Loctite 97113, 97114 User Manual

EQUIPMENT

Operation Manual

Loctite

®

Dispense Valve

Part Numbers 97113 and 97114

Contents

Page No.

1 Please Observe the Following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1 Emphasized Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 For Your Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.4 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.5 Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1 Operating Elements and Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3 Technical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.1 Installing Anti-Bubbler to .5 liter and 2 liter Reservoirs . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 Connecting the Airlines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5 Dispensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

5.1 Priming the Dispense Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2 Adjusting the Dispensed Quantity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2.1 Adjusting the Suck-Back Effect (Piston Stroke) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.2.2 Adjusting the Air (Outlet Chokes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5.3 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.4 Returning to Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.5 Disassembling the Dispense Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Accessories and Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

8 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9 Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1. Please Observe the Following

1

1.1 Emphasized Sections

Warning!

Refers to safety regulations and required safety measures that protect the operator or other

persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not damaged.

Notice:

Gives recommendations for better handling of the unit during operation or adjustment as well as

for service activities.

• Instruction steps in the illustrations are indicated

with arrows.

When several instruction steps are indicated in

an illustration, the shading of the arrow has the

following meaning:

Black arrow = 1st step

Grey arrow = 2nd step

White arrow = 3rd step

1.2 Items supplied

1 Dispense Valve - 97113 (with 6.3 mm Product Feedline connection) or Dispense Valve - 97114

(with 9.5 mm Product Feedline connection);

1 Needle Kit

1 Instruction Manual

1 Anti-Bubbler Adapter & Sleeve

As a result of technical development, the illustrations and descriptions in this instruction manual

can deviate in detail from the actual unit delivered.

1.3 For Your Safety

For safe and successful operation of the unit, read these instructions completely. If the instructions

are not observed, the manufacturer can assume no responsibility.

• Observe general safety regulations for the handling of chemicals!

• Observe manufacturer’s instructions! Request a safety data sheet for the product used!

• When working with pressurized air, wear protective glasses!

1.4 Features

• Slim, lightweight, patented sealless dispense valve

• Used in semi or fully-automatic process applications

• Two-part, modular construction equipped with a patented quick

disconnect for on-line serviceability

• Designed with a suck-back feature for dispensing accuracy and control

• Adaptable to optional reservoirs based on product package

• Dispenses Loctite innovative chemistries up to 80,000 cPs

• Worldwide Availability

• Worldwide Service

• Application support for integrating both the adhesive and

equipment interface

☞

☞

1. Please Observe the Following (continued)

2

1.5 Usage

The Loctite

®

Dispense Valve is a slim, lightweight, and user-friendly valve that contains a “suck-

back” feature that eliminates product dripping and stringing at the end of the dispense cycle.

It also features a two-part, modular construction for on-line serviceability.

The Dispense Valve applies Loctite

®

products in dots, drops, and beads by the process means of

semi or fully automatic systems. The valve can be used in both stationary or

advancing modes.

Recommended viscosity ranges: 97113 – up to 15,000 cPs

97114 – up to 80,000 cPs

2. Description

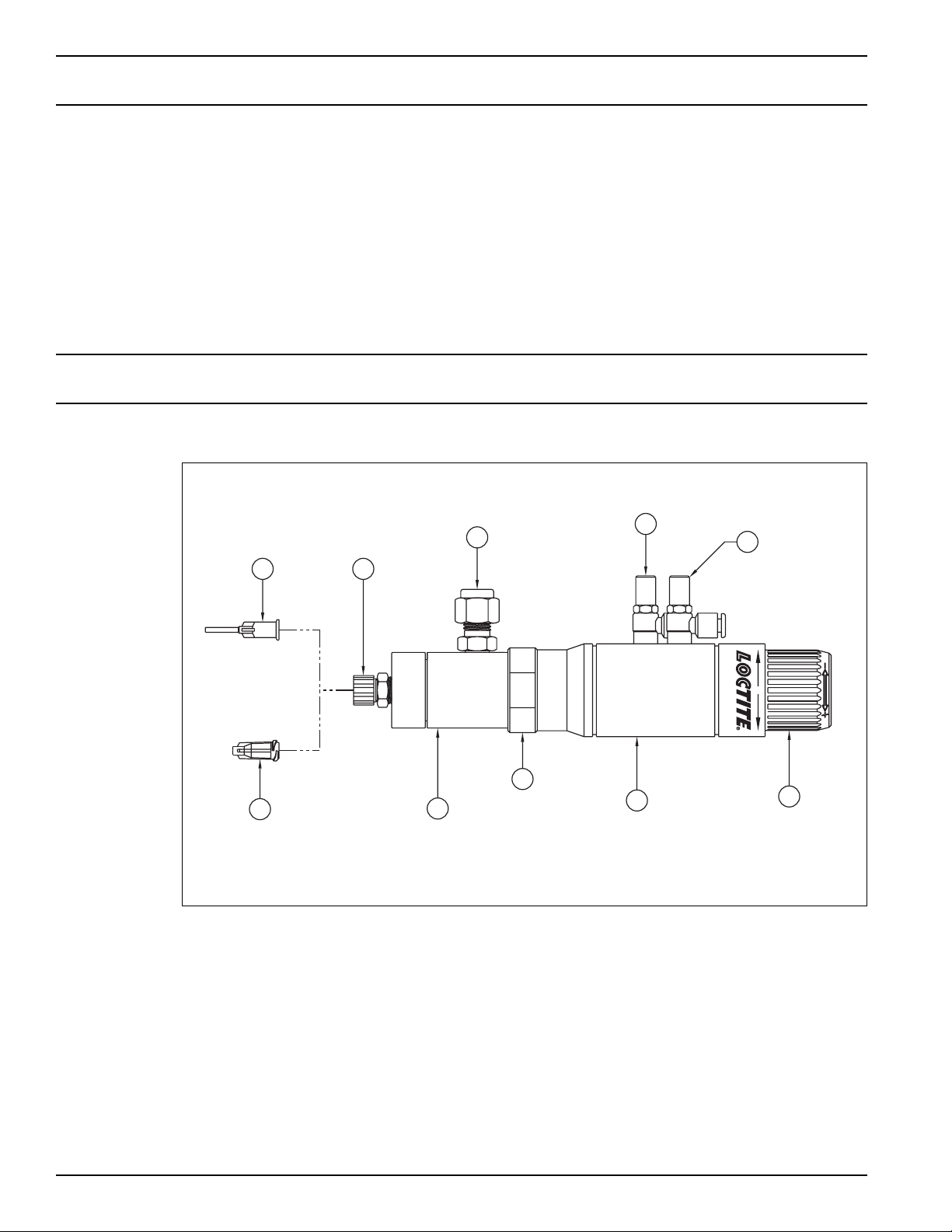

2.1 Operating Elements and Connections

1

3

5

8

9

Dispense

Needle

Luer-Lok

Adapter

Product Feed

Line Connection

Air Outlet

Choke Open

Air Outlet

Choke

Close

PART NO. 97113

10

7

6

4

2

Luer-Lok

Tip Cap

Shutoff Valve

Assembly

Locking

Nut

Actuator

Assembly

Adjustment

Knob

Figure 1. Component Identification

Locking nut

Locks the bayonet connection between the valve assembly 4 and the actuator assembly 7.

Air outlet choke

Affects the opening speed of the dispensing valve.

Air outlet choke

Affects the closing speed of the dispensing valve.

Adjustment knob

For the stroke of the shutoff piston.

2. Description (continued)

3

2.2 Theory of Operation

An uncovered bottle of Loctite

®

product is placed directly into the reservoir and the reservoir lid is

clamped in place.

The reservoir is then pressurized from a Loctite controller using clean, filtered dry air. Air within the

reservoir will push down on the liquid in the bottle and force it through the product feedline to the

shutoff valve.

The amount of product dispensed is controlled by 3 main factors:

1. Amount of pressure in the reservoir.

2. Length of time the shutoff valve remains open.

3. Dispensing needle size.

With the closing of the piston in the Dispensing Valve, a negative pressure (suck-back effect) is

produced that prevents the product from continuing to run or drip out of the dispensing needle 1.

This suck-back effect can be changed by adjusting the piston stroke with the adjustment knob 10.

The main purpose of the adjusting knob is to control the amount of suck-back. There is a small

amount of flow control in the first 1/2 turn of the adjusting knob - after that point, the adjusting

knob only controls the suck-back effect.

The opening and closing of the Dispense Valve 97113 / 97114 are influenced by the speed with

which the pressurized air can escape from the double action actuator assembly.

The opening speed of the dispensing valve can be changed with the air outlet choke 8.

The closing speed of the dispensing valve can be changed with the air outlet choke 9.

With the changing of the opening and closing speed for the Dispensing Valve, the dispensed

quantity is also changed.

☞

☞

Loading...

Loading...