Instruction Manual Rerailing Equipment

90000085 EN

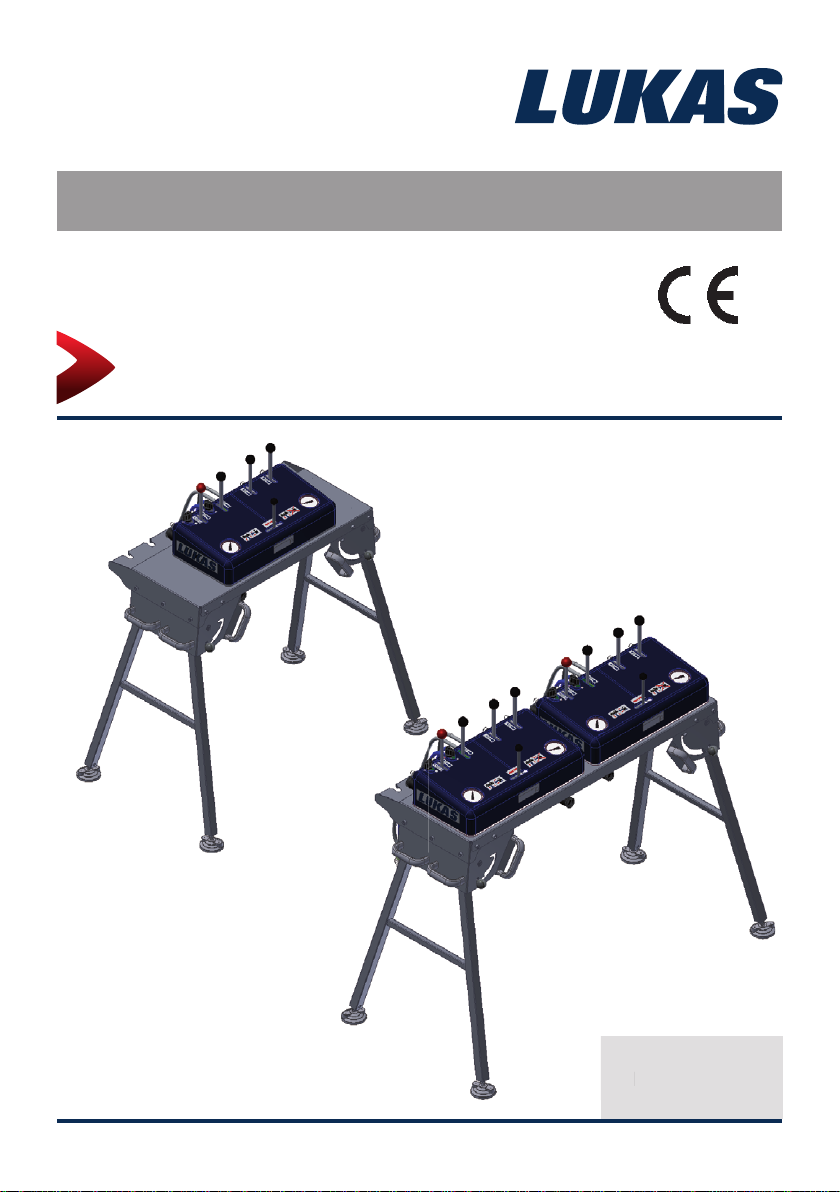

Control tables CU 2DV and CU 4DVV

CU 2DV

CU 4DVV

(Translation of the original instruction manual)

1490000085 EN

14

Edition 09.2014

Edition 09.2014

2

Content Page

1. Danger classifi cations 4

2. Product safety 5

3. Proper use 8

4. Components and functions 9

4.1 Description 9

4.2 Hydraulic supply 9

4.3 Installation of the control table 10

4.4 Functions and controls available at the control desk 11

5. Erection and start-up 13

5.1 Folding out the support frame 14

5.2 Connection of the working equipment 15

5.3 Coupling the quick-disconnect couplings 15

6. Dismantling the equipment / deactivation following operation 16

7. Maintenance and service 17

7.1 General information 17

7.2 Repairs 18

8. Troubleshooting 19

9. Technical data 21

9.1 Control unit CU 2DV 21

9.2 Control unit CU 4 DVV 22

9.3 Operating and storage temperature ranges 22

10. EC Declaration of Conformity 23

11. Notes 24

3

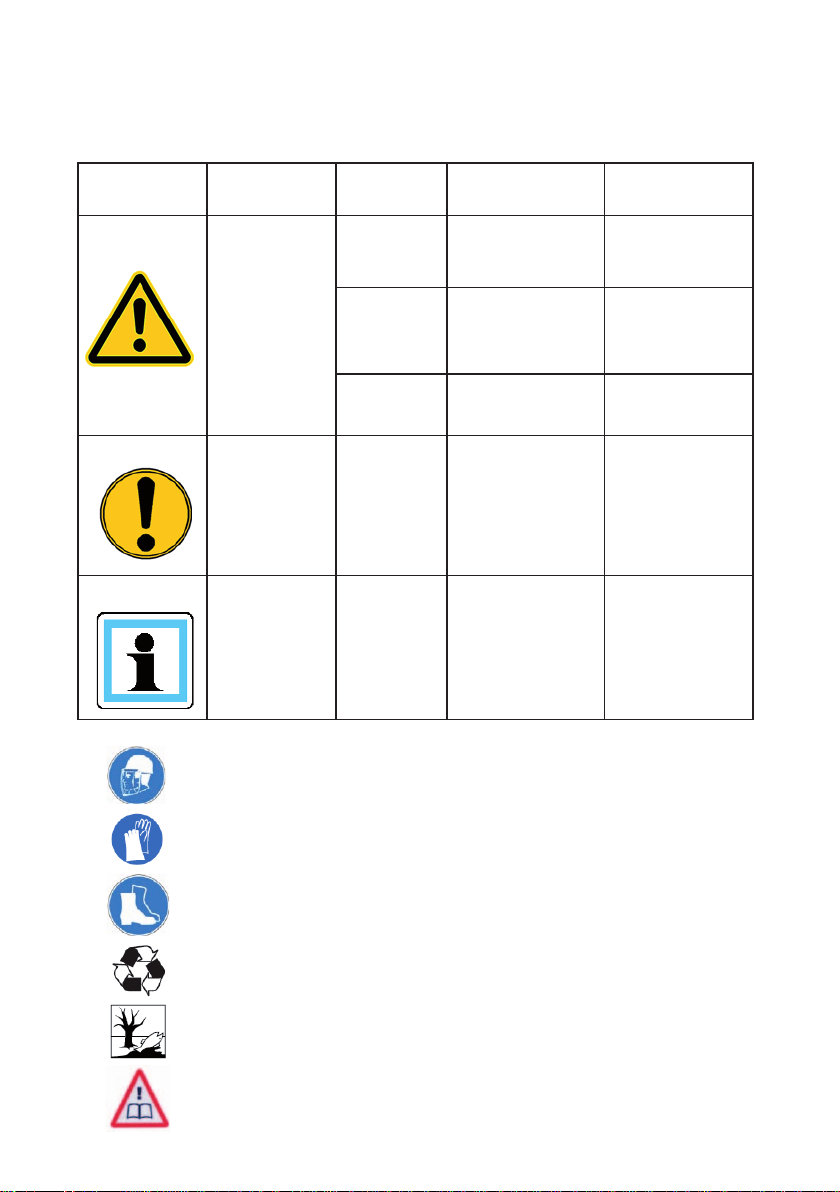

1. Danger classifi cations

We differentiate between various different categories of safety instructions. The table shown

below provides an overview of the assignment of symbols (pictograms) and signal words to

the specifi c danger and the possible consequences.

Pictogram

Damage /

injury to

Persons

Property

- NOTE

Key word Defi nition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

ATTENTION!

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to property/

environment

Handling tips and

other important/

useful information

and advice

Death or severe

injury

Potential death or

serious injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surroundings

No injury/damage

to persons/

environment/

device

Wear a helmet with a face guard

Wear protective gloves

Wear safety shoes

Proper recycling

Protect the environment

Read and follow the operating instructions

4

2. Product safety

LUKAS products are developed and manufactured to ensure the best performance and

quality when used as intended.

The safety of the operator is the most important consideration in product design. Furthermore,

the operating instructions are intended to help in using LUKAS products safely.

The generally applicable legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be complied with in addition to

the operating instructions.

The equipment must only be operated by persons with appropriate training in the safety

aspects of such equipment – otherwise, there is a danger of injury.

We would like to point out to all users that they should read carefully the operating instructions

and the instructions contained therein before they use the equipment, and that they should

carefully follow such.

We also recommend that you have a qualifi ed trainer show you how to use the product.

WARNING / CAUTION!

You must also observe the operating instructions for the hoses, the

accessories and the connected devices!

Even if you have already received instruction on how to use the equipment, you should still

read through the following safety instructions again.

WARNING / CAUTION!

Ensure that the accessories and connected equipment are suitable for the

maximum operating pressure!

Please ensure that no body

parts or clothing get stuck

between the visibly moving

parts.

Wear protective clothing,

a safety helmet with visor,

protective footwear and gloves

Immediately report any

changes that occur (including

changes in operating

behaviour) to the appropriate

persons/departments! If

necessary, the equipment is to

be shut down immediately and

secured!

Working under suspended

loads is not permitted where

such loads are being lifted

only using hydraulic devices.

If working under suspended

loads is unavoidable, suitable

mechanical props are also

required.

Inspect the device before and

after use for visible defects or

damage.

Check all lines, hoses and

screwed connections for leaks

and externally visible damage,

and repair immediately!

Escaping hydraulic fl uid can

cause injuries and fi res.

5

In the event of malfunctions,

immediately deactivate the

equipment and secure it.

Repair the fault immediately.

Do not carry out any changes

(additions or conversions)

to the equipment without

obtaining the approval of

LUKAS beforehand.

Observe all safety and danger

information on the device and

in the operating instructions.

Any mode of operation which

compromises the safety and/

or stability of the device is

forbidden!

Safety devices must never be

disabled!

Make sure before switching

on/starting up the device and

during its operation, that this

will put no one in danger.

When working close to live

components and cables,

suitable measures must be

taken to avoid current transfers

or high-voltage transfers to the

equipment.

All safety and danger

instructions on the device must

always be complete and in a

legible condition

Observe all intervals for

recurring tests and/or

inspections that are prescribed

or stated in the operating

instructions.

The maximum permitted

operating pressure noted on

the equipment must not be

exceeded.

Only genuine LUKAS

accessories and spare parts

are to be used for repairs.

Please ensure that, when

working with this equipment or

during transportation of such,

you don’t get caught up in the

looped hoses and trip.

The build-up of static charge

and therefore possible

sparking must be avoided

when handling the device.

6

The equipment is fi lled with

hydraulic fl uid. This hydraulic

fl uid can be detrimental to

health if it is swallowed or

its vapour is inhaled. Direct

contact with the skin must be

avoided for the same reason.

Also, when handling hydraulic

fl uid, note that it can negatively

affect biological systems.

When working with or storing

the equipment, ensure that the

function and the safety of the

equipment are not impaired

by the effects of severe

external temperatures or that

the equipment is damaged in

any way. Please note that the

equipment can also heat up

over a long period of use.

Make sure there is adequate

lighting while working.

Always keep these operating

instructions easily accessible

at the place of operation.

In addition to the safety instructions in this operating manual, all generally applicable,

statutory and otherwise binding national and international regulations for accident prevention

must be heeded and disseminated!

Before transporting the

equipment, always ensure that

the accessories are positioned

in such a way that they cannot

cause an accident.

Dispose properly of all

disassembled parts, oil and

left-over fl uid, as well as

packaging materials.

WARNING / CAUTION / ATTENTION!

The device is intended exclusively for the purpose stated in the operating instructions

(see chapter "Proper Use"). Any other use is not considered to be as intended. The

manufacturer/supplier is not liable for any damage resulting from use not as intended. The

user bears sole responsibility for such use.

Proper use includes observance of the operating instructions and compliance with the

inspection and maintenance conditions.

Never work in a fatigued or intoxicated state!

WARNING / CAUTION / ATTENTION!

However, if you do injure yourself on the hydraulic unit, clean the wound

immediately and consult a doctor to have it attended to!

If you get hydraulic fl uid in your eye, rinse it immediately several times with clear,

clean water and consult a doctor!

Also, if you swallow hydraulic fl uid you should consult a doctor!

7

3. Proper use

LUKAS control tables are especially designed for rerailing technology. They serve to

control the deployed hydraulic lifting and traversing equipment for rerailing, erection and

maintenance work on rail-bound vehicles.

When carrying out any work, use the control tables described here and the connected hoses

and equipment to ensure that you yourself, the involved and uninvolved persons in the

proximity of the work and objects in closer proximity during the lifting and traversing process

are not endangered.

Y ou can obtain accessories and replacement parts for the control tables from your authorised

LUKAS dealer!

System overview

Rail-bound vehicle erection

WARNING / CAUTION / ATTENTION!

The safety instructions in this operating instruction manual concerning the site of

erection and type of erection must always be observed!

The Type CU LUKAS control tables are not explosion-protected!

ATTENTION!

Watch out vigilantly for any leaks in order to avoid threats to the environment.

lifting cylinders and the

LUKAS traversing system

8

Control table

UnitLifting and rerailing with

4. Components and functions

4.1 Description

The CU range of control tables consist of a control desk with support frame and a large

number of valves. The valves are actuated by control levers. The control levers automatically

return to the neutral or middle position when released (dead man's handle - depressurised

circulation with hydraulic load holding).

The control table has been developed for connection of double-acting cylinders, but singleacting cylinders can also be connected and controlled to a limited extent. If necessary you

may need to consult LUKAS or one of their authorised dealers.

The control tables are rigidly mounted on a support frame that can be folded fl at for space-

saving storage.

Pressure gauges are mounted on the control tables as standard. Each pressure gauge

shows the pressure generated by each individual pump circuit and which is present at the

control table via the power unit.

The hydraulic power packs developed for the single control table are 2POWER packs with

two circuits, and the power packs developed for the double control table are 4POWER packs

with four circuits.

4.2 Hydraulic supply

Only LUKAS hydraulic power packs may be used to drive the equipment.

If the pump unit supplying the pressure is from a different manufacturer you need to make

sure that it is made in accordance with the stipulations laid down by LUKAS. If this is not the

case, dangers can arise that cannot be attributed to LUKAS.

Ensure in particular that the maximum permissible operating pressure for the connected

LUKAS equipment is not exceeded.

NOTE:

Before using pumps and power packs from a different manufacturer, you must

always contact LUKAS or an authorised dealer.

The connection to the hydraulic pump providing the supply and to the hydraulic working

equipment is by hoses that are connected by couplings.

ATTENTION!

Because of the back-pressure in the hoses, the maximum overall length of

the hoses from the power pack via the control table to the working equipment

must be 20 m (66 ft.). If necessary, it is, however, possible to use longer hoses.

However, each individual case must be agreed with LUKAS or with an authorised

dealer, in order to take account of the local conditions if necessary.

9

4.3 Installation of the control table

1a

1b

6

12

5

4

8

1 Control lever - lifting/lowering

1a Control lever black -

traversing cylinder

1b Control lever red - locking

pin

2 Control lever - preselection

valve

3 Pressure gauge

4 Transporting handle

5 Stop knob for swivel foot

6 Operating desk

7 Swivel foot left/right

8 Footplate - adjustable in

height

9 Connection for double-acting

hydraulic equipment (4x)

10 Connection hose with

sleeve for unit

11 Connection hose with nipple

for unit

12 Cut-out for hanging up the

hose ends

1

Operating side:

3

2

5

7

Working side:

7

9

11

10

10

4.4 Functions and controls available at the control desk

Red switching lever for anchoring

cylinder (holds the traversing unit),

alternatively LIFTING/LOWERING if

there is a lifting cylinder connected

Switching valve

for pressure relief

of the anchoring

cylinder before

uncoupling

Switching valve

for pressure relief

of the traversing

cylinder before

uncoupling

Switching lever for lateral movement/

sliding with connected traversing

cylinder, alternatively LIFTING/

LOWERING with connected lifting

cylinder

LIFTING/LOWERING

Lifting cylinder

LIFTING/LOWERING

Lifting cylinder

Pressure gauge

ATTENTION!

Even after having

switched the pressure

relief valve to position

“O”, cylinders can move

in or out (lower/lift).

Pressure

gauge

The selection lever (preselection valve) for pressurisation of the left or right side of the desk (after changing

over the selection lever to one side the right pressure

gauge shows the current pressure in the right-hand

circuit, and the left pressure gauge shows the pressure in the left-hand circuit)

11

Controlling double-acting hydraulic equipment

The double-acting hydraulic equipment is actuated by 4 or 8 (on the CU 4DW) control

levers on the drive side. The CU 4DW control table corresponds to two CU 2DV control

units mounted on a larger control table. Operating the CU 4DW control table is analogue to

that of the CU 2DV.

On the operator side , on the left, there are two smaller valve switching levers next to the

control levers (the black and red control lever ends), that are for de-pressurising before

uncoupling the anchor cylinder (control lever with red lever end) and the traversing

cylinder. Lifting cylinders can also be connected here if a DUO movement cylinder is not

used, or if one will only be used at a later time.

Proceed as follows if there is system pressure on the right-hand side and the connection

hoses cannot be coupled:

1. Connect the power pack,

2. create readiness for operation of the power pack (depends on the type)

3. Move the switching levers for pressurisation on the right-hand side to the pressure

position,

4. Set both control levers to lowering/retraction for three seconds (see illustration below)

This depressurises the system on the right on the operator side and the hoses can then be

coupled.

Pressure, or residual pressure in the supply circuit on the right of the control desk can be

created by actuating the <Lifting/Extending> control lever without connected end units. The

<Lifting/Extending> function contains the hydraulic load-holding function in order to hold the

load in its position by the system pressure. The pressure dissipates when moving downwards.

12

Moving the control lever to the middle (preselection valve is actuated) on the operator side,

in each case the left or right side is pressurised. After moving the middle lever to one side,

the condition of the other side remains static.

5. Erection and start-up

The control tables must be set up at a suffi ciently safe distance from the loads to be lifted

or moved.

Both the load and the operating equipment must be easily observed from the control table.

Make sure that the control table is standing securely. If necessary, pack it up with suitable

materials.

NOTE:

Make sure that you set up all other components being used in accordance with

the separate operating instructions for these components.

ATTENTION!

When commissioning you must observe the instructions and regulations in the

separate operating instructions of the additional components that are used in

your rerailing system!

Work to be carried out before commissioning:

Before commissioning you must carry out a visual check for damage and leaks on all

components being used. Damaged components must not be used and must be replaced!

The hydraulic components must be bled to remove air before commissioning!

Commissioning:

CAUTION / ATTENTION!

Secure the vehicle to be rerailed in accordance with the regulations to prevent its

rolling away, slipping and tipping over!

Procedure:

1. Set up all the components being used in accordance with the corresponding operating

instructions. When setting up you must comply with all the applicable standards, guidelines,

regulations and statutes! Then connect all the hydraulic components as described in the

Chapter "Connecting the hydraulic equipment".

CAUTION / ATTENTION!

Make sure that there are no persons remaining in the danger area!

13

5.1 Folding out the support frame

The support frame ensures secure mounting of the control unit and allows to operator to

work standing upright.

The control unit is delivered in the folded transport position.

Proceed as follows to erect the system (two people required):

1. Lift the control table with the handles at the side. Place your hands in the handles on the

left and right, that are located opposite the locking knob, in each case, in order fi rst to

fold out the lower support frame.

2. Release the support frame lock by pushing the locking knob with your thumb (see

illustration). The support frame swings down up to the stop.

ATTENTION!

Make sure that the support frame does not hit your knee when it swings down

if you have bent your legs in order to balance the load on your lower arms with

your thighs.

3. Pull the support frame back until the locking knob engages and the system is secure.

4. Proceed in the same way on the second folded support frame.

5. Folding the two support frames is carried out in reverse sequence.

14

5.2 Connection of the working equipment

On the double-acting hydraulically-actuated working equipment, there is, on the

pressure supply side (with cylinders: the cylinder base side) a quick-disconnect nipple,

and, on the return side (piston rod side) a quick-disconnect sleeve; and these are connected

to the control table using a pair of extension hoses. On the hose ends we connect, in each

case, a nipple on the sleeve on the end equipment and a sleeve on the nipple on the end

equipment to prevent mix-ups.

Y ou can also place coloured clip rings (supplied with the equipment) on the kink-preventer to

make it visually easier to make connections to several end equipment items.

A quick-disconnect nipple is provided on the single-acting hydraulically-actuated working

equipment to provide a pressure supply. they are connected to the control table via

an extension hose. If you are using earlier versions of single-acting cylinders, LUKAS

recommends that you contact LUKAS or an authorised dealer.

The connection between the control table and the hydraulic power pack is either via

the fi xed short connection hoses, in order to place the power pack under the control

table, or via hose extensions in order to allow the power pack to remain on the vehicle,

for example, and only the control table needs then to be transported to the site of

deployment. The hose extension pairs are supplied in various lengths. The individual hoses

can, if required, also be marked with coloured snap rings to make it easier to allocate the

hoses. (For specifi c details, please consult the LUKAS range of accessories or contact your

LUKAS dealer.)

WARNING / CAUTION / ATTENTION!

Prior to connecting the devices, ensure that all the components

being used are suitable for the maximum operating pressure

of the unit! In case of doubt you must consult LUKAS directly!

5.3 Coupling the quick-disconnect couplings

The device is connected to the hydraulic pump without risk of misconnection using

monocoupling halves (female and male coupling).

X

Y

Before coupling, remove dust caps and then pull back and hold the locking sleeve of the

female coupling half (position X). Connect the male and female couplings and release the

locking sleeve. Then turn the locking sleeve to position Y. The connection has been made

and locked. Uncoupling is done in the reverse order. Coupling of the devices is only possible,

when the hoses are depressurized. For dust protection, the supplied dust caps must be

refi tted.

ATTENTION!

Always connect the return line fi rst and then the supply line!

15

NOTE:

Coupling of the devices is only possible, when the hoses are depressurized.

For dust protection, the supplied dust caps must be refi tted.

WARNING / CAUTION / ATTENTION!

Some quick-disconnect couplings have special functions.Therefore, you must

not unscrew them from the hoses or swap them over!

6. Dismantling the equipment / deactivation following operation

WARNING / CAUTION / ATTENTION!

Before dismantling the rerailing equipment, please ensure that the moved load is

in a stable and fi rm position!

Procedure:

1. Retract all the hydraulic cylinders and traversing cylinders to just a few mm)* protrusion

(base position) when the work is complete. This relieves the hydraulic and mechanical

stress on the equipment.

2. Then switch the hydraulic unit off.

3. Switch the two levers on the control table of the manual pressure switch-off valves to the

0 position (turn clockwise up to the stop). In addition, switch all the other levers in both

directions (lift/lower). Operating pressure at the pressure gauge 0 bar/psi.

4. You can then dismantle the system in accordance with the instructions in Chapter "Connecting the hydraulic equipment" and the separate instructions for the rerailing equipment involved.

ATTENTION!

The operating pressure in the system must be dissipated before uncoupling

the hoses. When the rerailing work is complete you must release the operating

pressure in the installation/system.

A visual inspection must be carried out after every use, but at least once a year. Every

three years or if there is any doubt regarding the safety or reliability of the equipment, a

functional test must also be performed. (Please also observe the relevant valid national and

international regulations pertaining to service intervals of hydraulic equipment).

ATTENTION!

Clean off any dirt before checking the equipment!

WARNING / CAUTION / ATTENTION!

T o perform maintenance and repairs, personal protection equipment appropriate

for the work is an absolute requirement.

16

Inspections to be carried out:

Visual Inspection

• Control table free from damage and deformation

• General tightness (leaks),

• Handle present and secure,

• All screwed connections tight

• Type plate, warning signs and other markings present and legible,

• Couplings must be easy to couple,

• Dust protection caps must be available,

• All accessories used not damaged

Functional test

• Perfect ease of movement of the control levers

• No unusual noises

7. Maintenance and service

7.1 General information

Service work may only be performed by the device manufacturer or by personnel trained by

the device manufacturer and authorised LUKAS dealers.

Only LUKAS spare parts may be used to replace all components (see spare parts list) since

special tools and compliance with, assembly instructions, safety aspects and inspections are

required (see also chapter "Maintenance and Servicing").

During the assembly work, pay particular attention to the cleanliness of all components

because dirt can damage the equipment!

WARNING / CAUTION / ATTENTION!

Protective clothes must be worn when repairs are being carried out, since the

devices may also be pressurised when not in operation.

NOTE:

You should always contact LUKAS or an authorised dealer before using

couplings from another manufacturer.

A TTENTION!

Because LUKAS devices are designed for the highest performance, only components

may be replaced that are listed in the spare parts lists of the corresponding device.

Other components in the device may only be replaced if:

- You have participated in an appropriate LUKAS service training course.

- You have the express permission of LUKAS Customer Service (after request,

verifi cation that permission may be granted. An examination in each individual

case is necessary!)

7.1.1 Care instructions

The exterior of the equipment is to be cleaned from time to time in order to protect it from

external corrosion. Oil is to be applied to the metallic surfaces.

7.1.2 Function and load test

If there is any doubt regarding the safety or reliability of the equipment, a function and load

test must also be performed.

17

7.1.3 Replacing the hydraulic fl uid

After approx. 200 deployments, but after three years at the latest, replace the hydraulic fl uid

in the entire rerailing installation.

Because of the small quantity of hydraulic fl uid in the control table, separate fl uid

replacement on the control table is not required. It is adequate to fl ush the entire

installation with the new hydraulic fl uid during fl uid replacement. However, all the valves

need to be actuated (if necessary connect the supply and return lines of each valve

in order to fl ush).

ATTENTION!

Always perform the change of the hydraulic fl uid over a collection tank and

dispose of the collected fl uid in a proper manner!

ATTENTION!

The hydraulic fl uid must be completely replaced if the application conditions

(ambient temperatures) change substantially. When selecting a suitable

hydraulic fl uid, please refer to Chapter “Hydraulic fl uid recommendations” for

the relevant rerailing equipment.

7.2 Repairs

7.2.1 Coupling replacement

The couplings must be replaced if:

- there is external damage,

- the locking does not function,

- hydraulic fl uid continues to leak in the coupled/uncoupled state.

WARNING / CAUTION / ATTENTION!

Never repair couplings: they must be replaced by genuine LUKAS parts!

During assembly tighten the coupling to a torque of M

= 40 Nm.

A

Procedure:

1. Remove the coupling.

2. Place a new coupling in position and tighten to a torque of M

= 40 Nm.

A

7.2.2 Decals

All damaged and/or illegible decals (safety notices, type plate etc.) must be replaced.

Procedure:

1. Remove damaged and/or illegible decals.

2. Clean surfaces with acetone or industrial alcohol.

3. Affi x new decals.

T ake care to affi x the labels in the correct positions. If this is no longer known, you should ask

your authorised dealer or contact LUKAS directly.

18

8. Troubleshooting

Fault Check Cause Solution

Connected

working equipment

moves slowly

or jerkily when

activated

The connected

working equipment

does not move

when actuated

and no pressure

indication on

the control table

pressure gauge.

The connected

working equipment

does not move

when actuated

but pressure

indication on

the control table

pressure gauge.

Connected

working equipment

does not apply the

specifi ed force.

Are the hoses

connected

properly?

Does the pump

unit work?

Are the hoses

connected

properly?

Does the pump

unit work?

Hydraulic fl uid

level in the

supplying pump?

Check the

operating pressure

on the control

table pressure

gauge

Check working

equipment

Air in the hydraulic

system

Working unit

defective.

Hose connection

to hydraulic power

pack not made, or

made incorrectly.

Pump unit not

switched on or

defective.

Control table

defective

Problem with

the working

equipment.

Insuffi cient

hydraulic fl uid in

the pump

Pressure supply

has too low

pressure

Working

equipment

defective

Vent the hydraulic

system

Consult the

separate operating

instructions for the

working equipment.

Connecting hose

assemblies properly.

Consult the

separate operating

instructions for the

pump unit.

Have it repaired

by an authorised

dealer or directly by

LUKAS.

Consult the

separate operating

instructions for the

working equipment.

Top up hydraulic

fl uid and bleed the

air

If possible, increase

the max. operating

pressure on the

hydraulic unit to

max. operating

pressure of the

cylinder or use

another hydraulic

unit with a suffi cient

max. operating

pressure.

Consult the

operating

instructions for the

working equipment.

19

Hoses cannot be

coupled

Leak from the

couplings

Is the coupling

damaged?

Lines are under

pressure because

there is pressure in

the system

Coupling defective Coupling must

Coupling defective Coupling must

Remove the

pressure or residual

pressure (see Page

12)

be replaced

immediately

be replaced

immediately

Cylinders

automatically

lower under load

Contact an authorised LUKAS dealer or the LUKAS Customer Service Department directly

if the malfunctions cannot be rectifi ed.

The address for the LUKAS Customer Service department is:

LUKAS

Weinstrasse 39, D-91058 Erlangen, Germany

PO Box 2560 D-91013 Erlangen

Tel.: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

Check position

of pressure relief

valves

Operating error Switch pressure

relief valve to

position I

20

9. Technical data

Because all values are subject to tolerances, there may be small differences between the

data for your device and the data in the following tables!

9.1 Control unit CU 2DV

Device type CU 2DV Value Units Remarks

Item number 70-70-10

Dimensions l x w x h 1030 x 640 x 1112 mm set up

40.6 x 25.2 x 43.8 in.

Dimensions l x w x h 1030 x 640 x 450 mm folded

40.6 x 25.2 x 17.7 in.

Operating pressure max. 53 MPa

7700 psi

Control valve Lifting 2 Number

Control valve traversing/lifting 1 Number

Control valve Locking/lifting 1 Number

Hydraulic

connections

Ambient

temperature

Weight 43.5 kg

Specifi cation of

hydraulic fl uid

NW 06 quick-

disconnect-

coupling

-20 … +55 °C

-4 … 131 °F

95.9 lbs.

HM 10 ISO 6743-4

21

9.2 Control unit CU 4 DVV

Device type CU 4DVV Value Units Remarks

Item number 70-20-20

Dimensions l x w x h 1310 x 640 x 1112 mm set up

51.6 x 25.2 x 43.8 in.

Dimensions l x w x h 1215 x 640 x 450 mm folded

47.8 x 25.2 x 17.7 in.

Operating pressure max. 53 MPa

7700 psi

Control valve Lifting 4 Number

Control valve traversing/lifting 2 Number

Control valve Locking/lifting 2 Number

Hydraulic

connections

Ambient

temperature

Weight 68 kg

Specifi cation of

hydraulic fl uid

NW 06 quick-

disconnect-

coupling

-20 … +55 °C

-4 … 131 °F

150 lbs.

HM 10 ISO 6743-4

9.3 Operating and storage temperature ranges

Operating temperature [°C] / [°F] -20 … +55 -4 … +131

Environmental

temperature (device in

operation)

Storage temperature

(device not in operation)

[°C] / [°F] -25 … +45 -13 … +113

[°C] / [°F] -30 … +60 -22 … +140

22

10. EC Declaration of Conformity

23

11. Notes

24

252627

Please dispose of all packaging materials and

removed items properly.

LUKAS

A unit of the IDEX Corporation

Hydraulik GmbH

Weinstrasse 39, D-91058 Erlangen, Germany

Tel.: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

www.lukas.com

Made in GERMANY

© Copyright 2014 LUKAS Hydraulik GmbHCU_2DV_4DVV_manual_1490000085_en.indd

Subject to changes

Loading...

Loading...