Lowrance TH-FLWBL User Manual

Pub. 988-0154-081

TH-FLWBL

Polyurethane Marine Adhesive Sealant

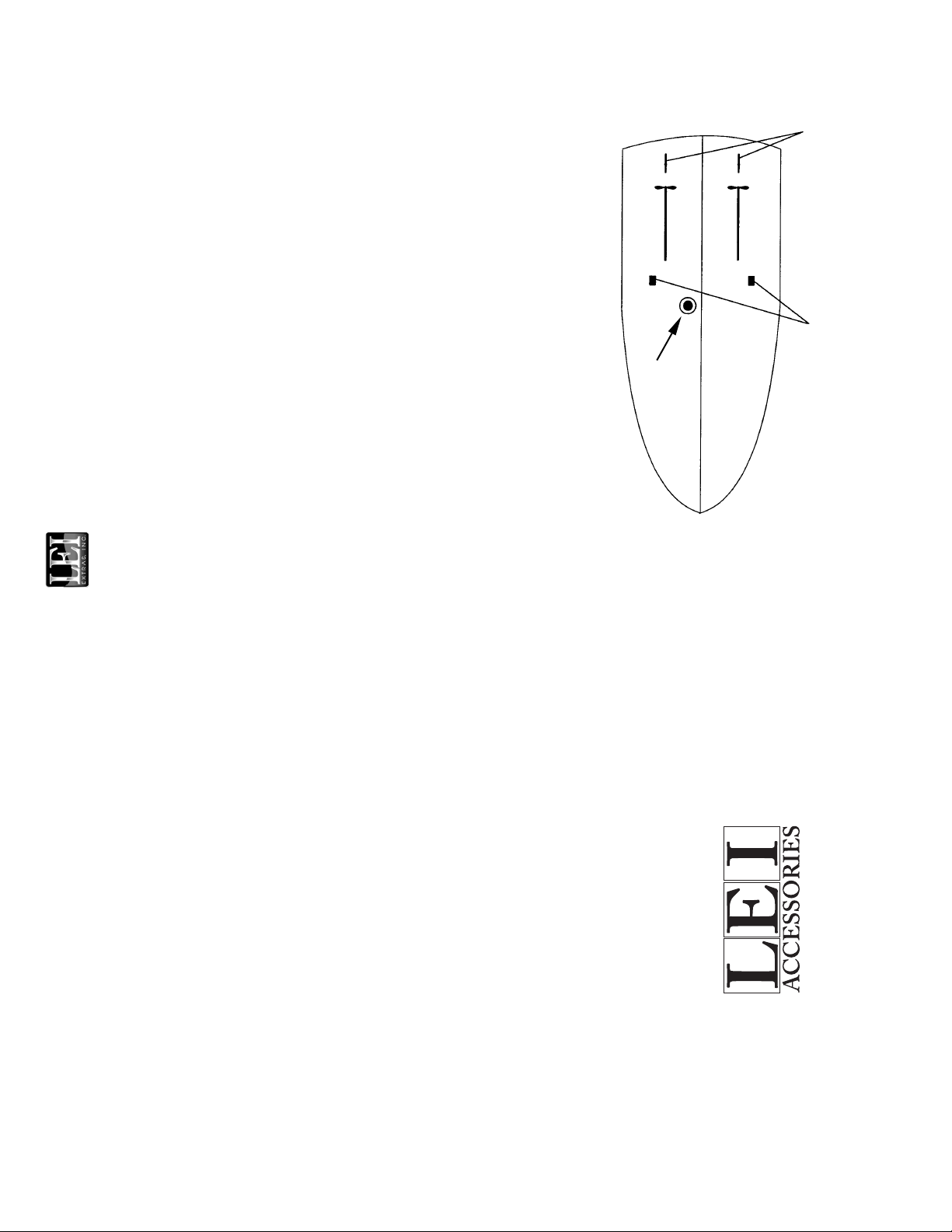

Rudders

Engine

intakes

1

Installation Instructions for

Through-Hull Transducer

The TH-FLWBL is an 11°, 200 kHz transducer designed for use with

Lowrance blue-connector sonar units. This instruction sheet will help you

install your TH-FLWBL through-hull transducer.

Read these instructions carefully before attempting the installation. De-

termine which mounting location is right for your transducer and boat.

Remember, the transducer installation is the most critical part of

a sonar installation.

Recommended Tools and supplies

Transducer

Recommended tools for this job include: drill, 1/8" (3.17 mm) drill bit for pilot

hole, hole saw with a blade appropriate to your hull type. Required supplies

for this job include: high quality, marine grade above- or below-waterline

5200 or equivalent). For saltwater use, you will also need a water-based anti-

fouling paint to prevent sea growth. (Supplies not included.)

Selecting a Transducer Location

The transducer's mounting location is an important factor in its performance.

Consider the following issues carefully before beginning installation.

1. Water flow: The transducer should be located in an area that has a

smooth water flow. This is typically close to the centerline of the hull.

2. Inboard powered hulls: On inboard powered hull boats, you should

install the transducer ahead of the propeller shafts and rudders. This is

sealant/adhesive compound (3M

typically an amidships location ahead of the engine's water intakes.

Mount the transducer amidships, forward of any fittings on the hull that

Products

will cause excessive water noise.

All Rights Reserved

Never use ketone-based antifouling paint. Ketones can attack

many plastics, and could cause damage to the transducer.

6. Route the transducer cable to the sonar unit. If the cable is too long, do

not cut it! Coil and store the excess cable.

7. Check for leaks! After the boat is placed in the water, check for leaks

immediately. Check the boat for leaks again several times during the

next 24 hours. If you notice any leakage at all, the transducer should be

re-installed with a new coat of adhesive.

Maintenance

Sea growth can accumulate rapidly on the transducer's surface. This

growth will reduce the transducer's performance. To prevent this, any

portions of the transducer surface exposed to saltwater must be coated

with antifouling paint. Use only water-based paint.

Caution:

Apply paint every 8 months or at the beginning of each boating season.

Clean the transducer periodically with a soft cloth and mild household

detergent. If fouling does occur, use a stiff brush or putty knife to remove

the growth. Wet sanding of the fouled surface is permissible with #220 or

finer-grade sandpaper.

and Eagle

For Lowrance

Pub. 988-0154-081 © Copyright 2004

4

Printed in USA 051204 LEI Extras, Inc.

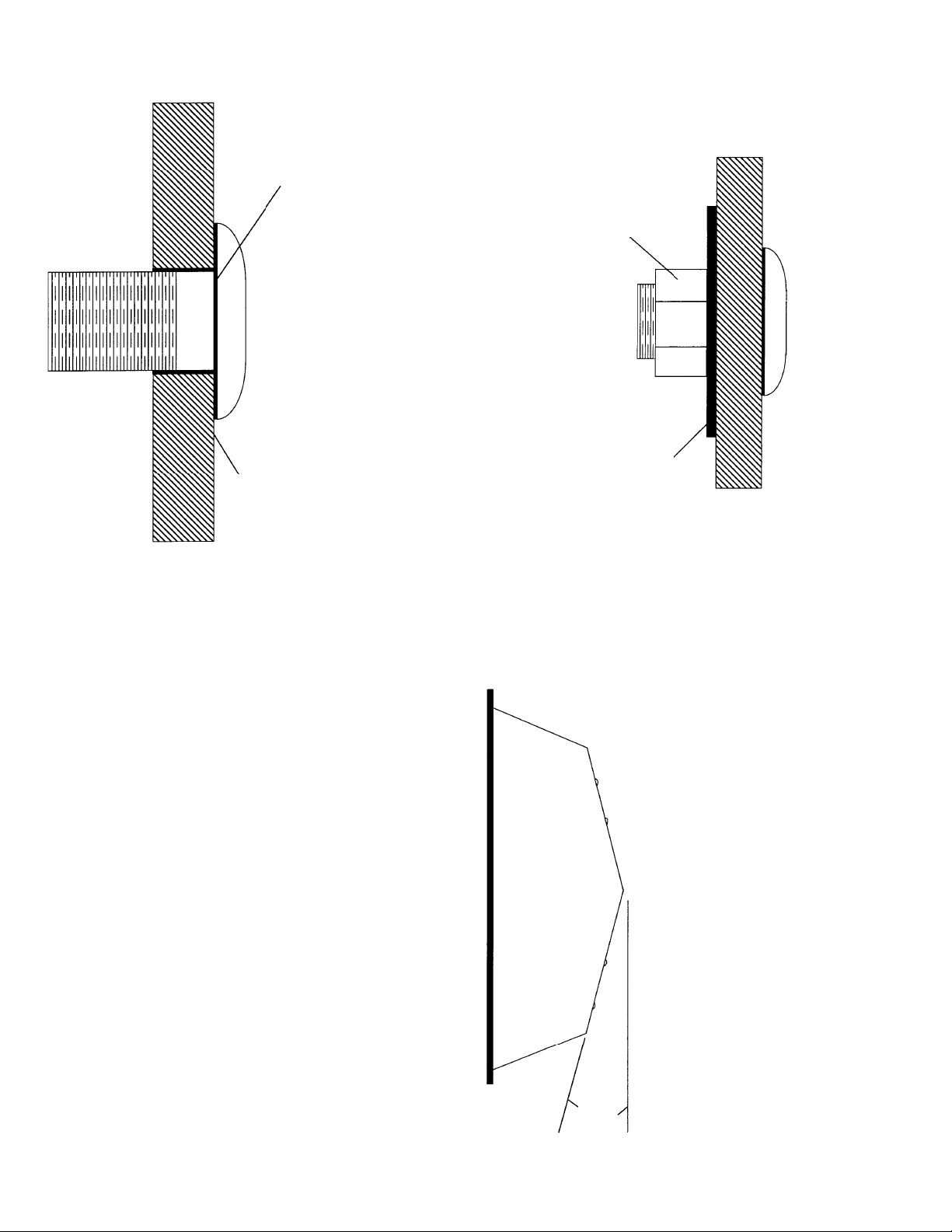

Apply adhesive

liberally

the lower part of the sensor as shown.

Nut

3

the transducer in place.

Hull

Washer

Spread adhesive around the lip of the transducer housing and up around

3. Using the marine-grade sealant/adhesive, apply a 1/8" (3.17 mm) bead

of sealant around the lip of the transducer housing. Also spread the seal-

ant up around the lower part of the sensor housing, spreading it higher

on the housing than the hull is thick.

4. From the outside of the hull, pass the transducer cable up through the

hole, then push the transducer with sealant into it. Use a twisting motion

to squeeze out excess sealant. Remove excess sealant from the outside of

the hull before it dries, to ensure a smooth flow of water around the

transducer.

5. On the inside of the hull, slide the provided rubber washer over the

housing and install the nut. Hand-tighten the nut, being careful not to

over-tighten. Do not use a wrench to tighten the nut!

After positioning the provided washer, use the provided nut to secure

2

This transducer is designed to perform best in boats with a hull deadrise

of 10° or less. The transducer will work at greater angles, but it will be

sending signals off at an angle instead of straight to the bottom, so it

won't return true depth readings. The higher angle will also prevent the

transducer from performing to its full depth potential.

3. Planing hulls: On planing hull boats with outboard motors or stern

drives, you should install the transducer close to the transom to ensure it

will be in the water at all times.

4. Noise: When choosing a transducer location, keep in mind that ambient

noise is always present, from the mechanical noise made by the engine(s),

the movement of the hull through the water, and other sources. These

sound waves can interfere with the operation of the transducer. While am-

bient noise can't be eliminated, careful selection of a mounting location can

minimize the effect of vessel-generated noise. The lower the noise level, the

greater the sonar's unit's usable sensitivity.

5. Surface obstructions: don't mount the transducer behind other

through-hull fittings. Such obstructions will interfere with the smooth

flow of water necessary for a clean sonar reading.

6. Clearance: Make sure there is enough room on the inside of the hull

to install the transducer and there is clearance to attach the nut.

NOTE:

Deadrise of

This transducer is designed for hulls with a deadrise of 10° or less.

10° or less

Installing the Transducer in Your Boat's Hull

1. After you've determined the proper location for the transducer, drill a

1/8" (3.17 mm) pilot hole from inside the hull. Check the outside of the hull

to make sure there is no obstruction in the way, such as a strake. If you

find a problem with the chosen location, fill the pilot hole with the sealant-

adhesive compound and choose another mounting location.

2. The TH-FLWBL transducer requires a 2" (50.8 mm) hole. Using a hole

saw, drill from the outside of the hull to prevent the gel coat from crack-

ing on fiberglass hulls. Use eye and face protection when drilling the hole.

Afterwards, clean the area around the hole with detergent or alcohol.

This will establish a good surface for the adhesive.

Loading...

Loading...