EQUIPMENT OPERATION MANUAL

Cartesian 200, 300, 400 and 500 Series

Features II

Variables/ Commands/ Functions

Thank you for purchasing the Loctite® Robot.

*Read this manual thoroughly in order to properly use this robot.

Be sure to read “For Your Safety” before you use the robot. It will

protect you from possible dangers during operation.

*After having read this manual, keep it in a handy place so that you or

the operator can refer to it whenever necessary.

r

(

)

(g

)

plug p

y

y

(

)

FOR YOUR SAFETY

Safety Precautions

The precautions stated in this manual are provided for the customer to make the best use of this

product safely, and to provide preventive measures against injury to the customer or damage to

property.

Various symbols are used in this manual. Please read the following explanations to understand

what each symbol stands for.

Symbols indicating the Degree of Damage or Danger

The following symbols indicate the degree of damage or danger which may be incurred if you

neglect the safety notes.

Warnings

Cautions

Symbols indicating the type of Danger and Preventive Measures

The following symbols indicate the type of safety measure that should be taken.

Indicates the type of safety measure that should be taken.

Take care.

Indicates prohibition.

Never do this.

Do not disassemble, modif

Do not touch.

Indicates necessit

Be sure to follow instructions.

Be sure to un

Be sure to check grounding.

Be sure to foll o w the instruct ions

General caution

eneral prohibition

contact prohibition

These “Warnings” indicate the possibility of death or serious

injury.

These “Cautions” indicate the possibility of accidental injury o

damage to property.

or repair.

ower supply from wall outlet.

Features II CARTESIAN Benchtop Robot

i

FOR YOUR SAFETY

r

w

k

CARTESIAN Series

W a rnings

Operators who are involved in the programming, inspection and/o

maintenance of this robot must take the “special training course” for industrial

robots spec ified in Article 59 of the Occupational Health an d Safety La

and relevant ministry ordinances.

Do not leave the unit plugged in (power cord and connectors) when it is not in

use for long periods of time. Dust can cause fire.

Be sure to shut off the power supply before removing t he power cor d.

Change the robot’s battery periodically (approximately every three years)

to prevent malfunction or breakdown.

Keep the emergency stop switch within reach of an ope rator while

teaching and running the robot.

Failure to do so may cause danger since the robot cannot be stopped

immediately and safely.

Regularly check that the I/O-S circuits and emergency stop switch wor

properly.

Failure to do so may cause danger since the robot cannot be stopped

immediately and safely.

Features II CARTESIAN Benchtop Robot

ii

FOR YOUR SAFETY

W a rnings

Check the mounting screws regularly so that they are always firmly

tightened.

Loose screws may cause injury or defect.

Power the unit only with the rated voltage.

Excessive voltage can cause fire or malfunction of the unit.

Do not sprinkle water or oil on the unit, control box, or its cable.

Contact with water can cause electric shock, fire, or malfunction of the unit.

IP Protection Rating is IP40.

Features II CARTESIAN Benchtop Robot

iii

FOR YOUR SAFETY

A

A

A

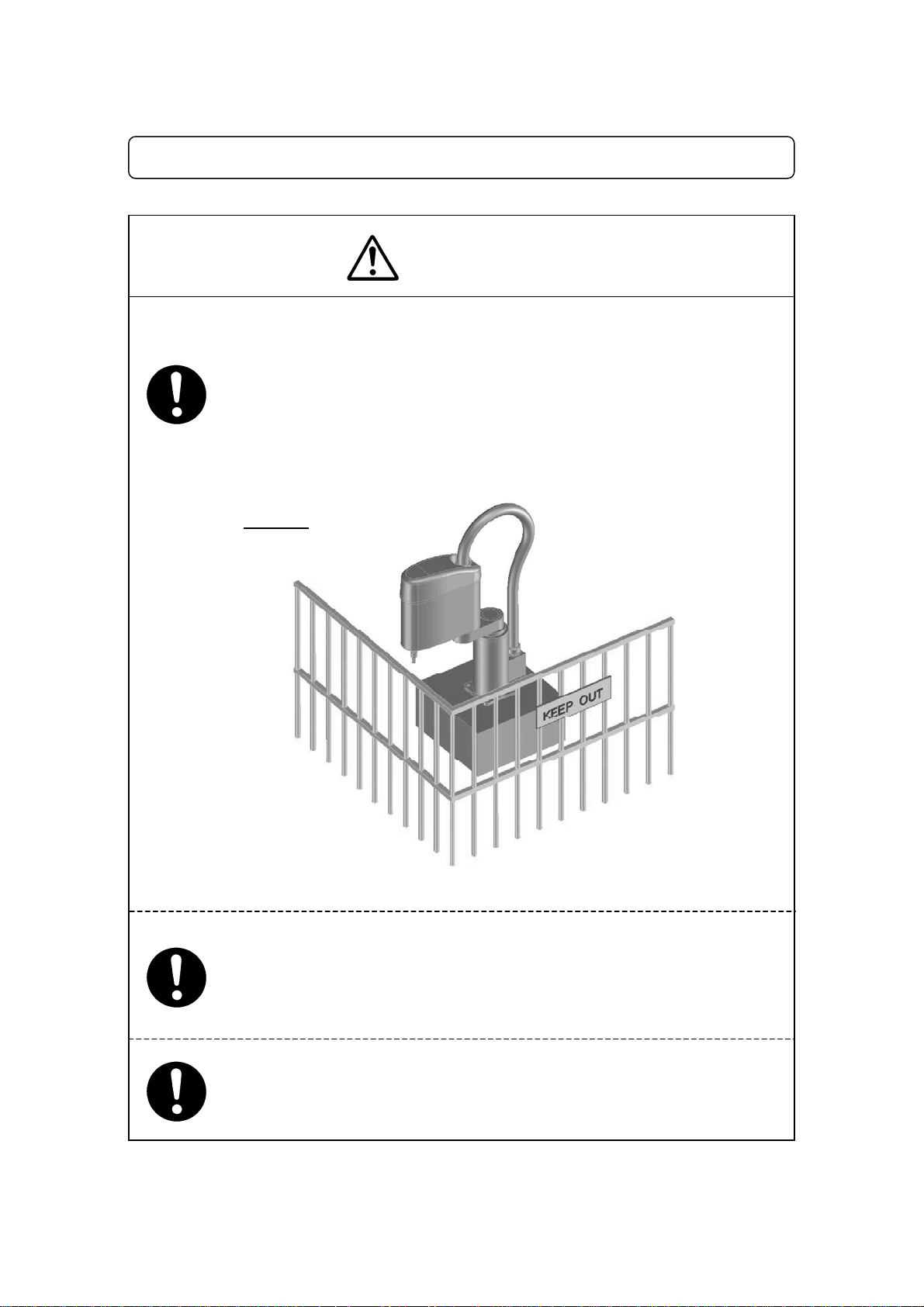

INSTALLATION

W a rnings

Always use a safety barrier .

person entering the robot’s restricted area may be injured.

t the entry/exit gate of the safety barrier, install an interlock that triggers

an emergency stop when the gate is opene d. Ensure there is no other

of entering the restricted area. Furthermore, put up a “No Entry” or

way

“No Operating” warning sign in a clearly visible position.

Example

Install a safety barrier of adequate strength so as to protect the

operator from moving tools and flying objects.

lways use protective wear (helmet, protective gloves, protective glasses,

and protective footwear) when going inside the safety barrier.

T ake a dequate precaut ions against objects the robot is gripping flying or

falling off t aking into account the object’s size, weight, temperature and

chemical composition.

Features II CARTESIAN Benchtop Robot

iv

t

A

FOR YOUR SAFETY

W a rnings

Confirm that the unit is properly grounded.

Power supply earth should be connected complying with Type D installation.

(under 100

Insufficient grounding can cause electric shock, fire, or malfunction of the unit.

Plug the power cord into the wall outlet firmly.

Incomplete insertion into the wall outlet makes the plug hot and can cause fire.

Check that the plug is not covered with dust.

Be sure to shut off the power supply before connecting the power cord to the

control box.

Place the unit on a suitable flat surface that can support its weight.

Be sure to leave a space greater than 30cm between the back of the robo

(equipped with a cooling fan) and the wall.

n insufficient or unstable area can cause the unit to fall, overturn, breakdown,

or overheat.

Do not attempt to disassemble or modify the machine.

Disassembly or modification may cause electric shocks, fire or malfunction.

Be sure to use within the voltage range indicated on the unit.

Failure to do so may cause electric shock or fire.

Do not use the unit near inflammable or corrosive gas.

If leaked gas accumulates around the unit, it can cause fire.

IP Protection Rating is IP40.

Place the unit in a well-ventilated area for the health and safety of the

operator .

T urn off the unit before inse rting a nd removing cables.

Failure to do so may result in electric shock, fire, or malfunction of the unit.

IP Protection Rating is

Ω of resistance.)

“IP40.”

Features II CARTESIAN Benchtop Robot

v

FOR YOUR SAFETY

W a rnings

Be sure to confirm that all the air tubes are connected correctly and firmly.

Use the robot in an environment between 0 to 40 degrees centigrade

with a humidity of 20 to 95 percent without condensation.

Failure to do so may result in malfunction. IP Protection Rating is

Use the robot in an environment where no electric noise is present.

Failure to do so may result in malfunction or defect.

Be sure to secure the movable parts of the robot before transportation.

Failure to do so may result in defect or injury.

Do not bump or jar the mac hine while it is being transpor ted or in st a lled.

This can cause defects.

Use the machine in an environment where it is not exposed to direct

sunlight.

Failure to do so may result in malfunction or defect.

Be sure to confirm that tools such as the electric screwdriver unit, etc.

are properly connected.

Failure to do so may result in injury or defect.

Be sure to check the wiring to the main unit.

Improper wiring may cause malfunction or defect.

Keep the emergency stop switch within reach of an ope rator while

teaching and running the robot.

Failure to do so may cause danger since the robot cannot be stopped

immediately and safely.

Be sure to shut off the power supply before plugging the power cord.

“IP40.”

Features II CARTESIAN Benchtop Robot

vi

FOR YOUR SAFETY

W a rnings

Be sure to remove the eye bolt after installing the robot so that it does

not hit the arm.

Failure to do so may result in injury or breakdown of the unit.

Features II CARTESIAN Benchtop Robot

vii

FOR YOUR SAFETY

A

WORKING ENVIRONMENT

When you lubricate or inspect the unit, unplug the power cord from

the control box.

Failure to do so may result in electric shock or injury.

Be sure to shut off the power supply before removing the power cord

from the control box.

When going inside the safety barrier, place a “Do Not Operate” sign on

the start switch.

During operation, always have t he e mergency stop switch within the

operator’s reach.

For the operator

quick and safe stop.

Install a safety barrier of ade quate st rength so as to protect operators

from moving tools and flying objects.

lways use protective wear (helmet, gloves, glasses, and footwear) when

going inside the safety barrier.

Be sure to confirm that all the air tubes are connected correctly and

firmly.

Always watch out for robot's movement, even in the teaching mode.

Special attention will protect the operator from injury.

W a rnings

’s safety, the emergency stop switch is necessary to make a

Features II CARTESIAN Benchtop Robot

viii

FOR YOUR SAFETY

f

DURING OPERATION

When operations are taking place within the safety barrier, ensure no one

enters the robot’s restricted area.

If you must go inside the safety barrier, be certain to push the emergency

stop switch and put a “Do Not Operate” sign on the start switch.

When starting the robot, check that, no one is within the safety barrier and

no object will interfere with the robot ope rating.

Under no circumsta nces sho uld y ou go inside the safety barrie r or

place your hands or hea d ins ide t he safety barr ier while t he r obot is

operating.

If anything unusual (e.g. a burning s mell) occ urs, stop opera tion and

unplug the cable immediately. Contact your dealer or the office listed

on the last page of this manual.

Continuous use without repair can cause electric shock, fire, or breakdown o

the unit.

During teaching, tests, and actual operat ion, al ways have the

Emergency stop switch within the operator’s reach.

For the operator

a quick and safe stop.

W a rnings

’s safety, the emergency stop switch is necessary to make

Features II CARTESIAN Benchtop Robot

ix

FOR YOUR SAFETY

CARTESIAN Series

W a rnings

Be sure to check grounding.

Improper grounding can cause electric shock or fire.

Be sure to use within the voltage range indicated on the unit.

Failure to do so may cause electric shock or fire.

Plug the power cord into the wall outlet firmly.

Failure to do so can cause the input to heat up and may result in fire.

Make sure that the power plug is clean.

Be sure to unplug the power cord from the wall outlet when you

examine or grease the machine.

Failure to do so may cause electric shock or fire.

Stop operation and unplug imme diately whenever y ou sense any

abnormalities, such as a pungent odor . Immediate ly cont act the

dealer from which you purchased the pr oduct.

Continued operation may result in electric shock, fire or malfunction.

Install the product in a place which can endure it’s weight and

conditions while running.

Be sure to leave a space greater than 30cm between the back of the robot

(equipped with a cooling fan) and the wall. Installation in an insufficient or

unstable place can cause the unit to fall, overturn, breakdown, or overheat.

Be sure to take protective measures such as installing an area sensor or

enclosure to avoid injury.

Entering the robot

Do not attempt to disassemble or modify the machine.

Disassembly or modification may cause electric shocks, fire or malfunction.

’s work range during operation could lead to injury.

Features II CARTESIAN Benchtop Robot

x

FOR YOUR SAFETY

W a rnings

Use the machine indoors where no flammable or corrosive gas is present.

Emission and accumulation of such gasses could lead to fire.

IP Protection Rating is

Be sure to unplug the power cord from the wall outlet if the robot will remain

unused for long periods of time.

Gathered dust could lead to fire.

Be sure to use power in the proper voltage range.

Failure to do so may result in fire or malfunction.

Keep the unit and the power cables away from water and oil.

Failure to do so may result in electric shock or fire.

T urn off the unit before inse rting a nd removing cables.

Failure to do so may result in electric shock, fire, or malfunction of the unit.

IP Protection Rating is

Keep the emergency stop switch within reach of an ope rator while

teaching and running the robot.

Failure to do so may lead to danger since the robot cannot be stopped

immediately and safely.

Regularly check that the emergency stop switch works properly.

For models with I/O-S circuits, also check that they work properly.

Failure to do so may lead to danger since the robot cannot be stopped

immediately and safely.

“IP30.” (“IP40” for CE specification)

“IP30.” (“IP40” for CE specification)

Features II CARTESIAN Benchtop Robot

xi

FOR YOUR SAFETY

Cautions

Be sure to check grounding.

Improper grounding may cause malfunction or defect.

Use the Benchtop Robot in an environment between 0 to 40 degrees

centigrade with a humidity of 20 to 95 percent without

condensation.

Failure to do so may result in malfunction.

IP Protection Rating is

Use the machine in an environment where no electric noise is

present.

Failure to do so may result in malfunction or defect.

Use the machine in an environment where it is not exposed to direct

sunlight. Failure to do so may result in malfunction or defect.

Be sure to confirm that tools such as the electric screwdriver unit,

etc. are properly connected.

Failure to do so may result in injury or defect.

Check the mounting screws regularly so that they are always firmly

tightened.

Loose screws may cause injury or defect.

Be sure to check the wiring to the main unit.

Improper wiring may cause malfunction or defect.

Be sure to secure the movable parts of the robot before transportation.

Failure to do so may result in defect or injury.

Do not bump or jar the machine while it is being transported or installed.

This can cause defects.

“IP30.” (“IP40” for CE specification)

Features II CARTESIAN Benchtop Robot

xii

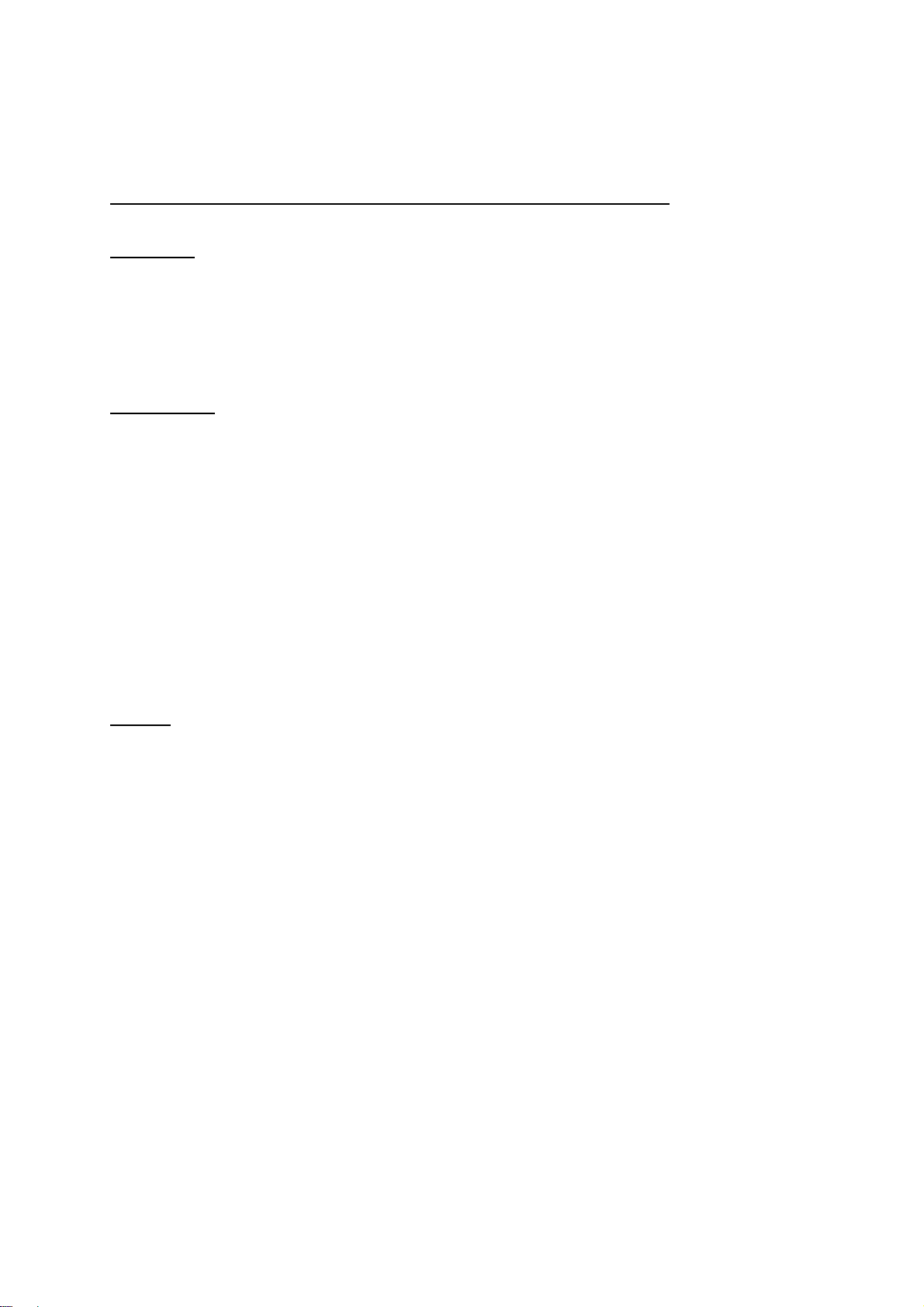

PREFACE

The Loctite

have succeeded in reducing price while maintaining functionality. Energy and space saving is made

possible through the combined use of stepping motors and special micro step driving circuits.

The Loctite

precision, and can accommodate a wide variety of requirements.

The operation manual consists of the following volumes.

Setup

Maintenance

Basic Instructions

Dispensing This volume explains dispensing applications for the Benchtop Series robot.

Quick Start

Teaching Pendant

Operation

PC Operation

Features I

Features II

Specifications

Note) The contents of this volume may be modified without prior notice to improve its quality.

® Benchtop Robot CARTESIAN Series is a new low cost, high performance robot. We

® Robot CARTESIAN Series features diverse applications, high speed, rigidity and

This volume explains how to set up the robot.

Therefore, it may not consistent with the specifications of the delivered series.

* For people who receive safety and installation instructions regarding the

robot.

This volume explains how to maintain the robot.

* For people who receive safety and installation instructions regarding the

robot.

This volume provides safety precautions, part names, and the basic knowledge

necessary to operate the Benchtop robot.

This volume explains the actual operation of the Benchtop robot with simple

running samples.

This volume explains how to operate the robot via the teaching pendant.

This volume explains how to operate the robot from a computer (JR C-Points.)

This volume explains point teaching.

This volume explains commands, variables, and functions.

This volume provides comprehensive specifications, including mechanical or

electrical requirements.

Features II CARTESIAN Benchtop Robot

xiii

Please be sure to follow the instructions described in these volumes. Proper use of the robot will

ensure continued functionality and high performance.

The contents described in this volume are based on the standard application. Menu items may

vary depending on models.

Be sure to shut off the power supply before plugging in the power cord.

BE SURE TO MAKE A PROPER GROUNDING WHEN YOU IN STALL THE ROBOT

Be sure to save data whenever it is added or modified. Otherwise, chang es will

not be saved if the power to the robot is cut off.

.

Features II CARTESIAN Benchtop Robot

xiv

CONTENTS

Features II

FOR YOUR SAFETY ______________________________________________________________ i

PREFACE ____________________________________________________________________ xiii

CONTENTS ____________________________________________________________________xv

EXPRESSION STRUCTURE_______________________________________________________ 1

COMMAND LIST ________________________________________________________________ 3

VARIABLE LIST _________________________________________________________________ 8

FUNCTION LIST _______________________________________________________________ 10

[ Variables ]____________________________________________________________________ 13

Free variables: #mv, #mkv, #nv, #nkv, #sv, #skv __________________________________ 13

Input variables:#sysIn1 to 15, #genIn1 to 18, #handIn1 to 4__________________________ 14

Output variables: #sysOut1 to 15, #genOut1 to 18, #handOut1 to 4 _____________________ 15

Down timer : #downTimer1 to 10 ______________________________________________ 15

Point job starting height : #jobStartHight _________________________________________ 16

Pallet : #palletflag (1 to 100), #palletCount (1 to 100) _______________________________ 17

Workpiece adjustment: #workAdj_X, #workAdj_Y,

#workAdj_Z, #workAdj_R, #workAdj_Rotation ______________________________________ 19

Point coordinates: #point_X,#point_Y,#point_Z,

#point_R,#point_TagCode _____________________________________________________ 21

Given point coordinates: #P_X, #P_Y, #P_Z, #P_R, #P_TagCode ____________________ 22

Given point coordinates in given programs: #prog_P_X,

#prog_P_Y, #prog_P_Z, #prog_P_R, #prog_P_TagCode _____________________________ 23

[ Functions ] ___________________________________________________________________ 24

Robot functions____________________________________________________________ 24

Arithmetic functions ________________________________________________________ 25

String functions ____________________________________________________________ 26

Features II CARTESIAN Benchtop Robot

xv

[ ON/OFF Output Control ] ________________________________________________________ 28

Outputting to I/O: set, reset, pulse, invPulse______________________________________ 28

Outputting after X second: delaySet, delayReset __________________________________ 31

Sounding an alarm buzzer: onoffBZ ____________________________________________ 32

Blinking the LED (Green): onoffGLED __________________________________________ 33

Blinking the LED (Red): onoffRLED ____________________________________________ 34

Outputting values from I/O: dataOut,dataOutBCD _________________________________ 35

[ If Branch, Wait Condition ] _______________________________________________________ 36

if Branch: if, then, else, endIf__________________________________________________ 36

Wait Condition: waitCond,waitCondTime,timeUp,endWait ___________________________ 38

[ Condition ] ___________________________________________________________________ 40

Condition Settings: ld, ldi, and, ani, or, ori, anb, orb ________________________________ 40

[ Delay, Data In, Wait Start ] _______________________________________________________ 43

Time Delay: delay__________________________________________________________ 43

Waiting for a start instruction: waitStart, waitStartBZ _______________________________ 45

Inputting from I/O: dataIn, dataInBCD___________________________________________ 47

[ Pallet Control ] ________________________________________________________________ 48

Pallet Command: loopPallet, resPallet, incPallet __________________________________ 48

[ Execution Flow Control ]_________________________________________________________ 51

Subroutine call of type setting job: callBase ______________________________________ 51

Subroutine call of point job data: callJob_________________________________________ 53

End of point job: returnJob ___________________________________________________ 55

Subroutine call of Program: callProg ___________________________________________ 56

Calling points: callPoints_____________________________________________________ 60

Ending a program: endProg __________________________________________________ 61

Assigning the returned value of a function: returnFunc______________________________ 62

Jumping to a specified point: goPoint, goRPoint, goCRPoint _________________________ 63

Jumping to a specified command line: jump, Label ________________________________ 65

[ For, Do-loop ] _________________________________________________________________ 66

For, Do-loop: for, next, exitFor, do, loop, exitDo ___________________________________ 66

Features II CARTESIAN Benchtop Robot

xvi

[ Controlling Tool Movement ]______________________________________________________ 68

Moving the Z axis: upZ, downZ, movetoZ________________________________________ 68

Moving straight in CP drive: lineMoveSpeed, lineMoveStopIf_________________________ 70

Executing mechanical initialization by a point job: initMec ___________________________ 72

Position error detection: checkPos _____________________________________________ 73

[ LCD, 7SLED ]_________________________________________________________________ 74

Displaying the specified strings on the teaching pendant:

clrLCD, clrLineLCD, outLCD, eoutLCD ______________________ 74

Displaying arbitrary numbers on the 7SLED: sys7SLED, out7SLED ___________________ 75

[ COM Input/Output ]_____________________________________________________________ 76

COM Input/Output: outCOM, eoutCOM, setCOM, _________________________________ 76

cmpCOM, ecmpCOM, clrCOM, shiftCOM___________________________ 76

PC Communication: stopPC, startPC___________________________________________ 80

[ Variables, Comments, System Control ]_____________________________________________ 81

Declaration and assignment of variable: declear, let________________________________ 81

Comment insertion: rem,crem ________________________________________________ 83

Changing a program number using point job: setProgNo ____________________________ 84

Changing a sequencer program using point job: setSeqNo __________________________ 85

Features II CARTESIAN Benchtop Robot

xvii

EXPRESSION STRUCTURE

Expression

An expression is fixed numbers, variables, functions (both of String type and Numeric type) and

operators combined.

Fixed Number

There are 2 types of fixed numbers, Numeric type (e.g.: 125, 2.0,2e15) and String type (e.g.: "ABC".)

String type fixed numbers, characters can be specified in hexadecimal code by using “%.” If you

want to display “%” on the screen, enter “%%.”

e.g.: eoutCOM port2,"%0D%0A"

If there is any character other than 0 to 9, A to F or % after “%”, “%” is dealt with as a

eoutCOM port2,"%%300"

character.

outputs CRLF code.

outputs %300.

Variable

A “variable” is a container into which a value such as numeric values or strings are placed.

Built-in variables, which are built-in as robot features, and user definition variables, which can be

freely defined, can be used with this robot.

User definition variables, other than local variables (variables effective only in defined point job data

defined by the “declear” command), are defined in the customizing mode. (Refer to the operation

manual “Features IV” for a description of the customizing mode.)

Boolean type: 1 bit variable. Keeps a value which is 1 (true)/0 (false) only.

Numeric type: Double type variable

String type: 255 byte variable

Features II CARTESIAN Benchtop Robot

1

Function

Function returns a converted value if values or strings are given.

Both built-in functions, which are built-in as robot features, and user definition functions, which can

be freely defined, can be used with this robot.

User definition functions are defined in the customizing mode.

Whether they are Numeric functions or String functions depends on the type of returned values.

Operator

Operator Description Value

>=,=>

<=、=<

<>,>< Returns 1 if the left value is not equal to the right value. 0 if they are equal. num,str

<Operator’s Priority>

+ Adds the left and right values. num

- Deducts the right value from the left value. num

* Multiplys the left and right values. num

/ Divides the left value by the right value. num

& Combines the left and right values. "A" & "B" "AB" str

= Assigns the right value to a left value. num,str

>

<

== Returns 1 if the left value is equal to the right value. 0 if they are not equal. num,str

1. Expression in brackets

2. Function, Variable

3. Independent “+”, “-“

4. “*”, “/”

5. “+”, “-“, “&”

6. Relational Operator (“>”, “>=”, “=>”, “=<”, “<=”, “<”, “<>”, “><”)

7. Assignment Operator (“=”)

Returns 1 if the left value is larger than the right value. 0 if the left value is

smaller or the same.

Returns 1 if the left value is smaller than the right value. 0 if the left value is

larger or the same.

Returns 1 if the left value is larger than the right value or the same. 0 if the

left value is smaller.

Returns 1 if the left value is smaller than the right value or the same. 0 if the

left value is larger.

num,str

num,str

num,str

num,str

Features II CARTESIAN Benchtop Robot

2

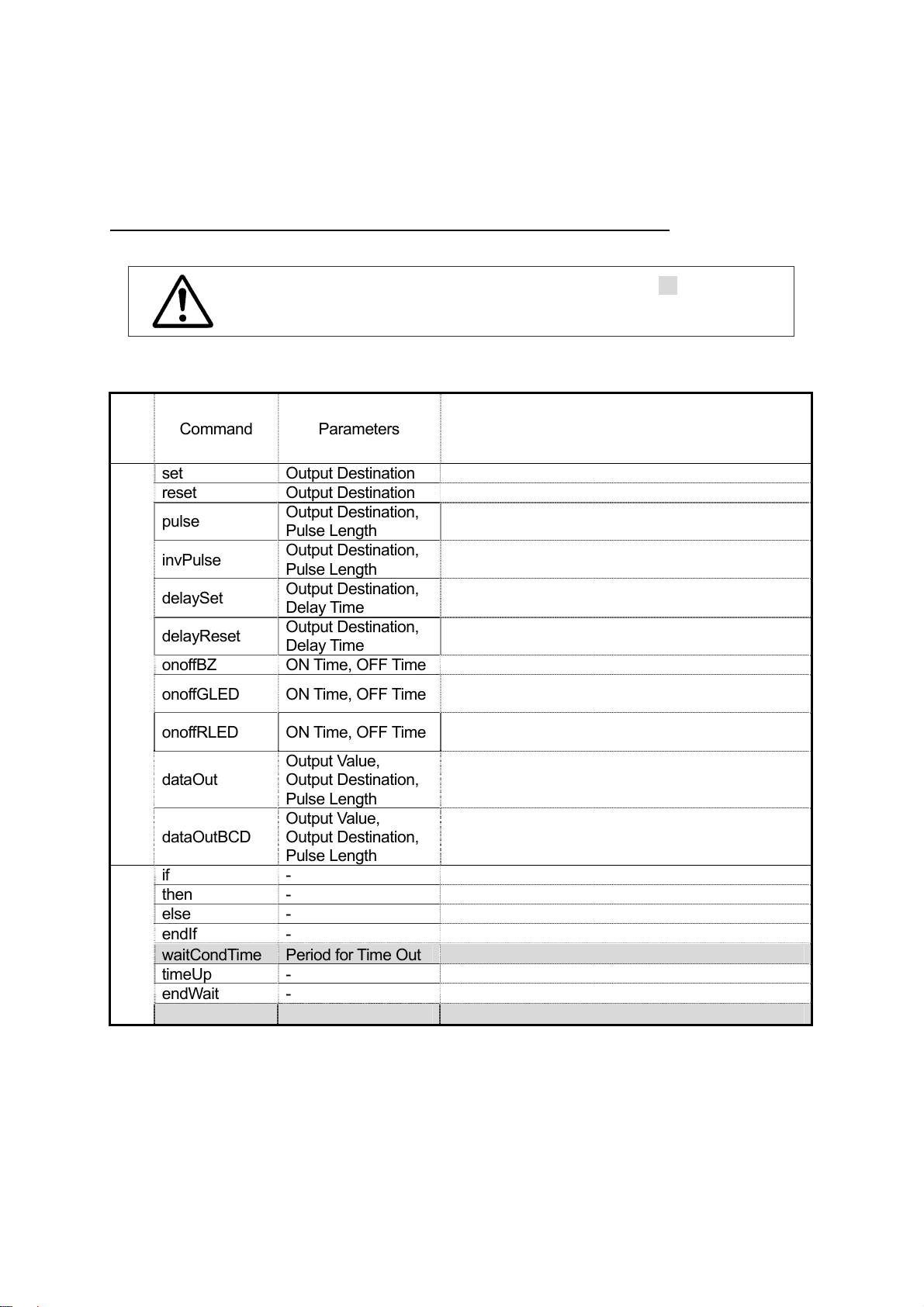

COMMAND LIST

Point Job Commands

Category

Command Parameters Content

set Output Destination ON output

reset Output Destination OFF output

pulse

invPulse

ON/OFF Output Control

delaySet

delayReset

onoffBZ ON Time, OFF Time Sounds an alarm buzzer off and on.

onoffGLED ON Time, OFF Time

onoffRLED ON Time, OFF Time

dataOut

dataOutBCD

if - if Branch

Wait Condition

then - Execute if true.

if Branch,

else - Execute if false.

endIf - End of if Branch

waitCondTime Period for Time Out Wait for conditions for a certain period

timeUp - Execute when time is up.

endWait - End of WAIT command

waitCond - Wait conditions.

If you assign point job data including one of the highlighted ( ) commands to

a CP Passing Point, this command will be ignored.

Output Destination,

Pulse Length

Output Destination,

Pulse Length

Output Destination,

Delay Time

Output Destination,

Delay Time

Output Value,

Output Destination,

Pulse Length

Output Value,

Output Destination,

Pulse Length

ON pulse output of specified pulse length

OFF pulse output of specified pulse length

ON output after specified delay time

OFF output after specified delay time

The LED (Green) on the front body blinks.

(for CARTESIAN only)

The LED (Red) on the front body blinks.

(for CARTESIAN only)

Outputs a tag code assigned to numeric data or a

point to I/O.

Outputs numeric data or a tag code assigned to a

point to I/O in BCD.

Features II CARTESIAN Benchtop Robot

3

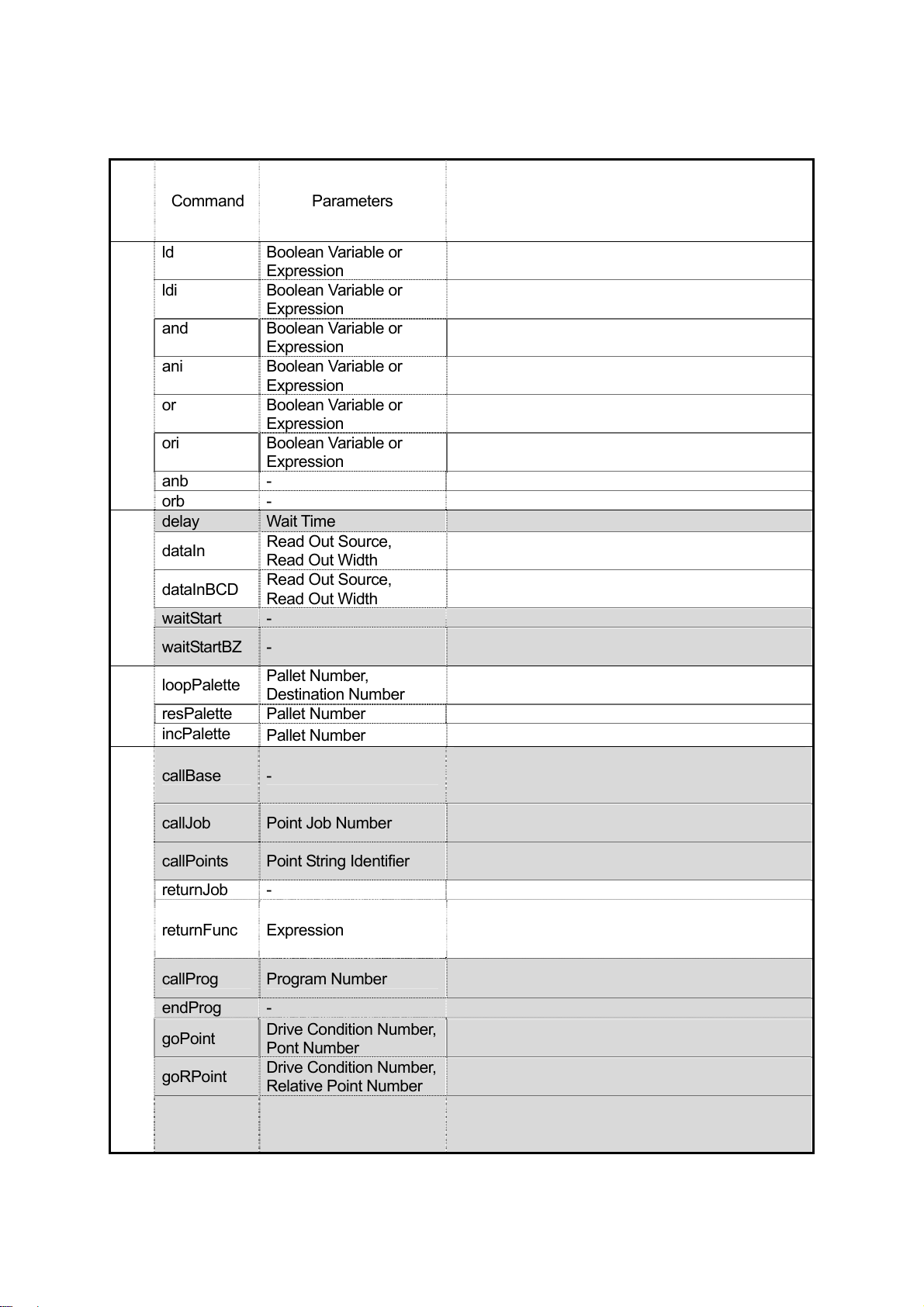

Category

Command Parameters Content

ld Boolean Variable or

Expression

ldi Boolean Variable or

Expression

and Boolean Variable or

Condition

Expression

ani Boolean Variable or

Expression

or Boolean Variable or

Expression

ori Boolean Variable or

Expression

ON input

OFF input

Serial ON input

Serial OFF input

Parallel ON input

Parallel OFF input

anb - Blocks serial connection

orb - Blocks parallel connection

delay Wait Time Stops for the specified time.

Read Out Source,

Read Out Width

Read Out Source,

Read Out Width

Reads out numeric data from I/O.

Reads numeric data in BCD from I/O.

Delay

dataIn

dataInBCD

waitStart - Waits for a start signal.

waitStartBZ -

Pallet

loopPalette

resPalette Pallet Number Resets pallet counter.

incPalette

Pallet Number,

Destination Number

Pallet Number

Increases pallet counter number. (+1)

Waits for a start signal while acknowledging an

error with an alarm buzzer.

Repetition loop of Pallet

Calls a point job defined by type at the user

callBase -

definition type point to which a Point Job Number

is set.

callJob Point Job Number

callPoints Point String Identifier

Execute Flow Control

returnJob -

Calls a subroutine of point job data specified by

number.

Executes a specified point string (defined in

Customising mode).

Point job end

Assigns a value of the specified expression as a

returnFunc Expression

callProg Program Number

endProg -

goPoint

goRPoint

Drive Condition Number,

Pont Number

Drive Condition Number,

Relative Point Number

Drive Condition Number,

goCRPoint

Destination Point

Selection

returned value and ends the function. (Valid in

functions only)

Calls a subroutine of a program specified by

number.

Program end.

Jumps to a specified point.

Jumps to a point specified relatively.

Jumps to a selected destination point during CP

drive.

Features II CARTESIAN Benchtop Robot

4

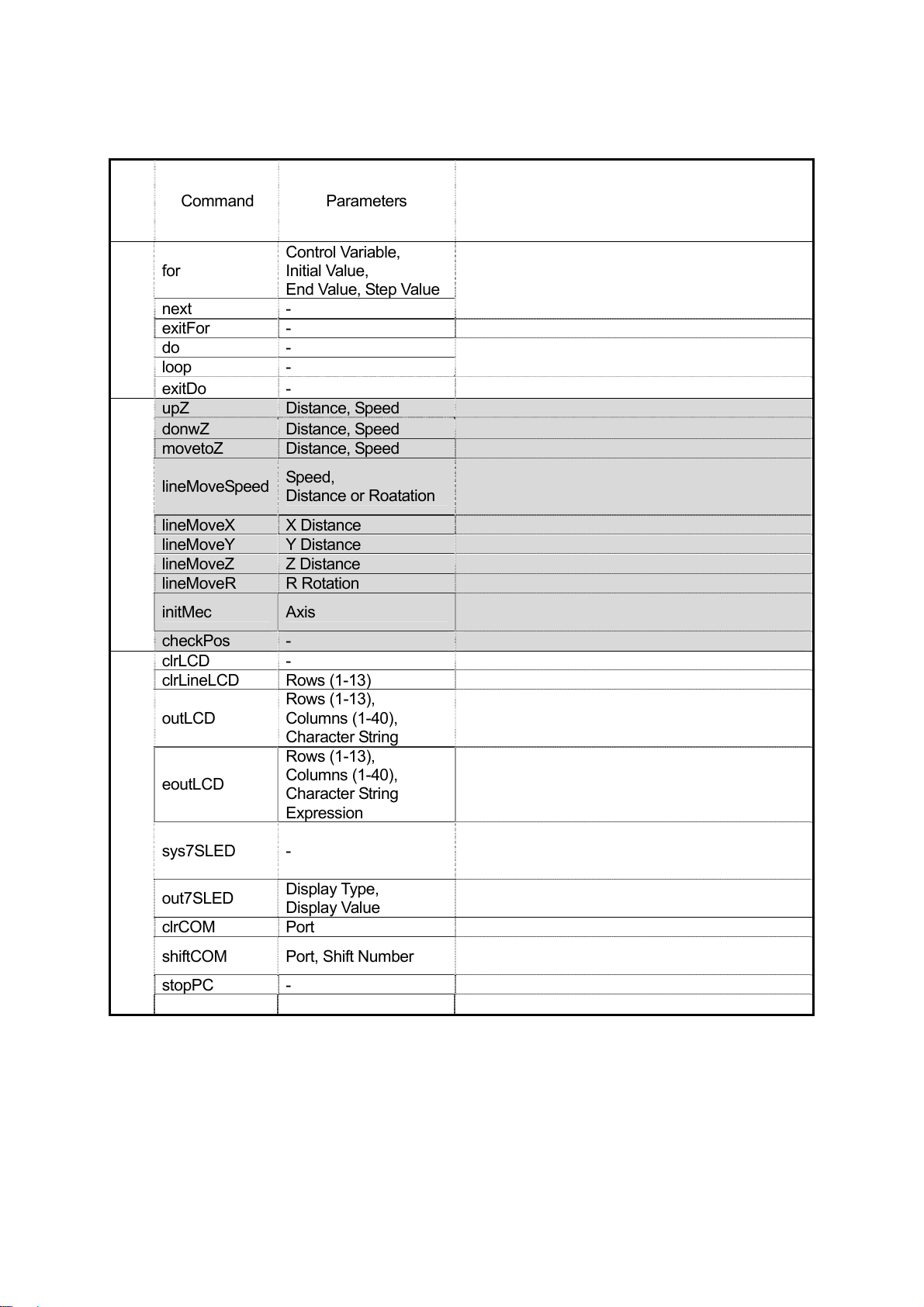

Category

for

for, do-loop

next -

exitFor -

do -

loop -

exitDo -

upZ Distance, Speed Up Z Axis.

donwZ Distance, Speed Down Z Axis.

movetoZ Distance, Speed Move Z Axis.

lineMoveSpeed

Move

lineMoveX X Distance Relative move command in the X direction

lineMoveY Y Distance Relative move command in the Y direction

lineMoveZ Z Distance Relative move command in the Z direction

lineMoveR R Rotation Relative move command in the R direction

initMec Axis

checkPos - Position error detection (for CARTESIAN only)

clrLCD - Clears the LCD display.

clrLineLCD Rows (1-13) Clears a specified line on the LCD display.

outLCD

LCD, 7SLED

eoutLCD

sys7SLED -

out7SLED

clrCOM Port Clears a buffer received from the COM.

shiftCOM Port, Shift Number

stopPC - Stops PC communication of COM1.

startPC - Starts PC communication of COM1.

Command Parameters Content

Control Variable,

Initial Value,

End Value, Step Value

Repeats commands from “for” to “next” until the

specified variable changes from Initial Value to

End value.

Exits “for” sentence.

Repeats commands from “do” to “loop.”

Exits from “do” sentence.

Speed,

Distance or Roatation

Shifts the specified distance (relative distance) at

the specified speed in CP line drive. (Relative

move command)

Mechanical initialization of a specified axis

(for CARTESIAN only)

Rows (1-13),

Columns (1-40),

Character String

Displays character strings on the LCD display.

Rows (1-13),

Columns (1-40),

Character String

Expression

Displays the result of a character string

expression on the LCD display.

Returns the display of the 7 segment LED

changed by ”out7SLED” to the previous program

Display Type,

Display Value

number. (for CARTESIAN only)

7 segment LED output (for CARTESIAN only)

Shifts data received from the COM.

Deletes data from the top to the Shift Number.

Features II CARTESIAN Benchtop Robot

5

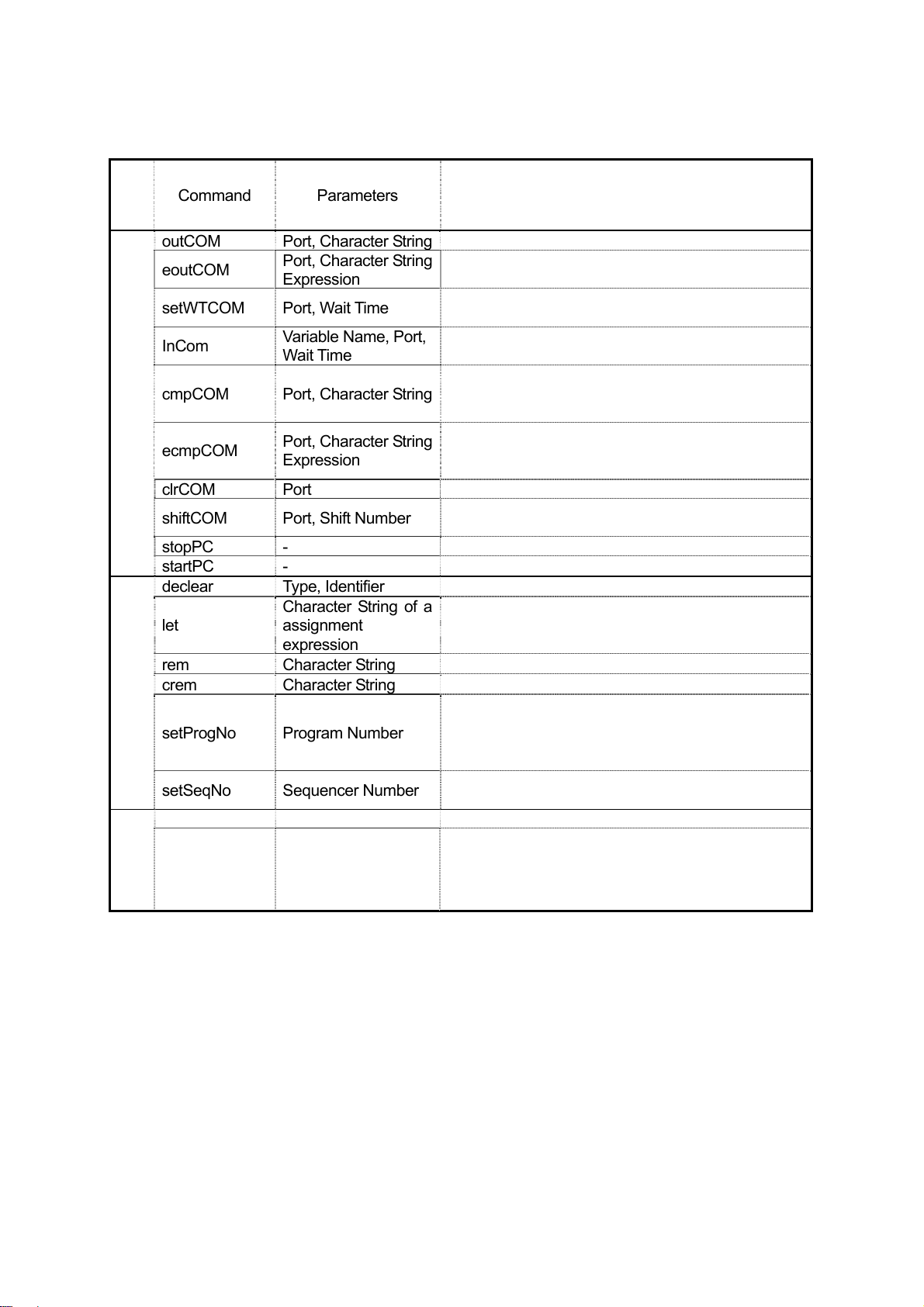

Category

Command Parameters Content

outCOM Port, Character String Outputs a character string from the COM.

eoutCOM

setWTCOM Port, Wait Time

COM Input/Output

InCom

cmpCOM Port, Character String

ecmpCOM

clrCOM Port Clears a buffer received from the COM.

shiftCOM Port, Shift Number

stopPC - Stops PC communication of COM1.

startPC - Starts PC communication of COM1.

declear Type, Identifier Declare a local variable.

Variable, Comment,

let

System Control

rem Character String One line comment

crem Character String Comment at the end of a command line

setProgNo Program Number

setSeqNo Sequencer Number

Z Sensor

Port, Character String

Expression

Variable Name, Port,

Wait Time

Port, Character String

Expression

Character String of a

assignment

expression

Outputs the result of an expression from the COM.

Sets Wait Time (Period for Time Out) for receiving

from the COM.

Assigns data received from the COM to the

specified variable.

Compares received data with a character string.

The result is entered into System Flag (sysFlag(1)

to (20).)

Compares received data with a character string

expression. The result is entered into System Flag

(sysFlag(1) to (20).)

Shifts data received from the COM.

Deletes data from the top to the Shift Number.

Assigns data calculated in the left-hand expression

to a variable in the right-hand expression.

+, -, *, /, =, (, ), & can be used.

Changes the Program number.

* Do not execute this command while running.

use the command “callProg.”

Changes the Sequencer program number of

“system data.”

If you want to run another program while running,

takeZWadj

Features II CARTESIAN Benchtop Robot

Work Adjustment

Number

Calculates the adjusting amount in the Z direction

with data gained from the Distance sensor/Touch

sensor using the [Workpiece Adjustment] setting.

6

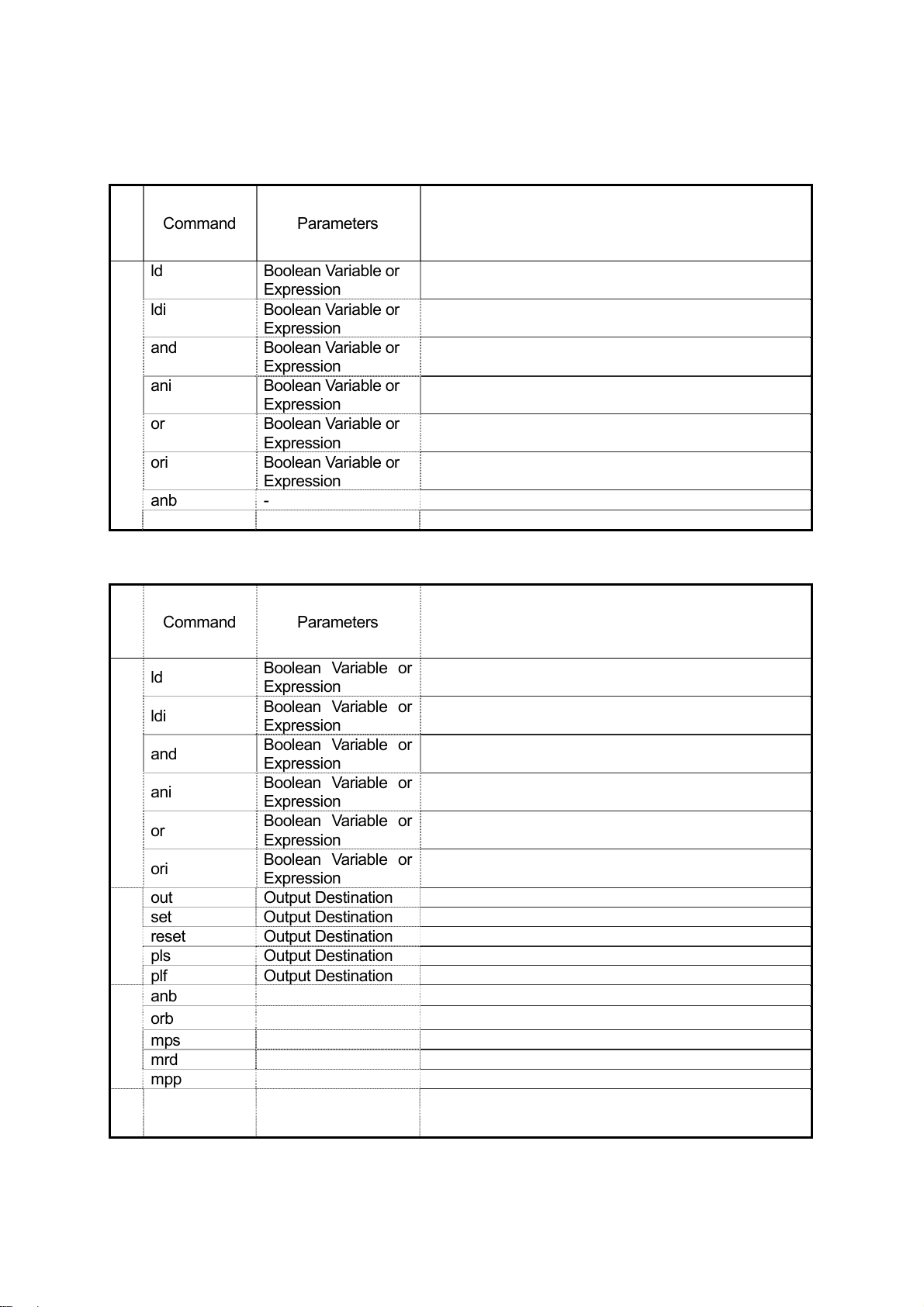

Execute Condition

Category

Command Parameters

ld Boolean Variable or

ldi Boolean Variable or

and Boolean Variable or

Condition

ani Boolean Variable or

or Boolean Variable or

ori Boolean Variable or

anb - Blocks serial connection

orb - Blocks parallel connection

Sequencer

Category

Expression

Expression

Expression

Expression

Expression

Expression

ON input

OFF input

Serial ON input

Serial OFF input

Parallel ON input

Parallel OFF input

Content

Command Parameters

ld

ldi

Condition

and

ani

or

ori

out Output Destination

set Output Destination

Coil

reset Output Destination

pls Output Destination

plf Output Destination

anb

Cnnection

orb

mps

mrd

mpp

Other

nop

Boolean Variable or

Expression

Boolean Variable or

Expression

Boolean Variable or

Expression

Boolean Variable or

Expression

Boolean Variable or

Expression

Boolean Variable or

Expression

ON input

Content

OFF input

Serial ON input

Serial OFF input

Parallel ON input

Parallel OFF input

Coil drive

Movement Holding Set

Movement Holding Reset

Output of the Leading Edge of Pulse

Output of the Trailing Edge of Pulse

Parallel Connection of Serial Circuit Blocks

Serial Connection of Parallel Circuit Blocks

Stores data in process of calculation

Reads out data in process of calculation

Reads out and resetting data in process of calculation

No process

Features II CARTESIAN Benchtop Robot

7

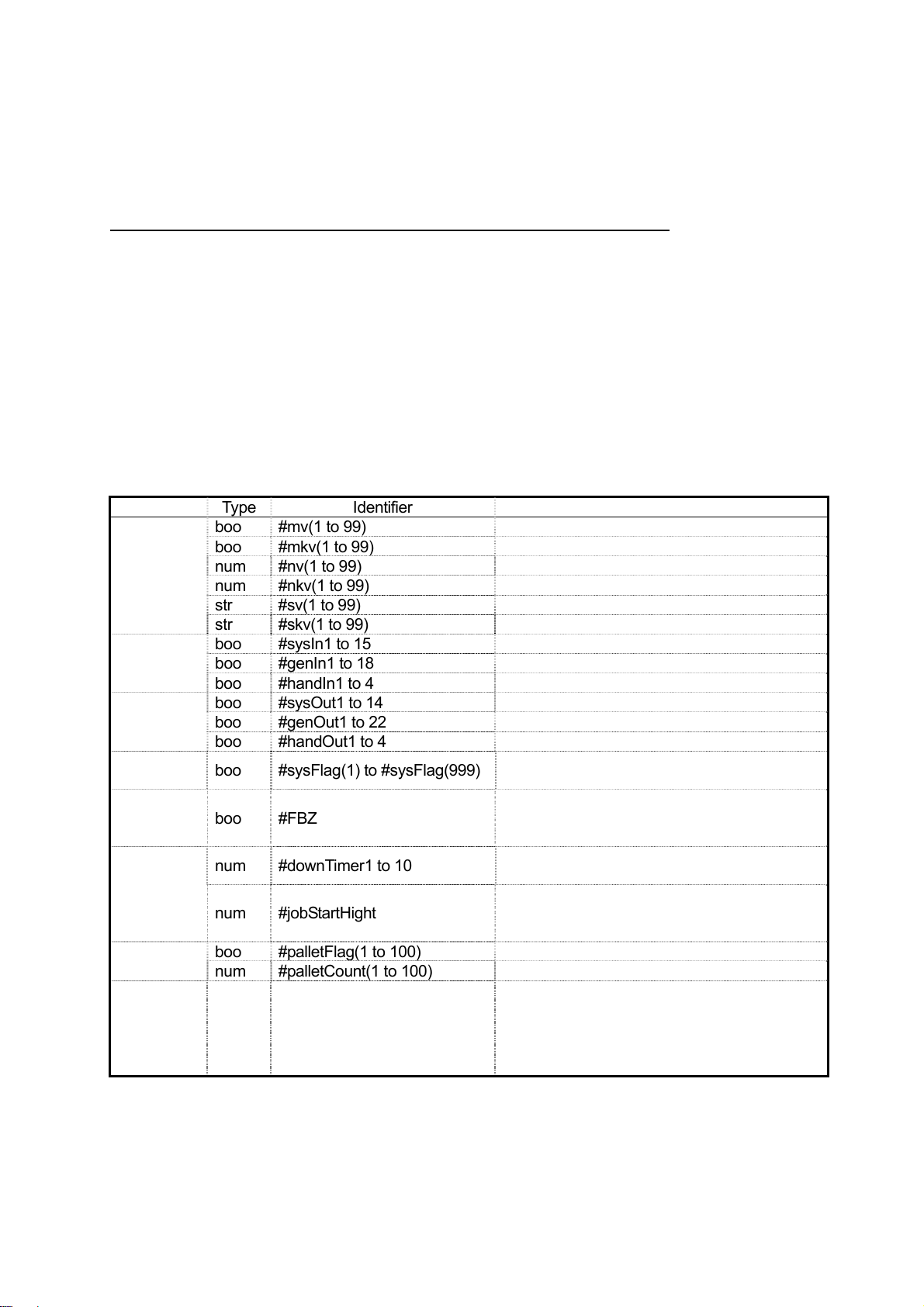

VARIABLE LIST

Built-in variables, which are built-in as robot functions, and user definition variables, which can be

freely defined, can be used with this robot.

User definition variables, except local variables (variables effective only in defined point job data

which are defined by the “declear” command), are defined in the customizing mode. (Refer to the

operation manual “Features IV” for a description of the customizing mode.)

Boolean type 1 bit variable (Holds only a value of 1 (true) or 0 (false).)

Numeric type 8 bytes real type (double type) variable.

String type 255 bytes variable

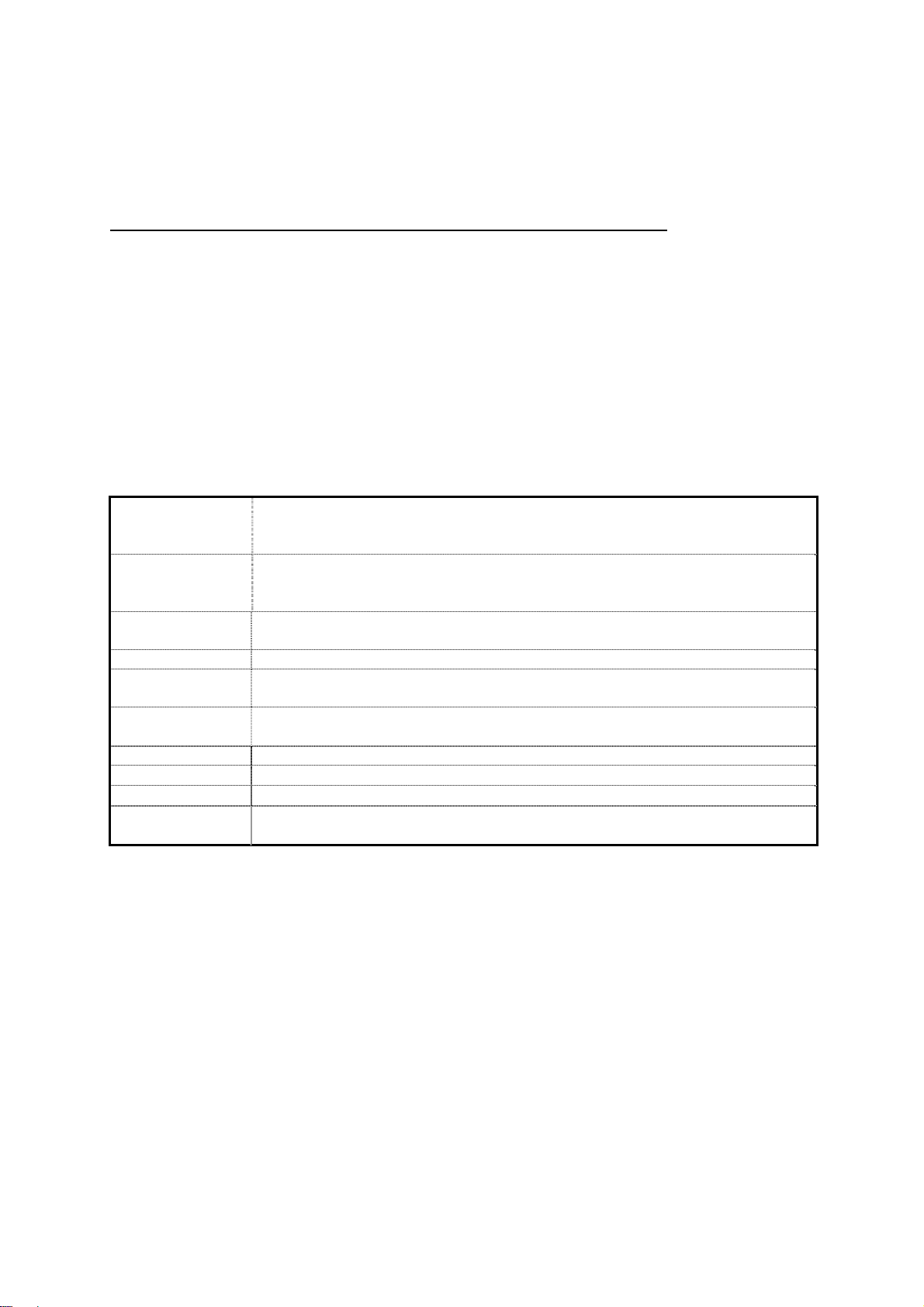

Category

Free

Variable

Input

Variable

Output

Variable

System

Flag

Special

Variable

Pallet

Workpiece

Adjustment

“Keeping variable” is a variable which holds its value even when the robot power is turned off.

Type Identifier Description

boo #mv(1 to 99) Boolean variable

boo #mkv(1 to 99) Boolean variable (keeping variable)

num #nv(1 to 99) Numeric variable

num #nkv(1 to 99) Numeric variable (keeping variable)

str #sv(1 to 99) String variable

str #skv(1 to 99) String variable (keeping variable)

boo #sysIn1 to 15 I/O-SYS

boo #genIn1 to 18 I/O-1

boo #handIn1 to 4 I/O-H

boo #sysOut1 to 14 I/O-SYS

boo #genOut1 to 22 I/O-1

boo #handOut1 to 4 I/O-H

boo #sysFlag(1) to #sysFlag(999) Refer to the system flag table.

boo #FBZ

num #downTimer1 to 10

num #jobStartHight

boo #palletFlag(1 to 100) Pallet flag (corresponds to pallet 1 to 100)

num #palletCount(1 to 100) Pallet counter (corresponds to pallet 1 to 100)

#workAdj_X(1 to 100)

#workAdj_Y(1 to 100)

num

#workAdj_Z(1 to 100)

#workAdj_R(1 to 100)

#workAdj_Rotation(1 to 100)

set #FBZ : Sound buzzer.

reset #FBZ : Stop buzzer. Buzzer

(onoffBZ : Sound buzzer intermittently.)

When a value is assigned, it counts down

automatically. (msec units)

Start a point job from an assigned value

above the set point Z coordinate. (Disabled in

CP drive)

Workpiece adjustment amount of each axis

(Corresponds to workpiece adjustment 1 to

100)

Features II CARTESIAN Benchtop Robot

8

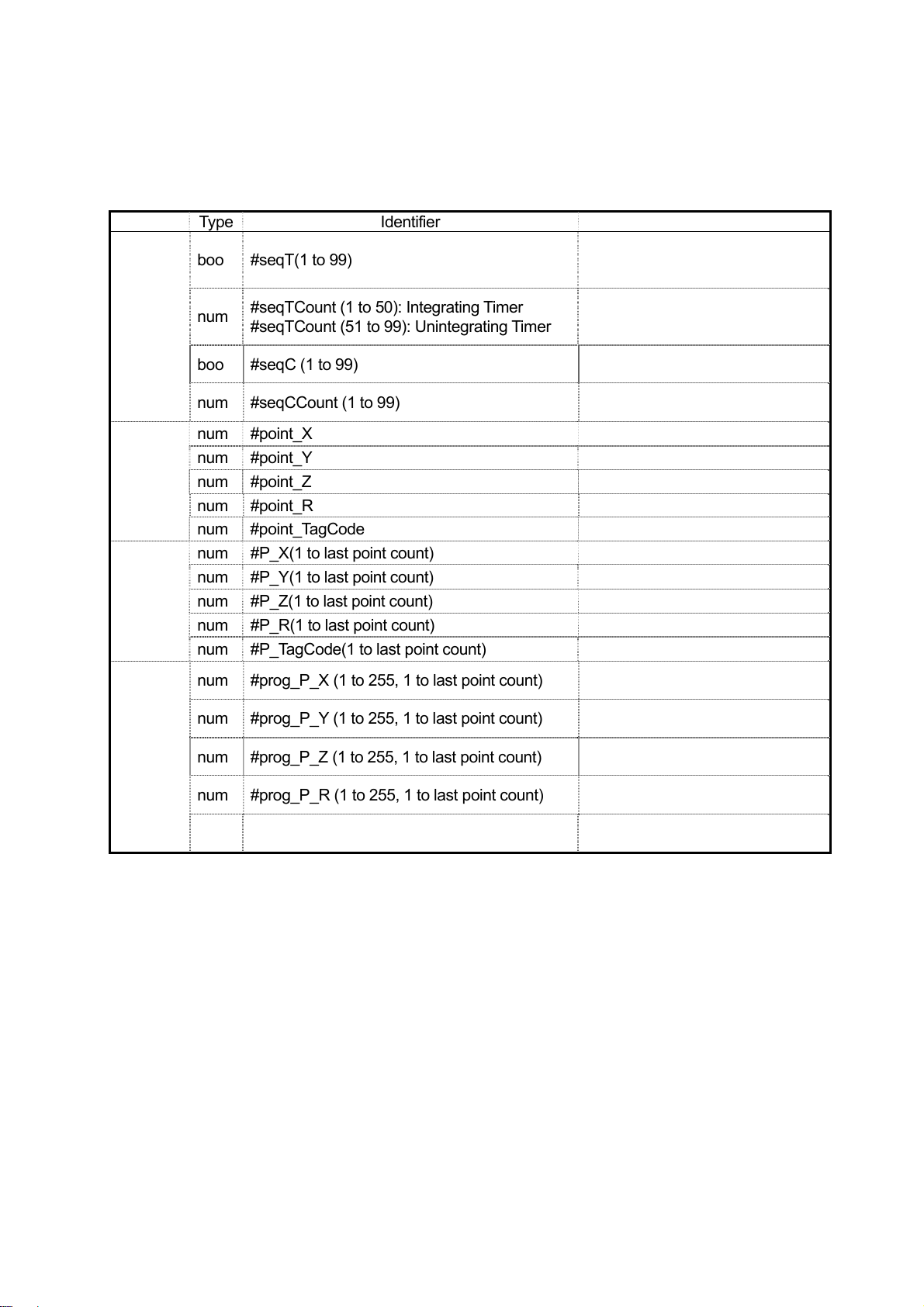

Vari able s]

[

Category Type Identifier

coordinates

coordinates

Given point coordinates

Sequencer program

boo #seqT(1 to 99)

num

boo #seqC (1 to 99)

num #seqCCount (1 to 99)

Current point

num #point_X X coordinate value of current point

num #point_Y Y coordinate value of current point

num #point_Z Z coordinate value of current point

num #point_R R coordinate value of current point

num #point_TagCode Tag code value of current point

num #P_X(1 to last point count) X coordinate value of given point

Given point

num #P_Y(1 to last point count) Y coordinate value of given point

num #P_Z(1 to last point count) Z coordinate value of given point

num #P_R(1 to last point count) R coordinate value of given point

num #P_TagCode(1 to last point count) Tag code value of given point

num #prog_P_X (1 to 255, 1 to last point count)

Given program

num #prog_P_Y (1 to 255, 1 to last point count)

num #prog_P_Z (1 to 255, 1 to last point count)

num #prog_P_R (1 to 255, 1 to last point count)

num

#seqTCount (1 to 50): Integrating Timer

#seqTCount (51 to 99): Unintegrating Timer

#prog_P_TagCode (1 to 255, 1 to last point

count)

Description

Set to 1 when #seqTCount

reaches the given value or

greater.

One counter can count from 0.001

to 2,147,483,647 seconds. (0.001

sec increment)

1 when #seqCCount reaches the

given value or greater.

One counter can count from 1 to

2,147,483,657.

X coordinate value of given

program and given point.

Y coordinate value of given

program and given point.

Z coordinate value of given

program and given point.

R coordinate value of given

program and given point.

Tag code value of given program

and given point

Features II CARTESIAN Benchtop Robot

9

FUNCTION LIST

Built-in functions, which are built in as robot functions, and user definition functions, which can be

freely defined, can be used with this robot.

User definition functions are defined in the customizing mode. (Refer to the operation manual

“Features IV” for a description of the customizing mode.)

x, y: Numeric value or numeric variable

n, m: Numeric value made a certain digit or greater by rounding or truncation

a, b: String or string variable

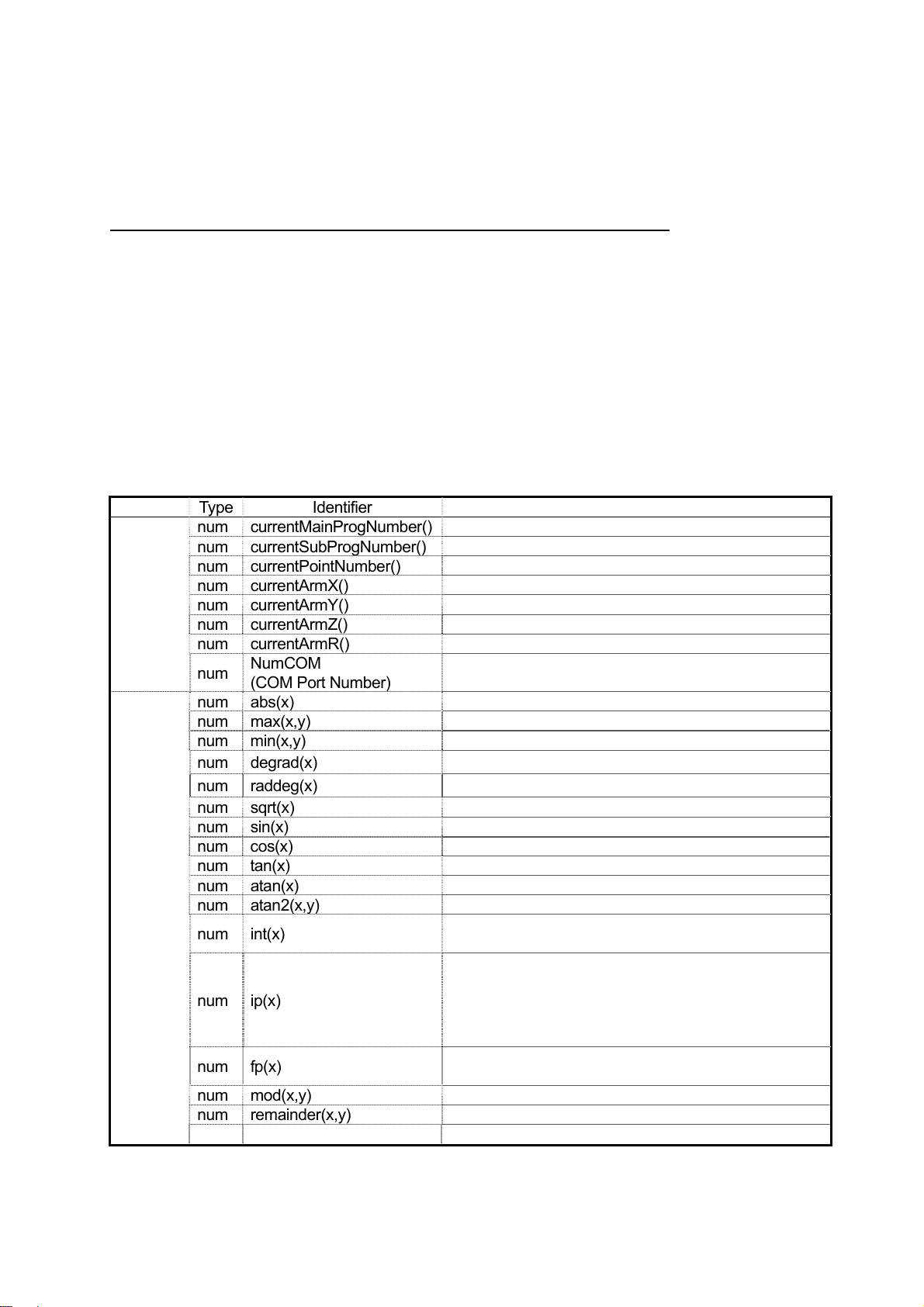

Category

Robot system

Arithmetic system

Type Identifier Description

num currentMainProgNumber() Main program No. currently running

num currentSubProgNumber() Subprogram No. currently running

num currentPointNumber() Point No. currently running

num currentArmX() Current arm coordinate X, [mm] units

num currentArmY() Current arm coordinate Y, [mm] units

num currentArmZ() Current arm coordinate Z, [mm] units

num currentArmR() Current arm coordinate R, [degree] units

num

num abs(x) Absolute value

num max(x,y) Maximum value

num min(x,y) Minimum value

num degrad(x)

num raddeg(x)

num sqrt(x) Square root

num sin(x) Sine

num cos(x) Cosine

num tan(x) Tangent

num atan(x) Arc tangent

num atan2(x,y) Arc tangent

num int(x)

num ip(x)

num fp(x)

num mod(x,y) Value of x which makes y modulo x-y*int (x/y)

num remainder(x,y) Remainder of dividing x by y x-y*ip (x/y)

num pow(x,y) x to the power of y

NumCOM

(COM Port Number)

Data byte count of COM receiving port

Conversion from degree to radian (x* π/180)

Conversion from radian to degree (x*180/π)

Large integer that does not exceed x.

Ex: int (1.3)=1, int (-1.3)=-2

Integer part of x. sgn (x)*int (abs(x))

(When x is a negative number, sgn (x) becomes -1

and when x is a positive number, sgn (x) becomes

+1.)

Ex: ip (1.3)=1, ip (-1.3)=-1

Decimal part of x x-ip (x)

Ex: fp (1.3)=0.3, fp (-1.3)=-0.3

Features II CARTESIAN Benchtop Robot

10

x, y: Numeric value or numeric variable

n, m: Numeric value made a certain digit or greater by rounding or truncation

a, b: String or string variable

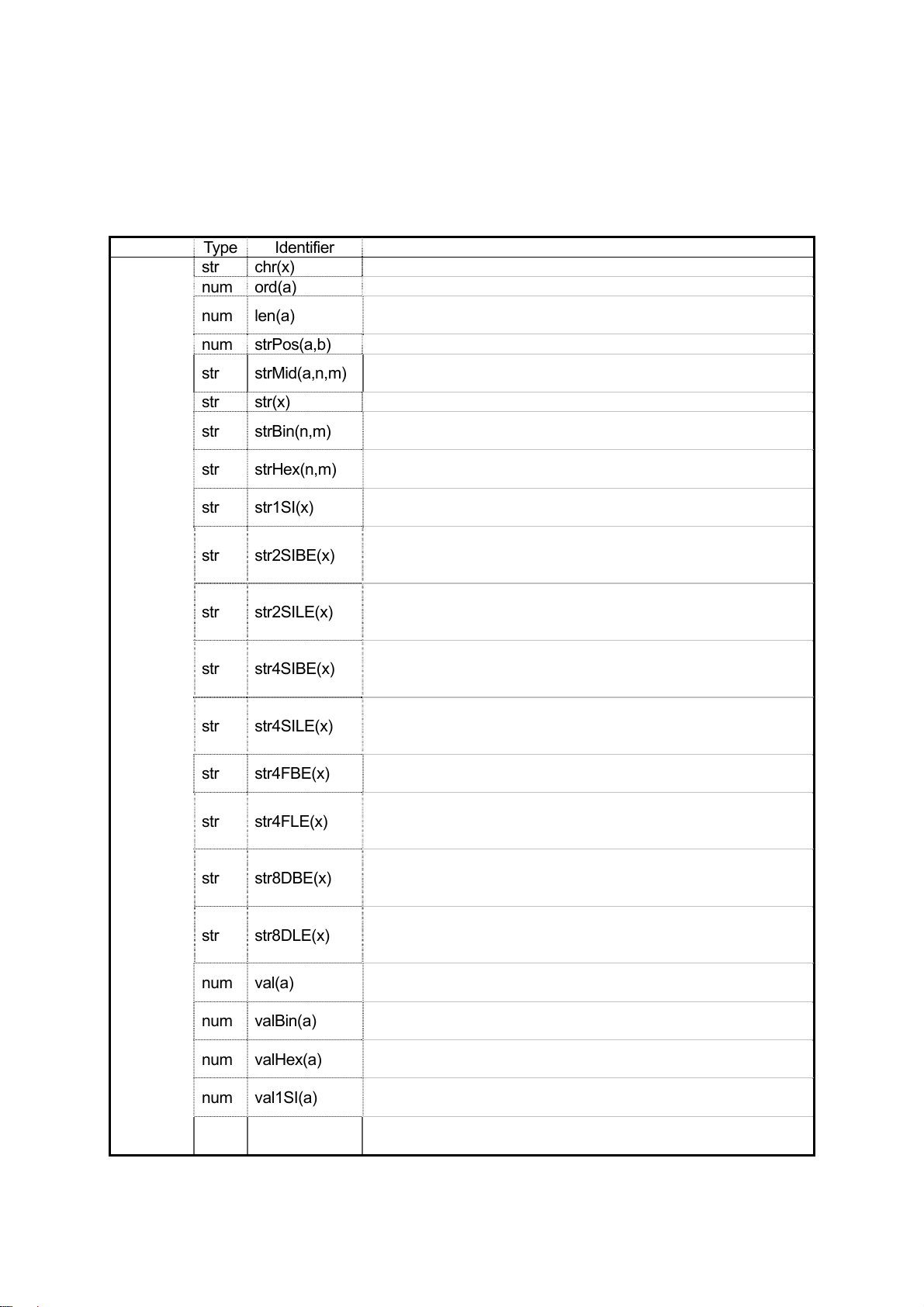

Category Type Identifier Description

str chr(x) Returns a string (1 character) with the given character code.

num ord(a) Returns the top string code. Other codes are ignored.

num len(a)

num strPos(a,b) Returns the first part string position matching b in a.

str strMid(a,n,m)

str str(x) Converts a numeric value to a decimal string.

str strBin(n,m)

str strHex(n,m)

str str1SI(x)

str str2SIBE(x)

str str2SILE(x)

String system

str str4SIBE(x)

str str4SILE(x)

str str4FBE(x)

str str4FLE(x)

str str8DBE(x)

str str8DLE(x)

num val(a)

num valBin(a)

num valHex(a)

num val1SI(a)

num val2SIBE(a)

Returns the string length (byte length).

Does not handle multiple byte codes.

Returns a character string from the n th to the m th characters,

counting from the top of character string a.

Converts a numeric value to a binary string.

m: Number of binary string digits

Converts a numeric value to a hexadecimal string.

m: Number of hexadecimal string digits

Rounds a numeric value to a 1 byte signed integer, and

converts it to a 1 byte string. (1 byte Signed Integer)

Rounds a numeric value to a 2 byte signed integer and

converts it to a 2 byte string big endian.

(2 byte Signed Integer Big Endian)

Rounds a numeric value to a 2 byte signed integer and

converts it to a 2 byte string little endian.

(2 byte Signed Integer Little Endian)

Rounds a numeric value to a 4 byte signed integer and

converts it to a 4 byte string big endian. (4 byte Signed Integer

Big Endian)

Rounds a numeric value to a 4 byte signed integer and

converts it to a 4 byte string little endian.

(4 byte Signed Integer Little Endian)

Regards a numeric value as a floating decimal and converts it

to 4 byte string big endian. (4 byte Float Big Endian)

Regards a numeric value as a floating decimal and converts it

to 4 byte string little endian.

(4 byte Float Little Endian)

Regards a numeric value as a double floating decimal and

converts it to 8 byte string big endian.

(8 byte Double Big Endian)

Regards a numeric value as a double floating decimal and

converts it to 8 byte string little endian.

(8 byte Double Little Endian)

Regards a string as a decimal string and converts it to a

numeric value.

Regards a string as a binary string (list of “0” and “1”) and

converts it to a numeric value.

Regards a string as a hexadecimal string (list of “0” to “1”, “A”

to “F”,, or “a” to “f”) and converts it to a numeric value.

Regards the top character as a 1 byte signed integer and

converts it. (1 byte Signed Integer )

Regards the top 2 characters as a 2 byte signed integer big

endian and converts it. (2 byte Signed Integer Big Endian )

Features II CARTESIAN Benchtop Robot

11

x, y: Numeric value or numeric variable

n, m: Numeric value made a certain digit or greater by rounding or truncation

a, b: String or string variable

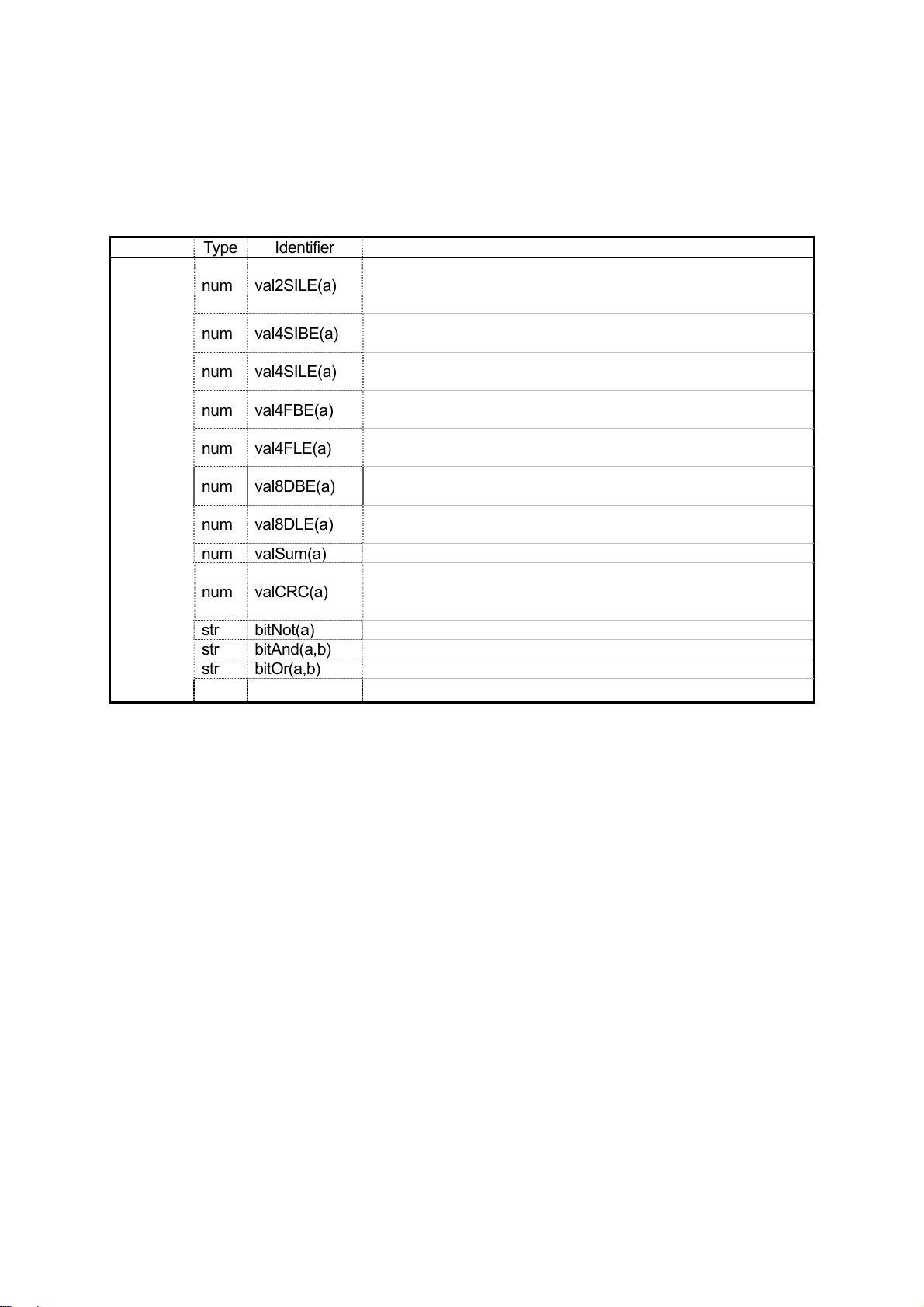

Category Type Identifier Description

Regards the top 2 characters as a 2 byte signed integer little

num val2SILE(a)

num val4SIBE(a)

num val4SILE(a)

num val4FBE(a)

String system

num val4FLE(a)

num val8DBE(a)

num val8DLE(a)

endian and converts it.

(2 byte Signed Integer Little Endian)

Regards the top 4 characters as a 4 byte signed integer big

endian and converts it. (4 byte Signed Integer Big Endian )

Regards the top 4 characters as a 4 byte signed integer little

endian and converts it. (4 byte Signed Integer Little Endian )

Regards the top 4 characters as a floating decimal big endian

and converts it. (4 byte Float Big Endian )

Regards the top 4 characters as a floating decimal little endian

and converts it. (4 byte Float Little Endian )

Regards the top 8 characters as a double floating decimal big

endian and converts it. (8 byte Double Big Endian )

Regards the top 8 characters as a double floating decimal little

endian and converts it. (8 byte Double Little Endian )

num valSum(a) Returns the sum of a string code added from top to bottom.

Remainder of dividing a character string as a bit string by

num valCRC(a)

str bitNot(a) Bit inversion

str bitAnd(a,b) Bit logical multiple

str bitOr(a,b) Bit logical add

str bitXor(a,b) Bit exclusive logical add

generation polynomial

16+X12+X5

X

+1

Features II CARTESIAN Benchtop Robot

12

[ Variables ]

Free variables: #mv, #mkv, #nv, #nkv, #sv, #skv

A “variable” is a container into which a value is placed. This robot has the following variables which

can be used freely. When using the following variables, variable declaration is unnecessary.

#mv(1 to 99) Boolean variable

#mkv(1 to 99) Boolean variable (keeping variable)

Free

variables

“Keeping variable” is a variable that retains its value even when the robot power is turned off.

#mv(1 to 99), #mkv(1 to 99)

Boolean variable. “Boolean variable” is a variable that can hold a 1-bit value of 0 or 1. It can be used

as a condition operation expression (ld, ldi) or assignment expression (let) parameter.

A sequencer program can also use Boolean type free variables (#mv (1 to 99), #mkv (1 to 99)).

#nv (1 to 99),#nkv (1 to 99)

Double type numeric variable that can be used as an assignment expression (let) parameter.

#sv (1 to 99),#skv (1 to 99)

String variable that can hold up to 255 bytes. When used as an assignment expression (let)

parameter, assignment by “=” and connection by “&” are possible.

#nv(1 to 99) Numeric variable

#nkv(1 to 99) Numeric variable (keeping variable)

#sv(1 to 99) String variable

#skv(1 to 99) String variable (keeping variable)

Identifier

Features II CARTESIAN Benchtop Robot

13

Input variables:#sysIn1 to 15, #genIn1 to 18, #handIn1 to 4

An input variable is a Boolean variable that can be referenced only. A value cannot be written.

The input variables correspond to the I/O-SYS, I/O-1, and I/O-H input pins. When an ON signal is

received, the input variable becomes “1” (true).

Category

Input

variable

#sysIn1 to 16 (I/O-SYS) are assigned a function in advance.

e.g.)#sysIn1: Start signal (When ON signal received, operation starts.)

If you want to use #sysIn1 to 16 (I/O-SYS) for a function other than the one to which it has been

assigned, switch the run mode parameter setting to free. (I/O-SYS function assignment)

Identifier

(JS Series)

#sysIn1 to 15 #sysIn1 to 16 I/O-SYS Reference only Boolean variable

#genIn1 to 18 #genIn1 to 8 I/O-1 Reference only Boolean variable

#handIn1 to 4

Identifier

(Cartesian)

Connector Description

I/O-H Reference only Boolean variable

Features II CARTESIAN Benchtop Robot

14

Output variables:

#sysOut1 to 15, #genOut1 to 18, #handOut1 to 4

Output variables are Boolean variables.

Output variables corresponds to the I/O-SYS, I/O-1, and I/O-H output pins. When an ON signal is

output, the output variables become “1” (true).

Category Connector Description

Output

variable

#sysOut1 to 16 (I/O-SYS) are assigned a function in advance.

Ex) #sysOut1: Ready for Start (ON signal: Operation can be started)

If you want to use #sysIn1 to 16 (I/O-SYS) for a function other than the one to which it has been

assigned, switch the run mode parameter setting to free. (I/O-SYS function assignment)

Identifier

(JS Series)

#sysOut1 to 14 #sysOut1 to 16 I/O-SYS Boolean variable

#genOut1 to 18 #genOut1 to 8 I/O-1 Boolean variable

#handOut1 to 4

Identifier

(Cartesian)

I/O-H Boolean variable

Down timer : #downT imer1 to 10

Numeric variable. When assigned (let) a value, counting down in msec units starts automatically. A

value can also be assigned during countdown.

The maximum value that can be assigned is 2,147,483,647 (msec).

Category

Special

variable

Features II CARTESIAN Benchtop Robot

Identifier

#downTimer1 to 10

When a value is assigned, counting down (in msec units)

starts automatically.

15

Description

2.5mm

Point job starting height : #jobStartHight

When a value is assigned (let) to the variable “#jobStartHight” before movement or during movement,

the point job starts from an assigned value above the set point Z coordinate.

Setting point job data that includes “#jobStartHight” at “point job” is meaningless because the robot

has already arrived at the point job start position. Also, since this variable acts only on the set point,

the point job start position of the next point does not change.

e.g.)

P01

Type: CP start point

Job before moving: Point job data 3

Point job: Point job data 12

Category

Special

variable

Identifier

#jobStartHight

”Point Job” execution start

P

Point job starts from a given value above the Z coordinate of

the point. (Invalid in CP drive)

Point Job Data 3

#jobStartHight 25

Description

Features II CARTESIAN Benchtop Robot

16

(

)

Pallet : #palletflag (1 to 100), #p alletCount (1 to 100)

#palletCount(1 to 100) is a numeric variable and #palletflag(1 to 100) is a Boolean variable.

These variables retain the value of the pallet counter and pallet flag of the “Pallet Routine” under

Additional function data (1 (true) when the pallet counter is full).

By using this variable, a pallet can be moved to the next point, etc. midway or a given pallet can be

skipped.

#palletFlag (1 to 100) does not become “1” (true) even if a value which fills the counter is

e.g.) Perform a pallet job by skipping a given pallet.

Pick up a workpiece at P1, places it on the pallet (set at P2) and advances to the next point (P3) where the

pallet becomes full. However, there are 2 points (P2-5, P2-11) on the pallet where a workpiece is not

placed.

The pallet becomes pallet number 3, and the tool is connected using the following settings.

“Pick up workpiece” (pick up): #handOut1=ON

Category

Pallet

”Place workpiece” (place): #handOut1=OFF

assigned to #palletcount (1 to 100).

Identifier

#palletflag

(1 to 100)

#palletCount

(1 to 100)

P1

Points where work is not performed

Pallet flag (corresponds to pallet 1 to 100)

Pallet counter (corresponds to pallet 1 to 100)

P2-5

P2-1(P0) P2-2

●

Description

Omitted

●

P2-11

To P3

P2-12

Features II CARTESIAN Benchtop Robot

17

Point job data set on P1

set #handOut1

Point job data set on P2

if

ld #palletCount(3) = 5

or #palletCount(3) = 11

else

reset #handOut1

endIf

loopPalette 3,1

Pick up workpiece.

If

#palletCount (3) is other than 5 (P2-5), 11 (P2-11),

Place (release) workpiece.

Increase the pallet 3 counter by 1. If the counter

becomes full, advance to the next command.

(In this case, the point job ends because there is no

next command.)

If the counter is not full, move to P1.

Features II CARTESIAN Benchtop Robot

18

t

t

Workpiece adjustment: #workAdj_X, #workAdj_Y,

#workAdj_Z, #workAdj_R, #workAdj_Rotation

Numeric variables. These variables hold the adjustment amount and rotation adjustment amount of

each axis of the [Workpiece Adjustment] under Additional function data.

Category

Workpiece

adjustment

e.g.) Line dispense between P2-P3.

At P1, workpiece adjustment amount (workpiece offset value) is received from the sensor connected to

COM.

The workpiece adjustment No. is made “6” and the tool is connected by the following setting.

“Dispensing end” : #handOut1=OFF

#workAdj_X (1 to 100)

#workAdj_Y (1 to 100)

#workAdj_Z (1 to 100)

#workAdj_R (1 to 100)

#workAdj_Rotation (1 to 100)

“Dispensing start” : #handOut1=ON

CP Start Point

Identifier

CP End Poin

P1

P3

Workpiece adjustment amount in the X direction

(Corresponds to workpiece adjustment 1 to 100)

Workpiece adjustment amount in the Y direction

(Corresponds to workpiece adjustment 1 to 100)

Workpiece adjustment amount in the Z direction

(Corresponds to workpiece adjustment 1 to 100)

Workpiece adjustment amount in the R direction

(Corresponds to workpiece adjustment 1 to 100)

Workpiece adjustment amount by rotating angle

(Corresponds to workpiece adjustment 1=100)

CP Start Point

P1

Workpiece Adjustment Amount

Description

P3

CP End Poin

Features II CARTESIAN Benchtop Robot

19

Point job data set in P1

declear str hosei

inCom hosei,port1,10

#workAdj_X(6) = hosei

Point job data set in P2 (Setting point of [Workpiece Adjustment])

set #handOut1

Point job data set in P3

reset #handOut1

When [Workpiece Adjustment] is set at the CP start point, it is valid until the tool unit reaches

the CP end point.

String type local variable “hosei” declaration.

Receive workpiece adjustment from COM1 at

“hosei”.

The “hosei” value is assigned to #workAdj_X (6)

(#workAdj_X(6)=X direction adjustment amount of

workpiece adjustment 6)

Dispensing start

Dispensing end

Features II CARTESIAN Benchtop Robot

20

t

A

P

Point coordinates: #point_X,#point_Y,#point_Z,

#point_R,#point_TagCode

These variables hold the coordinates and tag code value of the running point. “Running point” is the

point with point job data containing this variable set. When point job data containing this variable is

set to a job before moving, job while moving, or job while CP moving, the current position of the tool

center point and the value of this variable are different.

In the figure below, a job before moving set in P2 runs at point P1, but when the point job data set at

job before moving includes this variable, the P2 coordinates are retained.

Also, this variable holds the original coordinates of the point. This value does not change even when

[Workpiece Adjustment] and “#jogStartHight” are used.

Category

Current

point

coordinates

P1

Execute “Job before Moving (P2)”

Identifier

#point_X

#point_Y

#point_Z

#point_R

#point_TagCode

CP Start Poin

Execute “Job while

Moving (P2)” repeatedly

Running point X coordinate value

Running point Y coordinate value

Running point Z coordinate value

Running point R coordinate value

Running point tag code value

P2

CP Passing Point

Execute “Point Job (P2)”

P3

Passes P3

Moving (P2)” repeatedly

Execute “Job while C

Description

P4

rrive at P4

Features II CARTESIAN Benchtop Robot

21

Given point coordinates:

#P_X, #P_Y, #P_Z, #P_R, #P_T agCode

These variables hold the coordinates and tag code value of a given point in the current program.

This variable holds the original coordinates of the point. This value does not change even when

[Workpiece Adjustment] and “#jogStartHight” are used.

Category

Given

point

coordinate

#P_X (1 to last point count)

#P_Y (1 to last point count)

#P_Z (1 to last point count)

#P_R (1 to last point count)

#P_TagCode (1 to last point

count)

Identifier

Description

X coordinate value of given point in current

program

Y coordinate value of given point in current

program

Z coordinate value of given point in current

program

R coordinate value of given point in current

program

Tag code value of given point in current program

Features II CARTESIAN Benchtop Robot

22

Given point coordinates i n given programs:

#prog_P_X, #prog_P_Y, #prog_P_Z,

#prog_P_R, #prog_P_TagCode

These variables hold the coordinates and tag code value of a given point in a given program.

This variable retains the original coordinates of the point. This value does not change even when

[Workpiece Adjustment] and “#jogStartHight” are used.

Category

Coordinates

of given

point of

given

program

#prog_P_X (1 to 255, 1 to last point count)

#prog_P_Y (1 to 255, 1 to last point count)

#prog_P_Z (1 to 255, 1 to last point count)

#prog_P_R (1 to 255, 1 to last point count)

#prog_P_TagCode

(1 to 255, 1 to last point count)

Identifier

Description

X coordinate value of given point in

given program

Y coordinate value of given point in

given program

Z coordinate value of given point in

given program

R coordinate value of given point in

given program

Tag code value of given point in given

program

Features II CARTESIAN Benchtop Robot

23

[ Functions ]

Robot functions

Built-in functions, that are built-in as robot functions, and user definition functions, which can be

freely defined, can be used with this robot.

User definition functions are defined in the customizing mode. (Refer to operation manual “Features

IV” for a description of the customizing mode.)

The following can be used as robot system built-in functions.

Category Identifier Description

num currentMainProgNumber() Currently running main program No.

num currentSubProgNumber() Currently running subprogram No.

num currentPointNumber() Currently running point No.

num currentArmX() Current arm coordinate X, “mm” units

num currentArmY() Current arm coordinate Y, “mm” units

num currentArmZ() Current arm coordinate Z, “mm” units

num currentArmR() Current arm coordinate R, “degree” units

num numCOM(port#) COM receive port data byte count

currentMainProgNumber()

Holds the main program number currently running.

currentSubProgNumber()

Holds the subprogram number currently running. When a subprogram is not run, this variable

holds the main program number currently running.

currentPointNumber()

Holds the point number currently running. For work home, this variable is “0”.

currentArmX(),currentArmY(),currentArmZ()

Holds the current arm position (coordinate). (Absolute coordinate, “mm” units)

currentArmR()

Holds the number of rotations of the current R-axis (R-axis coordinate). (Absolute coordinate,

“degree” units)

Features II CARTESIAN Benchtop Robot

24

Arithmetic functions

The following can be used as arithmetic built-in functions.

x, y : Numeric value

n, m : Rounded integer value

Category Identifier Description

num max(x,y) Maximum value

num min(x,y) Minimum value

num degrad(x)

num raddeg(x)

num sqrt(x) Square root

num sin(x) Sine

num cos(x) Cosine

num tan(x) Tangent

num atan(x) Arc tangent

num atan2(x,y) Arc tangent

num int(x)

num ip(x)

num fp(x)

num mod(x,y) Value of x which makes y modulo. x-y*int (x/y)

num remainder(x,y) Remainder of dividing x by y. x-y*ip (x/y)

num pow(x,y) x to the power of y

Absolute value num abs(x)

Conversion from degree to radian (x*π/180)

Conversion from radian to degree (x*180/π)

Maximum integer which does not exceed x

Ex: int (1.3)=1, int (-1.3)=-2

Integer part of x. sgn (x)*int (abs (x))

(When x is a negative number, sgn(x) becomes -1 and

when x is a positive number, sgn(x) becomes +1.)

Ex: ip (1.3)=1, ip (-1.3)=-1

Decimal part of x. x-ip (x)

Ex: fp (1.3)=0.3, fp (-1.3)=-0.3

Features II CARTESIAN Benchtop Robot

25

String functions

The following can be used as string built-in functions.

x, y: Numeric value or Numeric variable

n, m: Numeric value made a certain digit or greater by rounding or truncation

a, b: String or string variable

Category

String system

Type Identifier Description

str chr(x) Returns a string (1 character) with the given character code.

num ord(a)

num len(a)

num strPos(a,b) Returns the first part string position that matches b in a.

str strMid(a,n,m)

str str(x) Converts a numeric value to a decimal string.

str strBin(n,m)

str strHex(n,m)

str str1SI(x)

str str2SIBE(x)

str str2SILE(x)

str str4SIBE(x)

str str4SILE(x)

str str4FBE(x)

str str4FLE(x)

str str8DBE(x)

str str8DLE(x)

num val(a)

Returns the value of the top character code. Other characters

are ignored.

Returns the string length (byte length). Does not handle multi

byte codes.

Returns a character string from the n th to the m th characters,

counting from the top of character string a.

Converts a numeric value to a binary string. m: Number of binary

string digits

Converts a numeric value to a hexadecimal string. m: Number of

hexadecimal string digits

Rounds a numeric value to a 1 byte signed integer and converts

it to a 1 byte string. (1 byte Signed Integer)

Rounds a numeric value to a 2 byte signed integer and converts

it to a 2 byte string big endian.

(2 byte Signed Integer Big Endian )

Rounds a numeric value to a 2 byte signed integer and converts

it to a 2 byte string little endian.

(2 byte Signed Integer Little Endian )

Rounds a numeric value to a 4 byte signed integer and converts

it to a 4 byte string big endian.

(4 byte Signed Integer Big Endian )

Rounds a numeric value to a 4 byte signed integer and converts

it to a 4 byte string little endian.

(4 byte Signed Integer Little Endian )

Regards a numeric value as a floating decimal and converts it to

a 4 byte string big endian. (4 byte Float Big Endian)

Regards a numeric value as a floating decimal and converts it to

a 4 byte string little endian. (4 byte Float Little Endian)

Regards a numeric value as a double floating decimal and

converts it to an 8 byte string big endian. (8 byte Double Big

Endian )

Regards a numeric value as a double floating decimal and

converts it to 8 byte string little endian. (8 byte Double Little

Endian )

Regards a string as a decimal string and converts it to a numeric

value.

Features II CARTESIAN Benchtop Robot

26

x, y: Numeric value or Numeric variable

n, m: Numeric value made a certain digit or greater by rounding or truncation

a, b: String or string variable

Category

Type Identifier Description

num valBin(a)

Regards a string as a binary string (list of “0” and “1”)

and converts it to a numeric value.

Regards a string as a hexadecimal string (list of “0” to

num valHex(a)

num val1SI(a)

“1”, “A” to “F”, or “a” to “f”) and converts it to a numeric

value.

Regards the top character as a 1 byte signed integer

and converts it. (1 byte Signed Integer )

Regards the top 2 characters as a 2 byte signed

num val2SIBE(a)

integer big endian and converts it. (2 byte Signed

Integer Big Endian )

Regards the top 2 characters as a 2 byte signed

num val2SILE(a)

integer little endian and converts it. (2 byte Signed

Integer Little Endian )

Regards the top 4 characters as a 4 byte signed

num val4SIBE(a)

String system

num val4SILE(a)

num val4FBE(a)

num val4FLE(a)

integer big endian and converts it. (4 byte Signed

Integer Big Endian )

Regards the top 4 characters as a 4 byte signed

integer little endian and converts it. (4 byte Signed

Integer Little Endian )

Regards the top 4 characters as a floating decimal big

endian and converts it. (4 byte Float Big Endian )

Regards the top 4 characters as a floating decimal little

endian and converts it. (4 byte Float Little Endian )

Regards the top 8 characters as a double floating

num

val8DBE(a)

decimal big endian and converts it. (8 byte Double Big

Endian )

Regards the top 8 characters as a double floating

num val8DLE(a)

num valSum(a)

decimal little endian and converts it. (8 byte Double

Little Endian )

Returns the sum of the string code added from top to

bottom.

Remainder of division of string assumed to be a bit

num valCRC(a)

str bitNot(a) Bit NOT

str bitAnd(a,b) Bit logical AND

str bitOr(a,b) Bit logical OR

str bitXor(a,b) Bit exclusive logical OR

string divided by generation polynomial

16+X12+X5

X

+1

Features II CARTESIAN Benchtop Robot

27

A

A

[ ON/OFF Output Control ]

Outputting to I/O: set, reset, pulse, invPulse

This section explains commands to be output to a tool (output to the I/O.) These commands belong

to the category [ON/OFF Output Control.]

Command Category Command

set

reset

ON/OFF Output

Control

pulse

invPulse

Parameter

Output Destination

Output Destination

Output

Destination

Output

Destination

Pulse

Width

Pulse

Width

Job

ON output to a specified output

destination

OFF output to a specified output

destination

ON pulse output with a specified

width to a specified output

destination

OFF pulse (inverting pulse) output

with a specified width to a specified

output destination

Example)

In this example, a hand tool is connected to the robot as shown in the following figure.

- Hand Tool OPEN Air 1 CLOSE & Air 2 OPEN

- Hand Tool CLOSE Air 1 OPEN & Air 2 CLOSE

- Air 1 OPEN Solenoid Valve 1 ON

- Air 2 OPEN Solenoid Valve 2 ON

- Air 1 CLOSE

- Air 2 CLOSE Solenoid Valve 2 OFF

- Solenoid Valve 1 ON #sysOut15 ON

- Solenoid Valve 2 ON #sysOut16 ON

- Solenoid Valve 1 OFF #sysOut15 OFF

- Solenoid Valve 2 OFF #sysOut16 OFF

Solenoid Valve 1 OFF

Hand Tool

Solenoid

Valve 2

Solenoid

Valve 1

ir 1

ir 2

I/O-SYS

Features II CARTESIAN Benchtop Robot

28

Therefore,

Hand Tool OPEN ← #sysOut15 OFF & #sysOut16 ON

Hand Tool CLOSE ← #sysOut15 ON & #sysOut16 OFF

Below are the output commands to open/close the hand tool.

set #sysOut15

reset #sysOut16

set #sysOut15

reset #sysOut16

The command [set] continues to output an ON signal unless the command [reset] is received.

Below are the output commands to open/close the hand tool using the pulse.

pulse #sysOut15 100 #sysOut15 0.1sec

invPulse #sysOut16 100 #sysOut16 0.1sec

pulse #sysOut15 100 #sysOut15 0.1sec

pulse #sysOut16 100 #sysOut16 0.1sec

#sysOut16 ON output

#sysOut15 OFF output

#sysOut16 ON output

#sysOut15 OFF output

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Open hand tool.

Close hand tool.

Open

hand tool.

Close

hand tool.

Features II CARTESIAN Benchtop Robot

29

The commands [pulse] and [invPulse] move on to the next command before the pulse stops.

In the following example 2 point job data have different results:

pulse #genOut1 100

pulse #genOut2 200

set #genOut3

↓ ↓

#genOut1

#genOut2

#genOut3

delay 100 = Stand by for 0.1 second in place.

You can set the pulse width for the commands [pulse] and [invPulse] using variables or

expressions.

0.1 sec 0.1 sec

set #genOut1

delay 100

reset #genOut1

set #genOut2

delay 200

reset #genOut2

set #genOut3

#genOut1

#genOut2

#genOut3

0.2 sec

Features II CARTESIAN Benchtop Robot

30

Outputting after X second: delaySet, delayReset

The commands “delaySet” and “delayReset” are used to output ON/OFF signals to a specified

output destination after a specified period of time.

The delay time can be set from 0.001 sec to 9999.999 sec.

Command Category

ON/OFF Output

Control

The commands “delaySet” and “delayReset” move on to the next command before the pulse stops.

Timing of the next command execution differs from the case where signals are output by set/reset

after “waitCondTime.”

Example) delaySet

1) delaySet #sysOut2 100

2) set #sysOut1

3) ٠ ٠ ٠ ٠ ٠ ٠

Delay Time can be set using variables or expressions.

0.1 sec

1)

2)

Command Parameter

delaySet

delayReset

Output

Destination

Output

Destination

Delay

Time

Delay

Time

Example) waitCondTime/set

1) waitCondTime 100

2) set #sysOut1

3) set #sysOut2

4) ٠ ٠ ٠ ٠ ٠ ٠

ON output after specified delay

OFF output after specified

0.1 sec

1)

Job

time

delay time

2)

3)

Features II CARTESIAN Benchtop Robot

31

Sounding an alarm buzzer: onoffBZ

A point job sounds an alarm buzzer.

Command Category Command Parameter Job

ON/OFF Output Control

If these commands “set/onoffBZ” are executed, an alarm buzzer continues to sound until the

“reset”command is executed.

ON Time and OFF Time for the command “onoffBZ” can be set using variables or expressions.

set

reset

onoffBZ ON Time, OFF Time

Output Destination

(BZ)

Output Destination

(BZ)

Sounds an alarm buzzer.

Stops an alarm buzzer.

Sounds an alarm buzzer off

and on.

Features II CARTESIAN Benchtop Robot

32

Blinking the LED (Green): onoffGLED

The following commands are valid for the CARTESIAN series only.

The following explains how to turn ON or blink the LED light on the front body using point job

commands.

After the onoffGLED command, which turns ON or blinks the LED (Green), is executed, the LED

(Green) stays ON or keeps blinking until the reset command, which turns the LED (Green) OFF, is

executed.

ON Time and OFF Time for “onoffGLED” command can be set using variables or expressions.

Command Category

ON/OFF Output

Control

Command

set

reset

onoffGLED

Parameter

Output Destination

Output Destination

ON Time, OFF Time

(GLED)

(GLED)

Job

Turns the LED (Green) ON.

Turns the LED (Green)

OFF.

Blinks the LED (Green.)

Features II CARTESIAN Benchtop Robot

33

Blinking the LED (Red): onoffRLED

The following commands are valid for the CARTESIAN series only.

The following explains how to turn ON or blink the LED light on the front body using point job

commands.

After the onoffRLED command, which turns ON or blinks the LED (Red), is executed, the LED (Red)

stays ON or keeps blinking until the reset command, which turns the LED (Red) OFF, is executed.

ON Time and OFF Time for “onoffRLED” command can be set using variables or expressions.

Command Category

ON/OFF Output

Control

Command Parameter

set

reset

onoffRLED ON Time, OFF Time

Output Destination

(RLED)

Output Destination

(RLED)

Job

Turns the LED (Red) ON.

Turns the LED (Red) OFF.

Blinks the LED (Red.)

Features II CARTESIAN Benchtop Robot

34

Outputting values from I/O: dataOut,dataOutBCD

The optional numeric values “0 to 999,999,999” or tag codes can be output to the I/O or the Boolean

free variables (#mv(1~99), #mkv(1~99).)

Command Category Command

ON/OFF Output

Control

Using tag code output, you can output different values using the same point job data if you set

different values as tag codes to multiple points.

Output Values and Output Width can be set using variables or expressions.

You need to set the following 2 parameters in addition to Output Value for the commands “dataOut”

and “dataOutBCD”.

- Output Width: The number of I/Os to be used for output

- Output Destination: The smallest number between I/Os to be used for output

The serial I/Os are used for the commands “dataOut” and “dataOutBCD”. You cannot use I/Os

that are not serial I/Os.

Example:

<Setting>

Output Value: 6

Output Width: 3

Output Destination: #genOut8

dataOut

dataOutBCD

e.g) If you use #genOut8 to 10, the Output Destination is “8.”

Output

Value

Output

Value

<Command>

dataOut 6,3,#genOut8

Parameter

Output

Destination

Output

Destination

Output

Width

Output

Width

<Output> 6=110 (binary)

#genOut8: 0 (OFF)

#genOut9: 1 (ON)

#genOut10: 1 (ON)