LorTonE

InSTruCTIonS and ParTS LIST

TS10-C Item # 059-093

TS10 Basic Item # 059-090

TS10-C

(including TS10 Basic)

LorTonE Trim Saws are high quality saws for trimming slabs to nished conguration.

Cuts cleanly and easily with excellent visibility and has plenty of room for larger slabs.

For use with oil or water coolants. Follow these basic operating and care instructions to

help keep your saw in optimal running condition.

• Stainless Steel Frame

• Spacious Work Table

• Accepts 10” Blade (included with TS10-C)

• Optional Clear Hood (included with TS10-C)

• Optional Vise (included with TS10-C)

5/10

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 • Phone: 425-493-1600

Copyright © 2010 Lortone, Inc

Page 1

SETTING UP YOUR MACHINE

Check to make sure you have the following parts:

•

(1) TS10 Frame with Bearings and Drive Belt (1) Blade Guard

(1) Splash Shield (1) Blade (included in TS10-C only)

(1) Belt Guard (1) Vise (included in TS10-C only)

(1) Belt (included in TS10-C only) (1) Hood (included in TS10-C only)

(1) Operators Manual (1) Warranty Card

If any parts are missing, please contact your dealers or the factory immediately.

Read the following instructions before assembly or use of your machine. Failure to

follow instructions could result in damage to the machine or injury to operator.

IMPORTANT!!!

MOTOR INSTALLATION

Note: A 1/3 hp, 1725 RPM is recommended for proper operation. Motor pulley should be 2” to 2 1/2” diameter.

Drive belt should be selected to match desired motor mounting position. Pulley and drive belt are included with

the TS10-C only.

Make sure the saw is secured to the base (TS10-C). For TS10 Basic, secure saw and motor to work area.

•

Place motor pulley on the motor shaft and securely tighten the set screw on at of motor shaft.

•

Install belt and adjust motor to obtain correct belt tension. Do not overtighten the belt as this will lead to

•

excessive noise and premature bearing wear. The belt should not deect more than 1”.

BLADE INSTALLATION

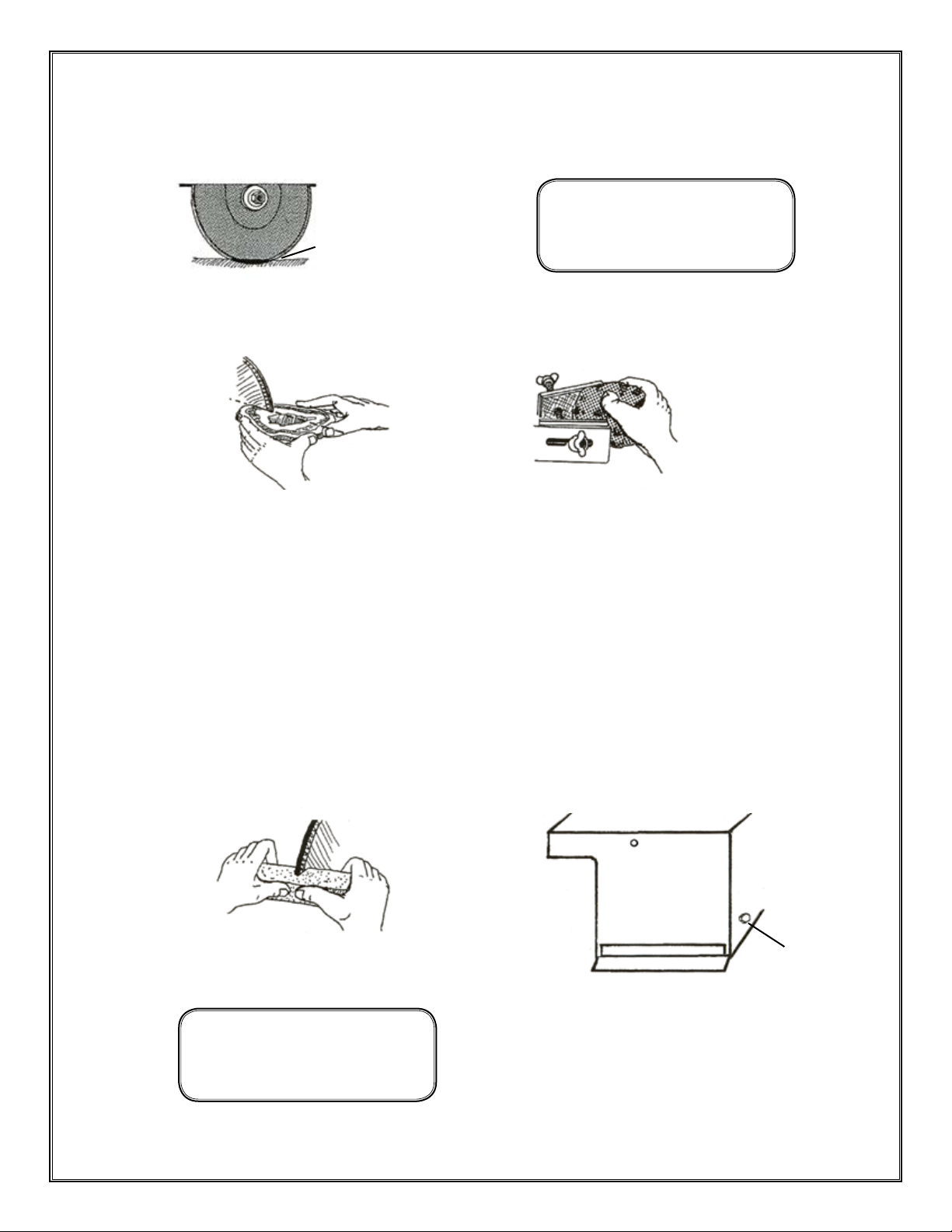

Slip the blade into the saw slot at an angle (Fig. 1) and slide it onto the shaft.

•

Slide the second ange next to the blade and tighten the arbor nut securely (Fig. 2).

•

Do not over tighten as this can warp the blade.

•

Fig. 1

Fig. 2

OPTIONAL VISE INSTALLATION

Attach the vise parallel to the trim table using the two self-tapping screws (Fig. 3).

•

Clamp a pencil into the vise with the point just touching the front of the blade behind the rim.

•

Rotate the blade (Fig. 4) rearward so pencil mark shows above the table.

•

Slide the vise and pencil rearward. Pencil point should touch the blade at the same spot.

•

If necessary loosen the screws and adjust the guide bar supports.

•

Fig. 4

5/10

Fig. 3

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 • Phone: 425-493-1600

Copyright © 2010 Lortone, Inc

Page 2

OPERATION

Fill the coolant tank with lapidary cutting oil or water until coolant covers approximately 1/4” of the blade rim

•

(Fig. 5). Note: Add a small amount of quality rust inhibitor when using water.

CAUTION!!!

Do not operate without coolant.

1/4”

Fig. 5

Cut slowly using a straight forward motion (Fig. 6). Do not force stone into blade or apply side pressure.

•

If using the vise, make sure the rock is clamped rmly before starting (Fig. 7). Slowly feed stone into blade.

•

Fig. 6

Injury to operator or damage to

blade and machine may occur.

Fig. 7

MAINTENANCE

The TS-10 is designed for minimum maintenance however the following should be periodically checked.

Check belt for wear and proper tension. Refer to Motor Installation.

•

Check blade for wear and correct alignment.

•

Keep blade sharpened by periodically making a cut into a dressing stick or an old medium grit

•

aluminum oxide or silicon carbide grinding wheel. This helps to expose fresh diamond crystals. (Fig 8).

Cascade™ dressing sticks #566-012 are recommended.

•

Maintain a proper coolant level.

Change the coolant frequently or when it becomes dirty. (Fig. 9).

•

Fig. 9

Fig. 8

Remove plug to

drain coolant.

5/10

IMPORTANT!!!

If using a water coolant,

always drain after every use to

ensure proper blade care.

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 • Phone: 425-493-1600

Copyright © 2010 Lortone, Inc

Page 3

PARTS LIST TS10 & TS10-C

Part No. Description

A 059-108 Arbor Shaft with Flange

B 059-006 Splash Shield

C 059-009 Blade Guard

D 059-100 Tank Assembly

E 059-101 Trim Table Assembly

F 059-102 Belt Guard Assembly

G 200-020 Bearing (2 required)

H 058-028 3” Machined Flange

I 205-010 Felt Washer

J 211-007 Arbor Pulley, 2 x 3/4”

K 481-057 5/8” Hex Nut

L 216-001 Drain plug, brass

Included with TS10-C Only

M 071-098 Vise

N 074-095 Hood

N

(Not shown)

300-022 1/3 hp motor

522-061 10” Blade

211-009 Motor Pulley, 2 1/4 x 1/2”

210-035 4L-310 Belt

M

J

A

F

G

C

B

E

H

K

I

D

5/10

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 • Phone: 425-493-1600

Copyright © 2010 Lortone, Inc

L

Page 4

Loading...

Loading...