PT-W

PD-W and

PD-WBK

PD-N and

PD-WBK

PT-W, PD-W, PD-WBK,

PD-N and PD-NBK

TRANSDUCERS

INSTALLATION MANUAL

NOTICE

When the transducer is mounted on the outside of the hull, periodically wash the transducer’s face with soap and water to remove any

oil film that may collect. Oil and dirt on the face will reduce the

sensitivity or may even prevent operation.

©©

©

Copyright Copyright

Copyright

Copyright Copyright

©©

1995, 1996 Lowrance Electronics, Inc. 1995, 1996 Lowrance Electronics, Inc.

1995, 1996 Lowrance Electronics, Inc.

1995, 1996 Lowrance Electronics, Inc. 1995, 1996 Lowrance Electronics, Inc.

All rights reserved.All rights reserved.

All rights reserved.

All rights reserved.All rights reserved.

PT-W INSTALLATION INSTRUCTIONS ONLY

The PT-W is a wide cone angle (20 degree) transducer designed to be

used with portable sonar units.

Assemble the transducer and bracket as shown below. Press the

rubber grommet into the hole in the top of the bracket. Tie one end of

the lanyard through this hole.

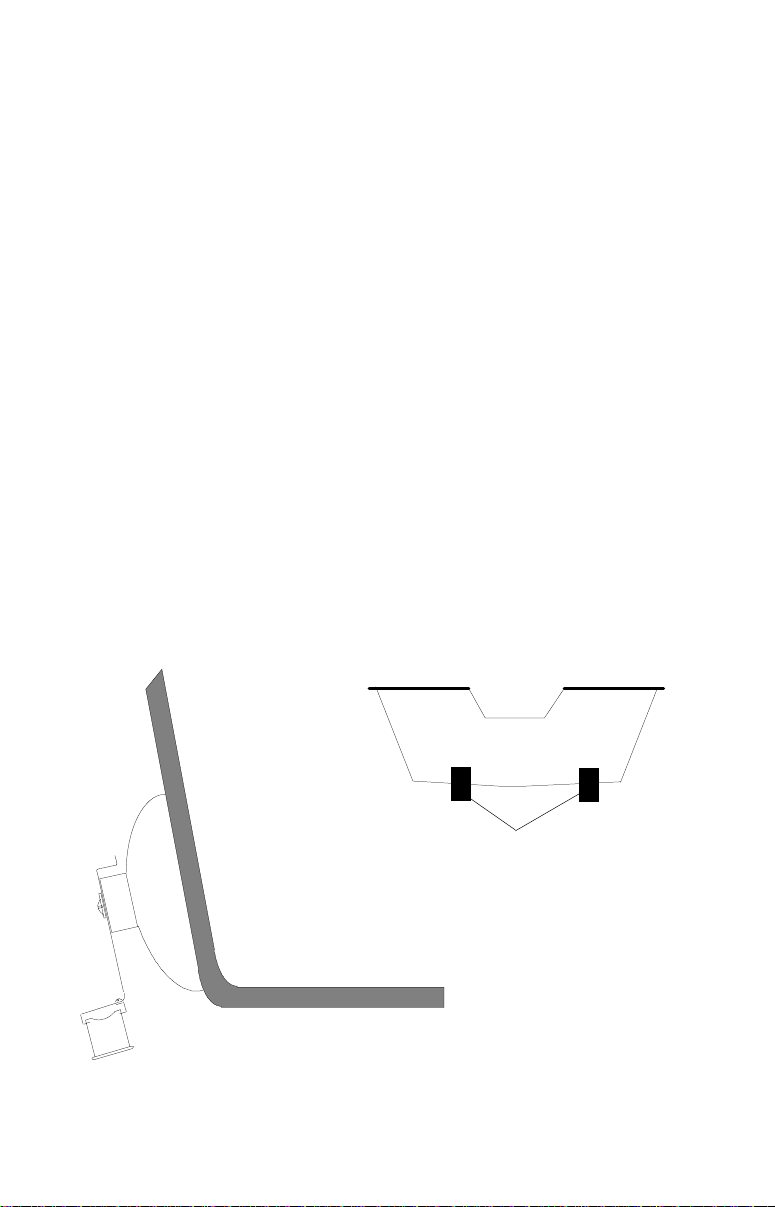

To use the PT-W, choose an area on the transom that is free from air

bubbles when the boat is moving. Although this is not a high speed

transducer, it will operate when the boat is moving faster than trolling

speeds. It is important to mount the transducer in an area that is free

from air bubbles, since they cause interference on the sonar's display.

Once a good location is found, clean the area before attaching the

suction cup. Moisen the suction cup and press it firmly onto the hull.

The suction cup should be mounted just above the bottom edge of the

hull. This allows the transducer a good chance to be in smooth water at

all times.

Tie the lanyard to the boat. This will prevent the loss of the transducer if

the suction cup comes loose. Route the transducer cable to the sonar

unit.

GOOD

MOUNTING

LOCATIONS

1

PD-W & PD-N INSTALLATION INSTRUCTIONS

The PD-W and PD-WBK are wide

cone angle (20 degree) transducers

and can be mounted to shoot

through the hull, or, with an automotive hose clamp, attached to a trolling motor. The PD-N and PD-NBK

narrow cone angle (8 degree) transducers are shoot-thru-hull mount

only.

Read this manual carefully before

attempting the installation. Use extreme care if mounting the transducer inside the hull, since once it is

epoxied into position, the transducer usually cannot be removed.

Remember, the transducer location

is the most critical part of a sonar

installation. If it isn’t done properly,

the sonar can’t perform at it’s designed potential.

PD-NPD-N

PD-N

PD-NPD-N

PD-NBKPD-NBK

PD-NBK

PD-NBKPD-NBK

PD-WPD-W

PD-W

PD-WPD-W

PD-WBKPD-WBK

PD-WBK

PD-WBKPD-WBK

Location - General

1. The transducer must be placed in a location that has a smooth flow of

water at all times. If the transducer is to be mounted inside the hull,

then the chosen location must be in the water at all times. If the

transducer is not placed in a smooth flow of water, interference will

show on the sonar’s display in the form of random lines or dots

whenever the boat is moving.

2. The transducer should be installed with it’s face pointing straight

down, if possible.

3. If possible, route the transducer cable away from other wiring on the

boat. Electrical noise from engine wiring can be displayed on the

sonar’s screen. Noise from bilge pumps and aerators can also be

picked up, so use caution when routing the transducer cable around

these wires, also.

2

SHOOT-THRU-HULL

The transducer installation inside a fiberglass hull must be in an area

that does not have air bubbles in the resin or separated fiberglass

layers. The sonar signal must pass through solid fiberglass. A successful transducer installation can be made on hulls with flotation materials

(such as plywood, balsa wood, or foam) between layers of fiberglass if

the material is removed from the chosen area. For example, some

manufacturers use a layer of fiberglass, then a core of balsa wood,

finishing with an outer layer of fiberglass. Removing the inner layer of

fiberglass and the balsa wood core exposes the outer layer of fiberglass.

The transducer can then be epoxied directly to the outer layer of fiberglass. Epoxy is poured into the hole and the transducer is then placed

into the epoxy. After the epoxy cures, the hull is watertight and structurally sound. Remember, the sonar signal must pass through solid fiberglass. Any air bubbles in the fiberglass or the epoxy will reduce or

eliminate the sonar signals.

To choose the proper location for thru-hull mounting, anchor the boat in

60 feet of water. Add a little water to the sump of the boat. Plug the

transducer into the sonar unit, turn it on, then hold the transducer over

the side of the boat. Adjust the sensitivity and range controls until a

second bottom echo is seen on the display. (you will need to turn the

automatic and ASP functions off on L.C.G. units.) Don’t touch the

controls once they’ve been set. Next, take the transducer out of the

water and place it in the water in the sump of the boat. Observe the

sonar signal to see if there is a noticeable decrease in sensitivity. The

second bottom signal may disappear and the bottom signal may decrease in intensity. Move the transducer around to find the best location.

If the sensitivity control has to be increased greatly to compensate, then

a different type of transducer should be mounted on the outside of the

hull. If not, then mark the location that shot through the hull the best and

follow the instructions below for a thru-hull mounting.

3

TRANSDUCER LOCATIONTRANSDUCER LOCATION

TRANSDUCER LOCATION

TRANSDUCER LOCATIONTRANSDUCER LOCATION

TRANSDUCER LOCATION

TRANSDUCER LOCATIONTRANSDUCER LOCATION

(HIGH SPEED)(HIGH SPEED)

(HIGH SPEED)

(HIGH SPEED)(HIGH SPEED)

Shoot-thru-hull Installation

TRANSDUCER LOCATIONTRANSDUCER LOCATION

(TROLLING SPEEDS)(TROLLING SPEEDS)

(TROLLING SPEEDS)

(TROLLING SPEEDS)(TROLLING SPEEDS)

DEADRISE LESS THAN TENDEADRISE LESS THAN TEN

DEADRISE LESS THAN TEN

DEADRISE LESS THAN TENDEADRISE LESS THAN TEN

DEGREESDEGREES

DEGREES

DEGREESDEGREES

1. Dry the chosen area thoroughly, then sand both the inside surface of

the hull and the face of the transducer with 100 grit sandpaper. The

surface of the hull must be flat so the entire transducer face is in

contact with the hull prior to bonding.

2. Make certain the area is clean, dry, and free of oil or grease. Build a

small dam out of caulking compound or RTV around the mounting

area. It should be at least 1/2" greater in diameter than the transducer. Use a good two-part epoxy that sets up rock hard. Do not use

5 minute or “fast setting” epoxy. Do not use RTV silicone rubber

adhesive or any other glue.

TRANSDUCERTRANSDUCER

TRANSDUCER

TRANSDUCERTRANSDUCER

RTV DAMRTV DAM

RTV DAM

RTV DAMRTV DAM

4

EPOXYEPOXY

EPOXY

EPOXYEPOXY

RTV DAMRTV DAM

RTV DAM

HULLHULL

HULL

HULLHULL

RTV DAMRTV DAM

3. Follow the instructions on the epoxy package and mix it thoroughly.

Do not mix it too fast, as it will cause bubbles to form in the epoxy.

Apply a small amount on the entire face of the transducer, then pour

1/16" level into the area contained by the dam. Place the transducer

into the epoxy, twisting and turning it to force any air bubbles out from

under the transducer face. The face of the transducer should be

parallel with the hull, with a minimum amount of epoxy between the

hull and transducer. Hold the transducer down with a weight until the

epoxy dries. Afterwards, route the cable to the sonar unit.

5

CABLE TIECABLE TIE

CABLE TIE

TRANSDUCERTRANSDUCER

TRANSDUCER

TRANSDUCERTRANSDUCER

CABLE TIECABLE TIE

TRANSDUCERTRANSDUCER

TRANSDUCER

TRANSDUCERTRANSDUCER

CABLE TIECABLE TIE

CABLE TIE

CABLE TIECABLE TIE

Trolling Motor Mount - PD-W Only

The top of the transducer is curved to fit the contour of the motor on

electric trolling motors. Attach it using a automotive hose clamp available at any auto parts store.

1. Measure the diameter of your trolling motor and purchase a hose

clamp slight larger.

2. Determine the mounting location. It should be ahead of the skeg.

Water turbulence is at a minimum at this position. Some trolling

motors have a wire brace from the motor to the skeg. The transducer

won’t be affected by this.

3. Position the transducer to aim straight down with the cable angled

away form the direction of travel. Mount it with the hose clamp.

4. Tie the cable to the motor shaft using plastic cable ties (available at

automotive or electrical supply stores). Be certain there is enough

slack for the motor to turn freely.

LITHO IN U.S.A. 988-0140-30

6

Loading...

Loading...