Page 1

Pub. 988-0154-641

EP-90R Pressure

Electronic Sensor

Installation and Configuration Instructions

This document shows how to install an EP-90R Pressure sensor and

how to connect it to a NMEA 2000

instructions on how to configure your pressure sensor with Lowrance

digital gauges (LMF-200 & LMF-400) and display units.

NMEA 2000 is the communication bus standard developed by the

National Marine Electronics Association (NMEA) for use in boats.

Lowrance has introduced a line of products that can communicate over

a NMEA 2000 network (LowranceNet).

All Lowrance NMEA 2000 capable devices are either NMEA 2000

certified or certification is pending.

CAUTION:

Installing LowranceNET NMEA 2000 devices is significantly

different from installing earlier Lowrance components without

NMEA 2000 features. You should read all of the installation

instructions before proceeding. Decide where you want to install

all components before drilling any holes in your vessel.

Some sonar or GPS display units may require a software upgrade to

display NMEA 2000 data correctly. For free software upgrades or

additional information on the LowranceNet NMEA 2000

system, visit our web site, www.lowrance.com.

®

network. It also provides

®

network

Red NMEA 2000

connector

Hose barb

attachment

EP-90R Pressure Sensor.

1

Page 2

The EP-90R consists of a red cable connector and the EP-90R housing

with standard size hose barb attachment.

The EP-90R Water Pressure sensor, like the other LowranceNet

Electronic Probe (EP) sensors, is designed for use with a NMEA 2000

DeviceNet Network. Your sensor, however, is also compatible with

LowranceNet blue connector networks. It can be added to a blue

connector network by using a red female to blue female adapter cable.

Your sensor MUST be connected to a NMEA 2000 network or it WILL

NOT function.

The NMEA 2000 red female to blue female adapter cable allows users

to add red connector devices to a blue connector network.

Tools and Supplies

Your EP sensor packs with a T connector needed to attach it to a

LowranceNET NMEA 2000 network. If this is the first sensor you are

connecting, you may also need a one-time purchase of a LowranceNET

Node Kit.

The following tools and supplies are NOT included. Required tools

include: a utility knife. For some installations, a Phillips screwdriver

will be needed. Supplies include: zip/cable tie.

LowranceNET Node Kit for a NMEA 2000 network. Includes a 2-foot

extension cable, T connector and two 120-ohm terminators.

2

Page 3

For complete instructions on setting up a new NMEA 2000 network or

expanding an existing one, see the other document packed with your

EP-90R, "Setup and Installation of NMEA 2000 Networks, General

Information" part number 988-0154-173. If that document is not

available, it can be downloaded free from the Lowrance web site.

Installation

The EP-90R Pressure sensor can provide pressure data for the

following categories: Atmospheric Pressure, Engine Boost Pressure,

Engine Oil Pressure, Engine Water Pressure, Fuel Pressure,

Transmission Oil Pressure and Pitot Speed.

WARNING:

The maximum pressure for an EP-90R Pressure sensor is

100 PSI (689 kPa). If that pressure level is exceeded you

not only risk damaging the EP-90R, but could also suffer

bodily injury.

Pitot Tube (Water Speed)

We recommend installing the EP-90R near the boat’s original

speedometer.

NOTE:

If your engine does not have a speedometer hose, you will have to

purchase a pitot tube kit to use the EP-90R Pressure sensor. For

pitot tube installation instructions, refer to your pitot tube

installation manual.

The following steps cover the recommended installation of the EP-90R.

You will attach the EP-90R to a pitot tube hose in the same manner.

1. Remove the pressure hose from the boat’s speedometer.

2. Clip off the end of the pressure hose that was connected to the

speedometer. This will help ensure the pressure hose will fit snugly on

the EP-90R hose barb attachment. The hose-barb attachment

requires a 1.4" (6.35 mm) hose.

1/4 " hose barb attachment

3

Page 4

3. Slide the pressure hose onto the EP-90R hose barb attachment. If it

does not fit snugly, secure it with a zip tie at the base of the hose barb

attachment.

4. Now you are ready to remove the speedometer. Refer to the

speedometer’s installation manual for removal instructions.

5. The EP-90R is ready to be connected to NMEA 2000 network. If the

NMEA 2000 network backbone is in another part of the boat, the EP90R can be linked to the display unit at the console — if one is present

— or either of the LMF digital gauges by using the T connector that

was included in the packaging. If the network backbone is near the

console, connect the EP-90R red male connector to a T connector in the

desired location on the network backbone. The EP-90R is ready for use.

The rest of this document contains detailed information on connecting

to a NMEA 2000 network.

Installing the EP-90R to measure other data:

Follow this installation to monitor the following data: Atmospheric

Pressure, Engine Boost Pressure, Engine Oil Pressure, Engine Water

Pressure, Fuel Pressure and Transmission Oil Pressure.

NOTE:

Make sure the pressure hose has enough slack to be attached to the

pressure sensor when the EP-90R is connected to the NMEA 2000

backbone.

1. Slide the (Atmospheric, Engine Boost, Engine Oil, Engine Water,

Fuel or Transmission Oil) pressure hose onto the EP-90R hose barb

attachment. Attach a zip tie or hose clamp at the base of the hose barb

attachment.

2. The EP-90R is ready to be connected to NMEA 2000 network. If the

NMEA 2000 network backbone is in another part of the boat, the EP90R can be linked to the display unit at the console — if one is present

— or either of the LMF digital gauges by using the T connector that

was included in the packaging. If the network backbone is near the

console, connect the EP-90R red female connector to a T connector in

the desired location on the network backbone.

Connecting to a NMEA 2000 Network

A NMEA 2000 network is a communications link between two or more

devices that transfer NMEA 2000 information. A NMEA 2000 network

functions like the phone wiring in a house. If, for example, you pick up

a phone in the living room you will be able to hear the conversation

someone is having on a phone in the bedroom.

4

Page 5

In similar fashion, a NMEA 2000 network allows multiple display units

to receive data from a GPS antenna or multiple sonar units to receive

messages sent from a temperature sensor. A NMEA 2000 network

gives you the flexibility to view information like, engine diagnostics

and fuel level data on digital gauges or display units located anywhere

on your boat.

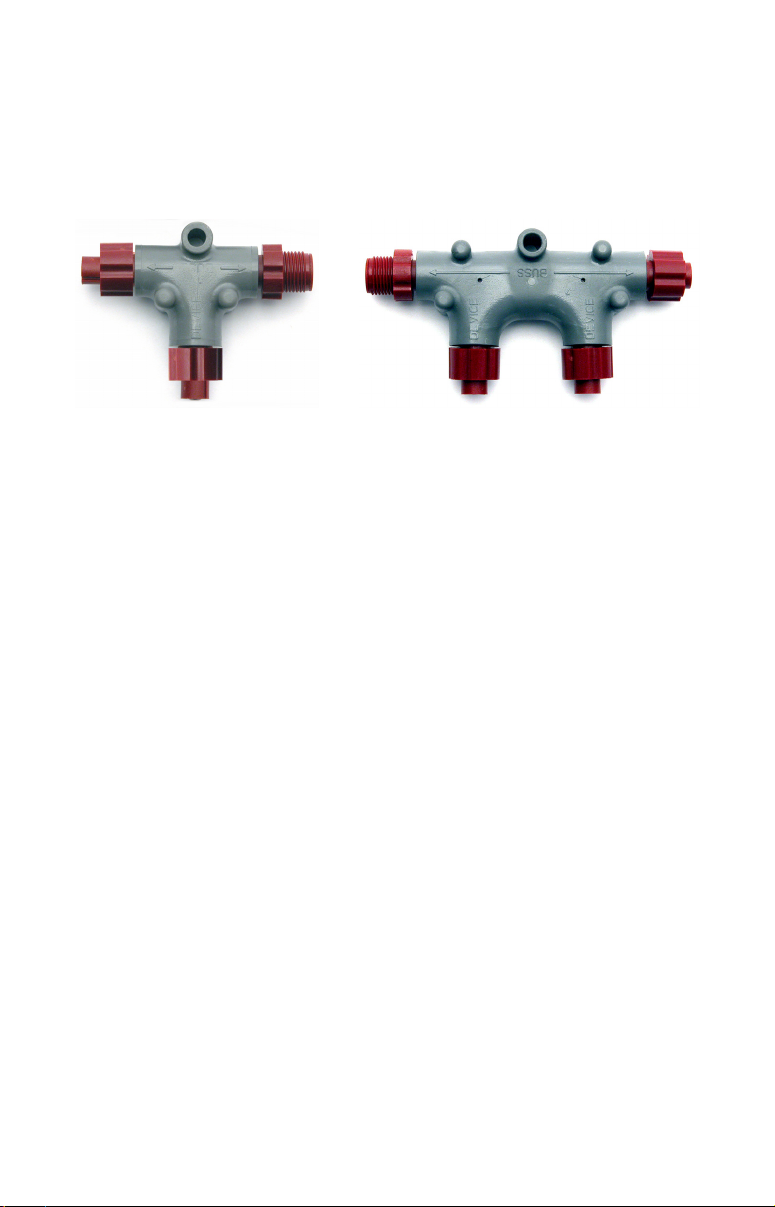

There are two types of LowranceNet red connectors: the single T

connector (left) and the double T connector (right).

Network Backbone and Network Nodes

A network bus backbone consists of network cabling, terminators and T

connectors. Network nodes are made by fitting T-shaped connectors into

the backbone (using the sockets on the sides) and attaching any network

device to the bottom of the T.

Staying with the previous phone wiring example, T connectors on the

backbone are the equivalent of phone jacks spread throughout a house.

To pick up a phone and be able to hear a conversation from another

phone in the house, both phones have to be connected to the main phone

line. In similar fashion, only sensors and display units plugged into the

NMEA network can share information.

The network backbone is like the phone wiring that runs throughout a

home. It connects the network nodes, allowing them to communicate

across the network. Connections found in the middle of the bus could have

T connectors or backbone network cable plugged into one or both sides.

Connections at the end of a network will have the backbone cable plugged

into one side and a terminator plugged into the other.

5

Page 6

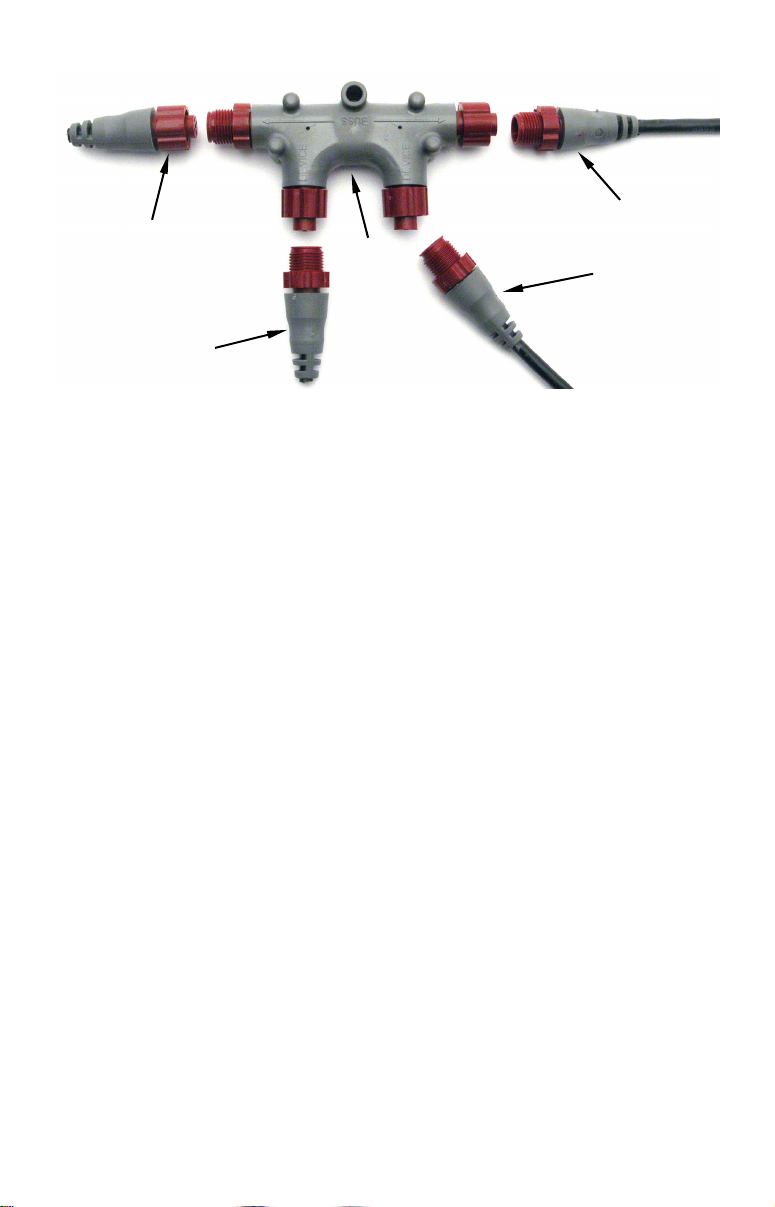

Terminator at

the end of the

backbone (bus)

Cap for unused

connector

Double T

connector

Backbone cable

(to rest of bus)

Cable from

sensor or

display unit

NMEA 2000 network node located at the end of a NMEA 2000 backbone.

NOTE:

If you have a double T Connector on your network that is not

attached to a device, you must cap the unused connector with a

NMEA 2000 cap. This will protect the pin connectors from

corrosion. The NMEA 2000 cap looks like a terminator, but has

"Cap" stamped into the connector housing.

If you want to add another node to a working network, add another T

connector. T connectors may be purchased from LEI. If you are adding a

Lowrance or LEI NMEA 2000 sensor, it will come with its own T

connector.

Adding a Network Node

You can add a node to any existing connection, anywhere along the

network backbone. This connection could be between a T connector and a

terminator, between two T connectors, between a T connector and a

backbone extension cable or between two extension cables. Wherever you

want to add the new node, separate the sockets of the existing connection

and install the T connector between them.

If you want to add a node at the end of the backbone (network bus)

remove the terminator from the last connector. Install the new T

connector and attach the terminator to the side of the connector.

6

Page 7

Use T-connector or double T connector to add

device to bus (maintaining linear architecture)

Attach

terminator at

end of bus

In this example, a new device is added to the NMEA 2000 bus by

installing a T connector between a T connector and a terminator at the

end of the backbone (network bus).

Backbone cable

to rest of bus

Existing network

node

Devices connect to

double T connector

Additional Network Information

For more information on creating or expanding a network refer to the

NMEA 2000 network setup booklet, part number 988-0154-173, which

came packed with this document.

7

Page 8

Notes

8

Page 9

LMF-200: EP-90R

Pressure Configuration

This section covers how to use EP-90R Pressure Sensor with the LMF200 Multi-function gauge.

NOTE:

You will notice the LMF-200 does not have an Exit key. Menus will

time out after a preset amount of time (3, 5, 10 or 15 seconds). The

default setting is 5 seconds. Refer to your LMF-200 instruction

manual for more information on the Timeout feature.

LMF-200 Multi-function Digital Gauge.

Boat Setup

If this is the first time you have turned on your LMF-200, you will have

to complete Boat Setup before you will be able to configure your

pressure sensor.

To execute Boat Setup:

1. With Boat Setup highlighted on the screen, press MENU. The Boat

Setup menu will appear, allowing you to select an engine-tank

configuration that matches the number of engines and fuel tanks on

your vessel. Boat Setup options include: 1 En/1 Tk, 1 En/2 Tk, 2 En/1

Tk, 2 En/2 Tk, 3 En/1 Tk and 3 En/3 Tk.

2. Select the configuration option that matches number of engines and

tanks on your vessel and press

3. Select the tank you want to set up and press

the Tank Size window.

MENU.

MENU, which will open

9

Page 10

4. Use the

will hold and press

UP and DOWN keys to input the number of gallons the tank

MENU. Repeat steps 3 and 4 for each additional

tank. After all tanks have been set up, you will be directed to the main

display.

Boat Setup Reset

If you want to access the Setup screen (Boat Setup) after an enginetank configuration has been chosen you will have to reset the

configuration to default settings.

To reset engine tank configuration:

1. Press MENU, highlight SYSTEM SETUP and press MENU.

2. Choose

ENG/TANK and press MENU twice. The following message will

appear: Hit menu to reset Eng/Tnk.

3. Press

MENU. The Setup screen will appear with Boat Setup

highlighted.

EP-90R Pressure Configuration

Your EP-90R Pressure Sensor can be configured to measure the

following data types: Pitot Speed (PTT:S), Water Pressure (WTR:P),

Engine Oil Pressure (Eng:O:P), Fuel Pressure (FUL:P), Boost Pressure

(BST:P), Transmission Oil Pressure (Trn:O:P) and Atmospheric

Pressure (ATM:P).

To configure the EP-90R:

1. Press MENU, select SYSTEM SETUP and press MENU.

2. Highlight

pressure sensor (

will appear: Hit Menu to Cfg Pres Snsr.

3. Press

Pressure),

(Boost Pressure), TRN:O:P (Transmission Oil Pressure) or ATM:P

(Atmospheric Pressure) and press MENU. The Select Engine menu will

appear with up to three options. (If your unit is set to a single-tank

configuration, or if you chose Pitot Speed or Atmospheric Pressure, you

will be directed to the Bus Devices list.)

BUS DEVICES and press MENU. Select an unconfigured

UNCFG PRES) and press MENU. The following message

MENU, then select PTT:S (Pitot Speed), WTR:P (Engine Water

ENG:O:P (Engine Oil Pressure), FUL:P (Fuel Pressure), BST:P

4. Select the desired tank and press

the Bus Devices list.

10

MENU. You will be taken back to

Page 11

To unconfigure the EP-90R:

1. Press MENU, select SYSTEM SETUP and press MENU.

2. Highlight

sensor and press

3. The pressure sensor menu will appear. Highlight

MENU. The following message will appear: Hit Menu to Unset Dev

BUS DEVICES and press MENU. Select a configured pressure

MENU.

UNCONFIG and press

Name.

4. Press

To reconfigure the EP-90R:

MENU. You will be taken back to the Bus Devices list.

1. Press MENU, select SYSTEM SETUP and press MENU.

2. Highlight

sensor and press

3. The pressure sensor menu will appear. Highlight

MENU.

4. Select

BUS DEVICES and press MENU. Select a configured pressure

MENU.

RECONFIG and press

PTT:S (Pitot Speed), WTR:P (Engine Water Pressure), ENG:O:P

(Engine Oil Pressure), FUL:P (Fuel Pressure), BST:P (Boost Pressure),

TRN:O:P (Transmission Oil Pressure) or ATM:P (Atmospheric Pressure)

and press

MENU. The Select Engine menu will appear with up to three

options. (If your unit is set to a single-tank configuration, or if you

chose Pitot Speed or Atmospheric Pressure, you will be directed to the

Bus Devices list.)

4. Select the desired engine and press

MENU. You will be taken back to

the Bus Devices list.

Displaying Pressure Sensor Data

You can display pressure data on the Gauge, Single Digital, Dual

Digital and Fuel Manager pages.

Page Screen Rotation

The Page Screen Rotation consists of multiple pages that have been set

for display. Once pages have been added to the rotation, they can be set

to scroll across the screen automatically or manually. Press the

DOWN keys to manually scroll pages across the screen. Pressing the UP

key moves the scroll in one direction. Pushing the

DOWN key moves the

scroll in the other direction. You can use Autoscroll if you want the

pages to automatically scroll across the screen. Refer to your LMF -200

manual for information about Autoscroll.

11

UP and

Page 12

Adding a page:

1. Press MENU, use the UP and DOWN keys to select PAGES and press

MENU, which will open the Pages menu with the following options: Add

Page, Rem Page, Autoscroll and Set Pop-up.

2. Highlight

3. Select Gauge, Single Digital or Dual Digital and press

ADD PAGE and press MENU.

MENU. You

will be taken back to the main display, where the page you selected will

be shown.

Customizing Pages

The customizing pages feature allows you to choose what data will be

displayed and where it will be displayed on select pages. You can

customize the Gauge, Single Digital and Dual Digital pages with

pressure sensor data: Pitot Speed (PTT:S), Water Pressure (WTR:P),

Engine Oil Pressure (Eng:O:P), Fuel Pressure (FUL:P), Boost Pressure

(BST:P), Transmission Oil Pressure (Trn:O:P) and Atmospheric

Pressure (ATM:P).

To customize Gauge page:

1. After the Gauge page has been added to the page screen rotation, use

the

UP and DOWN keys to display it on the screen.

2. Press

3. Highlight

ENG:O:P (Engine Oil Pressure), FUL:P (Fuel Pressure), BST:P (Boost

Pressure),

Pressure) and press

MENU, select CUSTOMIZE and press MENU.

PTT:S (Pitot Speed), WTR:P (Engine Water Pressure),

TRN:O:P (Transmission Oil Pressure) or ATM:P (Atmospheric

MENU. If your unit is configured for multiple tanks,

the Select Engine menu will appear with up to three options. (If you

are using a single-tank configuration, or if you chose Pitot Speed or

Atmospheric Pressure, you will be directed to the main display.)

4. Highlight the desired tank and press

MENU. You will be taken back

to the main display.

To customize Single Digital page:

1. After the Single Digital page has been added to the page screen

rotation, use the

2. Press

MENU, select CUSTOMIZE and press MENU.

3. Highlight

ENG:O:P (Engine Oil Pressure), FUL:P (Fuel Pressure), BST:P (Boost

Pressure),

TRN:O:P (Transmission Oil Pressure) or ATM:P (Atmospheric

Pressure) and press

UP and DOWN keys to display it on the screen.

PTT:S (Pitot Speed), WTR:P (Engine Water Pressure),

MENU. The Select Engine menu will appear with

12

Page 13

up to three options. (If your unit is configured for one engine, or if you

chose Pitot Speed or Atmospheric Pressure, you will be directed back to

the main display.)

4. Select the desired engine and press

MENU. You will be taken back to

the main display.

To customize Dual Digital page:

1. After the Dual Digital page has been added to the page screen

rotation, use the

2. Press

MENU, select CUSTOMIZE and press MENU. The Position menu will

UP and DOWN keys to display it on the screen.

appear with two options: Top Data and Bottom Data.

3. Select the desired data position and press

4. Highlight

ENG:O:P (Engine Oil Pressure), FUL:P (Fuel Pressure), BST:P (Boost

Pressure),

Pressure) and press

PTT:S (Pitot Speed), WTR:P (Engine Water Pressure),

TRN:O:P (Transmission Oil Pressure) or ATM:P (Atmospheric

MENU. The Select Engine menu will appear with

MENU.

up to three options. (If your unit is configured for one engine, or if you

chose Pitot Speed or Atmospheric Pressure, you will be directed back to

the main display.)

5. Select the desired engine and press

MENU. You will be taken back to

the main display.

To customize Fuel Manager page:

1. After the Fuel Manager page has been added to the page screen

rotation, use the

2. Press

MENU, select CUSTOMIZE and press MENU.

3. Highlight

UP and DOWN keys to display it on the screen.

PTT:S (Pitot Speed) and press MENU. You will be taken

back to the main display.

Pressure Range (Gauge Page only)

From the analog page, you can set pressure ranges for Boost, Oil, Fuel

and Transmission Oil Pressure.

To set pressure range:

1. From the Gauge page, press MENU and select SYSTEM SETUP.

2. Highlight

Pressure menu with the following options: FUL:P (Fuel Pressure),

BST:P (Boost Pressure), WTR:P (Engine Water Pressure), Eng:O:P

(Engine Oil Pressure) and Trn:O:P (Transmission Oil Pressure).

13

PRES RNGS (Pressure Ranges), which will open the Select

Page 14

3. Select the desired option and press

MENU. The Pressure Range menu

will appear with the following options: 0-30 psi, 0-60 psi, 0-80 psi and

0-100 psi.

4. Select the desired PSI range and press

MENU.

Warning Threshold

When you set a Warning Threshold for a pressure sensor, a pop-up

window will appear and an alarm will sound when pressure exceeds a

preset pressure level of your choosing.

NOTE:

Warning Thresholds may be set to monitor Boost Pressure, Engine

Water Pressure, Oil Pressure, Fuel Pressure and Transmission Oil

Pressure.

To set a warning threshold:

1. Press MENU, select SYSTEM SETUP and press MENU.

2. Highlight

3. Select the desired pressure sensor and press

TRHLD and press MENU.

4. Use the

the

DOWN key to turn off a warning threshold. The threshold will be set

BUS DEVICES and press MENU.

MENU. Highlight WRNING

UP and DOWN keys to select the desired PSI level. Depress

to Off by default.

5. When the threshold is set to the desired level, press

MENU.

Reset

The reset command switches pressure sensor settings (alarms and

configuration) to default values.

To reset EP-90R values:

1. Press MENU, select SYSTEM SETUP and press MENU.

2. Highlight

sensor and press

3. The pressure sensor menu will appear. Highlight

MENU. The following message will appear: Press Menu to Rst Values.

You will be taken back to the Bus Devices list where the sensor will be

shown as PTT:S (Pitot Speed).

BUS DEVICES and press MENU. Select a configured pressure

MENU.

RESET and press

14

Page 15

LMF-400: EP-90R

Pressure Configuration

This section covers how to use your EP-90R Pressure Sensor with the

LMF-400 Multi-function gauge.

LMF-400 Multi-function Digital gauge.

Boat Setup

If this is the first time you have turned on your LMF-400, you will have

to complete Boat Setup before you will be able to configure your water

pressure sensor.

To execute Boat Setup:

1. With Boat Setup highlighted on the screen, press ENTER. A menu

will appear, allowing you to choose the number of engines and fuel

tanks on your vessel. The Boat Setup menu options are: 1 Eng/1 Tank,

1 Eng/2 Tank, 2 Eng/1 Tank, 2 Eng/2 Tanks, 3 Eng/1 Tank or 3 Eng/3

Tanks.

2. Use the

that applies to your vessel and press

engine/tank configuration, the Tank Size menu will appear with up to

three options (Port Tank, Center Tank and Starboard Tank), depending

on the engine tank configuration you chose. (If you selected one tank

during Boat Setup, you will be taken directly to the Setting Tank Size

Window in Step 4.)

3. Select the desired tank and press

Tank Size window.

4. Use the

will hold and press

of the remaining tanks.

UP and DOWN keys to select the engine-tank configuration

ENTER. After setting the

ENTER, which will open the Setting

UP and DOWN keys to input the number of gallons the tank

ENTER. Press EXIT and repeat steps 3 and 4 for each

15

Page 16

5. After all tanks on your vessel have been set up, press

EXIT repeatedly

to return to the main display.

Boat Setup Reset

If you want to access the Setup screen (Boat Setup) after an enginetank configuration has been chosen you will have to reset the

configuration to default settings.

To reset engine-tank configuration:

1. Press MENU, highlight SYSTEM SETUP and press ENTER.

2. Choose

ENG/TANK CFG and press ENTER twice. The following message

will appear: Press ENTER to reset Eng/Tnk Cfg.

3. Press

MENU. The Setup Menu will appear with Boat Setup

highlighted.

EP-90R Pressure Configuration

Your EP-90R Pressure Sensor can be configured to monitor the

following data: Pitot Tube, Engine Boost Pressure, Engine Oil

Pressure, Engine Water Pressure, Fuel Pressure, Transmission Oil

Pressure and Atmospheric Pressure.

To configure the EP-90R:

1. Press MENU, select SYSTEM SETUP and press ENTER.

2. Highlight

pressure sensor and press

BUS DEVICES and press ENTER. Select an unconfigured

ENTER. The following message will appear:

Press Enter to Configure Pressure Snsr.

3. Select

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER.

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

4. The Select Engine menu will appear with up to three options. (If

your unit is set to a single-engine configuration, or if you chose Pitot

Tube or Atmospheric Pressure, you will be taken back to the Bus

Devices list.)

5. Select the desired engine and press

ENTER. You will be directed to

the Bus Devices list.

To unconfigure the EP-90R:

1. Press MENU, select SYSTEM SETUP and press ENTER.

2. Highlight

sensor and press

3. Highlight

BUS DEVICES and press ENTER. Select a configured pressure

ENTER.

UNCONFIGURE and press ENTER. The following message will

appear: Press Enter to Unconfig Device Name.

16

Page 17

4. Press

EXIT repeatedly to return to the main display.

To reconfigure the EP-90R:

ENTER. You will be taken back to the Bus Devices list. Press

1. Press MENU, select SYSTEM SETUP and press ENTER.

2. Highlight

sensor and press

3. Highlight

4. Select the

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

BUS DEVICES and press ENTER. Select a configured pressure

ENTER.

RECONFIGURE and press ENTER.

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If you are using a

single-engine configuration you will be taken back to the Bus Devices

list.)

5. Select the desired tank and press

the Bus Devices list. Press

EXIT repeatedly to return to the main

ENTER. You will be taken back to

display.

Displaying Pressure Sensor Data

You can display pressure sensor data on the Single Analog, Dual

Analog, Quad Analog, Single Digital, Dual Digital, Quad Digital and

Fuel Manager pages.

Page Screen Rotation

The Page Screen Rotation consists of multiple pages that have been set

up for display. Once pages have been added to the page screen rotation,

they can be set to scroll across the screen automatically or manually.

Use the

screen. Pressing the

Pushing the

use the Page Scrolling if you want pages to automatically scroll across

the screen. Refer to your LMF-400 manual for more information about

Page Scrolling.

To add a page to the display:

1. Press MENU, use the UP and DOWN keys to select PAGES and press

ENTER. A menu will pop up with four options: Add Page, Remove Page,

Page Scrolling and Pop-Ups Setup.

2. Select ADD PAGE and press ENTER.

3. Highlight Single Analog, Dual Analog, Quad Analog, Single Digital,

Dual Digital, Quad Digital or Fuel Manager and press

following message will appear: Press Enter to add the selected page.

4. Press

the page you selected will be shown on the screen.

17

ENTER and EXIT keys to manually scroll pages across the

ENTER key moves the scroll in one direction.

EXIT key moves the scroll in the other direction. You will

ENTER. The

ENTER, which will take you back to the main display, where

Page 18

Customizing Pages

The customizing pages feature allows you to choose what data will be

displayed on selected pages. You can use the Single Analog, Dual

Analog, Quad Analog, Single Digital, Dual Digital, Quad Digital pages

and Fuel Manager pages to display pressure sensor data.

To customize Single Analog page:

1. Make sure the Single Analog page has been added to the page screen

rotation.

2. Use the

ENTER and EXIT keys to scroll the Single Analog page onto

the main display.

3. Press

ENTER. The data menu will appear.

4. Select

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the Bus Devices list.)

5. Select the desired engine and press

the Bus Devices list. Press

EXIT repeatedly to return to the main

ENTER. You will be taken back to

display.

To customize Dual Analog page:

1. Make sure the Dual Analog page has been added to the page screen

rotation.

2. Use the

ENTER and EXIT keys to scroll the Dual Analog page onto the

main display.

3. Press

ENTER. The Position menu will appear with two options: Top Gauge

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

and Bottom Gauge.

4. Select the desired position

and press ENTER. The data menu will

appear.

5. Highlight

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the Position menu.)

6. Select the desired engine and press

ENTER. You will be directed to

the Position menu.

7. Repeat steps 4-6 to customize the other position or press

EXIT

repeatedly to return to the main display.

18

Page 19

To customize Quad Analog page:

1. Make sure the Quad Analog page has been added to the page screen

rotation.

2. Use the

ENTER and EXIT keys to scroll the Quad Analog page onto the

main display.

3. Press

MENU, select CUSTOMIZE and press ENTER. The Position menu

will appear with four options: Top Left, Top Right, Bottom Left and

Bottom Right.

4. Select the desired position and press ENTER. The data menu will

appear.

5. Highlight

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the Position menu.)

6. Select the desired engine and press

ENTER. You will be directed to

the Position menu.

7. Repeat steps 4-6 to customize the other positions or press

EXIT

repeatedly to return to the main display.

To customize Single Digital page:

1. After the Single Digital page has been added to the page screen

rotation, use the

2. Press

ENTER. The data menu will appear.

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

3. Highlight

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

ENTER and EXIT keys to display it on the main screen.

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the main display.)

4. Select the desired engine and press

ENTER. You will be taken back to

the main display, where the data you selected will be shown.

To customize Dual Digital page:

1. After the Dual Digital page has been added to the page screen

rotation, use the

2. Press

ENTER. The Position menu will appear with two options: Top Data and

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

ENTER and EXIT keys to display it on the main screen.

Bottom Data.

3. Highlight the desired data position and press

ENTER.

19

Page 20

5. Highlight

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the Position menu.)

6. Select the desired engine and press

ENTER. You will be directed to

the Position menu.

7. Repeat steps 4-6 to customize the other position or press

EXIT

repeatedly to return to the main display.

To customize Quad Digital page:

1. After the Quad Digital page has been added to the page screen

rotation, use the

2. Press

ENTER. The Position menu will appear with four options: Data Box 1,

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

ENTER and EXIT keys to display it on the main screen.

Data Box 2, Data Box 3 and Data Box 4.

3. Highlight the desired data position and press

5. Highlight

PRESSURE, TRNS OIL PRESS or ATM PRESSURE and press ENTER. The Select

PITOT SPEED, ENG BST PRESS, ENG OIL PRESS, ENG WTR PRESS, FUEL

ENTER.

Engine menu will appear with up to three options. (If your unit is set to

a single-engine configuration, or if you chose Pitot Speed or ATM

Pressure, you will be taken back to the Position menu.)

6. Select the desired engine and press

ENTER. You will be directed to

the Position menu.

7. Repeat steps 4-6 to customize the other positions or press

EXIT

repeatedly to return to the main display.

To customize Fuel Manager page:

1. After the Fuel Manager page has been added to the page screen

rotation, use the

2. Press

ENTER. The Position menu will appear with three options: Top Data,

MENU, use the UP and DOWN keys to select CUSTOMIZE and press

ENTER and EXIT keys to display it on the main screen.

Center Data and Bottom Data.

3. Highlight the desired data position and press

5. Highlight

6. Select the desired engine and press

PITOT SPEED and press ENTER.

ENTER. You will be directed to

ENTER.

the Position menu.

7. Repeat steps 4-6 to customize the other positions or press

EXIT

repeatedly to return to the main display.

20

Page 21

Pressure Range (Analog Pages only)

From the Single, Dual and Quad Analog pages, you can set pressure

ranges for Boost, Oil, Fuel and Transmission Oil Pressure.

To set pressure range:

1. From an analog page, press MENU, select SYSTEM SETUP and press

ENTER.

2. Highlight

PRESS RANGES (Pressure Ranges) and press ENTER. The

Select Pressure menu with the following options: Eng Water Pressure,

Eng Oil Pressure, Fuel Pressure, Eng Bst Press (Engine Boost

Pressure) and Trns Oil Press (Transmission Oil Pressure).

3. Select the desired option and press

ENTER. The Pressure Range

menu will appear with the following options: 0-15 psi, 0-30 psi, 0-60

psi, 0-80 psi and 0-100 psi.

4. Select the desired PSI range and press

ENTER.

Warning Threshold

When you set a Warning Threshold for a pressure sensor, a pop-up

window will appear and an alarm will sound when pressure exceeds a

preset pressure level of your choosing.

NOTE:

Warning Thresholds may be set to monitor Boost Pressure, Engine

Water Pressure, Oil Pressure, Fuel Pressure and Transmission Oil

Pressure.

To set a warning threshold:

1. Press MENU, select SYSTEM SETUP and press ENTER.

2. Highlight

3. Select the desired pressure sensor and press

4. Highlight

5. Use the

threshold. Press

6. Press

BUS DEVICES and press ENTER.

ENTER.

WRNG THRESHLD and press ENTER.

UP and Down KEYS to input the desired PSI level for the

ENTER. You will be taken back to the Bus Devices list.

EXIT repeatedly to return to the main display.

Reset Values

The Reset Values command switches pressure sensor settings (Alarms

and Configuration) to default values.

21

Page 22

To reset pressure sensor values:

1. Press MENU, select SYSTEM SETUP and press ENTER.

2. Highlight

3. Select the desired pressure sensor and press

4. Highlight

appear: Press Enter to Reset Values.

5. You will be taken back to the Bus Devices list. Press

to return to the main display.

BUS DEVICES and press ENTER.

ENTER.

RESET VALUES and press ENTER. The following message will

EXIT repeatedly

22

Page 23

Display Unit: EP-90R

Pressure Configuration

This section will show you how to use an EP-90R Pressure Sensor with

a display unit.

The LMS-525cDF is one of many Lowrance display units that may be

used with the EP-90R Pressure Sensor.

NOTE:

Your unit may have a NMEA 2000 menu or a Networking menu,

depending on the software version installed in your unit. Both

menus allow you to perform the same NMEA 2000-related

functions.

Bus Setup

Selecting Bus Setup from the NMEA 2000 or Networking menu will

open the Bus Configuration menu, giving you access to the EngineTank Configuration menu and the NMEA 2000 Devices list. The list,

located in the top half of the Bus Configuration menu, shows all devices

connected to the network. The Engine-Tank Configuration menu is

located in the bottom half of the Bus Configuration menu.

NOTE:

Some of the menus shown in this section may differ slightly from

the menus in your display unit, but your unit will perform the same

functions in a similar manner.

23

Page 24

Engine & Tank Configuration

The Engine-Tank configuration menu is located below the NMEA 2000

Devices list, but will only be accessible if engine- or fuel-related devices

are on the network.

When choosing an engine-tank configuration you will use the Tank

Select menu, Tank Size dialog box and Set Configuration button.

Bus Setup highlighted on the NMEA 2000 menu (left). Bus Setup

selected on Networking menu (right).

Setting Engine-Tank Configuration:

1. Press MENU twice, highlight NMEA 2000 or NETWORKING and press

ENTER.

2. The NMEA 2000 menu will appear with five options: Bus Setup,

Fuel Management, NMEA 2000 Alarms, Waypoint Sharing and

Backlight Synchronization. Choose

3. Select

ENGINE & TANK CONFIG and press ENTER, which will open the

Engine & Tank Configuration menu with the following configuration

options: 1 Engine/1 Tank, 1 Engine/2 Tanks, 2 Engines/1 Tank, 2

Engines/2 Tanks, 3 Engines/1 Tank, 3 Engine/3 Tanks and

Unconfigured Bus.

4. Choose the configuration that matches the number of engines and

tanks on your vessel and press

5. Highlight

TANK SELECT and press ENTER, which will open the Tank

Select menu.

6. Select the tank you want to set up and press

Tank Size dialog box and press

7. Input the capacity (gallons) of the tank you chose from the Tank

Select menu and press

ENTER.

8. Repeat Steps 5-7 for each remaining tank.

BUS SETUP and press ENTER.

ENTER.

ENTER. Highlight the

ENTER.

24

Page 25

9. When all tanks have been configured, highlight the

button and press

ENTER. The following confirmation message will

SET CONFIGURATION

appear: Are you sure you wish to change the bus configuration? Choose

YES and press ENTER, Press EXIT to return to the main display.

1 Engine/1Tank highlighted on Engine and Tank Configuration

menu (left). Starboard highlighted on Tank Select menu (center).

Tank Size set to 40 gallons (right).

9. When all tanks have been configured, highlight the SET CONFIGURATION

button and press

ENTER. The following confirmation message will

appear: Are you sure you wish to change the bus configuration? Choose

YES and press ENTER, Press EXIT to return to the main display.

EP-90R Pressure Sensor Configuration

The Location and Pressure Type menus will be used when configuring

you EP-90R. You can also change the sensor's Device Name.

Device Name

You can change how your pressure sensor will be displayed on your

unit's NMEA 2000 Devices list by inputting a customized device name

in the Device Name dialog box.

NOTE:

Changing the Device Name only will affect the way the EP-90R is

shown on your display unit. The customized device name will not

be seen by other devices or display units on the NMEA 2000

network.

To change Device Name:

1. Press MENU twice, select NMEA 2000 or NETWORKING and press ENTER.

2. Highlight

sensor from the Bus Devices list and press

3. Device Name will be highlighted. Press

Name dialog box.

25

BUS SETUP and press ENTER. Select the desired pressure

ENTER.

ENTER to access the Device

Page 26

4. Use the

have finished inputting the desired Device Name, press

EXIT repeatedly to return to the main display.

To reset device name to default setting:

UP and DOWN keys to change the Device Name. When you

ENTER. Press

1. Press MENU twice, select NMEA 2000 or NETWORKING and press ENTER. A

menu will appear with five options: Bus Setup, Fuel Management,

NMEA 2000 Alarms, Waypoint Sharing and Backlight

Synchronization.

2. Highlight

BUS SETUP and press ENTER, which will open the Bus

Configuration menu. A list of network devices will be at the top of the

page.

3. Select the pressure sensor with the device name you want to reset

and press

ENTER. The Device Configuration menu will appear with the

Device Name dialog box highlighted.

4. Press

disappears. Press

ENTER. Depress the left arrow key until the device name

ENTER, then press EXIT to return to the NMEA 2000

menu.

5. Highlight the device and press

ENTER. The Device Configuration

menu will open. The device name will be reset to its default setting.

Press

EXIT repeatedly to return to the main display.

To select Location:

1. Press MENU twice, select NMEA 2000 or NETWORKING and press ENTER. A

menu will appear with five options: Bus Setup, Fuel Management,

NMEA 2000 Alarms, Waypoint Sharing and Backlight

Synchronization.

2. Highlight

BUS SETUP and press ENTER, which will open the Bus

Configuration menu. A list of network devices will be at the top of the

page.

3. Select the desired pressure sensor and press

ENTER. The Device

Configuration menu will appear.

4. Highlight

LOCATION and press ENTER.

5. Select the desired location or the default (Unknown) and press

ENTER. The following message will appear: Are you sure you wish to

change this device's configuration?

6. Select

YES and press ENTER. Press EXIT repeatedly to return to the

main display.

26

Page 27

To select Pressure Type:

1. Press

MENU twice, select NMEA 2000 or NETWORKING and press ENTER. A

menu will appear with five options: Bus Setup, Fuel Management,

NMEA 2000 Alarms, Waypoint Sharing and Backlight

Synchronization.

2. Highlight

BUS SETUP and press ENTER, which will open the Bus

Configuration menu. A list of network devices will be at the top of the

page.

3. Select the desired pressure sensor and press

ENTER. The Device

Configuration menu will appear.

4. Highlight

PRESSURE TYPE and press ENTER. The following

configuration options will appear: Pitot Speed, Boost, Oil, Water, Fuel,

Transmission Oil, Atmospheric and the default setting, Unknown.

5. Highlight the desired Pressure Type and press

ENTER. The following

confirmation message will appear: Are you sure you wish to change this

device's configuration?

6. Highlight

YES and press ENTER. Press EXIT repeatedly to return to

the main display.

NOTE:

You can unconfigure your EP-90R by setting the Location and

Pressure Type to Unknown. You also can use the Restore Defaults

command.

Restore Defaults

The Restore Defaults command will reset your pressure sensor to

default settings.

To restore default settings:

1. Press

MENU twice, select NMEA 2000 or NETWORKING and press ENTER.

A menu will appear with five options: Bus Setup, Fuel Management,

NMEA 2000 Alarms, Waypoint Sharing and Backlight

Synchronization.

2. Highlight

BUS SETUP and press ENTER, which will open the Bus

Configuration menu. A list of network devices will be at the top of the

page.

3. Select the desired pressure sensor and press

ENTER. The Device

Configuration menu will appear.

4. Highlight

5. Select

ADVANCED OPTIONS and press ENTER.

RESTORE DEFAULTS and press ENTER. The following message will

appear: Are you sure you wish to change this device's configuration?

27

Page 28

6. Highlight

YES and press ENTER. Press EXIT repeatedly to return to

the main display.

NMEA 2000 Alarms

When you set a NMEA 2000 Alarm for a pressure sensor, a pop-up

window will appear and an alarm will sound when pressure exceeds or

falls below a preset PSI level of your choosing.

To turn on/off NMEA 2000 Alarm:

1. Press MENU twice, select NMEA 2000 or NETWORKING and press ENTER.

2. Highlight

3. Highlight

pressure sensor and press

4. Highlight the

or Low Pressure) and press

alarm is on an "X" will be placed in the Enabled Box.

5. To set the PSI level for an alarm, press → to highlight

press

ENT.

6. Use the arrow keys to input the desired PSI and press

Repeat Steps 3-4 to set the other alarm.

7. Highlight

settings. Press

NOTE:

To turn off (uncheck) an alarm, select its

ENTER. Highlight the SET CONFIGURATION button and press ENTER.

NMEA 2000 ALARMS and press ENTER.

FLUID LEVEL DEVICE and press ENTER. Select the desired

ENTER.

ENABLED box next to the desired alarm (High Pressure

ENTER to turn on the alarm. When the

VALUE and

ENTER.

SET CONFIGURATION and press ENTER to finalize alarm

EXIT repeatedly to get back to the main display.

ENABLED BOX and press

Alarm Status Tab

The Alarm Status tab is the second tab at the top of the NMEA 2000

Alarms page. When an alarm has been set for a device, the alarm and

its current status will be shown on the Alarm Status window.

To view Alarm Status:

1. Press MENU twice, select NMEA 2000 or NETWORKING and press ENTER.

2. Select

NMEA 2000 ALARMS and press ENTER.

3. Highlight the Alarm Status tab.

4. Press

EXIT repeatedly to return to the main display.

28

Page 29

Notes

29

Page 30

Notes

30

Page 31

LOWRANCE ELECTRONICS

FULL ONE-YEAR WARRANTY

"We," "our," or "us" refers to LOWRANCE ELECTRONICS, INC., the manufacturer of

this product. "You" or "your" refers to the first person who purchases this product as a

consumer item for personal, family or household use.

We warrant this product against defects or malfunctions in materials and workmanship,

and against failure to conform to this product's written specifications, all for one (1) year

from the date of original purchase by you. WE MAKE NO OTHER EXPRESS

WARRANTY OR REPRESENTATION OF ANY KIND WHATSOEVER CONCERNING

THIS PRODUCT. Your remedies under this warranty will be available so long as you can

show in a reasonable manner that any defect or malfunction in materials or

workmanship, or any non-conformity with the product's written specifications, occurred

within one year from the date of your original purchase, which must be substantiated by

a dated sales receipt or sales slip. Any such defect, malfunction, or non-conformity which

occurs within one year from your original purchase date will either be repaired without

charge or be replaced with a new product identical or reasonably equivalent to this

product, at our option, within a reasonable time after our receipt of the product. If such

defect, malfunction, or non-conformity remains after a reasonable number of attempts to

repair by us, you may elect to obtain without charge a replacement of the product or a

refund for the product. THIS REPAIR, OR REPLACEMENT OR REFUND (AS JUST

DESCRIBED) IS THE EXCLUSIVE REMEDY AVAILABLE TO YOU AGAINST US FOR

ANY DEFECT, MALFUNCTION, OR NON-CONFORMITY CONCERNING THE

PRODUCT OR FOR ANY LOSS OR DAMAGE RESULTING FROM ANY OTHER

CAUSE WHATSOEVER. WE WILL NOT UNDER ANY CIRCUMSTANCES BE LIABLE

TO ANYONE FOR ANY SPECIAL, CONSEQUENTIAL, INCIDENTAL, OR OTHER

INDIRECT DAMAGE OF ANY KIND.

Some states do not allow the exclusion or limitation of incidental or consequential

damages, so the above limitations or exclusions may not apply to you.

This warranty does NOT apply in the following circumstances: (1) when the product has

been serviced or repaired by anyone other than us; (2) when the product has been

connected, installed, combined, altered, adjusted, or handled in a manner other than

according to the instructions furnished with the product; (3) when any serial number has

been effaced, altered, or removed; or (4) when any defect, problem, loss, or damage has

resulted from any accident, misuse, negligence, or carelessness, or from any failure to

provide reasonable and necessary maintenance in accordance with the instructions of the

owner's manual for the product.

We reserve the right to make changes or improvements in our products from time to time

without incurring the obligation to install such improvements or changes on equipment or

items previously manufactured.

This warranty gives you specific legal rights and you may also have other rights which

may vary from state to state.

REMINDER: You must retain the sales slip or sales receipt proving the date of your

original purchase in case warranty service is ever required.

LOWRANCE ELECTRONICS

12000 E. SKELLY DRIVE, TULSA, OK 74128

(800) 324-1356

31

Page 32

How to Obtain Service…

…in the USA:

Contact the Factory Customer Service Department. Call toll-free:

For Lowrance: 800-324-1356. For Eagle: 800-324-1354

8 a.m. to 5 p.m. Central Standard Time, M-F

Lowrance Electronics and Eagle Electronics may find it necessary to change or end

their shipping policies, regulations and special offers at any time. They reserve the

right to do so without notice.

…in Canada:

Contact the Factory Customer Service Department. Call toll-free:

800-661-3983

905-629-1614 (not toll-free)

8 a.m. to 5 p.m. Eastern Standard Time, M-F

…outside Canada and the USA:

Contact the dealer in the country where you purchased your unit. To locate a

dealer near you, see the instructions in paragraph number 1 below.

Accessory Ordering Information

LEI Extras™, Inc. is the accessory source for sonar and GPS products

manufactured by Lowrance Electronics and Eagle Electronics. To order

Lowrance or Eagle accessories, please contact:

1) Your local marine dealer or consumer electronics store. To locate a Lowrance

dealer, visit the web site, www.lowrance.com, and look for the Dealer Locator.

To locate an Eagle dealer, visit the web site, www.eaglesonar.com, and look for

the Dealer Locator. Or, consult your telephone directory for listings.

2) U.S. cus+tomers: LEI Extras Inc., PO Box 129, Catoosa, OK 74015-0129

Call toll free in the U.S., 800-324-0045, 8 a.m. to 5 p.m. Central

Standard Time, M-F, or visit our web site www.lei-extras.com.

3) Canadian customers: Lowrance/Eagle Canada, 919 Matheson Blvd. E.

Mississauga, Ontario L4W2R7 or fax 905-629-3118.

Call toll free in Canada, 800-661-3983, or dial 905 629-1614 (not toll free), 8

a.m. to 5 p.m. Eastern Standard Time, M-F.

For Lowrance® and Eagle® Products

Pub. 988-0154-641 © Copyright 2007

All Rights Reserved

Printed in USA 091807 Lowrance Electronics, Inc.

32

Loading...

Loading...