap.

Grip area to small, tips

may break away

Tips grip securely

13

Use tips only, do not

damage the arms

10 Dismantling the device / switching off after use

10.1 Cutter

After end of working, the blades should be closed till a few mm of tip distance. This

releases the entire device in terms of the hydraulics and mechanically.

10.2 Hydraulic aggregate

After end of working, the engine must be shut down.

10.3 Hose lines

First disconnect the high pressure hose (red), then the return hose (blue) as described

under 7.2. Attach the dust caps to the plug connections.

10.4 Electric cables

The electric cables should be disconnected in case of longer periods between uses.

11 Maintenance

After each operartion and after the end of the shift respectively, a sight check must be

carried out, at least once a year. A function test must be accomplished every 500

operating hours or if there are doubts about the safety or reliability (clean first if dirty).

Sight check

Blades

• Cutting edges free from nicks and deformation,

• Distance of blades from each other in transverse direction < 4 mm for LSI 501 and

LSI 530, and < 3 mm for LSI 511 and LSI 55 (otherwise danger of breakage)

• Cutting edges cross contactless,

• Blades free of cracks

• Dirt in the protective hose (this dirt must immediately be removed)

Cutter

• General impermeability (leakages)),

• Mobility of the star grip,

• Handle in existent and fixed,

• Check torque of the central bolt (see picture in chapter 12.3.1)

MA = torque, see „Technical data“.

Hoses

• Check according to safety instructions for hose lines (see chapter 5),

• Check oil loss.

Function test

• Opens and closes properly using the star grip, electric controls or external controls

(depending on the type of controls).

• Check device for maximum nominal load using a manometer (available as a LUKAS

accessory).

The inspection value specifications are included under chapter „Technical data“.

14

12 Repairs

12.1 General

Servicing should only be carried out by the manufacturer of by staff trained by the

manufacturer and by authorised LUKAS dealers.

Only components, which are available as original LUKAS spare parts, may be

exchanged, because possibly there must be observed necessary special tools,

assembly instructions, safety aspects or tests. Therefore use only original LUKAS

spare parts.

Overpressure safety of the cutters (when not connected)

Undesired pressure could be charged in the device as a result of incorrect connections

and temperature increases. Therefore the blue return hose has a safety coupling (quick

connect plug, coloured yellow). Undesired overpressure (approx. 1.5 MPa) is

automatically released via this plug: oil escapes as well, this is not a malefunction.

If foreign couplings are used, which do not have this function, an overpressure safety

element (opens at 30 MPa) in the cutter valve will take care for pressure equalization.

Oil escapes in the area of the star grip. After the pressure has decreased, the valve is

leak-proof again.

If the valve is permanently leaking, the device must be checked by LUKAS.

12.2 Preventative service

12.2.1 Routine checks

The torque of the central bolt must be checked regularly.

For torques, see the chapter „Technical data“.

Damaged blades can be maintained by sharpening to a total of 0.5 mm. Please ensure

that the internal cutting edges are coplanar.

The central bolt must be lubricated once a day with LUKAS special grease.

A

B

The lubrication nipple (A) is directly in the

central bolt on the side of the self-locking

nut (B).

Lubricate the cutter with a grease gun with

LUKAS special grease as shown in the

picture right.

Excess grease on the lubrication nipple

(see left) after lubrication should be removed

and disposed of professional.

15

Attention!

When working with upturned blades, in particular, please ensure that no coarse

fragments reaches the mechanical parts under the hand guard of the device. Moveable

parts of the device could be blocked as a result and even be destroyed.

The device must be checked for dirt and impurities in the mechanical part after each

of such applications, and cleaned if necessary.

illustration 1

Unscrew handle and pull back the hand guard according to illustration 1.

illustration 2

Clean dirt and shards from mechanical parts as shown in Illustration 2 and blow

out with compressed air carefully.

If the hand guard tabs to the blades are considerably worn or torn, the entire hand

guard must be replaced.

12.2.2 Main checks

The mechanical transfer elements on the device are subject to very high

mechanical stresses and therefore they must be checked after 500 operating

hours at latest. Thereby, appearances of attrition can be detected early so that

breakages can be avoided by timely replacement of these worn parts.

Perfect parts can be reassembled after careful lubrication with LUKAS special

grease.

Parts with limited wear (fretting marks) can be refurbished by polishing and reassembled

after careful lubrication with the corresponding grease.

If there are heavier traces of wear, the damaged parts must be replaced (in pairs).

At these intervals, it is essential to check the blades for crack. A special crack test

kit is available.

From time to time the cutter must be cleaned and lubricated with oil to protect it

against external corrosion.

16

12.2.3 Function and load test

If there are doubts about the safety and reliability, an additional function and load

test must be carried out. For that purpose LUKAS offers a test equipment.

12.2.4 Changing the hydraulic oil

- Change the hydraulic oil after approx. 500 operating hours, but after 2 yeas at latest;

- Whenever the oil of the appropriated pump (motor / hand pump) is changed. Mixing

the cutters used oil with fresh oil must be avoided because of impurity.

Procedure

The cutter is in closed (retracted) position • Change oil of the pump. Unscrew return hose

on the pump:

- for hose connection: unscrew the connector from the blue return line;

- for quick couplings: Fully release the union nut on the plug-in coupling of the blue

return line.

Slowly extend the device with the pump. Collect the old oil from the annulus side in a

separate container and dispose it like the old oil from the pump • Actuate the pump no

longer.

Reconnect the return hose to the pump:

- Tighten the union nut on the plug-in coupling according to 12.3.6,

- Tighten hose nipple in the valve block with MA = 45 Nm,

- Ventilate device according to 8.1

12.3 Repairs

12.3.1 Blades / blade arm and levers

Blades / blade arm and levers must be replaced if there are breakages and cracks or

if the blades are no longer in order as a result of multiple regrinding of the cutting edges

(12.2.1).

- Unscrew the nut from the central bolt

(wrench size of the jaw wrench see chapter

blade arm

"Technical data") and remove the central bolt,

- Remove the retaining ring with retaining ring

nipper,

- Replace the blades and sliding plates,

- Insert bolts with retaining rings,

- Tighten the nut on the central bolt with torque

according to chapter „Technical data“.

sliding plate

self-locking nut

Note: The bolts are accessible, when the blades are closed.

central bolt

bolt

retaining ring

Attention:

Thoroughly clean all sliding surfaces before assembly and grease with LUKAS special

grease.

17

Note: Defective parts (blades, bolts, sliding plates) should always be replaced as

pairs. If you detect, when changing blades, that the levers are damaged (see 12.3.1),

their fit holes are deformed, fretting marks exist or they are otherwise damaged, these

must be replaced too.

This repair must be carried out by an authorised LUKAS dealer or by the LUKAS service

department.

12.3.2 Loss of oil at the hand hold (first page, pos. 11)

Hose connection of the pressure and return line leaky; tighten the hose connections

on the control valve:

Procedure:

Loosen the 2 screws with insulation cases in the hand hold (hexagon socket SW5)

• Remove hand hold and tighten threaded connections, if necessary replace seals.

• Fix hand hold with screws and insulation cases.

12.3.3 Replacing the hand guard

The hand guard protects the operator against injuries resulting caused by the moving

parts. In case of damage, the hand guard must be replaced.

Procedure:

Unscrew handle • remove blades / blade arms (see 12.3.1) • Remove hand guard •

move the new hand guard over the cylinder body until the holes of the hand guard and

the screw holes for the handle matches • mount handle.

12.3.4 Handle (first page, pos. 12)

Defectiv handles must be removed immediately.

Procedure:

Unscrew defective handle and remove it over the cylinder body • fix the new handle, if

necessary replace screws and washers.

12.3.5 Labels

All damaged labels must be replaced (safety instructions, type labels, etc).

Procedure:

Remove damaged labels • clean the surfaces with acetone and glue on the new labels.

12.3.6 Quick couplers

Quick couplers on the hoses must be changed, if:

• external damages are visible • interlock does not work • oil constantly leaks when

connected.

Note: Couplers must not be repaired, they must be replaced by original LUKAS parts.

When assembling tighten the union nut on the hose line with MA = 45 Nm.

18

13 Troubleshooting

Trouble Check Cause Remedy

Hos es cannot be

coupled

Pressurized Relieve pump

pres sure

Blades move slowly

or by jerks when

actuated

Hos es correctly

connected, power

pack operating

Air in the hydrallic

system

Thorougly vent

pum p unit

No pressure build-up Insufficient oitl in

the hand or m otor

pum p. Pump not

ventilated after oil

change

Refill oil an

ventilate the

system

Star grip does not

return to the middle

pos ition when

released

Dam age of the

return spring for

resetting, fouling

Repair by an

authorized dealer

or directly by

LUKAS

Oil leakage out of

hos es or hose fittings

Untightness ,

pos sible

dam ages

Replace hoses

Surface of the

hydraulic hos es is

dis solved

Contact wirh

aggress ive media

Replace hoses

Blades spread up at

tips to a gab of more

than 3 mm (LSI511

and LSI55) and more

than 5 mm (LSI501

and LSI530)

respectively

Torque of the

central bolt nut is

ins ufficient

Retighten, see

chapter 12.2.1

Leakages: leaks at

the pis ton rod

Defective piston

rod seal

Changing the

seals by an

authorized dealer

or directly by

LUKAS

If the defects cannot be repaired, contact an authorised LUKAS dealer or the

LUKAS service department.

The address of the LUKAS service department is:

LUKAS Hydraulik GmbH, Weinstraße 39, D-91058 Erlangen; PF 2560, D-91013

Erlangen Kundendienst Tel 09131/698 348; Fax 09131/698 353.

19

14 Technical data

Typ of cutter

Connection / control 4/3-way-valve Electric controls Cylinder bottom

Ref. no. 84150/1491 84150/91491 84150/81491

Dim ens ions l x w x h

without

connection hos es

(mm) 789 x 235 x 168 789 x 235 x 168 645 x 235 x 168

Opening at tips (mm)

Weight incl. oil filling (kg) 23,5 21,7 20,4

Operating pressure (Mpa)*

Necessary oil quantity (l)**

LSI 501

180

50

0,15

Typ of cutter

Connection / control 4/3-way-valve Electric controls Cylinder bottom

Ref. no. 84150/1492 84150/91492 84150/81492

Dim ens ions l x w x h

without

connection hos es

(mm) 755 x 235 x 168 754 x 235 x 168 610 x 235 x 168

Opening at tips (mm)

Weight incl. oil filling (kg) 23,4 21,5 20,3

Operating pressure (Mpa)*

Necessary oil quantity (l)**

LSI 511

132

50

0,15

Typ of cutter

Connection / control 4/3-way-valve Electric controls Cylinder bottom

Ref. no. 84150/1493 84150/91493 84150/81493

Dim ens ions l x w x h

without

connection hos es

(mm) 792 x 235 x 168 791 x 235 x 168 646 x 235 x 168

Opening at tips (mm)

Weight incl. oil filling (kg) 23,1 21,5 20,2

Operating pressure (Mpa)*

Necessary oil quantity (l)**

LSI 530

279

50

0,15

* 1MPa = 10 bar;

** Necessary oil quantity in the hydraulic power pack for operating the tool

(Difference in quantity piston / rod side)

20

* 1MPa = 10 bar;

Typ of cutter

Connection / control 4/3-way-valve Electric controls Cylinder bottom

Ref. no. 84150/1494 84150/91494 84150/81494

Dim ens ions l x w x h

without

connection hos es

(mm) 862 x 235 x 168 860 x 235 x 168 626 x 235 x 168

Opening at tips (mm)

Weight incl. oil filling (kg) 23,9 22,5 21

Operating pressure (Mpa)*

Necessary oil quantity (l)**

LSI 55

430

50

0,11

Range of oil temperature Visc osity rating Remarks

A -24 .... +30°C HL 5

B -18 .... +50°C HLP 10

C -8 .... +75°C HLP 22

D +5 .... +80°C HLP 32

E -8 .... +70°C HF - E15 biodegradable

** Necessary oil quantity in the hydraulic power pack for operating the tool

(Difference in quantity piston / rod side)

14.1 Central bolt / Torque

Type LSI 501 / LSI 511 / LSI 530 / LSI 55

Central bolt M 27 x 1,5

Wrench size (mm) 41

Torque (Nm) 130+10

14.2 Oil recommendations

Oil for LUKAS Hydraulic devices: Mineral oil DIN 51524 and others

Recommended viscosity range: 10 … 200 mm2/s

Delivered with HLP 22 DIN 51524

14.3 Hoses

Bending radius Rmin = 38 mm

Burst resistance Safety factor: burst pressure / max. operating pressure, min. 4 : 1

Temperature resistance - 40°C ... + 100°C

Operating medium Mineral oil according to DIN 51524

14.4 Temperature ranges

Operating temperature -20 ... +55°C

Ambient temperature (device in operation) -24 ... +45°C

Storage temperature (device not in operation) -30 ... +60°C

21

Cutting material

max.

continuous

operation

max.

continuous

operation

max.

continuous

operation

max.

continuous

operation

[mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

Round bar steel

(Rm 750 N/mm²)

28 24 30 25 28 24 28 24

Round bar steel

(Rm 550 N/mm²)

30 25 32 26 30 25 30 25

Round bar aluminum

(Rm 400 N/mm²)

36 32 38 34 36 32 36 32

Round bar copper

(Rm 200 N/mm²)

38 34 42 36 38 34 38 34

U-profile steel

(Rm 500 N/mm²)

50x40x5 40x25x5 60x40x6 60x25x6 65x45x6 60x40x5 65x45x6 60x40x5

Flat steel

(Rm 500 N/mm²)

125x10 80x10 115x10 80x10 100x15 80x10 100x15 80x10

Steel pipe

(Rm 500 N/mm²)

76x4 60x3 76x4 60x3 76x4 60x40x5 80x5 65x5

Square pipe

(Rm 500 N/mm²)

60x4 40x4 60x40x6 40x4 65x5 50x4 70x5 55x4

Angle steel

(Rm 500 N/mm²)

50x8 50x6 50x10 60x6 50x8 50x6 50x8 50x6

Cutting material dimensions with

LSI 501 LSI 511 LSI 530 LSI 55

14.5 Cutting performance

22

14.6 Test pressures

Type of cutter

Testing

pressure

Operating

pressure

LSI 501 225 bar

LSI 511 330 bar

LSI 530 340 bar

LSI 55 260 bar

50 MPa

The stated reference test pressures only refers to the measurement with the LUKAS

testing kit (from the LUKAS accessories programme).

Measurements and thresholds with other test equipment must be agreed in advance with

the LUKAS service department.

LUKAS Hydraulik GmbH

A Unit of IDEX Corporation

Weinstraße 39, 91058 Erlangen

Postfach 2560, 91013 Erlangen Germany

Telefon (09131) 698-0 • Telefax (09131) 698-394

E-Mail: info@lukas.de

LSI5XX_BA_GB_841501490_0706.p65 © Copyright 2006 LUKAS Hydraulik GmbH

23

subject to revision

Loading...

Loading...