Page 1

Operating instructions

Rescue

Hand pump LH2

and accessories

179101085 GB

Publication 12.2008

(Translation of the original operating instructions)

Page 2

2

Page 3

3

Contents Page

1. Danger classes 4

2. Product safety 4

3. Proper use 7

4. Main components of the hand pump 8

5. Functional description 8

5.1 Base pump 8

5.2 Adapter blocks 9

6. Connection options for rescue equipment 9

6.1 Fittings 9

6.2 Quick-disconnect-couplings 10

6.3 Monocouplings 11

7. Commissioning 12

7.1 Unlocking the pump 12

7.2 Retracting the handle 12

7.3 Bleeding the pump 12

8. Operation 13

8.1 Operation 13

8.2 Shutdown / storage 14

9. Transport 14

10. Maintenance and repair 14

10.1 Basic requirements 14

10.2 Maintenance 15

10.3 Hydraulic uid change or adding hydraulic uid 16

10.4 Care 16

10.5 Repair 17

11. Troubleshooting 20

12. Technical data 23

12.1 Data of the hand pumps 23

12.2 Hydraulic uid recommendation 24

12.3 Hose lines 25

12.4 Operating and storage temperature ranges 25

13. Notes 26

Page 4

4

Danger classes1.

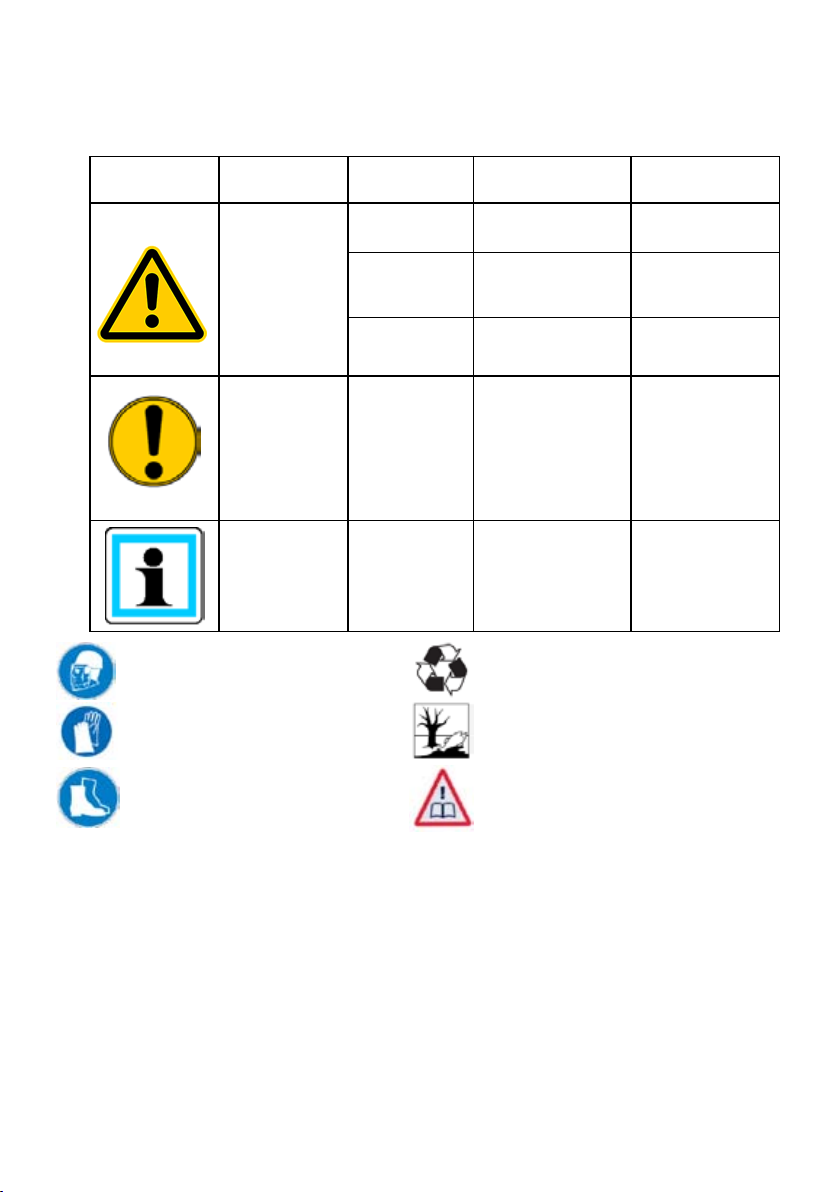

We distinguish between various categories of safety instructions. The table shown below

shows you the overview, via the assignment of symbols (pictograms) and signal words, of

the concrete danger and the possible consequences.

Pictogram

Damage /

injury to

human

device

- NOTE

Key word Denition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

CAUTION!

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to device /

environment

Advice for

application and

other important /

useful information

and advice

Death or major

injury

Potential death or

major injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surrounding

materials

No injury /

damage to

persons /

environment /

equipment

Wear helmet with face guard

Wear protective gloves

Wear safety shoes

Proper recycling

Protect the environment

Read and follow operating

instructions

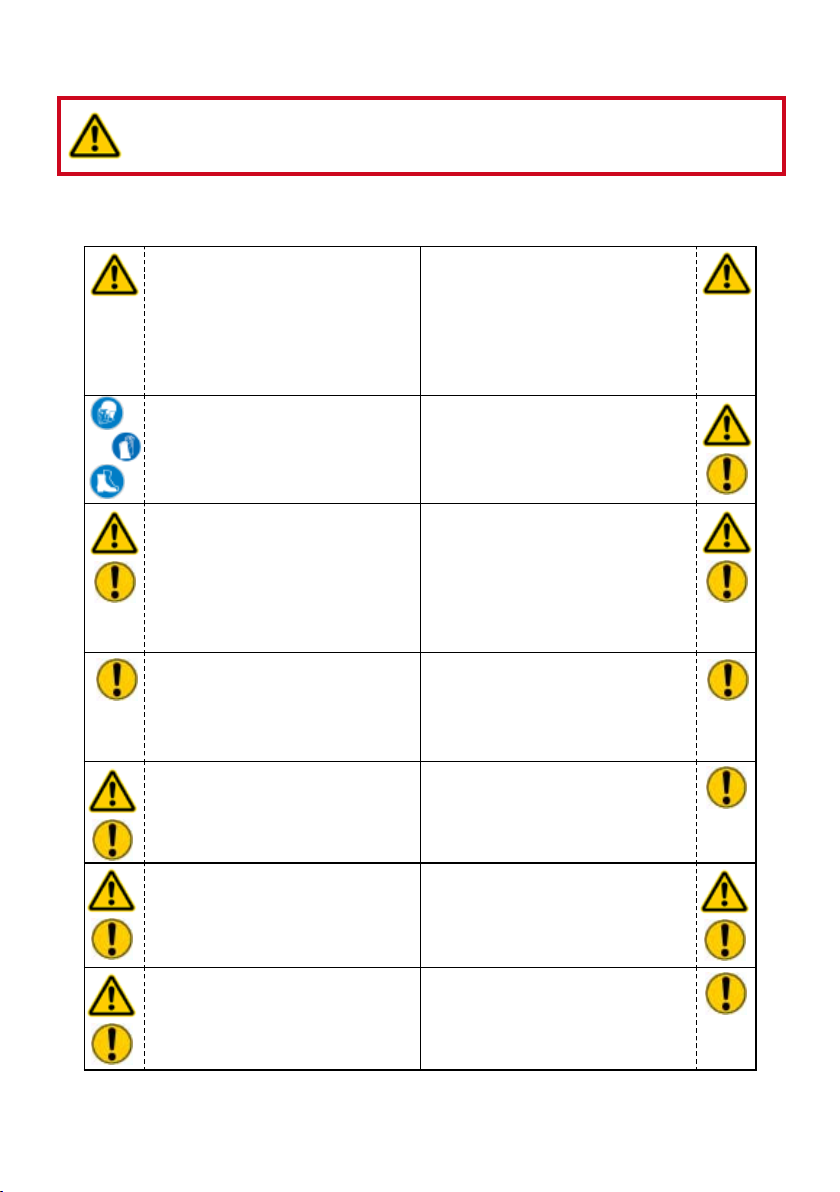

Product safety2.

LUKAS products are developed and produced in order to ensure the best performance and

quality with proper use.

The safety of the operator is the most important consideration in the product design.

In addition, the operating instructions are to help in using the LUKAS products safely.

In addition to the operating instructions, all generally applicable, statutory and other

binding rules for accident prevention and for environmental protection must be heeded and

disseminated.

The device must only be operated by educated persons who are trained in safety technology,

since otherwise there is a risk of injury.

We advise all users before using the device to carefully read through the operating instructions

and to follow the instructions contained therein without exception.

Page 5

5

We also recommend that you get instructed by a qualied trainer in the use of the product.

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

devices must also be heeded!

Even if you have already received instruction, you should read the following safety instructions

again.

Make sure that no body parts

or clothing get between the

openly visible moving parts of

the device.

Wear protective clothing,

protective helm with visor,

safety shoes and protective

gloves.

Working under loads is

prohibited if they are raised

exclusively with hydraulic

devices. If this work is

unavoidable, sufcient

mechanical supports are

additionally required.

In the event of malfunctions,

shut down the device

immediately and secure it. You

should have the malfunction

repaired immediately.

Heed all safety instructions

and hazard warnings on the

device and in the operating

instructions.

Immediately report changes

that occur (including changes

in operating behaviour) to

the appropriate persons/

departments! If necessary,

immediately shut down and

secure the device!

Check the device for visible

defects or damage before and

after use.

Check all lines, hoses and

screwed connections for leaks

and externally visible damages

and repair immediately!

Escaping hydraulic uid can

lead to injuries and res.

Do not make any changes

(add-ons or conversions) on the

device without the approval of

LUKAS.

All safety instructions and

hazard warnings on the device

are to be kept intact and in a

legible condition.

Make sure that all safety covers

are present on the device and

in proper working condition.

Safety equipment must never

be disabled!

Any work procedure that

detracts from the safety and/or

stability of the device should be

abandoned!

The maximum permissible

operating pressure must not be

changed.

Page 6

6

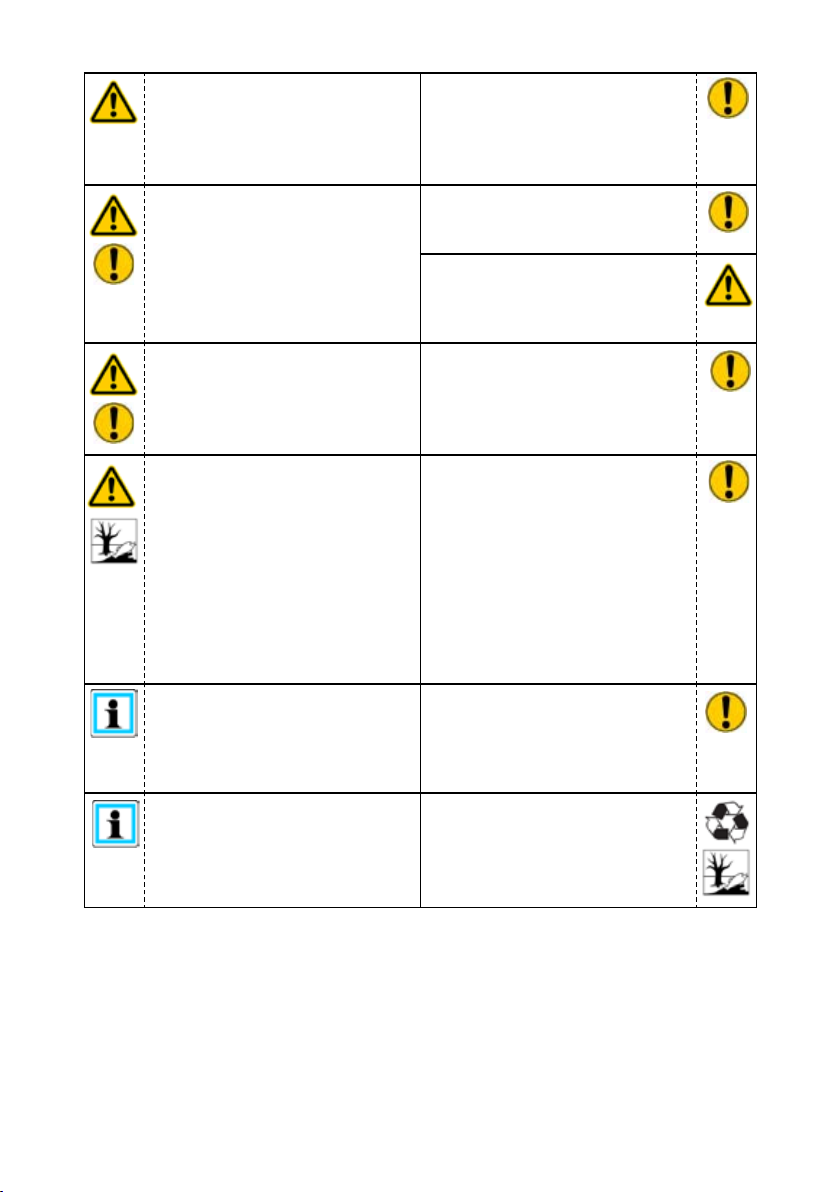

Before switching on/engaging

the device or while operating

the device, it must be ensured

that no one is endangered by

the operation of the device.

When working in the vicinity

of live components and lines,

take appropriate measures for

preventing current transfers or

high voltage ashovers to the

device.

Prevent electrostatic discharge,

which has the possible

consequence of spark

formation, when handling the

device.

The device is lled with

hydraulic uid. These hydraulic

uids can be detrimental to

health if they are swallowed

or their vapours are inhaled.

Direct contact with the skin

should be avoided for the same

reason. Also, when handling

hydraulic uids, note that they

can negatively affect biological

systems.

Make sure there is adequate

lighting while working.

Always keep these operating

instructions easily accessible

at the site where the device is

used.

Observe all intervals that

are prescribed or specied

in the operating instructions

for recurring tests and/or

inspections.

For repairs only original LUKAS

accessories and spare parts are

to be used.

Make sure that you do not

get caught in the hose loops

and trip when working with or

transporting the device.

When the hand pumps are set

up, care needs to be taken

that they are not impaired by

extremely strong temperature

changes.

When operating and/or storing

the device, make sure that the

function and the safety of the

device are not impaired by

strong external temperature

differences or that the device is

damaged. Keep in mind that the

device can also heat up when it

is continuously used.

Before transporting the device,

always check to see that the

accessories are positioned

securely to prevent the

possibility of an accident.

Make sure you properly dispose

of all removed parts, leftover

hydraulic uid, leftover oil and

packing materials.

In addition to the safety instructions of these operating instructions, all generally applicable,

statutory and otherwise binding national and international rules for accident prevention need

to be heeded and disseminated!

Page 7

7

WARNING / CAUTION / ATTENTION!

The device is specied exclusively for the purpose represented in the operating

instructions (see Chapter "Proper use"). Any use that differs or goes beyond this is

considered improper. The manufacturer/supplier shall not be held liable for damages

resulting from improper use. The risk shall be borne solely by the user.

Proper use also includes heeding the operating instructions and complying with the inspection

and maintenance requirements.

Never work in a fatigued or intoxicated state!

Proper use3.

The LUKAS hand pump is used for the operation of LUKAS rescue devices.

They can be used as an additional or replacement drive source along with the LUKAS

hydraulic unit (e.g. in areas at risk for explosion).

Use with equipment of other manufacturers is possible, but requires technical testing and

approval of LUKAS on a case-by-case basis.

WARNING / CAUTION / ATTENTION!

Always note the product limitations with respect to operating pressure, load limit

values and operating conditions. The operating pressure should not be higher

than the lowest maximum operating pressure of any system components.

The operating pressure should NEVER be set higher than that which is specied

in the "Technical Data" chapter. A higher setting may cause property damage

and/or injuries.

Make sure that the usable capacity of the hand pump (see chapter "Technical

Data") is sufcient for operating the connected cylinders or devices.

The required hydraulic uid operating quantity can be found in the chapter

"Technical Data" or in the operating instructions of the devices to be operated.

Accessories and spare parts for the rescue equipment can be obtained from your authorised

LUKAS dealer!

Page 8

8

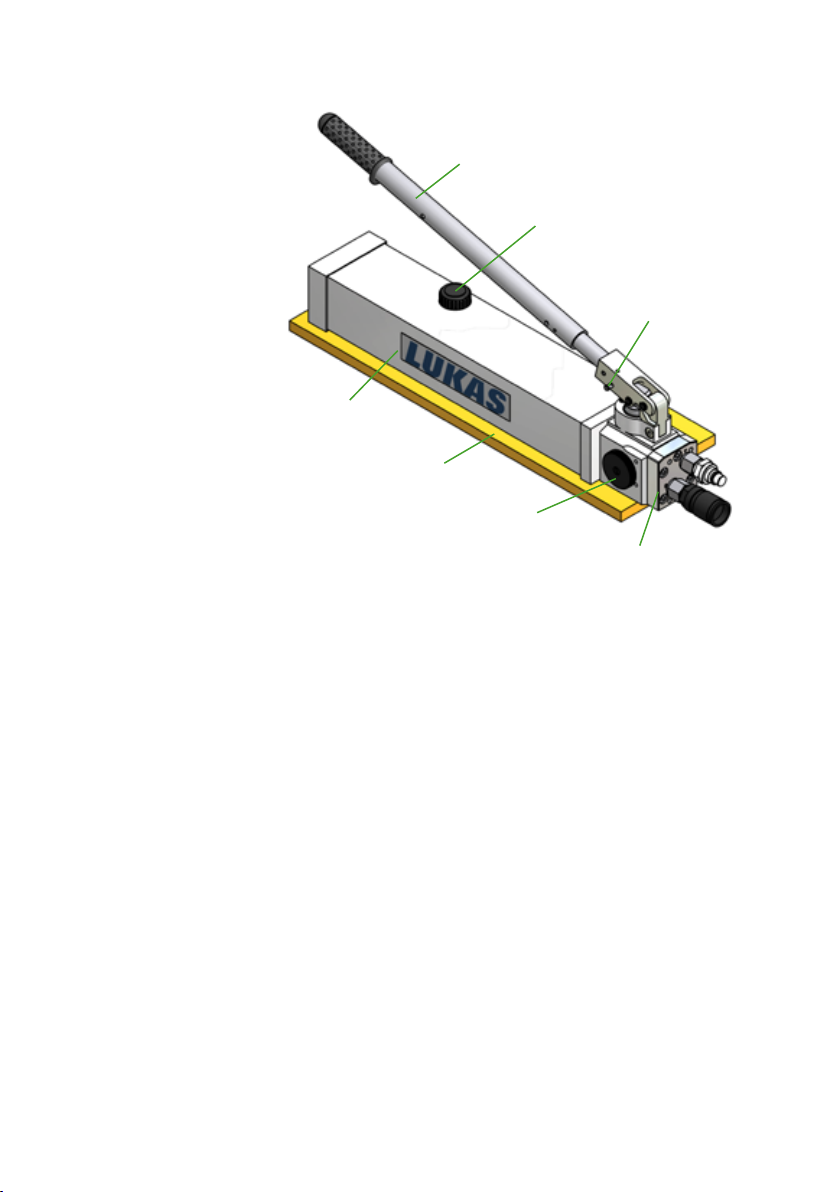

Main components of the hand pump4.

4

3

6

1 Drain valve

2 Connection plate with

ttings or couplings

3 Vent / ll cap

4 Retractable pump

lever

5 Tank

6 Lock

7 Base plate

5

7

1

2

Functional description5.

5.1 Base pump

All LUKAS hand pumps of this series are two-speed, i.e. they have two operating speeds:

• A high speed in the low pressure range (LP) for fast extension of the cylinder or device

while unloaded

• A low speed in the high pressure range (HP) for controlled extension of the cylinder or

device while loaded

The switch from low pressure (LP) to high pressure (HP) is automatic at the factory setting

for changeover pressure (see chapter "Technical Data").

A pressure port "P" with a G1/4" thread and a return port "T" with an M10 thread are directly

available as ports on the pump.

To connect rescue equipment, adapter blocks must be installed (see subchapter "Adapter

blocks" for more information). In the case of the hand pumps sold by LUKAS, one of these

adapter blocks is always included as standard equipment and is already installed.

Of course, the installed adapter blocks may be replaced with other ones. However, you must

contact an authorised LUKAS dealer or contact LUKAS directly.

The retractable handle of the LUKAS hand pump combines low required pumping force with

compact dimensions for storage and transport.

In addition, the LUKAS hand pumps for rescue equipment are equipped with a base plate to

ensure a more stable position during operation.

Page 9

9

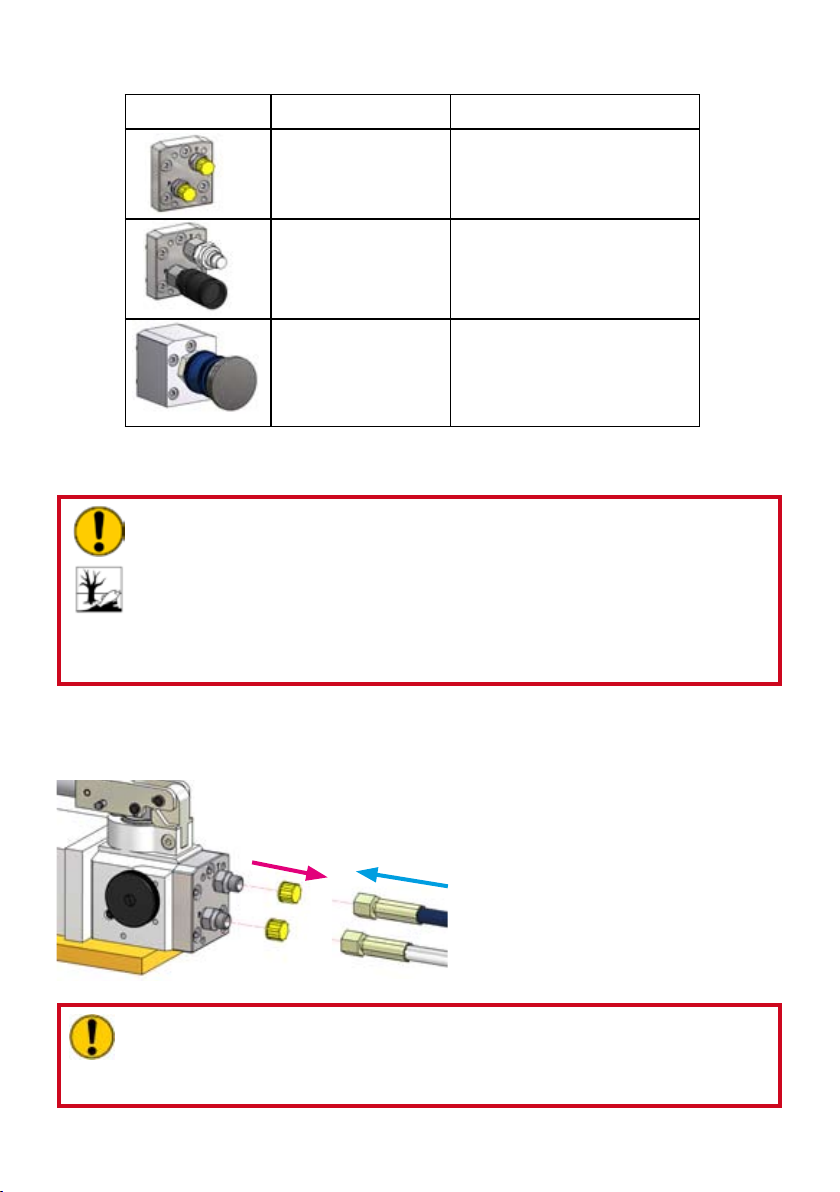

5.2 Adapter blocks

Adapter block Function/use

Connection plate

with ttings

Possibility of connecting hose

lines directly to the hand

pump

Connection

plate with quickdisconnect-couplings

Connection plate

with monocouplings

Possibility of connecting hose

lines directly to the hand

pump via quick-disconnectcouplings

Possibility of connecting hose

lines directly to the hand

pump via monocoupling

Connection options for rescue equipment6.

ATTENTION!

Make sure to store all plugs, screw plugs and/or dust caps in a way that

prevents them from getting dirty or lost.

After completion of the work, seal off all lines using screw plugs and/or dust

caps to prevent contamination of the hand pump.

When connecting lines to the hand pump, we recommend positioning it

vertically so that the ports point upward. This reduces the danger of hydraulic

uid escaping.

6.1 Fittings

The hose lines are connected via ttings to the hydraulic pump.

1. First remove the closure caps from

the ttings.

1.

2. Then, you can connect the hose lines

2.

to the ttings and tighten them with a

tightening torque of M

= 40 Nm.

A

ATTENTION!

The return hose must always be connected at the "T" port of the

connection block.

The supply hose line must instead be connected at the "P" port.

Page 10

10

6.2 Quick-disconnect-couplings

The hose lines are connected via quick-disconnect coupling halves (female and male) to the

hydraulic pump in such a way that they cannot be reversed.

X

Y

Before connecting the couplings, remove the dust cap, then pull back and hold the locking

sleeve of the female coupling (Position X). Push the male and female couplings together and

release the locking sleeve. Finally, turn the locking sleeve into Position Y. The connection is

then made and secured. Decoupling is done in the reverse sequence.

ATTENTION!

Always connect the return line rst and then the supply line!

NOTE:

Coupling the equipment is only possible if the hoses are depressurised.

For dust protection, the supplied dust caps must be reattached.

WARNING / CAUTION / ATTENTION!

The quick-disconnect-couplings have special functions, in part, and therefore

must not be unscrewed and/or reversed!

Page 11

11

6.3 Monocouplings

The hose lines are connected via quick-disconnect coupling halves (female and male) to the

hydraulic pump in such a way that they cannot be reversed.

Dust caps

Male coupling

Before coupling, remove dust caps, then connect male and female couplings and turn locking

sleeve of the female coupling in direction "1" until the locking sleeve latches. The connection

is then made and secured. The decoupling is accomplished by turning the locking sleeve in

direction "0".

The coupling of the devices under pressure is also possible, assuming the connected

equipment is not turned on.

NOTE:

We recommend, when ambient temperatures are low and extension hoses /

hose winders are used, connecting the coupling halves in a depressurised state

because decoupling may otherwise require a very large exertion of force.

For dust protection, the supplied dust caps must be reattached.

WARNING / CAUTION / ATTENTION!

The monocouplings must not be unscrewed and/or the hose lines reversed!

Female coupling

Page 12

12

Commissioning7.

NOTE:

With the LUKAS hand pump, a little idle stroke may occur when the unit is rst

used in the high pressure range.

However, this idle stroke independently stops after a device is operated

2-3 times.

ATTENTION!

The hand pump should be as close to horizontal as possible, because otherwise

the usable amount changes!

The oil ll plug must always be unscrewed one turn before starting operation of

the hand pump! This enables the aeration and bleeding of the hydraulic tank.

After the work is completed but before transport, the oil ll plug should be

retightened!

7.1 Unlocking the pump

2.

1.

Locking pin

Unlock (1.) the shipping lock of the pump by

sliding the locking pin in the direction of the

hand wheel until it comes against the stop.

To lock (2.) the pin, move it until it comes

against the stop in the other direction. To do

this, the lever must be in the home position

(at the tank).

7.2 Retracting the handle

You can pull out the handle by applying pressure to both sides of the thrust piece and

simultaneously pulling in the direction of the handle end until the thrust piece re-engages.

1. 2.

7.3 Bleeding the pump

1. Open the discharge valve.

2. Open the oil ll screw plug on the tank container and check the oil ll level. The oil ll

level should come up to approximately 1-2 cm below the top edge of the oil reservoir.

3. In this state, work the pump handle several times.

Hand wheel

Page 13

13

NOTE:

To bleed connected equipment, make sure that the highest point of the connected

devices are below the level of the pump.

Before operating the pump, you should also open the oil ll screw plug. Only in this

way can any trapped air escape the hydraulic system when the pump is operated.

You should operate the connected equipment several times without load.

When you do this, also follow the separate operating instructions of the connected

devices.

Operation8.

WARNING / CAUTION!

Under certain circumstances, the pump handle can "kick back". Make sure that

your body remains to the side of the pump.

ATTENTION!

Never attach an extension to the pump handle that does not belong to the

device. These extensions usually cause the pump to become unstable during

operation.

NOTE:

In order to limit the required force in high pressure operation, we recommended

using short strokes with the pump handle. The greatest pumping effect is produced

in the last 5 degrees of the stroke.

Should you use a female quick-disconnect-coupling as the port, quick stop may be

triggered if the discharge valve is opened too quickly (turning counter-clockwise),

i.e. the check valve incorporated in the male quick-disconnect coupling blocks

the return ow of oil while the connection between pump and female quick-

disconnect coupling is depressurised. This is provided as a safety function in case

the connection between the female quick-disconnect-coupling and pump starts

to leak and the pressure drops abruptly. In this case, the "quick stop" prevents,

for example, an abrupt drop in the load when an hydraulic cylinder is operated.

In order to release the quick stop again, more pressure must rst be supplied to

the device. Then, the pressure can be decreased again by slowly opening the

discharge valve.

8.1 Operation

Procedure:

1. Close discharge valve on the hand pump completely (rotate clockwise).

2. Connect the return line of the device at the return port "T" and then the high pressure line

at the pressure port "P".

3. Move the locking pin into the operating position.

4. Supply the device with hydraulic uid or pressurise by operating the pump lever (up and

down movements).

5. To reduce the pressure of the device, slowly open the discharge valve of the hand pump

(turn counter-clockwise). In this way, you can meter the pressure reduction precisely.

Page 14

14

8.2 Shutdown / storage

To shut down or store the pump, seal all hydraulic connections with the associated screw

plugs or dust caps.

After sealing the hydraulic ports, open the drain screw (not up to the stop!) to depressurise

the pump.

Then carefully clean the external dirt off of the hand pump.

In addition, with a longer storage time, the outside of the device should be cleaned and all

visible mechanical moving parts need to be oiled.

ATTENTION!

After completion of the work but before transport, check to make sure the oil ll

screw plug is screwed in tightly!

Make sure the pump is not stored in a damp environment.

Transport9.

The pump lever is used as a carrying handle! Special pumps may be the exception in this

case. These pumps are custom-assembled for each customer; therefore, there may be a

different transport device or none! In these cases, please refer to your authorised dealers

or LUKAS directly. The lever must be locked for transport, as described in the chapter

"Unlocking the pump".

Maintenance and repair10.

10.1 Basic requirements

Service work may only be performed by the device manufacturer or by personnel trained by

the device manufacturer and authorised LUKAS dealers.

All components must be replaced with original LUKAS spare parts, which are listed in the

spare parts list, because in this context even required special tools, assembly instructions,

safety aspects and/or checks absolutely must be taken into consideration.

During the assembly work, pay particular attention to the cleanliness of all components

because dirt can damage the equipment!

WARNING / CAUTION / ATTENTION!

To perform maintenance and repairs, personal safety equipment appropriate for

the work is an absolute requirement. (incl. shields).

Assembly and repair work on the pump may only be performed if the entire

hydraulic system is depressurised!

Couplings should not be repaired; they should be replaced with original LUKAS

parts!

NOTE:

Always send the warranty tab back to LUKAS hydraulics GmbH.

You should always contact LUKAS or an authorised dealer before using outside

couplings.

Do not perform any repairs without the corresponding LUKAS spare parts list,

because necessary tightening torques for screw connections and/or in some

cases also important additional information are listed there.

Page 15

15

ATTENTION!

Clean the device before checking for dirt!

Do not use any aggressive agents for cleaning; it could cause damage to the

equipment.

Because LUKAS devices are designed for the highest performance, only

components may be replaced that are listed in the spare parts lists of the

corresponding device.

Additional components of the equipment may only be replaced if:

- You have participated in a corresponding LUKAS service training course.

- You have the express permission of LUKAS customer service (by request,

check on the grant of permission. A check is necessary in each individual

case).

The equipment is subject to very high mechanical stresses. Therefore, a visual inspection

needs to be made after each use, at least once per month (if continually used, once per

week).

In this way, early signs of wear are recognisable so that damage to the device can be

avoided by prompt replacement of these worn parts. Also check regularly to make sure that

all attachment screws are tightened (heed any applicable tightening torque specications).

At least once a year (if continually used once every half year) or if there is a doubt about

the safety or reliability, a functional check should be also performed (for this purpose, also

heed the corresponding applicable national and international specications related to the

maintenance intervals of the devices).

10.2 Maintenance

Before performing maintenance work, clean the hand pump thoroughly.

After performing the maintenance work, you should carefully coat all metallic parts with oil

to prevent any corrosion.

Checks (Maintenance measures):

Perform a visual inspection of the hand pump at least once per month; in the case of

continuous use, once a week.

Visual inspection

Hand pump

• are all hydraulic connections still tightened,

• generally sealed, no leaks present (oil "sweat" has no effect on the operation),

• is damage to pump housings, valve blocks or attachment parts recognisable, especially

on the moving parts such as the piston rods,

• are all uid levels within the prescribed tolerances,

• are all non-moving parts rmly attached,

• is there no corrosion,

• freedom of movement for the pump lever and the hand wheels

(check in the depressurised state),

• the couplings are easy to couple (if attached),

• are dust caps in place,

• are identication plate, all control decals, instruction decals, labels and warnings present

and legible.

Page 16

16

Perform an operational check of the hand pump at least once per year; in the case of

continuous use, once every half year.

Operational check

• no suspicious noises,

• tests at maximum load.

Execution:

Place the hand pump on a solid base to operate. Then, connect a test manometer to the

supply hose line. Release the pump lever lock and close the discharge valve. Then, the

pressurisation to operating pressure corresponding to the specication on the identication

plate occurs.

NOTE:

In this test, an idle time of approximately 2 minutes needs to be observed and

the hand pump needs to be reloaded to operating pressure.

The resulting max. operating pressure must not drop by more than 5% after

10 seconds.

A test pressure gauge is available from the LUKAS line of accessories.

10.3 Hydraulicuidchangeoraddinghydraulicuid

The hydraulic uid should be changed if dirty at least once a year. When the hand pump is

operated in an especially dusty environment, we recommend changing the uid at least once

every half year.

ATTENTION!

Add hydraulic uid only if the hand pump is disconnected from the lines or the

equipment operated with the pump is hydraulically depressurised. Otherwise,

after lling the entire hydraulic system could contain more hydraulic uid than

the tank can hold.

Procedure:

1. Open the bleed/ll cap on the tank.

2. Add hydraulic uid until the uid level comes up to 1-2 cm below the top edge of the oil

tank.

3. Bleed the hand pump as described in the chapter "bleeding the pump".

4. Check the uid level again and close the tank again at the correct uid level with the

vent/ll cap on the tank. Should the tank no longer be sufciently full after bleeding, start

the ll procedure again at item 2.

NOTE:

Should the uid level in the tank still not be reached after repeated relling (during

maintenance), we recommend searching for leaks in the hydraulic system.

10.4 Care

If possible, do not store the hand pump in a damp or extremely dusty environment in order

to ensure a long service life. If this is unavoidable, you should perform more frequent

maintenance and/or shield the pump from these effects if possible.

Regularly coat all metal parts with oil to prevent any corrosion.

Page 17

17

10.5 Repair

ATTENTION!

Because LUKAS devices are designed for the highest performance, only

components may be replaced that are listed in the spare parts lists of the

corresponding device and whose replacement is described here.

Additional components of the equipment may only be replaced if:

- You have participated in a corresponding LUKAS service training course.

- You have the express permission of LUKAS customer service (by request,

check on the grant of permission. A check is necessary in each

individual case).

10.5.1 Base plate replacement

The base plate must be replaced if external damage is present that represents a danger for

user and device upon further use. In particular, the base plate must be replaced if the stability

of the hand pump can no longer be ensured.

Procedure:

1. Remove screws A and B.

C

A

2. Remove base plate C and replace it with a new one.

3. Reinsert screws A and B and tighten.

B

10.5.2 Removing tank for cleaning, replacing the tank or the seals

The tank should be cleaned at least once per year in order to remove the accumulated dirt.

The tank must be replaced if there is any external damage that impairs the safety of

the device.

The tank seals must be replaced if there are any leaks at the junction points of the tank.

Procedure:

1. Remove base plate as described in the chapter "Replacing

base plate".

2. Empty tank by removing the screw plug (item D) and emptying

the tank.

ATTENTION!

Properly dispose of the removed hydraulic uid and all

damaged components!

D

Page 18

18

3. Remove the nut (item E) and sealing ring situated under it (item F).

4. Remove base plate (item G) and the sealing ring (item H).

5. Remove tank and the seal (item J) as well as the connection plate (item K) and seal

(item L).

6. The assembly is done in reverse order. Replace all damaged parts with new ones.

The tightening torque of the nuts is 40 Nm.

E F G H Tank J K L

10.5.3 Lever replacement

The lever must be replaced if external damage is present that represents a danger for user

and device upon further use.

Procedure:

1. Drive out dowel pin (item M).

N

M

2. Remove lever (item N) and replace with a new one.

3. Reinsert dowel pin (item M).

10.5.4 Couplings

WARNING / CAUTION / ATTENTION!

Couplings should not be repaired; they should be replaced with original LUKAS

parts!

10.5.4.1 Monocouplings

The monocouplings must be replaced if:

- exterior damage is present,

- the lock does not function,

- in the coupled and/or decoupled state, hydraulic uid continuously escapes.

Page 19

19

Procedure for installation in the valve block:

1. Unscrew coupling from connection plate.

2. Screw new coupling into the connection plate with a torque of M

= 40 Nm.

A

10.5.4.2 Quick-disconnect-couplings

The quick-disconnect-couplings should be replaced if:

- exterior damage is present,

- the lock does not function,

- in the coupled and/or decoupled state, hydraulic uid continuously escapes.

Procedure:

1. Unscrew and remove coupling.

2. Screw in new screw-on male coupling and tighten with a torque of M

= 35 Nm.

A

ATTENTION!

The return port must always be equipped with a female quick-disconnect-coupling.

The supply port should instead be equipped with a male quick-disconnect-coupling.

10.5.5 Decals

All damaged and/or illegible decals (safety instructions, identication plate, etc.)

must be replaced.

Procedure:

1. Remove damaged and/or illegible decals.

2. Clean surfaces with acetone or industrial alcohol.

3. Adhere new decals.

Make sure to adhere the decals in the correct positions. If this is no longer known, you should

consult your authorised LUKAS dealer or contact LUKAS directly.

Page 20

20

Problem Cause Remedy

Connected device

does not move, moves

only slowly or moves

intermittently.

Connected device moves,

but does not hold pressure

or does not render the

specied performance.

Troubleshooting11.

Fluid level in the hydraulic

tank too low

Discharge valve open Close discharge valve.

Hose line not properly

connected or damaged

Load on the device

too high

Air in the hydraulic system Bleed system as described

Defect on the device Heed the specications

Hose line not properly

connected or damaged

Leaking seal Locate the leak and have

Internal leakage of the

pump

Add hydraulic uid up to

max. ll level.

Check connection of the

hose line and reconnect it

if necessary.

Use a different device.

in the chapter “Bleeding

the pump”.

of the separate operating

instructions of the

device.

Check connection of the

hose line and reconnect it

if necessary.

the hand pump serviced by

an authorised dealer, by

personnel specially trained

by LUKAS or by LUKAS

directly.

Have the hand pump

serviced by an authorised

dealer, by personnel

specially trained by LUKAS

or by LUKAS directly.

Page 21

21

Problem Cause Remedy

Device does not move

back into the starting

position, moves

incompletely back toward

the starting position or

moves more slowly into

the starting position than

normal.

Connected device not

reaching its limit position

Connected rescue device

does not achieve its

power-related performance

data

Fluid leaks on the

hydraulic uid tank

(especially at the rell tap)

Hydraulic uid with milky

cloudiness

Discharge valve closed Open discharge valve.

Fluid level in the hydraulic

tank too high

Loose hydraulic coupling Check all couplings and

Enclosed air in the system Bleed pump as described

Line length too long Use shorter lines.

Defect on the device Heed the specications

Fluid level in the hydraulic

tank too low

Usable hydraulic uid

quantity of the pump is

insufcient

Max. permissible operating

pressure of the pump is

not reached

Due to return ow of the

hydraulic uid from the

device, the maximum ll

quantity of the tank is

exceeded

Seals defective Replace seal.

Water or condensation

water in the system

Reduce hydraulic uid

down to max. ll level.

retighten them.

in the chapter “Bleeding

the pump”.

Use hydraulic uid with

a different, more suitable

viscosity.

of the separate operating

instructions of the

device.

Add hydraulic uid up to

max. ll level.

Attention: move the

device back into the

base position before

adding uid!

Use a different device with

a usable quantity below

the maximum usable

quantity of the pump.

Replace pressure

control valve or have

it recalibrated by an

authorised dealer or

directly by LUKAS.

Reduce hydraulic uid

down to max. ll level.

Perform hydraulic uid

change immediately.

Page 22

22

Problem Cause Remedy

In the case of a

monocoupling system:

Hose lines cannot be

coupled

In the case of a

monocoupling system:

Hose lines frequently

cannot be coupled

In the case of a quickdisconnect coupling

system: Hose lines cannot

be coupled

In the case of a

monocoupling system:

Leakage at the couplings

In the case of a quickdisconnect coupling

system: Leakage on the

male coupling

In the case of a quickdisconnect coupling

system: Leakage at the

female coupling

Hydraulic uid escaping

from the hoses or at the

joints

Damage on the surface of

the hydraulic hoses

They are under excessive

pressure (e.g. due to

excessive ambient

temperature)

Coupling defective Coupling should be

Hydraulic uid of the

application situation not

adapted

Coupling defective Coupling should be

System is under pressure Open discharge valve and

Coupling defective Coupling should be

Coupling defective Coupling should be

Safety valve has

responded (in the

decoupled state)

Male coupling defective Male coupling should be

Female coupling defective Female coupling should be

Leakage, possible damage Replace hoses.

Mechanical damage or

contact with aggressive

media

Open discharge valve and

bleed device.

replaced immediately.

Hydraulic uid needs

to be changed (see the

chapter “Hydraulic uid

recommendation” for more

information).

replaced immediately.

bleed device.

replaced immediately.

replaced immediately.

After depressurisation, no

further leakage occurs.

replaced immediately.

replaced immediately.

Replace hoses.

If the defects cannot be remedied, notify an authorised LUKAS dealer or contact LUKAS

Customer Service directly!

The address of LUKAS customer service is:

LUKAS

Weinstraße 39, D-91058 Erlangen

Postfach 2560, D-91013 Erlangen

Phone: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

Page 23

23

Technical data12.

Because all values are subject to tolerances, there cannot be any differences between the

data of your device and the data of the following tables!

12.1 Data of the hand pumps

12.1.1 Pump labelling

LH 2 / 1.8 - 50

Model series

NOTE:

The automatic pressure switch from low pressure to high pressure occurs at

2 MPa (= 20 bar)

12.1.2 Dimensions, weight, usable quantity and ll quantity

NOTE:

The dimensions of the hand pumps are exclusively dependent on the size of the

hydraulic uid tank. The types of hand pumps are not outwardly distinguishable

from the outside at the pump head.

The weights, usable quantities and ll quantities of the hand pumps are

exclusively dependent on the size of the hydraulic uid tank.

Hand pump with ttings:

Tank size max. operating

pressure in MPa

(1 MPa = 10 bar)

Tank size Dimensions Weight min. required

l x w x h

1,8 [l]

3,8 [l]

Hand pump with monocouplings:

660 x 200 x 160 [mm] 7 [kg] 2,38 [l]

25.98 x 7.87 x 6.30 [in.] 15.4 [lbs.] 0.63 [gal.-US]

676 x 200 x 160 [mm] 11,3 [kg] 4,61 [l]

26.61 x 7.87 x 6.30 [in.] 24.9 [lbs.] 1.22 [gal.-US]

(incl. max. hydraulic

uid ll level)

Fill quantity

Tank size Dimensions Weight min. required

(incl. max. hydraulic

uid ll level)

Fill quantity

1,8 [l]

3,8 [l]

l x w x h

761 x 200 x 160 [mm] 7,5 [kg] 2,38 [l]

29.96 x 7.87 x 6.30 [in.] 16.5 [lbs.] 0.63 [gal.-US]

777 x 200 x 160 [mm] 11,8 [kg] 4,61 [l]

30.59 x 7.87 x 6.30 [in.] 26.0 [lbs.] 1.22 [gal.-US]

Page 24

24

Hand pump with quick-disconnect-couplings:

Tank size Dimensions Weight min. required

(incl. max. hydraulic

uid ll level)

Fill quantity

1,8 [l]

3,8 [l]

12.1.4 Flow rates

28.96 x 7.87 x 6.30 [in.] 16.1 [lbs.] 0.63 [gal.-US]

29.13 x 7.87 x 6.30 [in.] 25.6 [lbs.] 1.22 [gal.-US]

NOTE:

The ow output per piston stroke of the hand pumps depend exclusively on the

model series.

l x w x h

724 x 200 x 160 [mm] 7,3 [kg] 2,38 [l]

740 x 200 x 160 [mm] 11,6 [kg] 4,61 [l]

Model series

LH 2

Flow output per piston

stroke (low pressure)

17 [cm³] 1,7 [cm³]

0.85 [Cubic in.] 0.10 [Cubic in.]

Flow output per piston

stroke (high pressure)

12.2 Hydraulicuidrecommendation

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil code Viscosity rating Remarks

A -20 .... +55°C HM 10 VG 10

Oil temperature range Oil code Viscosity rating Remarks

A -4.0 .... +131°F HM 10 VG 10

recommended viscosity range: 10...200 mm²/s (10…200 cSt.)

Supplied with HM 10 DIN ISO 6743-4.

ATTENTION!

Before using hydraulic uids that do not correspond to the aforementioned

specications and / or are not purchased from LUKAS, you must contact

LUKAS!

Page 25

25

12.3 Hose lines

Bending radius Rmin = 38 mm (Rmin = 1.5 in.)

Pressure resistance

Temperature resistance - 40°C ... + 100°C (- 40°F … + 212°F)

Operatinguid Mineral oil according to DIN EN ISO 6743-4

Safety factor: Burst pressure / max. Operating pressure, min.

4 : 1

12.4 Operating and storage temperature ranges

Operating temperature [°C] / [°F] -20 … +55 -4 … +131

Ambient temperature

(device in operation)

Storage temperature

(device not in operation)

[°C] / [°F] -25 … +45 -13 … +113

[°C] / [°F] -30 … +60 -22 … +140

Page 26

26

Notes13.

Page 27

27

Page 28

Please properly dispose of all packing

materials and removed parts.

LUKAS

Weinstraße 39, D-91058 Erlangen

Postfach 2560, D-91013 Erlangen

Phone: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

Hydraulik GmbH

Made in GERMANY

© Copyright 2008 LUKAS Hydraulik GmbHLH2_RG_BA_GB_1790101085_1208.indd

Subject to modications

Loading...

Loading...