Loctite 883976 Operation Manual

EQUIPMENT

Operation Manual

Loctite

Part Number 883976

Benutzerhandbuch

Loctite Digitales

Kartuschendosiergerät

Artikelnummer 883976

Digital Syringe Dispenser

Manual de operación

Loctite Dosificador

digital tipo jeringa

Número de parte 883976

Table of Contents 2

1. Safety - Please Observe the Following 3

1.1 Emphasized Sections

1.2 For Your Safety

1.3 Unpacking and Inspection

1.4 Items Supplied

2 Description 4

3 Technical Data 6

4 Installation 6

5 Operation 7

5.1 Set up Instructions

Manual Mode

5.2 Dispense Cycle Setting

Time Mode

Incremental Mode with Teach Function

Cycle Counter Reset

6 Troubleshooting 10

7 Maintenance & Operational Tips 11

8 Accessories and Spare Parts 11

9 I/O Configuration & Pneumatic Diagram 12

10 Warranty 13

11 Declaration of Conformity 15

2

1 Please Observe The Following

1.1 Emphasized Sections

Warning!

Refers to safety regulations and requires safety measures that

protect the operator or other persons from injury or danger to

life or property

Caution!

Emphasizes what must be done or avoided so that the unit or

other property is not damaged.

Notice:

Gives recommendations for better handling of the unit

during operation or adjustment as well as for service

activities.

1.2 For Your Safety

For safe and successful operation of the unit, read these

instructions completely. If the instructions are not observed,

the manufacturer can assume no responsibility.

Do not operate the unit in excess of rated capacities.

Do not use the unit to dispense flammable or corrosive

fluids.

Do not use in wet or exposed environments.

Observe general safety regulations for the handling of

®

chemicals such as Loctite

adhesives and sealants. Observe

the manufacturer’s instructions as stated in the Material

Safety Data Sheet (MSDS).

Make sure the Unit stands stable and secure.

3

1.3 Unpacking and Inspection

Carefully unpack the Loctite® Digital Syringe

Dispenser and examine the items contained in the

carton. Inspect the unit for any damage that might

have occurred in transit. If such damage has

occurred, notify the carrier immediately. Claims for

damage must be made by the consignee to the carrier

and should be reported to the manufacturer.

1.4 Items supplied

(1) Digital Syringe Dispenser 883976

(1) Universal Power Cord and Adapter

902520

(1) Foot Switch 902521

(1) Syringe Stand 901459

(1) 10ml and (1) 30ml Airline Adapter

(1) Dual Unit Stacking Lock Pin 8900574

(1) Air line Support Mast 8900575

(1) Needle Sample Kit

(1) Inlet Air Hose (6mm OD x 6ft) & Fitting

Kit 902523

2 Description

The Loctite® Digital Syringe Dispenser 883976 is semi

automatic dispensing system designed for adhesives and

fluids packaged in syringe barrels. The unit has digital

timing control, with decimal control to .001 seconds for

increased precision over typical pressure time systems. An

adjustable pressure regulator controls a pulse of air, and

when used in conjunction with a airline adapter attached to

an adhesive syringe barrel, it will provide a controlled

dispense of that adhesive. Additional features include

Vacuum suck-back that can effectively control

product dripping or stringing.

4

Timed or Incremental Mode to allow adhesive to be

applied at once or in an incremental fashion.

Convenient “Teach Mode” to help determine time

required when the dispense amount is not known.

Cycle counter option displays clearly in LCD screen

The unit can also be integrated into PLC

programming to facilitate a continuous operation.

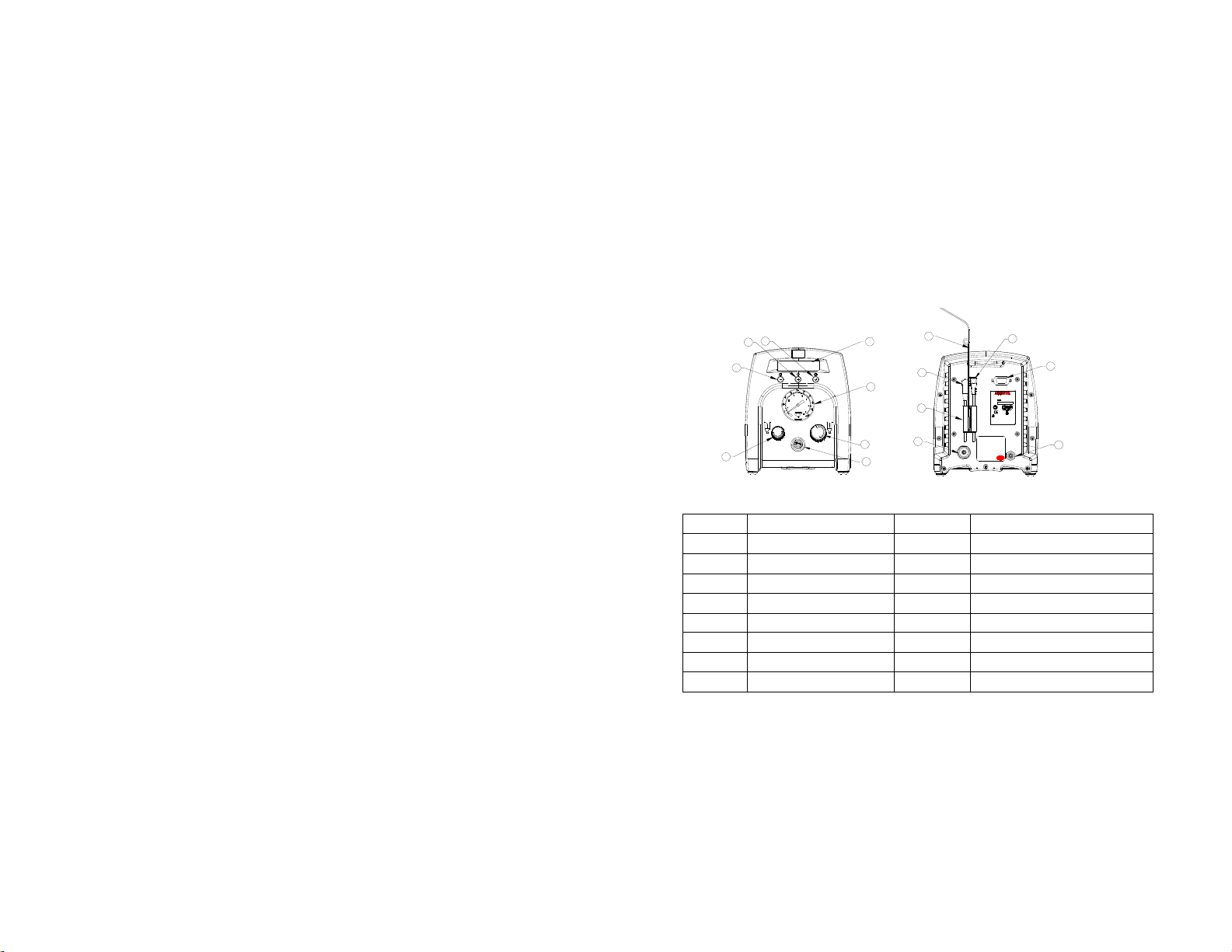

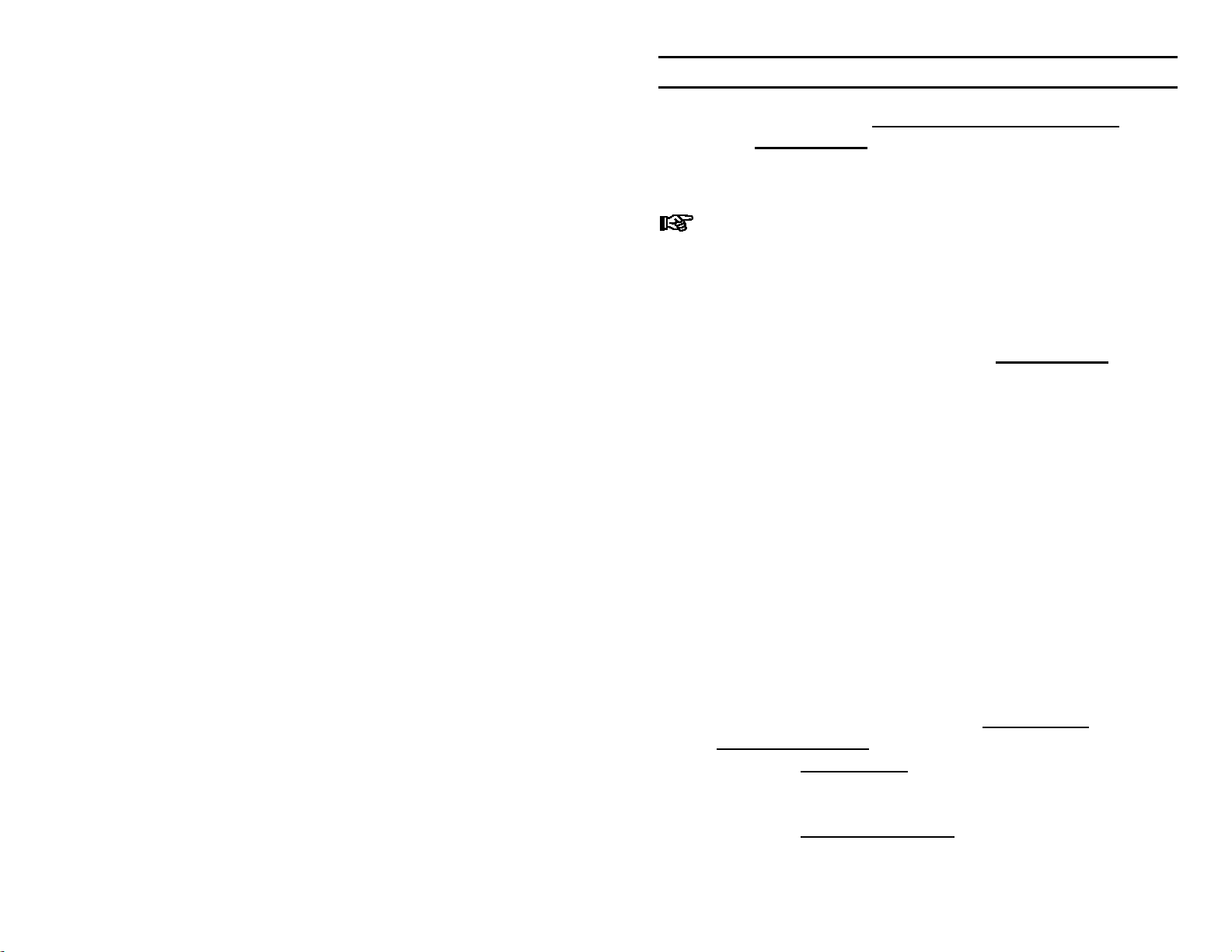

2.1 Feature Descriptions

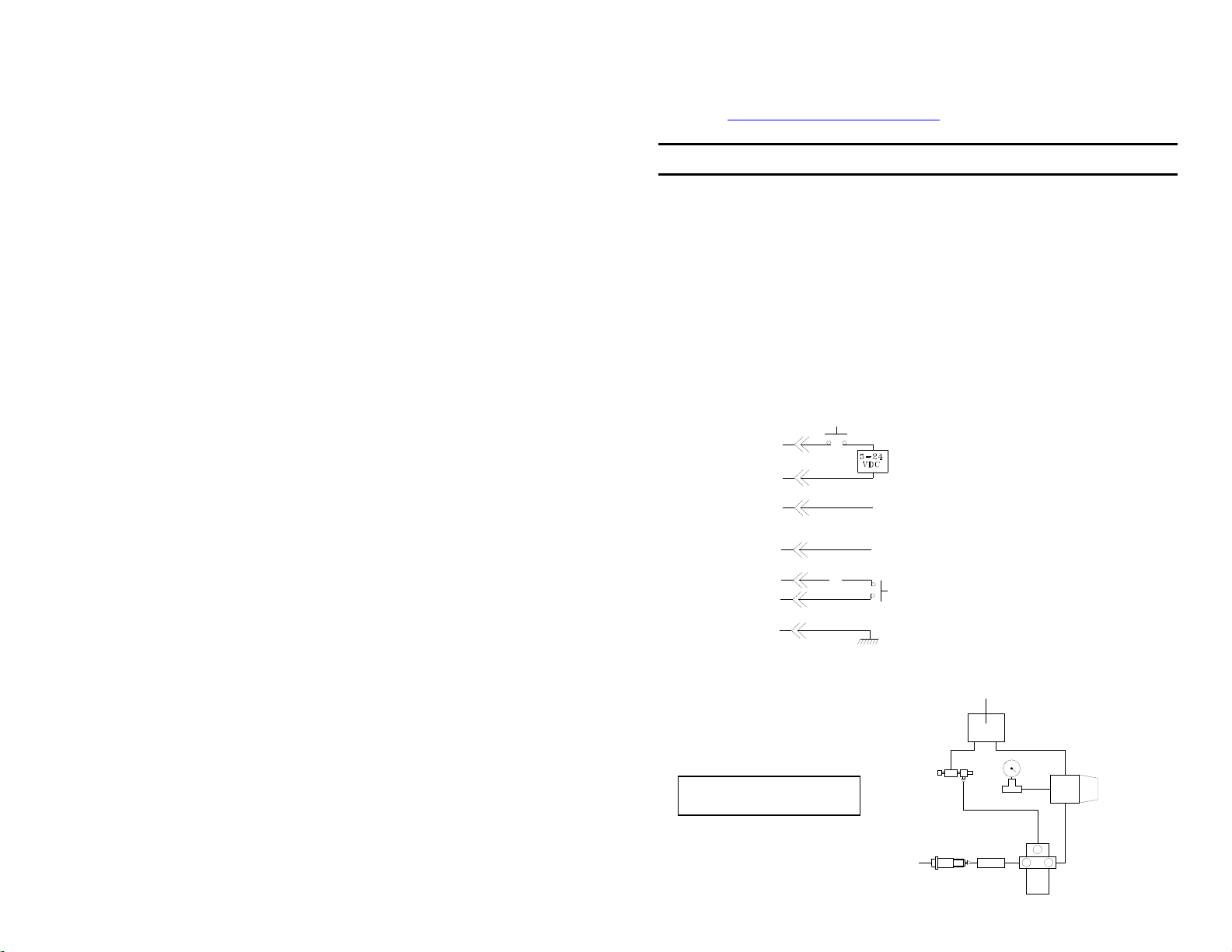

3

2

1

4

5

8

6

7

9

10

15

Corporation Contact Locations

For North America:

14

Henkel Corporation

One Henkel Way

Rocky Hill, CT 06067

For Other Worldwide Locations:

Henkel AG & Co. KGaA

Site Munich

Gutenbergstr. 3

85748 Garching

Germany

Label # 8900577

Items Description Items Description

1

2

3

4

5

6

7

8

Power Button

Mode Button

Set up/Save Button

Display

Air Pressure Gauge

Air Pressure Regulator

Pulsed Air Outlet

Vacuum Control

9

10

11

12

13

14

15

Receiver head air hose mast

Foot Switch Receptacle

Power Receptacle

I/O Connection

Exhaust Port

Air Inlet

Cord Lock

Fig 2.1

Digital Syringe Dis p en ser

Item # 98666

24V

S/N:

Pro

S

m

t

y

d

e

uct

onit

f

a

t

ed

or

ion

S

t

es

ed

VT

U

PRODUCT SERVICE

NRTL

C

US

CAUTION:

Please refer to the instruction

manual before installation

MADE IN CHINA

www.equipment.loctite.com

11

12

10W 100PSI

VU

T

SUD

geprufte

Sicherheit

13

5

3 Technical Data

)

152mm X 165mm X

Size

Weight 1.2 kg (2.6lbs

Minimum

Dispense

Time

Input Voltage 24VDC Vacuum 406mm (16”) of Hg

Rated Power 10W Timer 0.020 – 60.000 seconds

Air Input 100 psi (6.9 bars) Max. Cycle Mode Timed, Incremental, Manual

Pollution

Degree

Installation

Category

Indoor Use

Operating

Temperature

178mm

(6” X 6.5” X 7.0”)

0.020 Seconds

II

I

Altitude up to 2,000m

(6,562ft)

0˚C to 50˚C (32˚F to

122˚F)

Max.

Relative

Humidity

Air Output 0-100 psi (0-6.9 bars)

Maximum

Dispense

Time

Timing

Repeat

Tolerance

Cycle Rate 600 cycles/min

LCD 16 X 2 display segments

Storage

Temperature

80% for temperature up to

31˚C (87.8˚F) Decreasing

linearly to 50% relative

humility at 40˚C (104˚F)

60.000 seconds

+/- 0.001%

-10˚C to 60˚C (14˚F to

140˚F)

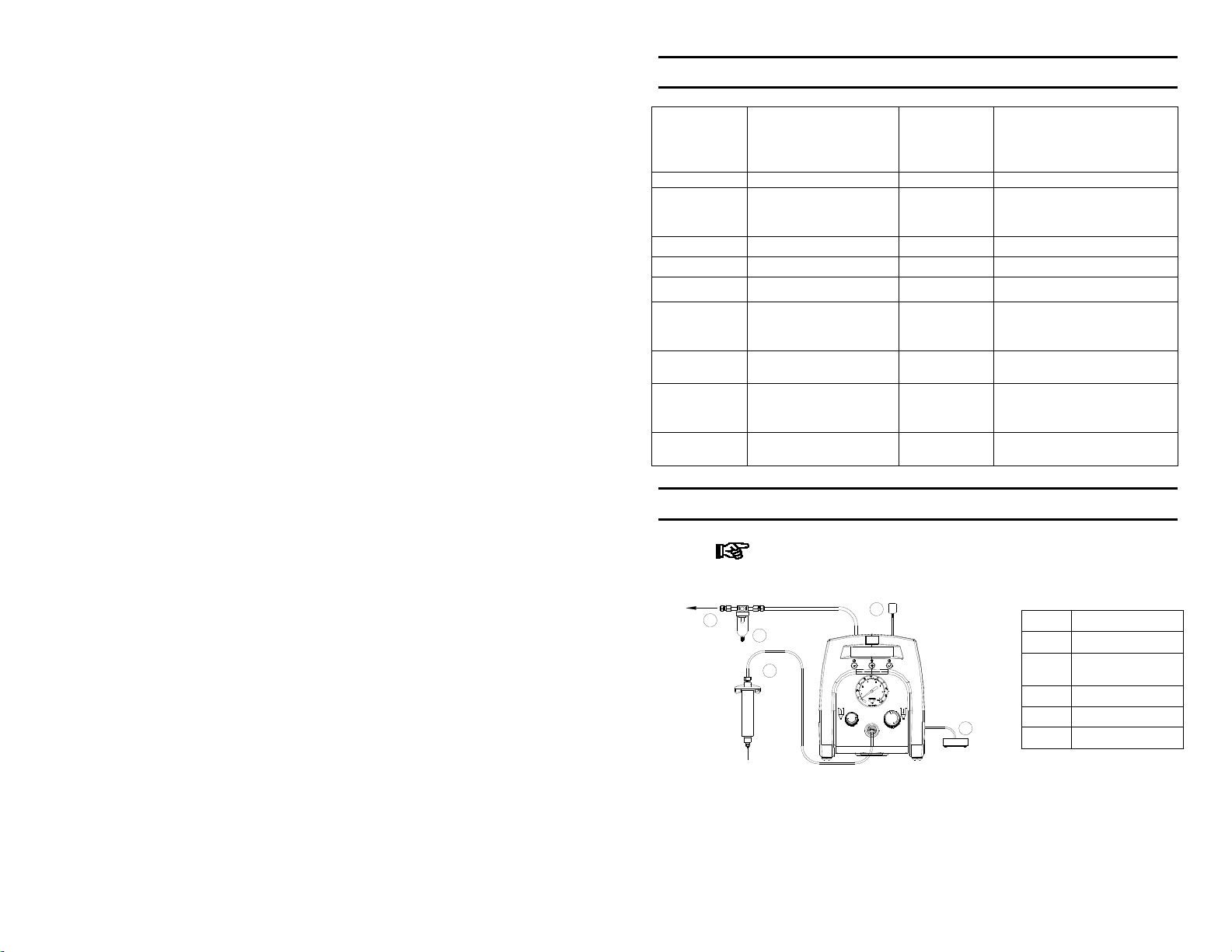

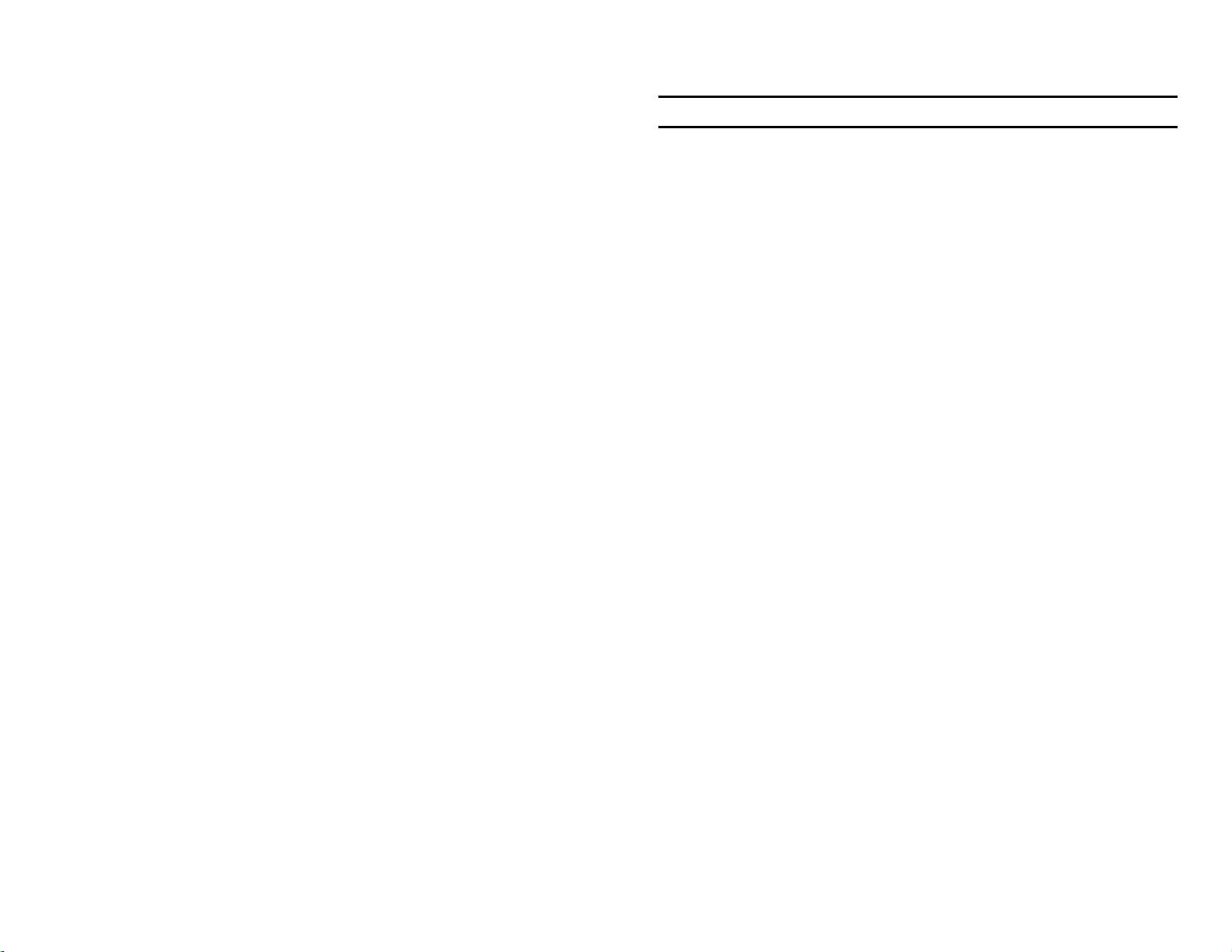

4 Installation

Use 5 micron Filter –Regulator –Loctite 985397 or

equivalent for inlet air supply

1

2

5

3

4

Items Description

1 To Air Source

Air Filter –sold

2

3 Power Adapter

4

5 Syringe Adapter

separately

Foot Switch

Fig. 4.1

4.1 10ml or 30ml syringe adapter attaches to Pulsed Air

Outlet (7) and syringe barrel.

6

5 Operation

5.1 Set up Instructions – Manual Dispense Cycle Setting

The Manual Mode allows the unit to pulse for the duration

that the foot switch is depressed. It is typically used to start up and

purging through a dispense needle.

The unit is factory pre-set with a dispense time of 0.1

seconds. Manual mode will not function unless there is time set

in the time display. (00.000 time setting will not allow the unit to

dispense in manual mode)

5.1.1 Turn on the unit by pressing the Power button (1).

5.1.2 Press the Mode button (2) until Manual Mode appears

on the display.

5.1.3 Turn up the air pressure by rotating the Air Pressure

Regulator knob (6) until the desired pressure is indicated on

the Air Pressure Gauge (5).

5.1.4 After filling the barrel or using pre-packaged adhesive,

attach the syringe to the syringe adapter. Make certain that

the syringe locks into place.

5.1.5 Connect the plug end of the receiver head assembly to

the Air Dispense Outlet (7).

5.1.6 If vacuum “suck back” is needed, rotate the Vacuum

Regulator (8) counter clockwise until the desired vacuum

pressure is obtained.

5.1.7 Press and hold the Footswitch to activate the dispense

cycle. (The Manual Mode is now activated)

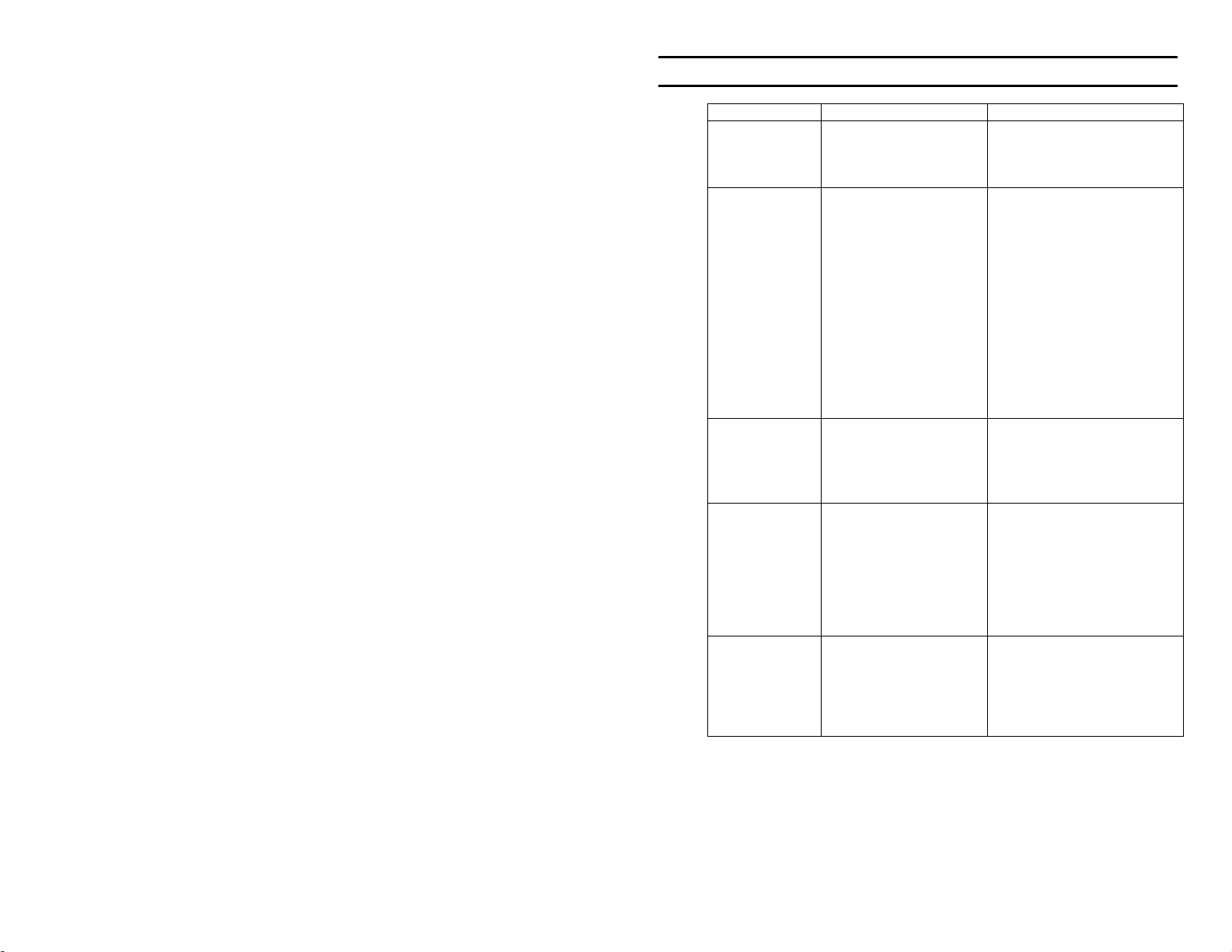

5.2 Dispense Cycle Setting – See Figure 5.1

Push the Mode button (2) to select Timed Mode or

Incremental Mode.

Timed Mode: Allows the unit to dispense for the

the complete amount of time set on the timer

when the foot switch is initiated

Incremental Mode: Allows the unit to dispense

for as long as the foot pedal is depressed and will

continue till the set time is reached. This allows a

7

5.2.1 Setting the Timer in the Timed Mode

5.2.1.1 From the Timed Mode , press and hold button the

5.2.1.2 Pressing the Set button (3) from this point moves

5.2.1.3 Press the (+) and (-) button to set the time for

5.2.1.4 When your desired time has been entered, press

5.2.2 Setting the Timer in the Incremental Mode

5.2.2.1 From the Incremental Mode, press and hold the

5.2.2.2 Press and hold down the foot switch. Product

5.2.2.3 Press and hold the Set button (3) for two seconds

pre-determined amount of product to be

incrementally added in steps if desired.

Set button (3) for 2 seconds. The unit will enter

the Set- up Mode and allow each or the time

digits to be set.

the the cursor to the next digit and back till the

desired time has been set

each digit desired. (You can not go past 0 with

either button.) Minimum dispense time is 00.020

seconds

and hold the Set button (3) for two seconds to

save the data.

Setting the timer from the Incremental mode, “Teach

Mode” is helpful in determining dispense time

required when dispense output is unknown. The timer

will continue to accumulate time as long as the foot

pedal is depressed, allowing the user to “teach” the

unit the exact time needed

Set button (3) to enter the “Teach Mode”. The

unit will still read Set-up, however the time will

show “0.000” in the LCD.

will dispense and time will accumulate. Continue

to release and press the foot switch till the desired

quantity has been dispensed.

to save the data.

8

5.2.2.4 Press the Mode button (2) to switch the Timed or

Incremental Mode as desired. The dispenser is

now ready to dispense this new time cycle

5.2.3 Resetting the Cycle Counter

The cycle counter records the numbers of automatic

dispense cycles being activated. Up to 65,535 cycles

can be recorded. This number is shown at the lower

right hand corner of the LCD. To reset the counter;

5.2.3.1 Press and hold the Set button (3) for two seconds

to enter the Set up mode.

5.2.3.2 Then re-press and hold the Set button (3) for three

to five more seconds to reset the counter. After

two seconds the screen will first show “Saving

Data” but continue holding till the cycle counter

resets to 00000 .

Prog

POWER

MODE

Counter

Time

SET

MODE

SETUP MODE

2.25

P1 00004

SETUP MODE

22.2 5

P1 00004

TIMED MODE

P1 2.251 00004

SETUP MODE

22.2 5

P1 00004

:Press then release

:Press and hold for approximately 4 seconds then release

OFF

TIMED MODE

2.250

P1 00004

Power ON/OFF

0

0

1

:Press and hold for approximately 2 seconds then release

Normal Operation

Setup

TIMED MODE

P1 2.250 00004

SETUP MODE

22.2 5

P1 00004

0

TIME SETTING

SETUP MODE

22.2 5

P1 00004

1

Save and Exit...

COUNTER RESET

Save and Exit...

Fig 5.1

TIMED MODE

2.250

00004

INCREMENTAL MODE

2.250

P1P100004

MANUAL MODE

*************************

Change Mode

Time setting

in TIMED mode

SETUP MODE

22.250

P1 00004

SETUP MODE

22.25

P1 00004

0

SETUP MODE

22.25

P1 00004

1

TIMED MODE

P1 2.251 00000

9

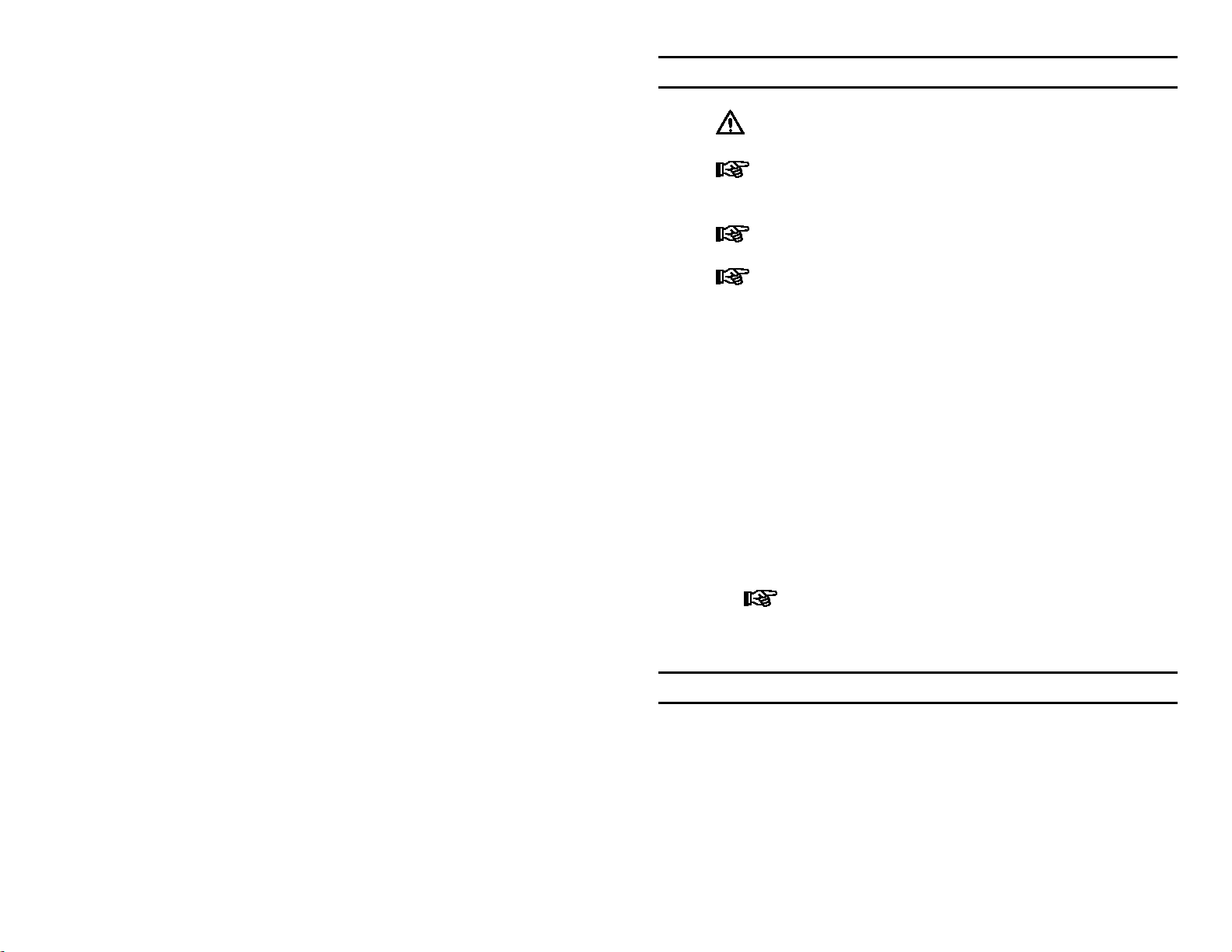

6 Troubleshooting

PROBLEM POSSIBLE CAUSE CORRECTION

LCD does not

light

System will not

actuate

System will not

pressurize

System will not

pull vacuum

Inconsistent

dispensing

No power input

Foot switch not

plugged in or

improperly plugged

in

Defective foot switch

Broken wire or loose

connection inside

unit

Defective solenoid

Defective PC board

Insufficient air

pressure

Air hoses not

plugged in

Regulator defective

Vacuum setting is

too low

Defective solenoid

Defective vacuum

venturi

Defective vacuum

needle valve

Air bubbles in

adhesive

Dispense time is too

low

Dispense needle

started to clog

Check power cord

connections

Turn on power

Check foot switch

connection

Foot switch needs to be

repaired or replaced

Unplug power cord and

disconnect air supply.

Remove cover and check

for broken wires or loose

connections

Replace solenoid

Replace PC board

Increase air supply

pressure

Check connection

Replace regulator

Increase vacuum setting

Replace solenoid valve

Replace venturi

Replace needle valve

Reduce vacuum setting

Increase dispensing time

Replace needle

10

7 Maintenance & Operational Tips

Use Loctite® Universal Power Supply 902520 only.

Always disconnect the power supply before servicing the unit.

If using to dispense from syringes without pistons,

optional In-Line Filter 984650 should be installed with the

Air Line Adapter to prevent fluids from entering the unit

Use 5 micron Filter –Regulator –Loctite 985397 or

equivalent for inlet air supply

The dispenser is designed and built to be relatively

maintenance free. To assure trouble free operation, the

following recommendations should be followed:

1. Make certain air supply is clean and dry.

2. When not in use turn vacuum off or disconnect air supply

to unit. Failure to do so could result in adhesive being

pulled back into the unit and rendering it non-functional.

3. Avoid turning barrels upside down or laying barrel so

that material may run through airline to internal

components.

4. Avoid connecting air supply exceeding 100 psi (6.9 bars)

5. Use only Amyl Alcohol to clean outside surface of the

main housing.

6. Use only soft cloth to clean the LCD.

While under warranty, the unit may be

repaired only by an authorized Henkel service

representative.

8 Accessories and Spare Parts

Universal Power Cord and Adapter 902520

Foot Switch 902521

Syringe Stand 901459

Dual Unit Stacking Lock Pin 8900574

Air line Support Mast 8900575

6mm Inlet Air Tubing (10 meters) 902523

11

Needle Kits and Air Line Adapters – check Disposable

Dispense Components listing at

www.equipment.loctite.com

9 I/O Configuration & Pneumatic Diagram

Upon completion of a dispense cycle, an open collector circuit

closes and remains closed until the next dispense cycle. This

circuit can be used to signal back to a host computer, start

another device in sequence, or drive any other operations that

need to be tied to the completion of the dispense cycle. Upon

closure, (end of dispense cycle), power from an external source

is allowed to pass through the circuit to operate a 5 to 24 VDC

load. Power consumption must not exceed 250 mA. The load

could be a relay, solenoid, counter, LED, or any device that will

operate within a 5 to 24 VDC range and a maximum of 250 mA.

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

PIN 5

Pin 7, 8 and 9 = available

Pneumatic Diagram

To init ia te a dispense cy cle

During cycle = GRO U N D

End of cycle = OPEN

During cycle = GRO U ND

End of cycle = OPEN

To ini tia te a dispense cy cl e

with con ta c t clo su r e

Chasis Ground

NEEDLE VALVE

AIR OUTLET

AIR INLET

AIR MANIFOLD

PRESSURE REGULATOR

3

21

SOLENOID VALVE

12

10 Warranty

Henkel expressly warrants that all products referred to in this

Instruction Manual for the Loctite

Dispesner (hereafter called “Products”) shall be free from defects in

materials and workmanship. Liability for Henkel shall be limited, as

its option, to replacing those Products which are shown to be

defective in either materials or workmanship or to credit the

purchaser the amount of the purchase price thereof (plus freight and

insurance charges paid therefor by the user). The purchaser’s sole

and exclusive remedy for breach of warranty shall be such

replacement or credit.

A claim of defect in materials or workmanship in any Products shall

be allowed only when it is submitted in writing within one month

after discovery of the defect or after the time the defect should

reasonably have been discovered and in any event, within (12)

months after the delivery of the Products to the purchaser. This

warranty does not apply to perishable items, such as, but not limited

to: (o-rings, seals, washers, filters, lights, etc.). No such claim shall

be allowed in respect of products which have been neglected or

improperly stored, transported, handled, installed, connected,

operated, used or maintained. In the event of unauthorized

modification of the Products including, where products, parts or

attachments for use in connection with the Products are available

from Henkel, the use of products, parts or attachments which are not

manufactured by Henkel, no claim shall be allowed.

No Products shall be returned to Henkel for any reason without prior

written approval from Henkel. Products shall be returned freight

prepaid, in accordance with instructions from Henkel.

NO WARRANTY IS EXTENDED TO ANY EQUIPMENT

WHICH HAS BEEN ALTERED, MISUSED, NEGLECTED, OR

DAMAGED BY ACCIDENT, OR IF THE SYSTEM WAS USED

TO DISPENSE ANY LIQUID MATERIAL OTHER THAN

LOCTITE® PRODUCTS.

®

883976 Digital Syringe

13

EXCEPT FOR THE EXPRESS WARRANTY CONTAINED IN

THIS SECTION, HENKEL MAKES NO WARRANTY OF ANY

KIND WHATSOEVER, EXPRESS OR IMPLIED, WITH

RESPECT TO THE PRODUCTS.

ALL WARRANTIES OF MERCHANTABILITY, FITNESS FOR

A PARTICULAR PURPOSE, AND OTHER WARRANTIES OF

WHATEVER KIND (INCLUDING AGAINST PATENT OR

TRADEMARK INFRINGEMENT) ARE HEREBY DISCLAIMED

BY HENKEL AND WAIVED BY THE PURCHASER.

THIS SECTION SETS FORTH EXCLUSIVELY ALL OF

LIABILITY FOR HENKEL TO THE PURCHASER IN

CONTRACT, IN TORT OR OTHERWISE IN THE EVENT OF

DEFECTIVE PRODUCTS.

WITHOUT LIMITATION OF THE FOREGOING, TO THE

FULLEST EXTENT POSSIBLE UNDER APPLICABLE LAWS,

HENKEL EXPRESSLY DISCLAIMS ANY LIABILITY

WHATSOEVER FOR ANY DAMAGES INCURRED DIRECTLY

OR INDIRECTLY IN CONNECTION WITH THE SALE OR USE

OF, OR OTHERWISE IN CONNECTION WITH, THE

PRODUCTS, INCLUDING, WITHOUT LIMITATION, LOSS OF

PROFITS AND SPECIAL, INDIRECT OR CONSEQUENTIAL

DAMAGES, WHETHER CAUSED BY NEGLIGENCE FROM

HENKEL OR OTHERWISE.

14

11 Declaration of Conformity

Conforms with the protection requirements of Council Directive

89/336/EEC, relating to Electromagnetic Compatility by the

appication of the following EMC Standards:

EN61326 / A3:2003

IEC61000-3-2:2000

IEC61000-3-3/A1:2001

Conforms to Council Directive 72/23/EEC (Low Voltage

Directive) by the application of the following standard:

IEC61010-1:2001 (2nd Edition)

Complies to RoHS Directive 2002/95/EC given by The

European Parliament and The Council of 27 January 2003 on the

restriction of the use of certain hazardous substances in electrical

and electronic equipment

Complies to European Waste Electrical and Electronic

Equipment (WEEE) Directive 2002/96/EC

Meets the requirements of the German Equipment and Product

Safety Act

Conforms to the following certification marks:

15

Henkel Corporation

Engineering

Adhesives

USA

Henkel Corporation

One Henkel Way

Rocky Hill, CT 060673910

For all world wide

locations

Visit www.loctite.com

Canada

Henkel Canada

Corporation

2515 Meadowpine

Boulevard

Mississauga, Ontario L5N

6C3

Canada

For Equipment in North

America visit

www.equipment.loctite.com

Mexico

Henkel Capital, S.A. de C.V.

Blvd Magnocentro No8 Piso 2

Interlomas

52760, Huixquilucan, Edo de

Mexico

Loctite is a registered trademark of Henkel Corporation © Copyright 2006. All rights reserved. Data

in this operation manual is subject to change without notice

Manual P/N: 8900580, Rev D, Date: 08/07/2014

16

Loading...

Loading...