Page 1

Operating Instructions - Hydraulic tools

Hydraulic cylinder

(Translation of the original operating instructions)

83145000085 GB

Edition 08.2011

replaces 09.2008

Page 2

2

Page 3

Contents Page

1. Hazard classes 4

2. Product safety 5

3. Intended use 8

4. Equipment designation 9

5. Functions and performance 9

5.1 Description 9

5.2 Basic construction of the cylinder 10

5.3 Controlling the operating movements 11

5.4 Hydraulic supply 12

6. Connecting the equipment 13

6.1 Hydraulic connections 13

6.2 Coupling the screwed couplings 13

6.3 Coupling Quick-disconnect Couplings 14

7. Operation 15

7.1 Basic selection of cylinder size 15

7.2 Positioning 15

7.3 Commissioning 18

7.4 Hydraulic control of the cylinder 19

8. Dismantling the equipment / deactivation following operation 20

8.1 Hydraulic cylinder 20

8.2 Hydraulic unit 20

8.3 Hoses 20

9. Care and Maintenance 21

10. Repairs 22

10.1 General information 22

10.2 Preventive maintenance 22

10.3 Repairs 23

11. Troubleshooting 26

12. Technical data 29

12.1 Cylinder data 29

12.2 Hydraulicuidrecommendations 29

13. Notes 30

3

Page 4

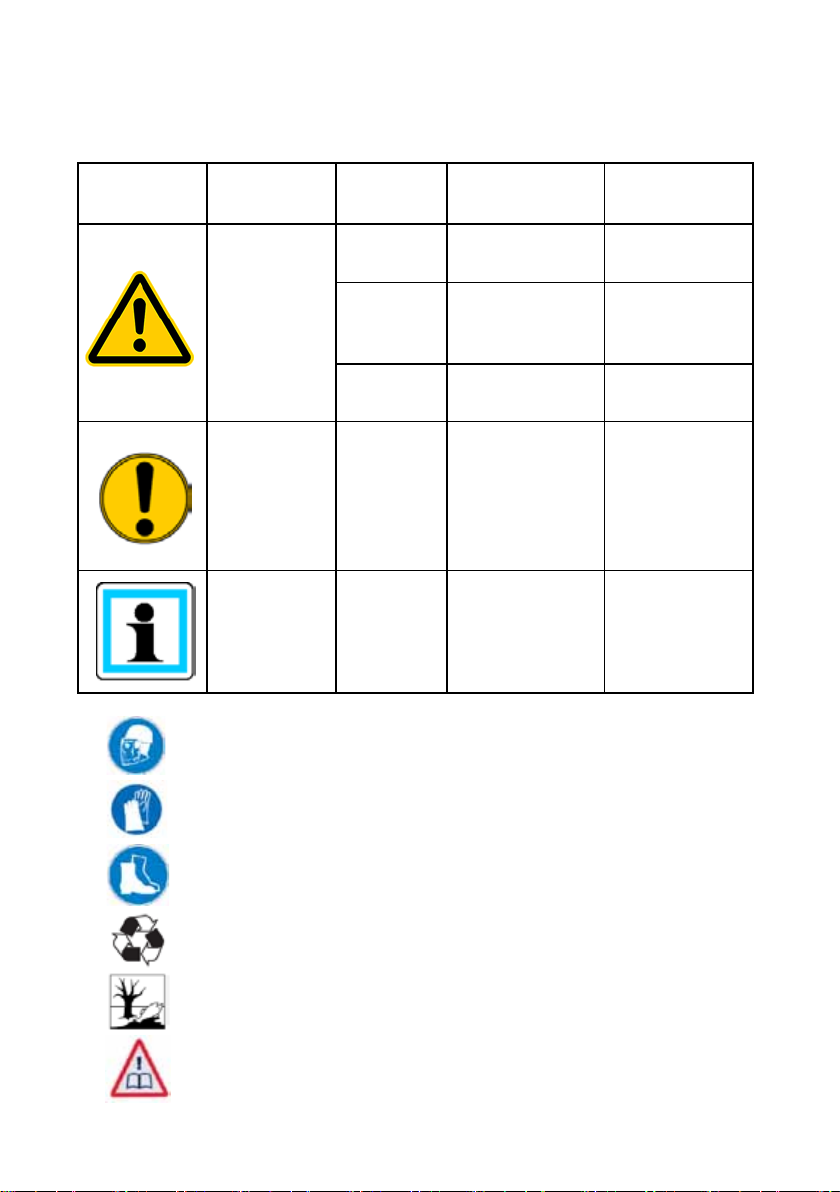

1. Hazard classes

We distinguish between various categories of safety instructions. The chart below provides

an overview, using symbols (pictograms) and signal words, of the specic danger and the

possible consequences.

Pictogram

Wear helmet with face protection

Damage /

injury to

human

device

- NOTE

Key word Denition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

CAUTION!

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to device /

environment

Advice for

application and

other important /

useful information

and advice

Death or major

injury

Potential death or

major injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surrounding

materials

No injury /

damage to

persons /

environment /

equipment

Wear protective gloves

Wear safety shoes

Proper recycling

Observe the principles of environmental protection

Read and observe the operating instructions

4

Page 5

2. Product safety

LUKAS products are developed and manufactured to ensure the best performance and

quality with intended use.

The safety of the operator is the most important consideration in the product design.

Furthermore, the operating instructions are intended to help in using LUKAS products safely.

In addition to the operating instructions, all generally applicable, statutory and other

binding rules for accident prevention and for environmental protection must be heeded and

disseminated.

The device may only be operated by appropriately educated, safety trained persons, since

otherwise there is a risk of injury.

We would like to point out to all users that they should read the operating instructions carefully

before using the equipment and comply with the instructions there without reservation.

We further recommend that a qualied instructor train you in the use of the product.

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

devices must also be heeded!

Even if you have already received instructions on how to use the equipment, you should still

read the following safety notes again.

WARNING / CAUTION!

Ensure that the accessories and connected equipment used are suitable for

the maximum operating pressure!

Please ensure that no body

parts or clothing are caught

between the visibly moving

parts (e.g. piston protection

plate and cylinder).

Wear protective clothing,

safety helmet with visor,

safety shoes and protective

gloves

The responsible department

must be informed immediately

of any changes (including to

the operating behaviour)! If

necessary, the device must

be deactivated immediately

and secured!

It is prohibited to work under

loads if the load is lifted

exclusively by hydraulic

equipment. If this work

is absolutely imperative,

additional mechanical

supports must be used.

Inspect the equipment before

and after use for visible

defects or damage

Check all lines, hoses and

screwed connections for

leaks and externally visible

damage. Rectify any damage

immediately. Squirting

hydraulic uid can result in

injuries and res.

5

Page 6

In the event of malfunctions,

immediately deactivate the

device and secure it. The

malfunction must be repaired

immediately.

Do not carry out any changes

(additions or conversions) to

the device without obtaining

the prior approval of LUKAS.

Observe all safety and danger

notes on the equipment and

in the operating instructions.

Any method of operation

which impairs safety and/or

stability of the equipment is

prohibited!

Safety devices must never be

deactivated!

Before the equipment is

switched on/started up, and

during its operation, it must

be ensured that nobody is

endangered by the operation

of the equipment.

When working close to live

components and cables,

suitable measures must

be taken to avoid current

transfers or high-voltage

ashovers to the equipment.

All safety instructions and

hazard warnings on the

device must be kept intact

and in a legible condition.

Comply with all specied

dates or dates specied in

the operating instructions

pertaining to regular checks /

inspections of the equipment.

The maximum permitted

operating pressure noted on

the equipment must not be

exceeded.

Only original LUKAS

accessories and spare parts

may be used for repairs.

Make sure that you do not

get caught in the hose loops

and trip when working with or

transporting the device.

Prevent electrostatic

discharge, which has the

possible consequence of

spark generation, when

handling the device.

6

Page 7

The device is lled with

hydraulic uid. These

hydraulic uids can be

harmful to your health if

swallowed or if their vapours

are inhaled. Direct contact

with the skin must be avoided

for the same reason. Please

note also that hydraulic uids

can have an adverse effect on

biological systems.

Ensure adequate lighting

when you are working.

When working with or storing

the equipment, ensure

that the function and the

safety of the equipment

are not impaired by the

effects of extreme external

temperatures and that the

equipment is not damaged in

any way. Please note that the

device can also heat up over

a long period of use.

Before transporting the

equipment, always ensure

that the accessories are

positioned such that they

cannot cause an accident.

Always keep these operating

instructions easily accessible

at the location where the

device is used.

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and

must be implemented in addition to the operating instructions.

Make sure you dispose of

all parts removed, oil and

uid residues and packaging

materials in a proper manner!

WARNING / CAUTION!

The equipment is to be used exclusively for the purpose stated in the operating

instructions (see chapter “Intended use”). Any other or further use is not considered

Intended use. The manufacturer / supplier is not liable for any damages resulting from not

intended use. The user bears sole responsibility for such.

Observance of the operating instructions and compliance with the inspection and maintenance

conditions are part of the Intended use.

Never work when you are overtired or intoxicated!

7

Page 8

3. Intended use

LUKAS hydraulic cylinders are designed specially for use in lifting and displacing work, use

in assembly and in service work.

In general, LUKAS hydraulic cylinders can be used to lift, push or relocate objects.

WARNING / CAUTION!

All objects which are to be moved must be secured using stable supports or

substructures. In addition, you have to make sure that the hydraulic cylinders

cannot slip.

CAUTION!

Pay strict attention to leaks in order to prevent threats to the environment.

Every time you use the equipment, make sure that the necessary accessories, such as the

piston protection plate etc., are used.

WARNING / CAUTION!

The following may not be crushed or damaged:

- live cables

- hardened parts such as steering columns and rollers

- Explosive objects, such as air bag cartridges and pressurised gas

cylinders

NEVER operate the hydraulic cylinders at a higher operating pressure than

shown on the identication plate. A higher setting may cause damage to property

and/or injuries.

Genuine spare parts, accessories for the equipment and suitable hydraulic uids can be

ordered from your authorised LUKAS dealer!

8

Page 9

4. Equipment designation

single-acting

cylinders:

double-acting

cylinders:

LFO 55 / 200 Z

HLMD 55 - 25 / 200 M

Cylinder range Cylinder type Stroke Connection

thread for

couplings

Coupling connection thread:

M = metric thread

Z = inch thread

5. Functions and performance

5.1 Description

LUKAS hydraulic cylinders can be either single or double acting. This can be seen in the

designation of the cylinder.

The movement of the piston when extending is carried out hydraulically for both cylinder

types. When retracting, only the double acting cylinders move under hydraulic force. On

single acting cylinders it takes place mechanically, e.g. by a release spring. Single acting

cylinders can also be equipped without release springs, and the retraction is actuated by the

lifted load which acts on the piston of the cylinder when the pressure is removed.

WARNING / CAUTION!

Please take care that single acting cylinders can move unexpectedly if the

pressure is removed and the line to the cylinder is not closed off!

The direction of movement is controlled by the application of pressure to the rod side of

the piston (only on double acting cylinders) or to the cylinder base side. The control of

the pressurisation must be effected by an external control unit (e.g. a control valve) and

a hydraulic aggregate connected to it. The use of a hand pump instead of the hydraulic

aggregate is also possible.

In general, all LUKAS double acting cylinders are equipped with an integrated safety valve on

the piston rod side. These safety valves protect the cylinder from damage caused by pressure

transmission. If the specied maximum pressure is exceed, the safety valves automatically

open and hydraulic oil (shielded) is ejected into the open air.

9

Page 10

LUKAS offers hydraulic cylinders in a wide variety of designs.

Depending on the type, the cylinders are made of different materials such as aluminium alloy, steel or stainless steel. The types of cylinder also vary by method of construction. They

are available as normal lifting cylinders, heavy duty, short stroke, locking and at cylinders.

Depending on the version, they can be used in a wide range of different applications.

If you have any doubts as to whether the cylinder you have selected is suitable for the

application in question, please consult LUKAS directly or one of the authorised LUKAS

dealers.

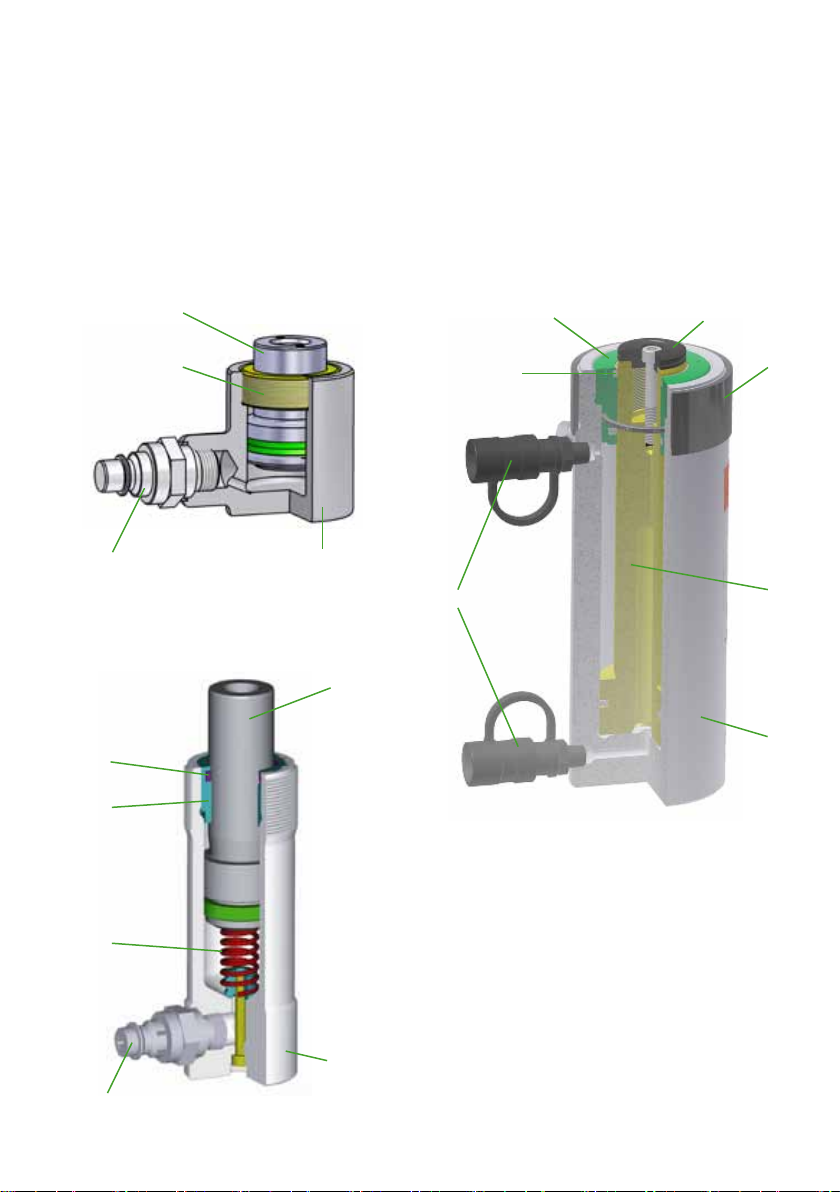

5.2 Basic construction of the cylinder

2

3

6

3

8

5

3

4

1

8

2

1 Cylinder body

2 Piston

3 Guiding ring

4 Piston return

5 Wiper

6 Piston protection plate

7 Thread protection ring

8 Connection coupling

1

(plug or screw coupling)

5

7

2

1

8

10

Page 11

5.3 Controlling the operating movements

5.3.1 Single acting hydraulic cylinders (with release spring)

The piston is extended by pressurising the connection (1) on the cylinder base

side (3). The piston retracts again using the release spring (2) as soon as the

pressure on the connection (1) is released and the pressure can dissipate

through the supply line (not closed off and not under pressure).

2

1

5.3.2 Single acting hydraulic cylinders (without release spring)

The piston is extended by pressurising the connection (4) on the cylinder base side (5).

After the pressure is released, the piston retracts solely as a result of the force of an external

load, provided the pressure can dissipate via the supply line (not closed off and not under

pressure).

4 4

5

2

1

3

11

Page 12

5.3.3 Double acting hydraulic cylinders

Pressurisation of the connection (6) on the cylinder base

side (7) causes the piston rod to extend and pressurisation

of the connection (8) on the piston rod side (9) causes the

piston rod to retract again.

9

9

8

6

8

6

7

5.4 Hydraulic supply

A LUKAS hydraulic unit or LUKAS hand pump may be used to drive the equipment.

If the pump unit is a different make, you must make sure that it complies with LUKAS

specications, otherwise potential dangers may arise which are not the responsibility

of LUKAS. Ensure in particular that the maximum permissible operating pressure for the

connected LUKAS equipment is not exceeded.

NOTE:

Before you use pumps from a different manufacturer, we recommend you

contact LUKAS or an authorised dealer. Otherwise LUKAS will accept no liability

for any damage caused.

The pump aggregate and the hydraulic cylinder are interconnected by hoses or pipework.

12

Page 13

6. Connecting the equipment

6.1 Hydraulic connections

On the side of the hydraulic cylinders are male Quick-disconnect connectors or female

screwed couplings; these are connected to the hydraulic source or control valve with

extension hoses or pipework.

Use LUKAS pairs of extension hoses which are generally colour-coded and fitted with

couplings so that they can be connected non-interchangeably.

WARNING / CAUTION!

Prior to connecting the devices, ensure that all the components

being used are suitable for the maximum operating pressure

of the pump unit. In case of doubt you must consult LUKAS

directly.

CAUTION!

Make sure that the connection on the cylinder base side is always connected

to the connection provided on the control valve for extending the cylinder,

and that the connection on the cylinder head (cylinder piston rod side) is

connected to the connection for retracting the cylinder.

6.2 Coupling the screwed couplings

The cylinder is connected to the hydraulic pump via screwed coupling halves (male and

female).

Remove the dust caps before coupling, then plug the male connector on the hose into

the female connector on the side of the cylinder. Finally screw the threaded sleeve on the

female connector onto the external thread on the male connector and tighten hand-tight.

The connection is now made.

Uncoupling is carried out in the reverse sequence. For dust protection, the supplied dust caps

must be reattached.

WARNING / CAUTION!

Coupling of the devices is only possible when the hoses are depressurised!

13

Page 14

CAUTION!

Always connect the hose to the connection on the cylinder head (cylinder

piston rod side) rst and then connect the hose to the connection on the base

of the cylinder!!

6.3 Coupling Quick-disconnect Couplings

The cylinder is connected to the hydraulic pump via Quick-disconnect coupling halves (male

and female).

X

Y

Before coupling, remove the dust caps then pull back and hold the locking sleeve on the

female half (position X). Plug the male and female halves together and release the locking

sleeve. Then turn the locking sleeve to position Y. The connection is now made and secured.

Uncoupling is carried out in the reverse sequence. Hoses can be connected only when

depressurised. For dust protection, the supplied dust caps must be reattached.

CAUTION!

Always connect the hose to the connection on the cylinder head (cylinder

piston rod side) rst and then connect the hose to the connection on the base

of the cylinder!!

NOTE:

Hoses can be connected only when depressurised.

For dust protection, the supplied dust caps must be reattached.

WARNING / CAUTION!

To some extent the quick-disconnect coupling have special functions and may

therefore not be unscrewed from the hydraulic lines and/or swapped!

14

Page 15

7. Operation

7.1 Basic selection of cylinder size

Before use, you should check that the lifting force of the cylinder(s) used is at least 25%

higher than the maximum loading expected in the least favourable case.

WARNING / CAUTION!

The load must NEVER exceed the lifting force of the cylinder!

We recommend that you select the stroke of the piston to leave a reserve stroke of approx.

30%. The system stability can thus be increased in marginal cases.

7.2 Positioning

CAUTION / PLEASE NOTE!

Prior to installing the cylinders, the load to be lifted must be secured against

slipping as prescribed in the respective applicable guidelines and regulations.

You must always observe the following when positioning the cylinder:

- Non-slip and at surface underneath, so that the entire cylinder base area is supported.

If there is any doubt about the load bearing capacity of the ground you should use suitable

plates made from wood or metal to increase the area of support.

WRONG RIGHT

CAUTION!

Hydraulic uids may produce a lubricating lm on the oor.

15

Page 16

- The ground must be a continuous surface (no gratings, gravel etc.)

- Never place cylinders on a yielding support

WARNING / CAUTION!

When using wooden packers, you should make sure that you use particularly

hard wood without any damage, so that splintering of the packer is not

possible. Additional strapping of other types of wood with metal straps is not

adequate!

- We recommend using the cylinders only with a piston protection plate to prevent damage

to the piston and to ensure safe application of the force. LUKAS accepts no liability for

damage which could have been prevented by the use of a piston protection plate!

Suitable piston protection plates for your application can be found in the LUKAS range of

accessories.

CAUTION!

Use an additional non-slip packer between the piston protection plate and

the load to be lifted because there may be a lm of lubricant on the point of

application of the load!

16

Page 17

- Please make sure that the load is applied centrally onto the piston rod.

NOTE:

Under certain circumstances it may be necessary to nd a more favourable

load application point!

Position the cylinder under the gravity center of the load, so that the load does not tip

over during lifting, thus causing danger to the operator or the cylinder itself. The load

must always be centrally located on the piston area. Side loading should be avoided!

Load

WRONG RIGHT

It is mostly not possible to allow the load to lie over the full face of the cylinder piston.

For this reason, we recommend using appropriate piston protection plates because

otherwise there may be damage caused to the piston rod and the cylinder. A bowed

piston protection plate or an equalisation plate re-distributes the load evenly on the

surface of the piston.

Load

WRONG

Load

Load

RIGHT

17

Page 18

When using several pistons at the same time, you should distribute the load as evenly

as possible over all the cylinders.

Load

share 1

Load share 1 < Load share 2

WRONG RIGHT

When using several pistons at the same time, you should lift the load as evenly as

possible using all the cylinders.

WRONG

Load

share 2

Load

share 1

Load share 1 = Load share 2

RIGHT

7.3 Commissioning

Load

share 2

WARNING / CAUTION!

Always keep a safe distance from the hydraulic cylinder when you pressurise it,

particularly when starting up after positioning the equipment!

CAUTION!

Always check, before each start-up, that the hydraulic connections are correctly

made and that they are functioning perfectly.

Incorrect connections or defective couplings can cause a safety valve to

respond (e.g. on double acting cylinders on the piston rod side or on hoses

with safety Quick-disconnect connectors on the male coupling!)

18

Page 19

7.3.1 Initial start-up

The equipment must be de-aerated before commissioning and following repairs.

- Connect the equipment to the hydraulic pump (see chapter “Connecting the equipment”).

- Extend and retract the equipment several times under no load.

NOTE:

We recommend that during the de-aeration, the unit connected for the hydraulic

supply should stand on a higher level than the cylinder.

The connections on the hydraulic cylinder should point upwards.

7.3.2 Checking the pump unit

See the separate operating instructions for the relevant aggregate (or the

handpump).

NOTE:

Before working on the pump aggregate or connecting/disconnecting hoses,

always make sure that the pump aggregate or electric pump is switched off and

disconnected from the electricity supply and that the control valves have been

set to depressurised recirculation.

7.4 Hydraulic control of the cylinder

The operation of the cylinder piston cannot be controlled directly by the cylinder.

The retraction and extension of the cylinder must be controlled by a separate control unit or

by the connected hydraulic unit.

19

Page 20

8. Dismantling the equipment / deactivation following

operation

WARNING / CAUTION!

Before dismantling the used equipment, you must ensure that the load being

moved is in a stable, non-slip location!

8.1 Hydraulic cylinder

After the work is completed the hydraulic cylinders should be retracted to leave just a few

*)

mm

protrusion (up to the end position on single acting cylinders). This relieves the hydraulic

and mechanical strain on the device.

NOTE:

When hydraulic cylinders are in storage, uctuations in ambient temperature can

cause the pistons to move slightly. This phenomenon is due to the difference in

the expansion of the hydraulic uid on the piston side and the rod side.

8.2 Hydraulic unit

Upon completion of work, the unit must be deactivated.

8.3 Hoses

Uncoupling is carried out in the reverse order, as described in Chapter “Connecting the

Equipment”.

Ensure that you replace the dust protection caps on the Quick-disconnect coupling halves.

*)

1 mm = 0.04 in.

20

Page 21

9. Care and Maintenance

A visual inspection must be carried out after every use; however, at least one visual inspection

must be carried out every year. Every three years or if there is any doubt regarding the safety

or reliability of the equipment, a functional test must also be performed. (Please also observe

the relevant valid national and international regulations pertaining to service intervals of

hydraulic equipment).

CAUTION!

Clean off any dirt before checking the equipment!

WARNING / CAUTION!

To perform maintenance and repairs, workshop and personal safety equipment

appropriate for the work is an absolute requirement

Inspections to be carried out:

Visual inspection

• Cylinder and piston rod undamaged and not deformed,

• Connections without damage or deformation

• General tightness (no leaks)

• All screwed connections tight

• Couplings present and tightened,

• Couplings easy to couple,

• Dust protection caps available

• Type plate, warning notices and other markings present and legible

• All used accessories undamaged

Functional test

• Piston can be retracted and extended over the full length of the stroke (see Chapter

“Technical Data”).

• Easy and smooth extension and retraction when pressurized.

• No suspicious noises when operating.

21

Page 22

10. Repairs

10.1 General information

Service work may only be performed by the device manufacturer or by personnel trained by

the device manufacturer and authorised LUKAS dealers.

Only LUKAS spare parts may be used to replace all components (see spare parts list) since

special tools, assembly instructions, safety aspects, inspections will have to be taken into

account (see also chapter „Maintenance and service”).

During assembly work, pay particular attention to the cleanliness of all components

because dirt can damage the equipment!

WARNING / CAUTION!

Protective clothing must be worn when repairs are being carried out, since the

units can also be pressurised when in an idle state.

NOTE:

Before you use couplings from a different company, you must always contact

LUKAS or an authorized dealer.

Do not perform any repairs without the corresponding LUKAS spare parts list,

because necessary tightening torques for screw connections and/or in some

cases also important additional information are listed there.

CAUTION!

Since LUKAS hydraulic cylinders are designed for top performance, only those

components in the spare parts lists for the relevant unit may be replaced.

Other components on the cylinders may only be replaced if:

- you have taken part in appropriate LUKAS service training,

- you have the explicit permission of the LUKAS Service department (After

request, check for the granting of permission. A check is necessary in each

individual case).

When cleaning the equipment, take care not to use any cleaning agent that has

a pH value outside the range 5 - 8!

The address of LUKAS Customer Service can be found in the Chapter “Fault Analysis”.

Genuine spare parts, accessories for the equipment and suitable hydraulic uids can be

ordered from your authorised LUKAS dealer!

10.2 Preventive maintenance

10.2.1 Care instructions

The exterior of the equipment must be cleaned from time to time in order to protect it from

external corrosion. A suitable agent must be applied to the metallic surfaces.

(In case of doubt, contact your authorised LUKAS dealer or LUKAS directly!)

22

Page 23

10.2.2 Function and load test

Perform a stress test if there is doubt about safety or reliability.

10.2.3 Replacingthehydraulicuid

- After approx. 200 deployments, but after three years at the latest, replace the hydraulic uid

CAUTION!

Always carry out the hydraulic uid change using a uid collection vessel and

dispose of the uid collected in a proper manner!

CAUTION!

The hydraulic uid must be completely replaced if the deployment

conditions (ambient temperatures) change considerably. When selecting the

appropriate hydraulic uid, please bear in mind the Chapter “Hydraulic Fluid

Recommendations”.

Procedure:

1. Retract the cylinder completely and depressurise the hydraulic system.

2. Remove the couplings from the cylinder.

3. Allow the hydraulic uid to run out

4. Flush

5. Ret the couplings

6. Connect the pump with new hydraulic uid.

7. Bleed as described in chapter “Initial Commissioning”.

8. Disconnect the pump again.

10.3 Repairs

10.3.1 Changing the seals

The seals must be replaced in the event of:

- Leaks,

- Externally visible damage (e.g. on the wiper),

WARNING / CAUTION!

Work on the internals of the cylinder, e.g. changing the seals, must only be

carried out by trained experts!

All parts must be replaced by genuine LUKAS parts!

NOTE:

Changing the seals is similar on all types of cylinder.

However, there are differences resulting from the type of cylinder and the size.

For this reason, it is absolutely imperative that you always have the appropriate

spare parts list for your cylinder to hand when carrying out a repair. All instructions

on the spare parts list must be taken into account as well as these operating

instructions!

23

Page 24

Procedure:

1. First, fully retract the cylinder and switch the hydraulic system to depressurised.

2. Then, on double acting cylinders, extend them by approx. 10 mm, without load.

This hydraulically depressurises them.

3. Uncouple the hydraulic pump.

4. Place the cylinder in a suitable vessel or on a suitable substrate to collect the hydraulic

uid that comes out.

5. Remove all attachments such as piston protection plates (if tted).

6. Now you will have to remove the couplings.

7. Release the guiding ring on the cylinder head.

WARNING / CAUTION!

With single acting cylinders with release spring please note that the

spring may remain under tension and take the appropriate precautionary

measures.

8. Pull the guiding ring from the piston rod.

24

Page 25

9. You can now remove the seals from the guiding ring using a suitable tool.

CAUTION!

Do not damage the guiding ring when removing the seals!

10. Carefully pull the piston out of the cylinder body!

On single acting cylinders with release spring, you must rst separate the release spring

from the cylinder body. This normally carried out by removing the xing screw and the

sealing ring. On single acting cylinders, the release spring is equipped with such a xing

screw on the bottom of the cylinder body and on the cylinder head. You should remove

the screw on the cylinder body bottom rst.

CAUTION!

Make sure that you do not tilt the piston when pulling it out! That could cause

damage to the piston and the cylinder body!

11. Now you can remove the seals from the piston using a suitable tool.

12. The assembly is carried out in reverse order.

NOTE:

During assembly, brush the seals with LUKAS special grease. This simplies

the assembly of the seals and increases the operating life!

13. The cylinder must then be deaerated!

25

Page 26

10.3.2 Couplings

The couplings must be replaced if:

- there is external damage

- the locking mechanism does not work

- hydraulic uid continues to leak in the coupled/uncoupled state.

WARNING / CAUTION!

Never repair couplings: they must be replaced by original LUKAS parts!

During assembly, tighten the coupling to the torque that is quoted in the relevant spare parts

list for the cylinder.

Procedure:

1. Remove the coupling.

2. Position the new coupling and tighten to the torque quoted in the relevant spare parts list

of the cylinder.

10.3.3 Labels

All damaged and/or illegible labels (safety notices, type plate etc.) must be replaced.

Procedure:

1. Remove damaged and/or illegible labels.

2. Clean surfaces with industrial alcohol.

3. Attach new labels.

Ensure that you attach the labels in the right position. If this is no longer known, you should

ask your authorised LUKAS dealer or contact LUKAS directly.

11. Troubleshooting

Trouble Check Cause Solution

Cylinder piston

moves slowly or

jerkily when activated

Are the hoses

connected

properly?

Does the pump

unit work?

Air in the hydraulic

system

Cylinder defective Remove the cylinder

26

De-aerate pump

system

from service and

have it repaired or

repair it

Page 27

Trouble Check Cause Solution

Piston on cylinder

(with Quickdisconnect coupling

system) does not

retract

Device does not

apply the specied

force

Hose assembly

cannot be coupled

Hydraulic uid leak

on the hoses or the

connections

Damage to the

surface of the

hydraulic hoses

Hydraulic uid leaks

on the piston rod

Hydraulic uid

level in the

supplying pump?

Check the

operating pressure

of the driving

hydraulic unit

Are the hoses

defective?

Quick stop

function on

cylinder effective

Cylinder defective Remove the cylinder

Insufcient

hydraulic uid in

the pump

Pressure of supply

too low

Cylinder defective Remove the cylinder

Pressurised Set hydraulic pump

Coupling defective Coupling needs to be

Leakage, possible

damage

Mechanical

damage or contact

with aggressive

agents

Defective rod seal Repair of fault by

Damage to the

piston

Extend the cylinder

piston a short

distance and then

retract the cylinder

piston slowly.

from service and

have it repaired or

repair it

Top up hydraulic uid,

de-aerate

If possible, increase

the max. operating

pressure on the

hydraulic unit to

the max. operating

pressure of the

cylinder or use a

different hydraulic

unit with adequate

max. operating

pressure.

from service and

have it repaired or

repair it

to pressureless

circulation

replaced immediately

Replace hoses.

Replace hoses.

authorised dealer,

specially trained

LUKAS staff or

directly by LUKAS

27

Page 28

Trouble Check Cause Solution

Hydraulic uid

coming out of overpressure valve

Increased load?

(only when pulling)

Load increase

(e.g. something

has fallen onto the

part to be pulled,

thereby suddenly

increasing the

load)

Secure the loads and

move them by using

other tools

Apply the cylinder at

another point where

the load to be moved

is lighter

Use supporting

equipment to move

the load.

Coupling on the

cylinder piston

side correctly

coupled or

defective?

Leak in the couplings Is the coupling

If it isn’t possible to rectify the malfunctions, inform an authorised LUKAS dealer or the

LUKAS customer service department immediately!

The address of the LUKAS Customer Service Department is:

LUKAS

Weinstrasse 39, D-91058 Erlangen

Germany

Phone: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

e-mail: lukas.info@idexcorp.com

Hydraulik GmbH

damaged?

Coupling on the

cylinder piston

side not coupled

or coupled

incorrectly

Coupling on the

cylinder piston

side defective

Coupling defective Coupling must be

Reconnect the

coupling

Coupling must be

replaced immediately

replaced immediately

28

Page 29

12. Technical data

12.1 Cylinder data

NOTE:

The technical data for your cylinder can be found on the provided, separate

datasheet. This datasheet also includes the CE declaration.

12.2 Hydraulicuidrecommendations

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil code Viscosity rating Remarks

A -24 .... +30°C HL 5 VG 5

B -18 .... +50°C HM 10 VG 10

C -8 .... +75°C HM 22 VG 22

D +5 .... +80°C HM 32 VG 32

E -8 .... +70°C HF-E15 VG 15 Bio-oil

Oil temperature range Oil code Viscosity rating Remarks

A -11.2 .... +86°F HL 5 VG 5

B -0.4 .... +122°F HM 10 VG 10

C +17.6 .... +167°F HM 22 VG 22

D +41.0 .... +176°F HM 32 VG 32

E +17.6 .... +158°F HF-E15 VG 15 Bio-oil

recommended viscosity range: 10...200 mm²/s (10…200 cSt.)

Supplied with HM 10 DIN ISO 6743-4.

NOTE:

The hydraulic uids listed here are the standard oils which could be used for

your LUKAS cylinder.

Special cylinders may be designed to use different special hydraulic uids.

Details of these uids can be found on the separate datasheet for your cylinder.

TheuseofdifferenthydraulicuidstooperateyourLUKAScylindersispossible

but will need approval by LUKAS directly in each particular case!

29

Page 30

13. Notes

30

Page 31

31

Page 32

Please dispose all packaging materials and

dismantled parts properly.

LUKAS

A unit of the IDEX Corporation

Hydraulik GmbH

Weinstrasse 39, D-91058 Erlangen

Germany

Phone: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

www.lukas.com

Made in GERMANY

© Copyright 2011 LUKAS Hydraulik GmbHZylinder_BA_GB_83145000085_0811.indd

Subject to revision

Loading...

Loading...