Loctite AC988557 User Manual

Operation Manual AC988557

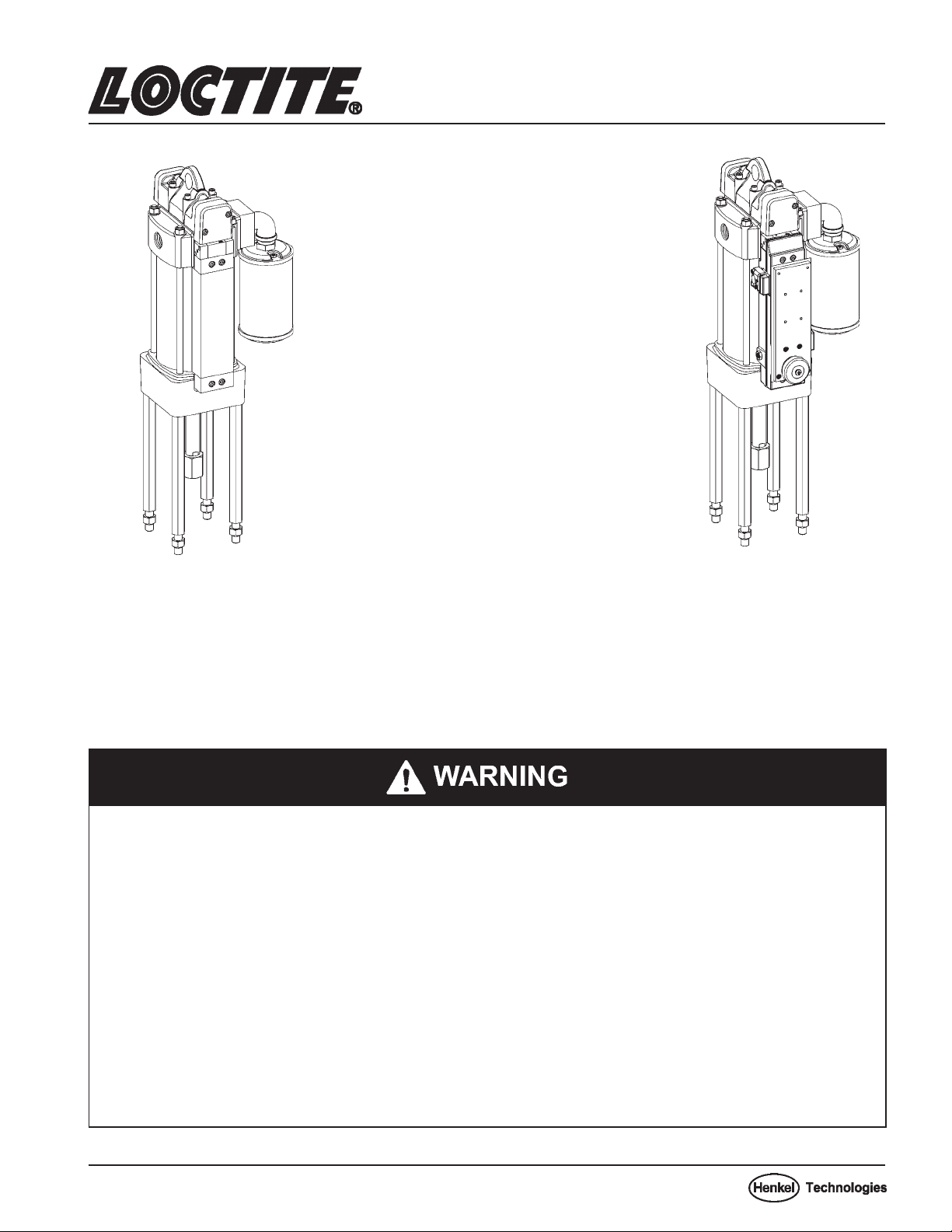

Loctite® Airmotors

Part Numbers

988526 (4-1/4” Airmotor)

988528 (6” Airmotor)

988545 (Pump Stop)

988552 (Low Level Micro Switch)

EQUIPMENT

IT IS THE RESPONSIBILITY OF THE OWNER AND/OR OPERATOR TO PROPERLY USE AND MAINTAIN THIS

EQUIPMENT. CAREFULLY READ AND UNDERSTAND THE INSTRUCTIONS AND WARNINGS IN THIS MANUAL

BEFORE OPERATING THIS EQUIPMENT.

If the operator is not fluent in English, the instructions and warnings shall be read and discussed in the operator’s native

language, making sure the operator comprehends the contents.

This equipment complies with OSHA Standards where applicable.

DO NOT exceed the stated maximum working pressure of the airmotor or of the lowest rated component in your system.

DO NOT alter or modify any part of this equipment.

DO NOT operate this equipment with combustible gas.

DO NOT attempt to repair or disassemble the equipment while the system is pressurized.

TIGHTEN all fluid connections securely before using this equipment.

ALWAYS read and follow the fluid manufacturer’s recommendations regarding fluid compatibility, and the use of protective

clothing and equipment.

CHECK all equipment regularly and repair or replace worn or damaged parts immediately.

IMPORTANT: Failure to heed these warnings including misuse,

overpressurizing, modifying parts, using incompatible chemicals and fluids, or using worn or damaged parts, may result

in equipment damage and/or serious personal injury, fire, explosion, or property damage.

This manual contains IMPORTANT WARNINGS and INSTRUCTIONS. READ AND RETAIN FOR REFERENCE.

JULY - 2004

Copyright 2004

Printed in U.S.A.

Form 403504

NOTE:

DO NOT OPERATE with

air contaminated with

materials not compatible

with BUNA-N seals.

SPECIFICATIONS

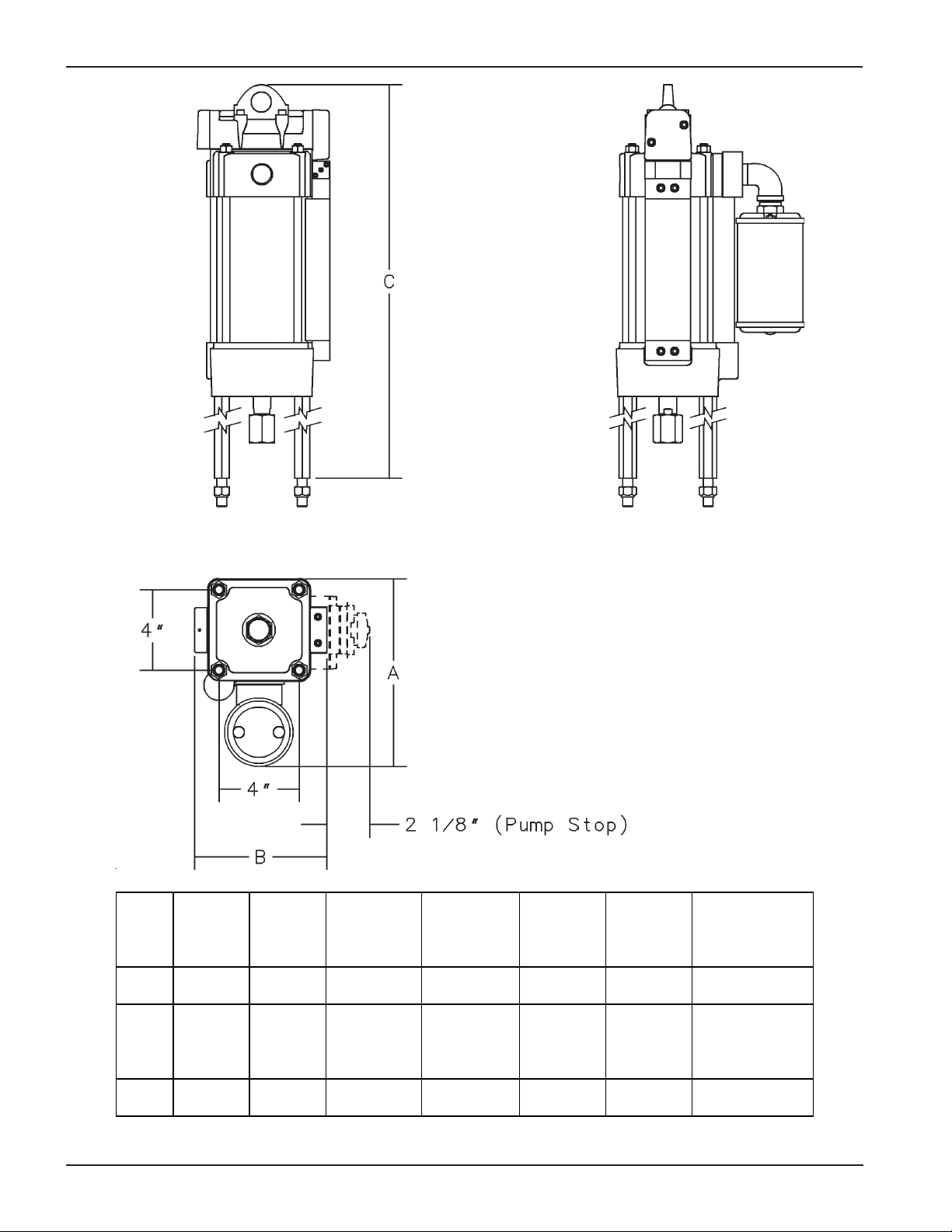

CYLINDER EFFECTIVE OPERATING OPERATING MIN. ID. AIR INLET AIR CONS. @ 1 0 0

ITEM # DIAMETER PISTON PRESS URE TEMP . RANGE OF AIR PSIG (7 BAR)

IN. (MM) AREA RANGE °F (°C) SUPPLY SCF/CYCLE

IN² (CM²) PSIG (BAR) IN. (M M) (L(N) /CYCLE)

988528 6 (152) 28 (182) 30-100 (2-7) -30 +200 1/2 (12) 3/4” NPTF 1.6 (46)

988526 4-1/4 (108) 14 (92) 30-100 (2-14) (-34 +93) 1/2 (12) 1/2" NPTF 1.1 (32)

MAX. STROKE

ITEM # RECOM. L ENGTH WEIGHT SEALS DIM. A DIM. B DIM . C

SPEED IN. (MM) LB. (KG) MATERIAL IN. (MM) IN. (MM) IN. (MM)

CPM

988528 75 6 (152) 34 (15.5) BUNA-N and 11-1/8 (283) 7-3/4 (197) 22-3/4 (577)

988526 26(11.7) *TEFLON 9-3/8 (238) 6-5/8 (168) 23-5/8 (599)

*TEFLON® Seals used with Power Valve Spool (Item 13) and Relay Valve (Item 17).

Page Number - 2

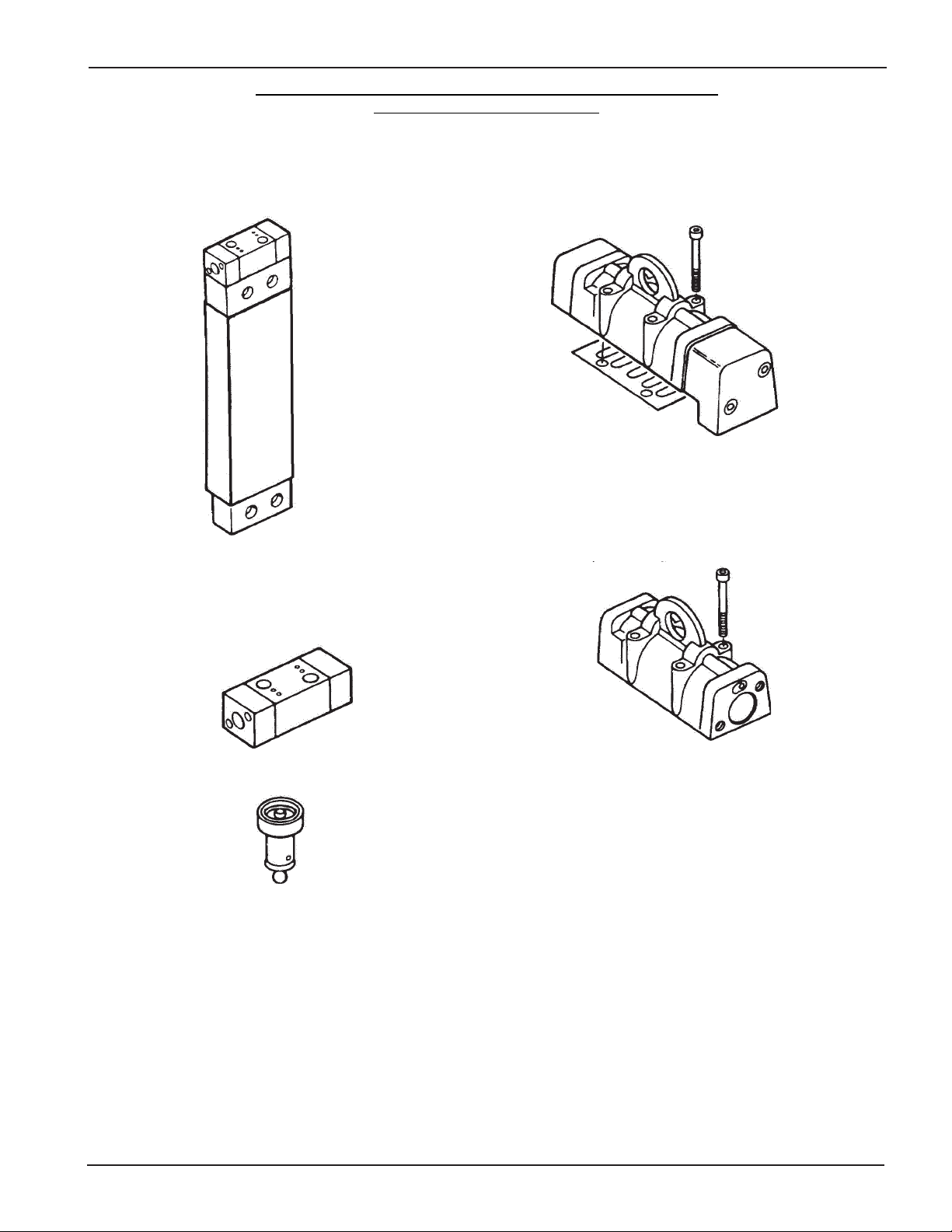

FOR STANDARD AIRMOTOR WITHOUT PUMP STOP

SERVICE ASSEMBLIES & KITS

To reduce down-time and take advantage of the modular design of the airmotor, Henkel recommends using the following

Service Assemblies for repair of the airmotor. After removal, the faulty assembly can then be repaired using the

corresponding Soft Parts Kit.

1. Pilot Bar Subassembly

P/N 988747

6. Power Valve Subassembly

P/N AC244806 (6” Airmotor)

P/N AC244808 (4-1/4” Airmotor)

7. Soft Parts Kit P/N 988751 for repair of Power Valve

Subassemblies listed above.

2. Soft Parts Kit P/N 988746 for repair of Pilot Bar

Subassemblies listed above. (Includes all necessary

“O”-rings.)

3. Relay Valve. P/N 988748

4. Air Signal Valve P/N 988749

5. Cylinder Tube Soft Parts Kit

( Includes all “O”-rings, piston seal. etc.)

P/N 988753 (6” Airmotor)

P/N 988752 (4-1/4” Airmotor)

8. Power Valve Spool & Body P/N 988750

IMPORTANT: When replacing soft parts, replace all parts

included in the soft parts kit.

Page Number - 3

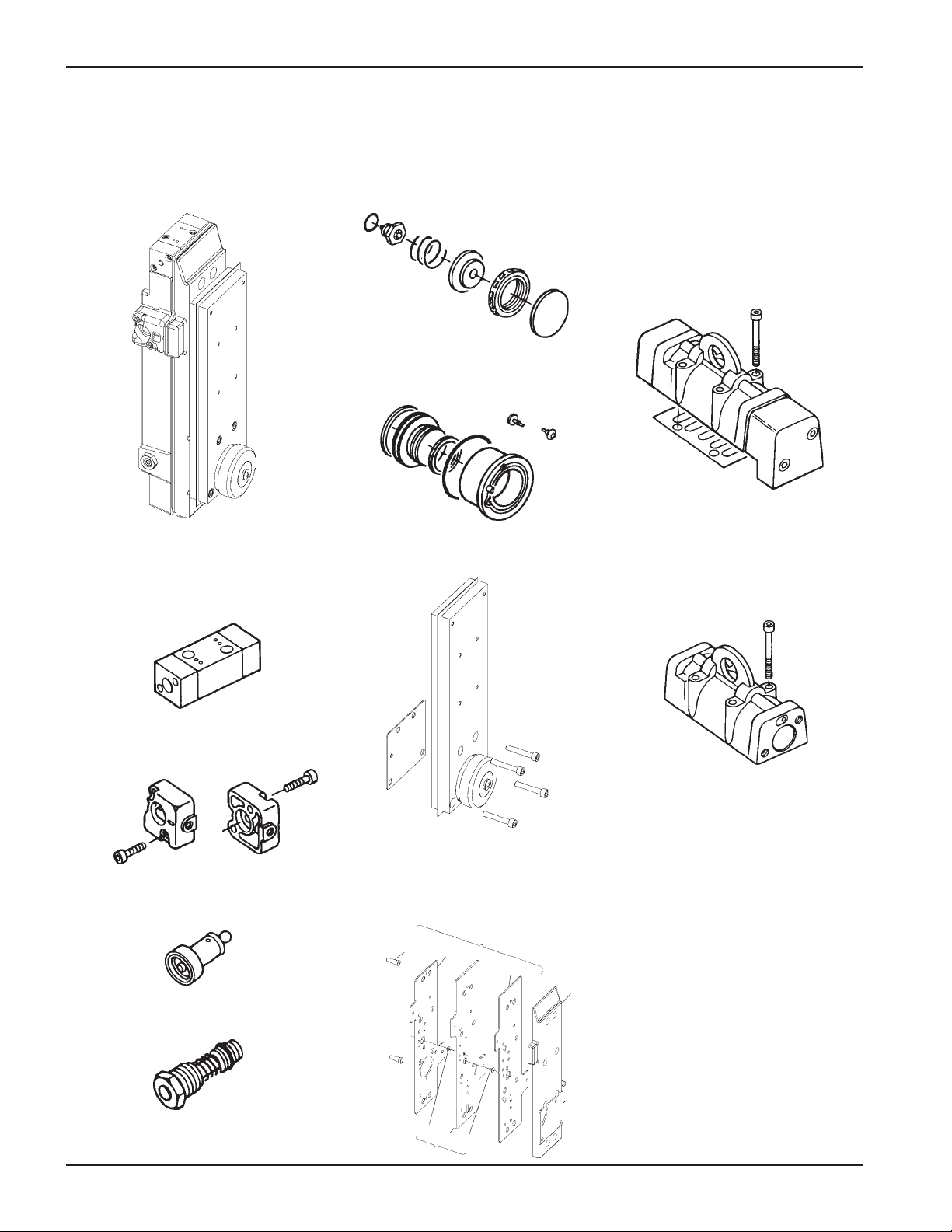

FOR AIRMOTORS WITH PUMP STOP

SERVICE ASSEMBLIES & KITS

To reduce down-time and take advantage of the modular design of the airmotor, Henkel recommends using the following

Service Assemblies for repair of the airmotor. After removal, the faulty assembly can then be repaired using the corresponding

Soft Parts Kit.

1. Pump Stop Subassembly

P/N 988545

2. Soft Parts Kit P/N 988746 for repair

of Pump Stop Subassembly. (See

Parts List for contents.)

3. Relay Valve P/N 988748 Item 17

7. Stop Valve Repair Kit P/N AC

244091 Item 91 (includes items

57, 58, 59, 60, 61)

8. Air Pump Repair Kit P/N AC244092

Item 92 (includes items 55, 56, 62,

63, 64, 65)

9. Bleed Assembly P/N AC273428

Item 67 (includes items 73 through

88)

12.Cylinder Tube Soft Parts Kit

(Includes “O”-rings, piston seal,

etc.) P/N 988753 (6" Airmotor)

P/N 988752 (4-1/4"Airmotor)

13.Power Valve Subassembly

P/N AC244806 (6" Airmotor)

P/N AC244808 (4-1/4" Airmotor)

14.Soft Parts Kit P/N 988751 for repair

of Power Valve Subassemblies

listed above.

15.Power Valve Spool & Body

P/N 988750.

4. Signal Valve Cap Kit P/N

AC243853 Item 31 (includes Item

32)

5. Air Signal Valve P/N 988749, Item

20

6. Trip Indicator P/N AC243852 Item

48

10.Gasket and Air Filter Kit Item 89

P/N AC273427 (Items 40, 51 & 53)

11. Gasket Plate with Check Valves

Item 90 P/N AC244093 (Items 52 &

63)

40

63

90

53

52

89

51

63

50

Page Number - 4

FOR STANDARD AIRMOTOR

ALWAYS check equipment for proper operation before each

use, making sure safety devices are in place and operating

properly. DO NOT alter or modify any part of the equipment as

this may cause a malfunction and result in serious bodily injury.

BEFORE CONNECTING AIRMOTOR TO AIR

LINE

LOCTITE® AIRMOTORS are fully pneumatic and require a minimum

specified size of air supply hose for proper operation. Check

specification for minimum ID. of the air supply hose and select

corresponding sizes of air controls and accessories for nonrestrictive air flow.

If quick disconnect coupling should be used, install supplied coupler

to insure proper airmotor operation.

NOTE: Whenever flammable materials are pumped, ground Airmotor

according to Local Codes.

OPERATING PRECAUTIONS

Use Loctite® replacement parts to assure compatible pressure

rating.

Heed ALL warnings.

DO NOT OPERATE Airmotor in excess of recommended pressure

range.

Disconnect air line and relieve (vent) pressure when Airmotor sits

idle for long periods of time and before servicing.

ALWAYS read and follow the fluid and solvent manufacturer’s

recommendations regarding the use of protective clothing and

equipment.

To reduce the risk of serious bodily injury or property damage.

NEVER exceed the maximum air or fluid working pressure of the

lowest rated system component.

ATTACHING AIRMOTOR TO PUMPTUBE

1 Tightly attach the tie rods (ltem 41) to the Airmotor lower

casting. Use short threaded end of tie rods.

2. Mount Airmotor on top of pump tube outlet and tightly connect

pump tube coupling nut to Airmotor Piston Rod (Item 5).

3. Hand tighten tie rods to the pump tube with four nuts (Item 42)

supplied with Airmotor.

4. Connect air supply and slowly cycle pump several times using

only enough air pressure to operate pump without stalling.

5. STOP pump on “UP” stroke and tighten four nuts to securely

fasten Airmotor to pump tube.

SERVICE AND DISASSEMBLY PROCEDURE

Always disconnect air supply to Airmotor and relieve pressure

before checking, servicing, or repairing any part of Airmotor

TOOLS REQUIRED

1. 7/64 (.109) Hex Wrench

2. 5/32 (.156) Hex Wrench

3. 3/16 (.189) Hex Wrench

4. 3/4 (.750) Open End Wrench (for 6” Airmotor)

5. 1/2” (.500) Open End Wrench (for 4-1/4” Airmotor)

6. Pliers

The modular design of the Airmotor and accessibility of vital

operation parts make service available without taking Airmotor out

of line or without complete disassembly.

Power Valve

1. Remove four screws (Items 27 & 34) with 3/16” hex wrench (2

on each side).

2. Remove End Caps (Items 10 & 14).

3. Push out Valve Spool (Item 13).

4. Remove Spool Bumpers (ltem 9) (One from each end).

5. Remove “O” Ring (Item 11) (One from each end of valve body).

6. Remove four Screws (Item 37) with 3/16” hex wrench and lift

valve body (Item 12).

7. Remove Gasket (Item 15) to complete valve disassembly.

8. To REASSEMBLE, REVERSE procedure.

Pilot Bar Subassembly

1. Remove four Screws (Item 23)(two on each end) with 3/16” hex

wrench and pull out Pilot Bar Subassembly.

2. Remove two Screws (Item 39), with 7/64” hex wrench and lift out

Valve Body (Item 17).

3. Remove four Screws (Item 40)(two on each side of Pilot Bar) and

lift off Upper Bracket (Item 31) and Lower Bracket (Item 32).

4. Remove Air Signal Valves (Item 20).

5. To REASSEMBLE, REVERSE procedure.

Cylinder Tube and Muffler

1. Remove Pilot Bar Subassembly (See previous instructions).

2. Remove two Screws (Item 30) with 3/16” hex wrench and remove muffler subassembly.

3. Remove Gasket (Items 28).

4. Remove four Nuts (Item 26) with open end wrench.

5. Lift upward and remove Upper Casting (Item 8).

6. Remove four Tie Rods (Item 25).

7. Remove Air Tube (Item 7).

8. Lift upward and remove Cylinder Tube (Item 6).

9. Remove Piston and Piston Rod (Item 5).

10. Remove four Connecting Rods (Item 41) with open end wrench.

11. To REASSEMBLE, REVERSE procedure.

NOTE: Align two holes on the the Cylinder

Tube (Item 6) with two holes on the Pilot Bar

(Item 24) before tightening Tie Rods (Item 25)

so that proper seal with “O”-rings is acheived.

Page Number - 5

FOR AIRMOTOR WITH PUMP STOP

NOTE: Whenever flammable materials

are pumped, ground Airmotor according to Local Codes.

BEFORE CONNECTING AIRMOTOR TO AIR LINE

LOCTITE® AIRMOTORS are fully pneumatic

and require a minimum specified size of air

supply hose for proper operation. Check

specification for minimum ID. of the air

supply hose and select corresponding

sizes of air controls and accessories for

non-restrictive air flow.

If quick disconnect coupling should be

used, install supplied coupler to insure

proper airmotor operation.

SERVICE AND DISASSEMBLY

PROCEDURE

Tools Required

1. 7/64" (.109) Allen Wrench

2. 5/32" (.156) Allen Wrench

3. 3/16" (.189) Allen Wrench

4. 1/8" (.125) Allen Wrench

5. 9/64" (.1406) Allen wrench

6. 3/4" (.750) Open End Wrench (for 6" Airmotor)

7. #1 Phillips screwdriver

8. 1/2” (.500) Open End Wrench

9. 1/2" (.500) Box End Wrench

10. Pliers

11. 0-100 in. lb. Torque Wrench

12. 0 - 75 Ft. lb. Torque Wrench.

The modular design of the Airmotor and

accessibility of vital operation parts make

service available without taking Airmotor

out of line or without complete disassembly.

Power Valve

1. Remove four screws (Items 27 & 34)

with 3/16” hex wrench (2 on each

side).

2. Remove End Caps (Items 10 & 14).

3. Push out Valve Spool (Item 13).

4. Remove Spool Bumpers (Item 9) (One

from each end).

OPERATING PRECAUTIONS

Use Loctite

compatible pressure rating.

Heed ALL warnings.

DO NOT OPERATE Airmotor in excess of

recommended pressure range.

Disconnect air line and relieve (vent)

pressure when Airmotor sits idle for long

periods of time and before servicing.

5. Remove “O” Ring (Item 11 )(One from

6. Remove four Screws (Item 37) with

7. Remove Gasket (Item 15) to complete

8. To REASSEMBLE, REVERSE procedure.

®

replacement parts to assure

each end of valve body).

3/16” hex wrench and lift valve body

(Item 12).

valve disassembly.

“Optional” Pump Stop

Subassembly

1. Remove four Screws (item 23) (two on

each end) with 3/16" Allen wrench and

pull out Pump Stop Subassembly.

2. Remove two Screws (Item 39) with

7/64" Allen wrench and lift out Valve

Body (item 17).

3. Remove four Screws (Item 32) (two on

each side of Pump Stop) with1/8" Allen

wrench and remove Signal Valve Caps

(Item 31) and Air Signal Valves (Item

20).

4. Remove four (4) screws (item 80) with

9/64" Allen wrench to remove labyrinth

sub-assembly from Pump Stop.

5. Remove four Screws (Item 24) with

3/16" Allen wrench and lift off Upper

Body (Item 50) and Upper Gasket (Item

51).

6. Remove Gasket Plate (Item 52) and

Lower Gasket (Item 53).

7. Remove Air Filter (Item 40) in two

locations.

8. Remove Pump Sleeve (Item 56) and

Piston (Item 55).

9. Remove Diaphragm Seal and Retainer,

Diaphragm, Spring and Stop Valve Assy.

(Items 61, 57, 58, 59 & 60).

10. Remove Trip Indicator (Item 48).

ATTACHING AIRMOTOR TO

PUMPTUBE

1. Tightly attach the tie rods(ltem 41) to

the Airmotor lower casting. Use short

threaded end of tie rods.

2. Mount Airmotor on top of pump tube

outlet and tightly connect pump tube

coupling nut to Airmotor Piston Rod (Item

5).

3. Hand tighten tie rods to the pump tube

with four nuts (Item 42) supplied with

Airmotor.

4. Connect air supply and slowly cycle

pump several times using only enough

air pressure to operate pump without

stalling.

5. STOP pump on "UP" stroke and tighten

four nuts to securely fasten Airmotor to

pump tube.

11. To re-assemble, reverse the disassembly procedure with the following

precautions

a. The upper and lower gaskets (items

51 & 53) should be coated with a

film of light oil (SAE 10) before

assembly.

b. When new umbrella valves (item 63)

are installed, note that the gasket

plate (item 52) has a circle and an

“X” stamped into both sides of the

gasket plate. The umbrella valve is

installed into the plate from the circle

side of the plate. One umbrella

valve should be installed into each

side of the plate so that the valve is

within the circle and the stub end

protrudes through the “X”.

c. After installing the umbrella valve

(item 63) the long rubber stem of the

valve is to be removed, leaving the

rubber ball end intact to secure the

valve to the plate.

d. When installing the pump sleeve,

(item 56) into the lower body, (item

54) the sleeve should be placed into

the lower body as shown in

Illustration on Page 12. When

properly installed the molded pin

protruding from the pump sleeve will

fit into a mating hole in gasket (item

53) and the gasket can then be

installed properly over pins, (item

66). If the sleeve is not properly

aligned as shown, the Pump Stop

cannot be assembled properly.

Page Number - 6

Loading...

Loading...