Loctite 97211 Operating Manual

1

Operating Manual

Bedienungsanleitung

Online Preamplifier

Online-Vorverstärker

97211

2

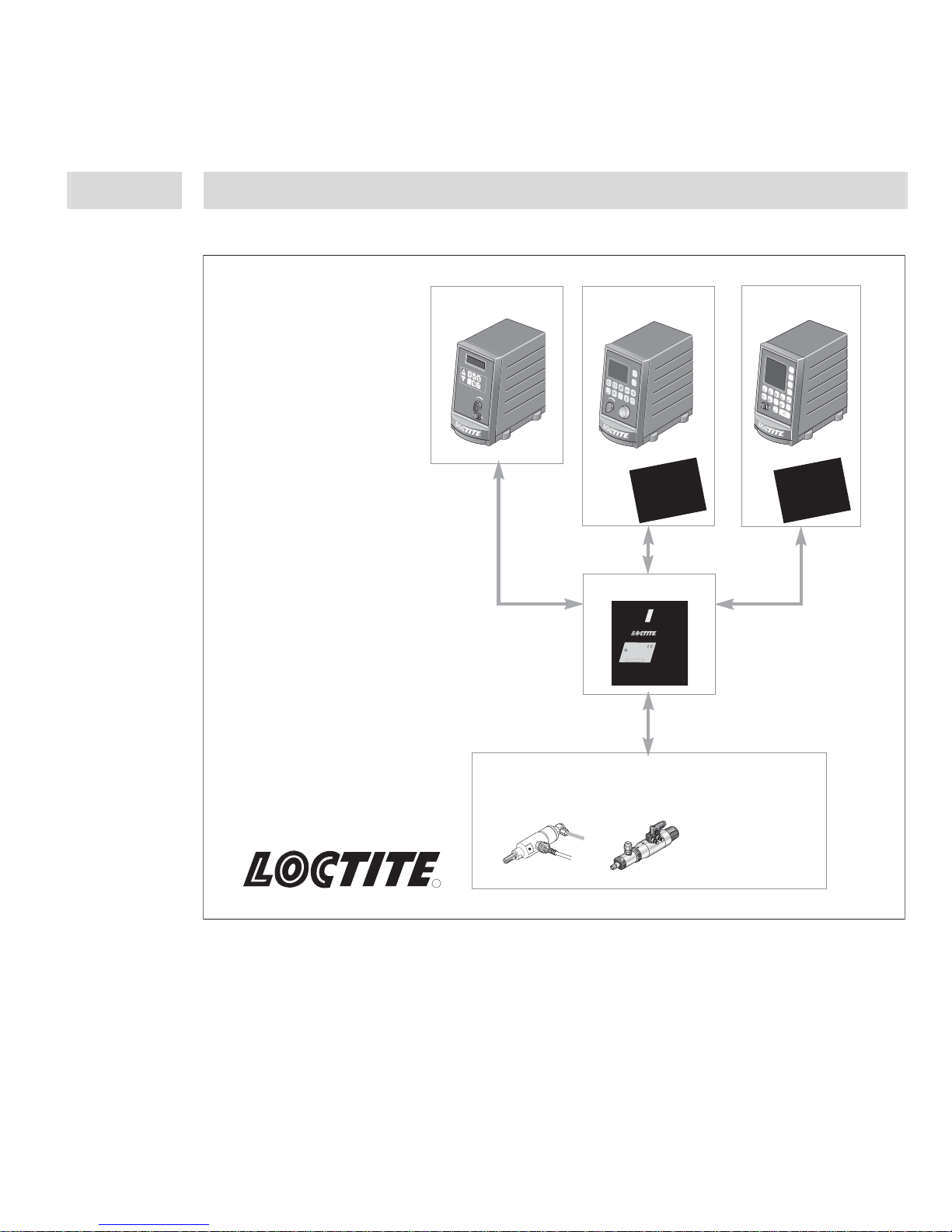

R

97123

R

97123

ESC

97211

Loctite Deutschland GmbH

Made in Germany

cat. no. 97211

R

97211

Output

1V

5V

10V

97152

1-2x

1x

97153

1

ESC

Num

0

9

6

-

8

Start

3

P

4

5

2

7

A

B

C

D

97153

+

1-4x

1x

97113/97295

97114/97295

97138

97140

97152

ESC

Start

A

B

97204

97204

3

Content

English.....................................................................................................................................4-31

Deutsch..................................................................................................................................32-57

4

Content

1 Please observe the following .................................................................................6

1.1 Emphasized Sections ....................................................................................................... 6

1.2 Items Supplied .................................................................................................................7

1.3 For Your Safety................................................................................................................7

1.4 Field of Application (Intended Usage) ............................................................................ 7

2 Description.............................................................................................................8

2.1 Theory of Operation......................................................................................................... 8

2.2 Displays, Operating Elements and Connections............................................................ 11

3 Technical Data.....................................................................................................12

4

Installation ...........................................................................................................13

4.1 Enviromental and Operating Conditions ....................................................................... 13

4.2 Space Requirements.......................................................................................................13

4.3 Connecting the Unit....................................................................................................... 14

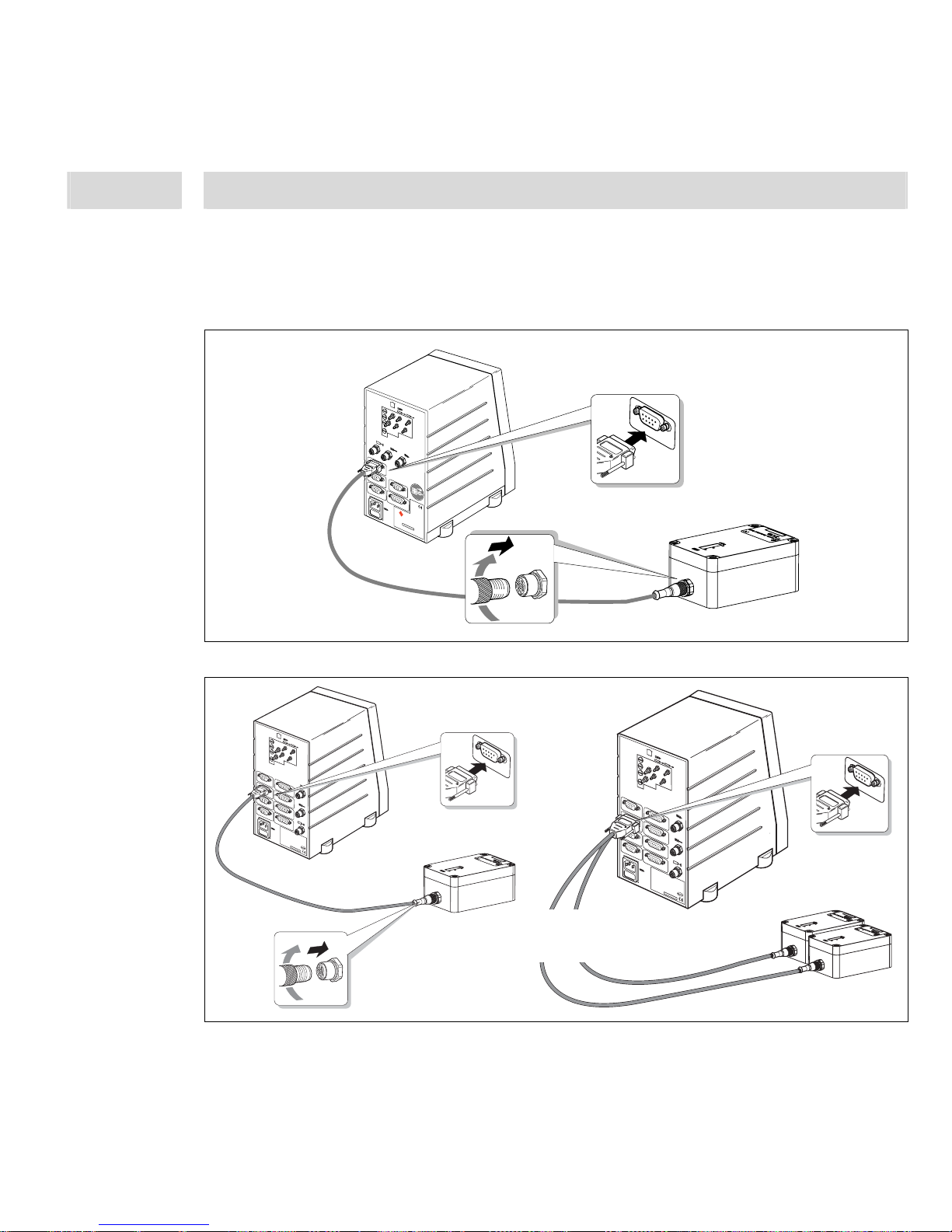

4.3.1 Automatic Controller 97123 .......................................................................................... 14

4.3.2 Dual Channel Automatic Controller 97152................................................................... 14

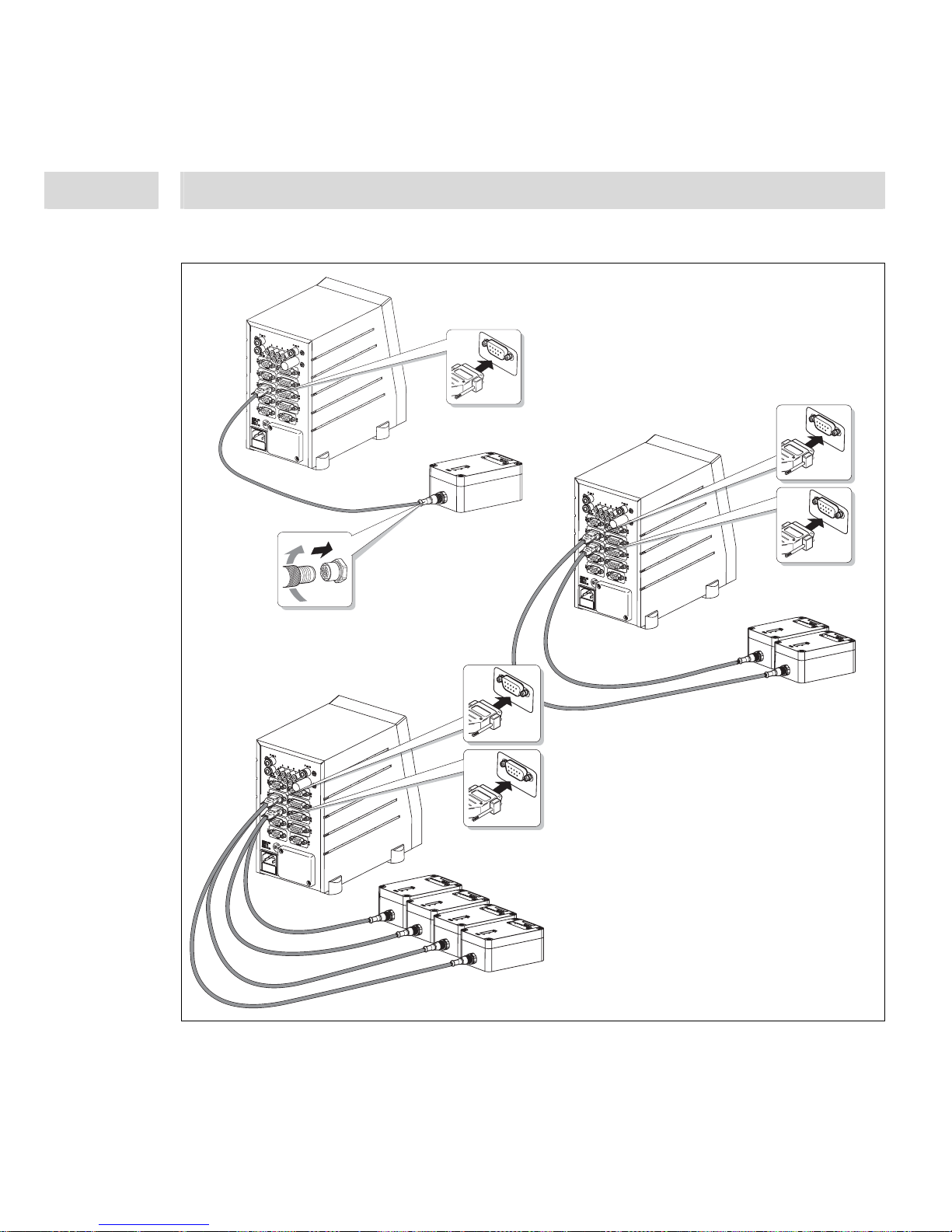

4.3.3 Multi Channel Automatic Controller 97153.................................................................. 15

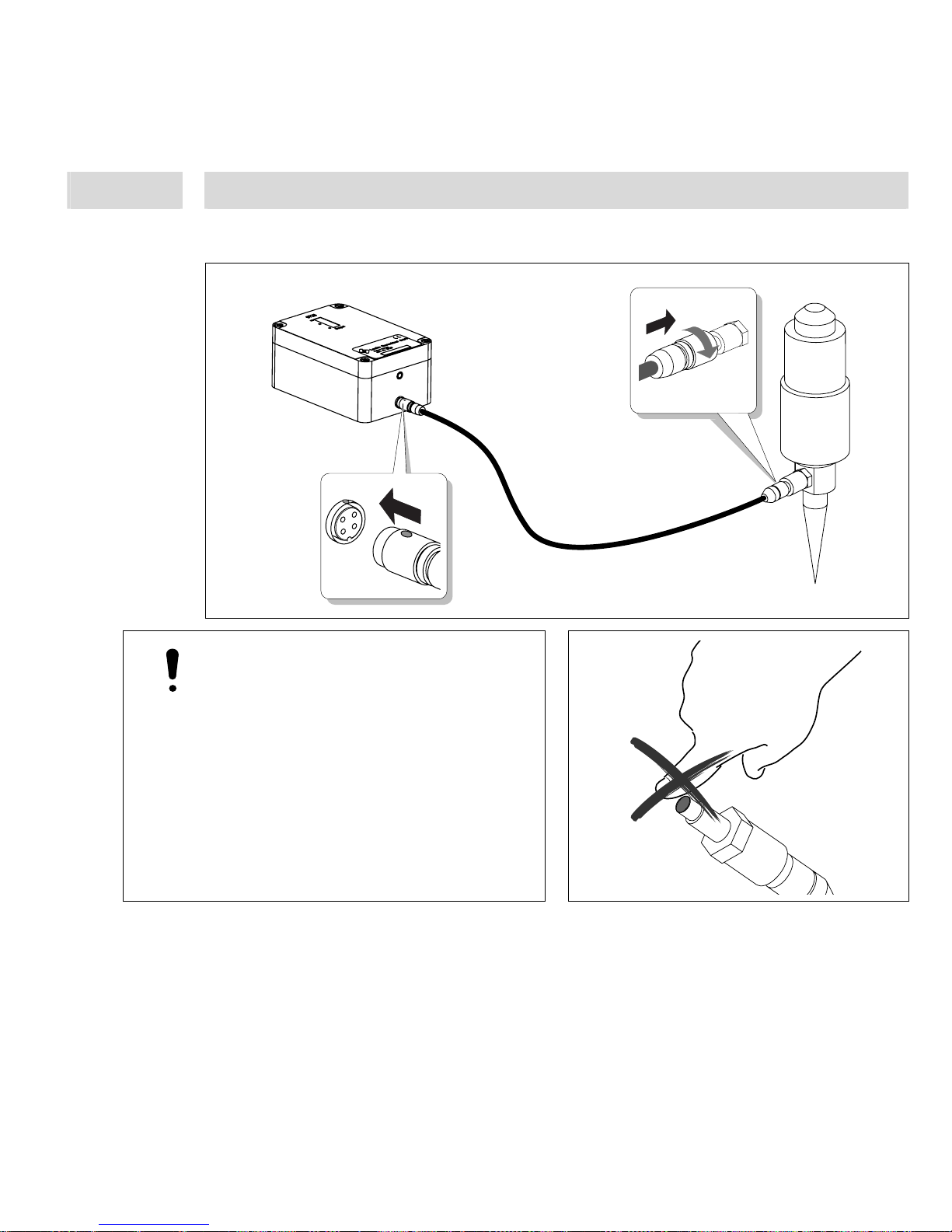

4.3.4 Pressure Sensor.............................................................................................................. 16

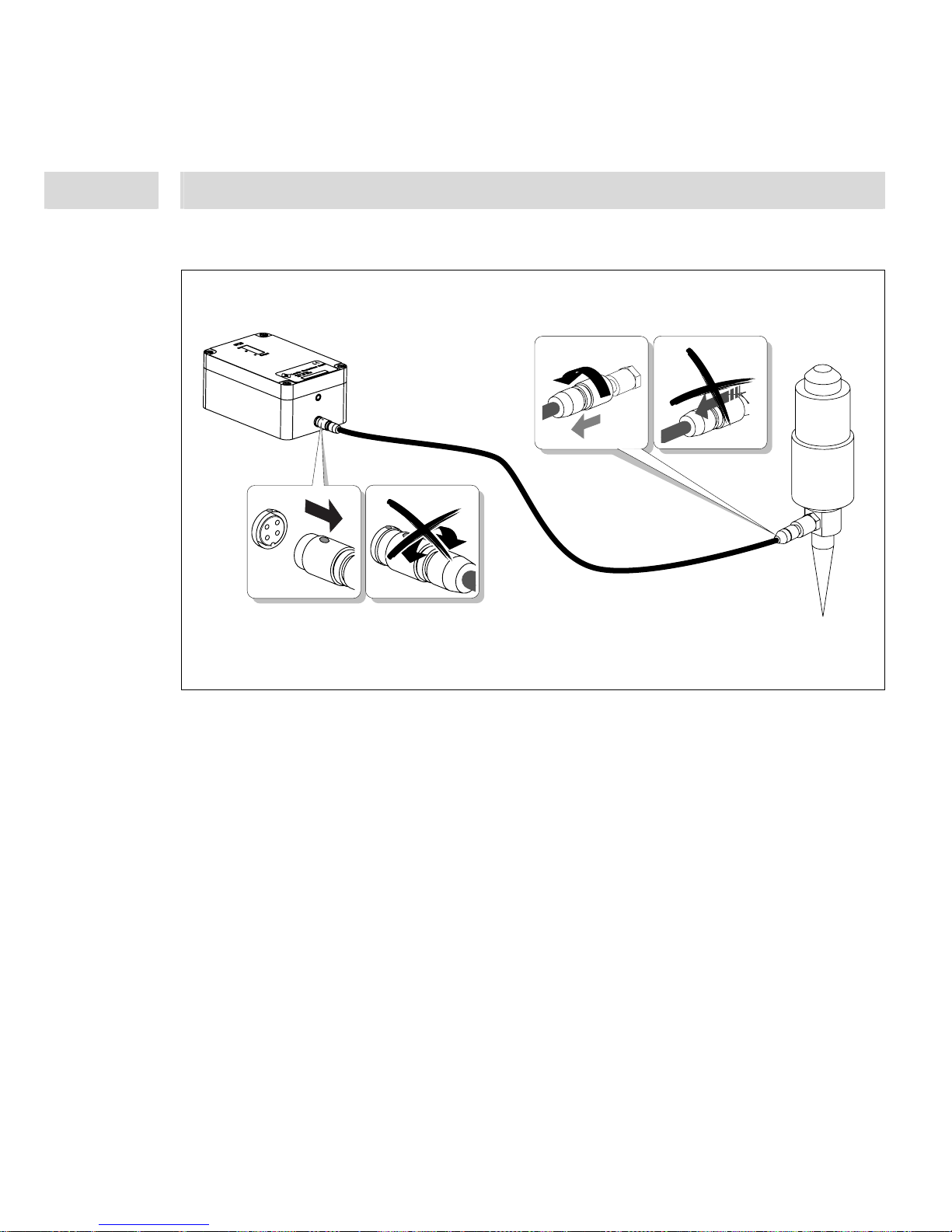

4.4 Disconnect the Pressure Sensor ..................................................................................... 17

5

Content

5 Measuring.............................................................................................................18

5.1 Adjusting of the Dispense Quantity................................................................................18

5.2 Adjusting the Preamplifier 97211...................................................................................19

5.3 Setup and Storing a Reference at the Controller ............................................................20

5.4 Monitoring......................................................................................................................21

5.5 Software Interface for Statistic Process Control (SPC)..................................................23

6 Care, Cleaning and Maintenance .........................................................................24

7

Troubleshooting ...................................................................................................24

8

Annex...................................................................................................................25

8.1 Spare Parts......................................................................................................................25

8.2 Pin Assignment...............................................................................................................26

8.2.1 4 pin Plug for Connection to Controller.........................................................................26

8.2.2 4 pin Socket for Connection to the Pressure Sensor.......................................................26

8.2.3 PLC Interfaces XS 5 Controller 97123 and

XS 10Controller 97152 (internal voltage)......................................................................27

8.2.4 PLC Interfaces XS 5 Controller 97123 and

XS 10 Controller 97152 (external voltage) ....................................................................28

8.2.5 SPS-Interface to Controller 97153 .................................................................................28

8.3 Declaration of Conformity..............................................................................................29

6

1 Please observe the following

For safe and successful operation of the unit, read these instructions completely.

If the instructions are not observed, the manufacturer can assume no responsibility.

Be sure to retain this manual for future reference.

Refer to the technical data sheet for the LOCTI TE

®

product used at www.loctite.com or contact

your local technical department.

1.1 Emphasized Sections

WARNING!

Warning is the signal word used to indicate a potentially hazardous situation which, if not

avoided, could result in death or severe injury.

CAUTION!

Caution is the signal word used to indicate a potentially hazardous situation which, if not

avoided, could result in moderate or minor injury.

☞

Note!

Gives recommendations for better handling of the unit during operation or adjustment as well as

for service activitie s.

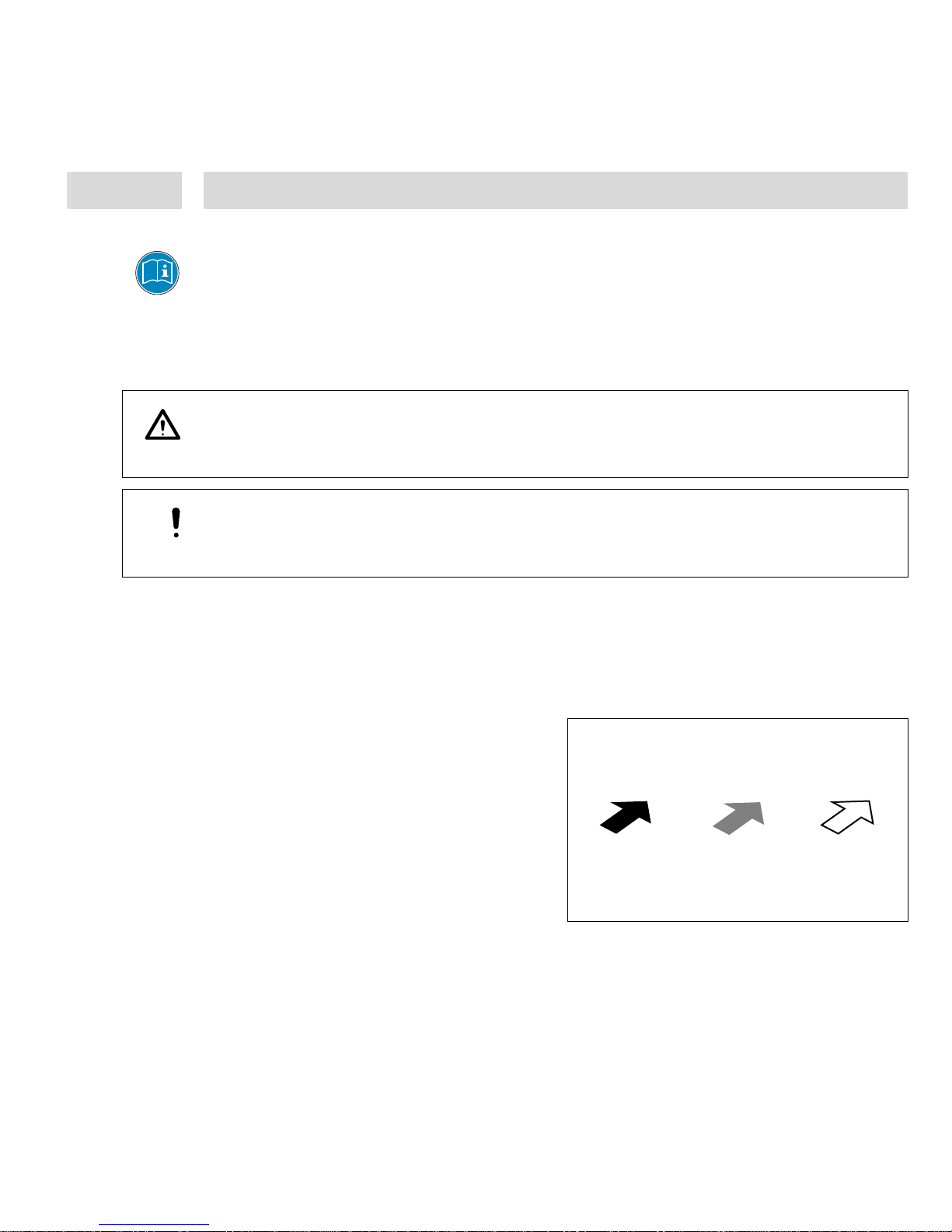

The numbers printed in bold in the text refer to the corresponding position numbers in the

illustration on page 11.

• The point emphasizes an instruction step.

Instruction steps in the illustrations are

indicated with arrows.

When several instruction steps are indicated

in an illustration, the shading of the arrow has

the following meaning:

Black arrow = 1

st

step

Grey arrow = 2

nd

step

White arrow = 3

rd

step

7

1 Please observe the following

1.2 Items Supplied

1 Preamplifier 97211, Order Code No. 215992 1 Connection Cord Preamplifier to

1 Operating Manual 97211 Controller

Purchasing the Preamplifier 97211 includes the permission to use the monitor software of the

controller 97123, 97152 and 97153

☞

Note!

As a result of technical development, the illustrations and descriptions in this instruction manual

can deviate in detail from the actual unit delivered.

1.3 For Your Safety

WARNING!

Only an authorized Henkel service representative may repair the unit.

Observe manufacturer’s instructions!

1.4 Field of Application (Intended Usage)

The integrated flow monitor of a Loctite controller in connection with the Preamplifier Online

Monitor 97211 is used for monitoring the quality and quantity of adhesive dispensed on parts, i.e.

the flow monitor recognizes and evaluates dispensing defects with respect to quality and quantity.

Such defects include:

– Air bubbles in the dispensing system

– Pressure changes in the dispensing system

– Lost or clogged dispensing nozzle

– Touch down of dispensing nozzle onto substrate.

It has been designed specifically for applications requiring high accuracy in dispensing Loctite

adhesives. It is an ideal tool for quality assurance. The flow monitor is used mainly in the

following types of workstations:

– Manual work stations handling precision manufacturing jobs or safety relevant parts.

– Assembly lines with robot stations.

– Assembly lines with automatic in-feed and out-feed.

– CNC workstations.

Necessary LOCTITE

®

controllers:

– Automatic Controller 97123 or

– Automatic Controller 97152 or

– Multi Channel Automatic Controller 97153

In order to integrate such a monitoring system in the production process a special dispensing

valve with an integrated pressure sensor is required.

8

2 Description

2.1 Theory of Operation

The integrated flow monitor of the Loctite® controller in connection with the Preamplifier 97211

measures the dispense pressure characteristic by means of a pressure sensor and stores this

parameter. The pressure sensor is integrated in the dispensing valve. The measuring time

corresponds with the dispense time sequence. The controller compares the measured pressure

characteristic with a previously stored reference characteristic, based on four different criteria:

– Dispensing time

– Integral of pressure characteristic; corresponds with quantity of product dispensed

– Length of envelope curve for pressure characteristic

– Center of gravity

If the measured values are within the pre-set tolerance zone in comparison to the reference value,

this dispensing cycle is recognized as o. k. and the ready signal will be available. If the deviation

is outside the tolerance zone, this dispensing cycle is detected as an error, and a fault is signaled.

This message is indicated on the display at the controller. It is also provided as a signal at the

PLC interface of the LOCTITE

®

controllers.

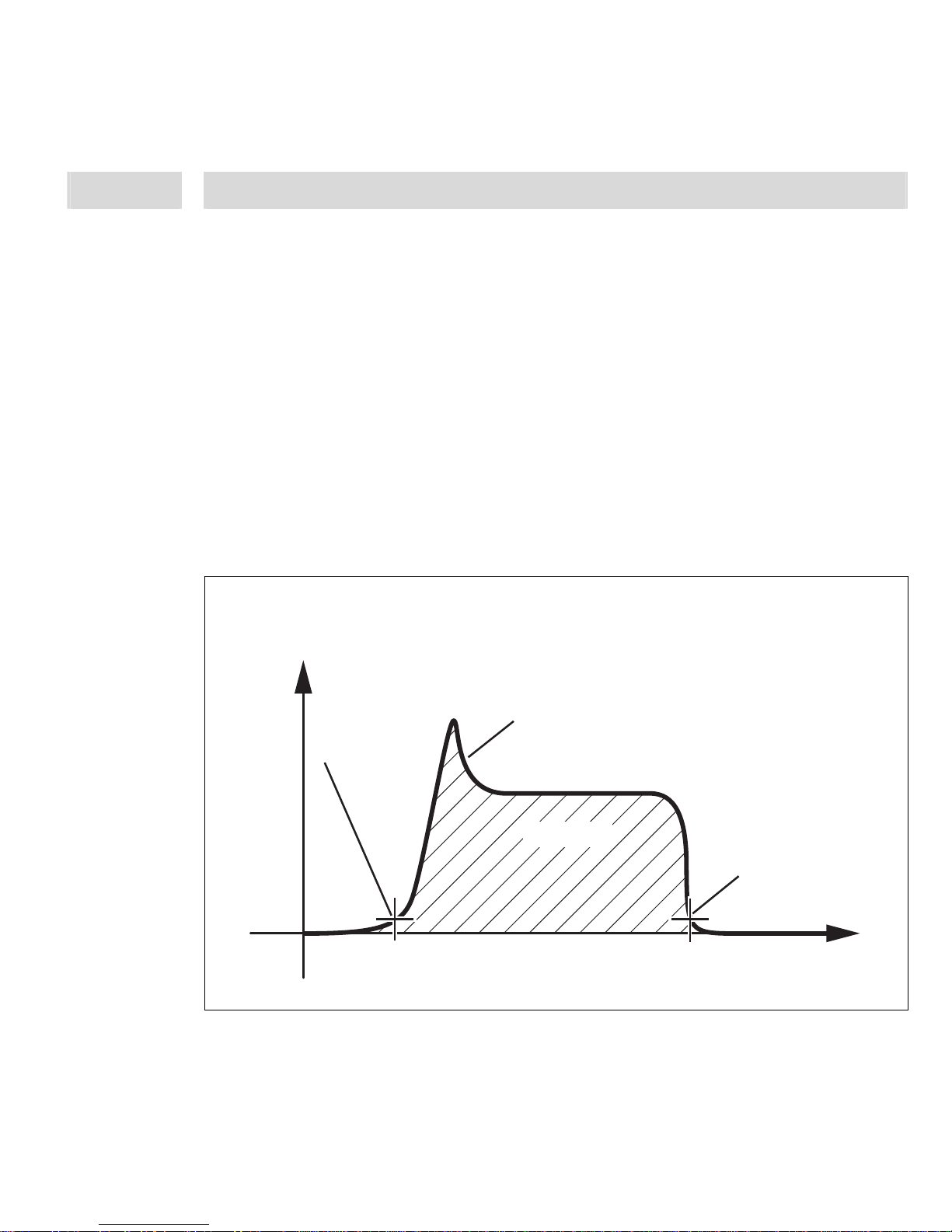

Integral (I)

P

Gesamtdosierzeit (T)

Total Dispensing Time

t

Hüllkurve (H)

Envelope Curve1. Offset

1

st

Offset

2. Offset

2

nd

Offset

Normaler Druckverlauf mit einem Dosierventil

Typical Pressure Characteristic with a Dispensing Valve

9

2 Description

It measures the last preceding dispensing cycle relative to a reference measurement previously

recorded and found to be o. k. The main adjustments have to be done in the setup menu of the

controller, to make sure that authorized personnel can store this reference value only. Depending

of the used controller the tolerance can be adjusted in 3 preadjusted ranges (low = 15%, middle =

35% or high = 55%) or from 1 to 99% to define the optimum between frequent false alarms and

reliable fault detection, see operating manual of the used controller. This value affects the

tolerance of the monitored parameters of integral and length of envelope curve.

Referred to the length of the envelope curve the tolerance value actually indicates accuracy in %.

An air bubble, a clogged needle or a needle touchdown each has a very strong effect on the

envelope curve length of the pressure characteristic. Therefore this is generally the governing

parameter for dispense monitoring.

If the controller 97152 or 97153 is used several different dispense quantities can be monitored.

The order of storing is fixed, but the reference can be selected per user’s own choice. The

advantage is, that different quantities on various work pieces can be preselected according to the

user’s requirement via the seri al inte rfac e.

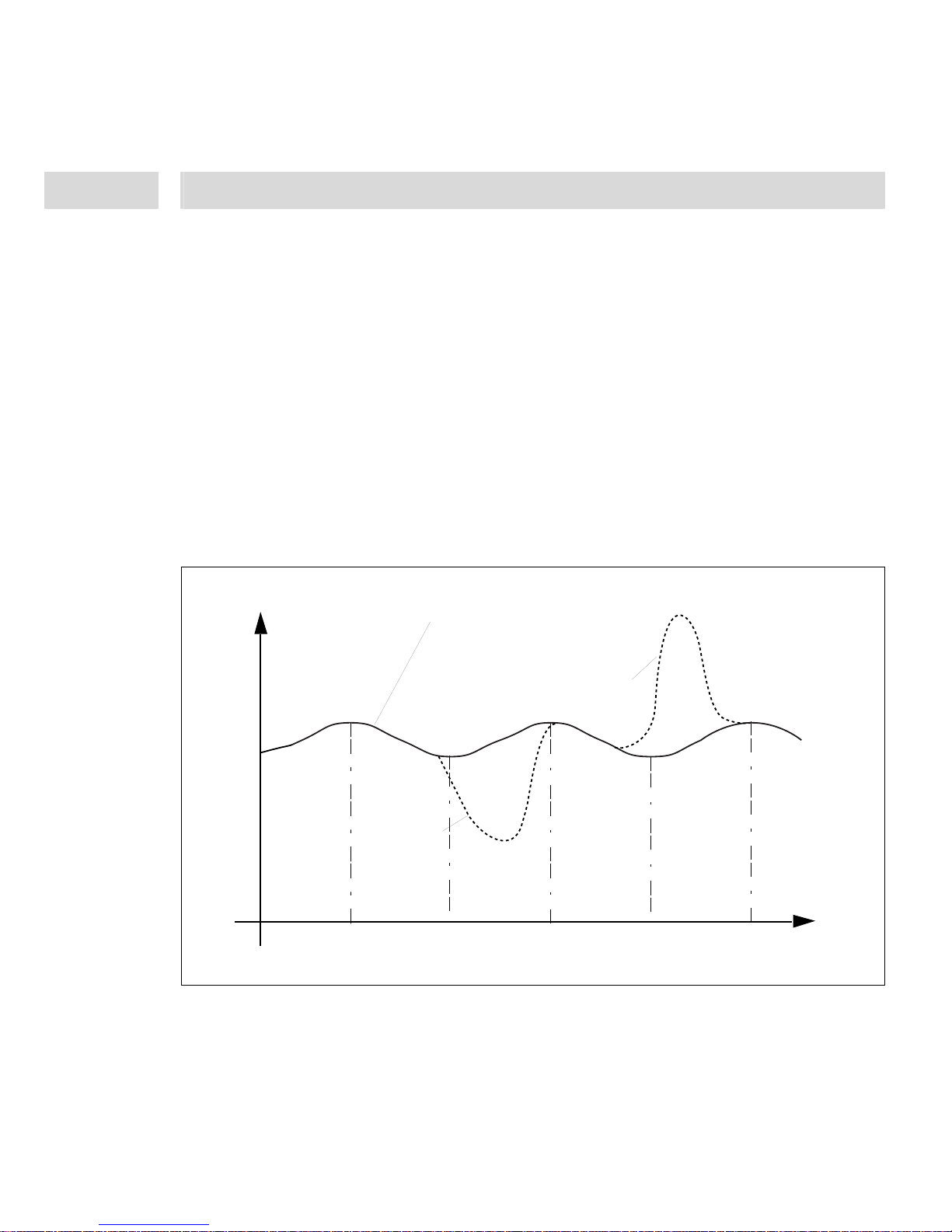

P

t

Luftblase

Air bubble

Aufsetzer

Needle touch-down

Normaler Druckverlauf mit Schneckenpumpe

Normal Pressure characteristic with Rotor Pump

250 ms

500 ms

750 ms

1000 ms

1250 ms

10

2 Description

At the Preamplifier Online Monitor 97211 the amplification factor has to be adjusted to get an

optimum signal for correct interpretation at the Loctite controller.

Before each new start of a dispensing cycle, the controller generates a ready signal or error

signal. This happens at the end of each dispensing cycle. In case of failure of the sensor, no

measuring signal corresponding to the reference measurement can be generated. For this reason,

whenever a failure occurs, the system will always generate a fault signal at the end of the

dispensing cycle. Therefore the complete system is fail-safe if linked to a Loctite controller, i.e.

even in case of partial or complete failure no dispensing cycle will pass unchecked.

The type sensors used in the system are absolute pressure sensors. Variations in atmospheric

pressure such as they may result from weather conditions will affect measurements in a slight but

negligible degree. Temperature fluctuations have an effect on viscosity and consequently on

product dispensing where pressure reservoir/valve systems are used.

The integrated flow monitor of the Loctite controller recognizes the consequences of these

influencing factors, such as changes in the quantity of material dispensed.

To achieve absolutely constant dispensing results would actually require adapting the dispense

pressure to the temperature and thus to the viscosity. In the field, these variations in quantity due

to temperature fluctuations can mostly be tolerated.

However, if the dispensing result deviates too much from the desired bead configuration due to

major temperature variations, the displayed error rate will increase, and the dispensing pressure

will have to be adapted by authorized personnel. In this case a new reference measurement has to

be made.

Therefore, a seasonal check and, if required, adaptation of settings may be advisable.

Monitoring specifications:

– The sample rate is 1 kHz, (1000 measuring points per second).

– The minimum and maximum time of measurement are 0,03 and 15 seconds.

11

2 Description

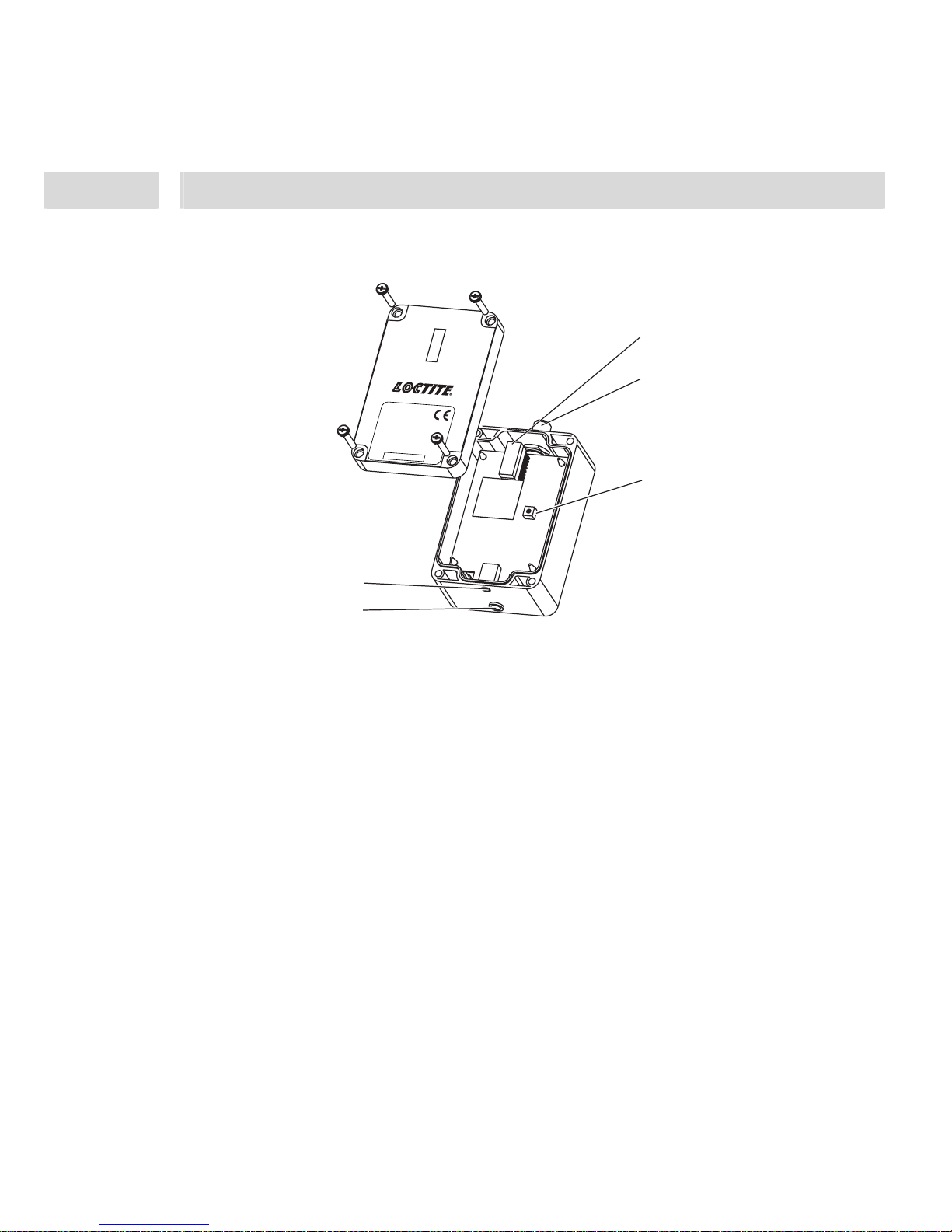

2.2 Displays, Operating Elements and Connections

1

LED Row 1-10 V OUTPUT

displays the measured and amplified signal from the sensor while measuring. The best adjustment

can be done by means of flushing the dispensing valve.

LED display:

– no dispensing: 0-2 LED lights,

– during flushing: 2 LED or more should light up additionally, but a few LED should not light.

This means that all LED must not light.

– during dispensing (or flushing) with clogged dispensing needle: it should light up at least 2

LED more, maximum all.

2

4 pin Plug for connection to controller

The supplied connection cord is connected here (Pin assignments see Section 8.2).

3

Potentiometer R10 to adjust the amplification factor

It is necessary to adjust the amplification factor for getting an optimum signal for the

interpretation at the Loctite controller.

4

Service Socket, for Loctite service only

5

4 pin Socket for connecting the pressure sensor

The cable of the pressure sensor is connected here (Pin assignments see Section 8.2).

1

2

3

4

5

Output

97211

10 V

5 V

1 V

Henke

l AG

& Co. KGaA

Standort M

ünchen

Gutenbergs

tr. 3

D-85748 Ga

rching b. M

ün

Order Code No. 215992

Made in Germany

Place for Serialnumbersticker

12

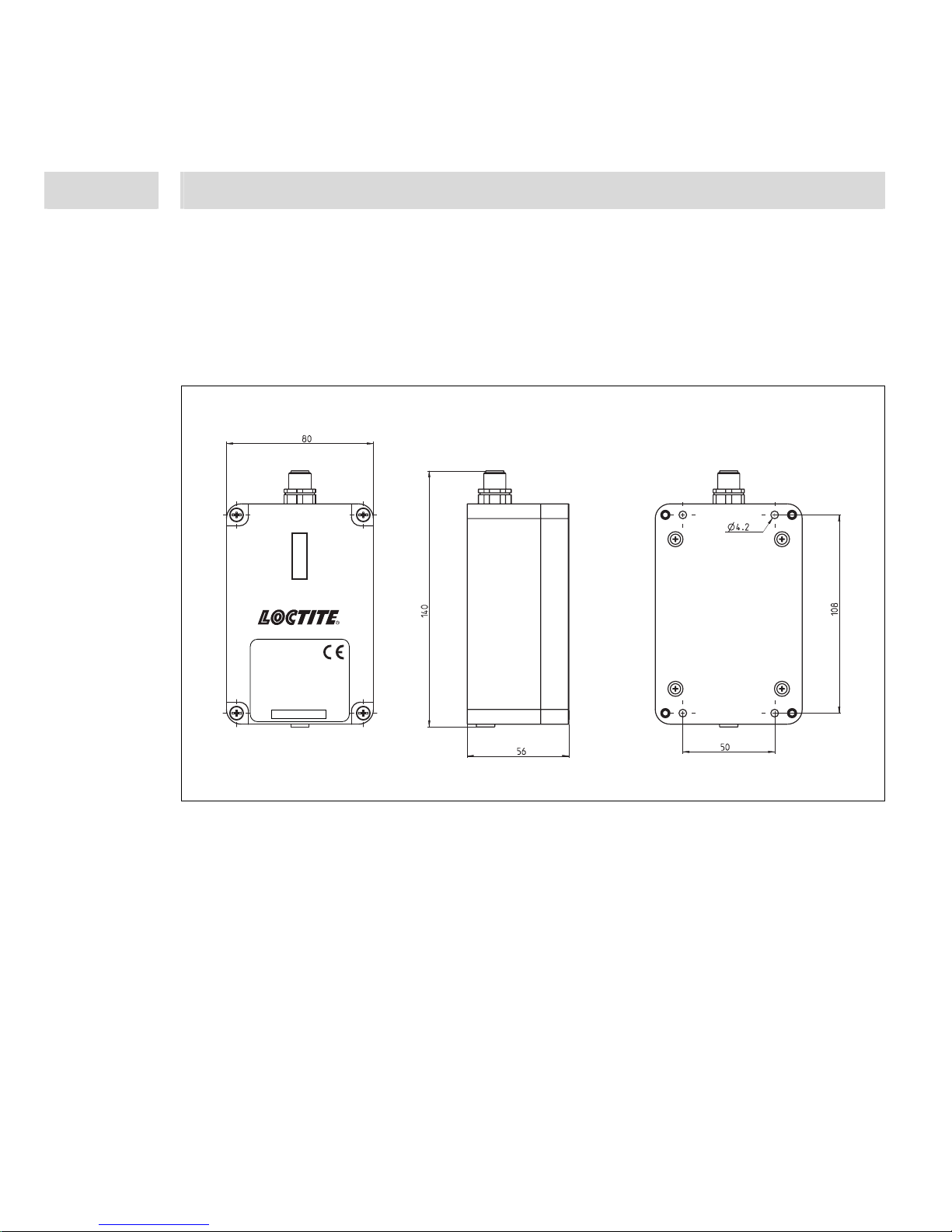

3 Technical Data

Power input 24 VDC

Signal output 1 – 10 VDC

Protection grade IP 65

Dimensions W x H x D: 80 mm x 57 mm x 141 mm:

Operating temperature +10 °C to +40 °C (+50 °F to +104 °F)

Storage temperature -10 °C to +60 °C (+14 °F to +140 °F)

Weight 0,24 kg

Max Length of the cable between Pressure

Sensor and Preamplifier

5 m

Max Length of the cable between Preamplifier

and Controller

10 m

13

4 Installation

4.1 Environmental and Operating Conditions

– Non-condensing humidity.

– No splash water.

– Housing may not get in touch with solvent!

4.2 Space Requirements

Output

97211

10 V

5 V

1 V

Henkel AG & Co. KGaA

Standort München

Gutenbergstr. 3

D-85748 Garching b. München

Order Code No. 215992

Made in Germany

Place for Serialnumbersticker

14

4 Installation

4.3 Connecting the Unit

• Use only the cable supplied

4.3.1 Automatic Controller 97123

4.3.2 Automatic Controller 97152

90-260 VAC

47-63 Hz

Phase = 1

XS1 Start

XS2 Reservoir

XS3 Flow Monitor

XS5 PLC Interface

XS4 RS232

2 AM

cat. no. 97123

Loctite (Ireland) Ltd.

Tallaght Business Park

Whitestown

Tallaght, Dublin 24, Ireland

Made in Germany

Power consumption max. 60 W

A

B

P in 6-8 bar

XS6

XS7

XS8

0

1

XS3 Flow Monitor

9

0

-2

6

0

V

A

C

47-63 H

z

P

h

a

se

=

1

XS1 S

tart

XS2 R

ese

rvoir

XS3 Flow Monitor

XS5 PLC Interface

XS4 R

S232

2

A

M

Type No. 97152

Henkel KGaA

Standort München

Gutenbergstr. 3

D-85748 Garching b. München

Made in Germany

Power consum

ption ma

x. 60 W

A

B

P in 6-8

bar

0

1

X

S

1

0

X

S

1

1

X

S

9

XS5 PLC Interface

XS5 PLC Interface

XS5 PLC Interface

P out

Order No. XXXXX

XS3

Flow Monitor

XS 3

A

B

90-260 VAC

47-63 Hz

Phase = 1

XS1 Start

XS2 Reservoir

XS3 Flow Monito

r

XS5 PLC

Interface

XS4 RS232

2 AM

Type No. 97152

Henkel KGaA

Standort M

ünchen

Gutenbergstr. 3

D-85748 Garching b.

München

Made in Germany

Power consumption max. 60 W

A

B

P in 6-8 bar

0

1

XS10

XS11

XS9

XS5 PLC

Interface

XS5 PLC

Interface

XS5 PLC

Interface

P out

Order No.

XXXXX

XS3 Flow Mo

nitor

XS 3

2 x 97211 with

1 x Splitter Cable 97529

15

4 Installation

4.3.3 Multi Channel Automatic Controller 97153

XS3 Flow Mo

nitor

XS4 Flow Mo

nitor

A

B

XS 3

XS 4

A

B

C

D

XS3 F

low Mo

nitor

XS4 F

low Mo

nitor

XS 3

XS 4

XS3

Flow Monitor

XS 3

4 x 97211 with

2 x Splitter Cable 97529

16

4 Installation

4.3.4 Pressure Sensor

Caution!

Handle sensor with absolute care!

No scratching or touching of the

membrane!

Never exceed a pointed pressure load in

the extremely thin and sensitive sensor

diaphragm.

Otherwise the sensor will be destroyed!

Apply the tightening torque:

min. 0.4 Nm, max. 0.6 Nm

17

4 Installation

4.4 Disconnect the Pressure Sensor

Loading...

Loading...