Lukas LS530 User Manual

Operating Instructions

Rescue Tools

Cutters

LS501EN, LS511EN, LS530EN

1

2

4

5

6

3

LS501EN

2

4

5

6

3

LS530EN

1 Control valve with star shape ring

2 Hydraulic cylinder

3 Handle

4 Protecting hose

5 Central bolt with selflocking nut

6 Cutter blades, resp. blade arm

7 Handle

8 Quick-connect plug

9 Hose, blue: Return

10 Quick-connect socket

11 Hose, red: Pressure

9

7

1

11

7

11

10

84150/1211-85 GB

Ausgabe 05.2006

8

9

10

9

11

7

2

8

4

5

6

1

3

LS511EN

1

Content Page

1 Basic operation and designated use of the machine 3

2 Organizational measures 3

3 General safety instructions 3

4 Instructions for maintenance and service 4

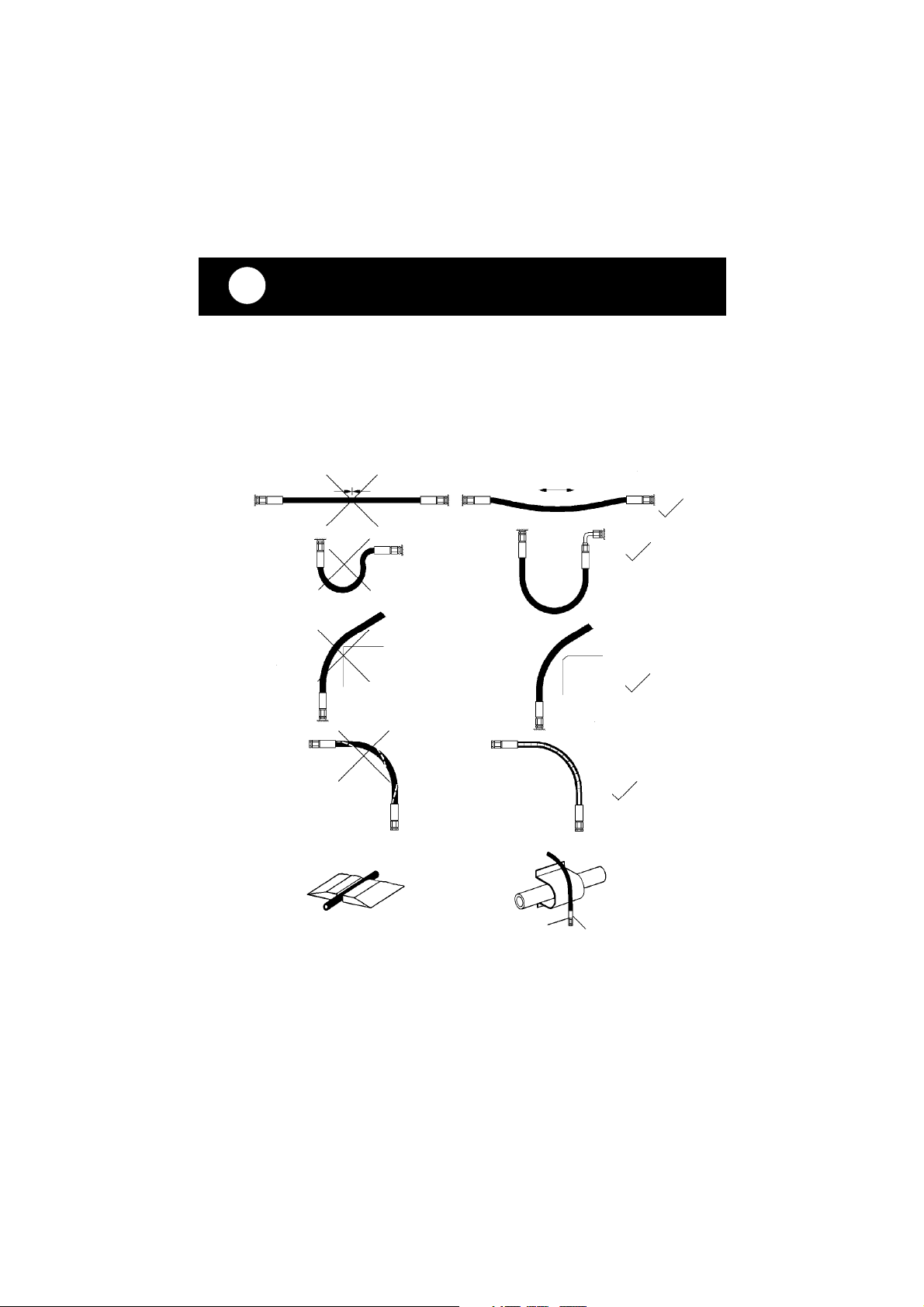

5 Safety Instructions for Hydraulic Hoses 5

6 Intended use 7

7 Function and performance 7

8 Connection of the tool 8

9 Operation 9

10 Cutting 9

11 Dismantling of the device / Stop after operation 10

12 Maintenance 10

13 Repairs 11

14 Troubleshooting 14

15 Technical data 15

2

1 Basic operation and designated use of the machine

1.1 The machine has been built in accordance with state-of-the-art standards and the

recognized safety rules. Nevertheless, its use may constitute a risk to life and limb of the

user or of third parties, or cause damage to the machine and to other material property.

1.2 The machine must only be used in technically perfect condition in accordance with

its designated use and the instructions set out in the operation manual, and only by

safety-conscious persons who are fully aware of the risks involved in operating the

machine. Any functional disorders, especially those affecting the safety of the machine/

plant, should therefore be rectified immediately!

1.3 The machine is exclusively designed for the use described in the operating

manual. Using the machine for purposes other than those mentioned in the manual,

such as driving and controlling other pneumatic systems, is considered contrary to its

designated use. The manufacturer/supplier cannot be held liable for any damage

resulting from such use. The risk of such misuse lies entirely with the user.

Operating the machine within the limits of its designated use also involves observing

the instructions set out in the operating manual and complying with the inspection and

maintenance directives.

2 Organizational measures

2.1 The operating manual must always be at hand at the place of use of the machine!

2.2 In addition to the operating instructions, observe and instruct the user in all other

generally applicable legal and other mandatory regulations relevant to accident

prevention and environmental protection.

This also applies for wearing protective clothing, helmet with visor or goggles and

protective gloves.

2.3 In order to avoid innjuries, the machine must only be operated by a specially

trained operator who has undergone a safety training.

2.4 Observe all safety instructions and warnings attached to the machine. Make sure

that safety instructions and warnings attached to the machine are always complete and

perfectly legible.

2.5 Never make any modifications, additions or conversions which might affect safety

without the supplier's approval. This also applies to the installation and adjustment of

safety devices and valves.

2.6 Spare parts must comply with the technical requirements specified by the

manufacturer. Spare parts from original equipment manufacturers can be relied to do

so. It is only allowed to use original LUKAS spare parts of LUKAS system components.

2.8 Adhere to prescribed intervals or those specified in the operating manual for

routine checks and inspections.

2.9 Make sure to dispose properly of packing material and dismounted parts!

3 General safety instructions

3.1 In the event of malfunctions, stop the machine immediately and lock it. Have any

defects rectified immediately.

3

3.2 Before starting up or setting the machine in motion and during operation of the

machine make sure that nobody is at risk.

3.3 Before transporting the machine always check that the accessories have been

safely stowed away.

3.4 Make sure that there is enough lighting during work.

3.5 Avoid any operation that might be a risk to machine stability.

3.6 Check the machine at least after every operation for obvious damage and defects.

Report any changes (incl. changes in the machine’s working behaviour) to the competent

organization / person immediately. If necessary, stop the machine immediately and lock

it. All lines, hoses and screwed connections have to be checked for leaks and obvious

damage. Repair damage immediately. Splashed oil may cause injury and fire.

3.7 All safety equipment has to be checked for completeness and flawless condition:

- instruction markings and warning signs (safety instructions)

- check safety cover (e.g. motor-safety covers, heat protection etc.) if they are available

and if they are in good condition.

3.8 Do not stress hoses mechanically (pulling, buckling etc.).

3.9 When working in the vicinity of live components and cables, suitable precautions

must be taken to avoid current conductions or high-voltage flashovers.

3.10 During use of the tool, the creation of electrostatic charges which could result in

sparking must be prevented.

3.11 The tool should always be placed in such a way that its function and safety will

not be impaired by strong external temperature influences.

4 Instructions for maintenance and service

4.1 For the execution of maintenance and service work, tools and workshop equipment

adapted to the task on hand are absolutely indispensable.

Work on the hydraulic system must be carried out only by personnel having special

knowledge and experience with hydraulic equipment.

4.2 Before putting into operation clean the machine, especially connections and

threaded unions, of any traces of oil, fuel or preservatives before carrying out maintenance/

repair. Never use aggressive detergents. Use lint-free cleaning rags and pay attention

that the components are meticulously clean during reassembling after repair.

4.3 During dismantling of machines it is necessary to collect the outrunning hydraulic

liquids completely, so that they cannot reach the ground. They have to be disposed

properly according to the instructions.

4.4 Always tighten any screwed and thread connections that have been loosened

during maintenance and repair. Observe the stipulated torques.

4.5 Aggressive material (acid, lye, solvent, vapour) can damage the machine. It is

necessary to clean the whole machine if it must be exceptionally operated under such

conditions or gets into touch with these materials. Additionally, the machine must be

checked as described under 3.6.

4

5 Safety Instructions for Hydraulic Hoses

A T T E N T I O N !

- by no means the hose must be exposed to brake fluid as this fluid will destroy outer

layer of hose

- do not expose the hose to any of the following aggressive fluids:

• acid, lye or solvent

• alcohol and fuel

• battery and automatic transmission fluid

• phosphate ester

Clean hose immediately with water and detergent when it was exposed to such fluids.

1

2

3

4

5

5

6

Loading...

Loading...