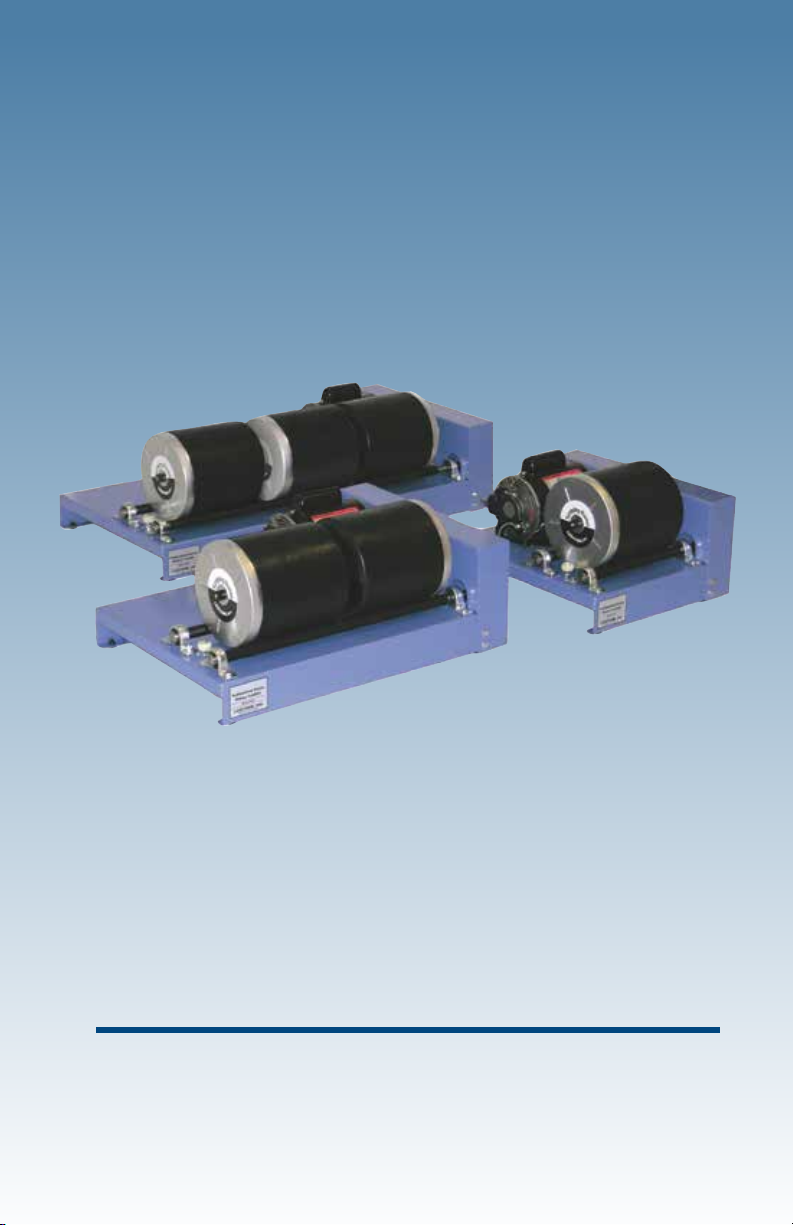

ROTARY TUMBLER

INSTRUCTIONS AND PARTS LIST

Model

C300

Model

C100

Model

C200

LORTONE

12130 Cyrus Way

Mukilteo, WA 98275

(425) 493-1600

GETTING STARTED

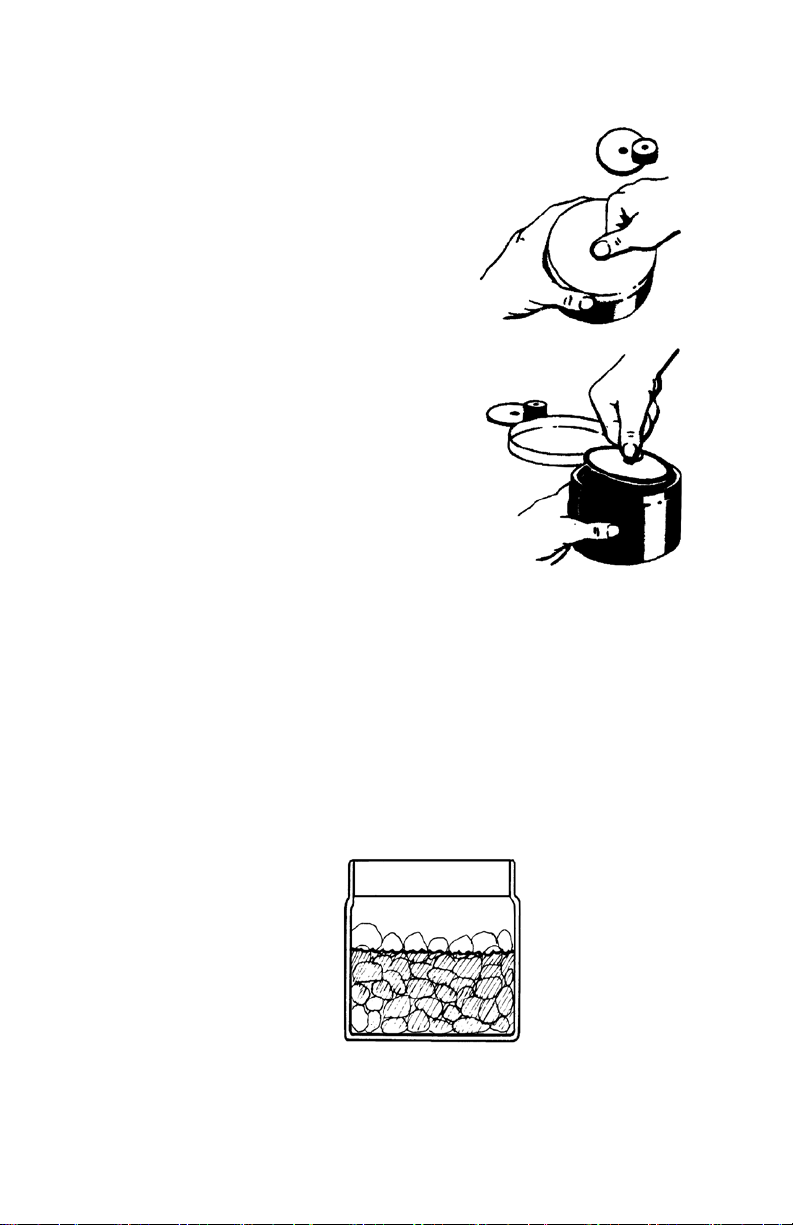

I. Open the Barrel: Remove nut

and washer, press down on bolt

with thumb while lifting up on

outside of outer lid with ngers.

If outer lid is difcult to remove,

insert washer between edge

of outer lid and barrel, twist to

loosen. After outer lid has been

removed, lift inner lid out by

center bolt.

II. Add Rocks: Fill Barrel about 1/2 to 2/3 full of rock.

Rocks should be of assorted sizes for best results.

III. Add Abrasive: Add 60/90 Silicon Carbide Abrasive.

Use 1-1/4 C. for a 12 lb. barrel. Add water to top layer

of rocks and abrasive.

Do not overll.

1

Copyright © 2009 Lortone, Inc

Add rocks

until 2/3 full.

Add water to

top layer of

rocks.

IV. Close the Barrel: Wipe the mating surfaces of the

barrel and inner lid clean with a damp cloth. Press

inner lid into barrel until it rests on shoulder. Press

outer lid rmly down onto the barrel. Install washer

and tighten nut.

Knurled nut only needs to be snug Do Not Use tools

to tighten. Over tightening of the nut can cause the

inner lid to distort and leak.

V. Tumble: Plug the tumbler into a suitable outlet. Place

the barrel on the tumbler making sure the groove in

the barrel nut sits on the tumbler guide. Tumble for 23 days. Open and check the rocks. The rough edges

should be wearing down. After 5-7 days, open the

barrel and rinse the rocks in a bucket of water. DO

NOT put the rinse water down a household drain as it

will clog the drain!

IMPORTANT: Clean the rocks and barrel parts

thoroughly using mild soap and water!

VI. Repeat steps II through V: Use succesively ner

abrasives according to your tumbling instruction

booklet and the chart below:

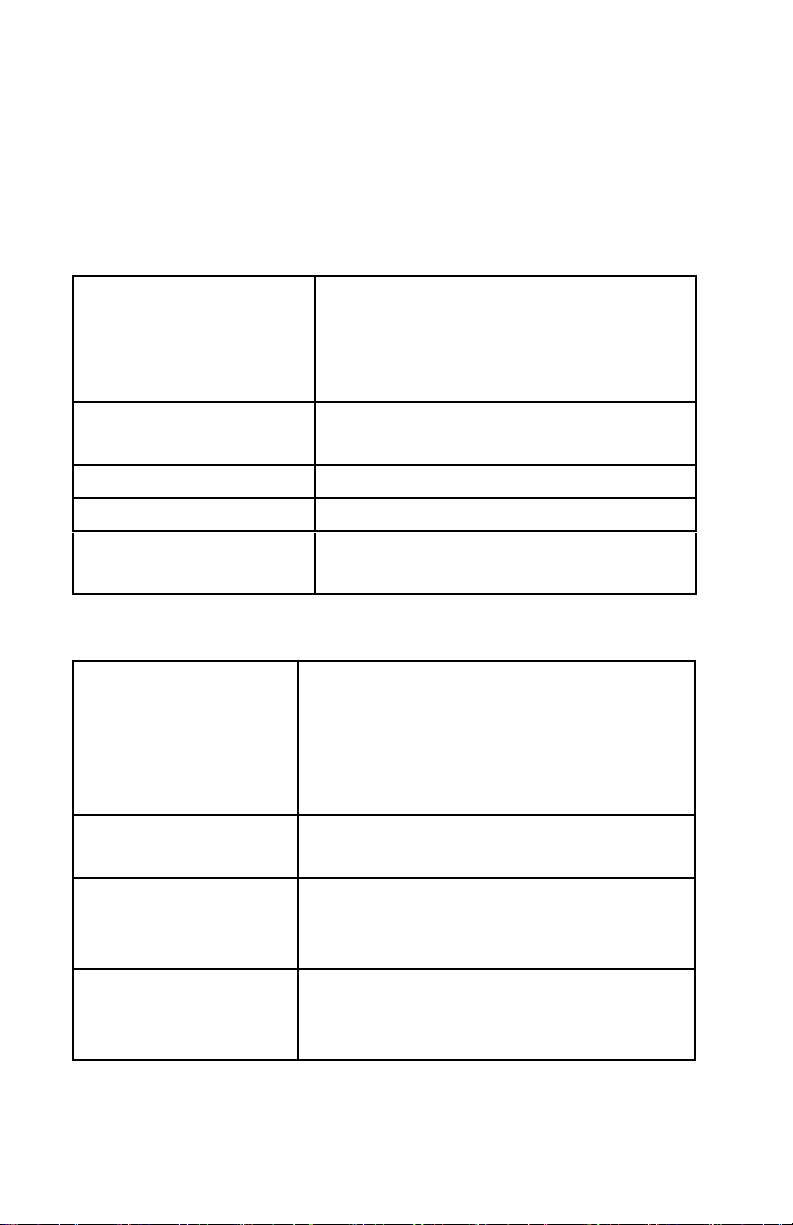

Step 1 Step 2 Step 3 Step 4

Compound 60/90 120/220 Pre-Polish Polish

Silicon Silicon Aluminum Aluminum

Carbide Carbide Oxide Oxide

12 lb Barrel 1-1/4 C. 1-1/4 C. 1-1/2 C. 1-1/2 C.

Copyright © 2009 Lortone, Inc

2

TROUBLESHOOTING

If your tumbler fails to operate correctly, check the

following:

Barrel does not turn, turns very slowly, or stops after

being placed on tumbler.

No power to unit. Make sure machine is plugged in

correctly.

Make sure electrical circuit is

operational.

Barrel not installed

correctly.

Barrel too heavy. Do not exceed rated capacity.

Drive belt broken. Remove cover and replace belt.

Motor doesn’t run or

runs intermittently.

Barrel leaks or barrel lid comes off during operation.

Align barrel correctly.

Replace motor.

Inner lid not seated

correctly.

Knurled nut over

tightened.

Gas build-up in

barrel.

Barrel or boot

gasket damaged.

3

Copyright © 2009 Lortone, Inc

Make sure inner lid and barrel

shoulder are clean and free of

contaminants.

Make sure inner lid is seated on

shoulder inside barrel.

Tighten knurled nut by hand only

until snug. Do not use tools.

Open barrel occasionally to vent

gas that might be formed during

tumbling.

Replace damaged barrel or boot

gasket.

MAINTENANCE

LORTONE Tumblers are capable of operating 24 hours/

day for years with proper care.

For best operation and results follow these simple, but

important steps:

MOTOR: The motor is designed for continuous use and

does not need oiling or other maintenance. It is normal for

the motor to run hot to the touch.

CLEANING: The outside of the barrel should be kept

clean. Clean by wiping with a wet soapy cloth and

rinse well with fresh water. DO NOT put the barrel in a

dishwasher or clean using solvents. If the outside of the

barrel becomes so slick that it slips on the rollers, roughen

slightly with very ne sandpaper or steel wool.

If you need assistance, please contact:

Lortone Customer Service (425) 493-1600 or

email: equipment@Lortone.com

Copyright © 2009 Lortone, Inc

4

PARTS LIST C100

Part No. Description

A 200-002 Bearing

B 203-920 Bearing, Nylon

C 204-002 Bearing Strap

D 210-023 Belt, Drive

E 210-025 Belt, Idler

F 211-001 Pulley, 1-1/2” x 1/2”

G 211-006 Pulley, 2” x 5/8”

H 211-041 Pulley, 5” x 5/8”

I 300-030 1/6 HP Motor

J 009-005 Shaft with cover

K 481-029 Nut, Hex, 5/16”-18 x 1-1/2”

L 484-015 Bolt, Hex, 1/4”-20, 3/4”

M 484-026 Bolt, Hex, 5/16”-18, 1-1/2”

N 489-012 Washer, Flat, 1/4”

O 009-070 Base

P 009-012 Belt Guard

Q 209-001 Rubber Foot

Part No. Description

020-094 Complete Rubber Barrel Assembly,

12 lb Capacity

R 020-102 Inner Lid w/Bolt

S 020-003 Outer Lid

T 481-070 Knurled Nut

U 240-012 Boot Gasket

V 240-005 Rubber Barrel Only

W 108-001 Barrel Washer

5

Copyright © 2009 Lortone, Inc

C100

A

C

K,M

I

P

J

B

L,N

0

Q

Belts & Pulleys

H

E

F

G

D

V

12 Lb. Barrel

U

R

Copyright © 2009 Lortone, Inc

T

W

S

6

PARTS LIST C200

Part No. Description

A 200-002 Bearing

B 203-920 Bearing, Nylon

C 204-002 Bearing Strap

D 210-023 Belt, Drive

E 210-025 Belt, Idler

F 211-001 Pulley, 1-1/2” x 1/2”

G 211-006 Pulley, 2” x 5/8”

H 211-041 Pulley, 5” x 5/8”

I 300-030 1/6 HP Motor

J 009-006 Shaft with cover

K 481-029 Nut, Hex, 5/16”-18 x 1-1/2”

L 484-015 Bolt, Hex, 1/4”-20, 3/4”

M 484-026 Bolt, Hex, 5/16”-18, 1-1/2”

N 489-012 Washer, Flat, 1/4”

O 009-071 Base

P 009-012 Belt Guard

Q 209-001 Rubber Foot

Part No. Description

020-094 Complete Rubber Barrel Assembly,

12 lb Capacity

R 020-102 Inner Lid w/Bolt

S 020-003 Outer Lid

T 481-070 Knurled Nut

U 240-012 Boot Gasket

V 240-005 Rubber Barrel Only

W 108-001 Barrel Washer

7

Copyright © 2009 Lortone, Inc

C200

A

C

K,M

B

I

P

J

O

L,N

Q

Belts & Pulleys

H

E

G

F

D

V

12 Lb. Barrel

U

R

Copyright © 2009 Lortone, Inc

T

W

S

8

PARTS LIST C300

Part No. Description

A 200-002 Bearing

B 203-920 Bearing, Nylon

C 204-002 Bearing Strap

D 210-023 Belt, Drive

E 210-025 Belt, Idler

F 211-001 Pulley, 1-1/2” x 1/2”

G 211-006 Pulley, 2” x 5/8”

H 211-041 Pulley, 5” x 5/8”

I 300-030 1/6 HP Motor

J 009-007 Shaft with cover

K 481-029 Nut, Hex, 5/16”-18 x 1-1/2”

L 484-015 Bolt, Hex, 1/4”-20, 3/4”

M 484-026 Bolt, Hex, 5/16”-18, 1-1/2”

N 489-012 Washer, Flat, 1/4”

O 009-072 Base

P 009-012 Belt Guard

Q 209-001 Rubber Foot

Part No. Description

020-094 Complete Rubber Barrel Assembly,

12 lb Capacity

R 020-102 Inner Lid w/Bolt

S 020-003 Outer Lid

T 481-070 Knurled Nut

U 240-012 Boot Gasket

V 240-005 Rubber Barrel Only

W 108-001 Barrel Washer

9

Copyright © 2009 Lortone, Inc

C300

C

A

K,M

B

I

P

J

O

L,N

Q

Belts & Pulleys

H

E

G

F

D

V

12 Lb. Barrel

U

R

Copyright © 2009 Lortone, Inc

T

W

S

10

LORTONE Rotary Tumblers

are quiet, durable grinding

and polishing machines.

Follow these basic operating

and care instructions to help

keep your tumbler in optimal

running condition.

LORTONE

12130 Cyrus Way

Mukilteo, WA 98275

(425) 493-1600

Loading...

Loading...