Page 1

StructureScan HD

Transom mount

Installation Guide

ENGLISH

www.bandg.com | www.simrad-yachting.com | www.lowrance.com

Page 2

Warning: It is your sole

responsibility to install and use the

instrument and transducer(s) in a

manner that will not cause accidents,

personal injury or property damage.

Always observe safe boating practices.

The choice, location, and installation

of transducers and other components

of the system are critical to the

performance of the system as intended.

If in doubt, consult your Navman dealer.

To reduce the risk of misusing or

misinterpreting this instrument, you

must read and understand all aspects

of this Installation and Operation

Manual. We also recommend that you

practice all operations using the built-in

simulator before using this instrument

on the water.

Sonar performance: The accuracy of

the sonar depth display can be affected

by many factors, including the type and

location of the transducer and water

conditions. Never use this instrument

to gauge depth or other conditions for

swimming or diving.

The choice, location, and installation

of transducers and other components

of the system are critical to the

performance of the system as intended.

If in doubt, consult your Navman dealer.

To reduce the risk of misusing or

misinterpreting this instrument, you

must read and understand all aspects

of this Installation and Operation

Manual. We also recommend that you

practice all operations using the built-in

simulator before using this instrument

on the water.

Page 3

1

Installation preparation

Accessories

If you received this manual with a StructureScan accessory, you will

notice that some information in the document does not apply to

the accessory. This manual has installation instructions for your accessory, and accessory pack content tables on the back cover.

Contents

Your StructureScan box is packed with the StructureScan HD module, a Power cable, fuse and fuse holder, StructureScan transducer,

mounting bracket, 15 foot (4.5m) ethernet cable and a hardware kit.

The transducer has a 20 foot (6m) cable attached.

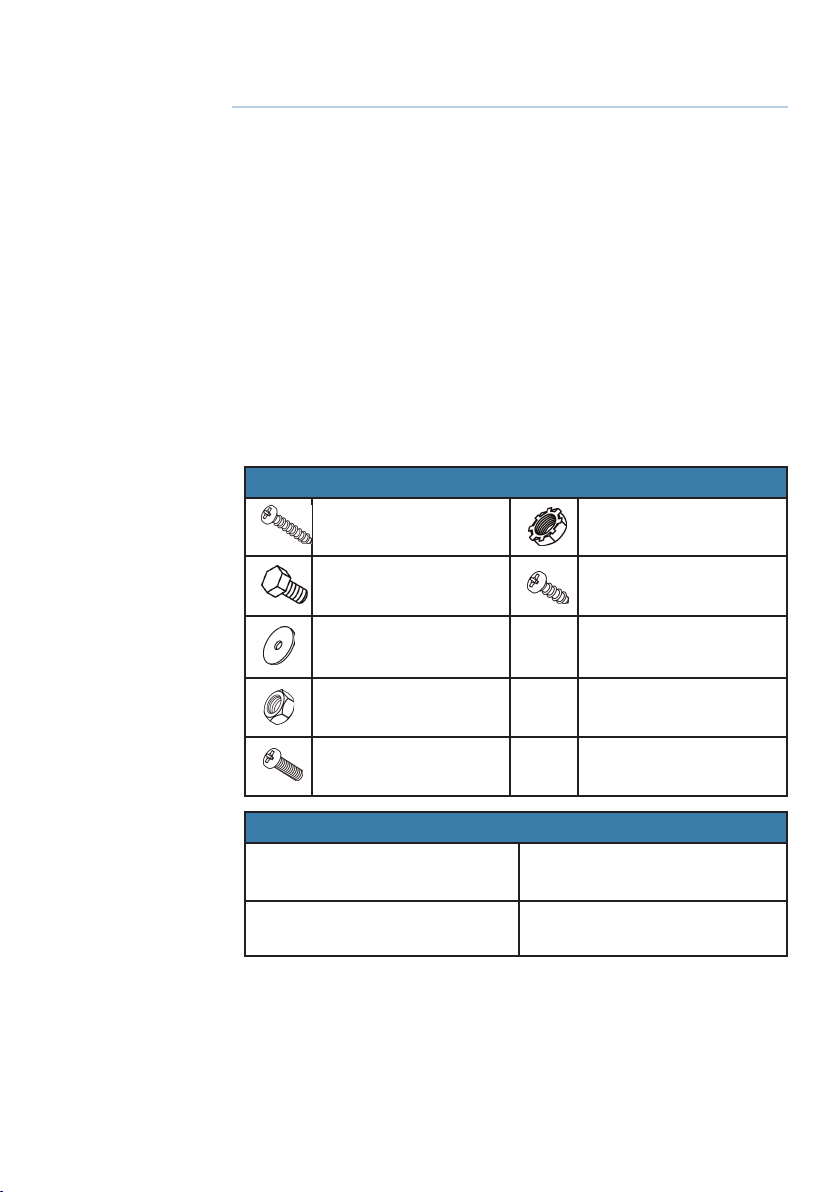

Hardware Mounting Kit (included)

Transom mount

screws (2)

Transducer attachment

lock nuts (6)

Bracket assembly

bolts (2)

Bracket assembly

washers (4)

Bracket assembly

nuts (2)

Transducer

attachment screws (6)

Required tools and supplies (not included)

Drill

Drill bits

StructureScan HD | Installation preparation

StructureScan HD

mounting screws (4)

Closed end crimp

connector (1)

Zip ties (2)

Phillips (slotted-head

screwdriver)

Marine grade above-or-below

waterline sealant

| 3

Page 4

Mounting options

The StructureScan transducer can be mounted on the transom,

jackplate, step or directly to your boat’s hull.

When mounting it directly to the hull, you must purchase a highquality, marine grade above- or below-waterline sealant/adhesive

compound.

Use the following table to determine which mounting option is best

suited to your boat/installation preferences.

¼ Note: When mounting the StructureScan transducer, make sure

there is nothing around the mounting location that could interfere

with StructureScan transducer sonar beams.

4 |

Jackplate mount

Transom mount

StructureScan HD | Installation preparation

Step mount

Page 5

StructureScan HD transducer mounting options

Transom mount

(Page 8)

Jackplate mount

(Page 9)

Step mount

(Page 10)

Direct mount/Step

(Page 11)

Trolling motor

mount (sold

separately)

Keeps transducer in the water when the boat

is on plane, allowing you to track bottom at

high speeds

Transducer angle can be adjusted so it is

parallel with the water

Transducer more likely to collide with

obstructions in the water and adds drag to

the boat

Transducer is not in the water when boat is on

plane; protects transducer and prevents drag from

transducer

Transducer angle can be adjusted so it is parallel

with the water

Allows you to mount transducer without drilling

holes in your boat

Does not track bottom when boat is on plane

Transducer is not in the water when boat is on

plane; protects transducer and prevents drag from

transducer

Transducer angle can be adjusted so it is parallel

with the water

Does not track bottom when boat is on plane

Transducer is not in the water when boat is on

plane

Protects transducer and prevents drag from

transducer

Transducer angle can not be adjusted so it is

parallel with the water

Does not track bottom when boat is on plane

Visit www.transducershieldandsaver.com

StructureScan HD | Installation preparation

| 5

Page 6

2

Installation

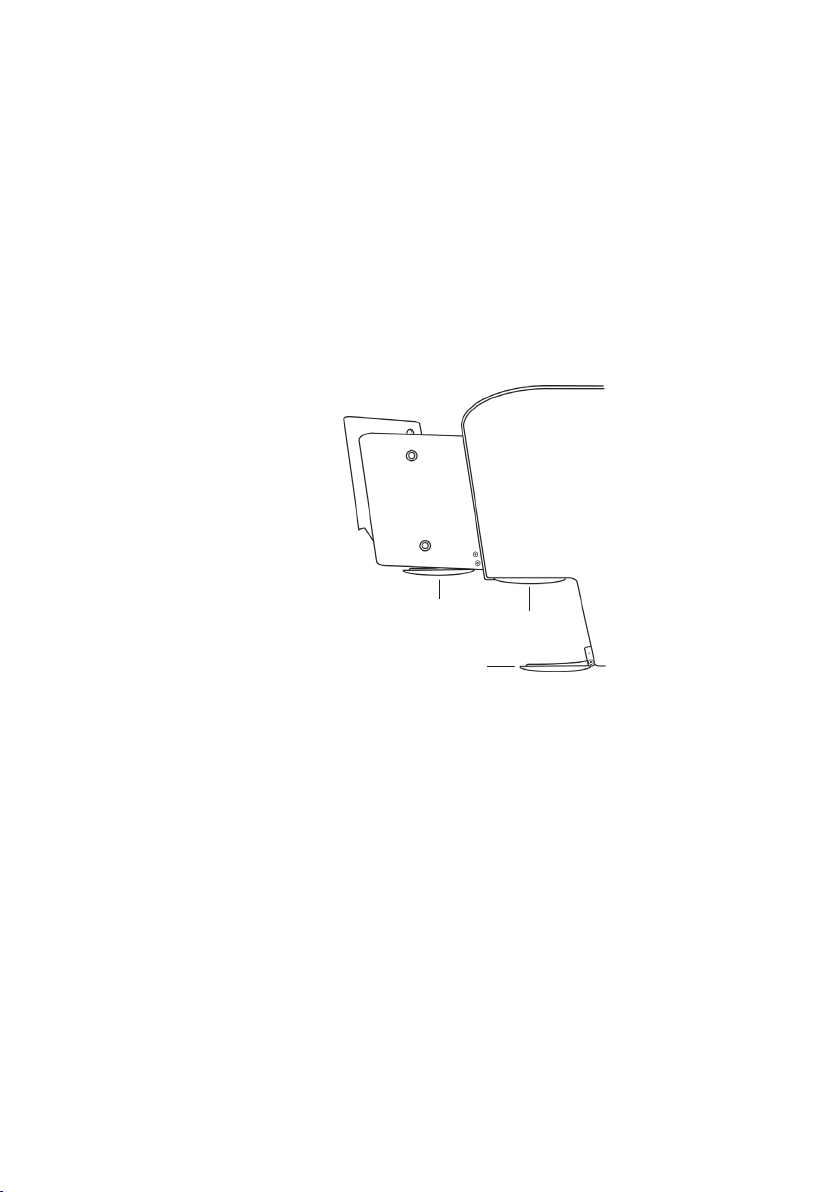

Bracket and transducer assembly

The StructureScan bracket comes with four washers, two bolts and

two nuts.

If you plan to mount the StructureScan transducer directly to the

step (Step Mount) or on the trolling motor, you do not need to assemble the bracket.

6 |

OR

StructureScan HD | Installation

Page 7

Transducer angle

After mounting the StructureScan transducer, make sure the

transducer is adjusted so it will be parallel with the waterline when

moving at trolling speed.

Downscan Overlay

The StructureScan transducer should be installed within approximately 1 foot of the broadband sounder transducer to get optimum

performance from the Downscan Overlay feature.

It is recommended you turn off Downscan Overlay when using

your trolling motor as the sonar source, unless the StructureScan

transducer and broadband sounder transducer both are installed on

the trolling motor.

Downscan overlay performance could be degraded if the StructureScan transducer is too far away from the broadband sounder

transducer installed on the trolling motor.

< 0.3m (1ft)

StructureScan HD | Installation

| 7

Page 8

Transom mount

The StructureScan transducer can be mounted just like a skimmer

transducer, where it is in the water when you are on plane or can be

mounted so it is only in the water, when you are moving at trolling

speed.

Transom Mount Supplies (not included)

1/8” Drill bit (Transom mount

pilot holes)

Transom Mount (Aluminum Hull) Supplies (not included)

M4 Machine Screws

Starboard (prevents corrosion between bracket and aluminum

hull)

To Mount StructureScan transducer on Transom:

1. Choose a transducer location and then route the transducer cable to the

location where the StructureScan module will be installed.

2. Place the transducer bracket against the transom and then align the bot-

tom of the transducer with the bottom of boat. Use a pencil to mark the

pilot holes through the slots in the transducer bracket.

3. Drill the pilot holes into the boat’s transom.

4. Apply a high-grade above- or below-waterline sealant to the pilot holes.

5. Align the bracket slots over the pilot holes and fasten the bracket to the

transom using your drill and the supplied screws.

6. To make adjustments to transducer position, loosen the screws and slide

bracket up or down.

7. Connect the transducer cable to the StructureScan module sonar port.

Marine grade above- or belowwaterline sealant

Marine grade above- or belowwaterline sealant

8 |

StructureScan HD | Installation

Page 9

Jackplate Mount

The StructureScan transducer can be mounted inside or outside of

the jackplate by drilling through the jackplate and then running bolts

though the hinge hole in the side of the bracket into the jackplate.

Jackplate Mount Supplies (not included)

M6 or 1/4” Drill bit (Jackplate

Mount) pilot holes

Warning: Before installing the StructureScan HD transducer

on the jackplate, lower the jackplate to its lowest setting to make

sure there is enough clearance between the jack plate/engine

and the transducer. Lack of clearance could damage the transducer when the engine is all the way down.

To Mount StructureScan on Jackplate:

1. Choose a transducer location on the inside or outside of the jackplate.

2. Adjust the jackplate up and down to make sure the transducer will not ob-

struct jackplate movement.

3. Make sure nothing blocks the sonar beam on either side of the transducer.

4. Route the transducer cable to the location where the module will be

installed.

5. Move the transducer bracket into the desired position and use a pencil to

mark the holes through the hinge hole and hole in the side of the bracket.

6. Using a M6 or equivalent drill bit, drill the holes into the jackplate.

7. Slide the bracket inside the jackplate and align the bracket holes with holes

you drilled in the jackplate.

8. Slide M6 bolts with washers into each hole on the side of jackplate.

9. Guide the bolts through the StructureScan bracket holes.

10. Place a washer over the end of the bolts and tighten the nuts.

11. Connect the transducer cable to the StructureScan module sonar port.

1/4” (M6) jackplate mount bolts

Jackplate

StructureScan bracket mounted

inside the jackplate. The bracket can

also be installed on the outside of

the jackplate.

StructureScan HD | Installation

| 9

Page 10

Step Mount

Mounting the StructureScan transducer under the step not only

protects the transducer from hitting objects in the water, but does

not cause any drag on your boat when it is on plane.

Step Mount Supplies (not included)

1/8” Drill bit (Transom mount

pilot holes)

To use Step Mount:

1. Choose a transducer location.

2. Route the transducer cable to the location where the StructureScan mod-

ule will be installed.

3. Move the transducer bracket into the desired position and then use a pencil

to mark the pilot holes through the slots in the bracket.

4. Drill the pilot holes.

5. Apply a high-grade above- or below-waterline sealant to the pilot holes.

6. Align the bracket slots over the pilot holes and fasten the bracket to the

transom using your drill and the supplied screws.

7. To make adjustments to transducer position, loosen the screws and slide

bracket up or down.

8. Connect the transducer cable to the StructureScan module sonar port.

Marine grade above- or belowwaterline sealant

10 |

Step

StructureScan HD | Installation

Page 11

Direct/Step Mount (No Bracket)

When using the direct mount installation shown below, you MUST

turn on the Flip Left/Right feature. Refer to your Operation manual

for more information..

Direct Step Mount Supplies (not included)

3/32 Drill bit (Direct/Step

mount pilot holes)

To use Direct Mount:

1. Make sure the boat’s step is the same length or longer than the StructureS-

can transducer.

2. After selecting a mounting location, route the transducer cable to the loca-

tion where the StructureScan module will be installed.

3. Hold the transducer in the desired position and then use a pencil to mark

pilot holes through the mounting holes on the transducer.

4. Drill the pilot holes.

5. Apply a high-grade above- or below-waterline sealant to the pilot holes.

6. Align the transducer mounting holes over the pilot holes and mount the

transducer to the step using self-tapping metal screws (not supplied). Do

NOT overtighten the screws; otherwise you could strip out the fiberglass

pilot holes or crack the mounting holes on the StructureScan transducer.

7. Connect the transducer cable to the StructureScan module and then turn

on the Flip Left/Right feature on your display unit.

Marine grade above- or belowwaterline sealant

Do not install

under boat hull!

Direct mount

(without bracket)

¼ NOTE: When using a Direct Step Mount, you must turn on the Flip

Left/Right feature in your display unit to ensure what is shown on

the left/right side on your display, corresponds with what is on the

left/right side of your boat.

StructureScan HD | Installation

| 11

Page 12

2.1”(55.5mm)

10.8”(274.3mm)

2.8”

(72.7mm)

10.1”(257.3mm)

Parts and accessories

StructureScan Module (000-10801-001)

StructureScan module

mounting screws (4)

Fuse and fuse holder

StructureScan Skimmer Bracket (000-10874-001)

Transom mount screws (2) Bracket assembly nuts (2)

Transducer attachment lock nuts (6)

Bracket assembly bolts (2) Zip ties (2)

Bracket assembly washers (4)

Closed-end crimp connector

Transducer attachment

screws (6)

12 |

StructureScan Skimmer Transducer (000-10802-001)

Transom mount screws (2) Bracket assembly nuts (2)

Transducer attachment lock nuts (6)

Transducer attachment

screws (6)

Bracket assembly bolts (2) Zip ties (2)

Bracket assembly washers (4)

StructureScan HD | Installation

Page 13

StructureScan Specifications

Power

Requirement

Voltage Input 10V - 17V

Transmit Power

Current Drain Max: .75A Typical: .60A

Fuse Type External: 3A Fast Acting Automotive Blade

Transducer Cable 20 feet (6m)

Target Separation

Transducer

Frequency

Communication Ethernet

Shared devices

supported

Weight

12 Volts

WRMS: 500W

WPK: 4000W

Inrush: 4.7A pk

1.5” (38.1mm)

455kHz

3

StructureScan module (1.8lbs)

Transducer (1.9lbs)

Transducer with bracket (2.55lbs)

Sidescan Specications

Max Range 455kHz (500ft — 250 per side)

Max Speed 35 mph (56 kmh)

Mark objects 15 mph (24 kmh)

Optimum speed 10 mph (16 kmh) or less

Downscan Specications

Max Depth 300 ft (455kHz)

Max Speed 55 mph (88 kmh)

Mark objects 35 mph (56 kmh)

Optimum speed 10 mph (16 kmh) or less

| 13

Page 14

StructureScan LED Guide

Indicator LED Status Definition

Transducer

LED

Transducer

LED

Transducer

LED

Power LED Off No power or not switched on

Power LED Red/stays on Product in booting process

Power LED

Power LED

Power LED

Ethernet

LED

Ethernet

LED

Off

Green/ stays onTransducer detected/locked on to

Green/

flashing

Green/stays

on

Red/Green/

slow flashing

Red/Green

fast flashing

Off

Yellow/

Flashing

Transducer not connected or

cable/transducer is broken

bottom

Transducer detected/not locked

on to bottom

Product has power/operating

Product in factory mode; ethernet

communication working

Product in factory mode; no

ethernet communication (cable

unplugged or bad cable)

No ethernet communication

(cable unplugged, bad cable or

remote unit not powered)

Ethernet communication is

working (link/active light)

14 |

Page 15

StructureScan Troubleshooting Tips

• Make sure StructureScan HD is pow-

ered

StructureScan not

displayed

No Data Check range or turn on auto range

Data washed out/

same color

Left/right data

swapped on screen

No Source is

displayed

• Check unit software; must have at least

version 2.5

• Make sure yellow wire is connected to

switched power source

• Check fuse

Turn down contrast; try different palettes

Toggle the Flip Left/Right feature

• Make sure HDS unit and StructureScan

are powered and connected to ethernet network

• Make sure all switches are powered

• Check link/active light to see which

units are not communicating

| 15

Page 16

*988-10284-001*

www.bandg.com

www.simrad-yachting.com

www.lowrance.com

Loading...

Loading...