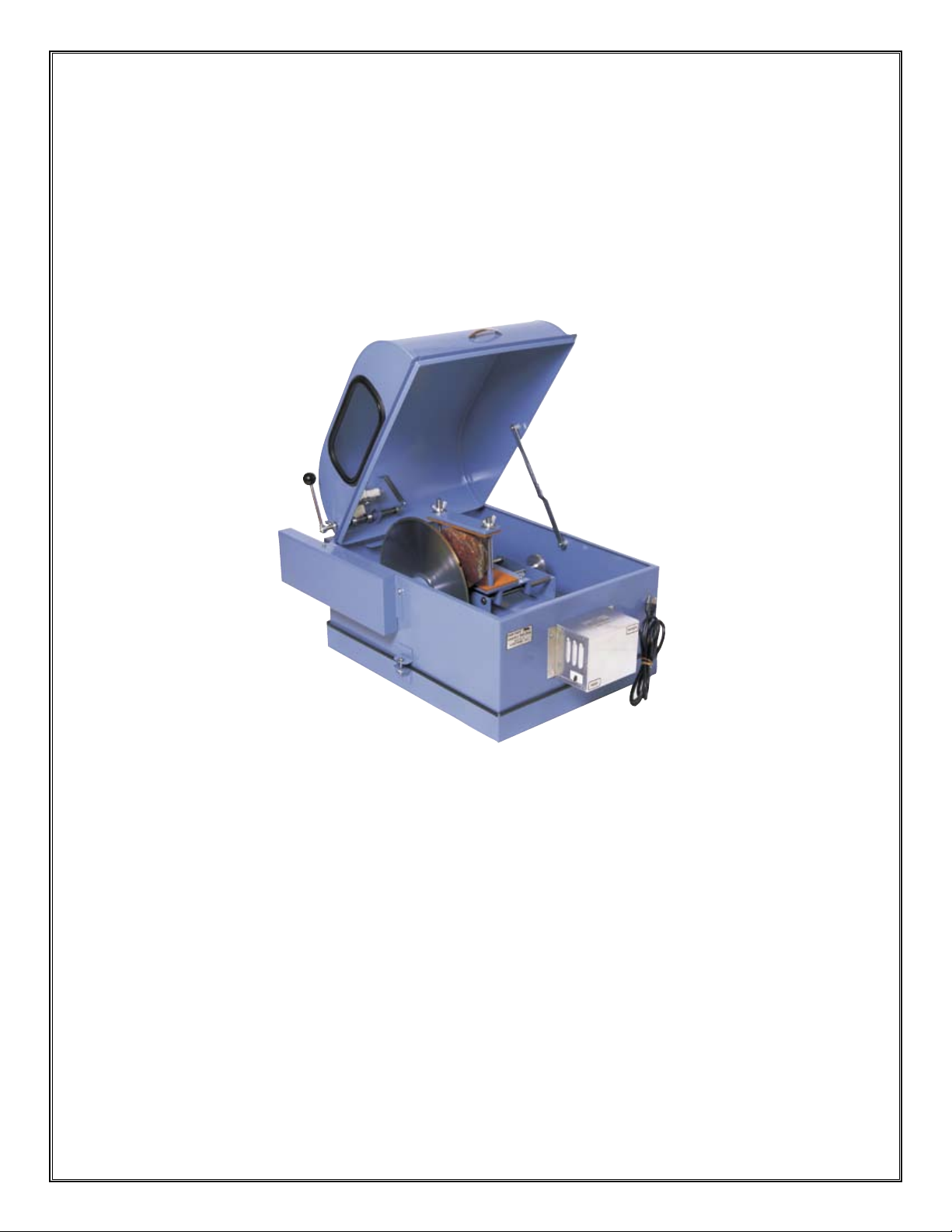

LortonE

InStructIonS and PartS LISt

LSS-14P Item # 058-090

LSS-14P

The LSS-14P is a quiet, clean 14” slab saw in a compact bench-top design.

Equipped with a fast, powerful screw-feed and a 5-1/2” capacity vise. Properly

set up, operated and maintained, the Panther will cut rock at twice the speed of

standard screw-feed saws. Oil coolant required.

• 14” Blade for Larger Cuts

• Bench-Top Design

• Fast Power Screw-Feed

• Sturdy Welded Steel Frame Won’t Crack or Warp

• Built-in Blade Sharpener

• Hinged Hood with Tempered Glass Window

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 1

SETUP

Check to make sure you have received the following parts:

•

(1) LSS14-P Saw

(1) Belt Guard with mounting screws

(1) Drive Belt

(1) Accessory Package Containing:

(4) Motor Mounting Bolts with Nuts and Washers

(2) Motor Mount Attachment Screws

(2) Adjusting Bolts with Nuts and Caps

(1) 3” x 5/8” Motor Pulley

(1) Operators Manual and Warranty Card

(1) 14” Diamond Blade

(1) 1/2 HP Drive Motor

Note: Motor for this unit is shipped separately.

Remove the saw from its packing and place on a sturdy, at, level surface.

•

Read the following instructions before

assembly or use. Failure to follow

instructions can result in damage to

the machine or injury to the operator.

IMPORTANT

MOTOR INSTALLATION

Secure motor to motor mount with bolts provided.

•

Install adjustment bolts in motor mount as shown and attach motor to saw frame.

•

Place motor pulley on the motor shaft. Tighten set screw securely.

•

Install belt and adjust motor to obtain correct belt alignment and tension.

•

Do not over tighten the belt as this can lead to excessive noise and premature bearing wear.

Motor Mount

Adjustment

Bolts

Adjust belt tension

for 1/2” -1” slack

BELT GUARD INSTALLATION

Place belt guard over the belt, motor pulley, and frame.

•

Install the two mounting screws, tighten securely.

•

SLAB CATCHER

Loosen hold-down screws and adjust slab catcher to clear blade by 1/8”.

•

BLADE SHARPENER

Loosen set screw on blade sharpener handle.

•

Rotate handle until it is straight up and tighten set screw securely.

•

Install Blade &

Outer Flange,

Tighten Arbor Nut

securely.

Slab

Catcher

1/8”

ELECTRICAL CONNECTION

Make sure all Switches on the Motor and Control Box are in the OFF position

•

Make sure the hood is closed.

•

Plug the Motor Cord into the outlet on the Control Box.

•

Plug the Saw Power Cord into a grounded outlet

•

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 2

COOLANT

We recommend LORTONE Cutting Oil #086-010 for optimal results.

Use a neutral petroleum base oil with a high ash point and no additives.

•

Add approximately 2 gallons of coolant until the bottom 1/4”-1/2” of the blade is covered.

•

CAUTION

DO NOT run saw without proper coolant.

DO NOT use Kerosene or other ammable solvents.

DO Not use water or water soluble oils.

Failure to follow these instructions can result in

damage to machine or serious injury to operator.

Use of these coolants will void the warranty.

Coolant 1/4”-1/2” on Blade

BLADE CARE & DRESSING

Clamp a Blade Dressing Stick in the vise. With the hood closed and the saw running, lightly pull the blade

•

sharpener handle forward. Repeat as needed.

Dress the blade frequently. Dull or glazed blades will quickly dish or warp.

•

Note: Dished or warped blades are not covered under warranty.

YOU MUST DRESS THE BLADE PRIOR TO INITIAL USE.

•

This removes the protective paint from the cutting edge of the blade.

OPERATION

Make sure all Switches on Control Box are in the “OFF” position (toward saw) before opening the hood.

•

Clamp material securely in vise. Check for looseness of material and re-tighten if necessary.

•

Adjust cross feed and hand tighten the carriage lock screw #488-056. See Fig A.

•

Check to be sure that material will clear the arbor shaft cover and the blade anges.

To release carriage, pull half nut lever toward control box. Slide the carriage to desired position and release

•

the half nut lever. Make sure the lever is fully engaged.

Adjust shutoff chain #447-001 for desired length of cut.

•

To Start Saw:

Note: The “Power” switch operates the motor and supplies power

to the “Feed” switch. The “Feed” switch operates the feed motor only

and will not work with the “Power” switch in the off position.

Close hood and make sure both switches are in the “OFF” position.

•

Turn the “Power” switch to “ON” position to start blade rotation.

•

To start power feed, turn “Feed” switch to “ON” position.

•

While Cutting: IMPORTANT- DO NOT LEAVE SAW UNATTENDED

•

Listen for changes in operating noise. Sudden changes can indicate damaged material or blade.

Over-heating of the main motor can result in tripping of the safety overload protector.

•

Note: Tripping the safety overload protector does not shut off the power feed. To prevent blade & saw

damage, IMMEDIATELY turn off both the “Power” & “Feed” switches. Inspect the machine and blade for

damage and correct any problems before continuing. When cool, press the red reset button on the drive

motor to reset the protector.

At End of Cut:

Push both switches toward saw to “OFF” position before opening the hood.

•

Remove the cut slab. Inspect the remaining material to make sure it is secure in the vise.

•

Loosen carriage lock screw and advance the carriage by turning the cross-feed wheel.

•

Each turn advances the cross-feed carriage approximately 1/16 inch (.062).

Do not operate saw with Hood open.

Turn off both switches and unplug

Failure to follow these instructions

CAUTION

saw prior to opening hood.

can result in serious injury.

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 3

CLEANING MAINTENANCE

The saw should be cleaned periodically when sediment builds up to a depth of 1/4”.

•

Unbolt the saw case from the coolant pan and lift out the case.

•

Empty the coolant pan and wipe sludge from the case and power feed screw.

•

Re-install case in coolant pan, attach bolts, and add clean and/or ltered oil.

•

Pour Out Used Oil &

Unbolt Pan to Clean

Dispose of Properly.

Item Description

119-001 Cross Feed Handle Assy.

053-001 Feed Rod

053-004 Bracket, Bearing

053-010 Vise Top Plate

053-011 Vise Top Pad

053-012 Slab Catcher

053-013 Arbor Cover

053-014 Motor Mount

053-016 Carriage Way

053-047 Window Key Rubber

053-048 Window Rubber Seal

053-109 Control Box (Box Only)

053-106 Belt Guard

054-007 Cross Feed Bolt

481-081 Wing Nut

058-108 Arbor Shaft with xed Flange

058-005 Channel, Carriage

058-006 Shaft, Cross Feed

053-009 Vise Bottom Plate

058-010 Spring Arm

058-014 Vise Handle

058-016 Sharpener Shaft

058-017 Vise Bottom Pad

058-020 Feed Rod Coupling

058-022 Power Feed Support

058-030 3” Sharpener Vise Bolt

058-032 3-1/2” Sharpener Vise Bolt

058-034 Sharpener Vise Bottom

058-036 Sharpener Vise Top

058-100 Hood

058-101 Case

058-102 Vise Carriage (Frame Only)

058-104 Coolant Pan

058-126 Complete Control Box

209-003 Foot

Model LSS-14P Parts List

Item Description

058-107 Half Nut

481-057 Arbor Nut

058-028 3” Flange

215-003 Set Collar

215-009 Set Collar

215-002 Carriage Collar

200-005 Carriage Bearing

200-006 Arbor Bearing

201-012 Feed Rod Bearing

203-001 Bearing

204-001 Bearing Strap

205-010 Felt Washer

206-031 Retaining Ring

210-041 Belt (4L370)

211-019 Motor Pulley (3”x5/8”)

211-031 Arbor Pulley (4”x3/4”)

213-002 Spring

213-014 Extension Spring

213-016 Compression Spring

215-005 Set Collar

260-001 Window

290-001 Hood Handle

290-012 Hood Brace

290-016 Knob

301-060 Power Feed Motor, 110V

301-061 Power Feed Motor, 220V (International)

304-012 Switch

304-013 Switch Hex Nut

304-014 Switch Lock Washer (not shown)

305-002 Receptacle

320-004 Strain Relief

350-002 Cord

447-002 Shutoff Chain (21” long)

488-056 Carriage Lock Screw

566-012 Blade Dressing Stick (3-pk.)

290-016 Handle Knob (for blade sharpener)

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 4

Arbor Shaft

Fig. B

Vise Carriage

Fig. A

053-010

053-011

058-005

058-102

215-002

200-005

053-004

(3)

481-081

058-017

058-107

053-009

488-056

206-031

200-005

213-002

054-007

119-001

058-006

205-010

350-002

053-013

204-001

Gear Box

Fig. C

320-004

058-108

See Fig. C2**

200-006

058-028

304-012

053-109

481-057

304-013

Fig. C2

**Switch

Blade Sharpener

Fig. D

290-016

058-036

058-014

203-001

058-016

058-032

058-034

058-030

305-002

See Fig. C2**

058-022

301-060

058-020

566-012

209-003

213-014

058-010

213-016

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 5

290-001

053-106

053-047

053-048

260-001

Blade Sharpener

See Fig. D

053-014

211-009

210-041

Arbor

See

Fig. B

215-009

201-012

215-003

058-100

290-012

Vise Carriage

See Fig. A

053-101

053-016

053-001

1/12

211-031

053-012

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

447-002

Control Box

See Fig. C

058-104

Page 6

CAUTION !!

Failure to follow these instructions

may result in injury to the operator

and damage to the machine.

FOR PROPER OPERATION USE ONLY

5-10 wt. PETROLEUM OIL,

NON-DETERGENT TYPE,

WITH A HIGH FLASH POINT

DO NOT USE water, water-soluble oil,

solvents, fuels, anti-freeze or vegetable oil.

Use of these or other materials will result in

substandard performance and damage to

the machine is not covered under warranty.

We suggest LORTONE Cutting Oil

#086-010

CAUTION !!

1/12

LORTONE, inc • 12130 Cyrus Way, Mukilteo, WA 98275 U.S.A

Phone: 425-493-1600 • www.lortone.com

Copyright © 2008 Lortone, Inc

Page 7

Loading...

Loading...