Lombardini LDW 1503, LDW 1603, LDW 2004, LDW 2004/T, LDW 2204 Workshop Manual

...

WORKSHOP MANUAL

CHD series Engine

cod. 1-5302-345

CHD Engine Series

PREFACE

-Every attempt has been made to present within this service manual, accurate and up to date technical information. However, development on the LOMBARDINI series is continuous.

Therefore, the information within this manual is subject to change without notice and without obligation.

-The information contained within this service manual is the sole property of LOMBARDINI.

As such, no reproduction or replication in whole or part is allowed without the express written permission of

LOMBARDINI.

Information presented within this manual assumes the following:

1 - The person or people performing service work on LOMBARDINI series engines is properly trained and equipped to safely and professionally perform the subject operation;

2 - The person or people performing service work on LOMBARDINI series engines possesses adequate hand and LOMBARDINI special tools to safely and professionally perform the subject service operation;

3 - The person or people performing service work on LOMBARDINI series engines has read the pertinent information regarding the subject service operations and fully understands the operation at hand.

-Thismanualwaswrittenbythemanufacturer toprovidetechnicalandoperatinginformationtoauthorised LOMBARDINI after-sales service centres to carry out assembly, disassembly, overhauling, replacement and tuning operations.

-As well as employing good operating techniques and observing the right timing for operations, operators must read the information very carefully and comply with it scrupulously.

-Time spent reading this information will help to prevent health and safety risks and financial damage.

Written information is accompanied by illustrations in order to facilitate your understanding of every step of the operating phases.

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 3 - |

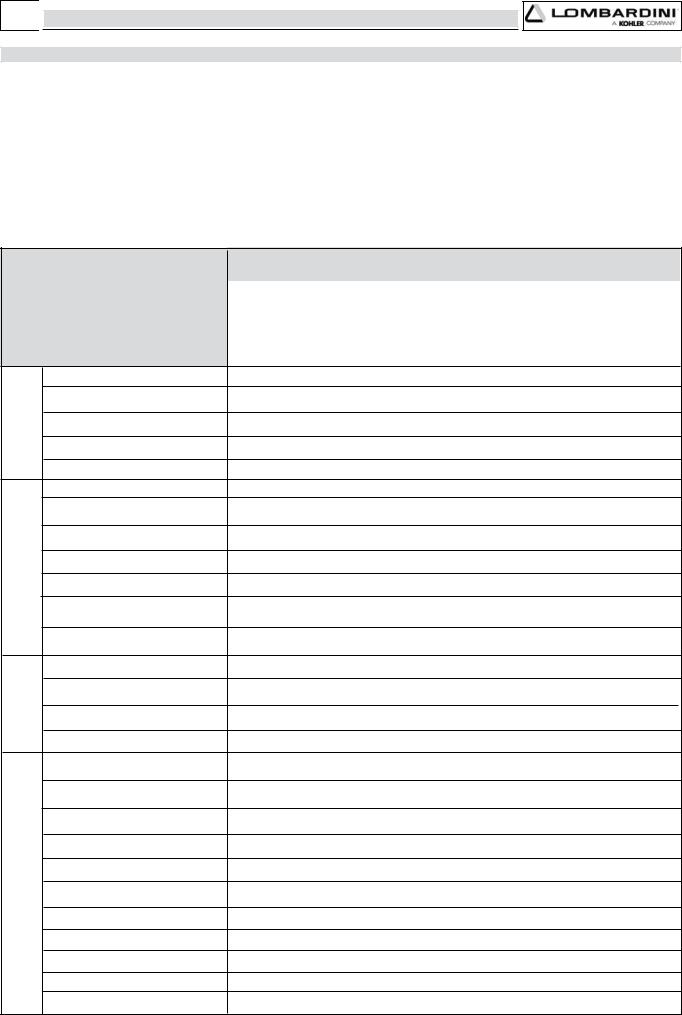

REGISTRATION OF MODIFICATIONS TO THE DOCUMENT

Any modifications to this document must be registered by the drafting body, by completing the following table.

Drafting |

Document |

Model |

Edition |

Revision |

Issue date |

Review |

Endorsed |

|

body |

code |

N° |

date |

|||||

|

|

|

|

|||||

CUSE/ATLO |

1-5302-345 |

50534 |

6° |

5 |

31-12-89 |

01-12-2009 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

- 4 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

CHAPTER INDEX

-

-

This manual gives the main instructions on how to repair LOMBARDINI diesel engines LDW 1503 - 1603 - 2004 - 2004/T - 2204 - 2204/T, fluid cooling circuit, updates as of December 1st 2009.

INDEX |

|

|

1 |

GENERAL REMARKS AND SAFETY INFORMATION.......................................................................... |

9 - 11 |

|

General safety during operating phases ......................................................................................................................... |

11 |

|

General Service manual notes.......................................................................................................................................... |

9 |

|

Glossary and terminology ................................................................................................................................................. |

9 |

|

Safety and environmental impact.................................................................................................................................... |

11 |

|

Safety and warning decals .............................................................................................................................................. |

10 |

|

Safety regulations ........................................................................................................................................................... |

10 |

|

Warranty certificate ........................................................................................................................................................... |

9 |

2 |

TECHNICAL INFORMATION ............................................................................................................... |

12 - 20 |

|

Approval data .................................................................................................................................................................. |

14 |

|

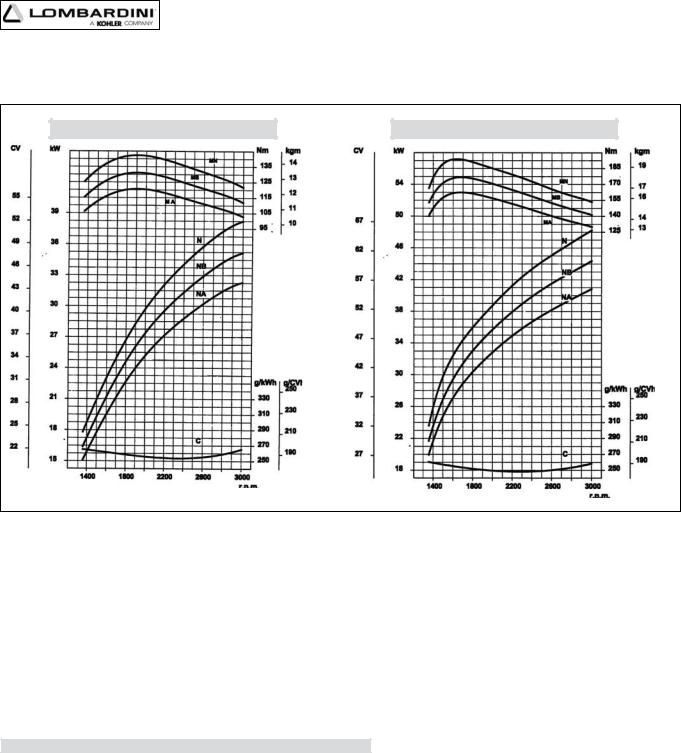

Characteristics power, torque and specific fuel consumption curves.............................................................................. |

20 |

|

Manufacturer and motor identification data..................................................................................................................... |

14 |

|

Overall dimensions.......................................................................................................................................................... |

15 |

|

Performance diagrams.................................................................................................................................................... |

20 |

|

Possible causes and trouble shooting............................................................................................................................. |

12 |

|

Table of likely anomalies and their symptoms................................................................................................................. |

12 |

|

Technical specifications................................................................................................................................................... |

18 |

3 |

MAINTENANCE - PRESCRIBED LUBRICANT - REFILLING ............................................................ |

22 - 25 |

|

ACEA Regualtions - ACEA Sequences ........................................................................................................................... |

23 |

|

API / MIL Sequences .................................................................................................................................................... |

23 |

|

Aviation fuel..................................................................................................................................................................... |

25 |

|

Biodiesel fuel................................................................................................................................................................... |

25 |

|

Coolant............................................................................................................................................................................ |

25 |

|

Extraordinary maintenance ............................................................................................................................................. |

22 |

|

Fuel recommendations.................................................................................................................................................... |

25 |

|

Fuel type ......................................................................................................................................................................... |

25 |

|

Fuels for low temperatures.............................................................................................................................................. |

25 |

|

International specifications.............................................................................................................................................. |

23 |

|

Lubricant ......................................................................................................................................................................... |

23 |

|

Ordinary maintenance..................................................................................................................................................... |

22 |

|

Prescribed lubricant ........................................................................................................................................................ |

24 |

|

Routine engine maintenance .......................................................................................................................................... |

22 |

|

SAE Classification.......................................................................................................................................................... |

23 |

4 |

DISASSEMBLY/REASSEMBLY ........................................................................................................... |

26 - 56 |

|

Air filter clogging indicator............................................................................................................................................... |

28 |

|

Assembling and tightening the cylinder head on engines with hydraulic tappets ........................................................... |

39 |

|

Camshaft......................................................................................................................................................................... |

51 |

|

Camshaft bushing replacement ...................................................................................................................................... |

52 |

|

Camshaft end play .......................................................................................................................................................... |

56 |

|

Camshaft gear - Speed governor counter weights ......................................................................................................... |

50 |

|

Camshaft journals and bushings in model LDW 1503 .................................................................................................... |

52 |

|

Camshaft journals and bushings in models LDW 2004-2004/T ...................................................................................... |

52 |

|

Camshaft removal ........................................................................................................................................................... |

51 |

|

Camshaft timing .............................................................................................................................................................. |

54 |

|

Center main bearings...................................................................................................................................................... |

42 |

|

Check clearance between main bearings and journals................................................................................................... |

43 |

|

Checking camshaft bushing internal diameter ................................................................................................................ |

52 |

|

Checking main journals and crank pins .......................................................................................................................... |

46 |

|

Connecting rod................................................................................................................................................................ |

40 |

|

Connecting rod alignment ............................................................................................................................................... |

41 |

|

Connecting rod and piston pin ........................................................................................................................................ |

40 |

|

Connecting rod weights................................................................................................................................................... |

40 |

|

Connecting rod/piston assemblies .................................................................................................................................. |

41 |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 5 - |

-Chapter index

Cooling fan ...................................................................................................................................................................... |

29 |

Crankshaft end play ........................................................................................................................................................ |

44 |

Crankshaft for engines with dynamic equalizer (only four-cylinder engines). ................................................................. |

47 |

Crankshaft front and rear oil seal .................................................................................................................................... |

45 |

Crankshaft lubrication ducts............................................................................................................................................ |

45 |

Crankshaft timing gear .................................................................................................................................................... |

45 |

Cylinder head .................................................................................................................................................................. |

31 |

Cylinder head gasket ...................................................................................................................................................... |

38 |

Cylinder head tightening for engines without hydraulic tappets ...................................................................................... |

39 |

Cylinder head tightening steps........................................................................................................................................ |

39 |

Cylinder roughness ......................................................................................................................................................... |

36 |

Cylinders ......................................................................................................................................................................... |

36 |

Dimensions for injection pump delivery control yoke adjustement.................................................................................. |

49 |

Driving pulley (2a P.T.O.)................................................................................................................................................. |

29 |

Dry air cleaner................................................................................................................................................................. |

27 |

Dry air components ......................................................................................................................................................... |

28 |

Dynamic balancer (on request) - Adjustment of clearance between teeth D and ring gear A........................................ |

47 |

Engines with hydraulic tappets........................................................................................................................................ |

55 |

Engines with mechanical tappets.................................................................................................................................... |

55 |

Exhaust manifold............................................................................................................................................................. |

28 |

Flywheel .......................................................................................................................................................................... |

30 |

Frame with idling speed governor spring ........................................................................................................................ |

50 |

Front cover ...................................................................................................................................................................... |

48 |

GR 1 and GR 2 hydraulic pump 3rd p.t.o........................................................................................................................ |

56 |

Hydraulic diagram for feeding the tappets ...................................................................................................................... |

34 |

Hydraulic pump p.t.o. ...................................................................................................................................................... |

56 |

Hydraulic tappet components:......................................................................................................................................... |

34 |

Hydraulic tappet operation .............................................................................................................................................. |

35 |

Hydraulic tappet valve control ......................................................................................................................................... |

34 |

Idler gear and hub ........................................................................................................................................................... |

48 |

Injection pump follower ................................................................................................................................................... |

35 |

Intake manifold................................................................................................................................................................ |

28 |

Intake, exhaust and injection cam height for models LDW 20042004/T....................................................................... |

53 |

Intake, exhaust and injecton cam height for model LDW 1503....................................................................................... |

53 |

Main bearing and connecting rod big bearing inside diameter (mm) .............................................................................. |

46 |

Main bearing caps timing side - flywheel side................................................................................................................. |

42 |

Main journal and connecting rod big end journal diameter ............................................................................................. |

46 |

Oil seal in the valves guides, (intake and exhaust) ......................................................................................................... |

33 |

Oil-bath air cleaner ......................................................................................................................................................... |

27 |

Oil-bath air cleaner components ..................................................................................................................................... |

27 |

Piston .............................................................................................................................................................................. |

36 |

Piston - Refitting.............................................................................................................................................................. |

38 |

Piston availability............................................................................................................................................................. |

36 |

Piston cooling sprayer..................................................................................................................................................... |

41 |

Piston position and clearance ......................................................................................................................................... |

38 |

Piston rings - Clearance between grooves ..................................................................................................................... |

37 |

Piston rings - End gaps ................................................................................................................................................. |

37 |

Piston rings - Fitting sequence........................................................................................................................................ |

37 |

Piston weight................................................................................................................................................................... |

37 |

Precombustion chamber ................................................................................................................................................. |

34 |

Recommendations for disassembling and assembling ................................................................................................... |

26 |

Recommendations for overhauls and tuning................................................................................................................... |

26 |

Rocker arm assemly ....................................................................................................................................................... |

31 |

Rocker arm cover for engines with recirculating vent ..................................................................................................... |

30 |

Rocker arm cover with vent into the air........................................................................................................................... |

30 |

Speed governor............................................................................................................................................................... |

49 |

Speed governor counter springs ..................................................................................................................................... |

50 |

Spring for extra fuel supply at starting............................................................................................................................. |

51 |

Summary tables of the governor equipment according to the speed variation. .............................................................. |

51 |

Table of pin-rocker arm dimensions ............................................................................................................................... |

31 |

Tank................................................................................................................................................................................. |

29 |

Thrust bearing, oversizes................................................................................................................................................ |

44 |

Thrust bearings ............................................................................................................................................................... |

43 |

Timing angles for checking puposes .............................................................................................................................. |

55 |

Timing angles for checking purposes LDW 2004/T ........................................................................................................ |

55 |

Timing angles for operating purposes ............................................................................................................................ |

55 |

Timing angles for operating purposes LDW 2004/T ....................................................................................................... |

55 |

- 6 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

|

|

Chapter index |

- |

|

Timing belt operating angles (with valve clearance set to zero)...................................................................................... |

|

55 |

|

V belt ............................................................................................................................................................................... |

|

29 |

|

Valve guide insertion, after driving .................................................................................................................................. |

|

33 |

|

Valve guides and cylinder head ...................................................................................................................................... |

|

32 |

|

Valve material.................................................................................................................................................................. |

|

32 |

|

Valve recess and sealing surfaces.................................................................................................................................. |

|

33 |

|

Valve removal.................................................................................................................................................................. |

|

31 |

|

Valve seats and bore....................................................................................................................................................... |

|

33 |

|

Valve spring - Check ....................................................................................................................................................... |

|

32 |

|

Valve spring - check under load ...................................................................................................................................... |

|

32 |

|

Valve timing check .......................................................................................................................................................... |

|

54 |

|

Valve timing without considering timing marks................................................................................................................ |

|

54 |

5 |

TURBOCHARGER ............................................................................................................................... |

58 - 59 |

|

|

Checking actuator setting - "Waste gate" valve control rod stroke adjustment............................................................... |

|

59 |

|

Turbocharger................................................................................................................................................................... |

|

58 |

|

Turbocharger components .............................................................................................................................................. |

|

58 |

|

Turbocharger Testing ...................................................................................................................................................... |

|

58 |

6 |

LUBRICATION SYSTEM ...................................................................................................................... |

60 - 62 |

|

|

Lubrication system layout................................................................................................................................................ |

|

60 |

|

Oil filter cartridge............................................................................................................................................................. |

|

61 |

|

Oil pressure adjusting valve ............................................................................................................................................ |

|

61 |

|

Oil pressure check .......................................................................................................................................................... |

|

62 |

|

Oil pressure curve for LDW 1503 - 1603........................................................................................................................ |

|

62 |

|

Oil pressure curve for LDW 2004 - 2204........................................................................................................................ |

|

62 |

|

Oil pressure curve for LDW 2004/T - 2204/T ................................................................................................................. |

|

62 |

|

Oil pump.......................................................................................................................................................................... |

|

61 |

|

Oil pump rotor clearance................................................................................................................................................. |

|

61 |

7 |

COOLING SYSTEM.............................................................................................................................. |

64 - 65 |

|

|

Cooling system layout ..................................................................................................................................................... |

|

64 |

|

Expansion tank and cap.................................................................................................................................................. |

|

65 |

|

Checking for cooling system leaks.................................................................................................................................. |

|

65 |

|

Coolant circulating pump................................................................................................................................................. |

|

65 |

|

Thermostat ...................................................................................................................................................................... |

|

65 |

8 |

FUEL SYSTEM ..................................................................................................................................... |

66 - 72 |

|

|

Checking injection pump delivery.................................................................................................................................... |

|

70 |

|

Checking low pressure injection timing for engines with hydraulic tappets.................................................................... |

|

71 |

|

Checking low pressure injection timing for engines with mechanical tappets................................................................. |

|

71 |

|

Electric fuel pump (24V).................................................................................................................................................. |

|

67 |

|

Fuel feeding pump .......................................................................................................................................................... |

|

66 |

|

Fuel feeding pump drive rod protrusion .......................................................................................................................... |

|

66 |

|

Fuel feeding/injection circuit............................................................................................................................................ |

|

66 |

|

Fuel filter ......................................................................................................................................................................... |

|

66 |

|

How to reassemble injection pump components............................................................................................................. |

|

68 |

|

How to reassemble injection pump feeding tubes........................................................................................................... |

|

69 |

|

How to remove injection pump feeding tubes ................................................................................................................. |

|

68 |

|

Injection pump................................................................................................................................................................. |

|

67 |

|

Injection pump control rod............................................................................................................................................... |

|

68 |

|

Injection pump delivery equalization. .............................................................................................................................. |

|

69 |

|

Injection pump disassembly ............................................................................................................................................ |

|

67 |

|

Injection pump non-return valve...................................................................................................................................... |

|

68 |

|

Injection pump P. No. 6590-249 - Plunger and barrel assembly ..................................................................................... |

|

70 |

|

Injection timing correction by changing the pad thickness .............................................................................................. |

|

72 |

|

Injector (pin type) ............................................................................................................................................................ |

|

72 |

|

Injector setting................................................................................................................................................................. |

|

72 |

|

Instrument for equalizing injection pump delivery ........................................................................................................... |

|

69 |

|

Test data of injection pump ............................................................................................................................................ |

|

70 |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 7 - |

- |

Chapter index |

|

9 |

ELECTRIC SYSTEM............................................................................................................................. |

73 - 82 |

|

Alternator type Iskra, AAK3139 14V 80A ..................................................................................................................... |

75 |

|

Alternator type Iskra, type AAK3570 28V 35A (for 24 V outfits)..................................................................................... |

77 |

|

Alternator type Marelli AA 125 R 14V 45A...................................................................................................................... |

73 |

|

Alternator type Marelli AA 125 R 14V 65A...................................................................................................................... |

74 |

|

Characteristic curves for alternator type AAK3570 28V 35A (for 24 V outfits)............................................................... |

77 |

|

Characteristic curves for alternator type Iskra, AAK3139 14V 80A ............................................................................. |

75 |

|

Characteristic curves for alternator type Marelli AA 125 R 14V 45A ............................................................................... |

73 |

|

Characteristic curves for alternator type Marelli AA 125 R 14V 65A ............................................................................... |

74 |

|

Characteristic curves for starting motor Iskra type AZE 4598 24V 3 kW ....................................................................... |

80 |

|

Characteristic curves for starting motor type Bosch EV 12V 2.2 kW ............................................................................. |

79 |

|

Characteristic voltage curve for regulator type AER 1528 .............................................................................................. |

75 |

|

Characteristic voltage curve for regulator type AER 1528 .............................................................................................. |

77 |

|

Characteristic voltage curve for regulator type RTT 119 AC ........................................................................................... |

73 |

|

Characteristic voltage curve for regulator type RTT 119 AC ........................................................................................... |

74 |

|

Connection diagram for preheating control unit .............................................................................................................. |

76 |

|

Connection diagram for preheating control unit .............................................................................................................. |

78 |

|

Coolant high temperature lamp switch............................................................................................................................ |

82 |

|

Glow plug controller relay with coolant temperature sensor ........................................................................................... |

81 |

|

Heavy starting conditions (max admitted): ...................................................................................................................... |

76 |

|

Heavy starting conditions (max admitted): ...................................................................................................................... |

78 |

|

Key switch electrical layout ............................................................................................................................................. |

79 |

|

Key switch electrical layout ............................................................................................................................................. |

80 |

|

Normal starting conditions:.............................................................................................................................................. |

76 |

|

Normal starting conditions:.............................................................................................................................................. |

78 |

|

Pre-heating glow plug ..................................................................................................................................................... |

81 |

|

Spacer flange for starter motor ....................................................................................................................................... |

80 |

|

Starting Motor 12V .......................................................................................................................................................... |

79 |

|

Starting Motor 24V .......................................................................................................................................................... |

80 |

|

Temperature sensor (Thermistor).................................................................................................................................... |

81 |

|

Thermistor for electric thermometer ................................................................................................................................ |

82 |

|

Thermistor for preheating water temperature – Thermal contact for water temperature indicator light .......................... |

82 |

|

Wiring diagram 24 V with alternator 35A......................................................................................................................... |

78 |

|

Wiring diagram with alternator 45A / 65A........................................................................................................................ |

76 |

10 |

SETTINGS ............................................................................................................................................ |

83 - 84 |

|

Application diagram for tampering system adjustment screw and |

|

|

torque gearing device for EPA-approved engines........................................................................................................... |

84 |

|

Fuel limiting device.......................................................................................................................................................... |

84 |

|

Fuel limiting device adjustment ....................................................................................................................................... |

84 |

|

Full speed setting in no-load conditions (standard)......................................................................................................... |

83 |

|

Idling speed setting in no-load conditions (standard)...................................................................................................... |

83 |

|

Injection pump delivery limiting and torque adjusting device .......................................................................................... |

83 |

|

Standard injection pump delivery setting without torque dynamometer.......................................................................... |

83 |

|

Stop setting ..................................................................................................................................................................... |

84 |

11 |

ENGINE STORAGE .................................................................................................................................... |

85 |

|

Engine storage ................................................................................................................................................................ |

85 |

|

Preparing the engine for operation after protective treatment......................................................................................... |

85 |

|

Protective treatment ........................................................................................................................................................ |

85 |

12 |

TORQUE SPECIFICATIONS AND USE OF SEALANT ...................................................................... |

86 - 87 |

|

Main torque specifications............................................................................................................................................... |

86 |

|

Table of tightening torques for standard screws (coarse thread) .................................................................................... |

87 |

|

Table of tightening torques for standard screws (fine thread)......................................................................................... |

87 |

13 |

SPECIAL TOOLS ........................................................................................................................................ |

88 |

- 8 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

GENERAL REMARKS AND SAFETY INFORMATION

1

1

WARRANTY CERTIFICATE

-The products manufactured by Lombardini Srl are warranted to be free from conformity defects for a period of 24 months from the date of delivery to the first end user.

-For engines fitted to stationary equipment, working at constant load and at constant and/or slightly variable speed within the setting limits, the warranty covers a period up to a limit of 2000 working hours, if the above mentioned period (24 months) is not expired.

-If no hour-meter is fitted , 12 working hours per calendar day will be considered.

-For what concerns the parts subject to wear and deterioration (injection/feeding system, electrical system, cooling system, sealing parts, non-metallic pipes, belts) warranty covers a maximum limit of 2000 working hours, if the above mentioned period (24 months) is not expired.

-For correct maintenance and replacement of these parts, it is necessary to follow the instructions reported in the documentation supplied with each engine.

-To ensure the engine warranty is valid, the engine installation, considering the product technical features, must be carried out by qualified personnel only.

-The list of the Lombardini authorized dealers is reported in the “Service” booklet, supplied with each engine.

-Special applications involving considerable modifications to the cooling/lubricating system (for ex.: dry oil sump), filtering system, turbo-charged models, will require special written warranty agreements.

-Within the above stated periods Lombardini Srl directly or through its authorized network will repair and/or replace free of charge any own part or component that, upon examination by Lombardini or by an authorized Lombardini agent, is found to be defective in conformity, workmanship or materials.

-Any other responsibility/obligation for different expenses, damages and direct/indirect losses deriving from the engine use or from both the total or partial impossibility of use, is excluded.

-The repair or replacement of any component will not extend or renew the warranty period.

Lombardini warranty obligations here above described will be cancelled if:

-Lombardini engines are not correctly installed and as a consequence the correct functional parameters are not respected and altered.

-Lombardini engines are not used according to the instructions reported in the “Use and Maintenance” booklet supplied with each engine.

-Any seal affixed to the engine by Lombardini has been tampered with or removed.

-Spare parts used are not original Lombardini.

-Feeding and injection systems are damaged by unauthorized or poor quality fuel types.

-Electrical system failure is due to components, connected to this system, which are not supplied or installed by Lombardini.

-Engines have been disassembled, repaired or altered by any part other than an authorized Lombardini agent.

-Following expiration of the above stated warranty periods and working hours, Lombardini will have no further responsibility for warranty and will consider its here above mentioned obligations for warranty complete.

-Any warranty request related to a non-conformity of the product must be addressed to the Lombardini Srl service agents.

GENERAL SERVICE MANUAL NOTES

1 - Use only genuine Lombardini repair parts.

Failure to use genuine Lombardini parts could result in sub-standard performance and low longevity.

2 - All data presented are in metric format. That is,

GLOSSARY AND TERMINOLOGY

dimensions are presented in millimeters (mm), torque is presented in Newton-meters (Nm), weight is presented in kilograms (Kg), volume is presented in liters or cubic centimeters (cc) and pressure is presented in barometric units (bar).

For clarity, here are the definitions of a number of terms used recurrently in the manual.

-Cylinder number one: is the piston timing belt side

«viewed from the flywheel side of the engine».

-Rotation direction: anticlockwise «viewed from the flywheel side of the engine».

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 9 - |

1 General remarks and safety information

SAFETY AND WARNING DECALS

-Important remarks and features of the text are highlighted using symbols, which are explained below:

Danger – Attention

This indicates situations of grave danger which, if ignored, may seriously threaten the health and safety of individuals.

SAFETY REGULATIONS

Caution – Warning

This indicates that it is necessary to take proper precautions to prevent any risk to the health and safety of individuals and avoid financial damage.

Important

This indicates particularly important technical information that should not be ignored.

•LOMBARDINI Engines are built to supply their performances in a safe and long-lasting way.

To obtain these results, it is essential for users to comply with the servicing instructions given in the relative manual along with the safety recommendations listed below.

•The engine has been made according to a machine manufacturer's specifications and all actions required to meet the essential safety and health safeguarding requisites have been taken, as prescribed by the current laws in merit.

All uses of the engine beyond those specifically established cannot therefore be considered as conforming to the use defined by LOMBARDINI which thus declines all liability for any accidents deriving from such operations.

•The following indications are dedicated to the user of the machine in order to reduce or eliminate risks concerning engine operation in particular, along with the relative routine maintenance work.

•The user must read these instructions carefully and become familiar with the operations described.

Failure to do this could lead to serious danger for his personal safety and health and that of any persons who may be in the vicinity of the machine.

•The engine may only be used or assembled on a machine by technicians who are adequately trained about its operation and the deriving dangers.

This condition is also essential when it comes to routine and, above all, extraordinary maintenance operations which, in the latter case, must only be carried out by persons specifically trained by LOMBARDINI and who work in compliance with the existing documentation.

•Variations to the functional parameters of the engine, adjustments to the fuel flow rate and rotation speed, removal of seals, demounting and refitting of parts not described in the operation and maintenance manual by unauthorized personnel shall relieve

LOMBARDINI from all and every liability for deriving accidents or for failure to comply with the laws in merit.

•On starting, make sure that the engine is as horizontal as possible, unless the machine specifications differ.

In the case of manual start-ups, make sure that the relative actions can take place without the risk of hitting walls or dangerous objects, also considering the movements made by the operator.

Pull-starting with a free cord (thus excluding self-winding starting only), is not permitted even in an emergency.

•Make sure that the machine is stable to prevent the risk of overturning.

•Become familiar with how to adjust the rotation speed and stop the engine.

•Never start the engine in a closed place or where there is insufficient ventilation.

Combustion creates carbon monoxide, an odourless and highly poisonous gas.

Lengthy stays in places where the engine freely exhausts this gas can lead to unconsciousness and death.

•The engine must not operate in places containing inflammable materials, in explosive atmospheres, where there is dust that can easily catch fire unles specific, adequate and clearly indicated precautions have been taken and have been certified for the machine.

•To prevent fire hazards, always keep the machine at least one meter from buildings or from other machinery.

•Children and animals must be kept at a due distance from operating machines in order to prevent hazards deriving from their operation.

•Fuel is inflammable.The tank must only be filled when the engine is off.

Thoroughly dry any spilt fuel and move the fuel container away along with any rags soaked in fuel or oil.

Make sure that no soundproofing panels made of porous material are soaked in fuel or oil.

Make sure that the ground or floor on which the machine is standing has not soaked up any fuel or oil.

•Fully tighten the tank plug each time after refuelling. Do not fill the tank right to the top but leave an adequate space for the fuel to expand. Fuel vapour is highly toxic. Only refuel outdoors or in a well ventilated place.

•Do not smoke or use naked flames when refuelling.

•The engine must be started in compliance with the specific instructions in the operation manual of the engine and/or machine itself. Do not use auxiliary starting aids that were not installed on the original machine (e.g. Startpilot’).

•Before starting, remove any tools that were used to service the engine and/or machine.

Make sure that all guards have been refitted.

•During operation, the surface of the engine can become dangerously hot. Avoid touching the exhaust system in particular.

•Before proceeding with any operation on the engine, stop it and allow it to cool.

- 10 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

General remarks and safety information 1

Never carry out any operation whilst the engine is running.

•The coolant fluid circuit is under pressure.

Never carry out any inspections until the engine has cooled and even in this case, only open the radiator plug or expansion chamber with the utmost caution, wearing protective garments and goggles. If there is an electric fan, do not approach the engine whilst it is still hot as the fan could also start operating when the engine is at a standstill.

Only clean the coolant system when the engine is at a standstill.

•When cleaning the oil-cooled air filter, make sure that the old oil is disposed of in the correct way in order to safeguard the environment.

The spongy filtering material in oil-cooled air filters must not be soaked in oil. The reservoir of the separator pre-filter must not be filled with oil.

•The oil must be drained whilst the engine is hot (oil T ~ 80°C). Particular care is required to prevent burns.

Do not allow the oil to come into contact with the skin.

•Pay attention to the temperature of the oil filter when the filter itself is replaced.

•Only check, top up and change the coolant fluid when the engine is off and cold.

Take care to prevent fluids containing nitrites from being mixed with others that do not contain these substances since "Nitrosamine", dangerous for the health, can form.

The coolant fluid is polluting and must therefore be disposed of in the correct way to safeguard the environment.

•During operations that involve access to moving parts of the engine and/or removal of rotating guards, disconnect and insulate the positive wire of the battery to prevent accidental short-circuits and to stop the starter motor from being energized.

•Only check belt tension when the engine is off.

•Only use the eyebolts installed by LOMBARDINI to move the engine.

These lifting points are not suitable for the entire machine; in this case, the eyebolts installed by the manufacturer should be used.

GENERAL SAFETY DURING OPERATING PHASES

–The procedures contained in this manual have been tested and selected by the manufacturer’s technical experts, and hence are to be recognised as authorised operating methods.

–Some tools are normal workshop ones, while others are special tools designed by the Manufacturer of the engine.

–All tools must be in good working condition so that engine components are not damaged and that operations are carried out properly and safely.

–It is important to wear the personal safety devices prescribed by work safety laws and also by the standards of this manual.

–Holes must be lined up methodically and with the aid of suitable equipment. Do not use your fingers to carry out this operation to avoid the risk of amputation.

–Some phases may require the assistance of more than one operator. If so, it is important to inform and train them regarding the type of activity they will be performing in order to prevent risks to the health and safety of all persons involved.

–Do not use flammable liquids (petrol, diesel, etc.) to degrease or wash components. Use special products.

–Use the oils and greases recommended by the manufacturer.

Do not mix different brands or combine oils with different characteristics.

–Discontinue use of the engine if any irregularities arise, particularly in the case of unusual vibrations.

–Do not tamper with any devices to alter the level of performance guaranteed by the manufacturer.

SAFETY AND ENVIRONMENTAL IMPACT

Every organisation has a duty to implement procedures to identify, assess and monitor the influence of its own activities

(products, services, etc.) on the environment.

Procedures for identifying the extent of the impact on the environment must consider the following factors:

-Liquid waste

-Waste management

-Soil contamination

-Atmospheric emissions

-Use of raw materials and natural resources

-Regulations and directives regarding environmental impact

In order to minimise the impact on the environment, the manufacturer now provides a number of indications to be followed by all persons handling the engine, for any reason, during its expected lifetime.

-All packaging components must be disposed of in accordance with the laws of the country in which disposal is taking place.

-Keep the fuel and engine control systems and the exhaust pipes in efficient working order to limit environmental and noise pollution.

-When discontinuing use of the engine, select all components according to their chemical characteristics and dispose of them separately.

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 11 - |

2

TECHNICAL INFORMATION

TECHNICAL INFORMATION

POSSIBLE CAUSES AND TROUBLE SHOOTING

THE ENGINE MUST BE STOPPED IMMEDIATELY WHEN:

1)- The engine rpms suddenly increase and decrease

2)- A sudden and unusual noise is heard

3)- The colour of the exhaust fumes suddenly darkens

4)- The oil pressure indicator light turns on while running.

TABLE OF LIKELY ANOMALIES AND THEIR SYMPTOMS

The following table contains the possible causes of some failures which may occur during operation. Always perform these simple checks before removing or replacing any part.

<![endif]>FUEL CIRCUIT

<![if ! IE]><![endif]>ELECTRIC SYSTEM

<![if ! IE]><![endif]>MAINTENANCE

<![if ! IE]><![endif]>SETTINGS REPAIRS

POSSIBLE CAUSE

Obstructed fuel line

Fuel filter clogged

Air or water leaks in fuel system The tank cap vent hole is clogged No fuel

Discharged battery

Cable connection uncertain or incorrect

Faulty starting switch

Faulty starting motor

Faulty glow plugs

Faulty glow plug control relay

Burnt fuse on preheating spark plugs

Clogged air filter

Excessive idle operation

Incomplete run-in

Overloaded engine

Incorrect governor linkage adjustment

Governor spring broken or unhooked

Low idle speed

Rings worn or sticking

Worn cylinder

Worn main con rod-rocker arm bearings

Badly sealed intake valve

Damaged cylinder head gasket

Defective timing system

Bent rods

Faulty hydraulic tappets

TROUBLE

| <![if ! IE]> <![endif]>Engine does not start |

<![if ! IE]> <![endif]>Engine starts but stops |

<![if ! IE]> <![endif]>No acceleration |

<![if ! IE]> <![endif]>Non-uniform speed |

<![if ! IE]> <![endif]>Black smoke |

<![if ! IE]> <![endif]>White smoke |

<![if ! IE]> <![endif]>Too low oil pressure |

<![if ! IE]> <![endif]>Overheats |

<![if ! IE]> <![endif]>Inadequate performance |

<![if ! IE]> <![endif]>Excessive oil consumption |

<![if ! IE]> <![endif]>High noise level |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 12 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

Technical information |

|

2 |

<![endif]>INJECTION

<![if ! IE]><![endif]>LUBRICATION CIRCUIT

<![if ! IE]><![endif]>COOLING CIRCUIT

POSSIBLE CAUSE

Damaged injector

Injection pump valve damaged

Injector not adjusted

Faulty fuel feeding pump

Hardened pump control rod

Broken or loose supplementary startup spring

Worn or damaged pumping element

Incorrecttuningofinjectioncomponents

(delivery balancing advance)

Cracked or broken precombustion chamber

Oil level too high

Oil level low

Oil pressure valve blocked or dirty

Worn oil pump

Oil sump suction line clogged

Faulty pressure gauge or pressure switch

Blocked draining pipe

Faulty spray nozzles (Turbo engines only).

Blocked draining pipe

Alternator fan belt loose or torn

Clogged radiator exchange surface

Insufficient coolant

Fault fan, radiator or radiator plug

Faulty thermostatic valve

Blockage inside the radiator or the coolant ducts

Coolant leaking from radiator, hoses, the crankcase or from the water pump

Faulty or worn water pump

TROUBLE

| <![if ! IE]> <![endif]>Engine does not start |

<![if ! IE]> <![endif]>Engine starts but stops |

<![if ! IE]> <![endif]>No acceleration |

<![if ! IE]> <![endif]>Non-uniform speed |

<![if ! IE]> <![endif]>Black smoke |

<![if ! IE]> <![endif]>White smoke |

<![if ! IE]> <![endif]>Too low oil pressure |

<![if ! IE]> <![endif]>Overheats |

<![if ! IE]> <![endif]>Inadequate performance |

<![if ! IE]> <![endif]>Excessive oil consumption |

<![if ! IE]> <![endif]>High noise level |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 13 - |

2 Technical information

MANUFACTURER AND MOTOR IDENTIFICATION DATA

B A D

C F E

|

|

|

|

|

1 |

|

|

|

|

|

|

||

2 |

|

|

|

|

|

3 |

|

|

|

|

|

||

4 |

|

|

|

|

|

5 |

|

|

|

|

|

||

6 |

|

|

|

|

||

|

|

|||||

|

|

|

|

|

7 |

|

|

|

|

|

|

||

|

|

|

|

|||

The identification plate shown in the figure can be found directly on the engine.

It contains the following information:

A)Manufacturer’s identity

B)Engine type

C)Engine serial number

D)Maximum operating speed

E)Number of the customer version (form K)

F)Approval data

Approval data

The approval reference directives EC are on the engine plate.

Plate for EPA regulations placed on the recoil starter or the rockerarm cap.

It contains the following information:

1)Current year

2)Engine displacement

3)Rated power, measured in kW

4)EPA family ID

5)Injection timing

6)Injection opening preassure

7)Valve clearance

- 14 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

Technical information |

|

2 |

OVERALL DIMENSIONS

LDW 1503-1603

A

B C P

D Q

E

J

K

R

L

F G H

M |

S |

N |

|

O |

|

|

T |

|

U |

|

|

|

|

|

|

|

|

|

|

|

Y |

W |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

Z |

|

|

|

|

|

|

|

|

V |

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

|

|

|

|

|

|

|

|

|

|

|

A1 |

B1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C1 |

|

D1 |

E1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note : Dimensions shown in mm |

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DIMENSIONS mm |

|

|

|

|

|

|||

A |

468 |

F |

208 |

|

L |

|

75 |

|

Q |

215.7 |

V |

|

70 |

A1 |

266 |

B |

235 |

G |

175 |

|

M |

|

220 |

|

R |

81 |

W |

|

356.4 |

B1 |

87 |

C |

233 max |

H |

147.5 |

|

N |

|

240 |

|

S |

348 |

X |

|

191 |

C1 |

99.6 |

D |

231.3 |

J |

250.2 |

|

O |

|

310 |

|

T |

250 |

Y |

|

283.3 |

D1 |

336 |

E |

425.2 |

K |

154.2 |

|

P |

|

171 |

|

U |

187.5 |

Z |

|

164 |

E1 |

68 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 15 - |

2 Technical information

LDW 2004 - 2204

B A C N O

D

E

J

P

K

F G H

L

M

Q

R

U S

V

TAPPO SCARICO ACQUA

WATER DRAIN PLUG

TAPPO SCARICO OLIO

OIL DRAIN PLUG

T

W

|

|

X |

Y |

Z |

A1 |

Note : Dimensions shown in mm

DIMENSIONS mm

A |

468 |

F |

208 |

L |

220 |

Q |

350 |

V |

164 |

A1 |

68 |

B |

235 |

G |

175 |

M |

240 |

R |

187.5 |

W |

366 |

|

|

C |

233 |

H |

156.5 |

N |

171 |

S |

356.3 |

X |

133 |

|

|

D |

231.3 |

J |

154.2 |

O |

215.7 |

T |

191 |

Y |

99.6 |

|

|

E |

425.2 |

K |

75 |

P |

81 |

U |

283.3 |

Z |

436 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- 16 - |

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

Technical information |

|

2 |

LDW 2004/T - 2204/T

F

A G

H

B J

C K

D L M N

E O

P

Q S R

T X

V

Y

W

U

Z

A1

B1

Note : Dimensions shown in mm

DIMENSIONS mm

A |

166.7 |

F |

350 |

L |

186.3 |

Q |

235 |

V |

224.8 |

A1 |

210 |

B |

195 |

G |

210 |

M |

366 |

R |

233.1 |

W |

156.5 |

B1 |

310 |

C |

153.5 |

H |

386.1 |

N |

68 |

S |

168.7 |

X |

373.2 |

|

|

D |

160 |

J |

164 |

O |

133 |

T |

452.5 |

Y |

133.5 |

|

|

E |

348 |

K |

190.5 |

P |

468.1 |

U |

208 |

Z |

220 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Workshop Manual LDW CHD _ cod. 1.5302.345 - 6° ed_rev. 05 |

- 17 - |

2 Technical information

TECHINICAL SPECIFICATIONS

|

|

|

|

|

ENGINE TYPE CHD |

|

LDW 1503 |

LDW 2004 |

LDW 2004/T |

|

|

|

|

|

|

|

|

|

|

|

Cylindres |

|

|

N. |

3 |

4 |

4 |

||

|

Bore |

|

|

mm |

88 |

88 |

88 |

||

|

Stroke |

|

|

mm |

85 |

85 |

85 |

||

|

|

|

|

|

|

|

|

|

|

|

Displacement |

|

|

Cm³ |

1551 |

2068 |

2068 |

||

|

Compression ratio |

|

|

|

22:1 |

22:1 |

22:1 |

||

|

R.P.M. |

|

|

|

3000 |

3000 |

3000 |

||

|

Power KW |

|

N |

80/1269/CEE-ISO 1585-DIN 70020 |

|

26.4 |

35 |

44.1 |

|

|

|

NB |

ISO 3046 - 1 IFN - DIN 6270 |

|

24.6 |

33.0 |

42.0 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NA ISO 3046 - 1 ICXN - DIN 6270 |

|

22.2 |

29.6 |

37.8 |

|

|

Max. torque * |

|

|

Nm @ RPM |

95.4 |

128 |

165.7 |

||

|

|

|

|

|

|

|

@ 2100 |

@ 2100 |

@ 2000 |

|

Max. torque 3rd + 4th p.t.o. |

Nm @ RPM |

39.2 |

39.2 |

39.2 |

||||

|

|

|

|

|

|

|

@ 3000 |

@ 3000 |

@ 3000 |

|

|

|

|

|

|

|

|

|

|

|

Oil consumption ** |

|

|

Kg/h |

0.024 |

0.032 |

0.04 |

||

|

Dry weight |

|

|

Kg |

155 |

190 |

195 |

||

|

Combustion air volume at 3000 r.p.m. |

l/min |

2326 |

3100 |

3900 |

||||

|

|

|

|

|

|

|

|

|

|

|

Cooling air volume at 3000 r.p.m. |

m3/min |

108.3 |

128 |

180 |

||||

|

Max. permissible driving shaft axial load in both directions |

Kg |

300 |

300 |

300 |

||||

|

|

|

|