Lotos TIG200-DC User Manual

LOTOS TIG200-DC

TIG/Stick Welder

www.uwelding.com

CONTENTS

1. Contents ································································································ 1

2. Safety warning ························································································ 2

3. Machine description ················································································· 3

4. Technical parameters table ········································································· 4

5. Installation instruction ·············································································· 5

6. Panel function instruction ·········································································· 7

7. Operation instruction ················································································ 8

8. Notes or preventive measures ······································································ 9

9. Questions to be run into during welding ························································ 10

10. Maintenance ························································································· 11

11. Before checking ····················································································· 12

- 1 -

SAFETY WARNING

On the process of welding or cutting, there will be any possibility of injury, so

please take protection into consideration during operation. More details please

review the Operator Safety Guide, which complies with the preventive

requirements of the manufacturer

Electric shock——may lead to death ! !

·Set the earth fitting according to applying standard.

·It is forbidden to touch the electric parts and electrode when the skin is naked, wearing wet

gloves

or clothes.

·Make sure you are insulated from the ground and the workshop.

·Make sure you are in safe position.

Gas——may be harmful to health!

·Keep your head out of the gas.

·When arc welding, air extractor should be used to prevent from breathing gas.

Arc radiation——Harmful to your eye and burn your skin.

·Use suitable helmet and light filter, wear protective garment to protect eye and body.

·Use suitable helmet or curtain to protect looker-on.

Fire

·Welding spark may cause fire, make sure the welding area no tinder around.

Noise——extreme noise harmful to ear.

·Use ear protector or others means to protect ear.

·Warn that noise harmful to hearing if looker-on around.

Malfunction——When trouble, count on the professionals

·If trouble in installation and operation, please follow this manual instruction to check up.

·If fail to fully understand the manual, or fail to solve the problem with the instruction, you

should contact the suppliers or our service center for professional help.

CAUTION!

Creep age-protecting switch should be added when using the machine!!!

- 2 -

MACHINE DESCRIPTION

Welding machine is a rectifier adopting the most advanced inverter technology.

The development of inverter gas-shielded welding equipment profits from the development of

the inverter power supply theory and components. Inverter gas-shielded welding power source

utilizes high-power component MOSFET to transfer 50/60HZ frequency up to 100KHZ, then

reduce the voltage and commutate, and output high-power voltage via PWM technology. Because

of the great reduce of the main transformer’s weight and volume; the efficiency increases by 30%.

The appearance of inverter welding equipment is considered to be a revolution for welding industry.

Welding power source can offer stronger, more concentrated and more stable arc. When stick

and work piece get short, its response will be quicker. It means that it is easier to design into

welding machine with different dynamic characteristics, and it even can be adjusted for specialty to

make arc softer or harder.

TIG welding machine is easy for arc initiation and has the functions of arc initiation current,

arc stop current, welding current, basic value current, current ascending time, current descending

time, gas delay time, continuous adjustment. What’s more, pulse frequency and pulse duty can also

be adjusted independently. It has the characteristics of automatic control of arc initiation, arc stop

and stable arc, which make the best result for shape and inner quality of the welding surface. Its

exclusive design is especially suitable for bicycle industry.

The machine can be for multi-use, and can weld stainless steel, carbon steel, copper and other

color metal, and also can use for traditional electric welding. Its transfer efficiency is above 85%.

The machine is suitable for welding stainless steel, mild steel, aluminum, and other metal

materials.

The machine accessories and consumables can be purchased on www.uwelding.com.au to

order.

CAUTION!

The machine is mainly used in industry. It will produce radio wave, so the worker should

make fully preparation for protection.

- 3 -

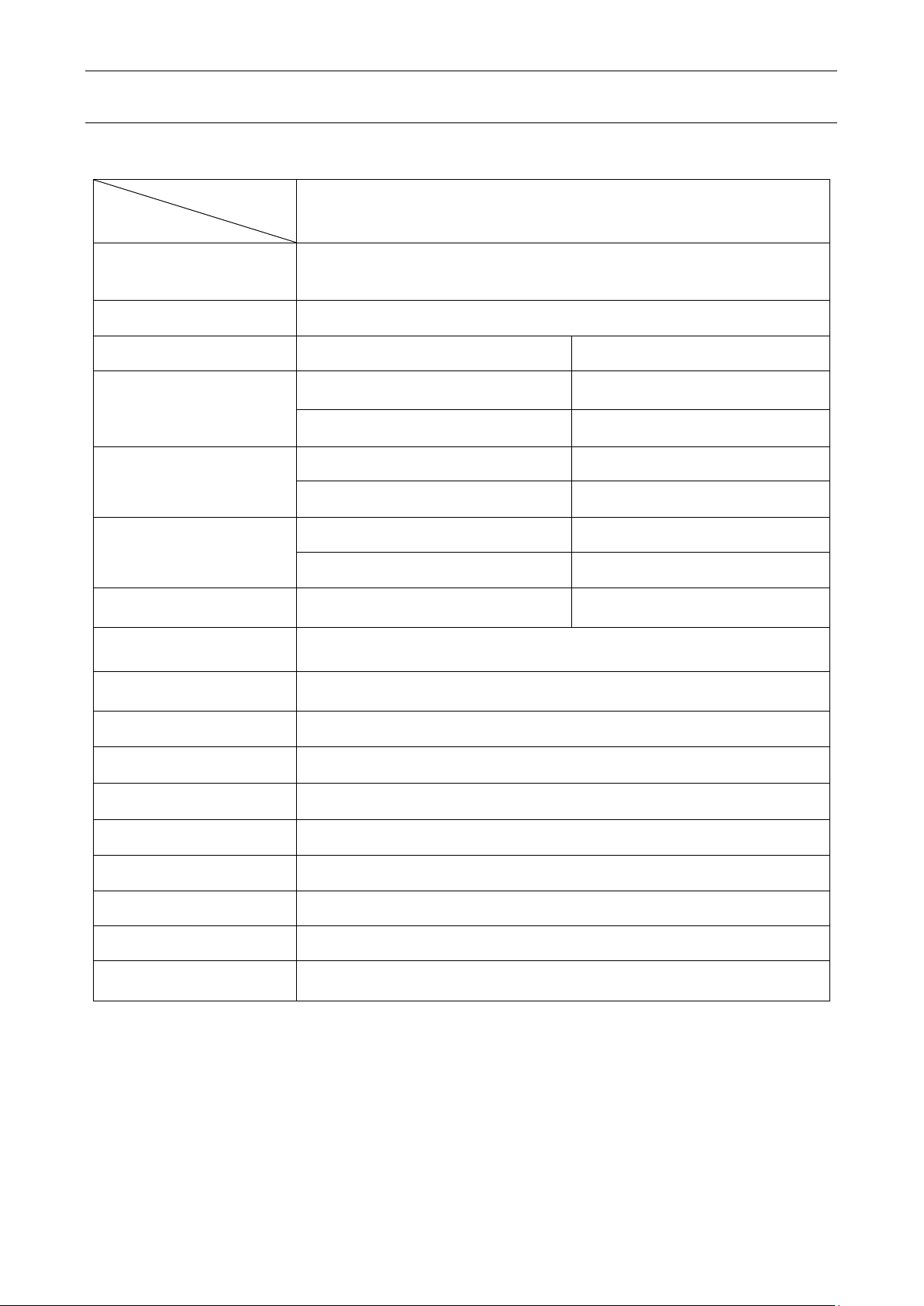

TECHNICAL PARAMETERS TABLE

model

TIG 200-DC

parameters

Input Power voltage(V) 110/220V ± 15%, 1-PH, 50/60Hz

Frequency (HZ) 50/60

110V

TIG: 27.6A TIG: 26A

Rated input current (A)

MMA: 46.3A MMA: 39.5A

TIG: 14.8V TIG: 17.6V

Rated output voltage (V)

MMA: 24.8V MMA: 27.4V

TIG: 10~120 TIG: 10~190

Rated output current(A)

MMA: 30~120 MMA: 30~185

No-load voltage(V) 56

220V

56

Arcing way HF

Duty cycle (%) 60

Post gas time(S) After descending 2/5S

No-load loss(W) 40

Efficiency (%) 80

Power factor 0.73

Insulation grade

Housing

weight(kg) 17

Dimensions (mm) 485×395×360

IP21

F

- 4 -

Loading...

Loading...