Loctite 980160 Operating Manual

®

EQUIPMENT

OPERATION MANUAL

Loctite

High Intensity

Ultraviolet

Source

®

980160

Contents

Page No.

1 Please observe the following . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Emphasized Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Items Supplied . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 For Your Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.1 Ultraviolet Light Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3.2 Ozone Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.3 Thermal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.4 Electrical Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Field of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Operating Elements and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Utility and Space Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Initial Set Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Additional Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Shut Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.3 Idle Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5 Care and Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.1 Cleaning the Lamp and Reflector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 Removing the Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.3 Removing the Reflector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Recommended Spare Parts and Accessories . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9.1 Figure 2 Lamp Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

9.2 Figure 3 Electrical Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1 Please observe the following

1.1 Emphasized Sections

WARNING!

Refers to safety regulations and required safety measures that protect the operator or other

persons from injury or danger to life.

Caution!

Emphasizes what must be done or avoided so that the unit or other property is not damaged.

☞

Notice:

Gives recommendations for better handling of the unit during operation or adjustment as well as

for service activities.

1.2 Items Supplied

Carefully remove the system from its shipping carton and inspect it for any signs of damage. Any

damage should be reported immediately to the carrier. Refer to the list of supplied parts below

and compare to the contents. Report any missing parts promptly to the Loctite customer service

department at 1-800-LOCTITE or 1-800-562-8483.

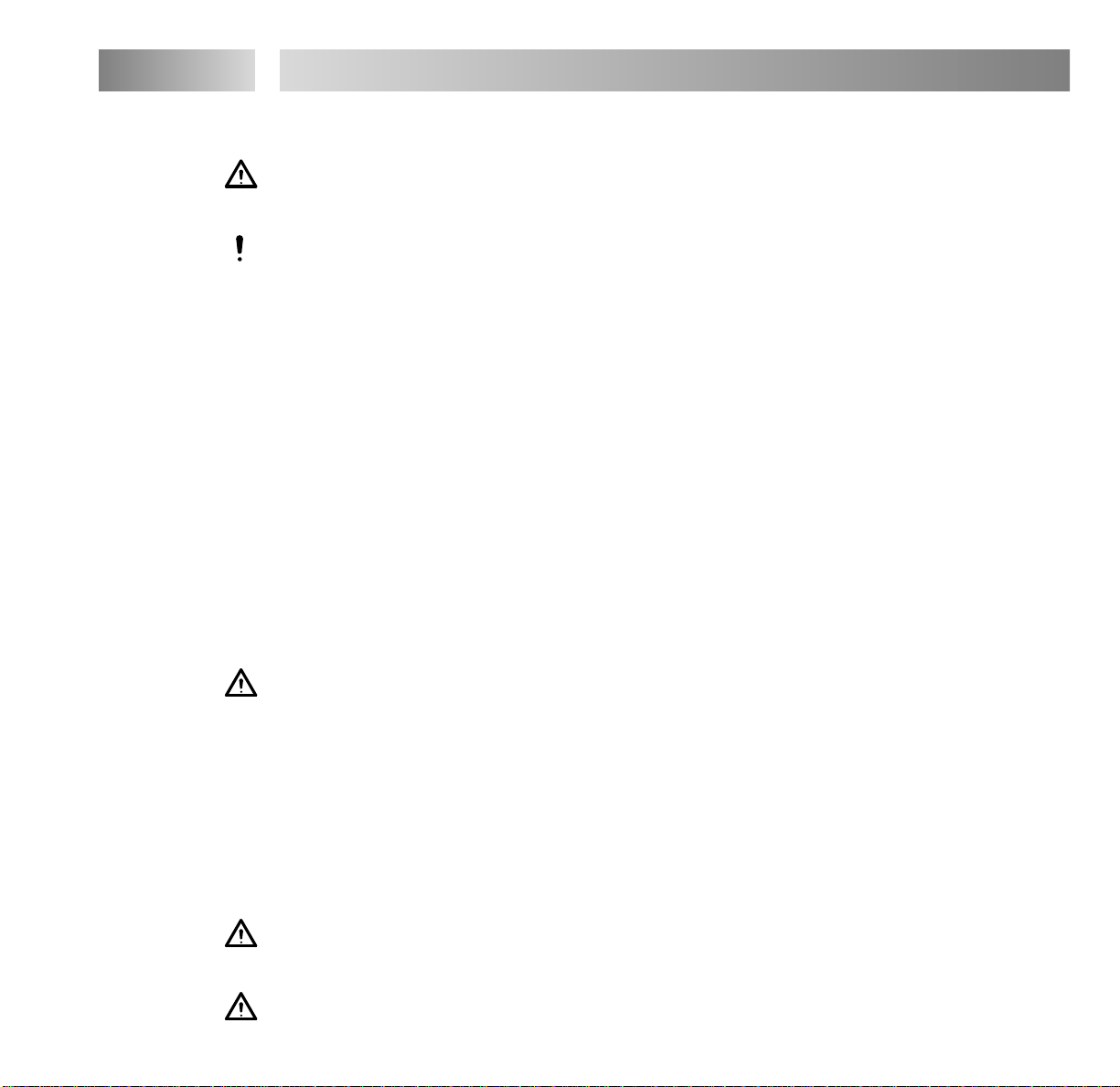

(1) Power Supply with attached input power line cord and output cable with connector to

irradiator.

(1) UV Lamp and Irradiator (reflector) Assembly.

(1) Pair UV Safety Glasses.

(1) Instruction manual.

1.3 For Your Safety

IMPORTANT!

Do Not operate the unit before reading this section.

1.3.1 Ultraviolet Light Safety

The Loctite®High Intensity Ultraviolet Source is a source of long wavelength ultraviolet light

used to cure light sensitive products. It produces intense ultraviolet (UV) light, which can cause

serious burns to the skin and eyes. The light is similar to that which causes sunburn but is

much stronger. Like a sunburn, UV burns of the eyes or skin are not felt until several hours

after the burn occurs. All personnel involved in the operation of the High Intensity Ultraviolet

Source should be familiar with the safety guidelines described in this manual. The following

guidelines should be followed at all times to ensure protection from the ultraviolet light.

1. The High Intensity Ultraviolet Source has no shielding. The user must provide shielding to

prevent exposure of operating personnel to direct or first bounce reflected light. Refer to

Section 3 of this manual for additional information.

2. UV protective glasses with side shields should be worn when working with and around the

lamp system. Glasses should meet ANSI Z87.1 certification.

1

1 Please observe the following (continued)

3. Potentially exposed skin should be covered. Long sleeves and protective gloves should be

worn when placing and removing parts from under the lamp.

4. Never look directly at the output from the lamp or directly into the lamp/reflector.

5. Removing the glass filter from the lamp housing may speed up the cure of some products,

however, this will also speed injury to eyes and unprotected skin. DO NOT OPERATE THE

LAMP WITH THE FILTER REMOVED.

UV safety is the responsibility of the user, especially when operating the unit in a non-standard

configuration. When in doubt about UV safety, consult a Loctite technical specialist at

1-800-LOCTITE OR 1-800-562-8483.

1.3.2 Ozone Safety

3

A secondary hazard is the ozone (O

< 240 nanometers with atmospheric oxygen. Use this equipment with adequate ventilation.

The current (Feb. 1999) threshold limit value (TLV) for ozone is 0.1 ppm (parts per million).

There are several techniques for monitoring ozone concentrations. One of the simplest, is

equipment supplied by National Draeger, Inc., of Pittsburgh, PA. Their devices employ a direct

reading, disposable detection tube which is capable of measuring ozone concentrations of 0.05

ppm to 14 ppm.

Ozone concentrations can be minimized with good local ventilation. Ozone generation can be

prevented entirely by the use of an oxygen-excluding nitrogen atmosphere under the lamp or by

using an “ozone free” lamp. “Ozone free” lamps have a quartz sleeve or tube which blocks

wavelengths < 240 nanometers. See the Spare Parts List on page 10 of this manual for the part

number of the “ozone free” lamp.

). Ozone is generated by reaction of UV light of wavelength

1.3.3 Thermal Safety

A third safety concern with medium-pressure mercury light sources is heat. UV lamps generate

significant amounts of energy in the infrared region. Infrared radiation heats all nearby objects. In

addition, the quartz sleeve of the UV lamp must be maintained at between 600°C and 800°C to

vaporize the mercury in the lamp. The user must supply sufficient cooling and/or heat shielding

to keep the system at a safe temperature for the operators. The cooling must also keep the parts

being cured at a safe operating temperature.

1.3.4 Electrical Safety

1. Connect the unit to a three-wire (grounded) outlet with correct ampere capacity.

2. The power supply enclosure contains a high voltage transformer which supplies high lamp

starting voltages. This unit should be serviced only by qualified electricians or by a Loctite

Service Technician.

2

2 Description

2.1 Field of Application

The High Intensity Ultraviolet Source is a ultraviolet energy source designed for a wide range of

applications involving the curing of Loctite®ultraviolet activated adhesives and coatings. With the

proper ultraviolet light shielding, and cooling, and venting this light source can be used in both

prototype and production applications.

2.2 Theory of Operation

The Ultraviolet Source is designed for the curing of Loctite®UV activated adhesives and

coatings. It is ideal for adapting to customers' current production equipment; the lamp unit can

be mounted to existing conveyors and indexing equipment (UV shielding isrequired to protect

the operator). Aseparately packaged power supply is powered by 120 VAC, 20 Amp, 60 Hz

electrical power and can be located up to 5 feet from the lamp. Power can be monitored with the

built-in watt meter. A high/low intensity switch (300 w/inch to 200 w/inch) located on the front

panel of the power supply unit allows the lamp to idle at low power when not in use.

The lamp unit should be located approximately 5 inches above the curing plane. When placed at

this height, the curing area will be approximately 4.5 inches x 6 inches for a single UV Source.

Multiple sources can be used for larger curing area.

3

Loading...

Loading...