Lowrance X59DF, X52 User Manual

www.lowrance.com

Pub. 988-0151-211

X52 and X59DF

Fish-Finding & Depth-Sounding Sonars

Installation and Operation

Instructions

Copyright © 2004 Lowrance Electronics, Inc.

All rights reserved.

Lowrance

®

is a registered trademark of Lowrance Electronics, Inc.

No part of this manual may be copied, reproduced, republished,

transmitted or distributed for any purpose, without prior written

consent of Lowrance. Any unauthorized commercial distribution

of this manual is strictly prohibited.

Lowrance Electronics may find it necessary to change or end our

policies, regulations, and special offers at any time. We reserve the

right to do so without notice. All features and specifications subject to

change without notice. All screens in this manual are simulated.

For free owner's manuals and the most current information on

this product, its operation and accessories,

visit our web site:

www.lowrance.com

Lowrance Electronics Inc.

12000 E. Skelly Dr.

Tulsa, OK USA 74128-2486

Printed in USA.

Table of Contents

Introduction ......................................................................................i

Capabilities and Specifications: X52 and X59DF.............................. 1

Installation & Accessories............................................................. 3

Preparations........................................................................................ 3

Transducer Installation...................................................................... 3

Recommended Tools and supplies.................................................. 4

Selecting a Transducer Location.................................................... 4

How low should you go?.................................................................. 5

Shoot-Thru-Hull vs. Transom Mounting ....................................... 6

Transom Transducer Assembly and Mounting ............................. 7

Trolling Motor Bracket Installation................................................. 13

Transducer Orientation and Fish Arches .................................... 14

Shoot-Thru-Hull Preparation....................................................... 15

Testing Determines Best Location............................................... 16

Shoot-Thru-Hull Installation ....................................................... 17

Speed/Temperature Sensors............................................................. 19

Optional Temperature Sensor...................................................... 19

Optional Speed Sensor Installation ............................................. 19

Power Connections............................................................................ 20

Powering a NMEA 2000 Buss (NMEA 2000 Power cable).......... 21

Powering Your Unit ...................................................................... 21

NMEA 2000 Cable Connections ....................................................... 24

NMEA 0183 Cable Connections ....................................................... 24

Mounting the Unit: Bracket, In-Dash or Portable .......................... 25

Other Accessories.............................................................................. 29

Basic Sonar Operation ................................................................. 31

KEYBOARD BASICS ....................................................................... 31

Memory.............................................................................................. 32

Menus ................................................................................................ 32

Main Menu .................................................................................... 32

Sonar Menu ................................................................................... 34

Pages ................................................................................................. 35

Basic Sonar Quick Reference ........................................................... 38

Sonar Operations .............................................................................. 39

Fish Symbols vs. Full Sonar Chart .............................................. 41

Other Free Training Aids ............................................................. 42

Advanced Sonar Options & Other Features............................ 43

ASP (Advanced Signal Processing)............................................... 43

Alarms ............................................................................................... 44

Depth Alarms ................................................................................ 44

Fish Alarm..................................................................................... 45

i

Backlight Level ................................................................................. 46

Calibrate Speed................................................................................. 46

Chart Speed....................................................................................... 46

Grayline

........................................................................................... 47

Contrast............................................................................................. 48

Depth Cursor..................................................................................... 49

Depth Range - Automatic ................................................................. 50

Depth Range - Manual ..................................................................... 50

Depth Range - Upper and Lower Limits ......................................... 51

To change the upper and lower limits:......................................... 51

To turn off upper and lower limits: .............................................. 52

FasTrack ........................................................................................ 52

Fish I.D. (Fish Symbols & Depths) ............................................... 52

FishTrack ....................................................................................... 53

Overlay Data ..................................................................................... 54

Ping Speed & HyperScroll............................................................. 56

To change Ping Speed: .................................................................. 57

To adjust Sensitivity:.................................................................... 57

To turn off HyperScroll:................................................................ 57

Pop-up Help....................................................................................... 58

Reset Options .................................................................................... 58

Reset Water Distance ....................................................................... 59

Sensitivity & Auto Sensitivity.......................................................... 59

To turn Auto Sensitivity back on: ................................................ 61

Set Keel Offset .................................................................................. 61

Set Language .................................................................................... 62

Software Version Information.......................................................... 62

Sonar Chart Mode............................................................................. 63

Sonar Page & Sonar Chart Display Options ................................... 63

Full Sonar Chart ........................................................................... 63

Split Zoom Sonar Chart................................................................ 64

Digital Data/Chart ........................................................................ 65

Flasher........................................................................................... 66

Sonar Simulator................................................................................ 66

Stop Chart ......................................................................................... 66

Surface Clarity.................................................................................. 67

Units of Measure............................................................................... 68

Zoom Pan........................................................................................... 70

Troubleshooting ............................................................................ 71

Index................................................................................................. 75

ii

Introduction

Thank you for buying a Lowrance sonar! Your unit is a high-quality

sonar designed for both professional and novice fishermen. All

Lowrance sonars have an automatic mode that finds and displays the

bottom, fish, underwater structure and more – right out of the box. All

you have to do is press the on (

However, if you want to fine-tune your unit, press the

X52 and X59DF have several powerful features you can control by

scrolling through easy-to-use menus with the arrow and menu keys.

To get started with your Lowrance sonar, first read the installation

section. It contains instructions for mounting the sonar unit, the

transducer and any optional accessories, such as a speed sensor.

Following recommended installation practices will pay off in optimum

performance of your Lowrance sonar. Improper installation can cause

problems down the road, especially if the transducer is badly mounted.

After you've read the installation instructions, install the unit and

accessories. Then, read the rest of the manual. The more you know

about your sonar, the better it will work for you.

Take advantage of the Simulator feature. It allows you to practice

operating your sonar before you get it in the water. And when you finally

head for your favorite fishing hole, take this manual along for reference.

Capabilities and Specifications: X52 and X59DF

Case size:......................... 5.2" H x 5.4" W x 2.6" D (13.2 cm H x 13.6 cm

Display:............................ High-contrast Film SuperTwist LCD; 4.0"

Resolution:...................... 240 pixels (vert.) x 160 pixel (horiz.)

Backlighting:.................. White LED backlit screen and keypad for

Input power:................... 10 to 17 volts DC.

Current drain: ............... 300 ma lights off; 400 ma lights on.

Back-up memory: .......... Built-in memory stores sonar settings when

PWR) key.

MENU key. The

General

W x 6.6 cm D) sealed, waterproof; suitable

for saltwater use.

(10.2 cm) diagonal viewing area.

resolution; 38,400 total pixels

night use.

unit is turned off.

1

Sonar

Frequency:...................... 200 kHz (or 50/200 kHz – X59DF only).

Transducers: .................. A dual-frequency Skimmer

transducer

comes packed with the X59DF. It has 35°/12°

cone angles. Single frequency models for X52

with a 20° cone angle are sold separately.

Both models offer a wide fish detection area

of up to 60º with high sensitivity settings.

Transmitter: ................... 1500 watts peak-to-peak power (typical); 188

watts RMS power (typical).

Sonar sounding

depth capability: ........... 800 feet (244 meters) at 200 kHz; 1500 feet

(450 meters) at 50 kHz (X59DF only). Actual

capability depends on transducer

configuration and installation, bottom

composition and water conditions. All sonar

units typically read deeper in fresh water

than in salt water.

Depth display:................ Continuous digital readout.

Audible alarms: ............. Deep/shallow/fish.

Automatic ranging:....... Yes, with instant screen updates.

Zoom bottom track: ...... Yes.

Split-screen zoom:......... Yes.

Surface water temp: ..... Yes, with optional external temperature

sensor, combo speed/temp sensor or

transducer with built-in temp.

Speed/distance log: ....... Yes, with optional speed sensor or combo

speed/temp sensor.

NOTICE!

The storage temperature for your unit is from -4 degrees to +167

degrees Fahrenheit (-20 degrees to +75 degrees Celsius). Extended

storage in temperatures higher or lower than specified will damage

the liquid crystal display in your unit. This type of damage is not

covered by the warranty. For more information, contact the

factory's Customer Service Department; phone numbers are inside

the manual's back cover.

2

Installation & Accessories

Preparations

You can install the sonar system in some other order if you prefer, but

we recommend this installation sequence:

CAUTION:

You should read over this entire installation section before

drilling any holes in your vehicle or vessel!

1. Determine the approximate location for the sonar unit, so you can

plan how and where to route the cables for the transducer and power.

This will help you make sure you have enough cable length for the

desired configuration.

2. Determine the approximate location for the transducer and its cable

route.

3. Determine the location of your battery or other power connection,

along with the power cable route.

4. Install the transducer and route the transducer cable to the sonar

unit.

5. Route the power cable from the unit's location to an appropriate

power source and connect it there.

6. Connect the transducer/power cable to the unit and mount the sonar

unit on the bracket.

Transducer Installation

These instructions will help you install your Skimmer

transom, on a trolling motor or inside a hull. Please read all

instructions before proceeding with any installation.

Your Skimmer transducer typically comes packaged with a one-piece

stainless steel bracket for mounting it to the transom of your boat. The

optional trolling motor mount uses a one-piece plastic bracket with an

adjustable strap. These are "kick-up" mounting brackets. They help

prevent damage if the transducer strikes an object while the boat is

moving. If the transducer does "kick-up," the bracket can easily be

pushed back into place without tools.

Read these instructions carefully before attempting the installation.

Determine which of the installation methods is right for your boat.

Remember, the transducer location and installation is the most

critical part of a sonar installation.

transducer on a

3

Recommended Tools and supplies

If you prefer the option of routing the cable through the transom, you

will need a 5/8" drill bit. (If you intend to install an additional speed or

temp sensor and route its cable through the same hole in the transom,

you will need a 1" (25.4 mm) drill bit to accommodate all the cables.)

NOTE:

The following installation types also call for these recommended

tools and required supplies that you must provide (supplies listed

here are not included):

Single-frequency transom installations

Tools include: two adjustable wrenches, drill, #29 (0.136") drill bit, flathead screwdriver. Supplies: none.

Dual-frequency transom installations

Tools: two adjustable wrenches, drill, #20 (0.161") drill bit, flat-head

screwdriver. Supplies: four, 1" long, #12 stainless steel slotted wood

screws.

Single-frequency trolling motor installations

Tools: two adjustable wrenches, flat-head screwdriver. Supplies: plastic

cable ties.

Shoot-through hull installations

Tools: these will vary depending on your hull's composition. Consult

your boat dealer or manufacturer. Other tools are a wooden craft stick

or similar tool for stirring and applying epoxy, and a paper plate or

piece of cardboard to mix the epoxy on. Supplies: rubbing alcohol, 100

grit sandpaper, specially formulated epoxy adhesive available from LEI

(see ordering information on page 20). A sandwich hull also requires

polyester resin.

Selecting a Transducer Location

1. The location must be in the water at all times, at all operating speeds.

2. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is not placed in a smooth flow of

water, interference caused by bubbles and turbulence will show on the

sonar's display in the form of random lines or dots whenever the boat is

moving.

NOTE:

Some aluminum boats with strakes or ribs on the outside of the

hull create large amounts of turbulence at high speed. These boats

typically have large outboard motors capable of propelling the boat

at speeds faster than 35 mph. Typically, a good transom location on

aluminum boats is between the ribs closest to the engine.

4

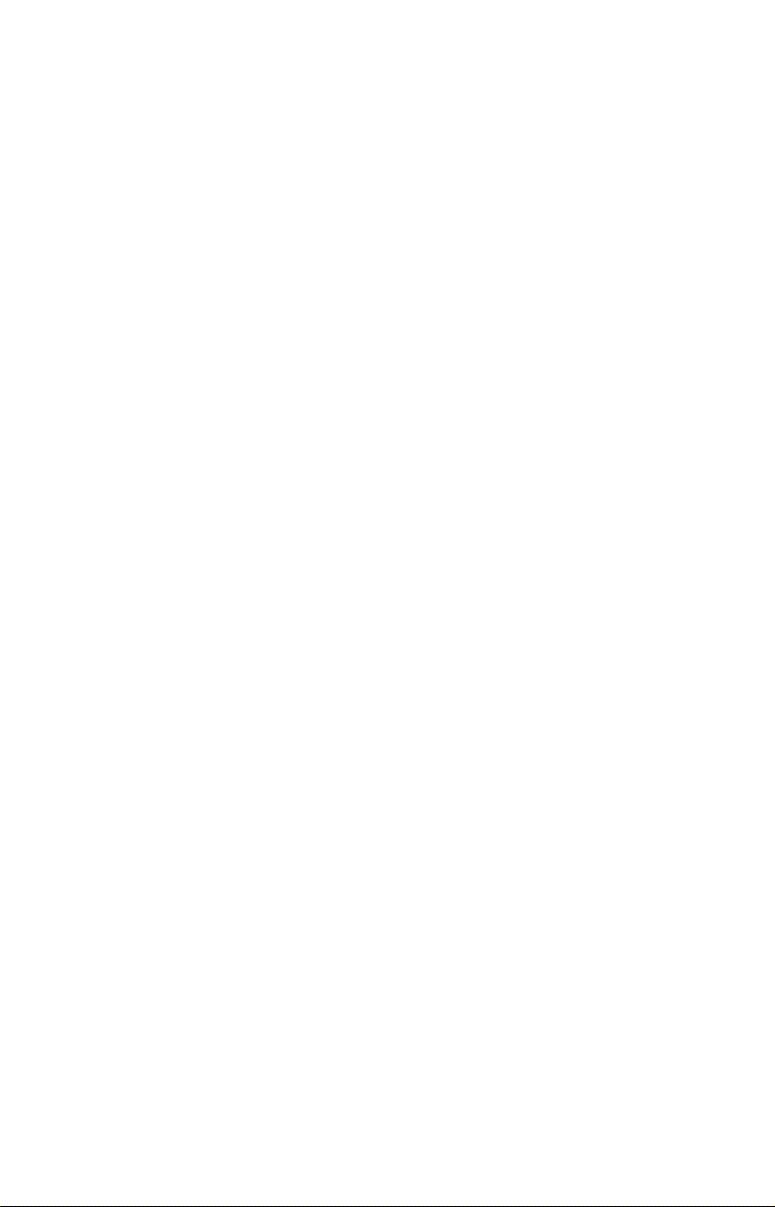

3. The transducer should be installed with its face pointing straight

down, if possible. For shoot-thru applications: Many popular fishing

boat hulls have a flat keel pad that offers a good mounting surface. On

vee hulls, try to place the transducer where the deadrise is 10° or less.

Deadrise less than 10°

Pad

Left, vee pad hull; right, vee hull. A pod style transducer is shown here,

but the principle is the same for Skimmers inside a hull.

Strakes

4. If the transducer is mounted on the transom, make sure it doesn't

interfere with the trailer or hauling of the boat. Also, don't mount it

closer than approximately one foot from the engine's lower unit. This

will prevent cavitation (bubble) interference with propeller operation.

5. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring, bilge pumps and aerators can

be displayed on the sonar's screen. Use caution when routing the

transducer cable around these wires.

CAUTION: Clamp the

transducer cable to transom

near the transducer. This will

help prevent the transducer

from entering the boat if it is

knocked off at high speed.

Good location

Poor location

Good

location

Poor angle

Good and poor transducer locations.

Good location

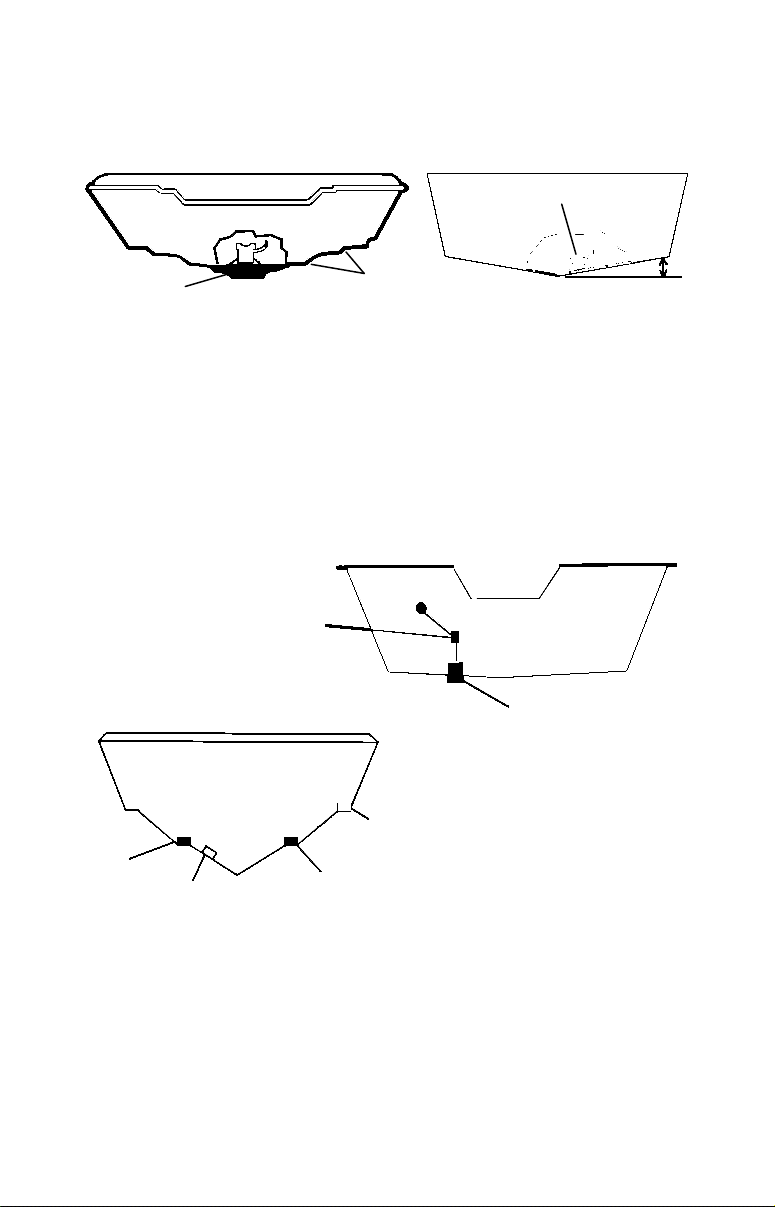

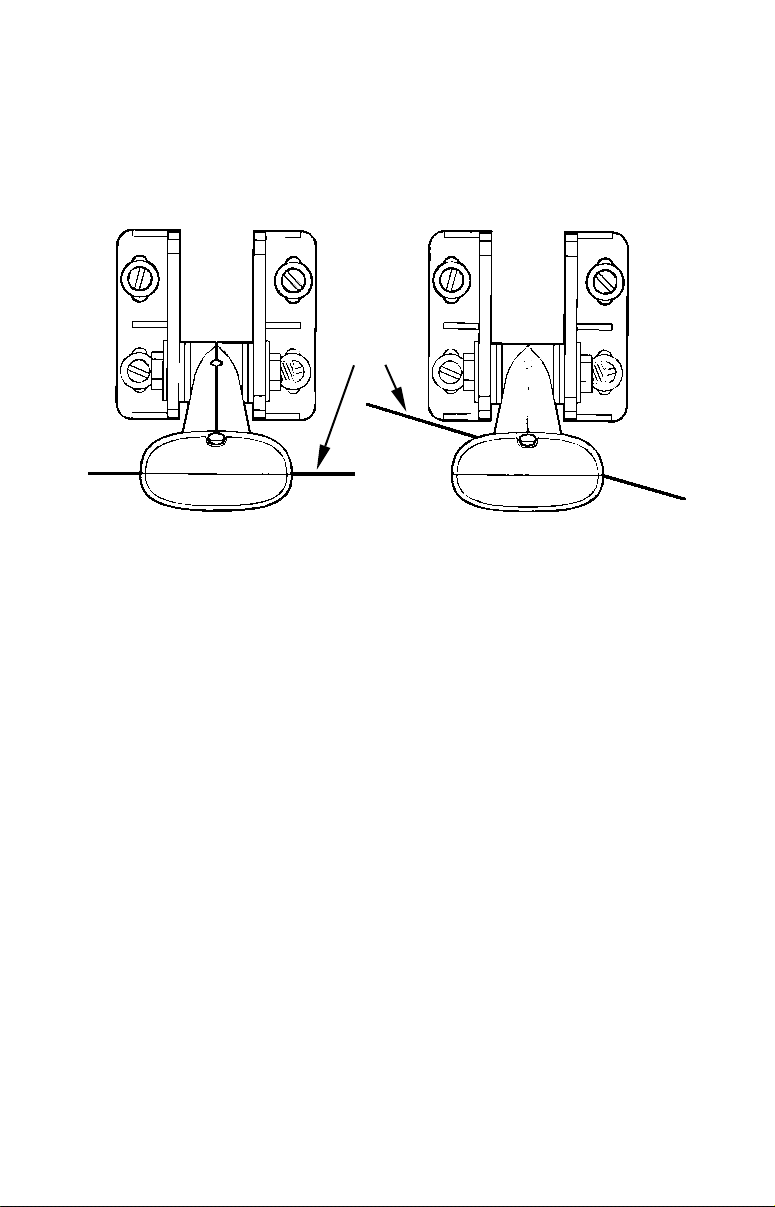

How low should you go?

For most situations, you should install your Skimmer transducer so

that its centerline is level with the bottom of the boat hull. This will

usually give you the best combination of smooth water flow and

protection from bangs and bumps.

5

Transom

Transom

Transducer

centerline

Hull bottom

Align transducer centerline with hull bottom. A dual frequency

transducer is shown at left and a single frequency transducer at right.

Hull bottom

However, there are times when you may need to adjust the transducer

slightly higher or lower. (The slots in the mounting brackets allow you

to loosen the screws and slide the transducer up or down.) If you

frequently lose bottom signal lock while running at high speed, the

transducer may be coming out of the water as you cross waves or

wakes. Move the transducer a little lower to help prevent this.

If you cruise or fish around lots of structure and cover, your transducer

may be frequently kicking up from object strikes. If you wish, you may

move the transducer a little higher for more protection.

There are two extremes you should avoid. Never let the edge of the

mounting bracket extend below the bottom of the hull. Never let the

bottom – the face – of the transducer rise above the bottom of the hull.

Shoot-Thru-Hull vs. Transom Mounting

In a shoot-thru-hull installation, the transducer is bonded to the inside

of the hull with epoxy. The sonar "ping" signal actually passes through

the hull and into the water. This differs from a bolt-thru-hull

installation (often called simply "thru-hull"). In that case, a hole is cut

in the hull and a specially designed transducer is mounted through the

hull with a threaded shaft and nut. This puts the transducer in direct

contact with the water.

Typically, shoot-thru-hull installations give excellent high speed

operation and good to excellent depth capability. There is no possibility

of transducer damage from floating objects, as there is with a transommounted transducer. A transducer mounted inside the hull can't be

knocked off when docking or loading on a trailer.

However, the shoot-thru-hull installation does have its drawbacks.

First, some loss of sensitivity does occur, even on the best hulls. This

varies from hull to hull, even from different installations on the same

hull. This is caused by differences in hull lay-up and construction.

6

Second, the transducer angle cannot be adjusted for the best fish arches

on your sonar display. (This is not an issue for flasher-style sonars.)

Lack of angle adjustment can be particularly troublesome on hulls that

sit with the bow high when at rest or at slow trolling speeds.

Third, a transducer CAN NOT shoot through wood and metal hulls.

Those hulls require either a transom mount or a thru-hull installation.

Fourth, if your Skimmer transducer has a built in temp sensor, it will

only show the temperature of the bilge, not the water surface temp.

Follow the testing procedures listed in the shoot-thru-hull installation

section at the end of this instruction booklet to determine if you can

satisfactorily shoot through the hull.

Transom Transducer Assembly and Mounting

The best way to install these transducers is to loosely assemble all of

the parts first, place the transducer's bracket against the transom and

see if you can move the transducer so that it's parallel with the ground.

The following instructions sometimes vary depending on the mounting

bracket that came with your transducer. Single frequency Skimmers

come with a one-piece stainless steel bracket, while dual frequency

Skimmers come with a two-piece plastic mounting bracket. Use the set

of instructions that fits your model.

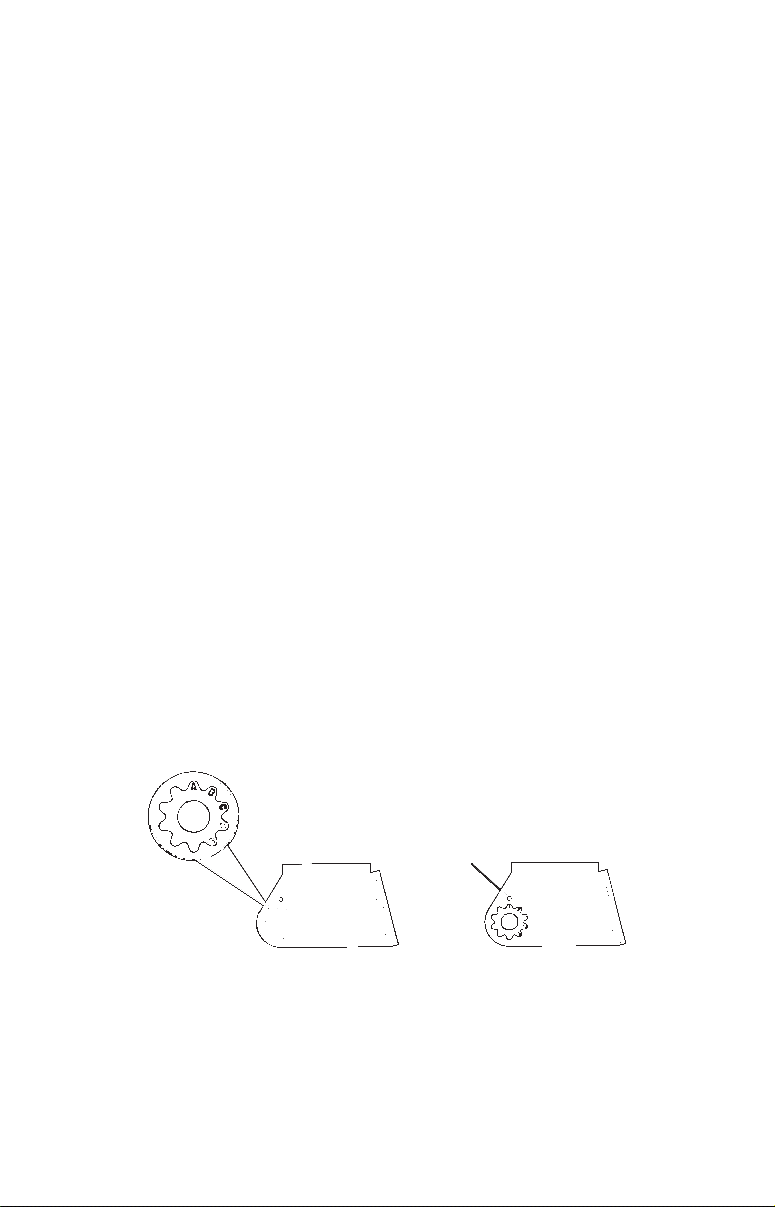

1. Assembling the bracket.

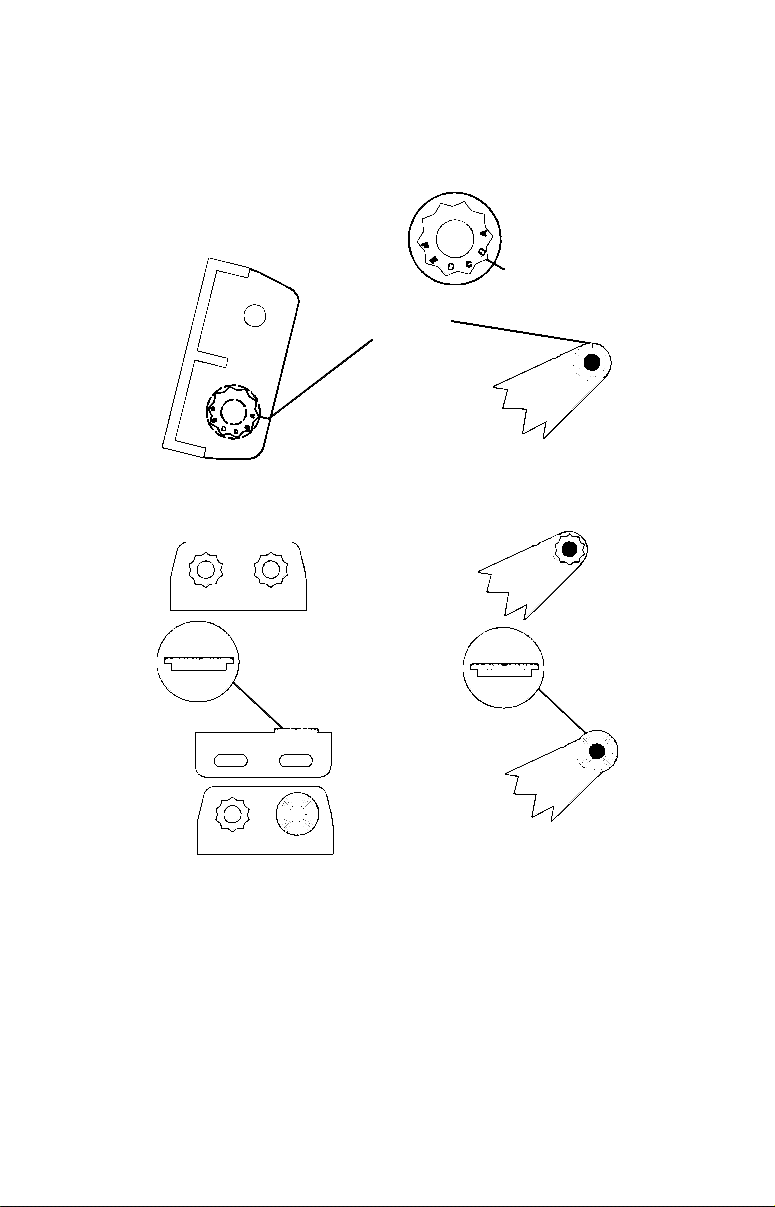

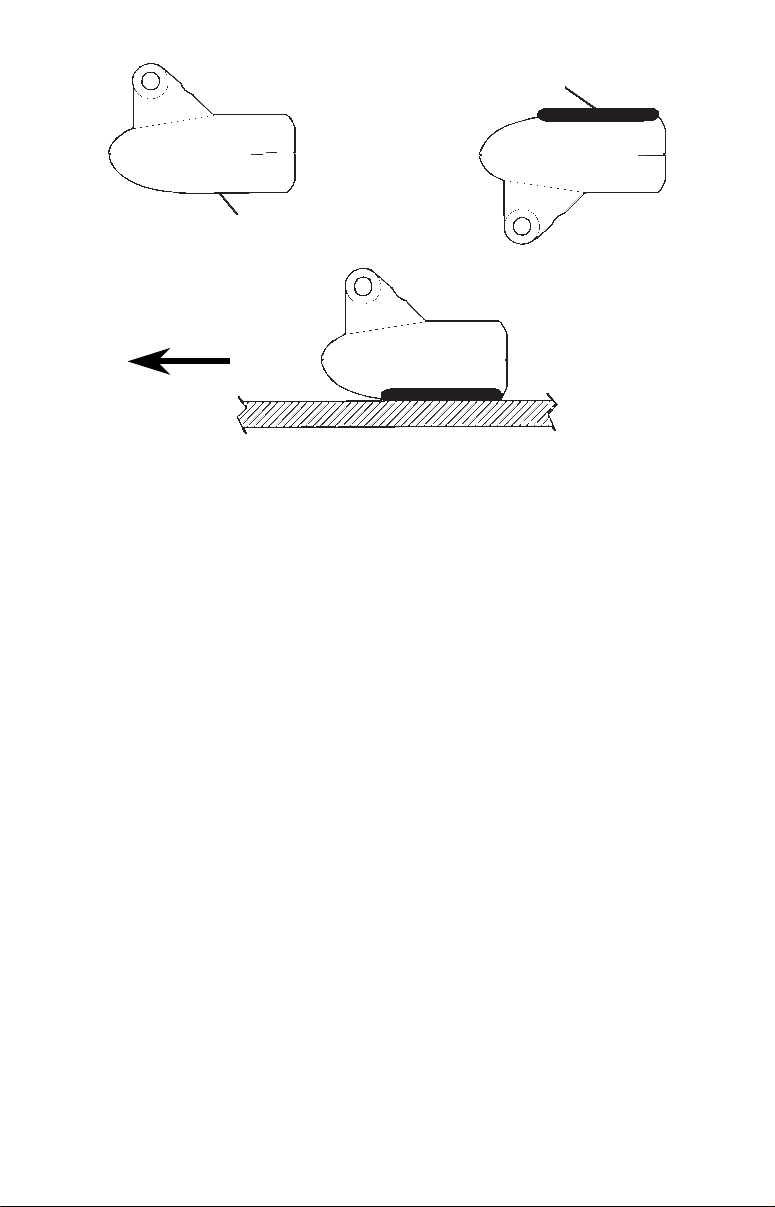

A. One-piece bracket: Press the two small plastic ratchets into the

sides of the metal bracket as shown in the following illustration. Notice

there are letters molded into each ratchet. Place each ratchet into the

bracket with the letter "A" aligned with the dot stamped into the metal

bracket. This position sets the transducer's coarse angle adjustment for a

14° transom. Most outboard and stern-drive transoms have a 14° angle.

Dot

Align plastic ratchets in bracket.

B. Two-piece bracket: Locate the four plastic ratchets in the

transducer's hardware package. Press two ratchets into the sides of

the plastic bracket and two on either side of the transducer as shown

in the following illustrations. Notice there are letters molded into each

ratchet. Place the ratchets into the bracket with the letter "A" aligned

7

with the alignment mark molded into the bracket. Place the ratchets

onto the transducer with the letter "A" aligned with the 12 o'clock

position on the transducer stem. These positions set the transducer's

coarse angle adjustment for a 14° transom. Most outboard and sterndrive transoms have a 14° angle.

Alignment letters

Alignment

positions

Transducer

Transducer bracket

Insert and align ratchets.

Transducer

bracket

Transducer

Ratchet

Add ratchets to bracket and transducer.

Ratchet

2. Aligning the transducer on the transom.

A. One-piece bracket: Slide the transducer between the two

ratchets. Temporarily slide the bolt though the transducer assembly

and hold it against the transom. Looking at the transducer from the

side, check to see if it will adjust so that its face is parallel to the

ground. If it does, then the "A" position is correct for your hull.

If the transducer's face isn't parallel with the ground, remove the

transducer and ratchets from the bracket. Place the ratchets into the

8

holes in the bracket with the letter "B" aligned with the dot stamped

in the bracket.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's

parallel with the ground. If you can, then go to step 3A. If it doesn't,

repeat step 2A, but use a different alignment letter until you can

place the transducer on the transom correctly.

Ratchets

Insert bolt and check transducer position on transom.

B. Two-piece bracket: Assemble the transducer and bracket as

shown in the following figure. Temporarily slide the bolt though the

transducer assembly but don't tighten the nut at this time. Hold the

assembled transducer and bracket against the transom. Looking at the

transducer from the side, check to see if it will adjust so that its face is

parallel to the ground. If it does, then the "A" positions are correct for

your hull.

If the transducer's face isn't parallel with the ground, remove and

disassemble the transducer and ratchets. Place the ratchets into the

bracket holes with the letter "B" aligned with the bracket alignment

mark. Place them on the transducer aligned with the 12 o'clock

position on the transducer stem.

Reassemble the transducer and bracket and place them against the

transom. Again, check to see if you can move the transducer so it's

parallel with the ground. If you can, then go to step 3B. If it doesn't,

repeat step 2B, but use a different alignment letter until you can

place the transducer on the transom correctly.

9

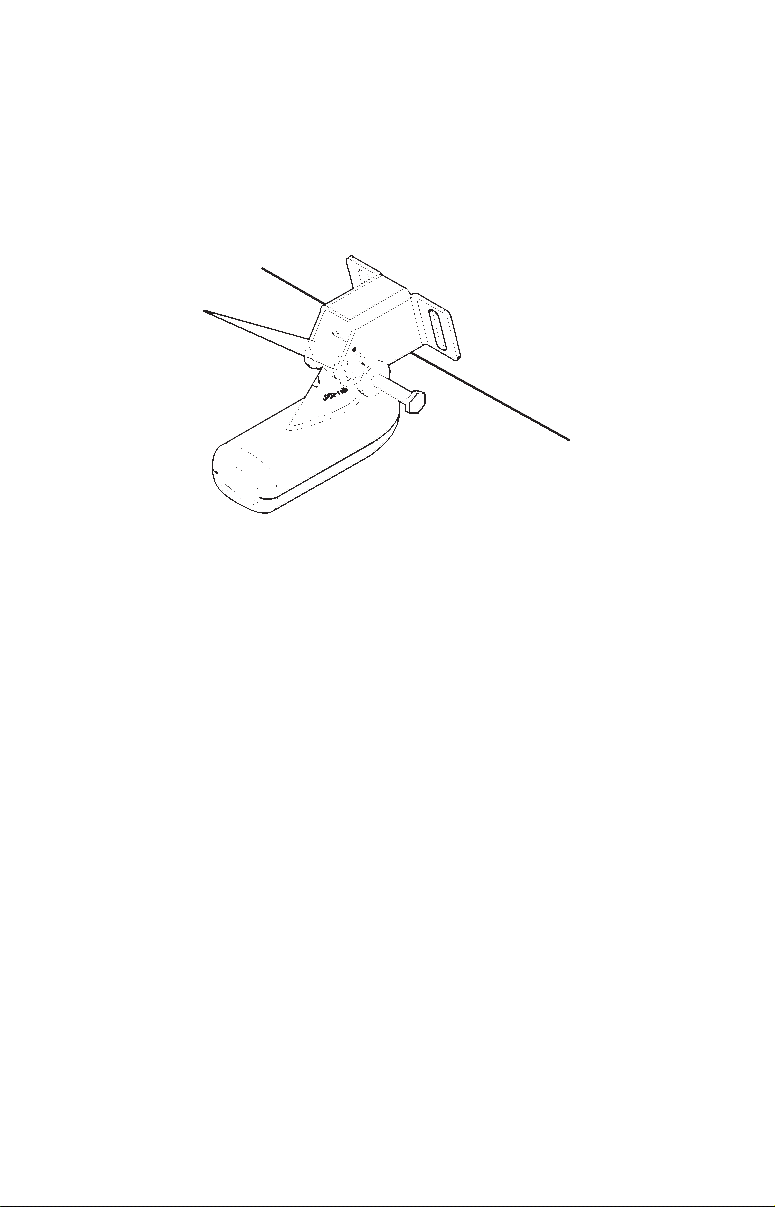

Bolt

Lock washer

Nut

Flat washer

Assemble transducer and bracket.

Flat washer

3. Assembling the transducer.

A. One-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the following

figure. Don't tighten the lock nut at this time.

Metal

Nut

Rubber

washers

washer

Metal washer

Bolt

Assemble transducer and bracket.

B. Two-piece bracket: Once you determine the correct position for

the ratchets, assemble the transducer as shown in the figure in step

2B. Don't tighten the lock nut at this time.

4. Drilling mounting holes.

Hold the transducer and bracket assembly against the transom. The

transducer should be roughly parallel to the ground. The

transducer's centerline should be in line with the bottom of the hull.

Don't let the bracket extend below the hull!

Mark the center of each slot for the mounting screw pilot holes. You

will drill one hole in the center of each slot.

10

Drill the holes. For the one-piece bracket, use the #29 bit (for the #10

screws). For the two-piece bracket, use the #20 bit (for the #12

screws).

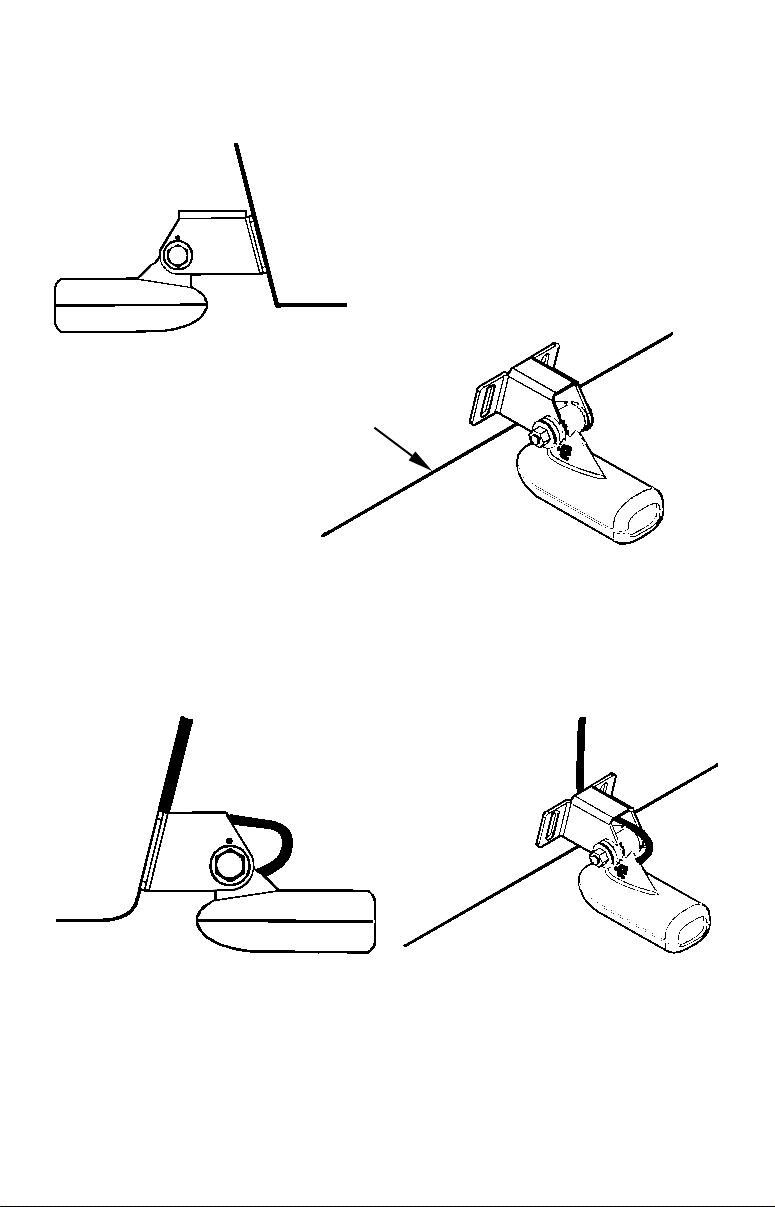

Transom

Transom

Position transducer mount on transom and mark mounting holes.

Side view shown at left and seen from above at right.

5. Attaching transducer to transom.

A. One-piece bracket: Remove the transducer from the bracket and

re-assemble it with the cable passing through the bracket over the

bolt as shown in the following figures.

For single frequency Skimmer, route cable over bolt and through

bracket. Side view shown at left and seen from above at right.

Both bracket types: Attach the transducer to the transom. Slide the

transducer up or down until it's aligned properly with the bottom of

the hull as shown in the preceding and following figures. Tighten the

11

bracket's mounting screws, sealing them with the sealant/adhesive

compound.

Adjust the transducer so that it's parallel to the ground and tighten

the nut until it touches the outer washer, then add 1/4 turn. Don't

over tighten the lock nut! If you do, the transducer won't "kick-up" if

it strikes an object in the water.

Bottom

of

hull

Flat-bottom hull

Align transducer centerline with hull bottom and attach transducer to

transom. Rear view of dual frequency Skimmer shown.

Deep-"vee" hull

6. Route the transducer cable through or over the transom to

the sonar unit. Make sure to leave some slack in the cable at the

transducer. If possible, route the transducer cable away from other

wiring on the boat. Electrical noise from the engine's wiring, bilge

pumps, VHF radio wires and cables, and aerators can be picked up by

the sonar. Use caution when routing the transducer cable around

these wires.

WARNING:

Clamp the transducer cable to the transom close to the

transducer. This can prevent the transducer from

entering the boat if it is knocked off at high speed.

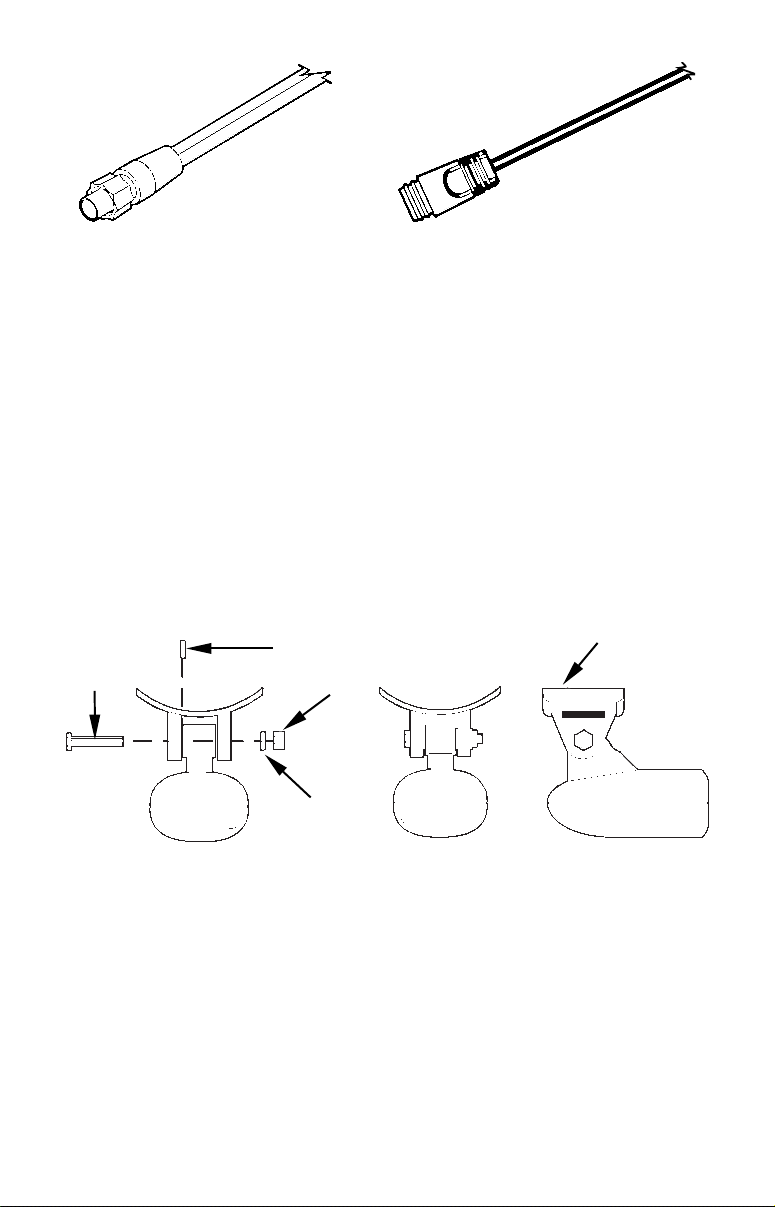

If you need to drill a hole in the transom to pass the connector through,

the required hole size will depend on the connector on the end of your

transducer's cable. If the transducer has a manual locking collar

connector, you will need to drill a 1" hole. If it has a push-on selfsealing connector, you will need to drill a 5/8" hole.

12

Manual locking collar connector Push-on self-sealing connector

requires a 1" hole. requires a 5/8" hole.

Caution:

If you drill a hole in the transom for the cable, make sure it is

located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline

sealant/adhesive used for the mounting screws.

7. Make a test run to determine the results. If the bottom is lost at

high speed, or if noise appears on the display, try sliding the

transducer bracket down. This puts the transducer deeper into the

water, hopefully below the turbulence causing the noise. Don't allow

the transducer bracket to go below the bottom of the hull!

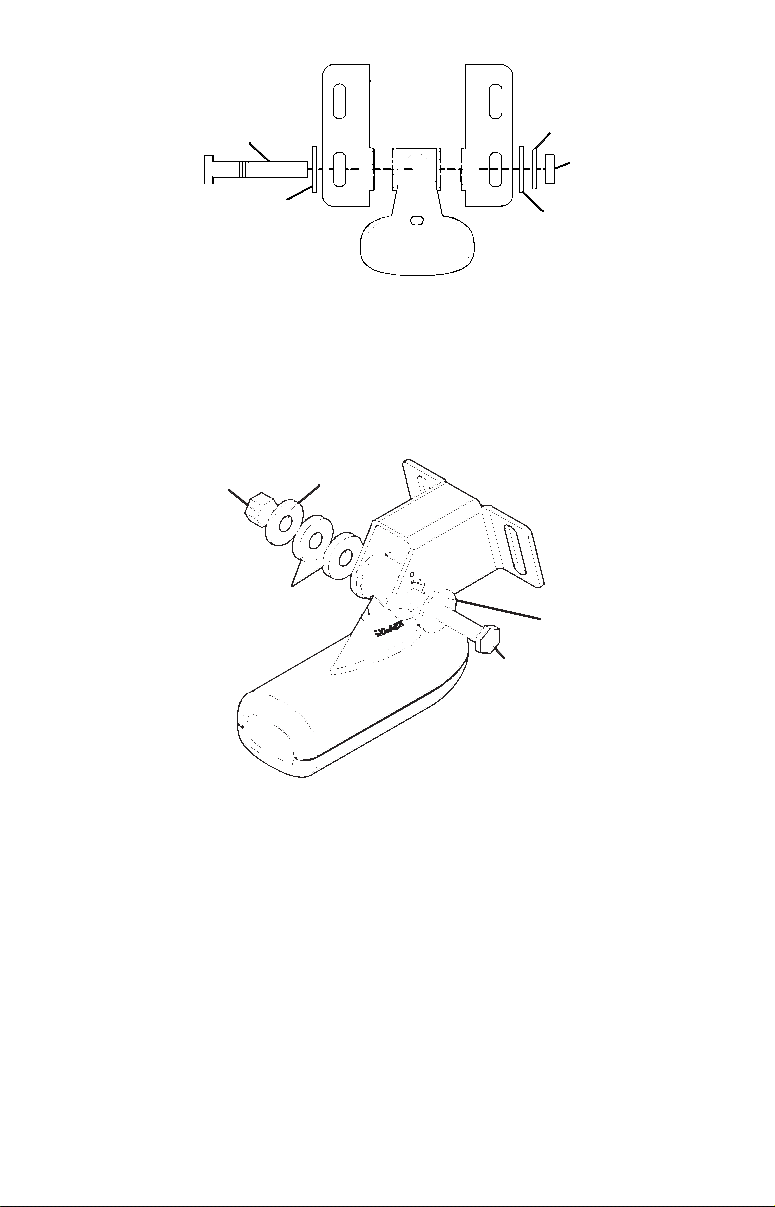

Trolling Motor Bracket Installation

1. Attach the TMB-S bracket to the transducer as shown in the

following figure, using the hardware supplied with the transducer.

(Note: The internal tooth washer is supplied with the TMB-S.)

TMB-S

bracket

Bolt

Internal tooth washer

Nut

Flat washer

Attach motor mounting bracket to transducer.

2. Slide the adjustable strap supplied with the TMB-S through the slot

in the transducer bracket and wrap it around the trolling motor.

Position the transducer to aim straight down when the motor is in the

water. Tighten the strap securely.

3. Route the transducer cable alongside the trolling motor shaft. Use

plastic ties (not included) to attach the transducer cable to the trolling

motor shaft. Make sure there is enough slack in the cable for the motor

to turn freely. Route the cable to the sonar unit and the transducer is

ready for use.

13

Transducer mounted on trolling motor, side view.

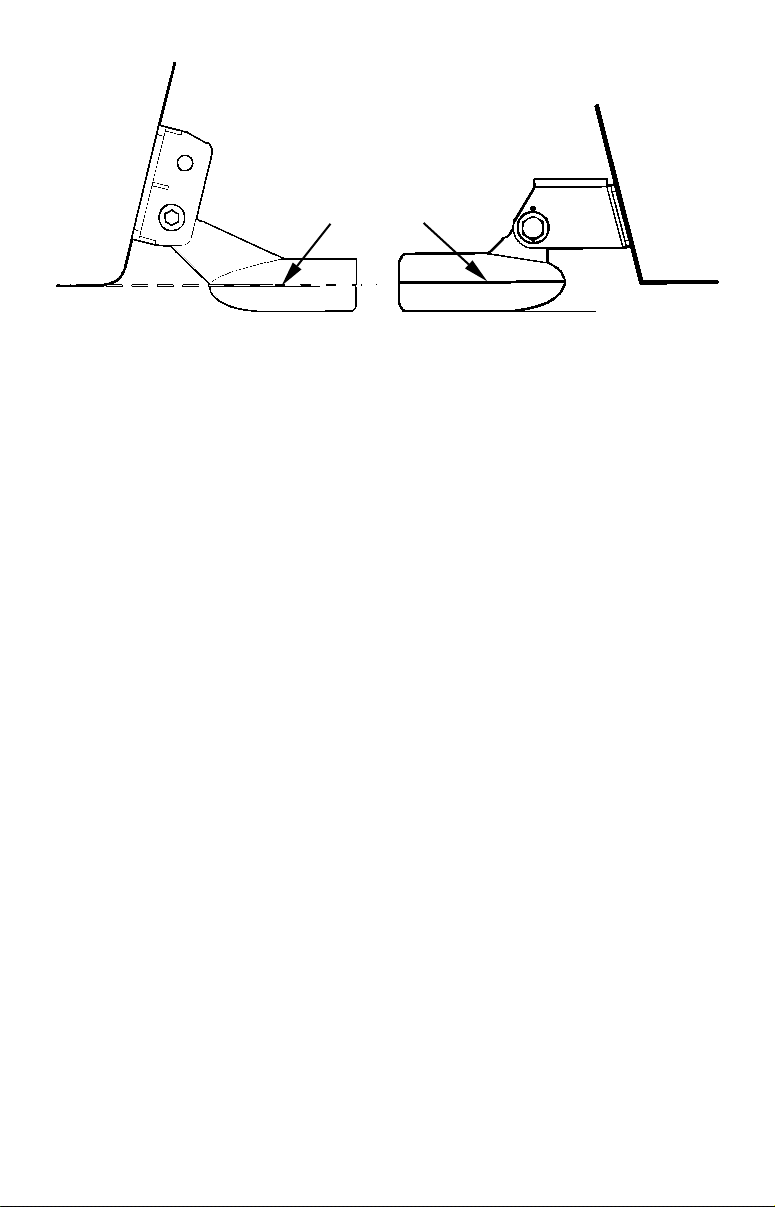

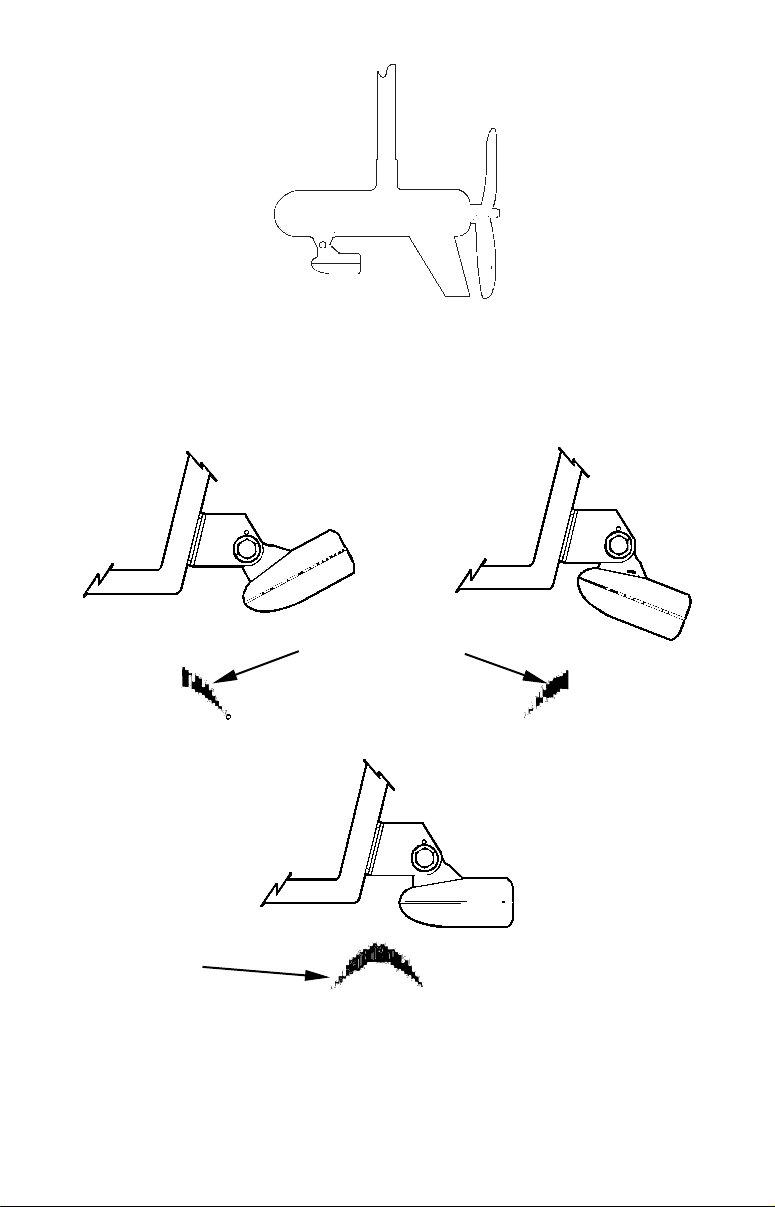

Transducer Orientation and Fish Arches

If you do not get good fish arches on your display, it could be because

the transducer is not parallel with the ground when the boat is at rest

in the water or at slow trolling speeds.

Partial fish arches

Transducer aimed

too far back

Transducer aimed

too far forward

Full fish arch

Proper transducer angle

Transducer angles and their effects on fish arches.

If the arch slopes up – but not back down – then the front of the

transducer is too high and needs to be lowered. If only the back half of

14

the arch is printed, then the nose of the transducer is angled too far

down and needs to be raised.

NOTE:

Periodically wash the transducer's face with soap and water to

remove any oil film. Oil and dirt on the face will reduce the

sensitivity or may even prevent operation.

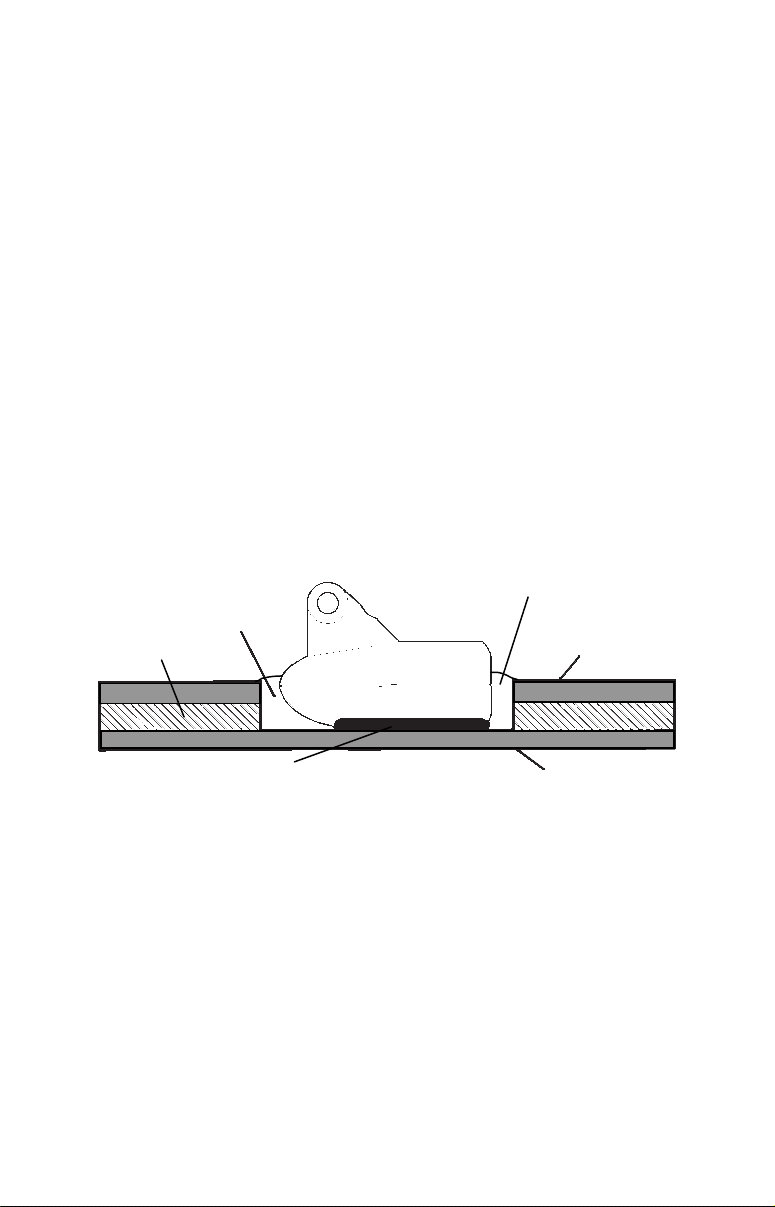

Shoot-Thru-Hull Preparation

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass

layers. The sonar signal must pass through solid fiberglass. A

successful transducer installation can be made on hulls with flotation

materials (such as plywood, balsa wood or foam) between layers of

fiberglass if the material is removed from the chosen area. See the

figure below.

WARNING:

Do not remove any material from your inner hull unless

you know the hull's composition. Careless grinding or

cutting on your hull can result in damage that could

sink your boat. Contact your boat dealer or

manufacturer to confirm your hull specifications.

Fill with resin

Fill with resin

Flotation material

Inner hull

Epoxy to hull first

Epoxy the transducer to a solid portion of the hull.

Outer hull

For example, some (but not all) manufacturers use a layer of fiberglass,

then a core of balsa wood, finishing with an outer layer of fiberglass.

Removing the inner layer of fiberglass and the balsa wood core exposes

the outer layer of fiberglass. The transducer can then be epoxied

directly to the outer layer of fiberglass. After the epoxy cures for 24

hours, fill the remaining space with polyester resin. When the job is

finished, the hull is watertight and structurally sound. Remember, the

sonar signal must pass through solid fiberglass. Any air bubbles in the

fiberglass or the epoxy will reduce or eliminate the sonar signals.

15

Testing Determines Best Location

Ideally, the shoot-thru transducer should be installed as close to the

transom as possible, close to the centerline. This will give you the best

performance during high speed maneuvers.

Transducer location

(high speed)

Shoot-thru-hull transducer locations for

high speed or trolling speed operation.

Transducer location

(trolling speed)

To choose the proper location for shoot-thru-hull mounting, follow these

testing procedures: (You may need a helper to complete these steps.)

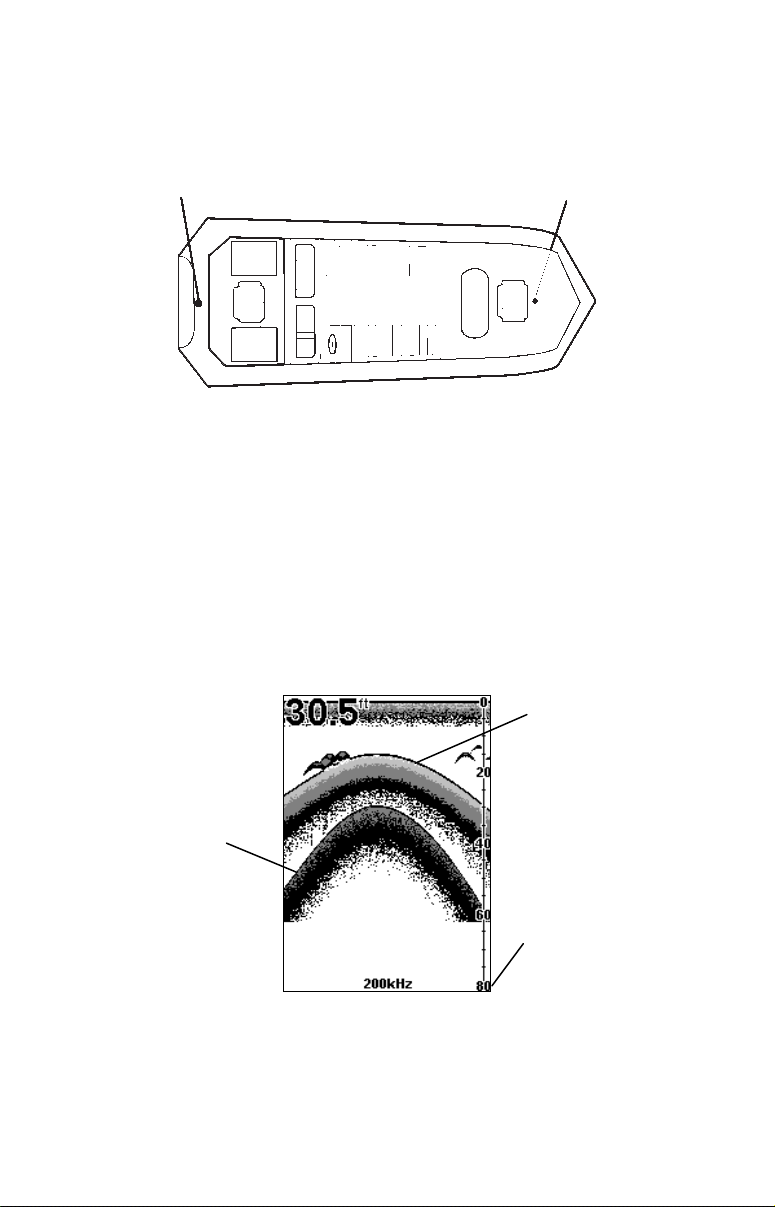

1. Anchor the boat in about 30 feet of water. Add a little water to the

sump of the boat. Plug the transducer into the sonar unit, turn it on,

then hold the transducer over the side of the boat in the water. Adjust

the sensitivity and range controls until a second bottom echo is seen on

the display. (You'll need to turn off Auto Sensitivity, Auto Depth Range

and ASP. Try a range setting that is two to three times the water

depth. The harder (more rocky) the bottom, the easier it will be to get a

second bottom signal.) Don't touch the controls once they've been set.

True bottom

Second bottom

Manual range setting

Example of a second bottom signal. Unit is in 30 feet of water, with

range set at 80 feet and sensitivity set at 87 percent.

2. Next, take the transducer out of the water and place it in the water

in the sump of the boat, face down. (The transducer face is shown in the

16

figure on the following page.) Notice how the signal strength decreases.

The second bottom signal will probably disappear and the bottom signal

intensity will likely decrease.

3. Now move the transducer around to find the best location with the

strongest possible bottom signal. If you find a spot with an acceptable

bottom signal, mark the location and move on to step 4.

If you can't get an acceptable bottom signal, try turning up the sensitivity

by three or five keystrokes and then move the transducer around once

more. If you find a spot that works, mark it and move on to step 4.

If you have to turn up sensitivity by more than five keystrokes to get a

good signal, the transducer should be mounted on the outside of the

hull. This is especially true if you have to turn sensitivity all the way

up to get a decent bottom signal.

4. Most people can get good results by following steps 1 through 3, so

this step is optional. If you want to make an extra effort to be

absolutely sure that your selected location will work under all

conditions, make a test run with the boat on plane and observe the

bottom signal. You'll need to figure some way to prop the transducer

into position while you make your test run. (A brick or two might be

sufficient to hold it in place.)

5. When you're satisfied with a location, mark it and proceed with

the installation.

Shoot-Thru-Hull Installation

If you are installing the transducer on a hull with flotation material

sandwiched within the hull, refer to the subsection "Shoot-Thru-Hull

Preparation,” beginning on page 15.

1. Make sure the area is clean, dry and free of oil or grease, then sand

both the inside surface of the hull and the face of the transducer with

100 grit sandpaper. The sanded hull area should be about 1-1/2 times

the diameter of the transducer. The surface of the hull must be flat so

the entire transducer face is in contact with the hull prior to bonding.

After sanding, clean the hull and transducer with rubbing alcohol to

remove any sanding debris.

WARNING:

Use only the epoxy available from LEI. It has been

formulated to work with these installation procedures.

Other epoxy types may be too thin or may not cure to the

right consistency for optimum transducer performance.

17

Spread epoxy here

Sand this surface

(unit's face)

Orient the Skimmer

with the nose facing

the bow of the boat.

To bow

Epoxy transducer to hull.

2. The epoxy consists of the epoxy itself and a hardener. Remove the

two compounds from the package and place them on the paper plate.

Thoroughly stir the two compounds together until the mixture has a

uniform color and consistency. Do not mix too fast or bubbles will form

in the epoxy. After mixing, you have 20 minutes to complete the

installation before the epoxy becomes unworkable.

Spread a thin layer of epoxy (about 1/16" or 1.5 mm thick) on the face of

the transducer as shown in the previous figure. Make sure there are no

air pockets in the epoxy layer! Then, apply the remaining epoxy to the

sanded area on the hull.

3. Press the transducer into the epoxy, twisting and turning it to force

any air bubbles out from under the transducer face. Stop pressing when

you bottom out on the hull. When you're finished, the face of the

transducer should be parallel with the hull, with a minimum amount of

epoxy between the hull and transducer.

4. Apply a weight, such as a brick, to hold the transducer in place while

the epoxy cures. Be careful not to bump the transducer while the epoxy

is wet. Leave the weight in place for a minimum of three hours. Allow

the epoxy to cure for 24 hours before moving the boat.

5. After the epoxy has cured, route the cable to the sonar unit and it's

ready to use.

18

Speed/Temperature Sensors

Optional Temperature Sensor

All the units in this series can display water temperature from a single

analog sensor. Your unit comes packed with a transducer with a temp

sensor built into it. If you wish to purchase an optional additional

sensor for your unit, refer to the accessory ordering information inside

the back cover of this manual.

However, please note that the Sonar socket on your unit is designed to

read only one temp sensor. Since your transducer contains a built-in

temp sensor, attaching the optional temp sensor to your unit's Sonar

socket will override the temperature information provided by the

transducer's temp sensor. Your unit will only display the temperature

provided by the optional sensor.

Optional Speed Sensor Installation

All the units in this series can display speed and distance traveled, but

only the X59DF comes packed with a speed sensor. If you wish to

purchase an optional additional sensor for your unit, refer to the

accessory ordering information inside the back cover of this manual.

The following instructions describe how to install the speed sensor.

Recommended tools for this job include: drill, 7/8" drill bit, 1/8" drill bit

for pilot holes, screwdriver. Required supplies for this job include: four

#8 stainless steel wood screws (3/4" long), high quality, marine grade

above- or below-waterline sealant.

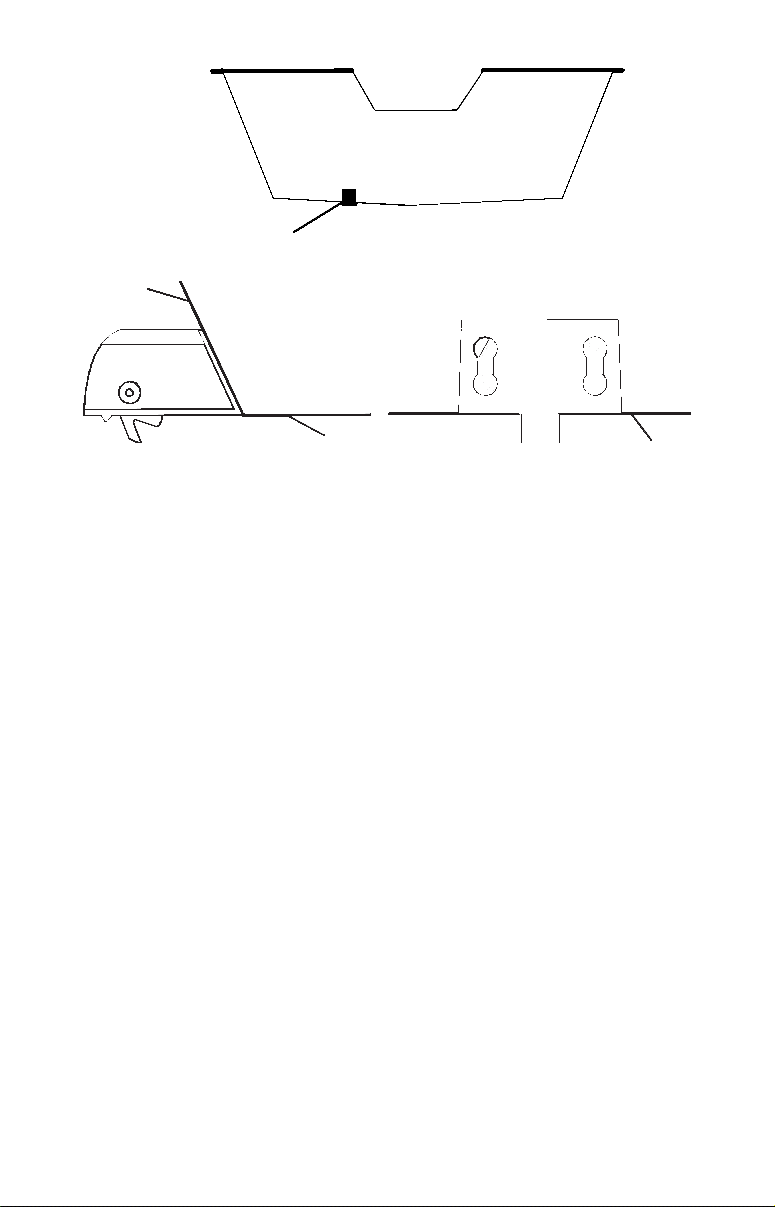

First find a location on the boat's transom where the water flow is

smoothest. Don't mount the sensor behind strakes or ribs. These will

disturb the water flow to the speed sensor. Make sure the sensor will

remain in the water when the boat is on plane. Also make sure the

location doesn't interfere with the boat's trailer. Typically, the sensor is

mounted about one foot to the side of the transom's centerline.

Once you've determined the proper location for the unit, place the

sensor on the transom. The bottom of the bracket should be flush with

the hull's bottom. Using the sensor as a template, mark the hull for the

screws' pilot holes. Drill four 1/8" holes, one in each end of the slots.

Mount the sensor to the hull using #8 stainless steel wood screws (not

included). Use a high quality, marine grade above- or below-waterline

sealant to seal the screws. Make sure the sensor is flush with the

bottom of the hull and tighten the screws.

19

Good location

Stern view showing good location for mounting sensor on transom.

Transom

Bottom of hull

Speed sensor mounting configuration:

side view (left) and rear view (right.)

Bottom of hull

If the base of the transom has a radius, fill the gap between the

transom and the sensor with the sealant. This will help ensure a

smooth water flow.

Route the sensor's cable through or over the transom to the sonar unit.

If you need to drill a hole in the transom to pass the connector through,

the required hole size is 7/8".

CAUTION:

If you drill a hole in the transom for the cable, make sure it is

located above the waterline. After installation, be sure to seal the

hole with the same marine grade above- or below-waterline

sealant used for the screws.

The sensor is now ready for use. Connect the sensor to the sonar socket

on the back of your unit and connect the transducer to the speed

sensor's socket. If you have any questions concerning the installation of

the sensor, please contact your local boat dealer.

Power Connections

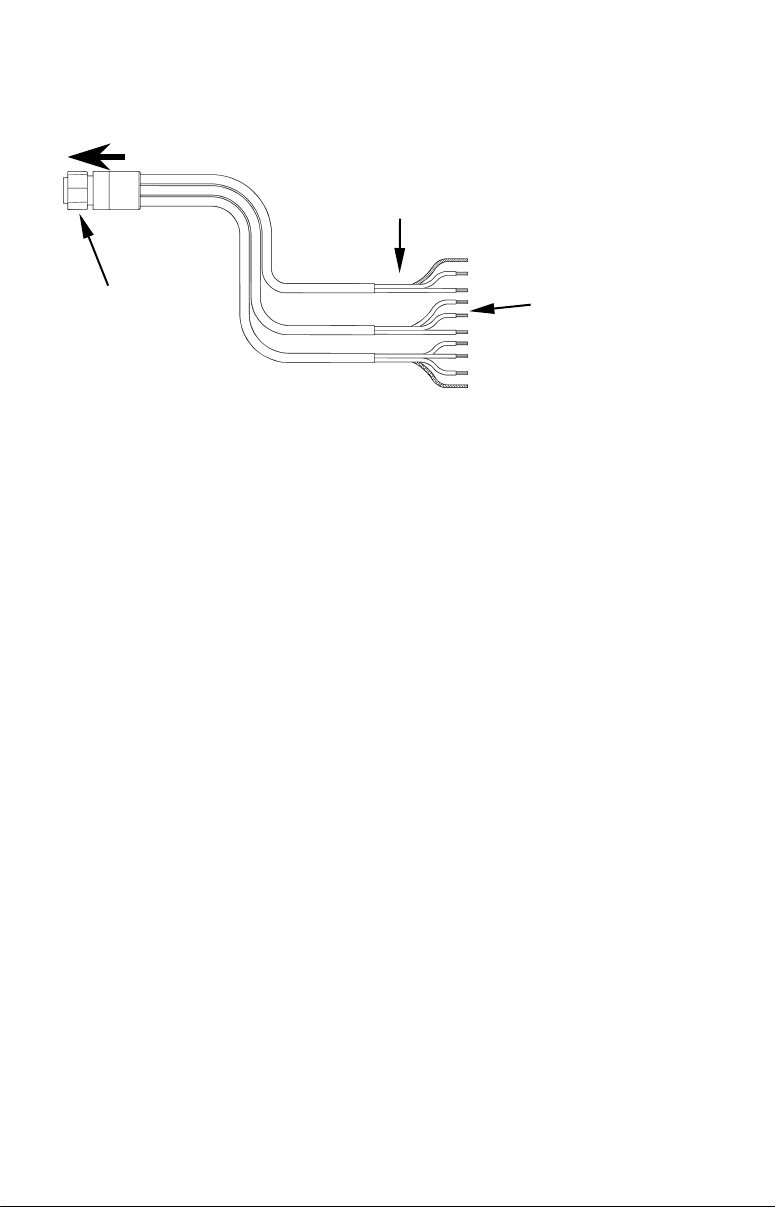

Your unit comes with a power/data cable that splits into three ends,

each with several exposed wires (shown in the following figure). The

end with 4 wires (blue, yellow, orange and shield) is a data cable that

connects to a NMEA 0183 interface; the cable label says "RS-232

COMM". The end with three wires (red, black and shield) is a power

cable that supports a NMEA 2000

buss; the cable label says "NMEA

20

2000 Power". The thicker three-wire cable (red, black and white) is the

Power Supply for your unit (and optional external speaker connection

for some units); it has no label on the cable.

To unit

Power Supply wires:

red, black and white

Blue connector

The Power/Data cable for this unit.

NMEA 2000 Power wires:

red, black and shield

Data Cable wires: blue,

yellow, orange and shield

Depending on your configuration, you may not use all of these wires.

(For example, many units cannot operate an optional external speaker,

so the white wire on the Power Supply cable isn't functional.) The

following segments include instructions for installing all the wires that

you will use with this unit.

Powering a NMEA 2000 Buss

(NMEA 2000 Power cable)

A NMEA 2000 buss must be connected to a power source to operate. If

you have a pre-existing NMEA 2000 installation, it may already be

connected to another power source. If your NMEA 2000 buss is already

powered, you can ignore the NMEA 2000 Power cable. Never attach

two power sources to a single NMEA 2000 buss.

If you do need to power your NMEA 2000 buss, attach the NMEA 2000

Power cable to your boat's battery just as indicated in the following

segment for connecting your unit's Power Supply cable. The NMEA

2000 Power cable's red wire should be attached (with provided 3-amp

fuse) to the boat battery's positive terminal, and the NMEA 2000 Power

cable's black and shield wires should both be attached to the battery's

negative terminal.

Powering Your Unit

(Power Supply cable – red and black wires)

The unit works from a 12-volt battery system. For the best results,

attach the power cable directly to the battery. You can attach the power

cable to an accessory or power buss, however you may have problems

21

with electrical interference. Therefore, it's safer to go ahead and attach

the power cable directly to the battery.

CAUTION:

When using the unit in a saltwater environment, we strongly

recommend that you shut off the power supply to the power cable

when the unit is not in use. When the unit is turned off but still

connected to a power supply, electrolysis can occur in the power

cable plug. This may result in corrosion of the plug body along with

the electrical contacts in the cable and the unit's power socket.

In saltwater environments we recommend you connect the power

cable to the auxiliary power switch included in most boat designs.

If that results in electrical interference, or if such a switch is not

available, we recommend connecting direct to the battery and

installing an inline switch. This will let you shut off power to the

power cable when the unit is not in use. When you are not using

the unit, you should always shut off power to the power cable,

especially when the power cable is disconnected from the unit.

If possible, keep the power cable away from other boat wiring, especially

the engine's wires. This will provide the best isolation from electrical

noise. If the cable is not long enough, splice #18 gauge wire onto it. The

power cable has two wires, red and black. Red is the positive lead, black

is negative or ground. (There is also a white wire to power an optional

external speaker for some units. This unit does not use a speaker, so to

prevent an electrical short, we recommend capping the exposed speaker

wire end with a wire nut or electrical tape) Make sure to attach the inline fuse holder to the red lead as close to the power source as possible.

For example, if you have to extend the power cable to the battery or

power buss, attach one end of the fuse holder directly to the battery or

power buss. This will protect both the unit and the power cable in the

event of a short. It uses a 3-amp fuse.

22

Loading...

Loading...