Page 1

www.lowrance.com

Pub. 988-0151-062

X67C

Fish-finding & Depth Sounding Sonar

Installation and Operation

Instructions

Page 2

Copyright © 2003 Lowrance Electronics, Inc.

All rights reserved.

Lowrance

®

is a registered trademark of Lowrance Electronics, Inc.

Marine-Tex is a trademark of Illinois Tool Works Inc.

Lowrance Electronics may find it necessary to change or end our

policies, regulations, and special offers at any time. We reserve the

right to do so without notice. All features and specifications subject to

change without notice. All screens in this manual are simulated.

For free owner's manuals and other information,

visit our web site:

www.lowrance.com

Lowrance Electronics Inc.

12000 E. Skelly Dr.

Tulsa, OK USA 74128-2486

Printed in USA.

Page 3

Table of Contents

Introduction ...............................................................................1

Capabilities and Specifications: X67C ......................................... 1

How Sonar Works ......................................................................... 2

How to Use this Manual: Typographical Conventions................ 3

Installation and Accessories................................................... 5

Transducer Installation................................................................ 5

Recommended Tools and Supplies ........................................... 5

Selecting a Transducer Location.............................................. 6

Shoot-Thru-Hull vs. Transom Mounting ................................. 8

Transom Transducer Assembly and Mounting .......................8

Trolling Motor Bracket Installation....................................... 11

Transducer Orientation and Fish Arches .............................. 12

Shoot-Thru-Hull Preparation and Installation ..................... 13

Speed/Temperature Sensors....................................................... 15

Speed Sensor Installation....................................................... 18

Power Connections...................................................................... 19

Mounting the Sonar Unit:Bracket or Portable.......................... 20

Bracket Installation................................................................ 21

Portable Sonar Installation .................................................... 23

Portable Transducer Assembly .............................................. 25

Basic Sonar Operation ........................................................... 27

Keyboard Basics.......................................................................... 27

Memory........................................................................................ 28

Menus .......................................................................................... 28

Main Menu .............................................................................. 28

Sonar Menu ............................................................................. 30

Pages ........................................................................................... 31

Basic Sonar Quick Reference ...............................................34

Sonar Operations ........................................................................ 35

Fish Symbols vs. Full Sonar Chart ........................................ 37

Other Free Training Aids ....................................................... 38

Advanced Sonar Options & Other Features...................... 39

ASP (Advanced Signal Processing) ......................................... 39

Alarms ......................................................................................... 40

Depth Alarms .......................................................................... 40

Fish Alarm............................................................................... 41

Backlight Level ........................................................................... 41

Calibrate Speed........................................................................... 42

Chart Speed................................................................................. 42

Colorline ................................................................................... 43

Contrast....................................................................................... 44

Depth Cursor............................................................................... 45

i

Page 4

Depth Range - Automatic ........................................................... 46

Depth Range - Manual................................................................ 46

Depth Range - Upper and Lower Limits ................................... 47

FasTrack .................................................................................. 48

Fish I.D. (Fish Symbols & Depths) ......................................... 49

FishTrack ................................................................................. 50

Overlay Data ............................................................................... 51

Ping Speed & HyperScroll....................................................... 52

Pop-Up Help................................................................................ 54

Reset Options .............................................................................. 55

Reset Water Distance ................................................................. 55

Sensitivity & Auto Sensitivity.................................................... 55

Set Keel Offset ............................................................................57

Set Language .............................................................................. 58

Software Version Information.................................................... 59

Sonar Color Mode........................................................................ 59

Sonar Page & Sonar Chart Display Options ............................. 60

Full Sonar Chart ..................................................................... 60

Split Zoom Sonar Chart.......................................................... 60

Digital Data/Chart .................................................................. 61

Flasher..................................................................................... 62

Sonar Simulator.......................................................................... 62

Stop Chart ................................................................................... 62

Surface Clarity............................................................................ 63

Transparency ..............................................................................64

Units of Measure......................................................................... 64

Zoom & Zoom Bar ....................................................................... 65

Zoom Pan..................................................................................... 66

Troubleshooting ......................................................................67

Warranty and Service Information ..................................... 73

ii

Page 5

Introduction

Thank you for buying a Lowrance sonar! Your unit is a high-quality,

remarkably-priced color sonar designed for both professional and novice

fishermen. All Lowrance sonars have an automatic mode that finds and

displays the bottom, fish, underwater structure and more – right out of

the box. All you have to do is press the on (

MENU/PWR

) key.

However, if you want to fine-tune your unit, press the

The X67C has several powerful features you can control by scrolling

through easy-to-use menus with the arrow and menu keys.

To get started with your Lowrance sonar, first read the installation section. It contains instructions for mounting the sonar unit, the transducer and any optional accessories, such as a speed sensor.

Following recommended installation practices will pay off in optimum

performance of your X67C. Improper installation can cause problems

down the road, especially if the transducer is badly mounted.

After you've read the installation instructions, install the unit and accessories. Then, read the rest of the manual. The more you know about

your sonar, the better it will work for you.

Take advantage of the Simulator feature. It allows you to practice operating your sonar before you get it in the water. And when you finally

head for your favorite fishing hole, take this manual along for reference.

MENU

key again.

Capabilities and Specifications: X67C

General

Case size:......................... 5.8" H x 4.3" W x 2.5" D (14.7 cm H x 10.8 cm

W x 6.6 cm D) sealed, waterproof; suitable for

saltwater use.

Display:............................ 1/4 VGA color, transflective TFT display; 3.5"

(8.9 cm) diagonal viewing area.

Resolution:...................... 320 pixels (vert.) x 240 pixel (horiz.) resolu-

tion; 153,600 total pixels

Backlighting:.................. Backlit screen and keypad for night use.

Input power:................... 10 to 17 volts DC.

Current drain: ............... 200 ma lights off; 250 ma lights on.

Back-up memory: .......... Built-in memory stores sonar settings when

unit is turned off.

1

Page 6

Sonar

Frequency:...................... 200 kHz.

Transducers: .................. A model HST-WSU Skimmer

transducer

comes packed with your sonar unit. Operates

at speeds up to 70 mph (61 kts). Optional thruhull, portable and trolling motor transducers

are available.

Transmitter: ................... 800 watts peak-to-peak power (typical); 100

watts RMS power (typical).

Sonar sounding

depth capability: ........... 600 feet (182 meters). Actual capability de-

pends on transducer configuration and installation, bottom composition and water conditions. All sonar units typically read deeper

in fresh water than in salt water.

Depth display:................ Continuous digital readout.

Audible alarms: ............. Deep/shallow/fish.

Automatic ranging:....... Yes, with instant screen updates.

Zoom bottom track: ...... Yes.

Split-screen zoom:......... Yes.

Surface water temp: ..... Yes, built into transducer. Optional addi-

tional temp sensors for live well, bait well,

etc. are available.

Speed/distance log: ....... Yes, with optional speed sensor.

NOTICE!

The storage and operation temperature for your unit is from -4 degrees to +167 degrees Fahrenheit (-20 degrees to +75 degrees Celsius). Extended storage in temperatures higher or lower than specified will damage the liquid crystal display in your unit. This type of

damage is not covered by the warranty. For more information, contact the factory's Customer Service Department; phone numbers

are inside the manual's back cover.

How Sonar Works

Sonar has been around since the 1940s, so if you already know how it

works, skip ahead to the next segment on the typographical conventions

used in this manual. But, if you've never owned a sonar fish finder, this

segment will tell you the underwater basics.

Sonar is an abbreviation for SOund NA

ogy developed during World War II for tracking enemy submarines.

vigation and Ranging, a technol-

2

Page 7

(Lowrance developed the world's first transistorized sportfishing sonar in

1957.) A sonar consists of a transmitter, transducer, receiver and display. In simple terms, here's how it finds the bottom, or the fish:

The transmitter emits an electrical impulse, which the transducer converts into a sound wave and sends into the water. (The sound frequency

can't be heard by humans or fish.) The sound wave strikes an object

(fish, structure, bottom) and bounces back to the transducer, which

converts the sound back into an electrical signal.

The receiver amplifies this return signal, or echo, and sends it to the

display, where an image of the object appears on the scrolling sonar

chart. The sonar's microprocessor calculates the time lapse between the

transmitted signal and echo return to determine the distance to the

object. The whole process repeats itself several times each second.

How to use this manual: typographical conventions

Many instructions are listed as numbered steps. The keypad and arrow

"keystrokes" appear as boldface type. So, if you're in a real hurry (or

just need a reminder), you can skim the instructions and pick out what

menu command to use by finding the boldface command text. The following paragraphs explain how to interpret the text formatting for

those commands and other instructions:

Arrow Keys

The arrow keys control a horizontal line depth cursor on the sonar

screen. The arrow keys also help you move around the menus so you

can execute different commands. They are represented by symbols like

these, which denote the down arrow key and the up arrow: ↓ ↑.

Keyboard

The other keys perform a variety of functions. When the text refers to a

key to press, the key is shown in bold, sans serif type. For example, the

"Enter/Pages" key is shown as

as

MENU

.

and the "Menu/Power" key is shown

ENT

Menu Commands

A menu command or a menu option will appear in small capital letters,

in a bold sans serif type like this:

D

EPTH CURSOR

. These indicate that you

are to select this command or option from a menu or take an action of

some kind with the menu item. Text that you may need to enter or file

names you need to select are show in italic type, such as data type.

3

Page 8

Instructions = Menu Sequences

Most functions you perform with the sonar unit are described as a sequence of key strokes and selecting menu commands. We've written

them in a condensed manner for quick and easy reading.

For example, instructions for turning on the Fish ID feature would

look like this:

1. From the Sonar Page, press

2. Press ↓ to

F

ISH

ID S

YMBOLS

|

ENT|EXIT|EXIT

MENU

|↓ to

S

ONAR FEATURES

.

|

ENT

.

Translated into complete English, step 1 above would mean: "Start on

the Sonar Page. Press the Menu key then repeatedly press (or press and

hold) the down arrow key to scroll down the menu and select (highlight)

the Sonar Features menu command. Then press the Enter key."

Step 2 would mean: "Press the down arrow key to select (highlight) the

Fish ID symbols command. Next, press the Enter key, then press the

Exit key twice."

4

Page 9

Installation and Accessories

Installation Preparations

You can install the sonar system in some other order if you prefer, but

we recommend this installation sequence:

Caution:

You should read over this entire installation section before drilling any holes in your vessel!

1. Determine the approximate location for the sonar unit, so you can

plan how and where to route the cables for the transducer and power.

This will help you make sure you have enough cable length for the desired configuration.

2. Determine the approximate location for the transducer and its cable

route.

3. Determine the location of your battery or other power connection,

along with the power cable route.

4. Install the transducer and route the transducer cable to the sonar

unit.

5. Install the power cable and route it to the sonar unit.

6. Mount the sonar unit.

Transducer Installation

These instructions will help you install your Skimmer

transom, on a trolling motor or inside a hull.

transducer on a

Your Skimmer transducer typically comes packaged with a one-piece

stainless steel bracket for mounting it to the transom of your boat. The

optional trolling motor mount uses a one-piece plastic bracket with an

adjustable strap. These are "kick-up" mounting brackets. They help prevent damage if the transducer strikes an object while the boat is moving.

If the transducer does "kick-up," the bracket can easily be pushed back

into place without tools.

Read these instructions carefully before attempting the installation.

Determine which of the installation methods is right for your boat.

Remember, the transducer installation is the most critical part

of a sonar installation.

Recommended Tools and supplies

If you prefer the option of routing the cable through the transom, you

will need a drill and a 5/8" drill bit. (If you intend to install an additional

5

Page 10

speed or temp sensor and route its cable through the same hole in the

transom, you will need a 1" (25.4 mm) drill bit to accommodate all the

cables.) The following installation types also call for these recommended

tools and required supplies (supplies are not included):

Transom installation

Tools include: two adjustable wrenches, drill, #29 (0.136") drill bit, flathead screwdriver. Supplies: high quality, marine grade above- or belowwaterline caulking compound.

Trolling motor installations

Tools: two adjustable wrenches, flat-head screwdriver. Supplies: plastic

cable ties.

Shoot-through hull installations

Tools: these will vary depending on your hull's composition. Consult your

boat dealer or manufacturer. Supplies: 100 grit sandpaper, good quality

epoxy adhesive.

Selecting a Transducer Location

1. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is to be mounted inside the hull,

then the chosen location must be in the water at all times. If the

transducer is not placed in a smooth flow of water, interference

caused by bubbles and turbulence will show on the sonar's display in

the form of random lines or dots whenever the boat is moving.

NOTE:

Some aluminum boats with strakes or ribs on the outside of the

hull create large amounts of turbulence at high speed. These boats

typically have large outboard motors capable of propelling the boat

at speeds faster than 35 mph. Typically, a good location on aluminum boats is between the ribs closest to the engine.

2. The transducer should be installed with its face pointing straight

down, if possible.

3. If the transducer is mounted on the transom, make sure it doesn't

interfere with the trailer or hauling of the boat. Also, don't mount it

closer than approximately one foot from the engine's lower unit. This

will prevent cavitation (bubble) interference with propeller operation.

4. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps and aerators

can be displayed on the sonar's screen. Use caution when routing the

transducer cable around these wires.

6

Page 11

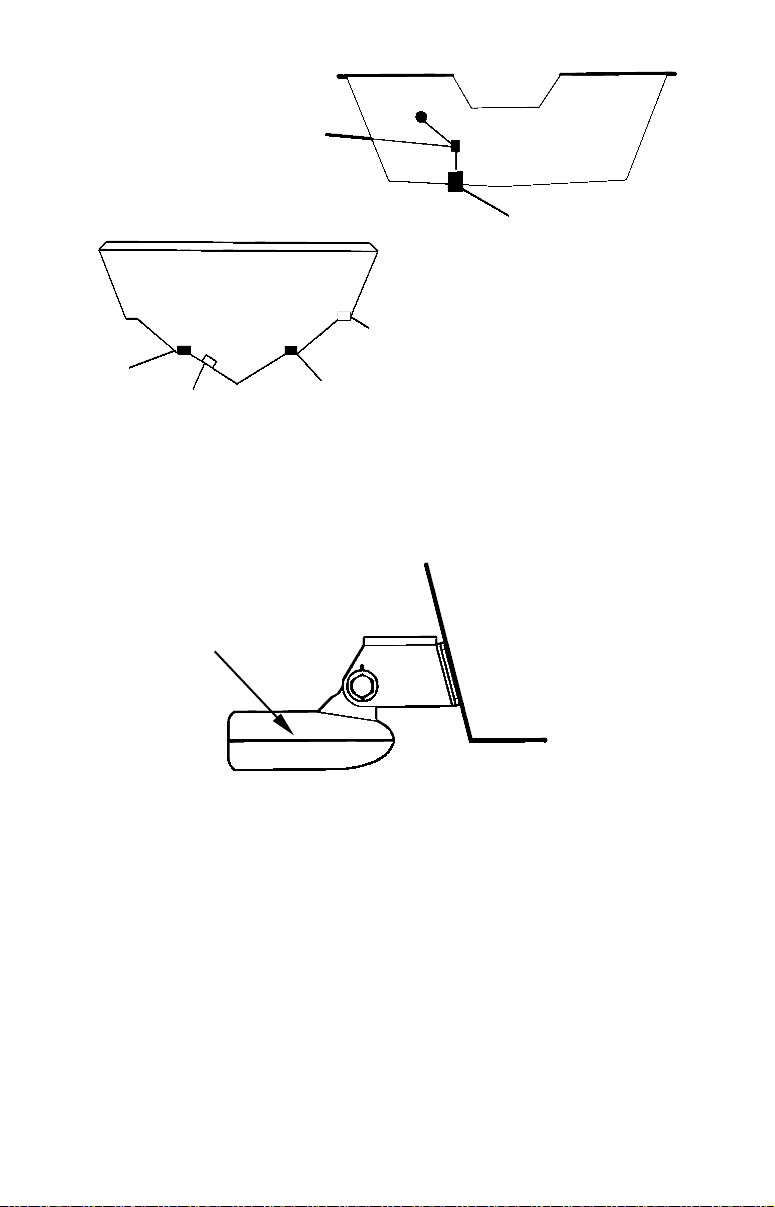

CAUTION: Clamp the transducer cable to transom near

the transducer. This will help

prevent the transducer from

entering the boat if it is

knocked off at high speed.

Good location

Poor location

Good

location

Poor angle

Good and poor transducer locations.

Good location

How low should you go?

For most situations, you should install your Skimmer transducer so

that its centerline is level with the bottom of the boat hull. This will

usually give you the best combination of smooth water flow and protection from bangs and bumps.

Transducer

centerline

Align transducer centerline with hull bottom.

Transom

Hull bottom

However, there are times when you may need to adjust the transducer

slightly higher or lower. (The slots in the mounting brackets allow you

to loosen the screws and slide the transducer up or down.) If you frequently lose bottom signal lock while running at high speed, the transducer may be coming out of the water as you cross waves or wakes.

Move the transducer a little lower to help prevent this.

If you cruise or fish around lots of structure and cover, your transducer

may be frequently kicking up from object strikes. If you wish, you may

move the transducer a little higher for more protection.

There are two extremes you should avoid. Never let the edge of the

mounting bracket extend below the bottom of the hull. Never let the

bottom – the face – of the transducer rise above the bottom of the hull.

7

Page 12

Shoot-thru-hull vs. Transom Mounting

Typically, shoot-thru-hull installations give excellent high speed operation and good to excellent depth capability. There is no possibility of

damage from floating objects. It can't be knocked off when docking or

loading on the trailer.

However, the shoot-thru-hull installation does have its drawbacks.

First, some loss of sensitivity does occur, even on the best hulls. This

varies from hull to hull, even from different installations on the same

hull. This is caused by differences in hull lay-up and construction.

Second, the transducer angle cannot be adjusted for the best fish

arches. This can be a problem on some hulls that sit with the bow high

when at rest or at slow trolling speeds. Follow the procedure listed in

the shoot-thru-hull installation section at the end of this segment to

determine if you can satisfactorily shoot through the hull.

TRANSOM TRANSDUCER ASSEMBLY AND MOUNTING

The best way to install the transducer is to loosely assemble all of the

parts first, place the transducer's bracket against the transom and see if

you can move the transducer so that it's parallel with the ground.

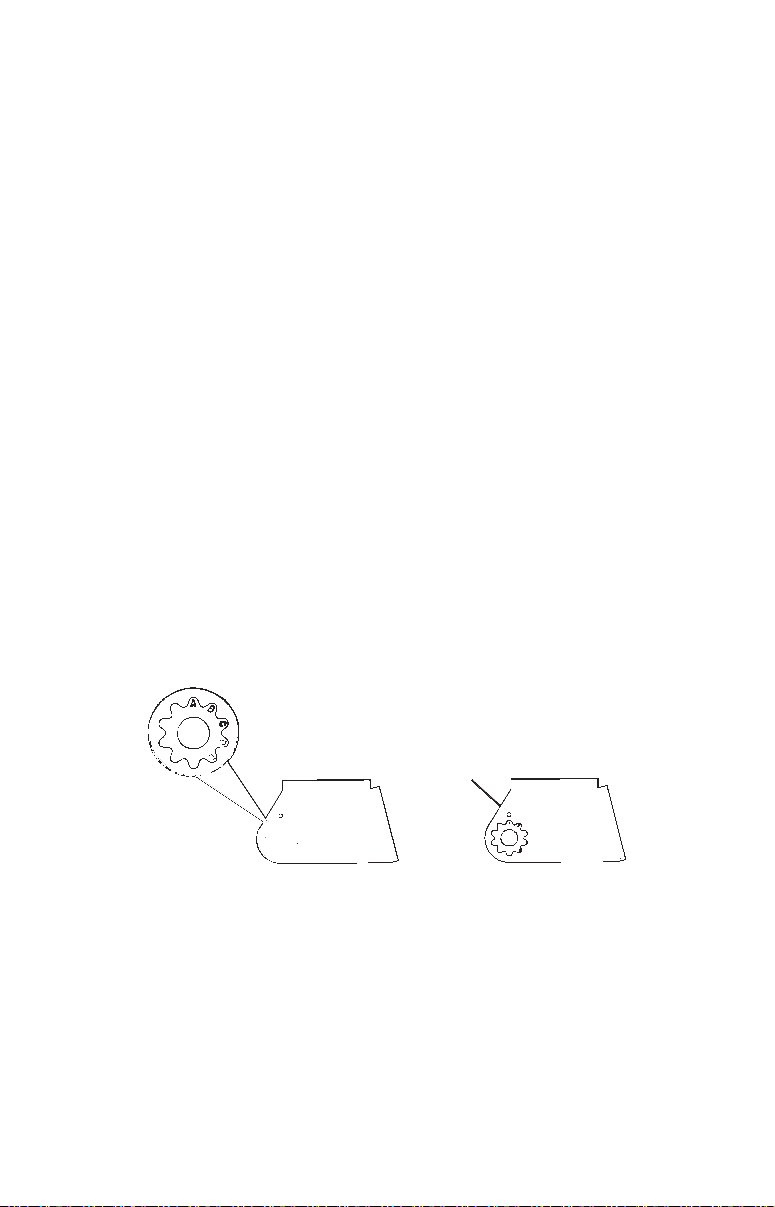

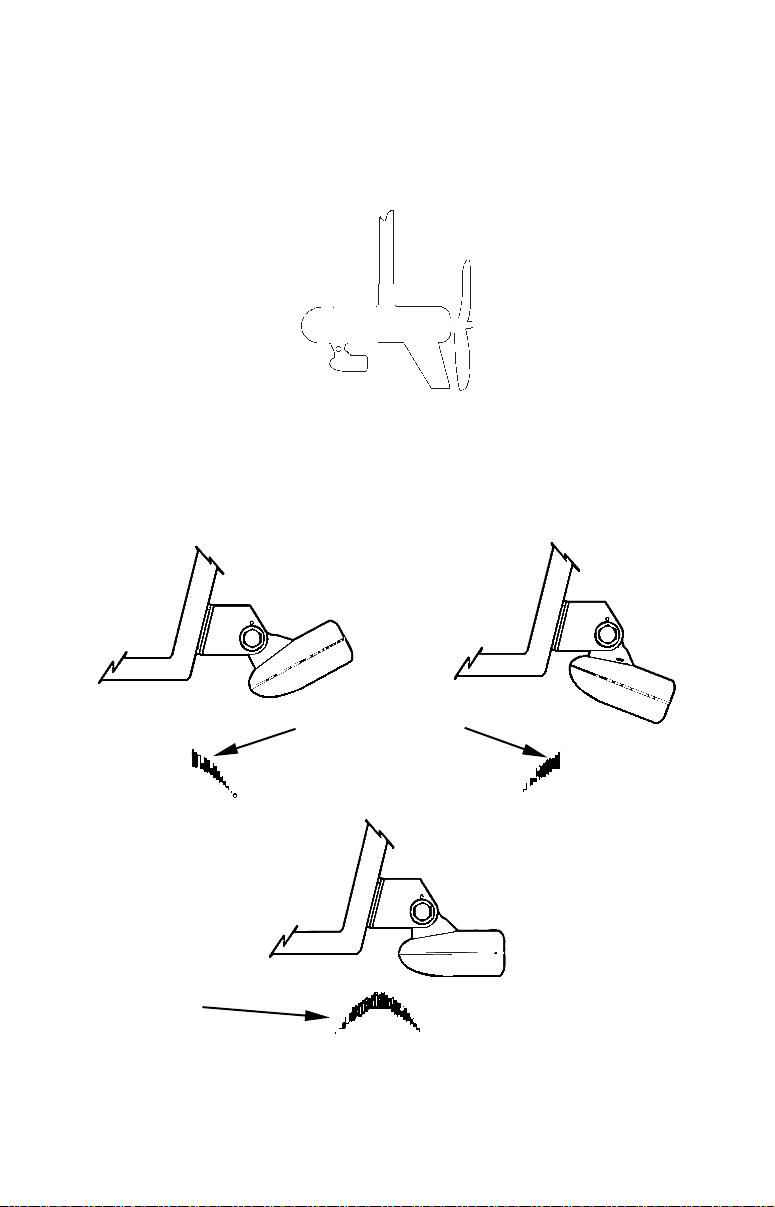

1. Assembling the bracket. Press the two small plastic ratchets into the

sides of the metal bracket as shown in the following illustration. Notice

there are letters molded into each ratchet. Place each ratchet into the

bracket with the letter "A" aligned with the dot stamped into the metal

bracket. This position sets the transducer's coarse angle adjustment for a

14° transom. Most outboard and stern-drive transoms have a 14° angle.

Dot

Align plastic ratchets in bracket.

2. Aligning the transducer on the transom. Slide the transducer

between the two ratchets. Temporarily slide the bolt though the

transducer assembly and hold it against the transom. Looking at the

transducer from the side, check to see if it will adjust so that its face

is parallel to the ground. If it does, then the "A" position is correct for

your hull.

If the transducer's face isn't parallel with the ground, remove the

transducer and ratchets from the bracket. Place the ratchets into the

8

Page 13

holes in the bracket with the letter "B" aligned with the dot stamped

in the bracket.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's

parallel with the ground. If you can, then go to step 3. If it doesn't,

repeat step 2, but use a different alignment letter until you can place

the transducer on the transom correctly.

Ratchets

Insert bolt and check transducer position on transom.

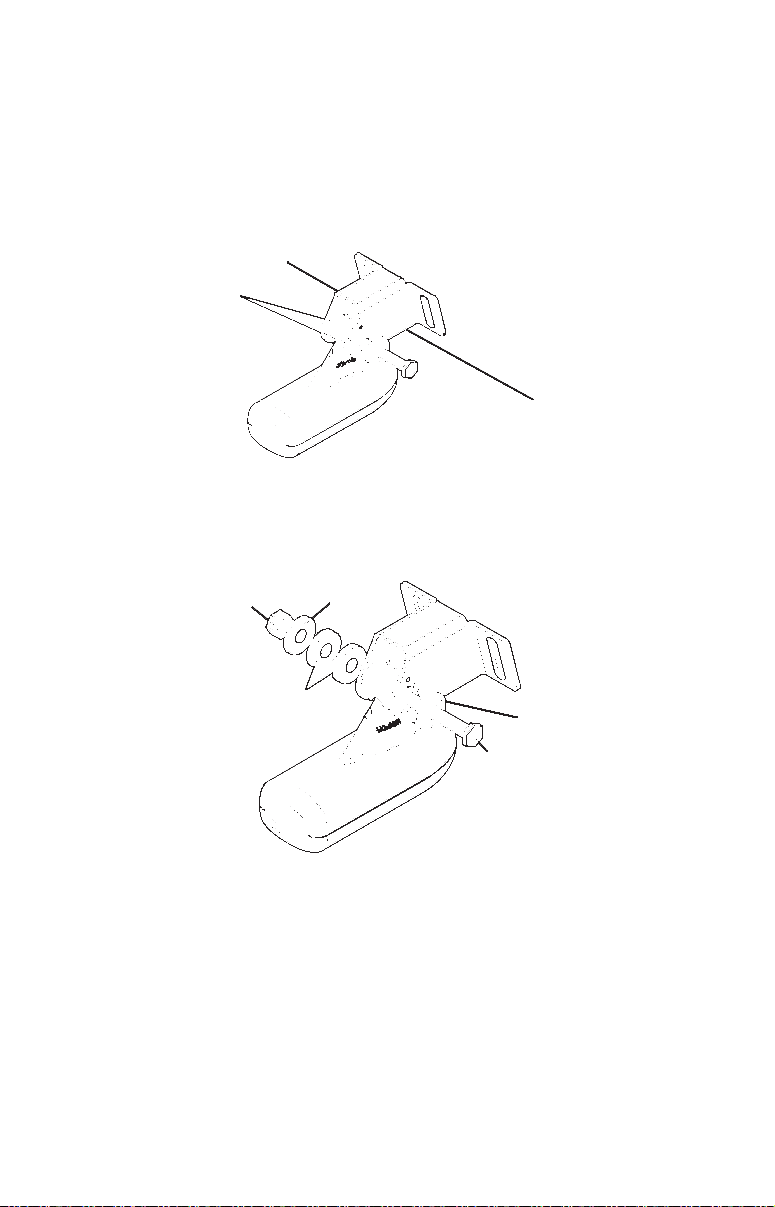

3. Assembling the transducer. Once you determine the correct posi-

tion for the ratchets, assemble the transducer as shown in the following figure. Don't tighten the lock nut at this time.

Metal

Nut

washer

Rubber

washers

Assemble transducer and bracket.

Metal washer

Bolt

4. Drilling mounting holes. Hold the transducer and bracket assembly

against the transom. The transducer should be roughly parallel to the

ground. The transducer's centerline should be in line with the bottom

of the hull. Don't let the bracket extend below the hull!

Mark the center of each slot for the mounting screw pilot holes. You

will drill one hole in the center of each slot.

Drill the holes using the #29 bit (for the #10 screws).

9

Page 14

Transom

Transom

Position transducer mount on transom and mark mounting holes.

Side view shown at left and seen from above at right.

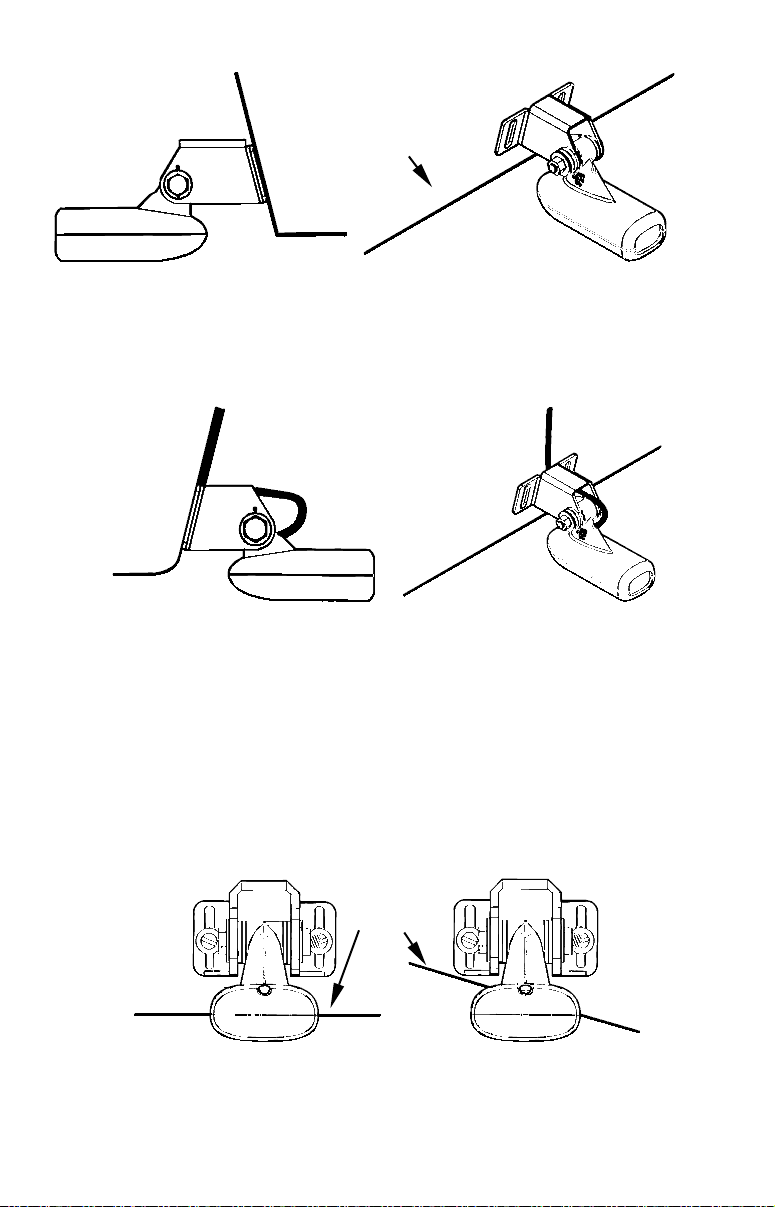

5. Attaching transducer to transom. Remove the transducer from

the bracket and re-assemble it with the cable passing through the

bracket over the bolt as shown in the following figures.

Route cable over bolt and through bracket. Side view shown at left and

seen from above at right.

Attach the transducer to the transom. Slide the transducer up or

down until it's aligned properly with the bottom of the hull as shown

in the preceding and following figures. Tighten the bracket's mounting screws, sealing them with the caulking compound.

Adjust the transducer so that it's parallel to the ground and tighten

the nut until it touches the outer washer, then add 1/4 turn. Don't

over tighten the lock nut! If you do, the transducer won't "kick-up" if

it strikes an object in the water.

Bottom

of

hull

Flat-bottom hull

Align transducer centerline with hull bottom and attach to transom.

Deep-"vee" hull

10

Page 15

6. Route the transducer cable through or over the transom to

the sonar unit. Make sure to leave some slack in the cable at the

transducer. If possible, route the transducer cable away from other

wiring on the boat. Electrical noise from the engine's wiring, bilge

pumps, VHF radio wires and cables, and aerators can be picked up by

the sonar. Use caution when routing the transducer cable around

these wires.

WARNING:

Clamp the transducer cable to the transom close to the

transducer. This can prevent the transducer from entering the boat if it is knocked off at high speed.

If you need to drill a hole in the transom to pass the connector through,

the required hole size is 5/8". (If you intend to route an additional speed

or temp sensor cable through the same hole, you will need a 1" (25.4 mm)

drill bit instead.)

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline sealant used for the mounting screws.

7. Make a test run to determine the results. If the bottom is lost at

high speed, or if noise appears on the display, try sliding the transducer bracket down. This puts the transducer deeper into the water,

hopefully below the turbulence causing the noise. Don't allow the

transducer bracket to go below the bottom of the hull!

TROLLING MOTOR BRACKET INSTALLATION

1. Attach the optional TMB-S bracket to the transducer as shown in the

following figure, using the hardware supplied with the transducer.

(Note: The internal tooth washer is supplied with the TMB-S.)

Bolt

Internal tooth washer

Nut

TMB-S bracket

Flat washer

Attach motor mounting bracket to transducer.

2. Slide the adjustable strap supplied with the TMB-S through the slot

in the transducer bracket and wrap it around the trolling motor. Position the transducer to aim straight down when the motor is in the

water. Tighten the strap securely.

11

Page 16

3. Route the transducer cable alongside the trolling motor shaft. Use

plastic ties (not included) to attach the transducer cable to the trolling motor shaft. Make sure there is enough slack in the cable for the

motor to turn freely. Route the cable to the sonar unit and the transducer is ready for use.

Transducer mounted on trolling motor, side view.

TRANSDUCER ORIENTATION AND FISH ARCHES

If you do not get good fish arches on your display, it could be because

the transducer is not parallel with the ground when the boat is at rest

in the water or at slow trolling speeds.

Transducer aimed

too far back

Full fish arch

Transducer angles and their effects on fish arches.

Partial fish arches

Proper transducer angle

12

Transducer aimed

too far forward

Page 17

If the arch slopes up – but not back down – then the front of the transducer is too high and needs to be lowered. If only the back half of the

arch is printed, then the nose of the transducer is angled too far down

and needs to be raised.

NOTE:

Periodically wash the transducer's face with soap and water to remove any oil film. Oil and dirt on the face will reduce the sensitivity

or may even prevent operation.

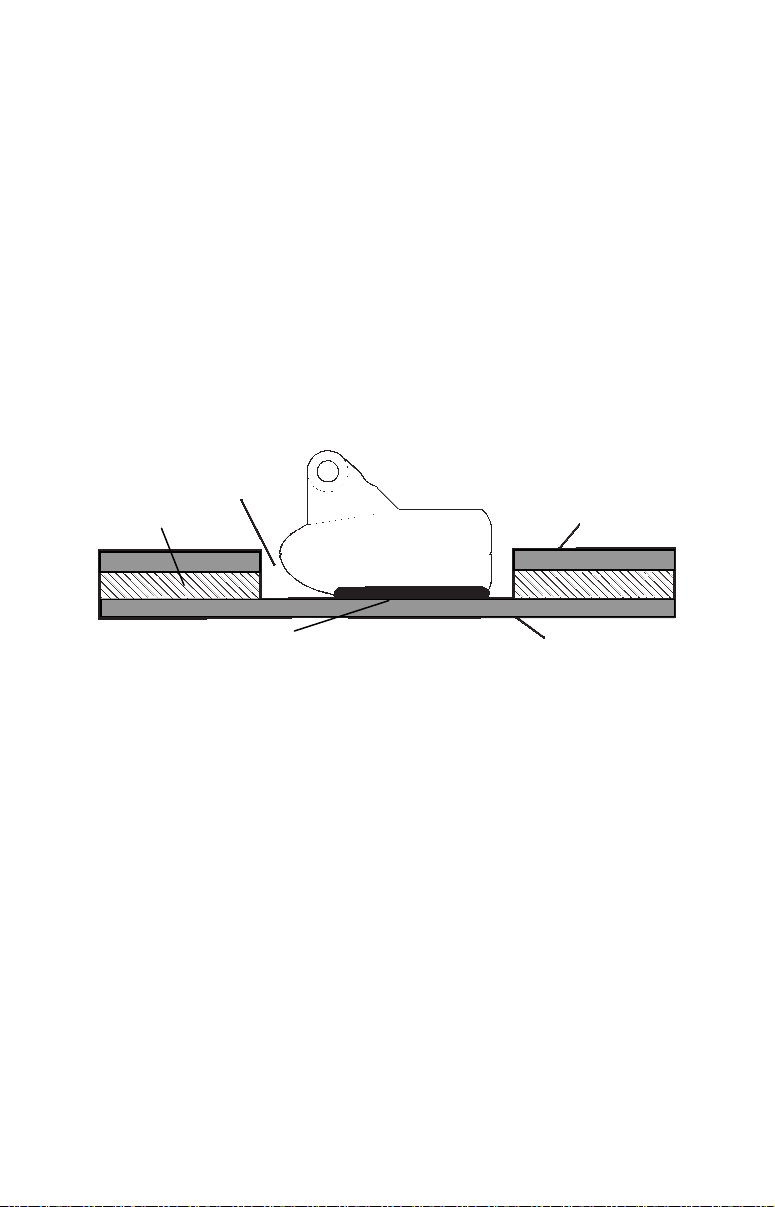

SHOOT-THRU-HULL PREPARATION

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass layers. The sonar signal must pass through solid fiberglass. A successful

transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood or foam) between layers of fiberglass if

the material is removed from the chosen area.

Fill with epoxy

Flotation material

Inner hull

Epoxy to hull first

Epoxy the transducer to a solid portion of the hull.

Outer hull

For example, some (but not all) manufacturers use a layer of fiberglass,

then a core of balsa wood, finishing with an outer layer of fiberglass.

Removing the inner layer of fiberglass and the balsa wood core exposes

the outer layer of fiberglass. The transducer can then be epoxied directly to the outer layer of fiberglass. After the epoxy cures, the hull is

watertight and structurally sound. Remember, the sonar signal must

pass through solid fiberglass. Any air bubbles in the fiberglass or the

epoxy will reduce or eliminate the sonar signals.

WARNING:

Do not remove any material from your inner hull unless

you know the hull's composition. Careless grinding or

cutting on your hull can result in damage that could sink

your boat. Contact your boat dealer or manufacturer to

confirm your hull specifications.

To choose the proper location for thru-hull mounting, anchor the boat in 60

feet of water. Add a little water to the sump of the boat. Plug the transducer into the sonar unit, turn it on, then hold the transducer over the side

13

Page 18

of the boat. Adjust the sensitivity and range controls until a second bottom

echo is seen on the display. (You will need to turn off both Automatic Sensitivity and ASP.) Don't touch the controls once they've been set.

Next, take the transducer out of the water and place it in the water in

the sump of the boat. Observe the sonar signal to see if there is a noticeable decrease in sensitivity. The second bottom signal may disappear and the bottom signal may decrease in intensity.

Move the transducer around to find the best location. If the sensitivity

control must be increased greatly to compensate, then the transducer

should be mounted on the outside of the hull. If not, then mark the location that shot through the hull the best and follow the instructions on

the following pages for a shoot-thru-hull mounting.

Transducer location

(high speed)

Shoot-thru-hull transducer locations for

high speed or trolling speed operation.

Transducer location

(trolling speed)

Shoot-thru-hull Installation

1. Make sure the area is clean, dry and free of oil or grease, then sand

both the inside surface of the hull and the face of the transducer with

100 grit sandpaper. The surface of the hull must be flat so the entire

transducer face is in contact with the hull prior to bonding.

2. Follow the instructions on the epoxy package and mix it thoroughly.

Do not mix it too fast, because it will cause bubbles to form in the epoxy. Apply a small amount on the face of the transducer as shown

above, then spread a small amount onto the sanded area on the hull.

14

Page 19

Spread epoxy here

Sand this surface

Epoxy transducer to hull.

Place the transducer into the epoxy, twisting and turning it to force

any air bubbles out from under the transducer face. The face of the

transducer should be parallel with the hull, with a minimum amount

of epoxy between the hull and transducer. After the epoxy dries, remember to fill in the area around the transducer with more epoxy

and route the cable to the sonar unit.

Speed/Temperature Sensors

The X67C can accept as many as two temperature sensors, which can be

used to monitor the temperature of surface water, a live well or some

other location. These units can accept an optional speed sensor for showing speed and distance traveled. However, you can only use one accessory

at a time. If you would like to use a speed sensor and a secondary temperature sensor at the same time, you will need a combination device.

NOTE:

If a second temp sensor is used, it must be the model TS-2U. This

model has a fixed electronic "address" which designates it as the

second of two temp sensors.

15

Page 20

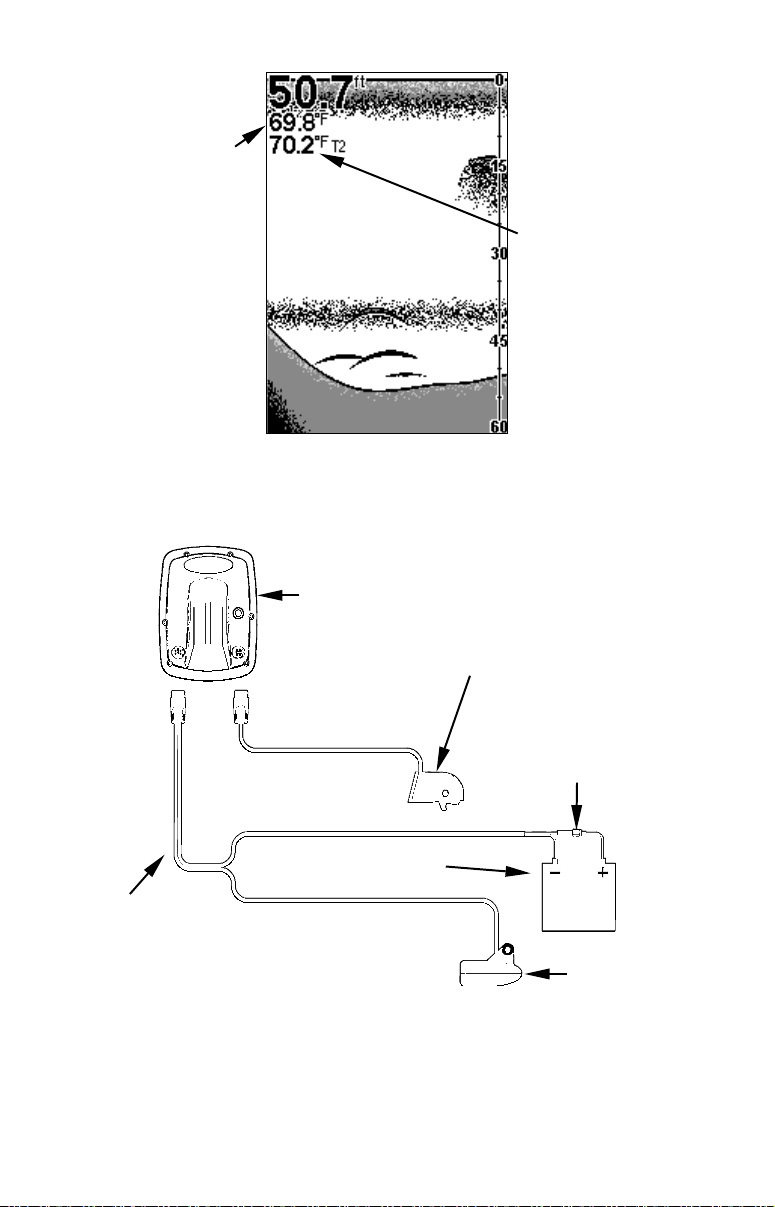

Primary temp sensor

built into transducer

TS-2U secondary

external temp sensor

shown as T2

Full Chart page showing dual temperature display.

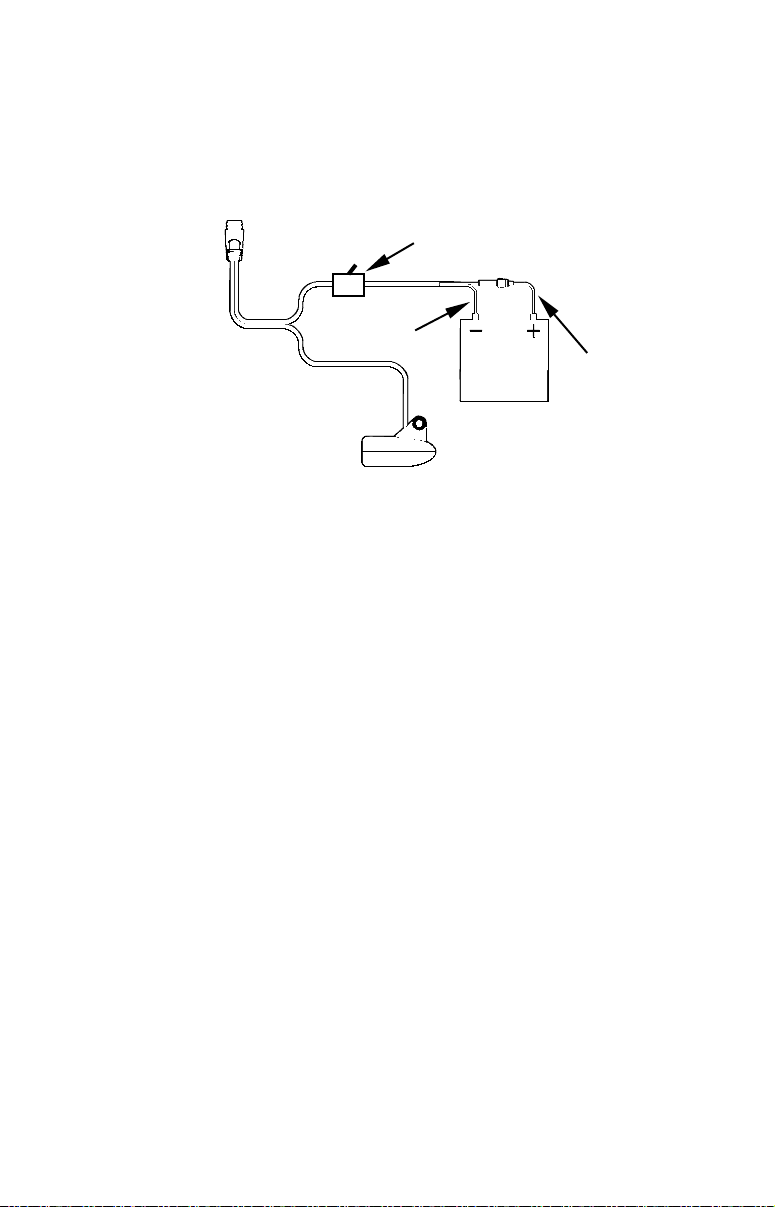

See the following charts for sample sensor combinations and cable connections.

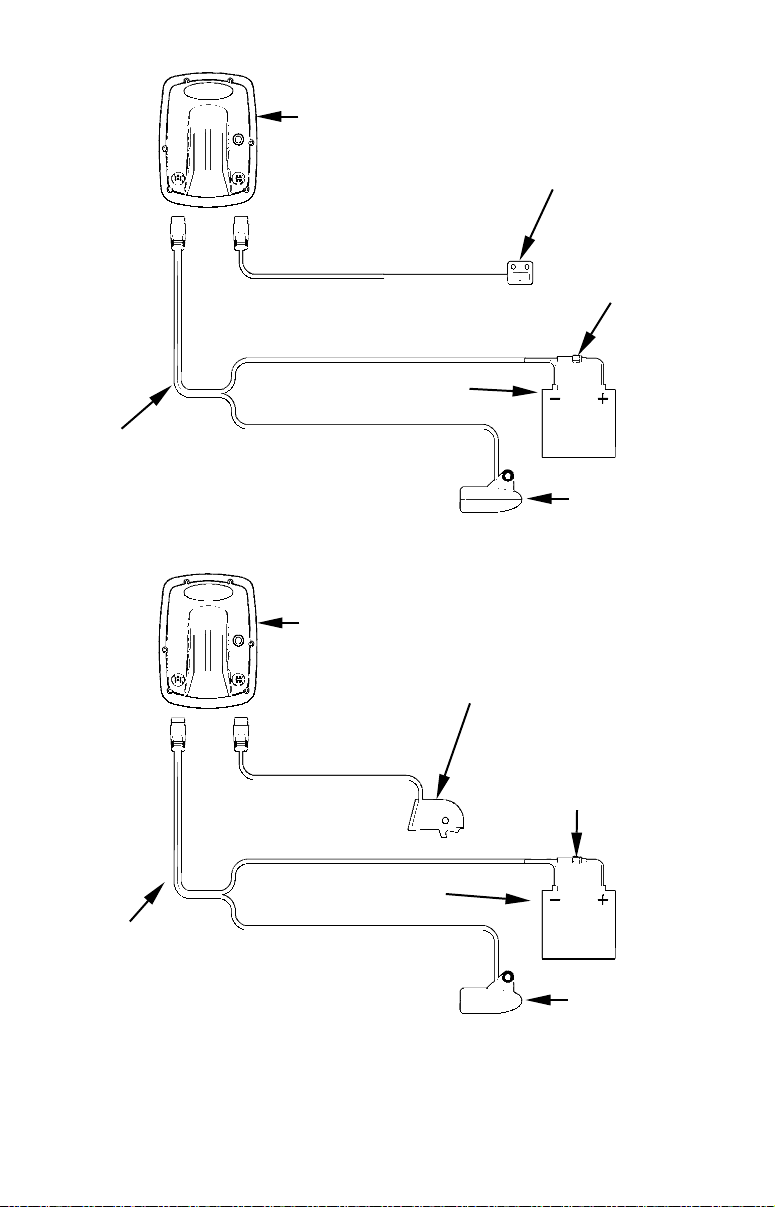

Sonar unit

rear view

ST-TU combination

speed and temperature

sensor

3-amp fuse

12-volt battery

Power/transducer cable

Sonar unit with external combination speed and temperature sensor.

Primary temp sensor is built into the transducer.

Temperature sensor

built into transducer

HST-WSU

16

Page 21

Sonar unit

rear view

TS-2U

temperature

sensor

3-amp fuse

12-volt battery

Power/transducer cable

Sonar unit with secondary external temperature sensor. Primary temp

Temperature sensor

built into transducer

sensor is built into the transducer.

Sonar unit

rear view

HST-WSU

Power/transducer cable

The temperature sensor is built into the transducer.

SP-U speed only

sensor

3-amp fuse

12-volt battery

12-volt battery

Temperature sensor

built into transducer

HST-WSU

Sonar unit with external speed sensor.

17

Page 22

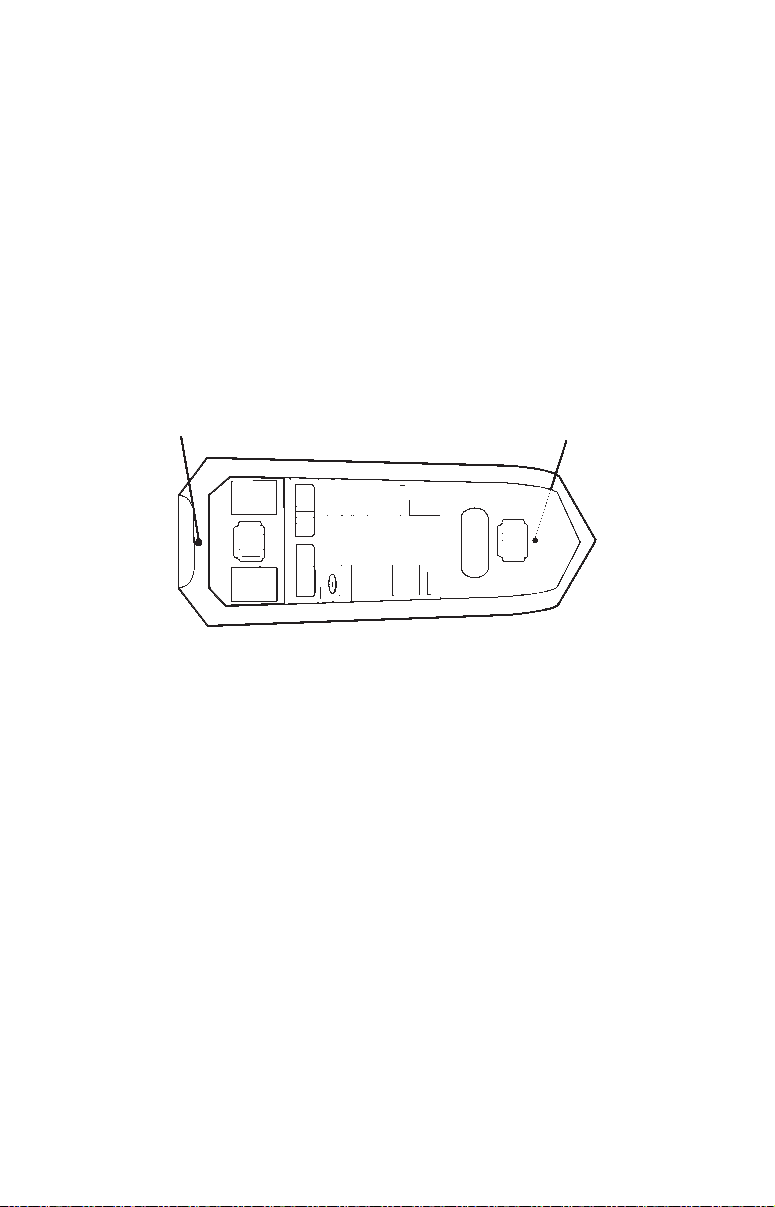

Speed Sensor Installation

If you wish to purchase an optional sensor for your unit, refer to the

accessory ordering information inside the back cover of this manual.

The following instructions describe how to install the speed sensor.

Recommended tools for this job include: drill, 5/8" drill bit, 1/8" drill bit for

pilot holes, screwdriver. Required supplies for this job include: four #8

stainless steel wood screws (3/4" long), high quality, marine grade aboveor below-waterline caulking compound. (If you intend to route the sensor

cable through the same hole as the transducer cable, you will need a 1"

(25.4 mm) drill bit instead of the 5/8" drill bit.)

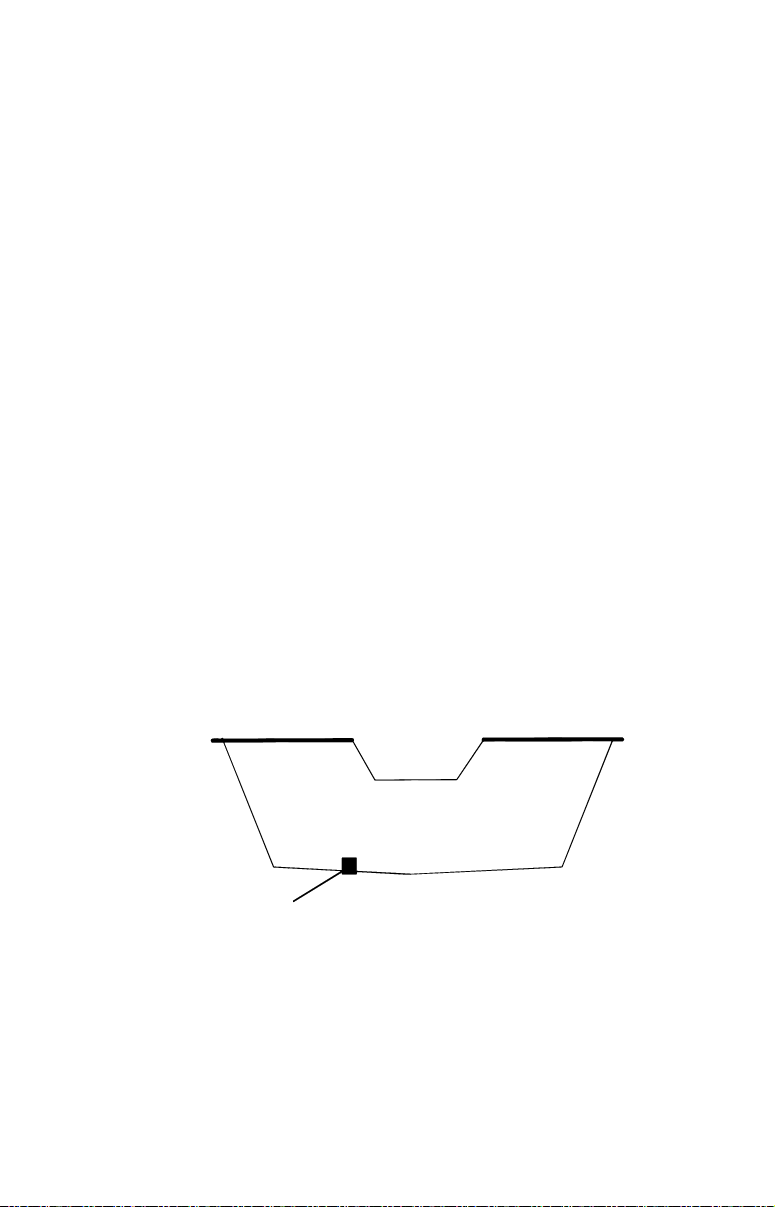

First find a location on the boat's transom where the water flow is smoothest. Don't mount the sensor behind strakes or ribs. These will disturb the

water flow to the speed sensor. Make sure the sensor will remain in the

water when the boat is on plane. Also make sure the location doesn't interfere with the boat's trailer. Typically, the sensor is mounted about one foot

to the side of the transom's centerline.

Once you've determined the proper location for the unit, place the sensor on the transom. The bottom of the bracket should be flush with the

hull's bottom. Using the sensor as a template, mark the hull for the

screws' pilot holes. Drill four 1/8" holes, one in each end of the slots.

Mount the sensor to the hull using #8 stainless steel wood screws (not

included). Use a high quality, marine grade above- or below-waterline

caulking compound to seal the screws. Make sure the sensor is flush

with the bottom of the hull and tighten the screws.

Good location

Stern view showing good location for mounting sensor on transom.

18

Page 23

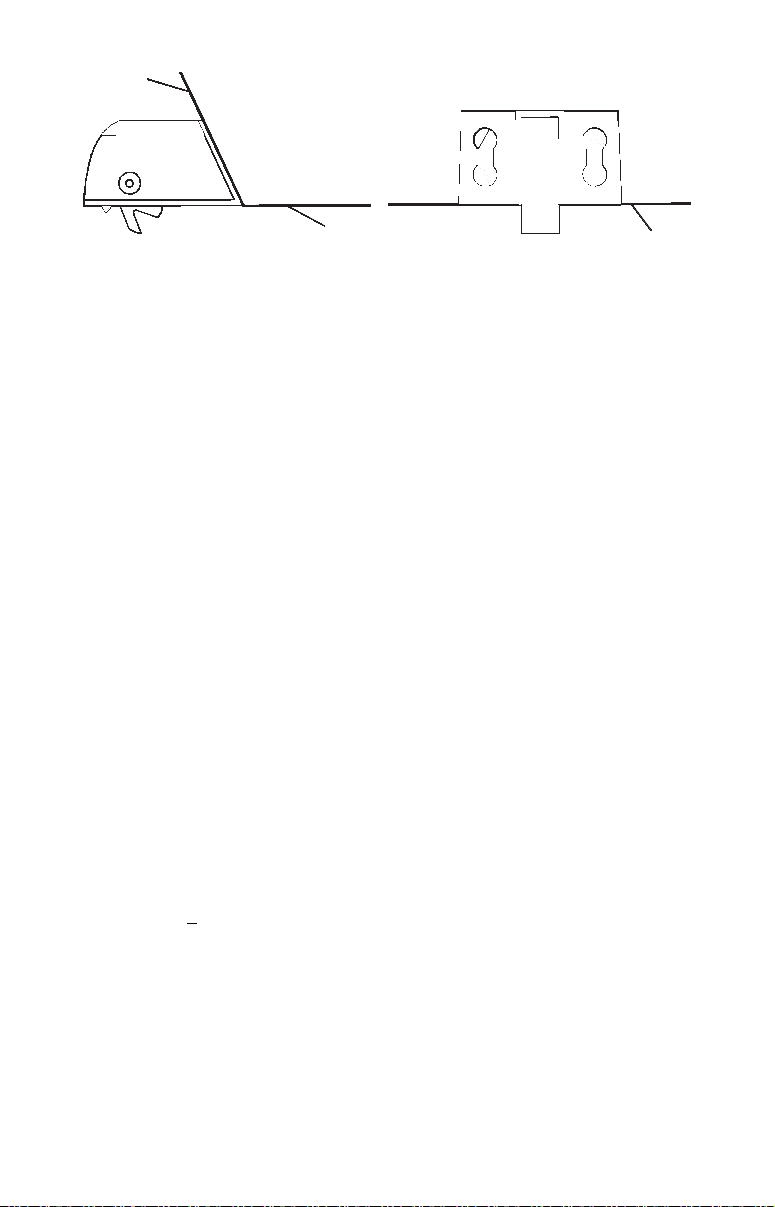

Transom

Bottom of hull

Speed sensor mounting configuration:

side view (left) and rear view (right.)

Bottom of hull

If the base of the transom has a radius, fill the gap between the transom and the sensor with the caulking compound. This will help ensure

a smooth water flow.

Route the sensor's cable through or over the transom to the sonar unit.

If you need to drill a hole in the transom to pass the connector through,

the required hole size is 5/8". (The hole is 1" (25.4 mm) if you intend to

route the sensor cable through the same hole as the transducer cable.)

Caution:

If you drill a hole in the transom for the cable, make sure it is located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline sealant used for the screws.

The sensor is now ready for use. Connect the sensor to the accessory

socket on the back of the unit. If you have any questions concerning the

installation of the sensor, please contact your local boat dealer.

POWER CONNECTIONS

The unit works from a 12-volt battery system. You can attach the

power cable to your boat's accessory or power buss or directly to the

battery. If you use an accessory buss but have problems with electrical

interference, attach the power cable directly to the battery. If the cable

is not long enough, splice #18 gauge wire onto it.

CAUTION:

When using the unit in a saltwater environment, we strongly recommend that you shut off the power supply to the power cable when

the unit is not in use. When the unit is turned off but still connected

to a power supply, electrolysis can occur in the power cable plug.

This may result in corrosion of the plug body along with the electrical contacts in the cable and the unit's power socket.

In saltwater environments we recommend you connect the power

cable to the auxiliary power switch included in most boat designs.

19

Page 24

If that results in electrical interference, or if such a switch is not

available, we recommend connecting direct to the battery and installing an inline switch. This will let you shut off power to the

power cable when the unit is not in use. When you are not using

the unit, you should always shut off power to the power cable, especially when the power cable is disconnected from the unit.

To unit

Black wire

Power and transducer connections for the X67C sonar

unit (direct battery connection shown).

Optional power off switch

for saltwater installations

12 volt

battery

Red wire with

3 amp fuse

If possible, keep the power cable away from other boat wiring, especially the engine's wires. This will provide the best isolation from electrical noise. The power cable has two wires, red and black. Red is the

positive lead, black is negative or ground. Make sure to attach the inline fuse holder to the red lead as close to the power source as possible.

For example, if you have to extend the power cable to the battery or

power buss, attach one end of the fuse holder directly to the battery or

power buss. This will protect both the unit and the power cable in the

event of a short. It uses a 3-amp fuse.

CAUTION:

Do not use this product without a 3-amp fuse wired into the

power cable! Failure to use a 3-amp fuse will void your warranty.

NOTE:

For more corrosion protection in saltwater or high humidity environments, apply a thin layer of electrical-grade grease to each end

of the fuse before installing it in the fuse holder.

This unit has reverse polarity protection. No damage will occur if the

power wires are reversed. However, the unit will not work until the

wires are attached correctly.

MOUNTING THE SONAR UNIT: In-Dash, Bracket or Portable

You can install the sonar unit on the top of a dash with the supplied

bracket. At the time of this printing, we do not produce an in-dash

mounting kit for the X67C. If you wish to check on the future availabil-

20

Page 25

ity of this kit, refer to the accessory ordering information inside the

[

]

back cover of this manual.

Bracket Installation

Recommended tools for this job include: drill, 1" (25.4 mm) drill bit, screwdriver. Required supplies for this job include: high quality, marine grade

above- or below-waterline caulking compound, three #10 stainless steel

screws. Screw length and type should be suitable for the material on which

you intend to mount the bracket.

Mount the unit in any convenient location, provided there is clearance

when it’s tilted for the best viewing angle. You should also make sure

there is enough room behind the unit to attach the power/transducer

cable. (See the following drawings, which show the dimensions of a

gimbal-mounted X67C sonar unit.)

Holes in the bracket’s base allow wood screw or through-bolt mounting.

You may need to place a piece of plywood on the back side of thin panels to reinforce the panel and secure the mounting hardware.

Drill a 1" (25.4 mm) hole in the dash for the power/transducer and accessory cables. The best location for this hole is immediately under the

gimbal bracket location. This way, the bracket can be installed so that

it covers the hole, holds the cables in position and results in a neat installation. Some customers, however, prefer to mount the bracket to the

side of the cable hole — it's a matter of personal preference.

107.5

[4.23]

82.7

[3.26]

156

[6.26]

12.09 [0.48]

76.9

[3.03]

Front view (left) and side view (right) showing dimensions

of the X67C when mounted on quick release bracket.

Millimeter

[Inch]

70.3

2.77

21

Page 26

After drilling the hole, pass the connectors up through the hole from

under the dash. If you wish, you can fill in the hole around the cable

with a good marine caulking compound. (Some marine dealers stock cable hole covers to conceal the opening.)

Using the Quick Release Mounting Bracket

These units use a quick release mounting bracket. When you run the

cables through the bracket's cable slots, make sure you allow enough

slack for tilting the unit and attaching the connector. (The snug fit of

the push-on waterproof connector requires some force to attach.)

Align the bracket over the cable hole with the cable slots facing away

from you and fit the cable through one of the slots. Fasten the bracket

to the dash using the three screw holes.

Ratchet

Rear

(away from viewer)

Screw hole

Power/transducer cable

X67C quick release mounting bracket. Slots in the base allow

routing the cable from beneath the mount.

Cable slot

Attach the unit to the bracket by first connecting the power/transducer

and accessory cables. Then, hold the sonar unit vertically and slide it

onto the bracket from above. (The back of the unit should be touching

the front of the bracket as you lower it into position.) As you push

down, the unit will lock into place with a distinct click.

To adjust the viewing angle, pinch the ratchets with one hand, then tilt

the unit with your other hand. Release the ratchets and the unit locks

into the new position. To dismount the unit for storage, press the ratchets and lift the unit off the bracket.

22

Page 27

Bracket front

Mount the sonar: slide the unit onto the bracket from above.

Depress

ratchets to

release

Adjust viewing angle: use one hand to press and release the spring-

loaded ratchets while you move the unit with the other hand.

Portable Sonar Installation

Like many Lowrance products, the X67C sonar is capable of portable

operation. It uses the optional PPP-12 portable power pack.

The power pack and portable transducers expand the uses for your sonar. You can use your X67C sonar unit on your boat or take it to the

dock, on a float tube, on an ice fishing trip or use it as a second sonar in

a friend's boat.

The PPP-12 package includes the power pack, battery adapter and a portable transducer. The transducer can be stored inside the power pack. The

PPP-12 requires eight AA alkaline batteries. Batteries are not included.

23

Page 28

To use a portable power pack, you simply install the batteries and then

attach the sonar unit to the power pack's bracket. Plug in the

power/transducer cable and you're ready to fish.

The PPP-12 has a quick-release mounting bracket built into the case.

Installing the Batteries

Release the latch on the front of the power pack case. Open the compartment and install eight AA batteries into the adapter. For the longest life, we recommend you use alkaline batteries.

NOTE:

When the unit is not in use, we recommend you unplug the power

connector to reduce the possibility of corrosion or battery drain.

When you store the unit, always remove the batteries because dead

batteries can leak and corrode the contacts.

After installing the batteries, close the case and plug the sonar unit's

power cable into the socket on the power pack case.

PPP-12 Portable Power Pack with an X67C stowed for transport.

Turn the sonar unit on. If it doesn't work, make sure the battery terminals are making good contact against the battery contacts. Also check

the wiring connections on the battery adapter. The red wire on the

24

Page 29

power cable should be attached to the red wire on the battery adapter

and the power cable's black wire should be connected to the black wire

on the battery adapter.

If it still doesn't work, check the battery voltage. Most of the complaints

we receive about portable units result from stale batteries. Make sure

the ones you buy are fresh.

In cold weather the efficiency of dry cell batteries drops with the temperature. We find it a good idea to have the sonar unit good and warm

along with the batteries before we leave home.

If the batteries do lose a charge, you can sometimes restore them by

placing them in a warm room or car interior. A better way is to replace

them with batteries that have been kept warm.

WARNING:

Never heat the batteries over an open flame or direct hot

air onto them. A fire or explosion could result.

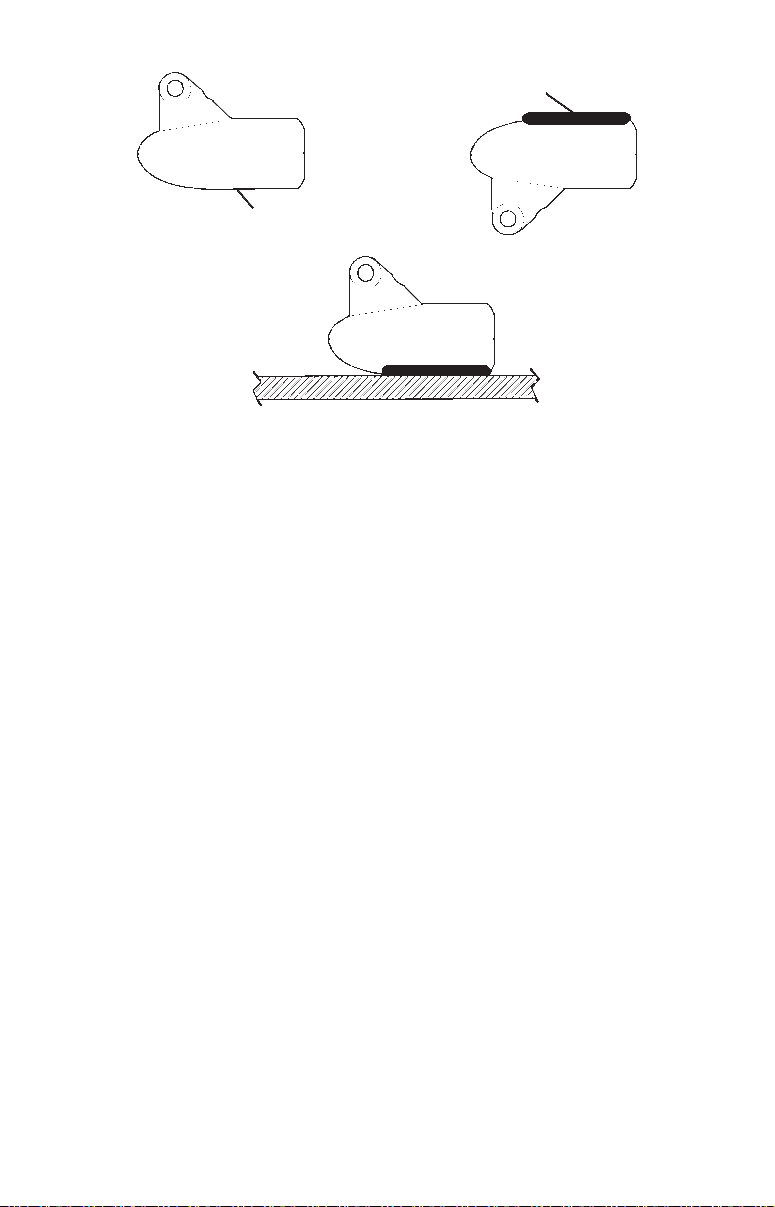

Portable Transducer Assembly

Recommended tools for installation include a slotted screw driver and

two adjustable wrenches.

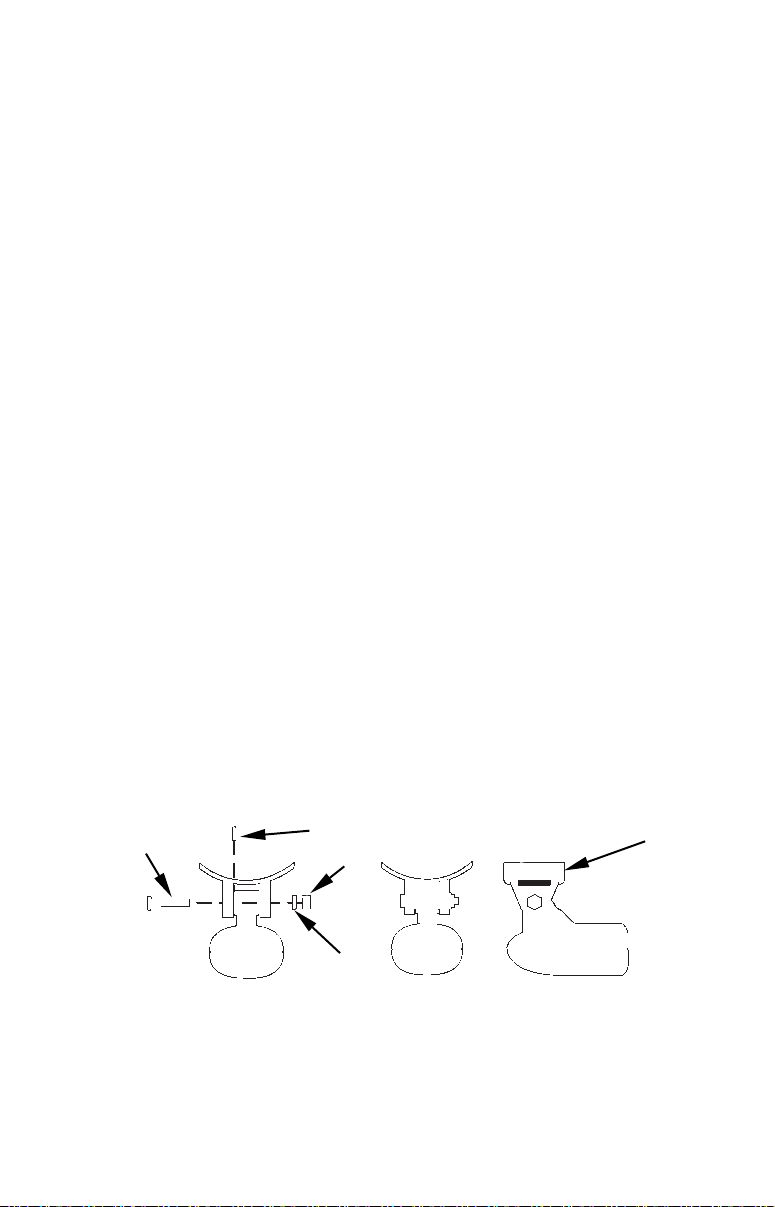

Assemble the transducer and bracket as shown in the following figure.

Attach the transducer to the bracket with the supplied hardware.

Make sure there is one washer on each side of the transducer, inside

the bracket. Slide the other washer over the end of the bolt and thread

the nut onto it.

Screw the suction cup onto the bracket using the supplied screw and flat

washer. Tie the nylon cord through the hole in the top of the bracket.

When using this transducer, tie the other end of the nylon cord to the boat.

This will help prevent the loss of the transducer if it comes off the boat.

25

Page 30

Tie nylon

cord here

Screw

Bolt

Washer

Suction

cup

Nut

Washer

Transducer

Portable transducer assembly: rear view (left) and side view (right.)

Clean the chosen area of the hull before attaching the suction cup. Locate the transducer on the hull as shown in the following figure. Don't

allow the bracket to extend below the hull, because water pressure

against it can cause the suction cup to come off at speed.

Moisten the cup, then press it onto the hull as firmly as possible. Tie

the nylon cord to the boat and route the transducer cable to the sonar

unit. Your portable sonar is now ready for use.

Suction

cup

Hull

Bracket

Transducer

Portable transducer installed on boat transom.

NOTE:

For optimum operation, the portable transducer should be adjusted

so that it is parallel to the ground. For more information on this,

see the earlier segment on Transducer Orientation and Fish

Arches.

26

Page 31

Basic Sonar Operation

KEYBOARD BASICS

The unit sounds a tone when you press any key. This tells you the unit

has accepted a command. Numbers in the photo correspond to key explanations below:

1

4

Lowrance X67C Sonar, front view, showing screen and keyboard.

1. MENU/PWR (menu and power)

This key appears in the manual text simply as

turn the unit on and off. While the unit is on, you can use this key to

open the two major menus that access the many features that control

the unit's operation. Press

twice to access the Main Menu.

NOTE:

You must hold the

to turn the unit off.

MENU

once to access the Sonar Menu, or

MENU

key down for a countdown of five in order

27

2

3

. Press this key to

MENU

Page 32

2. ENT/PAGES (enter and pages)

. When viewing a

This key appears in the manual text simply as

ENT

menu or adjusting a feature, use this key to select a highlighted option.

When no menus are on the screen, pressing this key will make the unit

cycle through the four Sonar Chart Display Options.

3. EXIT

Press this key to clear menus from the screen and return to the Sonar

Chart display. You will also use

to cancel alarms, and to clear any

EXIT

information windows that may appear on the screen.

4. UP and DOWN ARROWS

These keys appear in the manual text as ↓ or ↑. Use these keys to move

through the menu options and to adjust virtually every feature and

function on the sonar unit.

Memory

This unit has permanent memory that saves all user settings, even when

power is removed. It does not require, nor does it use an internal backup

battery, so you never have to worry about replacement batteries.

Menus

Your sonar unit will work fine right out of the box with the factory default settings. You only need to learn a few basic functions to enhance

your viewing. We'll discuss them briefly here, then talk about them and

all the other commands in more detail in the next section, which begins

on page 39.

Your unit has two primary menus that control its operation.

They are the Main Menu and the Sonar Menu.

Main Menu

The Main Menu contains some basic function commands and some setup

option commands. You access the Main Menu by pressing

MENU|MENU

You run a command by using ↑ or ↓ to highlight the command and then

pressing

play, press

. To clear the Main Menu screen and return to the Page dis-

ENT

. (Remember, our text style for "

EXIT

MENU|MENU

" means

"press the Menu key twice." See a full explanation of our instruction text

formatting on page 4, Instructions = Menu Sequences.)

28

.

Page 33

Main Menu.

Main Menu Commands

There are four "basic" Main Menu commands that you'll really want to

read more about. They are:

• Screen commands (

C

ONTRAST

,

B

ACKLIGHT LEVEL

and

T

RANSPARENCY

change the appearance of the display screen. Use these commands to

adjust how the screen looks under various lighting conditions.

• Volume command: controls sound levels for key strokes and alarms. If

you don't like to hear a beep each time you press a key, you can turn all

sounds off by setting the volume to zero. Sound is especially useful when

used with the Fish I.D. fish symbol feature and fish alarm feature.

• Sonar Alarms command: turns alarms on or off and changes alarm

thresholds. The fish alarm, used with Fish I.D., is the most popular

use. It tells you when the sonar sees a fish. You can also set deep or

shallow depth alarms.

• Popup Help command: turns the pop-up help boxes on or off. When

you select a menu command, these information boxes appear to tell you

what the command does or how to use the command. The default setting is on, which is really handy while you're learning.

The remaining Main Menu commands are for more advanced functions,

mostly setting various sonar options. (They're all detailed in the Advanced Section.)

• Units of Measure command: selects the units of measure used for

showing speed/distance, depth and temperature.

):

29

Page 34

• Set Keel Offset command: calibrates the unit to show depth under

the keel or actual depth from the surface.

• Calibrate Water Speed command: adjusts how a speed sensor

measures water speed.

• Reset Water Distance command: resets water distance log to zero.

• Sonar Simulator command: turns the simulator feature on and off.

Useful for learning how to operate the unit and all its functions.

• Reset Options command: returns all options and auto functions to

their original factory settings. It's a great safety net while you're

learning and experimenting with various settings.

• Set Language command: your unit has menus in 10 different lan-

guages. This command switches from one language to another.

• Software Information command: tells you which version of the op-

erating software is loaded in your unit.

Sonar Menu

The Sonar Menu contains commands for the major sonar features and

options. You access the Sonar Menu by pressing the

MENU

key one

time. You run a command by using the ↑ or ↓ to highlight the command

and then pressing

Page display, press

. To clear the menu screen and return to the

ENT

.

EXIT

Sonar Page Menu. Most of these functions are discussed in the Ad-

vanced Section.

Sonar Menu Commands

The Sonar Menu contains commands for the major sonar features and

options. Most of them are only described in detail in the Advanced Sec-

30

Page 35

tion, but Sensitivity and Auto Sensitivity are important basic functions

that are discussed both here and in the Advanced Section. The other Sonar Menu commands include:

• ColorLine command: separates fish and structure near the bottom

from the actual bottom, and defines bottom composition/hardness.

• Depth Range command: manually sets the depth range shown on

the sonar chart.

• Auto Depth Range command: automatically sets the depth range

shown on the sonar chart to always keep the bottom in view.

• Upper and Lower Limits command: sets the upper and lower depth

limits of the sonar chart. Lets you zoom in on a specific portion of the

water column.

• Stop Chart command: stops the sonar chart from scrolling. Used

when you want to "freeze" the image for closer study.

• Chart Speed command: sets the scrolling speed of the sonar chart.

• Depth Cursor command: displays a cursor line on the sonar chart

which allows you to accurately measure the depth of a sonar target.

• Overlay Data command: chooses what types of information (such as

water temperature) to show overlaid on the sonar chart screen.

• Sonar Features command: launches the Sonar Features menu which

controls many functions and options, including screen color mode, auto

depth and sensitivity, surface clarity, noise rejection, Fish I.D. symbols, the zoom bar and zone bar.

• Ping Speed command: sets the rate at which sonar pings are made.

• Zoom command: controls the display size of sonar signal images.

Pages

The X67C has four major display options. They are the Full Sonar

Chart, Split Zoom Sonar Chart, Digital Data and Flasher.

You access the various display modes by pressing the

As you press this key, the unit cycles among the four page options. To

return to a previous page, simply press

pears again.

The Full Sonar Chart is the main display option. This is a "crosssection" view of the water column beneath the boat. The chart moves

across the screen, displaying sonar signal echoes that represent fish,

structure and the bottom.

ENT until the desired page ap-

31

ENT/PAGES key.

Page 36

Digital data

overlay

(depth &

temperature)

Fish arches

around

school of

Surface signal

Surface clutter

Depth scale

In FasTrack, fish

arches show as

horizontal bars.

Structure

Bottom signal

Sonar Page, showing full sonar chart mode.

Zoom bar

FasTrack

bar graph

Sonar chart display options (from left) full sonar chart and split zoom.

32

Page 37

Sonar chart display options (from left) digital data and flasher.

You can customize how the Sonar Page pictures and other data are displayed in many ways. We'll discuss all of those features and options in

the Advanced Section, but to show you how easy the sonar unit is to operate, the following page contains a simplified, 10-step quick reference

that will cover most fish finding situations. The quick reference describes how your unit will operate with all the sonar features in their

automatic modes, which are set at the factory.

33

Page 38

Basic Sonar Quick Reference

1. Mount the transducer and unit. Connect the unit to electric power

and the transducer.

2. Launch your boat.

3. To turn on the unit, press and release

4. Head for your fishing grounds. Your unit automatically displays digital depth and surface water temperature in the corner of the screen.

The auto settings will track the bottom, displaying it in the lower portion of the screen. The full sonar chart will scroll from right to left,

showing you what's under the boat as you cruise across the water.

5. As you're watching the sonar returns, you can change the display by:

Zoom in to enlarge the chart for more detail, or…

Zoom out to return to full chart mode.

Press

MENU

|↑|

to select which Zoom Mode you want to use.

ENT

6. If necessary, adjust sensitivity to improve chart readability. Press

MENU|ENT

and the Sensitivity Menu will appear on the left of your

screen. Use ↑ and ↓ to change the setting.

Boosting sensitivity will show more information on your screen, which

may cause clutter. Reducing sensitivity will filter out some information,

but could omit important images. We recommend adjusting sensitivity

until the background is lightly "peppered" — that is, scattered dots appear, but individual objects (like fish arches or bottom structure) can be

easily picked out of the background.

7. Watch the display for the appearance of fish arches. When you see

arches, you've found fish! Stop the boat and get your lure or bait into

the water at the depth indicated on the sonar chart.

8. Gauge the fish depth by visually comparing the fish arches with the

depth scale on the right side of the screen, or get a more accurate

measure with the Depth Cursor. Press

Press ↓ (or ↑) to align the cursor line with the fish arch. The exact

depth appears in a box at the right end of the cursor line. To clear the

cursor, press

EXIT

.

9. If you are drifting at a very low speed or anchored, you are not moving fast enough for a fish to return the tell-tale fish arch signal. As you

drift over a fish, or as a fish swims through the transducer's signal

cone, the fish echo will appear as a straight line suspended between the

surface and the bottom.

10. To turn off the unit, press and hold

MENU

key.

MENU

|↓ to

MENU

D

EPTH CURSOR

key for three seconds.

|

ENT

.

34

Page 39

Sonar Operations

As you can see from the quick reference on the previous page, basic operation

is pretty easy, right out of the box. If you are a sonar novice, try operating the

unit with the factory defaults until you get a feel for how it's working.

As you're learning the basics, there is one setting you might want to tinker

with from time to time — Sensitivity.

Sensitivity controls the unit's ability to pick up echoes. If you want to

see more detail, try increasing the sensitivity, a little at a time. There

are situations when too much clutter appears on the screen. Decreasing

the sensitivity can reduce the clutter and show the strongest fish echoes, if fish are present. As you change the sensitivity setting, you can

see the difference on the chart as it scrolls.

Fig. 1

Bait

school

Thermocline

with fish

Fish

arches

Fig. 2

Fig. 3 Fig. 4

These figures show results of different sensitivity levels on the same

location. Fig. 1: Sensitivity at 87 percent, determined by Auto Sensitiv-

ity. Typical of full auto mode. Fig. 2: Sensitivity set at 50 percent. Fig.

3: Sensitivity set at 20 percent. Fig. 4: Sensitivity set at 100 percent.

35

Page 40

You can change the sensitivity level whether you are in Auto Sensitivity mode or Manual Sensitivity mode. The adjustment method works

the same in both modes, but it gives you slightly different results.

Adjusting sensitivity in Auto Sensitivity Mode is similar to manually adjusting a car's speed with the accelerator pedal while cruise control is on.

You can tell the car to run faster, but when you let off the gas the cruise

control automatically keeps you from running slower than the minimum

speed setting. In the sonar unit, auto mode will let you increase sensitivity to 100 percent, but the unit will limit your minimum setting. This prevents you from turning sensitivity down too low to allow automatic bottom tracking. When you change the setting with auto turned on, the unit

will continue to track the bottom and make minor adjustments to the sensitivity level, with a bias toward the setting you selected.

Adjusting sensitivity in Manual Sensitivity Mode is similar to driving a

car without cruise control — you have complete manual control of the

car's speed. In the sonar unit, manual mode allows you to set sensitivity at 100 percent (maximum) or zero percent (minimum.) Depending

on water conditions, the bottom signal may completely disappear from

the screen when you reduce sensitivity to about 50 percent or less!

Try adjusting sensitivity in both auto and manual modes to see how

they work.

To adjust sensitivity:

1. Press

MENU|ENT

.

2. The Sensitivity Control Bar appears. Press ↓ to decrease sensitivity;

press ↑ to increase sensitivity. When it's set at the desired level, press

. (When you reach the maximum or minimum limit, a tone sounds.)

EXIT

At left, Sonar Menu with Sensitivity command selected. At right, the

Sensitivity Control Bar.

36

Page 41

NOTE:

If you want to change the sensitivity in Manual Mode, first turn off

|↓ to

Auto Sensitivity: from the Sonar Page, press

|

S

ENSITIVITY

ENT

|↑ to

S

ENSITIVITY

|

. Press ↓ or ↑ to pick a different

ENT

MENU

sensitivity setting. When it's set at the desired level, press

EXIT

A

UTO

.

Important Tip:

While you are experimenting and learning, it's possible to scramble

the settings so that the sonar picture disappears from your screen.

If that happens, remember that it's easy to switch back to full

automatic operation by simply restoring the factory auto settings.

Here's how:

To Restore Factory Settings

1. Press

MENU|MENU

2. The unit asks if you want to reset all the options. Press ↑ or ↓ to

|

Y

ES

. All options are reset, and the unit reverts back to the

ENT

original settings.

Fish Symbols vs. Full Sonar Chart

You may have noticed in the quick reference that we used fish arches in

full sonar chart mode for our example, and not the popular Fish I.D.

fish symbol feature. Here's why.

Fish I.D. is an easier way for a sonar novice to recognize a fishy signal

return when he sees it. However, locating fish by symbol only has some

limitations.

|↓ to

R

ESET OPTIONS

|

ENT

.

Your sonar unit's microprocessor is remarkably powerful, but it can be

fooled. Some of the echoes calculated to be fish could be tree limbs or

turtles! To see what's under your boat in maximum detail, we recom-

mend you turn off Fish I.D. and begin learning to interpret fish arches.

Fish I.D. is most handy when you're in another part of the boat or performing some task that prevents you from watching the sonar screen.

Then, you can turn on Fish I.D. and the audible fish alarm. When that

lunker swims under your boat, you'll hear it!

Fish I.D. can also be useful when you want to screen out some of the

sonar detail gathered by your unit. For example, in one case fishermen

in San Francisco Bay saw clouds of clutter in the water but no fish

arches. When a down rigger was pulled up, it brought up several small

jellyfish. The fishermen switched their Lowrance sonar to Fish I.D.,

which screened out the schools of jellyfish and clearly showed the game

fish there as fish symbols.

37

Page 42

Other Free Training Aids

The following section discusses Fish I.D., fish alarms and other features in greater detail. If you or a friend has Internet access, you can

also learn more about interpreting what you see on your sonar screen.

Visit our web site,

WWW.LOWRANCE.COM. Be sure to check out the free

Sonar Tutorial, which includes animated illustrations and more pictures of actual sonar returns, all described in detail. There's even a

"printer friendly" version of the tutorial available on our web site…it

makes a great supplement to this operation manual!

For the ultimate training aid, be sure to download the free emulator

software for your unit. Aside from being just plain fun, this program

can help you learn both basic and advanced operations without burning

boat fuel! Lowrance is the first sonar manufacturer to provide this type

of training tool for customers.

This PC application simulates the actual sonar unit on your computer.

You can run it from your computer keyboard or use your mouse to press

the virtual keys. Easy download and installation instructions are available on our web site.

Free training emulator is available for your unit on our web site. To

run it, click the buttons with your mouse pointer.

38

Page 43

Advanced Sonar Options & Other Features

Material in this section is arranged in alphabetical order.

ASP (Advanced Signal Processing)

The ASP feature is a noise rejection system built into the sonar unit

that constantly evaluates the effects of boat speed, water conditions

and interference. This automatic feature gives you the best display possible under most conditions.

The ASP feature is an effective tool in combating noise. In sonar terms,

noise is any undesired signal. It is caused by electrical and mechanical

sources such as bilge pumps, engine ignition systems and wiring, air

bubbles passing over the face of the transducer, even vibration from the

engine. In all cases, noise can produce unwanted marks on the display.

The ASP feature has four settings — Off, Low, Medium and High. If

you have high noise levels, try using the "High" ASP setting. However,

if you are having trouble with noise, we suggest that you take steps to

find the interference source and fix it, rather than continually using the

unit with the high ASP setting.

There are times when you may want to turn the ASP feature off. This

allows you to view all incoming echoes before they are processed by the

ASP feature.

At left, Sonar Menu with Sonar Features selected. In the Sonar Features

menu, Noise Rejection is selected with ASP in the default low setting.

To change the ASP level:

1. From the Sonar Page, press

2. Press ↓ to

3. Press ↓ or ↑ to select a setting, then press

4. To return to the previous page, press

NOISE REJECTION|ENT.

MENU|↓ to SONAR FEATURES|ENT.

ENT.

EXIT|EXIT.

39

Page 44

Alarms

This unit has two different types of sonar alarms. The first is a Fish Alarm.

It sounds when the Fish I.D. feature determines that an echo is a fish.

The other alarm is the Depth Alarm, which has both a Shallow and a

Deep setting. Only the bottom signal will trigger this alarm. This is

useful as an anchor watch, a shallow water alert or for navigation.

Depth Alarms

The depth alarms sound a tone when the bottom signal goes shallower

than the shallow alarm's setting or deeper than the deep alarm's setting. For example, if you set the shallow alarm to 10 feet, the alarm will

sound a tone if the bottom signal is less than 10 feet. It will continue to

sound until the bottom goes deeper than 10 feet.

The deep alarm works just the opposite. It sounds a warning tone if the

bottom depth goes deeper than the alarm's setting. Both depth alarms

work only off the digital bottom depth signals. No other targets will trip

these alarms. These alarms can be used at the same time or individually.

At left, Main Menu and Sonar Alarms command.

At right, the Sonar Alarms menu.

To adjust and turn on the shallow alarm:

1. Press

2. Press ↓ to

MENU|MENU

S

HALLOW ALARM DEPTH

3. Press ↑ or ↓ until the depth is correct, then press

4. Press ↑ to

S

HALLOW ALARM ENABLED

5. To turn off the alarm, press

ENT|ENT|EXIT

.

|↓ to

S

ONAR ALARMS

|

ENT

|

|

.

ENT

.

ENT|EXIT

MENU|MENU

.

ENT

|↓ to

.

S

ONAR ALARMS

To switch to a different depth setting, open the Sonar Alarms menu and

repeat the instructions in step 3 above.

40

|

Page 45

To adjust and turn on the deep alarm:

1. Press

2. Press ↓ to

MENU|MENU

D

EEP ALARM DEPTH

3. Press ↑ or ↓ until the depth is correct, then press

4. Press ↑ to

D

EEP ALARM ENABLED

5. To turn off the alarm, press

to

D

EEP ALARM ENABLED

|↓ to

S

|

ENT|EXIT

ONAR ALARMS

|

.

ENT

|

ENT|EXIT

MENU|MENU

.

|

ENT

.

.

|↓ to

.

ENT

S

ONAR ALARMS

|

ENT

|↓

To switch to a different depth setting, open the Sonar Alarms menu and

repeat the instructions in step 3 above.

Fish Alarm

Use the fish alarm for a distinctive audible alarm when fish or other

suspended objects are detected by the Fish I.D. feature (Fish I.D.

must be turned on for the Fish Alarm to work). A different tone sounds

for each fish symbol size shown on the display.

Sonar Alarms menu with Fish Alarm selected. The check box

to the left is checked, indicating the alarm is turned on.

To turn the fish alarm on:

1. Press

2. Press ↓ to

MENU|MENU

F

ISH ALARM

3. To turn off the alarm, press

to

F

ISH ALARM

|

ENT|EXIT

|↓ to

|

ENT|EXIT

.

S

ONAR ALARMS

.

MENU|MENU

|

ENT

.

|↓ to

S

ONAR ALARMS

|

ENT

|↓

Backlight Level

The unit defaults to the maximum backlight level. To adjust the display's backlight level:

Press

MENU|MENU

bar appears. Press ↑ or ↓ to move the bar. At The lower end of the scale

backlighting is turned off; the upper end is maximum backlight level.

|↓ to

B

ACKLIGHT LEVEL

41

|

ENT

. The

B

ACKLIGHT LEVEL

slider

Page 46

Backlight Level Command, left, and Backlight Level control bar, right.

The control bar appears automatically whenever you turn on the unit.

Calibrate Speed

The speed sensor can be calibrated to compensate for inaccuracies. Before you change the setting, first calculate the percentage that the

speed is off. You will enter this percentage in a moment.

For example, if you figure the sensor is reading 10 percent faster than

actual speed, you will enter – 10 in the calibration window. If the sensor is reading 5 percent slower than true speed, you will enter + 5 in

the window.

Perform your test in relatively calm water free of current, if possible.

(Unless, of course, you are taking the current speed into consideration

when making your calculation.) After you have a correction figure,

here's how to enter it:

1. Press

MENU|MENU

|↓ to

C

ALIBRATE WATER SPEED

|

ENT

.

2. Enter the number you calculated earlier: press ↑ or ↓ to change the displayed number. Continue until the percentage is correct, then press

EXIT

.

Chart Speed

The rate that echoes scroll across the screen is called the chart speed.

The default is maximum; we recommend that you leave the speed set

there for virtually all fishing conditions.

However, you might consider experimenting with chart speed when you

are stationary or drifting very slowly. You may sometimes achieve better images as you slow down the chart speed to match how fast you are

moving across the bottom.

If you are at anchor, ice fishing or fishing from a dock, experiment with

a chart speed around 50 percent. If you are drifting slowly, try a chart

42

Page 47

speed around 75 percent. When you are stationary and a fish swims

through the sonar signal cone, the image appears on the screen as a

long line instead of a fish arch. Reducing the chart speed may result in

a shorter line that more closely resembles a regular fish return.

At left, Sonar Page menu with Chart Speed command selected.

At right, Chart Speed Control Bar.

If you do experiment with chart speed, remember to reset it to maximum when you resume trolling or moving across the water at higher

speed. To change chart speed:

1. From the Sonar Page, press

MENU

|↓ to

C

HART SPEED

|

ENT

.

2. The Chart Speed Control Bar appears. Press ↓ to decrease chart

speed; press ↑ to increase chart speed.

3. When it's set at the desired level, press

ColorLine

EXIT

.

ColorLine lets you distinguish between strong and weak echoes. It

"paints" a brighter color on targets that are stronger than a preset

value. This allows you to tell the difference between a hard and soft

bottom. For example, a soft, muddy or weedy bottom returns a weaker

signal which is shown with a narrow, colored line (dark blue tinged

with red or a little yellow.) Since fish are among the weakest echoes,

they show up mostly as blue arches. A hard bottom or other relatively

hard target returns a strong signal which causes a wider brightly colored line (reddish yellow to bright yellow.)

If you have two signals of equal size, one with red to yellow color and

the other without, then the target with brighter color (yellow) is the

stronger signal. This helps distinguish weeds from trees on the bottom,

or fish from structure.

43

Page 48

ColorLine is adjustable. Experiment with your unit to find the ColorLine setting that's best for you.

At left, Sonar Page menu with ColorLine command selected.

At right, the ColorLine control bar.

To adjust the ColorLine level:

1. From the Sonar Page, press

MENU|↓ to COLORLINE|ENT.

2. The ColorLine Control Bar appears. Press ↓ to decrease ColorLine;