Page 1

Operating instructions

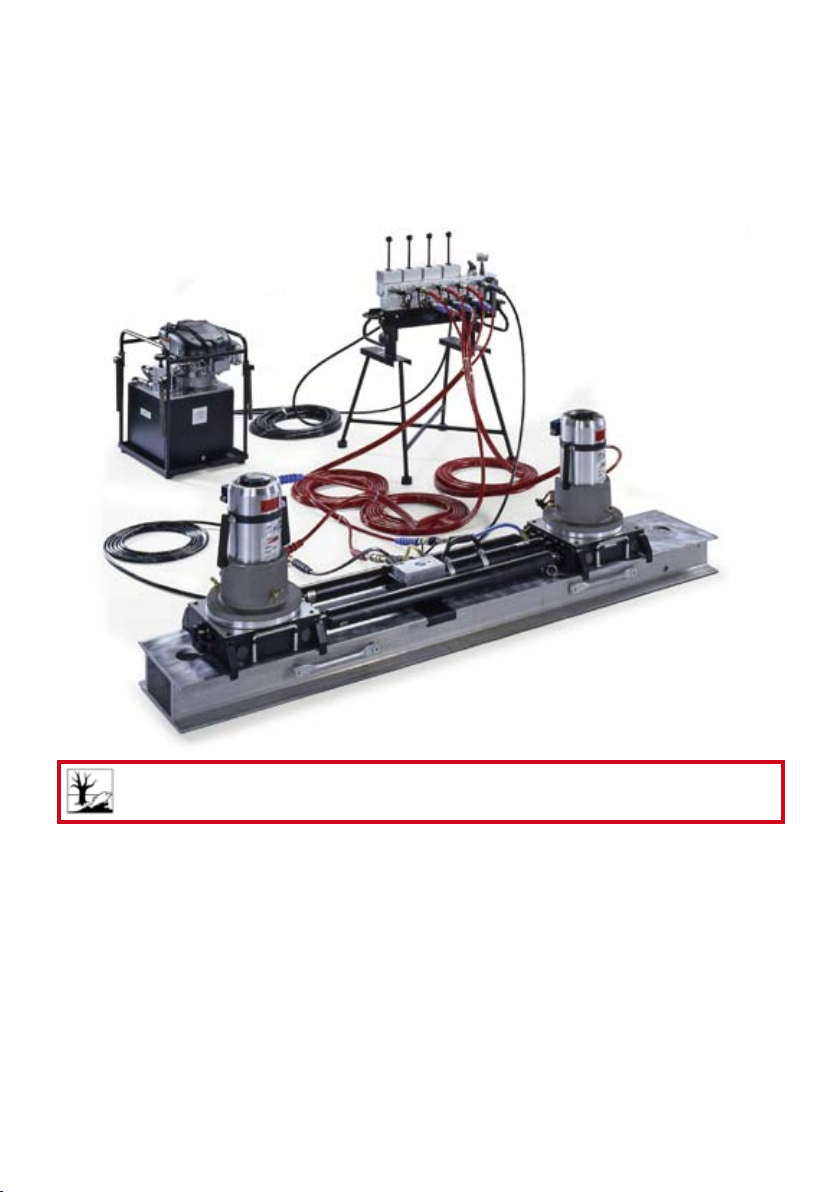

Rerailing Equipment

Control desks (model CT7)

84072134485 GB

Edition 08.2009

(Translation of the original operating instructions)

Page 2

2

Page 3

3

Content Page

1. Hazard classes 4

2. Product safety 5

3. Proper use 8

4. Functions and performance 9

4.1 Description 9

4.2 Hydraulic supply 9

4.3 Overview 10

4.4 Hydraulic circuit diagrams for standard control desks 11

4.5 Optional accessories 14

5. Connection of hydraulic devices 14

5.1 Basic information 14

5.2 Connection of quick-connect couplings 15

6. Operation 16

6.1 Setting up the control desk 16

6.2 Start-up 16

6.3 Control desk controls 17

7. Dismantling the equipment / deactivation following operation 18

8. Maintenance and service 19

9. Repairs 19

9.1 General 19

9.2 Preventive service 20

9.3 Repairs 21

10. Troubleshooting 22

11. Technical data 24

11.1 Control unit 24

11.2 Pedestal 24

11.3 Control desk (control unit + pedestal) 25

11.4 Recommendedhydraulicuids 25

11.5 Operating temperature and storage temperature ranges 25

12. EC Declaration of Conformity 26

13. Notes 27

Page 4

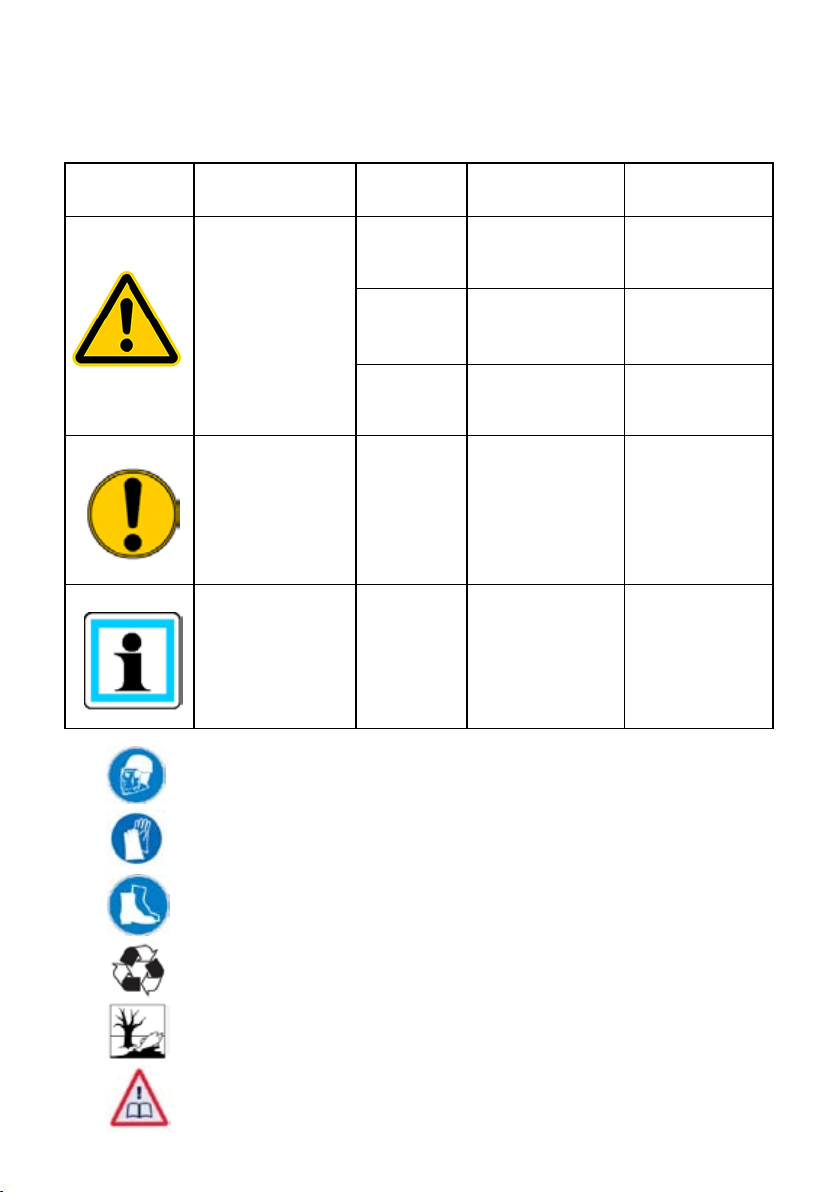

4

Hazard classes1.

We distinguish between various categories of safety instructions. The table below gives you

an overview of the assignment of symbols (pictograms) and key words to the specic hazard

and possible consequences.

Pictogram

Damage / injury

to

human

device

- REMARK

Key word Denition Consequences

DANGER! Immediate danger

WARNING!

CAUTION!

CAUTION!

Potentially

dangerous

situation

Less dangerous

situation

Danger of damage

to device /

environment

Advice for

application and

other important /

useful information

and advice

Death or major

injury

Potential death or

major injury

Minor or slight

injury

Damage to the

equipment,

damage to the

environment,

damage to

surrounding

materials

No injury /

damage to

persons /

environment /

equipment

Wear helmet with face protection

Wear safety gloves

Wear safety shoes

Proper recycling

Observe principles of environmental protection

Read and observe operating instructions

Page 5

5

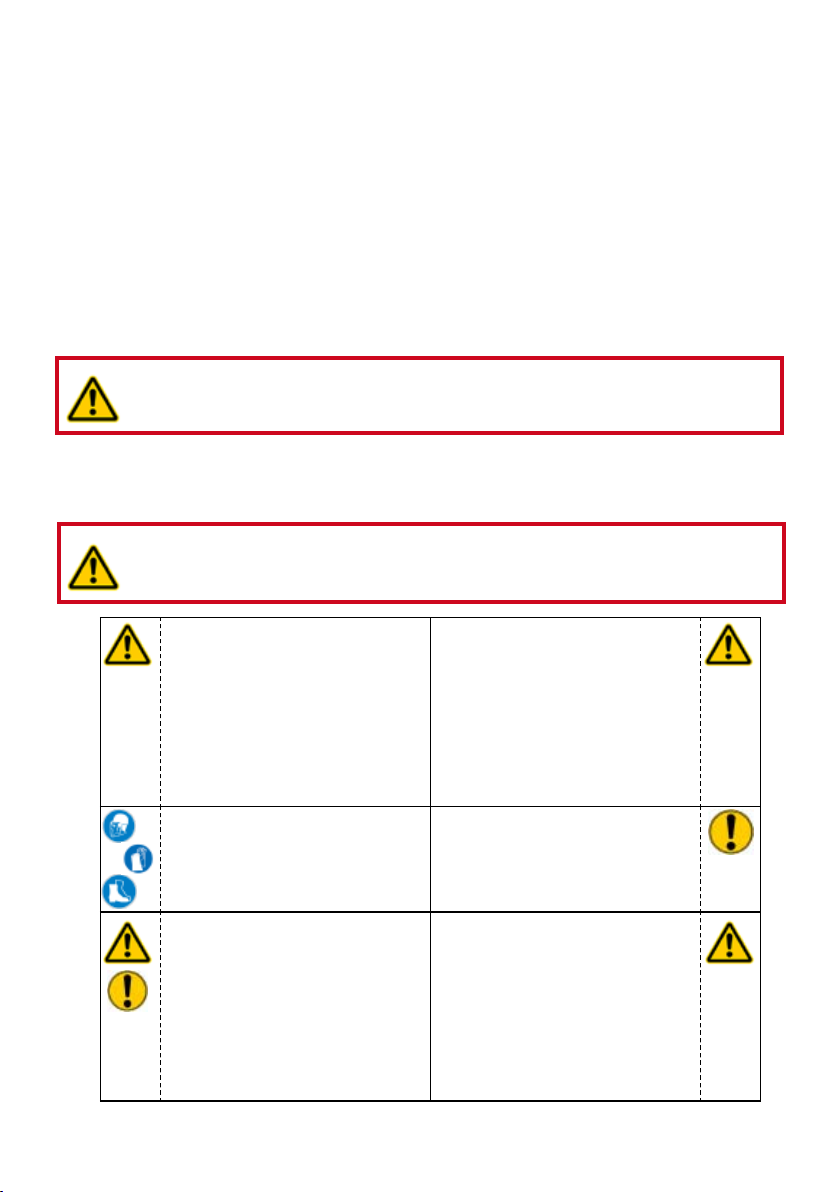

Product safety2.

LUKAS products are developed and manufactured in order to guarantee the best performance

and quality when used properly.

Operator safety is the most important aspect of the product design. Moreover, the operating

instructions are intended to ensure LUKAS products are used safely.

The generally applicable legal and other binding regulations pertaining to the prevention of

accidents and protection of the environment apply and are to be complied with in addition to

the operating instructions.

The equipment may only be operated by persons with appropriate training in the safety

aspects of such equipment – otherwise, there is a danger of injury occurring.

We would like to point out to all users that they should read the operating instructions carefully

before using the equipment and comply with the instructions there without restriction.

We further recommend that a qualied instructor train you in the use of the product.

WARNING / CAUTION!

The operating instructions for the hoses, the accessories and the connected

hydraulic equipment must also be observed.

Even if you have already received instructions on how to use the equipment, you should still

read through the following safety instructions once again.

WARNING / CAUTION!

Ensure that the accessories and connected equipment used are suitable for

the maximum operating pressure.

Please ensure that no body

parts or clothing get stuck

between the visibly moving

parts.

Wear protective clothing, safety

helmet with visor, safety shoes

and protective gloves

The department responsible

is to be informed immediately

of any changes (including to

the operating behaviour). If

necessary, the equipment is to

be shut down immediately and

secured.

It is prohibited to work under

load if this load is lifted

exclusively by hydraulic

equipment. If this work

is absolutely imperative,

additional mechanical supports

must be used.

Inspect the equipment before

and after use for visible defects

or damage.

Inspect all lines, hoses and

screwed connections for

leaks and externally visible

damage. If necessary,

repair immediately. Squirting

hydraulic liquids can result in

injuries and res.

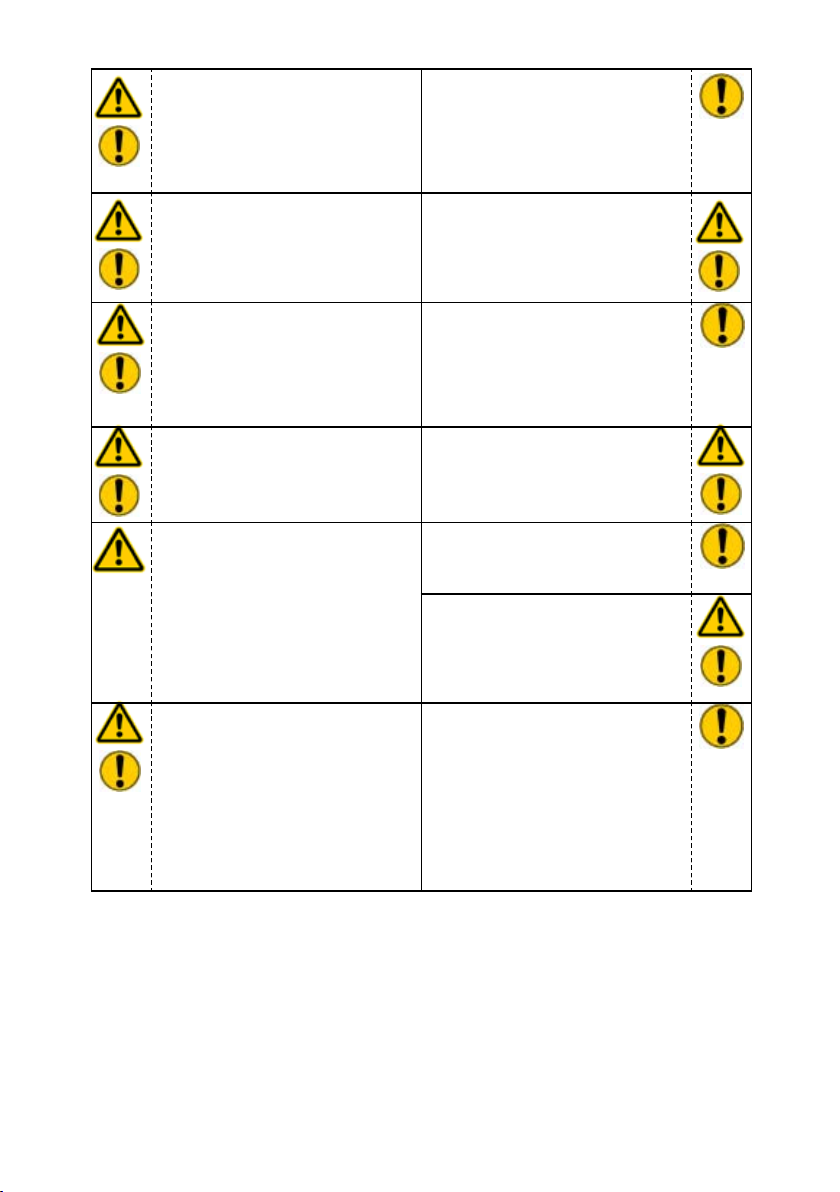

Page 6

6

In the event of malfunctions,

immediately shut down the

equipment and secure it. The

malfunction is to be repaired

immediately.

Do not carry out any changes

(additions or conversions)

to the equipment without

obtaining the prior approval of

LUKAS.

Comply with all the instructions

regarding safety and danger

on the equipment and in the

operating instructions.

Any method of operation which

impairs safety and/or stability

of the equipment is prohibited.

Safety devices may never be

deactivated.

Before the equipment is

switched on / started up, and

during its operation, it must

be ensured that nobody is

endangered by the operation of

the equipment.

When working close to live

components and cables,

suitable measures must be

taken to avoid current transfers

or high-voltage transfers to the

equipment.

All the instructions regarding

safety and danger on the

equipment are to be kept

complete and in a legible

condition.

Comply with all specied

dates or dates specied in

the operating instructions

pertaining to regular checks /

inspections of the equipment.

The maximum operating

pressure marked on the

equipment must not be

exceeded.

Only original LUKAS

accessories and spare parts

may be used for repairs.

During all work and transport

operations involving the

equipment, take care not to trip

and become caught in hose

loops.

The build-up of static charge

with the potential consequence

of spark formation is to be

avoided when handling the

equipment.

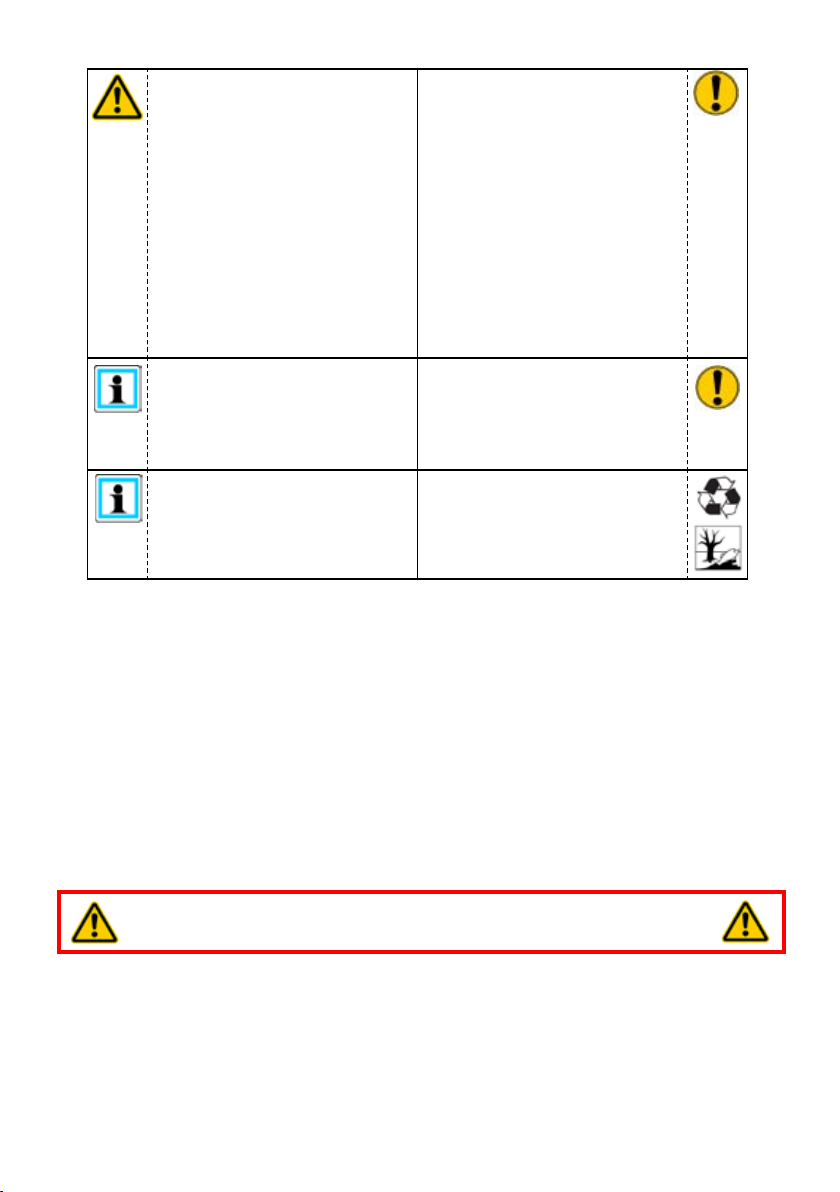

Page 7

7

The equipment is lled with

hydraulic uid. These hydraulic

uids can be harmful to your

health if swallowed or if their

vapours inhaled. Direct contact

with the skin is to be avoided

for the same reason. Please

also note that hydraulic uids

can also have a negative effect

on biological systems.

When working with or storing

the equipment, ensure that the

function and the safety of the

equipment are not impaired by

the effects of extreme external

temperatures and that the

equipment is not damaged in

any way. Please note that the

equipment can also heat up

over a long period of use.

Ensure adequate lighting when

you are working.

Always keep these operating

instructions within reach where

the equipment is used.

The generally applicable, legal and other binding national and international regulations

pertaining to the prevention of accidents and protection of the environment apply and are to

be implemented in addition to the operating instructions.

Before transporting the

equipment, always ensure that

the accessories are positioned

in such a way that they cannot

cause an accident.

Ensure the proper disposal

of all removed parts, leftover

oil and uid, and packaging

materials.

WARNING / DANGER / CAUTION!

The equipment is to be used exclusively for the purpose stated in the operating

instructions (see chapter "Proper use"). Any form of use beyond this is not considered

proper use. The manufacturer / supplier is not liable for any damages resulting from improper

use. The user bears sole responsibility for such use.

Observance of the operating instructions and compliance with the inspection and maintenance

conditions are covered by the denition of proper use.

Never work when you are overtired or intoxicated.

Page 8

8

Proper use3.

LUKAS control desks have been developed specically for rerailing operations. They are

intended to control the hydraulic jacks and pushers used in the event of a railway vehicle

derailment.

The accessories required for the derailment incident concerned must be used (depending

on the variant, e.g. pedestal).

CAUTION!

To minimise the risk to the environment, remedy leaks as soon as possible.

Accessories and spare parts for the control desks are available from your authorised LUKAS

dealer.

Page 9

9

Functions and performance4.

4.1 Description

The control desks in the CT7 model series comprise a number of valves housed in a control

block. The valves are controlled by means of control levers.

Depending on the version, up to 6 double-acting and 2 single-acting hydraulic devices can

be connected and controlled without the need for a separate controller.

The attached, manually operated pressure shut-off valve opens and closes the supply to the

control valves. With the manual pressure shut-off valve in the “closed” position, the ow to

WARNING / DANGER / CAUTION!

The manual pressure shut-off valve closes only the connection to the hydraulic

unit to be supplied.

It is NOT provided as an “emergency stop” function. This means that the

connected hydraulic devices could still move if one of the control levers were

operated. This could happen if residual pressure in the system or external loads

were to act on the connected hydraulic devices.

the hydraulic pump is automatically depressurised.

The control desks are usually mounted on a separate pedestal or secured directly to the unit

frame. LUKAS control desks are normally always delivered mounted on a pedestal or tted

to a frame. To nd out more, please contact your authorised LUKAS dealer.

The control desk also features a pressure gauge on the inlet block as standard. This pressure

gauge indicates the pressure acting on the control desk from the unit.

4.2 Hydraulic supply

Only LUKAS motor pumps are permitted to be used to drive the devices.

If an other-make pump power pack is used, it is important to ensure that it complies with

LUKAS specications, as otherwise dangerous situations beyond the control of LUKAS

could arise. Particular care must be taken to ensure that the maximum permissible operating

pressure of the connected LUKAS devices is not exceeded.

REMARK:

Before you use pumps of a different manufacturer, you must contact LUKAS or

an authorised dealer.

The connection to the supplied hydraulic pump and to the implements is established by

means of hose lines, which are connected to each other by couplings.

CAUTION!

Due to ram pressures in the hose lines, the maximum overall length of the hose

lines, from the unit to the control desk to the hydraulic device, is limited to 40 m

(131.2 ft.).

Long hose lines between the implement and control desk or unit and control desk

may result in delayed movement of the hydraulic implements (particularly in the

event of the automatic return of single-acting implements).

For work involving long hose lines at low ambient temperature, we recommend

theuseofahydraulicuidwithalowviscosity.

Page 10

10

4.3 Overview

Operato r ' s

4

5

1

3

6

W o r k i n g

4

7

9

1 Switch valves

2 Switch lever

3 Manual pressure

shut-off valve

4 Pushbutton valve

5 Pressure gauge

6 Connection for hydraulic

supply

7 Connection for single-

acting hydraulic devices

(e.g. anchor cylinders)

8 Connection for double-

acting hydraulic devices

9 Pedestal

9

2

5

4

7

8

Page 11

11

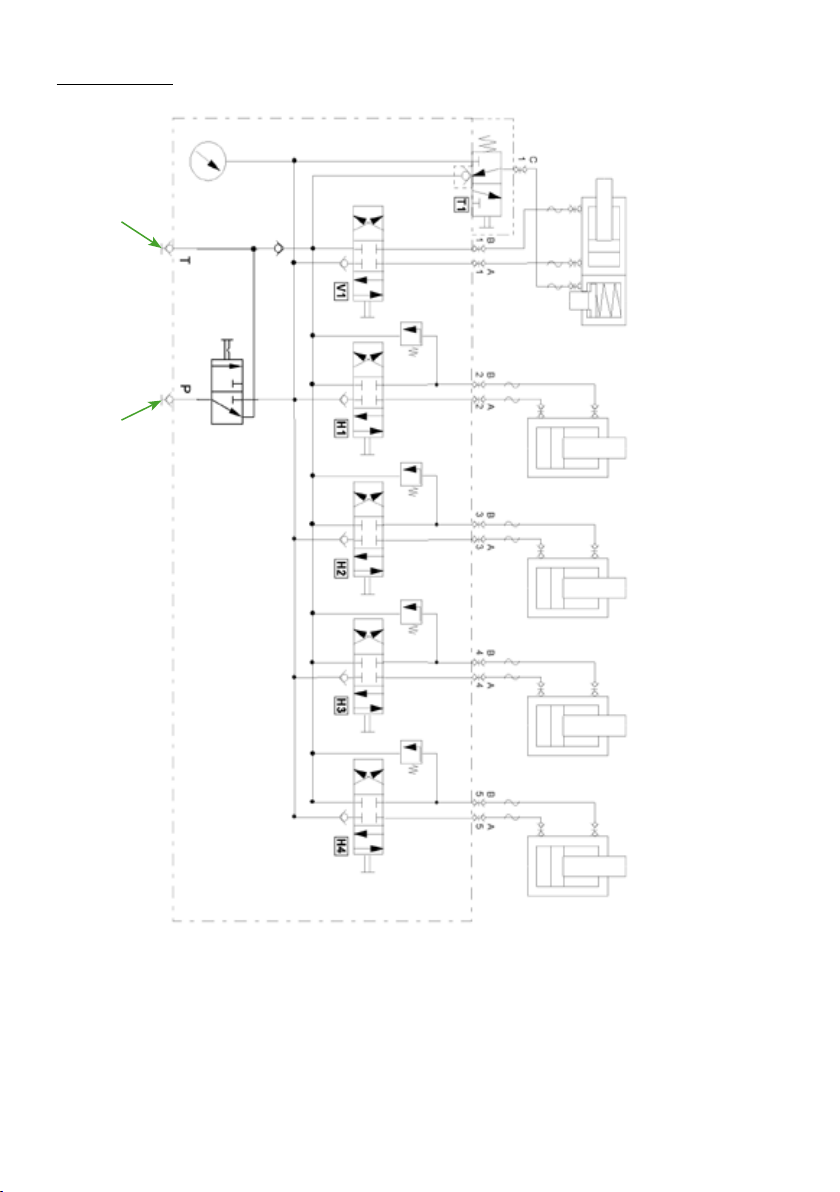

4.4 Hydraulic circuit diagrams for standard control desks

CT7 - 6/3DV:

30 MPa30 MPa30 MPa

Supply line from

hydraulic unit

Return line to

hydraulic unit

Page 12

12

CT7 - 6/4DV:

Return line to

hydraulic unit

Supply line from

hydraulic unit

30 MPa 30 MPa 30 MPa 30 MPa

Page 13

13

CT7 - 6/4DVV:

30 MPa 30 MPa 30 MPa 30 MPa

Supply line from

hydraulic unit

Return line to

hydraulic unit

Page 14

14

4.5 Optional accessories

4.5.1 Pedestal

The pedestal is intended to provide safe support for the control unit and to enable the

operator to work standing up.

Thecontrolunitisttedtothepedestalasfollows:

1. Loosen connection “F” approximately 15 mm (in.)

on pedestal “G”.

2. Fit control unit “J”, mounted on leg “H”, onto the

pedestal and retighten connection “F” on both sides.

3. Removal in reverse order.

4.5.2 Pressure gauge

To supplement the pressure gauge already tted to the control unit, it is possible to t an

additional pressure gauge for each pressure line so that you can read the pressure acting on

the implement. There are two possible installation arrangements. One directly between the

control unit and the hose line of the individual pressure line outlets on the switch valves, and

one that requires an extra measurement hose, which taps the pressure directly at the switch

valve. The measurement hose solution requires a special mounting plate for the pressure

gauge units. To nd out more about optional pressure gauges, please contact your authorised LUKAS dealer.

J

H

F

G

Connection of hydraulic devices5.

5.1 Basic information

Double-acting, hydraulically operated implements are tted with a male quick-disconnect

coupling on the pressure supply side (with cylinders: cylinder bottom end) and a female

quick-disconnect coupling on the return side (with cylinders: piston rod end); these are

connected to the control desk by a pair of extension hoses (nominal diameter DN 6).

Single-acting, hydraulically operated implements are tted with a male quick-disconnect

coupling on the pressure supply side; this is connected to the control desk by an extension

hose line (nominal diameter DN 10).

The connection between the control desk and the hydraulic unit is always established by

means of extension hose lines (nominal diameter DN 10).

All LUKAS extension hose pairs/lines are colour-coded and equipped with quick-disconnect

couplings to minimise the possibility of misconnection.

Page 15

15

WARNING / DANGER / CAUTION!

Before connecting equipment, make sure that all the components

used are suitable for the maximum operating pressure of the

pump unit. In cases of doubt, you must consult LUKAS directly.

5.2 Connection of quick-connect couplings

The device connects to the hydraulic pump by means of individually coded quick-connect

coupling halves (plug and socket).

X

Before coupling, remove the dust protection caps, then pull back and hold the locking sleeve

of the female coupling (position X). Fit the socket and plug together and release the locking

sleeve. Then turn the locking sleeve to position Y. The connection has now been made and

locked. Disconnection is made in the reverse order. Hoses can be connected only when

depressurised. To protect against dust, the accompanying dust protection caps must be

replaced.

CAUTION!

Always connect the return hose rst and then the supply hose.

REMARK:

Hoses can be connected only when depressurised.

To protect against dust, the accompanying dust protection caps must be replaced.

WARNING / DANGER / CAUTION!

Some quick-disconnect couplings have special functions. Therefore it is not

permitted to screw them off the hoses or to swap them.

Page 16

16

Operation6.

6.1 Setting up the control desk

Control desks must be set up at a safe distance from the load to be lifted or pushed.

Both the load and the implements must be clearly visible from the control desk position.

Make sure that the control desk has stable footing. Use suitable material for support if

necessary.

REMARK:

Set up all other necessary components as described in the separate operating

instructions for these components.

Check that the manual pressure shut-off valve is closed (home position) and then connect

the hydraulic unit to the implements.

6.2 Start-up

CAUTION!

During start-up, observe all information and instructions in the separate operating

instructions for the other components of your rerailing system.

Preparations before start-up:

Before start-up, all components must be visually inspected for damage and leaks. Damaged

components must not be used and must be exchanged.

Hydraulic components must be bled before start-up takes place.

Start-up:

DANGER / CAUTION!

Correctly secure the derailed vehicle against rolling away, slipping and tipping.

Procedure:

1. Set up the necessary components as described in the separate operating instructions for

these components. During set-up, observe all applicable standards, directives, laws and

regulations. Now connect up all hydraulic components as described in the “Connection of

hydraulic devices” chapter.

DANGER / CAUTION!

Make sure that nobody is present in the danger zone.

Page 17

17

2. Then start the hydraulic unit.

3. Move the lever on the manual pressure shut-off valve

into the working position (turn anti-clockwise to the

stop).

WARNING / DANGER / CAUTION!

In the interests of safety, control desk functions

should not remain enabled (manual pressure

shut-off valve opened) unless at least one

appropriately trained operator is manning the

control desk.

For emergency use, a single handle is

provided to close the pressure shut-off

valve. This shuts off the hydraulic circuit to

all implements. The pressure shut-off valve

interrupts only the hydraulic supply between

the control desk and the pump. It is NOT

provided as an “emergency stop” function.

After the hydraulic implements have been bled, your

rerailing system is ready for operation.

6.3 Control desk controls

6.3.1 Controlling single-acting hydraulic devices

To supply single-acting hydraulic devices with

hydraulic uid, you need to press the relevant button.

As soon as the button is released, uid stops

being supplied to the associated hydraulic device.

Page 18

18

6.3.2 Controlling double-acting hydraulic devices

Double-acting hydraulic devices are controlled by

control levers.

Throwing the control lever away from the operator's

side causes the lower hydraulic connection (usually

colour-coded blue) to be supplied with hydraulic uid.

Throwing the control lever towards the operator's side

causes the upper hydraulic connection (usually colour-

coded red) to be supplied with hydraulic uid.

How far the control lever is thrown determines the ow

rate in the associated line

and thus the speed of motion

of the implement.

upper hydraulic

connection

Dismantling the equipment / deactivation following 7.

operation

lower

hydraulic

connection

WARNING / DANGER / CAUTION!

Before the rerailing equipment concerned is removed, make sure that the load is

in a stable, immovable condition.

Procedure:

1. Return all implements to home position.

2. Switch off the hydraulic unit.

3. Move the lever on the manual pressure shut-off valve into the closed position (turn

clockwise to the stop). Also check the pressure on the attached pressure gauge. This

should be practically “0”.

4. You can now disassemble the system as described in “Connection of hydraulic devices”

and in the separate instructions for the rerailing equipment used.

REMARK:

Components should be disassembled in reverse order to assembly.

Page 19

19

Maintenance and service8.

A visual inspection must be carried out after each use and at least once a year regardless

of use. In addition, a function test must be carried out every 3 years, or whenever there is

any doubt as to the safety or reliability of the equipment (observe all applicable national

and international rules and regulations relating to the maintenance intervals of the hydraulic

devices).

CAUTION!

Clean off any dirt before checking the equipment.

WARNING / DANGER / CAUTION!

In order to carry out maintenance and repair work, tools appropriate for the job

and personal protection equipment obligatory

Checks to be performed:

Visual inspection

• Control desk shows no damage or deformation

• General tightness (no leaks)

• Handles present and secure

• All screw connections tightened

• Type plate, warning labels and other markings present and legible

• Couplings must be easy to couple

• Dust protection caps must be available

• All accessories undamaged

Function test

• Control levers and buttons for proper ease of movement

• No suspicious noises

Repairs9.

9.1 General

Servicing may only be carried out by the manufacturer or personnel trained by the

manufacturer and by authorised LUKAS dealers.

Only LUKAS spare parts may be used to replace all components (see spare parts list) since

special tools, assembly instructions, safety aspects, inspections might have to complied with

(see also chapter "Maintenance and service”).

During all installation work, pay particular attention to the cleanliness of all components

as contaminants could cause damage to the equipment.

WARNING / DANGER / CAUTION!

Protective clothing must be worn when repairs are being carried out, since

parts of the units can also be pressurised in an idle state.

Page 20

20

REMARK:

Before you use couplings from a different company, you must contact LUKAS or

an authorised dealer.

CAUTION!

Since LUKAS rerailing devices are designed for top performance, only those

components in the spare parts lists of the relevant unit may be replaced.

Further components in the devices may only be replaced if:

- You have participated in appropriate LUKAS service training,

- You have the explicit permission of the LUKAS customer service (on request,

check for granting permission. Check is necessary in each individual case.)

9.2 Preventive service

9.2.1 Care regulations

The exterior of the equipment is to be cleaned from time to time in order to protect it from

external corrosion. Oil is to be applied to the metallic surfaces.

9.2.2 Stress test

If there is any doubt regarding the safety or reliability of the equipment, a function and load

test must also be performed.

9.2.3Replacingthehydraulicuid

After approx. 200 deployments, but after three years at the latest, the hydraulic uid in the

entire rerailing system must be replaced.

Due to the small amount of hydraulic uid in the control desk, a uid replacement does not

need to be carried out separately here. It is sufcient to ush it with the new hydraulic uid

at the time of a uid replacement in the entire system. All valves should be actuated in the

process (if necessary, connect the supply and return lines of each valve to each other to

ush them with the new uid).

CAUTION!

During a hydraulic uid replacement, always use a suitable receptacle to collect

escaping uid and dispose of the collected uid correctly.

CAUTION!

All of the hydraulic uid in the system must be replaced if conditions of use

(ambient temperatures) vary considerably. When selecting the appropriate

hydraulic uid, please observe the “Recommended hydraulic uids” chapter.

Page 21

21

9.3 Repairs

9.3.1 Coupling replacement

The couplings must be replaced in the event of:

- external damage

- the locking device not working

- hydraulic uid continually leaking in a coupled/uncoupled state.

WARNING / DANGER / CAUTION!

Never repair couplings: they are to be replaced by original LUKAS parts.

During installation, tighten the coupling to a torque of M

= 40 Nm.

A

Procedure:

1. Remove the coupling.

2. Fit the new coupling and screw it in with a torque of M

= 40 Nm.

A

9.3.7 Labels

All damaged and/or illegible labels (safety notices, type plate, etc.) must be renewed.

Procedure:

1. Remove damaged and/or illegible labels.

2. Clean the surfaces using industrial alcohol.

3. Attach new labels.

Make sure that the labels are attached in the right position. If you are no longer sure about

this, contact your authorised LUKAS dealer or LUKAS directly.

Page 22

22

Troubleshooting10.

Trouble Check Cause Solution

Connected

implements move

slowly or jerk in

response to control

command

Connected

implements do not

move in response to

control command and

no pressure reading

on the control desk

pressure gauge.

Connected

implements do not

move in response to

control command but

a pressure reading is

shown on the control

desk pressure gauge.

Connected implement

does not produce its

rated force.

Hose lines

connected

correctly?

Pump assembly

running?

Hose lines

connected

correctly?

Pump assembly

running?

Switch position

of the manual

pressure shut-off

valve

Hydraulic uid

level in the supply

pump?

Check the

operating pressure

on the control desk

pressure gauge

Check the

implements

Air in the hydraulic

system

Defective

implement.

Hose line to

hydraulic unit

not connected

correctly.

Pump assembly

not switched on or

defective.

Manual pressure

shut-off valve in

“closed position”

Defective control

desk

Problem with the

implement.

Insufcient

hydraulic uid in

the pump

Insufcient supply

pressure

Defective

implements

Vent the hydraulic

system

Consult the operating

instructions for the

implement.

Connect the hose

lines correctly.

Consult the operating

instructions for the

pump assembly.

Switch the manual

pressure shut-off

valve to the “working

position”.

Have repaired by

authorised dealer or

directly by LUKAS.

Consult the operating

instructions for the

implement.

Top up the hydraulic

uid and bleed

If possible, increase

the max. operating

pressure at the

hydraulic unit to

the max. operating

pressure of the

cylinder or use a

different hydraulic

unit with sufcient

max. operating

pressure.

Consult the operating

instructions for the

implements.

Page 23

23

hose assembly

cannot be coupled

Leak in the couplings Coupling

damaged?

If it is not possible to rectify the malfunctions, inform an authorised LUKAS dealer or the

LUKAS Customer Service department immediately.

The address of the LUKAS Customer Service Department is:

Pressurised Switch the pump

to depressurised

circulation

Coupling defective Coupling needs to be

replaced immediately

Coupling defective Coupling needs to be

replaced immediately

LUKAS

Weinstraße 39, D-91058 Erlangen

Postfach 2560, D-91013 Erlangen

Tel.: (+49) 09131 / 698 - 348

Fax.: (+49) 09131 / 698 - 353

Hydraulik GmbH

Page 24

24

Technical data11.

As all values are subject to tolerances, there may be minor differences between the data

achieved by your equipment and the data specied in the following table.

11.1 Control unit

Designation CT7-6/3DV CT7-6/4DV CT7-6/4DVV

Ref. no. 840721344 840721345 840721346

Dimensions

(L x W x H)

Max. operating

pressure

(HP)

Max. operating

pressure

(LP)

Weight

[mm] 801 x 335 x 500 931 x 335 x 500 986 x 335 x 500

[in.] 35.5 x 13.2 x 19.7 36.7 x 13.2 x 19.7 38.8 x 13.2 x 19.7

[Mpa]* 53 53 53

[psi.] 7,687 7,687 7,687

[Mpa]* 23 23 23

[psi.] 3,336 3,336 3,336

[kg] 36,7 44,2 51,5

[lbs.] 80.9 97.4 113.5

Number of controls

(double-acting)

Number of controls

(single-acting)

Hydraulic

connections

Remark

* 1 MPa = 10 bar

Quick-disconnect

automatic spring-

4 5 6

1 1 2

couplings

Control with

loaded return

11.2 Pedestal

Designation Pedestal for CT7

Ref. no. 840720325

Dimensions

(L x W x H)

Weight

[mm] 650 x 700 x 710

[in.] 25.6 x 27.6 x 28.0

[kg] 7,8

[lbs.] 17.2

Quick-disconnect

couplings

Control with

automatic spring-

loaded return

Quick-disconnect

couplings

Control with

automatic spring-

loaded return

Page 25

25

11.3 Control desk (control unit + pedestal)

Designation

Ref. no. 840721341 840721342 840721343

Comprising:

(ref. nos.)

Dimensions

(L x W x H)

Weight

[mm] 801 x 700 x 1100 931 x 700 x 1100 986 x 700 x 1100

[in.] 35.5 x 27.6 x 43.3 36.7 x 27.6 x 43.3 38.8 x 27.6 x 43.3

[kg] 44,5 52,0 59,3

[lbs.] 98.1 114.6 130.7

CT7-6/3DV CT7-6/4DV CT7-6/4DVV

(with pedestal) (with pedestal) (with pedestal)

840721344 840721345 840721346

840720325 840720325 840720325

11.4 Recommendedhydraulicuids

Mineral oil DIN ISO 6743-4 for LUKAS hydraulic equipment and others

Oil temperature range Oil code Viscosity rating Remarks

A -24 .... +30°C HL 5 VG 5

B -18 .... +50°C HM 10 VG 10

C -8 .... +75°C HM 22 VG 22

D +5 .... +80°C HM 32 VG 32

E -8 .... +70°C HF-E15 VG 15 Bio-oil

Oil temperature range Oil code Viscosity rating Remarks

A -11.2 .... +86°F HL 5 VG 5

B -0.4 .... +122°F HM 10 VG 10

C +17.6 .... +167°F HM 22 VG 22

D +41.0 .... +176°F HM 32 VG 32

E +17.6 .... +158°F HF-E15 VG 15 Bio-oil

recommended viscosity range: 10...200 mm²/s (10…200 cSt.)

Supplied with HM 22 DIN ISO 6743-4.

11.5 Operating temperature and storage temperature ranges

Operating temperature [°C] -20 … +55

Ambient temperature (device in operation) [°C] -25 … +45

Storage temperature (device not in operation) [°C] -30 … +60

Operating temperature [°F] -4 … +131

Ambient temperature (device in operation) [°F] -13 … +113

Storage temperature (device not in operation) [°F] -22 … +140

Page 26

26

EC Declaration of Conformity12.

Page 27

27

Notes13.

Page 28

Please dispose all packaging materials and

dismantled parts properly.

LUKAS

Weinstraße 39, D-91058 Erlangen

Postfach 2560, D-91013 Erlangen

Tel.: (+49) 0 91 31 / 698 - 0

Fax.: (+49) 0 91 31 / 698 - 394

e-mail: lukas.info@idexcorp.com

Hydraulik GmbH

Made in GERMANY

© Copyright 2010 LUKAS Hydraulik GmbHCT7_BA_GB_84072134485_0809.indd

Subject to revision

Loading...

Loading...